1. Introduction

As for the improvement of living level along with the continuous growth of national economy, the interest in the well-being of residents is increasing. Accordingly, the interest of residents is increasing in a quiet living for the comfortable and pleasant residential environment. Especially, due to the high weight on the apartment and the living habit of a sitting type, the occurring frequency of a floor impact noise is so high that its damage and conflict occur often in reality. By this reason, in domestic, studies and developments are continuously in progress to block the noise between floors. As a result of it, the current major block type for the floor impact noise used in domestic, only increases the thickness of structural slaves or uses the resilient materials of light quality such as EPS and EVA. [

1] However, this kind of structure has such a problem that it not only increases the floor thickness but also the total construction cost.[

2]

As the measuring method of dynamic modulus of elasticity of resilient material for the floor impact noise was established, the interest in the performance of resilient material has been heightened, and its performance has been recognized as the important element for the reduction of the floor impact noise. According to the study result by J.W. LEE, in case of the light impact noise, it shows a tendency that, as the dynamic modulus of elasticity increased, the reduction amount was reduced in large scale; and that in a constant level, it was reduced by the ratio of exponential function without any change but was maintained. It was shown that within the range of dynamic modulus of elasticity of 20~80MN/m

3, there was a change of about 5~6dB.[

3] In a study by K.W. Kim, the relationship between the dynamic modulus of elasticity and the reduction amount of heavy impact noise of resilient material for the floor impact noise was identified, and the coefficient of determination was shown to be higher in most of frequencies. Therefore, it was shown that, if the resilient material with the dynamic modulus of elasticity of 8MN/m

3 and below is used to reduce the heavy impact noise, it might prevent the resonance which occurs at 63Hz. In addition, the dynamic modulus of elasticity of resilient material decreased when materials with different quality were layered, and the reduction amount of light impact noise in-creased.[

4] Also, according to the study of J.K RYU, in case of the resilient material in EPS series, it was shown that the products which contain embossing at the bottom had the improving effect of performance for the heavy impact noise, which was not a simple in-crease of thickness. In case of the resilient material in EVA series, it was found out that by the composition of complex materials of EP net and noise absorbing material, the reduction performance for the heavy impact noise was improved.[

5] The study by J.H. Kim investigated the effect of resilient materials on heavy-impact sound in wall-structured apartment buildings. According to the research results, it was found that, generally, as the dynamic modulus of elasticity increases, the sound pressure level also increases at frequencies above 80 Hz. The responses at 50 Hz, 60 Hz, and 80 Hz showed amplification due to the resonance phenomenon of the resilient materials, and the frequency at which this amplification occurs varied depending on the type of resilient material.[

6] Lee undertook floor impact noise tests using 19 different resilient materials, including EVA, PET, PP, and PS sheets. The results showed that a maximum reduction of 5dB in heavy-weight floor impact noise could be achieved compared to a bare concrete slab.[

7] Similarly, Kim measured the dynamic elastic modulus of nine specimens comprising EVA, EPS, PE, crumb rubber, and glass fiber materials. He found that the dynamic elastic modulus decreases with increasing thickness of the composite materials, regardless of the type of resilient material used.[

8] Another similar experiment used 20mm of EVA resilient material with a concrete slab of 180mm thickness, resulting in a 2dB reduction in heavy-weight floor impact noise.[

9] Considering from the above results, as for the composition of resilient material, it is predicted that the complex composition of materials with different quality will lower the dynamic modulus of elasticity and have the improvement of reduced performance for the light and heavy impact noises.

Therefore, much research are discussed with the composition of various elastic materials. According to the thickness and composition of the buffer material, the thicker the buffer layer, the lower the dynamic modulus, thereby reducing the weight impact sound. [

10] As a result of investigating the difference in the reduction performance of the floor impact sound through shape transformation for the EVA single material, it was confirmed that there is an effective shape difference according to the frequency characteristics of the impact sound.[

11] Furthermore, studies have shown that the floor impact sound reduction performance can be improved by adjusting the composition ratio of the buffer material, even when using the same material.[12, 13]

Especially, the annual global production of waste tires is estimated to be around 1 billion units (approximately 17 million tons) [

14], and this figure is expected to continue to increase due to global population growth and the rising number of automobiles in emerging countries. Accordingly, recycling waste tires by shredding them into tire chips offers advantages such as reducing environmental burden and lowering overall construction costs due to the low material cost. Due to their cost-effectiveness and environmental friendliness, waste tire chips are used as various additional materials. Research results have been published that have proven usability by mixing waste tire chips with wood. [

15] Based on the evaluation method proposed by the Japanese Architectural Association, research has shown that waste tire chips can effectively block lightweight impact sound. [

16] Crumb rubber is also a prospective material with a high block performance in the floor impact noise due to a high elasticity and a gap which occurs between particles. In addition, utilizing the crumb rubber with a crushed type is convenient to use those as a layered structure, and will be used for various fields. In a study by Navid Chalangaran, waste tire chips were added to concrete to create samples, and the sound insulation performance was measured using an impedance tube to recycle waste tires. It is concluded that substituting sand aggregates with rubber crumbs specimens containing 15% fine-grained crumbs or 15% coarse-grained crumbs could improve the STL by up to 190% and 228%, respectively, while the implementation of 5% and 10% rubber crumb material has desirable effects on reducing low-frequency noises.[

17] In the study by Anu Bala, thermal resistivity and sound absorption performance were measured for rubberized concrete (RC), in which waste tire chips were incorporated into concrete. Increasing rubber content in-creases the porosity of the concrete mix, thereby increasing thermal resistivity and sound absorption.[

18] However, when crumb rubber is mixed with concrete, the compressive strength is lowered, so these structural limitations must be solved.[

19]

Therefore, in this study, by applying the crumb rubber as a resilient material for the floor impact noise, such resilient material shall be developed that can control the impact noise in the current floor structure system. Also, based on the dynamic characteristic according to the change in the composition of resilient material for the floor impact noise, the study for a method shall be performed, which can satisfy the block performance for the floor impact noise.

