Submitted:

11 April 2025

Posted:

11 April 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

| Material | Specification / Source |

| Cement | OPC 43 Grade (IS 8112) |

| Fine Aggregates | River sand (<4.75 mm, IS 383 compliant) |

| Coarse Aggregates | Crushed granite (10–20 mm, IS 383) |

| Water | Potable tap water |

| Denim Fibers | Recycled jeans, 30 mm length |

2.2. Mix Design and Proportions

2.3. Specimen Casting and Curing Specimens included:

- Cubes (150mm x 150mm x 150mm): For compressive strength tests.

- Prisms (100mm x 100mm x 500mm): For flexural strength tests.

- Cylinders (100mm diameter x 200mm height): For split tensile strength (future scope). After casting, specimens were de-molded after 24 hours and cured in clean water tanks at 27 ± 2°C for 28 days.

2.4. Testing Procedures

- Slump Test (IS 1199): To assess fresh concrete workability.

- Compressive Strength (IS 516): At 7, 14, and 28 days.

- Flexural Strength (IS 516): Using third-point loading method on prisms.

- Water Absorption Test (ASTM C642): To evaluate porosity and water permeability.

- Surface Crack Inspection: Visual and microscopic crack width analysis after drying shrinkage cycles.

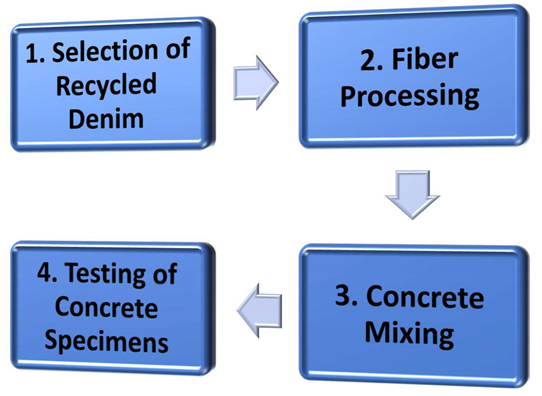

2.5. Methodology & Flowchart

-

Collection and Preparation of Denim Fibers:

- ∘

- Post-consumer denim garments were collected.

- ∘

- Denim was washed, dried, and mechanically shredded into 30 mm fibers.

-

Concrete Mix Design:

- ∘

- M25 grade concrete was chosen as the reference mix.

- ∘

- Denim fibers were incorporated at varying dosages (0%, 0.5%, 1.0%, 1.5% by weight of cement).

-

Batching and Mixing:

- ∘

- Weighed quantities of cement, sand, coarse aggregate, and fibers were mixed in a concrete mixer.

- ∘

- Water was gradually added to maintain uniformity.

-

Casting of Specimens:

- ∘

- The fresh concrete was poured into standard cube, prism, and cylinder molds.

- ∘

- Proper compaction and finishing were ensured.

-

Curing:

- ∘

- After 24 hours, specimens were demolded.

- ∘

- Curing was done in a water tank maintained at 27 ± 2°C for 28 days.

-

Testing:

- ∘

- Tests for slump, compressive strength, and flexural strength were conducted.

- ∘

- Water absorption and visual inspection for surface cracking were carried out.

-

Analysis:

- ∘

- Results were tabulated and graphed.

- ∘

- Comparative analysis was done to evaluate the performance of denim-reinforced concrete mixes.

