1. Introduction and Background of the Study

Every manufacturing company wants to improve and adapt their operating system in order to survive the industry competition. The success of textile and garment companies in their competition for global market control their focus on more effective and efficient manufacturing processes. The necessity to reduce the cost of production has also caused manufacturers to focus on waste minimization. Garment industries are among the most labor intensive industries known in many countries.

It is important to understand exactly what waste is and where, how and why it exists. Waste is an uneconomical use of resources and This waste includes materials, machines, labor, time, and revenue, resulting in a supply of products in an unwanted quantity (over and above, less and below). For any waste, there is a strategy to reduce or eliminate its effect on a company, and improve overall performance and quality of the product or service delivered by the factory.

In manufacturing organizations, to improve their system it might mean to reduce the operating costs that come from the wastes in production line by Optimization and simulation of Manufacturing Processes are choice in problem solving.

The main work for balancing production lines is using of Line balancing technique to solve problems occurred in assembly line process. It is a technique to minimize unbalance between the workers and workloads to achieve required run rate. This can be done by equalizing the amount of work in each station and assign the smallest number of workers in the particular workstation [

1]. But the major obstacle to attaining a perfectly balanced line is the difficulty of forming task bundles that have the same duration. Here the job is divided into small part called job element. The aim job element is to keep up production at equal rate. Line that is perfectly balanced will have a smooth flow of work as activities along the lines are synchronized to achieve maximum utilization of labor and equipment. On the basis of time taken of each operation the reason for line balance is that; Maximum output, avoid any bottleneck, Smooth flow of work (production), less supervision and effort.

Improving Productivity could come from reduction in wastage of resources such as labor, machines, materials, power, space, time, capital, and by initiating operators and offer incentives to produce more and more with less and less inputs of resources. It leads for the development of an attitude of mind and a constant urge to find better performance of operators and their leaders. Aims at the maximum utilization of resources for yielding as many goods and services as possible, of the kinds most wanted by consumers at lowest possible cost. Provide improvements in the layout of lines and work, better working conditions and simplification of work [

2].

Using a valid simulation model gives several benefit and advantages in developing a better system and in predicting the manufacturing processes behavior under varying set of circumstances in order to improve the manufacturing processes performance. Since Optimization and simulation are potential engineering tools for analysis as well as increase productivity by eliminates processes constraint in apparel of garment industries. The visual simulation of manufacturing processes is connected with automated preparation and realization of the production.

Optimize and simulation Process operation is one of the best engineering tools to eliminate production constraints during operation and to balance work load distribution in each work line. Optimization methods typically include line balancing, minimize production cost, minimize deliver time but can also involve more specialized types of simulation, such as work-center simulation or whole-factory discrete event simulation.

Thus, these industries are not as profitable as they were expected to be [

3]. Due to these reasons this research has concerned with development optimization and simulation of manufacturing processes in garment industries for eliminate manufacturing processes constraints.

1.1. Problem Statement

Most of these Tigray garment industries are not as profitable as they were expected to be and their customers are becoming dissatisfied due to different manufacturing constraints. The common problem existing in Tigray garment industries are high production costs, late deliver time to their client, low quality of products, expansion defects and non-value added processes which leads the companies to low productivities.

To design new manufacturing processes and implement optimization, simulation techniques to improve the manufacturing processes in order to eliminate bottleneck or constraints of the processes.

There is also unbalanced line that hinders production efficiency, speed and effectiveness of the company in one and another way. There is a difference between the planned and real outputs of products on sewing line that have a huge amount of variations.

1.2. Objective of the Study

1.2.1. General Objective

General objective of this paper is optimization of manufacturing processes using ARENA simulation and algorithm tools to enhance productivities of the garment industries.

1.2.2. Specific Objective

- ❖

To set prioritize of the problem based on their degree of negative impacts for productivities

- ❖

To analyze the standard minute value of each activity and the long pant

- ❖

To analyze the standard performance of each operation.

- ❖

To provide a comprehensive review of the existing manufacturing processes through value stream mapping

- ❖

To optimize the processes by eliminate the problems (manufacturing process constraints)

- ❖

To simulate the optimize manufacturing processes using arena software

- ❖

To propose an improved model for the sewing sections

1.3. The Scope of the Study

Scope of this research is on optimization using arena simulation and algorithm tools to enhance productivities of Tigray garment industries. The research shows that; how the garment industry increases their productivities and to be competitive in a sustainable manner and can contribute to national economic growth, employment generation, foreign exchange earning etc. Even though the research aims on the general country level, due to time and financial limitation, this research focuses on garment industries in Tigray region. This research work makes an assessment on productivities related problems in selected Tigray garment industries and provides concrete and applicable study and improvement production system so that the overall activities of the industries can be improved overall their productivities and can be competitive in the local as well as international markets.

1.4. Significance of the Study

This research focus on garment industries on manufacturing process optimization to enhance productivities of the companies as we know in Ethiopia garment factories are more expanded and the Ethiopia government as well as Tigray region, however the companies have not become productive as much as possible due to so many manufacturing constraints. Thus implementing the findings of this research will improve productivities of the companies since optimization tools are a key for enhancement of the manufacturing processes.

3. Methodology

3.1. Data Collocation

3.1.1. Primary Data Collection

- ❖

Visual observations; Conducted to know where the bottleneck was and Observing overall of the company specifically on sewing section.

- ❖

Interview; conducted to know a detailed know how on garment section specifically in sewing area by doing interview with production manager, planning manager, time study and line balance man, line supervisors and workers of the company.

- ❖

Direct recording of data; conducted to know standard minute value (SMV) for each operation and the researchers have taken direct recording on operation time of each tasks and have taken 20 times for each operation.

3.1.2. Secondary Data Collection

The secondary data sources that used for conducting this study are recorded planning activities, Daily reports inputs and outputs of the long pant, performance of each operator, Official documents and Referring to some books.

3.2. Data Analysis

This research is analyzed by reviewing of the existing time study and line balancing for Identification of bottle necks area and Applying different line balancing techniques and calculations such as labor productivity, machine productivity, output per day, theoretical man labor and profit for comparison of existing line before and after line balanced. In addition, in this study arena software was used for constructing bar diagram that is used to show the bottleneck area.

3.3. Sewing Operation Line Parameters

This study needs a lot of data like man power, machine capacity, and sequence of jobs; inter arrival of parts for assembling, processing time at each machine, efficiency, quality product outputs (number of defects, rework, and normal). Such data are used for model the production line. Therefore; the researchers have used primary data and secondary data. And the researchers have used different tools for recording some necessary information like processing time for new products transfer time from one station to the next one. The researchers have tried to find the causes; why the company did not achieve its goals. And finally discussed the causes of poor efficiency and its remedy action to attain the profit maximization by optimization the processes.