2. Experiment

2.1. Outline of Experiment

In order to check the reduction performance for the floor impact noise of resilient material, an experiment was proceeded in the standard test room for the floor impact noise in which the construction of floor structure was equivalent to the apartment located in K.C.L. (Korea Conformity Laboratories)

The standard test room for the floor impact noise consists of a total of sixteen sound receiving rooms on the first floor and sound source rooms on the second floor with the same size of spaces. The inner size of each room has a rectangular space of 4.5×5.1(m), and the thickness of every floor slave is 180mm. The sound receiving room is required to be installed with a plaster ceiling with 100mm air space thickness. The following

Table 1 shows the summary of building dimensions of the standard test room for the floor impact noise.

2.2. Method of Experiment

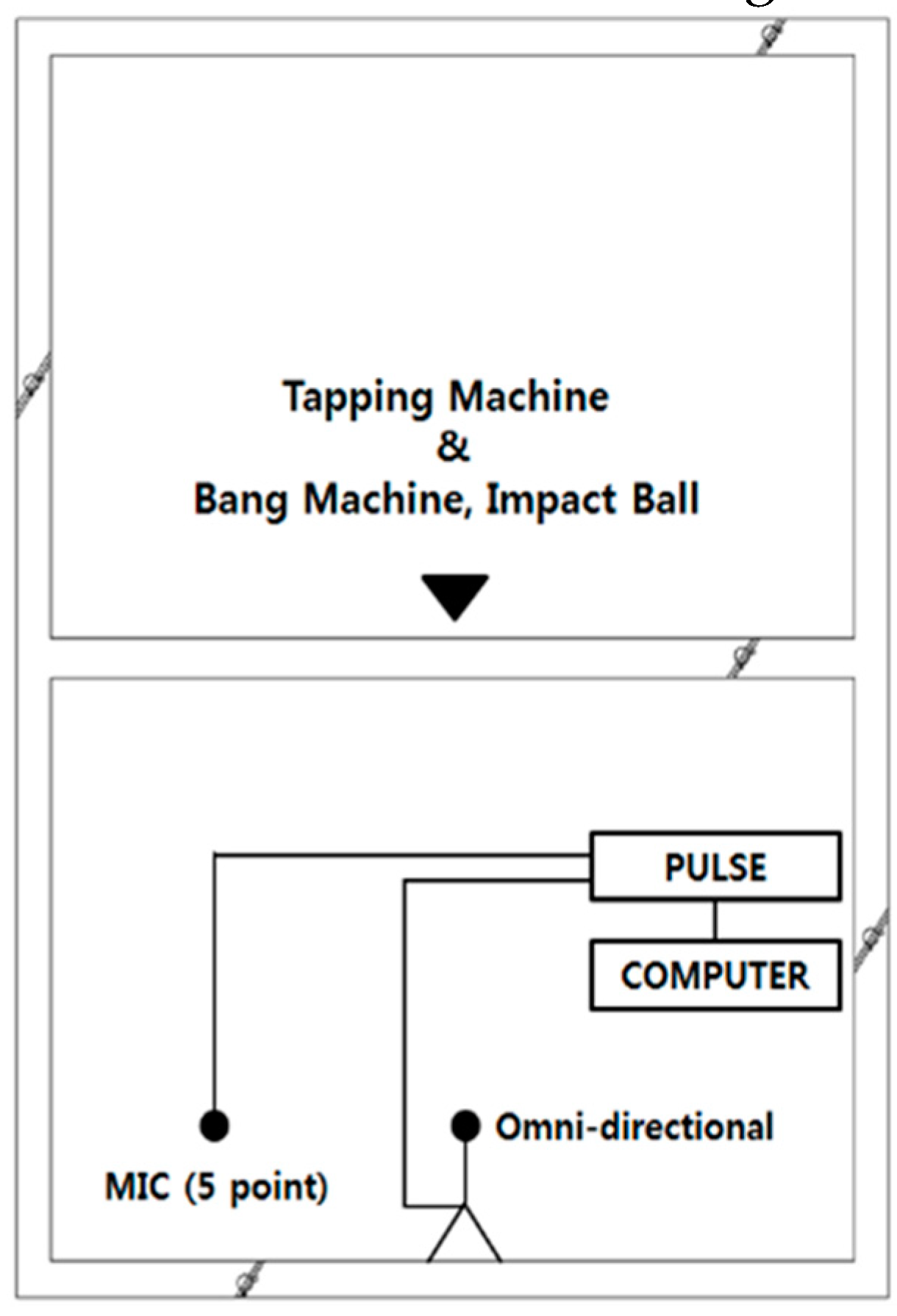

The measurement for the floor impact noise was measured and evaluated, based on KS F 2810-1,2 by the standard onsite measuring method. Through the following