3. Results and Discussion

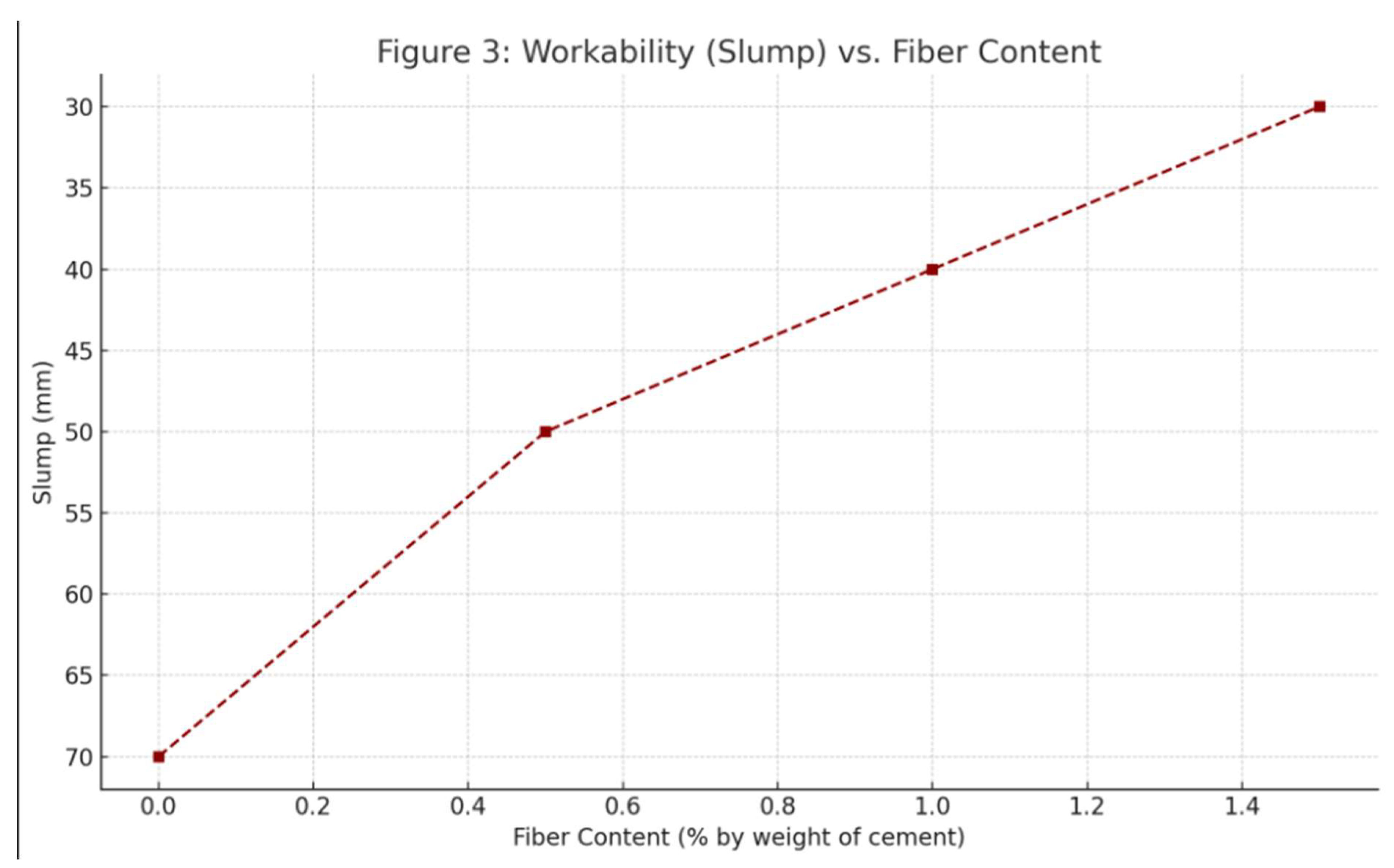

3.1. Workability

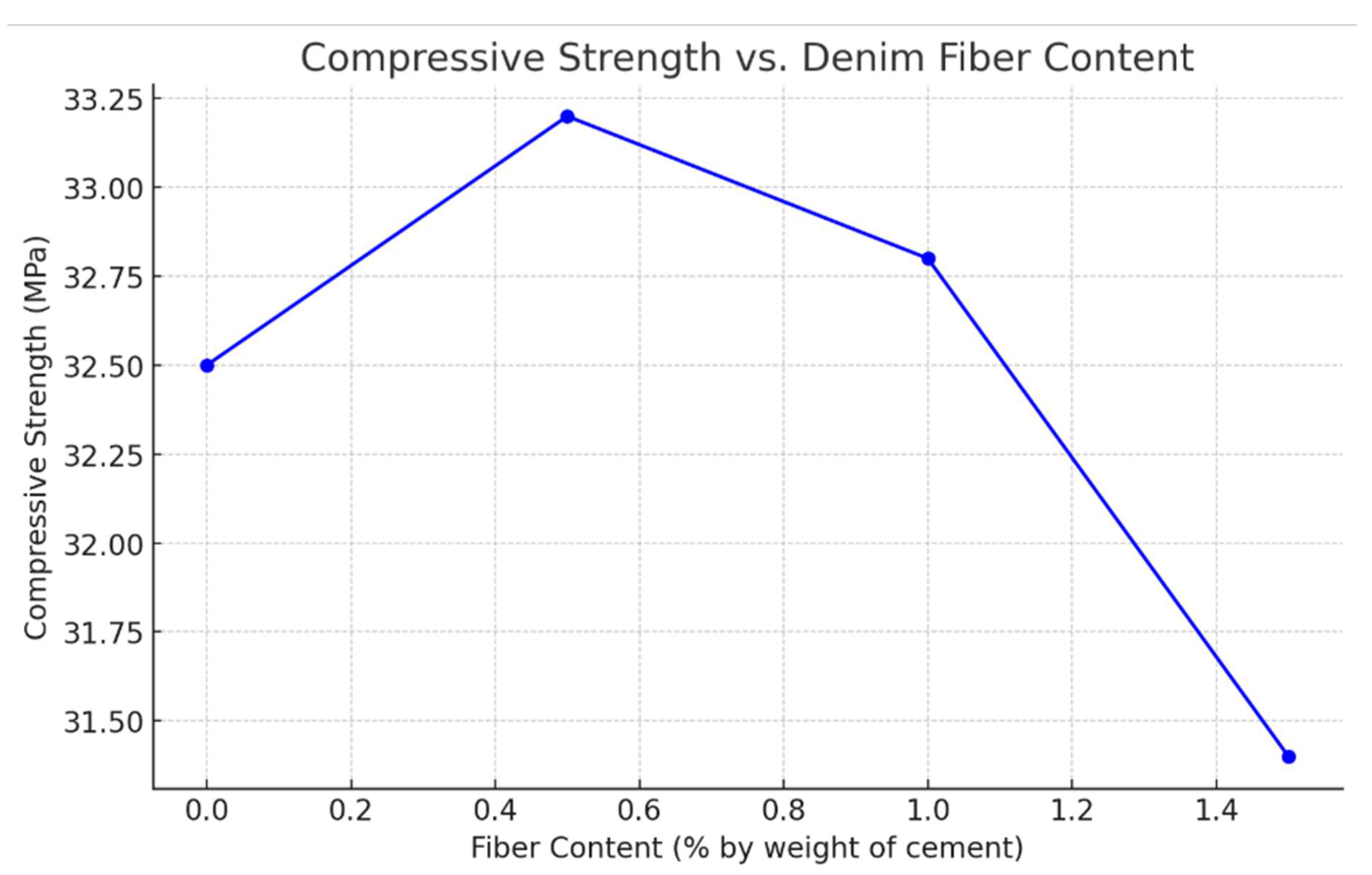

3.2. Compressive Strength

| Fiber Content (% by weight of cement) | 7 Days (MPa) | 14 Days (MPa) | 28 Days (MPa) |