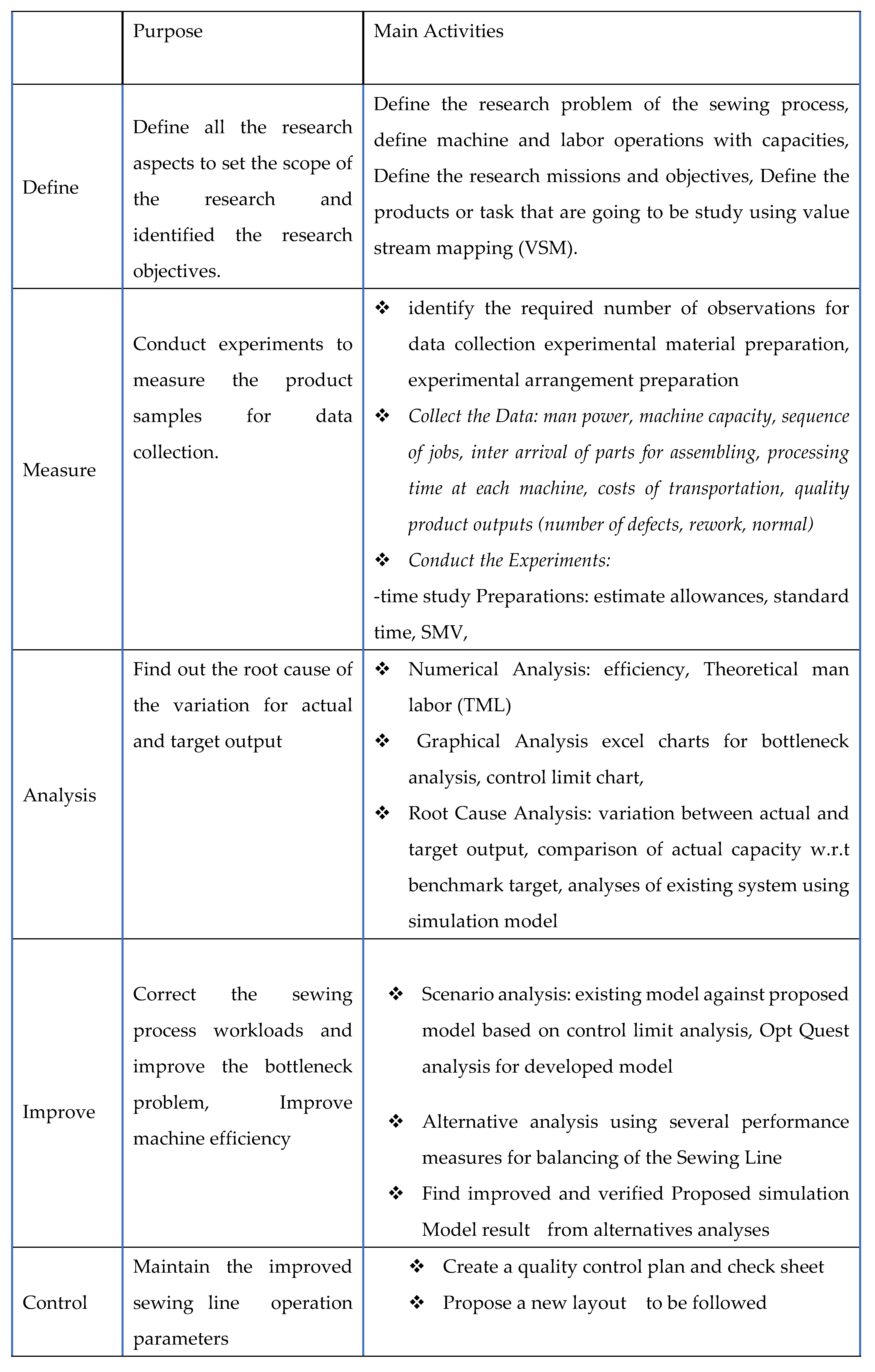

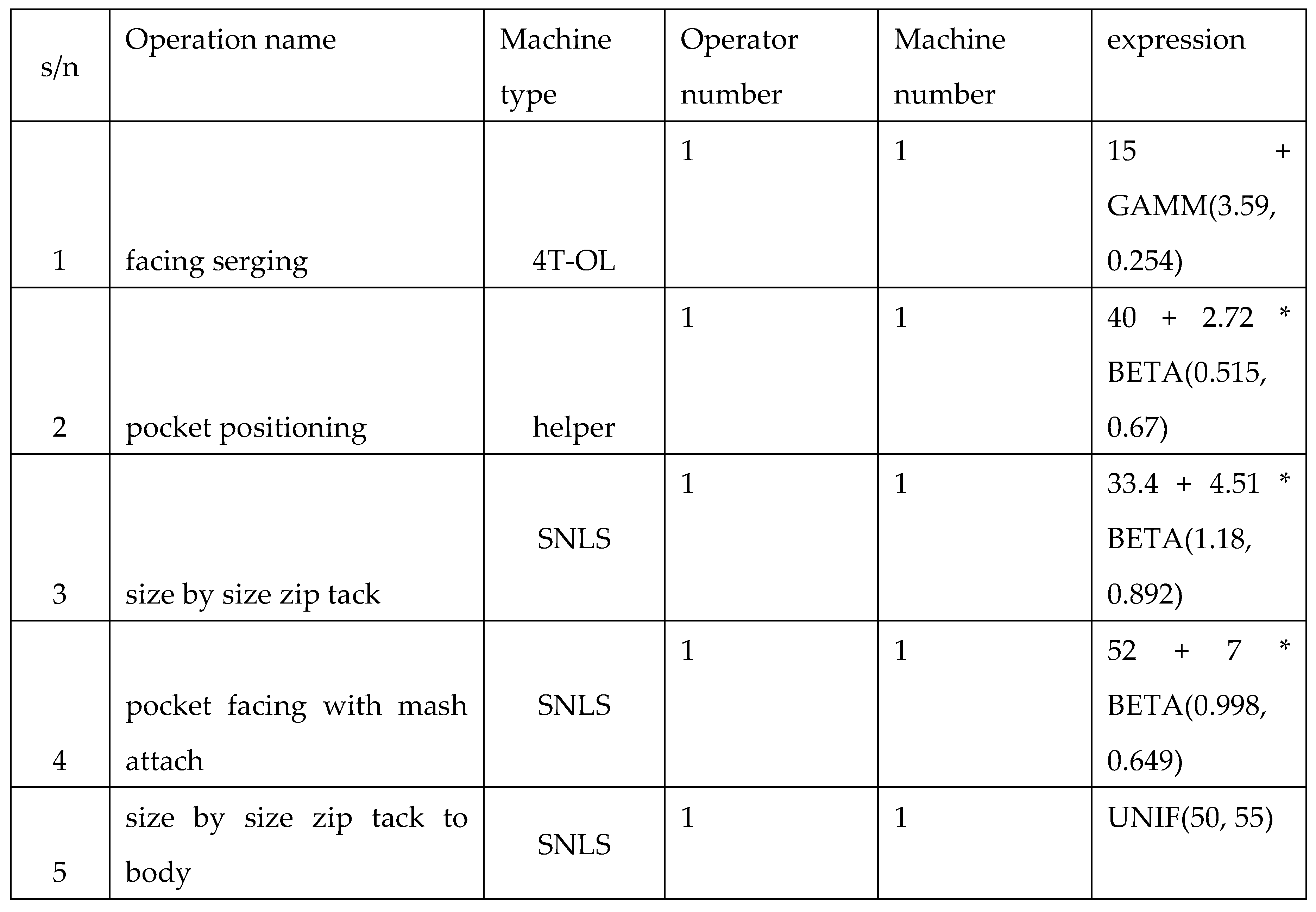

Table 1.

The DMAIC process route & content of the research .

Table 1.

The DMAIC process route & content of the research .