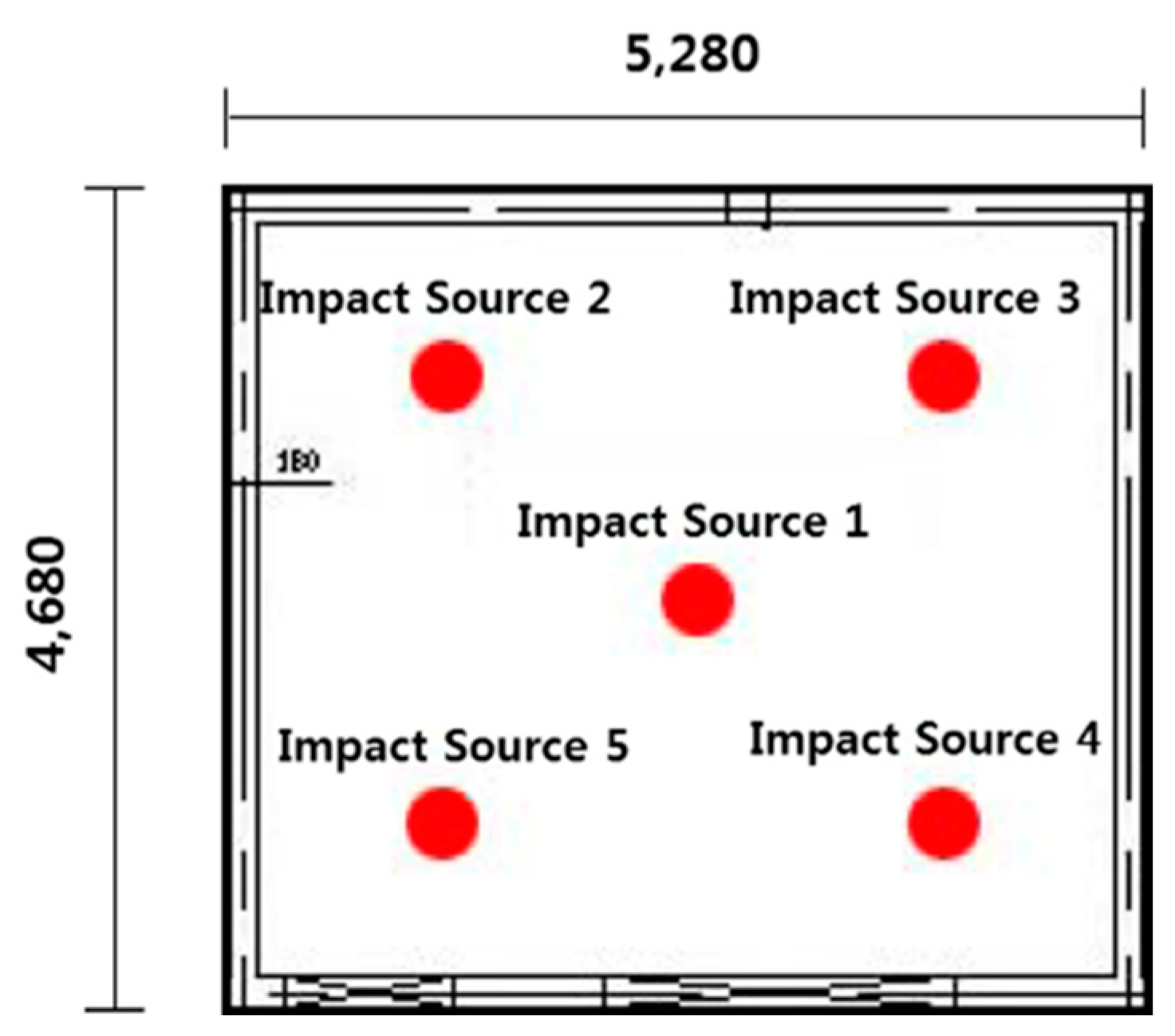

Figure 1, the outline diagram of experiment has been expressed. Five sites were selected for the installation position of impact source in the sound source room including the center point. It was installed with 0.75 m separated from the surrounding walls of the room, and it is as in

Figure 2. Five sites were selected for the installation position of microphone including the center point of receiving room equivalent to the installation position of impact source in the sound source room. It was installed at the 1.2 m height from the floor at the site separated by 0.75 m from the walls of the surrounding room.

2.3. Objectives of Experiment

Based on the results of previous studies, design criteria for the resilient material was completed by using crumb rubber and EPS complexify. Especially, at the time of reviewing the design criteria for the resilient material, the reduction performance of the floor impact noise was compared by changing the particle size of crumb rubber within the range of thickness of resilient layer unchanged.

Also, PP sheet was used between layers of EPS and crumb rubber, and the reason was that the crumb rubber may cause deformation by penetrating the light quality EPS which is layered at the top part. Also, it may lower the reduction performance for the floor impact noise as the area increases in which the floor slave contacts with EPS. Therefore, to solve this kind of problem, a structure was completed which had inserted PP sheet between crumb rubber and EPS layer.