| 0.0% (Control) | 22.5 | 28.6 | 32.5 |

| 0.5% | 23.1 | 29.4 | 33.2 |

| 1.0% | 22.9 | 28.9 | 32.8 |

| 1.5% | 21.8 | 27.6 | 31.4 |

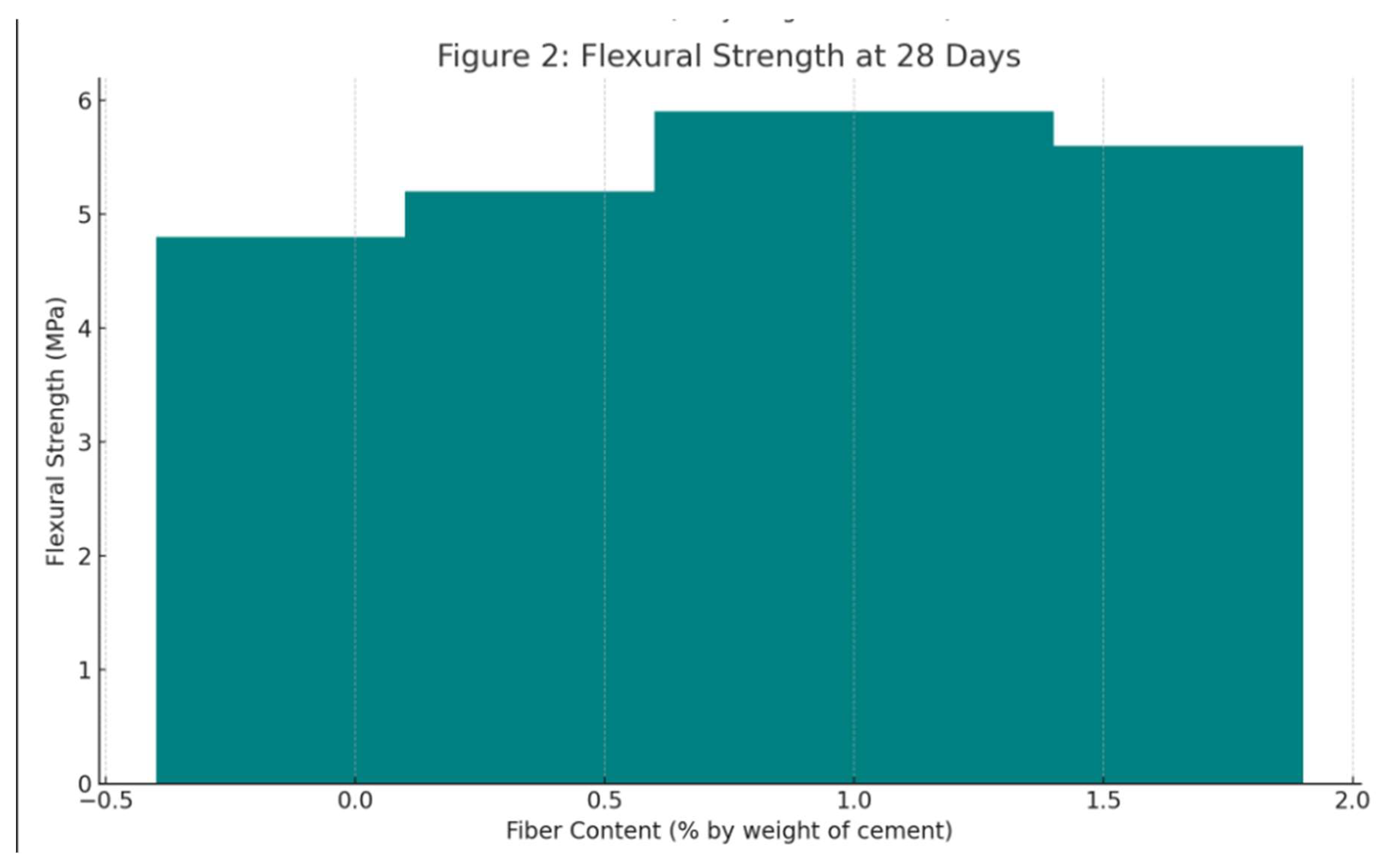

3.3. Flexural Strength

| Fiber Content (% by weight of cement) | Flexural Strength at 28 Days (MPa) |

| 0.0% (Control) | 4.8 |

| 0.5% | 5.2 |

| 1.0% | 5.9 |

| 1.5% | 5.6 |

3.4. Durability

4. Conclusion

References

- Pacheco-Torgal, F. , & Jalali, S. Cementitious building materials reinforced with textile wastes. Construction and Building Materials 2011, 25, 360–368. [Google Scholar] [CrossRef]

- Mohammed, B. S. , et al. Sustainable concrete with recycled textile fiber: A review. Journal of Cleaner Production 2019, 229, 870–887. [Google Scholar] [CrossRef]

- Li, V. C. , et al. Fiber reinforced concrete: Present and future. Journal of Engineering Mechanics 1992, 118, 1035–1050. [Google Scholar] [CrossRef]

- Castro, J. , & Wills, J. Textile waste as reinforcement for concrete. Environmental Engineering & Management Journal 2013, 12, 995–1003. [Google Scholar]

- Rebeiz, K. , & Scott, L. Application of natural fibers as reinforcements in concrete. Construction and Building Materials 2005, 19, 487–494. [Google Scholar] [CrossRef]

- Girão, S. , & Costa, S. Recycled fibers in construction materials: A comprehensive study. Construction Science Journal 2020, 19, 541–555. [Google Scholar] [CrossRef]

- Tiwari, P. , & Singh, A. Evaluation of textile waste fibers for concrete reinforcement. Journal of Environmental Management 2021, 88, 348–360. [Google Scholar] [CrossRef]

- Muthu, S. S. , et al. Sustainability of textile waste management: A review on the impact of recycling textiles. Environmental Progress & Sustainable Energy 2012, 31, 428–438. [Google Scholar] [CrossRef]

- Atul, M. K. , et al. Utilizing post-consumer textile waste in the construction industry: A step toward sustainability. Journal of Sustainable Construction Materials 2021, 28, 1059–1069. [Google Scholar] [CrossRef]

- Ghosh, S. , & Banerjee, D. Sustainable utilization of textile waste in concrete: An innovative solution for eco-friendly construction. Sustainable Building Materials Journal 2020, 34, 234–245. [Google Scholar] [CrossRef]

- Ghosh, S. , & Kumar, R. Recycling denim waste as a sustainable solution for concrete reinforcement. Sustainable Materials and Technologies 2022, 28, 101315. [Google Scholar] [CrossRef]

- Hwang, S. , & Lee, K. Textile waste as a potential resource for concrete production. Construction Materials & Sustainability Journal 2019, 15, 217–229. [Google Scholar] [CrossRef]

- Talukdar, S. , & Singh, M. Exploring the feasibility of recycled textiles in concrete: Mechanical properties and performance. Construction and Building Materials 2021, 295, 123583. [Google Scholar] [CrossRef]

- Sinha, R. , & Agarwal, N. Investigating the influence of recycled fibers on the properties of concrete. Journal of Civil Engineering Research 2022, 25, 112–124. [Google Scholar] [CrossRef]

- Zhang, L. , & Liu, W. Long-term behavior of concrete reinforced with textile fibers. Materials Science and Engineering Journal 2021, 122, 655–663. [Google Scholar] [CrossRef]

- Dong, Y. , & Liu, X. Environmental sustainability in concrete production: The role of textile fibers. Sustainable Engineering Review 2020, 35, 138–145. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).