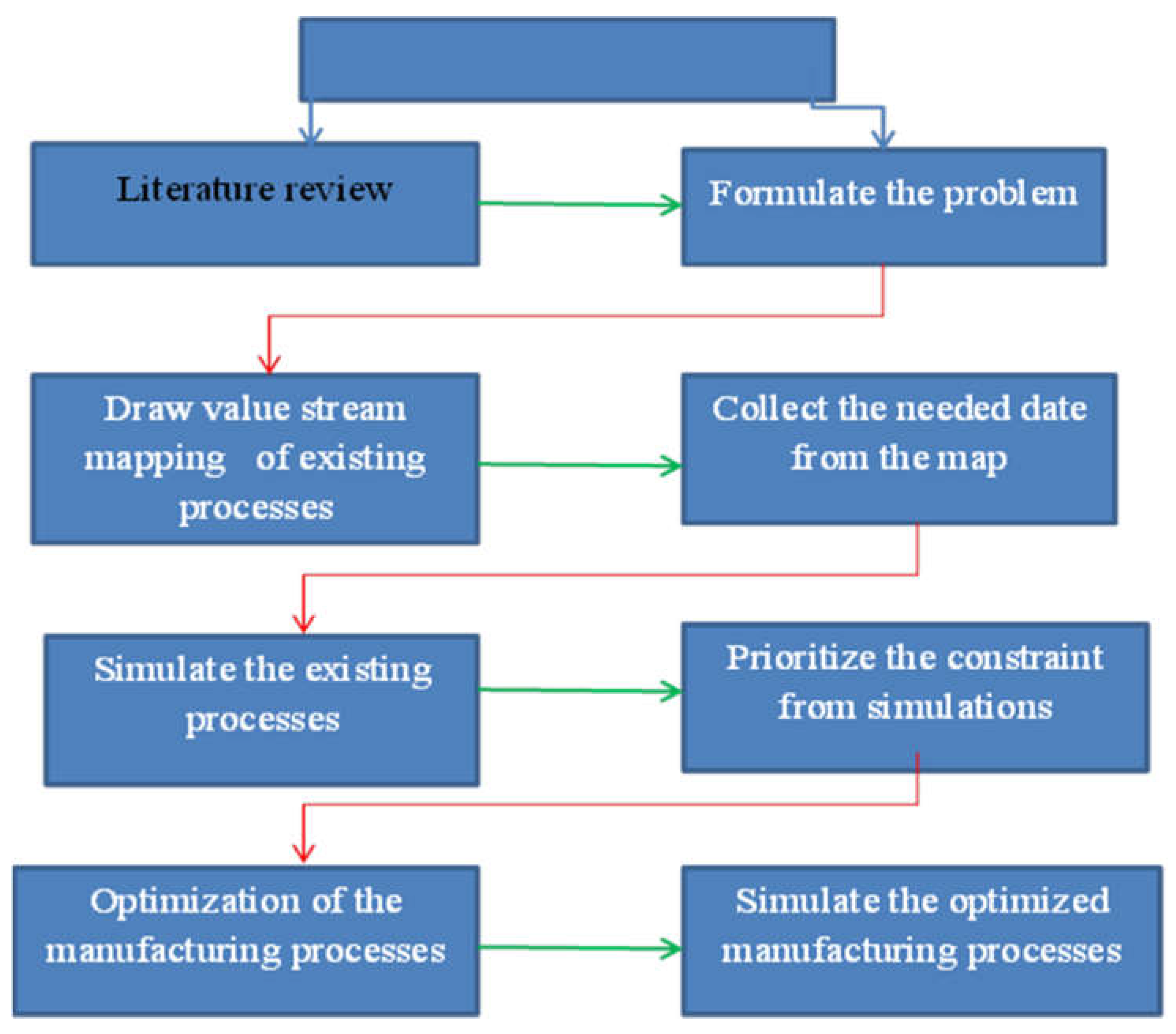

This methodology will use both qualitative and quantities approach and the methodology flows as the figure indicate.

Figure 1.

research methodology.

Figure 1.

research methodology.

3.4. DMAIC Approach Methodology

Step 1 Defines;

This stage is very important phase, an organization has to ask or to identify themselves some very crucial questions like what are the flaws in the production process and what how have any problems affected business operations. At these phase to measure effectiveness of the garment industries by comparing their plan and actual status in terms of effectiveness and efficiencies.

Step 2 Measurement phase;

At this phase garment industry here needs to look at their production system and see what’s working and what isn’t. When everything is measured up, an organization is able to know what the root cause of their production problem is and start looking for ways to solve it. Having a data collection plan is very useful when conducting this phase. At this phase the magnification tools like fishbone diagram to identify the root cause of the problem.

Step 3 Analysis phase;

During this phase, the researcher will analyze what they have gathered during the measurement phase about their production process. When data is analyzed by the management, an organization is able to narrow down the cause of their production problems and figure out ways to maximize things.

Step 4 improvement phase;

At this phase the production problem is will well understand by everyone, it is time for everyone in the organization to start brainstorming ideas on how to make things better. This is the stage where garment industries test and implements all their ideas in terms of improving production and makes any changes if needed. At this phase the optimization by algorithm will conduct.

Step 5 control phase;

At this phase Implement the optimize production system or solution to the production problem is only the beginning; on the garment industries has to make sure that they maintain it. This is the last stage of the continuous improvement process and it is all about coming up with strategies to maintain high levels of production all the time. At this stage the new optimize production system will introduce to the companies by giving training for the responsible persons.

Data Collection methods

Part arrival rates, part processing rates, number and availability of resources, workload distribution, and operation time are essential parameters to calculate system performance measures and identify the problem as well as to know such as average waiting time, resource utilization, and average time in the system. For each part, the arrival time of parts, part’s processing start time, and processing end time from each work station using time study method has been recorded for seven working days each of seven work hours using stop watch to the responsible person for primary data. And as secondary data; manual of the companies and literature has been used for conducting this research.

Data Analysis tools and techniques

- ➣

All collected data have been evaluated by the Arena Input Analyzer software in order to determine distribution function and simulate the modeling.

- ➣

Optimization tools and techniques like opt quest

3.5. Verification and Validation of the Research

The simulation model has been verified using traces and animation technique; the sample t- test with the confidence interval 95% will use to compare the mean throughput from Arena simulation model and the throughput sample from the production line system. The hypothesis test has been accomplished with the help of Minitab statistical software (version 18) to validate the simulation model with a t-test and p-value (0.05). The regression Meta model will analyze using ANOVA analysis of the response (throughput) versus factors with the help of Minitab software.

4. Result and Discussion

4.1. Techniques of Standard Time

The standard time of an operation (tasks) can be determined using the following techniques;

1. time study

2. predetermined motion time system

3. standard data system

4. work sampling

4.2. Method of Calculation

The standard time is the product out of the three factors and these are listed as fellows;

1. Observed time:- the time measured to complete the operation (task) or the activity.

2. Performance rating factor: - this factor is calculated by an experienced worker who is trained to observe and determine the rating factor.