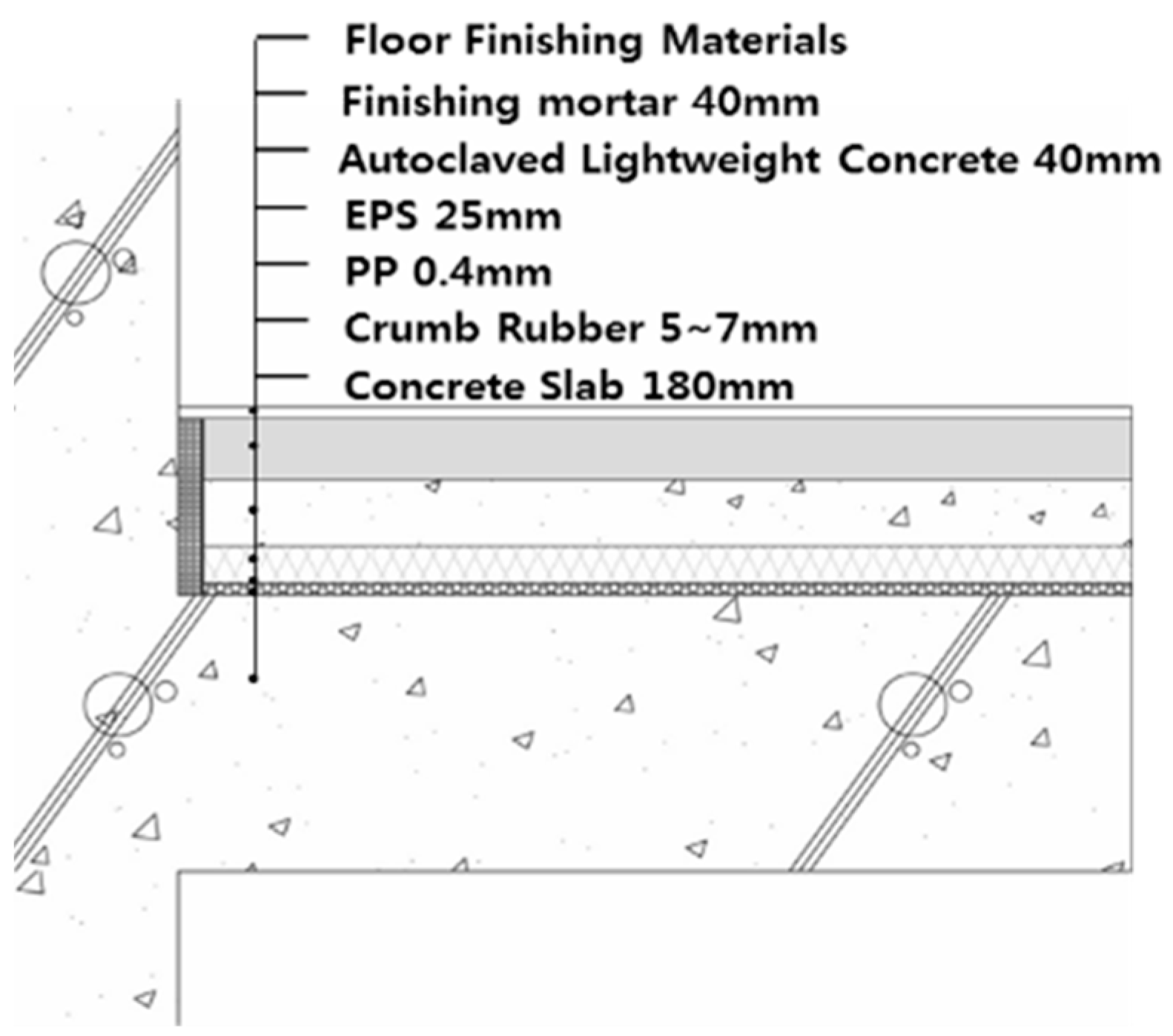

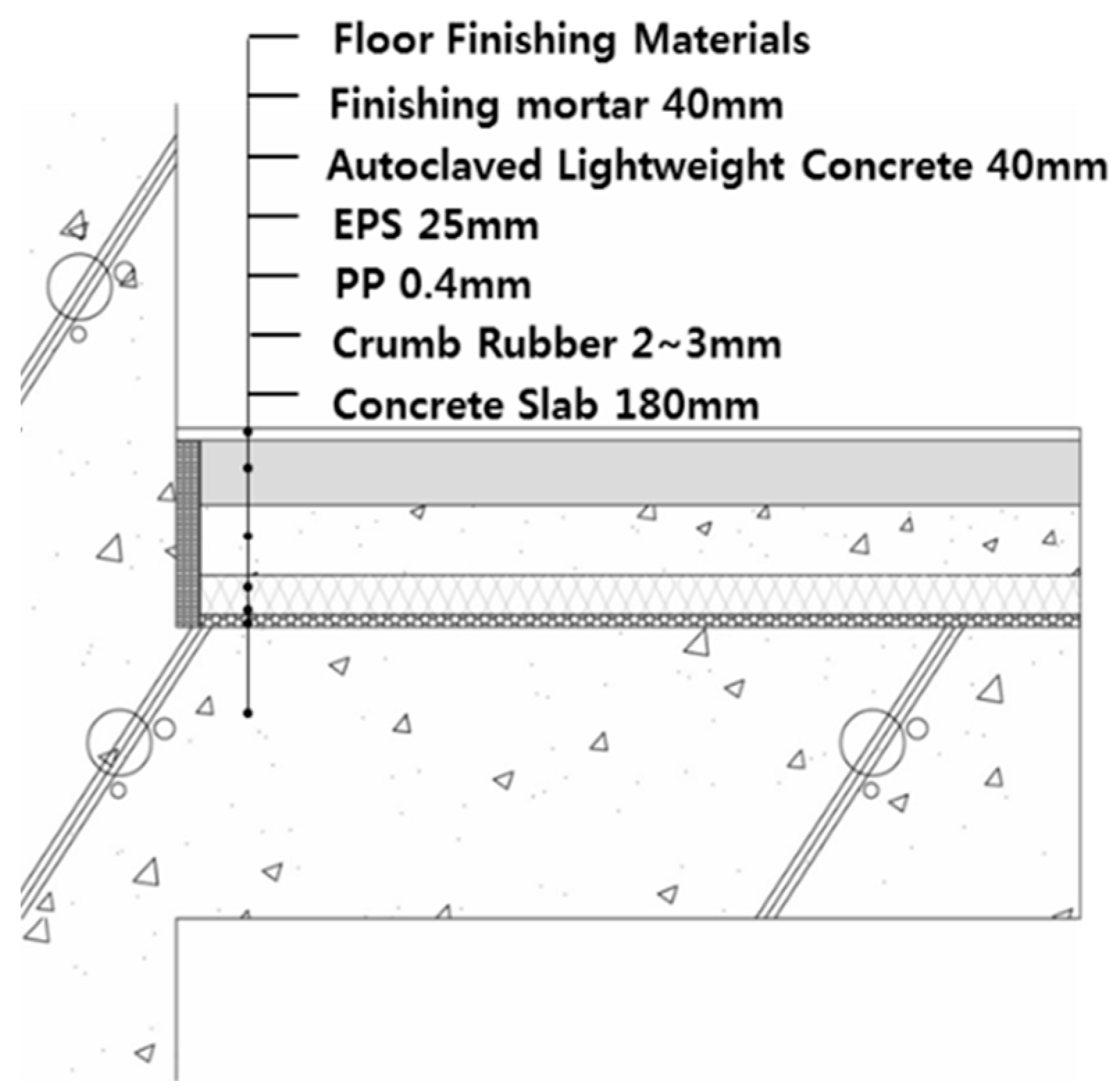

The experiment was performed for objectives of floor Type 1 with a particle size of crumb rubber 5∼7 mm, PP sheet 0.4 mm, EPS 25 mm and floor Type 2 with a particle size of crumb rubber 2∼3 mm, PP sheet 0.4 mm, EPS 28 mm. The following

Figure 3 and

Figure 4 show the cross sections of floor Type 1 and 2 of floating floor structure according to the change of particle size. Especially, as the resilient material for the floor impact noise had a weak re-duction performance, to check the reduction performance for the heavy impact noise level from the measured result of floor impact noise, the heavy impact noise level was measured for the objective of 180 mm concrete slave, excluding the construction of floating floor structure.

3. Results

Table 2 shows the floor impact noise standards of Korea for lightweight and heavy-weight impact sound with four different grades that have been implemented since 2006. These standards have been implemented to ensure acceptable levels of noise within residential buildings, improving the quality of living by mitigating floor impact noise.

3.1. Floor Impact Noise Level by Standard Light-weight Impact Source(Tapping Machine)

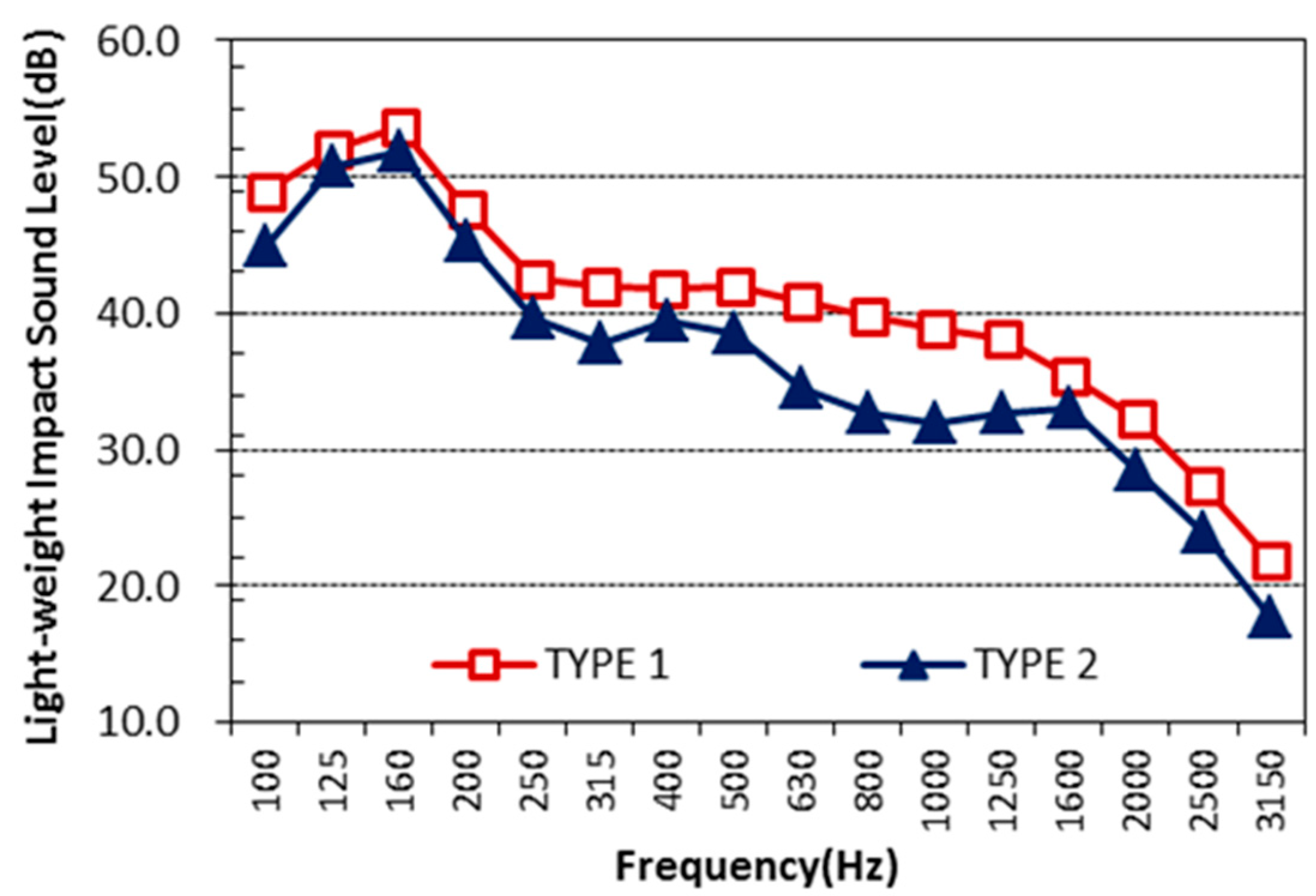

The value of floor impact noise level by the standard light impact source was computed for the 1/3 octave band with the level which had modified the background noise. A comparison graph for the light impact noise level according to the frequency per TYPE of level computed by this is as in

Figure 5. As shown in the

Figure 5, through the values of the light impact noise level by the standard light impact source, in case of floor Type 2, the reduction performance for the light impact noise was improved. By that reason, according to the study result by K.W.Kim, it can be known that, as the thickness of resilient material became thicker, the reduction performance of the light impact noise increased.[

4] Accordingly, it is judged that even though the thickness of resilient materials complex composition’ was the same as 30 mm in case of floor Type 2, the effective thickness of EPS for the reduction performance of the light impact noise appeared to be 3 mm thicker than that of floor Type 1. On the other hand, it was shown from the study result that, if the dynamic modulus of elasticity of resilient material increased, the reduction performance of the light impact noise also decreased. However, it was shown that, although the dynamic modulus of elasticity in floor Type 2 was higher than that of floor Type 1, the reduction performance of the light impact noise was excellent.

When the light impact noise levels of floor Type 1 and 2 per frequency were compared, it can be known that in both floor Type 1 and 2, as for the result which had generally appeared from the resilient material for the floor impact noise utilizing EPS, the light impact noise level became lower as it is moved to the middle & high frequency bands.

3.2. Floor Impact Noise Level by Standard Heavy-weight Impact Sources (Bang Machine, Impact Ball)

The value of floor impact noise level by the standard heavy impact source was computed for the 1/3 octave band with the level which had modified the background noise. Especially, the reduction characteristic of heavy impact noise level by the floor impact noise resilient material utilizing crumb rubbers was compared and analyzed with the heavy impact noise level measured at slaves only.