3. Personal, delay allowance and fatigue: - allowance is the adjustment done to the normal time to obtain the standard time for the purpose to recover the lost time due to fatigue, personal needs, and unavoidable delays by providing a small increase can still be able to cover lost time and complete the work assigned to the operator (groover, 2007). And then, standard time can be calculated using the formula below;

Standard time (TS) = normal time (TN) + allowance time (TA)

Normal time =observed time (TO) *rating factor (RF)

Standard time= (observed time) *(rating factor) *(1+allowance)

Standard time = normal time*(1+ allowance)

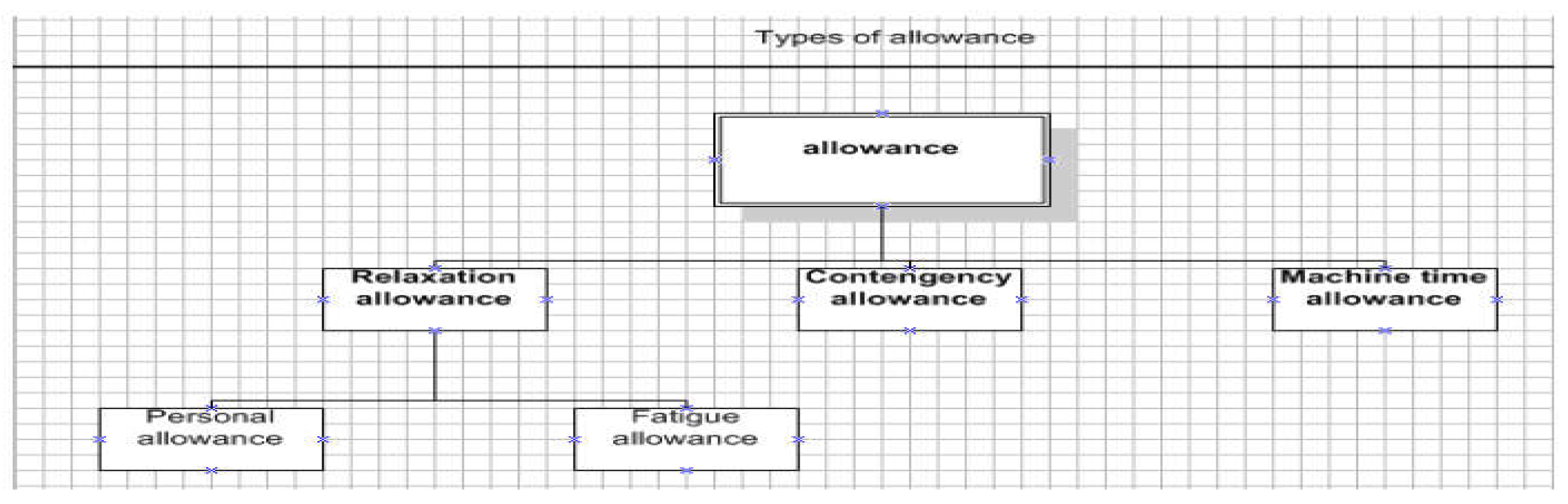

4.2.1. Allowance Technique

There are two types of interruption;

1. Interruption related to work

2. Interruption not related to work for example rest break to overcome fatigue machine break down and receiving instruction from manager are the interruption related to work, but personal needs, lunch break and personal calls are the interruption not related to work. However, the two types of interruption are essential for the worker because it seems to be impossible to work continually during a regular shift.

Figure 2.

types of allowance.

Figure 2.

types of allowance.

4.2.1.1. Personal Needs Allowance

The personal needs allowance is the time that is associated with workers daily personal needs which include restroom, phone call, going to wash room, fetching a drink etc the common figure is about 5-7 % of the basic time. And it is conditional to work environment in term of uncomfortably and temperature for example.

4.2.1.2. Fatigue Allowance

The fatigue allowance is intended to cover the time that the worker should give to overcome fatigue due to work related stress and conditions. There are three factors that cause fatigue: 1. physical factor like standing and use of force 2. mental and eye strain 3. environmental and work factor like poor lighting, noise and heat. Normally it is counted as 4% on basic time.

4.2.1.3. Unavoidable Delays Allowance

Unavoidable delays are categorized under unavoidable interruption that occurs at random times during the day in work place. They usually refer to work related events like cleaning up at the end of the shift and machine breakdowns or malfunction. Unavoidable delays occur because of many random events in work stations. Sometime garments, machines are off due to mechanical or technical problems these are applied to the total basic time for those elements which are concerned with the operation of machinery (sudar, 2015).

4.2.1.4. Contingency Allowance

A Small amount of allowance which is given to meet the legitimate delay of work is counted less than 5%.

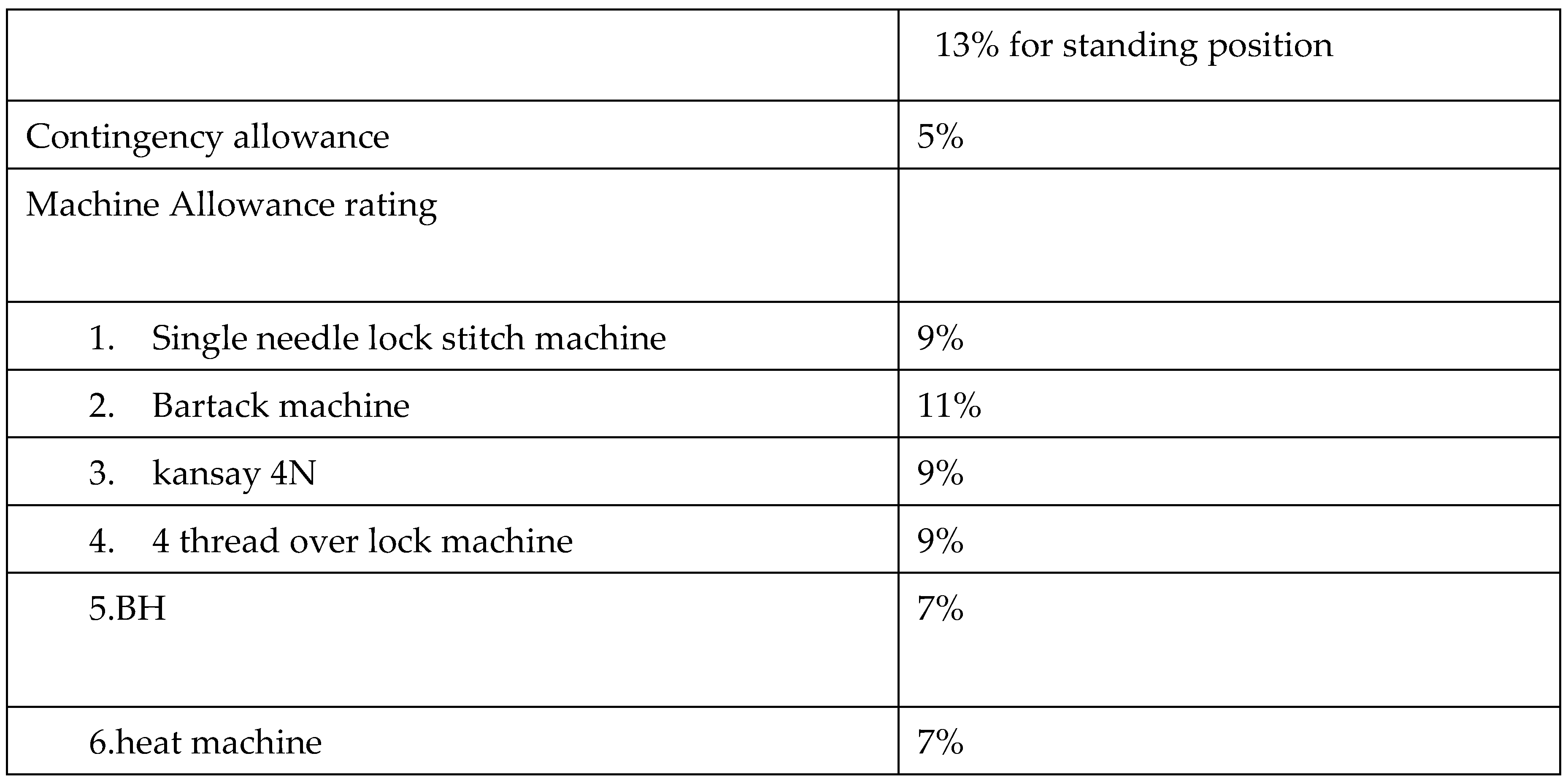

Standard allowances for determining standard time of operations are;

According to the company’s information the performance rate of the operators is assumed to as 100%.

4.3. Standard Time

Standard time for each operation of the long pant type model is as follows.

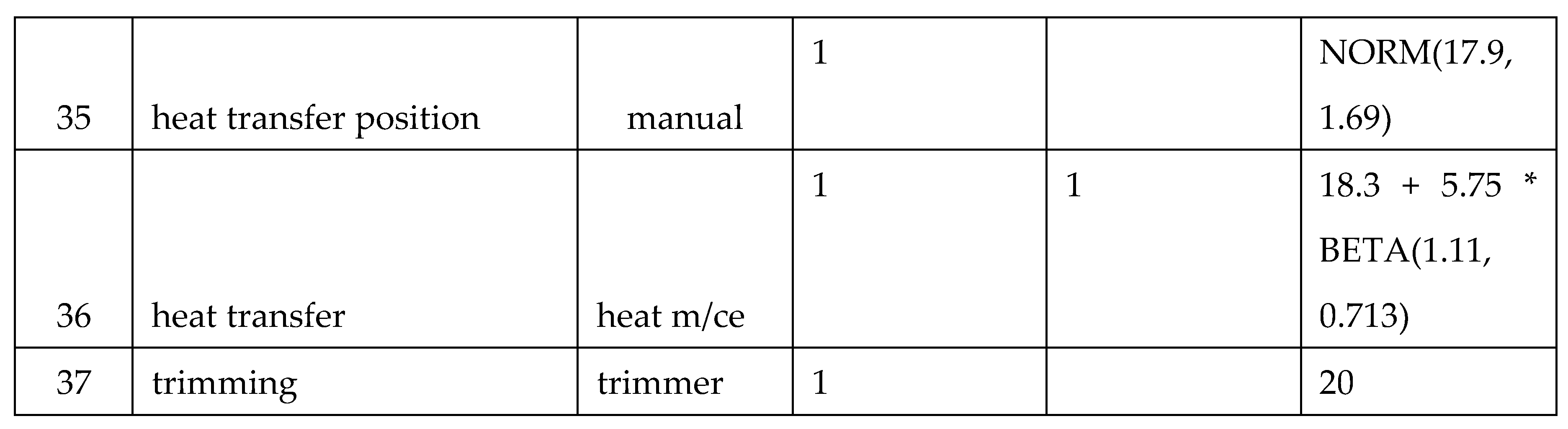

4.4. Data Input Analyzer

All collected data have been evaluated by the Arena Input Analyzer software in order to determine distribution function and used as an input parameter for simulation modeling of the production.

Table 3.

distribution time.

Table 3.

distribution time.

Figure 3.

distribution summarysequence of operations.

Figure 3.

distribution summarysequence of operations.