3.2.1. Bang Machine

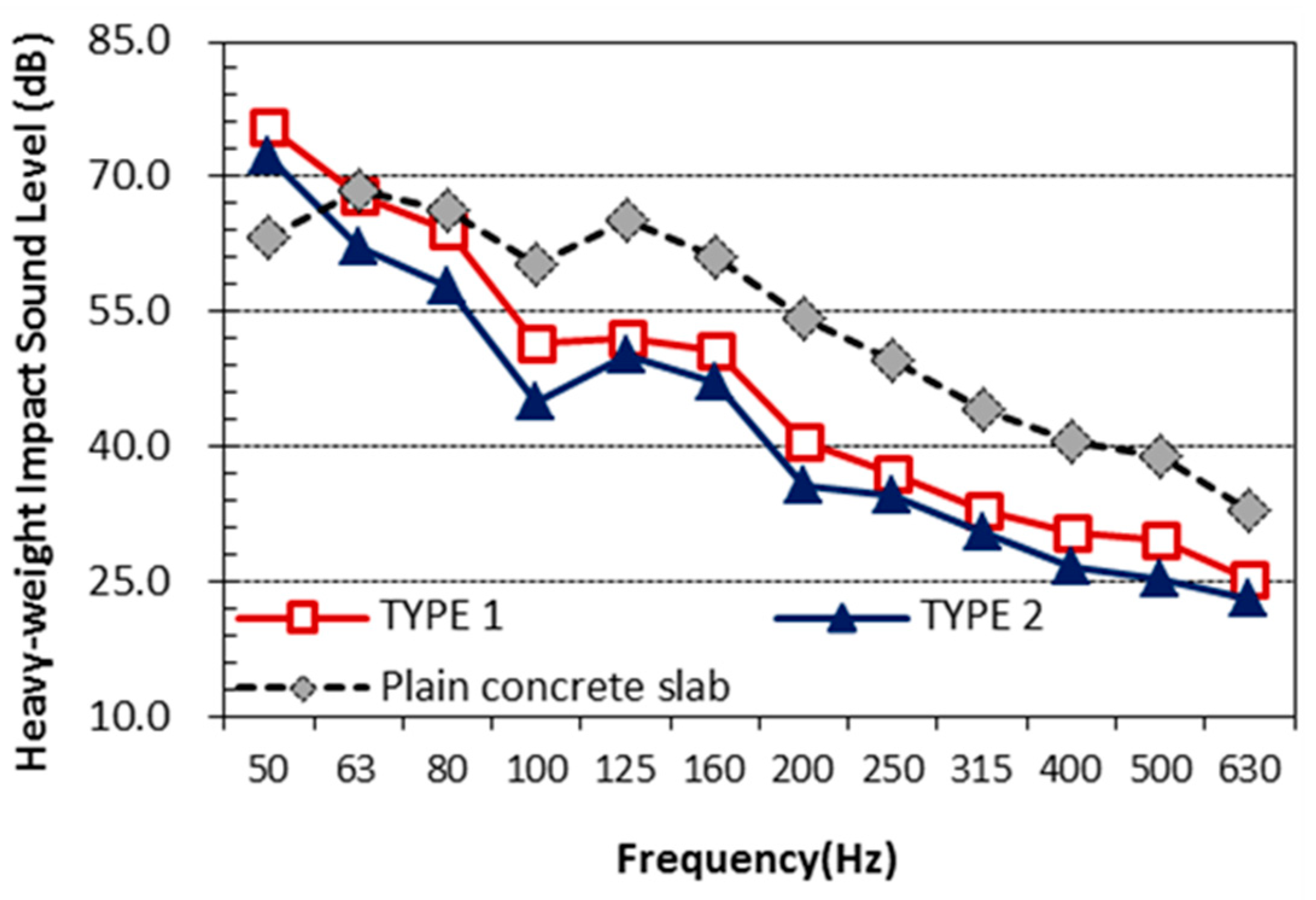

The value of floor impact noise level by Bang Machine was computed for the 1/3 octave band with the level which had modified the background noise. The measured result of the heavy impact noise level computed by this is as in

Figure 6. It was shown that in the

Figure 6, through the value of heavy impact noise level by Bang Machine among the standard heavy impact sources, the resilient material of floor Type 2 showed the higher reduction performance of heavy impact noise than that of floor Type 1. In addition, the reduction performance of heavy impact noise showed outstanding in the low frequency band, which is the major cause for the noise between floors by the heavy impact noise. In the previous studies of this thesis, it was shown that the lower the dynamic modulus of elasticity was, the higher the reduction performance was. However, from the result of actual construction of resilient material in the standard experiment room for the floor impact noise, it was shown that the reduction performance of floor Type 2 with the higher dynamic modulus of elasticity was more excellent. It is believed that the difference of dynamic modulus of elasticity per TYPE was minimal, and also that when the composition of resilient layers of floor Type 1 and floor Type 2 was compared, the particle size of crumb rubbers might have affected the reduction performance of heavy impact noise. When the block performance of heavy impact noise per frequency was compared, it can be verified that at 50 Hz, the heavy impact noise level increased more when resilient materials were installed than when only the slaves were installed. In case of concrete slave, it seemed that the inherent vibration frequency of resilient material by the heavy impact source installed for 63 Hz band (40 Hz~80 Hz) was located at 50 Hz to generate the resonance and rather to increase the heavy impact noise level.