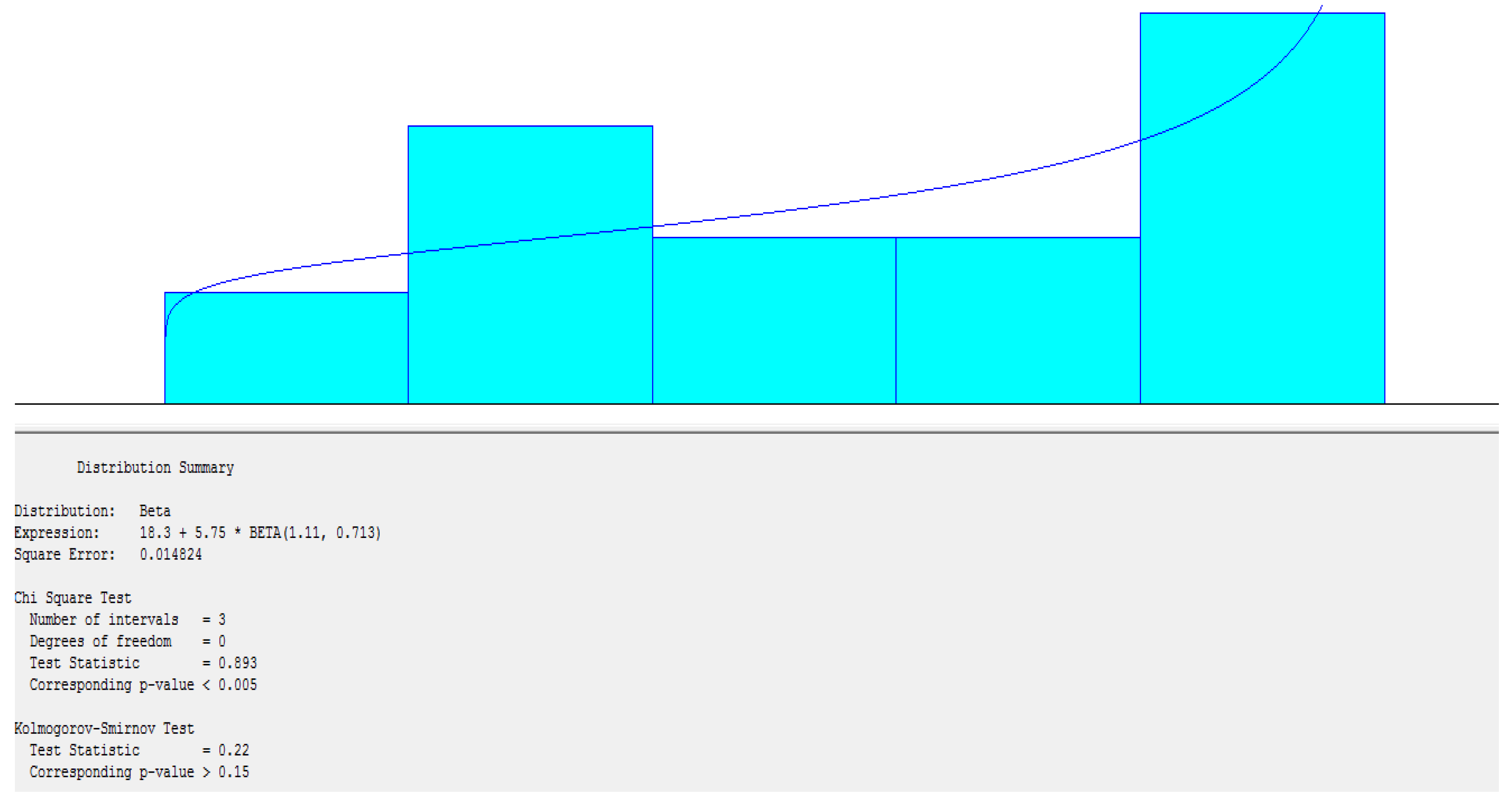

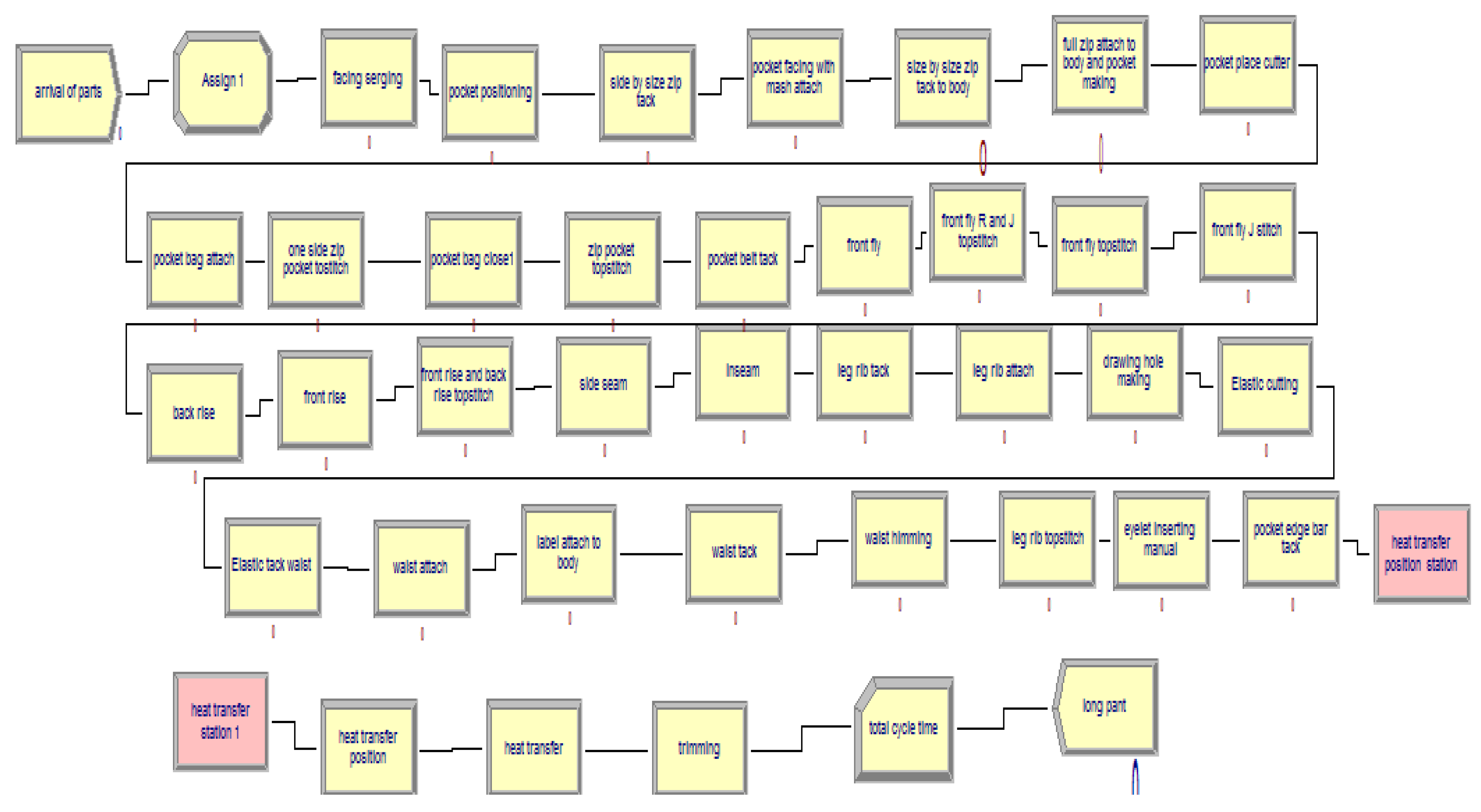

4.5. Development of Standard Simulation Model

The simulation model of the current production system is developed with the aim of identifying bottlenecks in the production system and further experimentation on the system using various what if conditions or scenarios and finally selecting one scenario and develop an optimization for the selected scenario constraints, responses and objective function for the developed model by using opt quest as a tool.

The simulation model is developed based on a production process flow of the company’s long pant assembly line. This study represents discrete-event simulation modeling and the long pant assembly line works for 450 minutes (7.5 hours) in a shift. The following assumptions have been taken in to consideration while modeling the production system;

- ➣

The long pant assembly line is never lacking input materials from cutting section

- ➣

Initially each operation in the sewing assembly line is assumed to begin empty

- ➣

Set-up times are not taken into consideration while modeling the system, because in a real system the setup process is usually carried out at the end of the working hours

- ➣

Maintenance work is not carried out during the working hours

- ➣

450 minutes which is the working time does not include tea or any other breaks

Figure 4.

existing production model.

Figure 4.

existing production model.

4.6. Model Verification and Validation

A model is simplified representation of a real system which includes the most important system components and the interaction between them, a model cannot represent the real system exactly rather it can approximate the system how it behaves and interact. This is mainly due to the assumptions made while developing the model. The performance measures extracted from a model will only represent the real system if the model is a good representation of the system. So verification and validation of the simulation model of this study were carried out using the daily production statistic validity by comparing the actual system and the simulation model results for the existing long pant model. One way for verification is by reviewing the SIMAN code and check if the model is performing exactly what was planned for it to do. But, this way of verification requires a skill in the SIMAN programming language. So the best way for us to verify the model is by looking at the animation. In this verification method it’s allowed only a single entity to enter the system and follow that entity to be sure that the model logic and data are correct. In this simulation model, allowing only a single entity to go through the system has shown that the entity is going through every module as per programmed.

The researchers have made simulation trial runs under a variety of settings of the run parameters, and checked the model output result for its appropriateness. The researchers have taken the real data i.e. the assembly line produces 500 long pants per shift on average from the production line. The simulation model output is tested to run for 7.5 hours and its output is 499 which is almost the same with that of actual data and this is a clear indication that the model is valid [

16]. In addition to this some work stations which are found to be idle and at the same time busy in the actual system were having low and high utilization in the simulation model.

Model validation for this study is made using statistical validity by comparing the daily output of long pant model of the real system as well as the simulation modeling outputs for the long pant of the existing system. If there is no significant statistical difference between the data sets, therefor, the simulation model considered as a valid model. If not the model needs additional works before analyzing the model reports. In this case the average outputs of long pant per day or working hour of eight hours is ranges from 470-520 long pants per day with an average of 500. And the simulation model output is 499 long pants per shift of a day. There for, the simulation model outputs are approaches to the real system outputs. In this case the simulation system representing the real system so this model is valid. In addition to this in the simulation model result some workstations have high work in progress and low work in progress in the real system as well as the simulation model.

4.7. Calculation of Replication Number

In order to determine the number of replication for the model first the researcher have been calculated the mean, standard deviation and half width of the first ten replications of the simulation outputs. In other words, half width is a sampling error that introduce in taking sample. Therefore, the value of half width can be calculated by considering a 95% confidence level where as the value of t can be read from students t probability distribution table (yemane, 2013), (gorema , et al., 2014), (herell, et al., 2004) and for initial number of replication determination it is recommended 10 number of replication for 95% confidence level and arena have 95% confidence level by default (w.david kelton, et al., 2000).

Table 4.

initial number of replication.

Table 4.

initial number of replication.

Mean = summation of long pant output/number of replication

X = (500+498+499+498+498+494+499+498+499+499)/10

X = 498.2

Standard deviation(S):

where; n = number of replications

S =1.619

where α is 0.05 from the 95% confidence interval 95%.

h0=t90.975*s/√n from the t table t90.975 is 2.2622.

Half width for long pant model is: -

h0 = 2.2622*1.619h0 = 1.158185

Actual number of replication

Actual replication of the production system is:

n= Z20.975*S2/h22, but h2=1.158185/4 = 0.289546

n = (1.96)2*(1.619)2/ (0.289546)2

n = 121 --------------------------option 1

n n0*h02/h22

n 10*[(1.158185)2/ (0.289546)2]

n 160 -------------------------option 2

Therefore, from the two alternatives the maximum number of replication has been selected and that is 160 [

4].

4.8. Simulation Model Run Results and Interpretation

The output generated from run simulation model is used to know and predict the performance of the production system. The output analysis also used to predict the initial model performance measurements of the production system of the long pant model. Therefore, based on the output of the simulation model run the performance measurements analyzed for the production system of the long pant are measures as follows.

The performance measurements are selected to analysis the entity performance, queue performance, process performance and resource performance.

Entity performance: the following points are identified from the entity performance:

- ❖

The WIP of the production line of long pant is high for some resources for instance number waiting for full zip attach and body pocket making is 314, for pocket facing with mash attach is 187, pocket positioning is 118 and for facing serging queue is 36.

- ❖

The time required for entities to wait is higher due to the large number of queues for operations which have high WIP and the waiting time is greater than the value added time, it shows that additional resources should be required to minimize the waiting time of the entity.

Queue performance: from the model run result of queue performance, the waiting time and number waiting in full zip attach and body pocket making and pocket facing with mash is higher. Conversely, the waiting time and number waiting of back rise, front fly R and J topstitch, front fly, waist attach, heat transfer position and heat transfer is low. This result shows that, there is unbalance allocation of resources to each station.

Process performance: from the simulation model run results of process performance, the following points are identified and briefly discussed as below:

- ❖

The average waiting time of full zip attach body and pocket making is higher than their value added time. It also has higher waiting time of any other process of the production system of long pant. This means, the entities at this station spend more waiting time have been processed.

- ❖

Average waiting time for processes like waist attach, back rise, front fly, front fly R and J topstitch, heat transfer positioning and heat transfer is low.

Resource performance: the model can give us, a usage of resources like instantaneous utilization, number busy, number scheduled, scheduled utilized and total number seized. In this case some resources are over utilized like SNLa3, SNLa4 and SNLb2 are over utilized resources. And resources like 4TOLa1,4TOLa10,4TOLa2a,4TOLa2b, BH, manual operator 2 and trimmer are below utilized.

Bottleneck identification: the waiting and number of waiting in the full zip attach and body pocket making and pocket making with mash attach are higher than other operations. The resources attached in these operations are highly utilized while; on the back rise and front fly R and J topstitch, resources are less utilized. Therefore, the full zip attach and body pocket making and pocket making with mash attach stations are bottleneck operations. Therefore, the production system of the long pant model requires an improvement.

4.9. Simulation Run Results and Interpretation

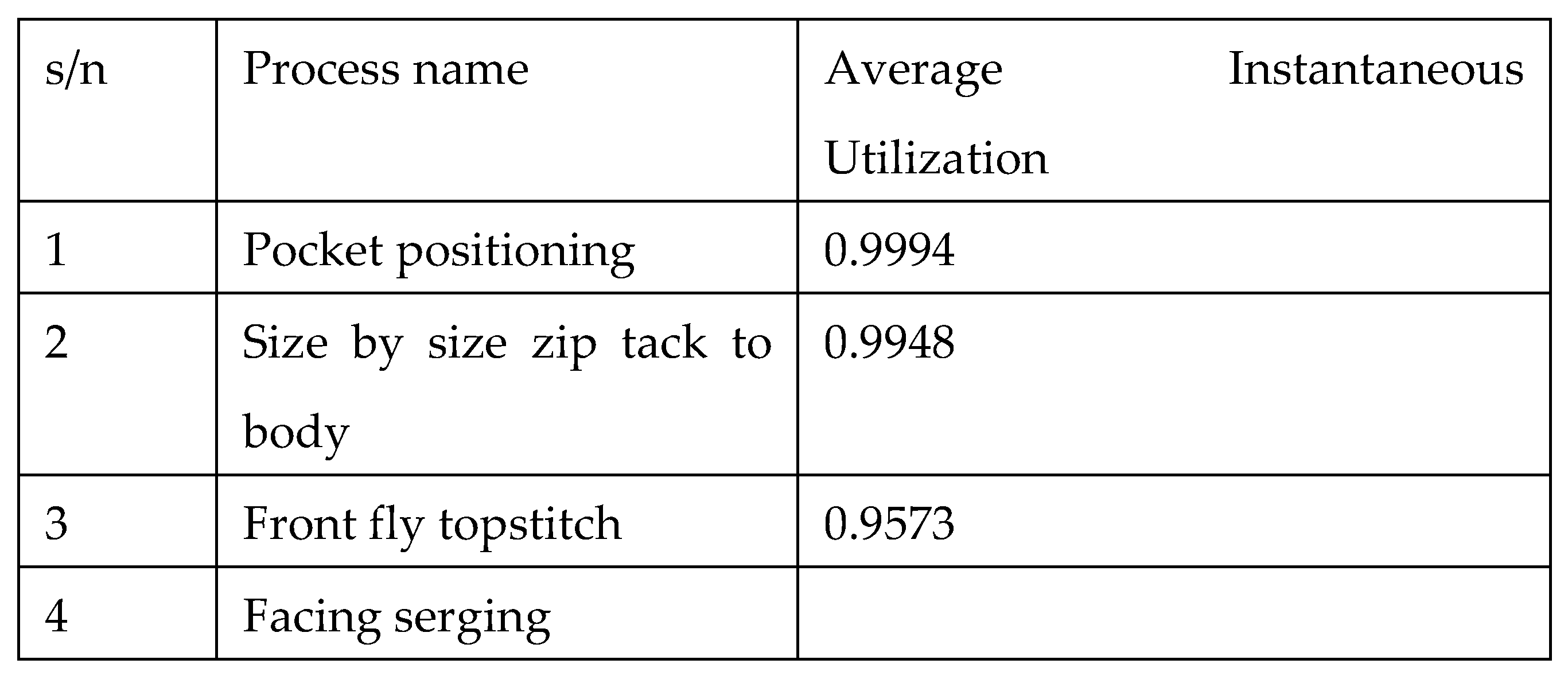

Once the model is developed and run for 160 number of replications; there are many possibilities to manipulate the developed simulation model, but since the objective of this research is to model the long pant assembly line and balance the activities that assemble the long pant components; the researchers have identified the bottleneck and idle operations for further analysis so as to balance the assembly line of the long pant model. A bottleneck is one process in the chain of processes, such that its limited capacity reduces the capacity of the whole assembly process or simply the output of the system is determined by this process; whereas those which work under capacity are termed as idle processes. Total production has been blocked in these 3 work stations and large WIP has been stuck in these bottleneck processes. The bottlenecks and idle processes of the existing system are summarized as follows;

Table 5.

Bottleneck operations in the current production system.

Table 5.