3.2.2. Impact Ball

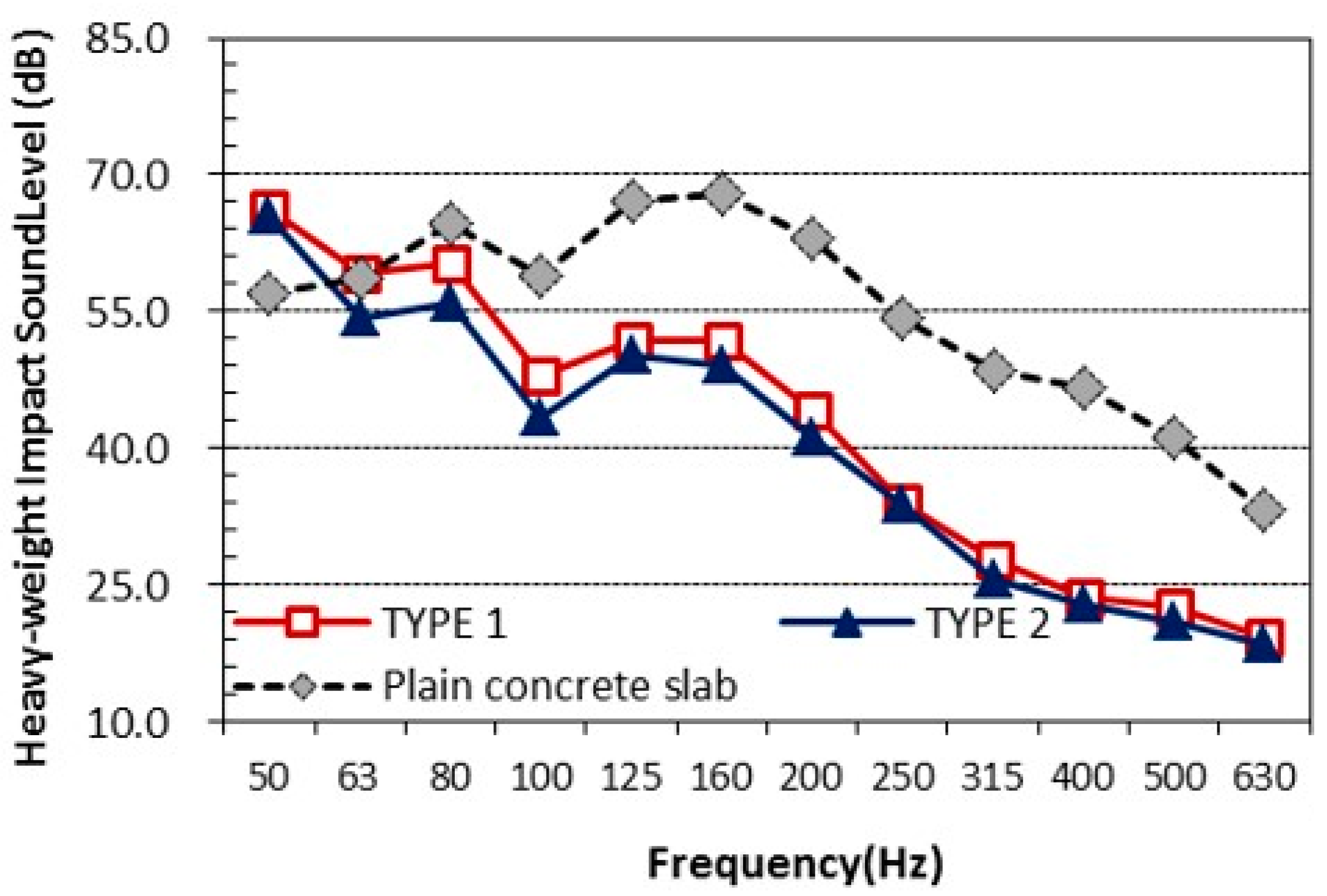

The value of floor impact noise level by Impact Ball was computed for the 1/3 octave band with the level which had modified the background noise. The measured result of the heavy impact noise level computed per floor Type by this was compared by the frequency and shown in

Figure 7. It was shown in the

Figure 7 that, through the value of heavy impact noise level by impact Ball among the standard heavy impact sources, the reduction performance of the heavy impact noise of floor Type 2 was higher than that of floor Type 1, same as in the Bang Machine. Especially, the difference of the reduction amount of heavy impact noise in the 80 Hz band excluding 50 Hz and lower showed to be higher than that in the frequency band above 125 Hz. In the frequency band of 125 Hz and higher, the re-duction amount of floor Type 1 and floor Type 2 showed almost similar.

When the block performance of heavy impact noise per frequency was compared, it can be verified that the heavy impact noise level rather increased when the resilient material was installed at 50 Hz than when slaves were installed only, which was equivalent to the heavy impact noise level measured by the Bang Machine as the heavy impact source.

3.3. Performance Grade of Floor Impact Noise of Resilient Material Utilizing Crumb Rubber

The block performance of the floor impact noise of resilient material utilizing crumb rubber was evaluated through the grade standard of the block performance of floor impact noise according to the detailed measuring standard in the management standard of floor impact noise.

Table 3 shows the impact noise level by evaluating the floor impact noise according to KS F 2863, which was measured by exciting the standard light impact source and heavy impact source.

Accordingly, the grade standard has been marked for the block performance of floor impact noise. It was shown that for floor Type 1, the block performance of the floor impact noise of resilient material utilizing crumb rubber corresponded to the first grade in the light impact noise, and among heavy impact noises, the third grade in case of exciting the Bang Machine, the second grade in case of exciting the Impact Ball. For floor Type 2, it was shown that the block performance was the first grade in the light impact noise, and in case of exciting the Bang Machine and the Impact Ball, both showed the second grade.

4. Conclusions

In this study, based on the resilient material designed for the floor impact noise utilizing crumb rubber, the floor structure was constructed in the standard test room. The floor impact noises were measured, and the reduction performance was analyzed. The result of this study can be summarized as follows.

1) When the standard impact source was excited, the reduction performance of the resilient material of floor Type 2 showed excellence for both the light impact noise and the heavy impact noise.

2) It was predicted that the block performance of the floor impact noise of floor Type 2, which has a lower dynamic modulus of elasticity, would be poorer than that of floor Type 2, but it showed that the performance of floor Type 2 was excellent at the time of onsite measurement.

3) In both floor Type 1 and 2, a resonance was generated at 50 Hz so that the heavy impact noise was not reduced but rather increased.

4) For floor Type 1, the block performance in the light impact noise satisfied the first-grade standard, and among the heavy impact noises, the third-grade standard when exciting the Bang Machine, the second-grade standard when exciting the Impact Ball. For floor Type 2, the block performance satisfied the first grade in the light impact noise, and the block performance in the heavy impact noise satisfied the second-grade standard when exciting both the Bang Machine and the Impact Ball.

5) Regardless of the different characteristics of impact sources which the Bang Machine and the Impact Ball have as the standard heavy impact source, floor Type 2 showed the reduction performance of floor impact noise which was similar to those two impact sources.

Through the present study, utilizing the crumb rubber as a resilient material for the floor impact noise, it has been judged that the reduction performance of floor impact noise was excellent. In addition, supplementing the weak resilient material to the reduction performance of heavy impact noise, an effective structure has been developed for controlling the heavy impact noise. It is judged that in the future, it will be necessary to verify the reduction performance of floor impact noise by constructing at the actual field of apartment.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “Conceptualization, C.H.Haan.; methodology, C.H.Haan.; software, C.H.Haan.; validation, J.H.Park and C.H.Haan.; formal analysis, J.H.Park.; investigation, J.H.Park.; resources, X.X.; data curation, J.H.Park.; writing—original draft preparation, J.H.Park.; writing—review and editing, C.H.Haan.; visualization, J.H.Park..; supervision, C.H.Haan.; project administration, C.H.Haan.; funding acquisition, C.H.Haan. All authors have read and agreed to the published version of the manuscript.” Please turn to the CRediT taxonomy for the term explanation. Authorship must be limited to those who have contributed substantially to the work reported.

Funding

This research was funded by NAME OF FUNDER, grant number XXX” and “The APC was funded by XXX”. Check carefully that the details given are accurate and use the standard spelling of funding agency names at

https://search.crossref.org/funding. Any errors may affect your future funding.

Data Availability Statement

We encourage all authors of articles published in MDPI journals to share their research data. In this section, please provide details regarding where data supporting reported results can be found, including links to publicly archived datasets analyzed or generated during the study. Where no new data were created, or where data is unavailable due to privacy or ethical restrictions, a statement is still required. Suggested Data Availability Statements are available in section “MDPI Research Data Policies” at

https://www.mdpi.com/ethics.

Acknowledgments

In this section, you can acknowledge any support given which is not covered by the author contribution or funding sections. This may include administrative and technical support, or donations in kind (e.g., materials used for experiments).

Conflicts of Interest

The authors declare no conflicts of interest.” Authors must identify and declare any personal circumstances or interest that may be perceived as inappropriately influencing the representation or interpretation of reported research results. Any role of the funders in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript; or in the decision to publish the results must be declared in this section. If there is no role, please state “The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results”.

References

- Hong, S. S.; Lee, S.M.; Haan, C.H. Floor structure for the reduction of floor impact noise of apartment with concrete slab less than 210 mm. J. Acoustical Soc. Kr. 2004, 43(6), 724-736.

- Chung, J. Y. Minor repair technology using floor covering to reduce floor impact sound. Archit. Sci. Rev. 2023. 67, 41-44.

- Lee, J.W.; Jeong, G.C.; Kwon, Y.P. Correlation between Dynamic Characteristics of Isolation Material and Impact Noise Reduction of Light-weight Impact Source. Proceedings of the KSNVE Annual Spring Conf., 2003. 191-195.

- Kim, K.W.; Jeong, G.C.; Sohn, J.Y. Evaluation of the Dynamic Stiffness and Heavy-weight Floor Impact Sound Reduction by Composition of Resilient Materials. Trans. Korean Soc. for Noise and Vibration Engineering. 2008, 18(2), 247-254. [CrossRef]

- Ryu, J.K. Relationship between property of isolator for standardized floor structure and floor impact sound level. Proceedings of the KSNVE Annual Spring Conf., 2002. 278-279.

- Kim, J.H.; Mun, D.H.; Jeong, G.C.; Park, H.G. Influence of Floor Dimension and Resilient Material on Heavy Impact Noise of Floating Floor System. Trans. Korean Soc. for Noise and Vibration Engineering, 2017. 27(4), 434-443. [CrossRef]

- Lee, K.J. A study on the floor impact sound insulation characteristics due to resilient layer compositions. Master thesis, Dong shin University, Naju, Republic of Korea, 2013.

- Kim, K.W.; Jeong, G.C.; Sohn, J.Y. Evaluation of the dynamic stiffness and heavy-weight floor impact sound reduction by composition of resilient materials. Trans. Korean Soc. for Noise and Vibration Engineering, 2008. 18(2), 247-254. [CrossRef]

- Lee, B.K.; Bae, S.H.; Hong, C.H. A evaluation study on reduction method of floor impact noise through field test and the effective method for heavy impact noise. Proceedings of the KSNVE Annual Autumn Conf., 2004. 451-456.

- Ryu, J.K.; Jeong, G.; Lee, J.; Kim, H. Effect of thickness and composition of isolator for standardized floor structure on floor impact sound level. Proceedings of the KSNVE Annual Autumn Conf. 2013. 382-383.

- Lee, J.; Lee, S.M.; Haan, C.H. Investigation of the level difference of floor impact noises through the shape variation of EVA resilient materials with composite floor structure. J. Acoustical Soc. Kr. 2024. 43(1), 60-71.

- Koo, B.S.; Lee, B.K.; Hong, S.S. Developed plaster type of floor insulation material for remodel apartment. Proceedings of the KSNVE Annual Spring Conf., 2018. 267.

- Koo, B.S.; Lee, B.K.; Hong, S.S. Analysis of reduction method of floor impact noise in remodeling apartment. Proceedings of the KSNVE Annual Autumn Conf., 2020. 176.

- World Business Council for Sustainable Development. End-of-life tire management Toolkit. 2021.

- Lee, W. H.; Byeon, H. S.; Bae, H. M. Studies on physical properties of wood-based composite panel with recycled tire chip-Change of properties on composite panel by mixing ratio of combined materials. Journal of the Korean Wood Science and Technology, 1998. 26(1), 70-75.

- Yang, K.S.; Lee, S.H.; Kim, H.Y.; Kim, S.M. The Experimental Study on the Impact Sound Insulation Floors due to Waste Tire Chip. Trans. Korean Soc. for Noise and Vibration Engineering, 1999. 9(3), 477-484.

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr, 2021. 11, 447-454.

- Bala, A.; Gupta, S. Thermal resistivity, sound absorption and vibration damping of concrete composite doped with waste tire Rubber: A review. Construction and Building Materials, 2021. 299, 123939.

- Kim, I.H.; Choi, Y.; Jeong, D.H.; Park, D.H. A Study of Compressive Strength estimation of Rubberized Concrete using Ultrasonic Pulse Velocity Method. Proceedings of the Architectural Institute of Korea Annual Autumn Conf., 2015. 519-520.

- Ministry of Land Infrastructure and Transport. Standards of approval and inspection for the floor impact noise insulation structure of apartment. Ministry of Environment of Korea: Sejong, Republic of Korea, 2023.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).