Bottleneck operations in the current production system.

Table 6.

Idle stations of the current production system.

Table 6.

Idle stations of the current production system.

From the study of the current system simulation model the researchers have found out the idle and bottleneck stations. This will be the input for carrying out line balancing calculations and developing alternatives using various what if scenarios and an optimized assembly line.

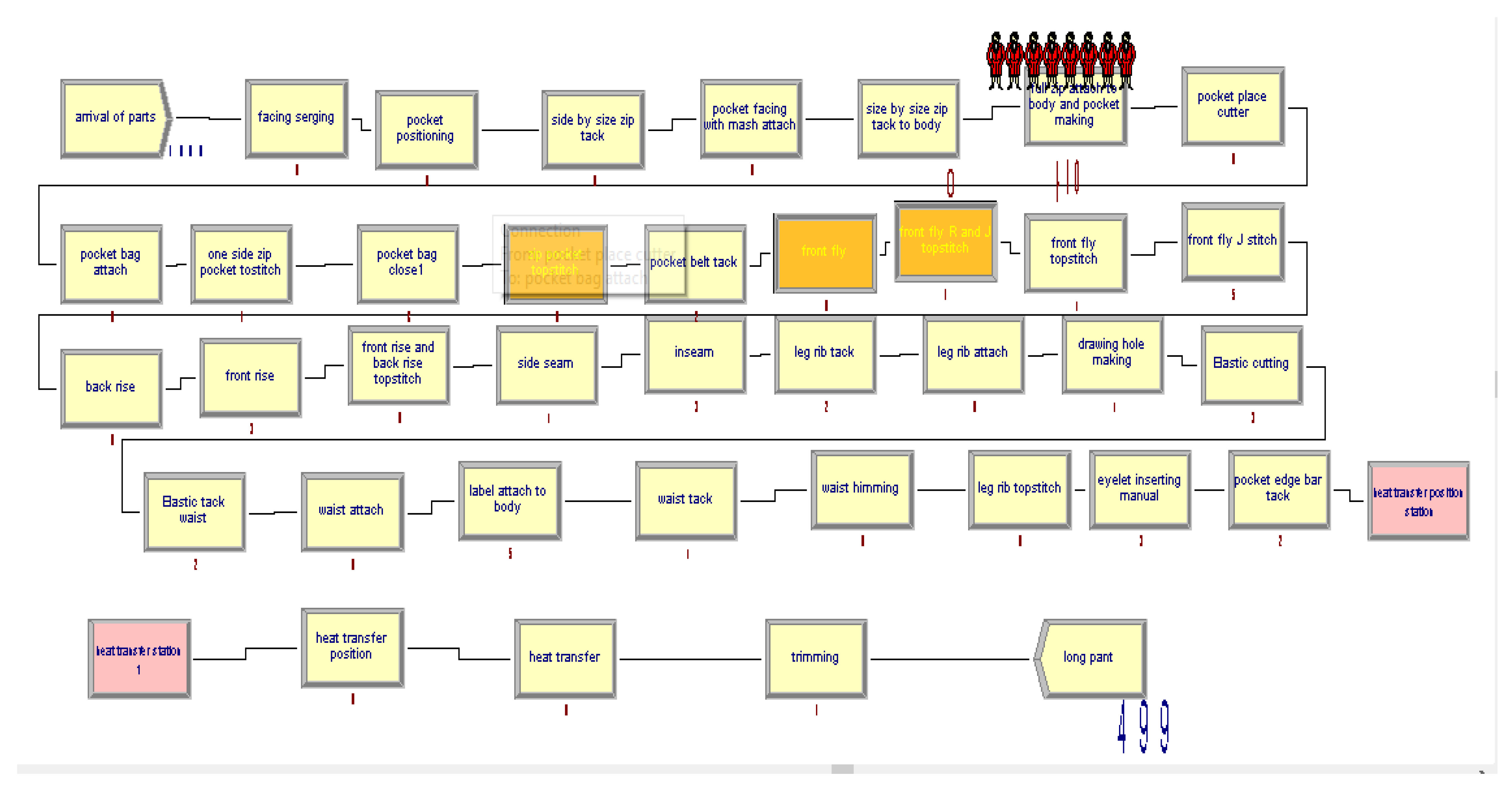

Line balancing is very essential to make the production flow smoother compare to the previous layout or the current assembly line of the long pant model. Considering working distance, type of machines and efficiency and workers’ skill; various what if scenarios are developed and tested. These various alternatives to the current system are developed mainly by adding capacity, sharing resources and a combination of all the methods.

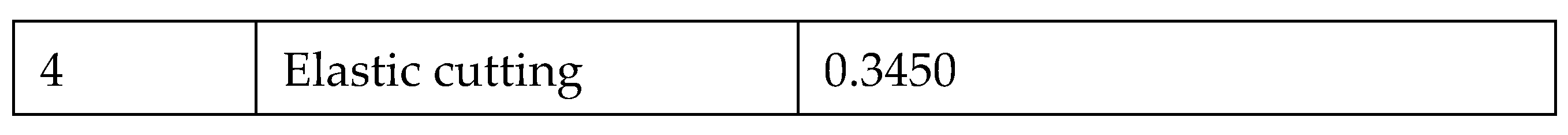

Scenario 1 add resources: - The result of the simulation run shows that face serging, pocket positioning, front fly topstitch and size by size zip tack to body are bottleneck operations in the long pant assembly line because the machines and operators in these processes are over utilized and this have made the waiting line lengthy. For this reason, the researchers have added extra three machines and three operators in the current system to develop this scenario.

Scenario 2 share resources: - The result of the simulation run shows that not only are some resources over utilized but some are also under-utilized creating idle resources in processed like heat transfer positioning, heat transfer, drawing hole making and elasting cutting. The current production system uses two machines for drawing hole making and heat transfer and one operator in each of these processes making them idle in most of the working hours. For this reason, the researchers have reduced two operators from the four operations. So that, the in production line one operator can share in heat transfer positioning and heat transfer and the second operator can share in operations drawing hole making and elasting cutting.

Scenario 3 combined (Add resources+ share resources): One of the best ways to increase the efficiency of an assembly line is by decreasing length of the assembly line as much as possible and one way to do this is by sharing nearest operations which are idle or under-utilized in some way. based on this the researchers have developed the third alternative from scenario 1 and 2. The following figure summarizes the performance measures of the various alternatives and their respective output.

Scenario 4 reduce: - The current production system uses two TOLa1 in the pocket close process making them idle in most of the working hours. For this reason, the researchers have reduced one operator and machine from this operation without affecting the final output to minimize labor cost.

Scenario 5 a combination of scenario 3 and scenario 4: - in this case reduce 4TOLa1 from pocket close and add resources and share resources and finally the researchers have developed a model for the long pant.

Figure 5.

The comparison of the current system with various alternatives and their respective output.

Figure 5.

The comparison of the current system with various alternatives and their respective output.

5. Proposed Model Development

In this research, the researchers have focused and selected one product that is the long pant model in the MAA garment of textile factory. The long pants simulation model is built based on the existing parameters and has analyzed its performance. During the analysis the idle resources and bottlenecks were identified based on its’ number waiting in queue and resource utilization. The idle resources are that resources with low utilization that is below 50% utilizations like BH machine, manual operator2, helper a2 and heat machine and some of stations have also high waiting queue like facing serging queue, pocket positioning queue, size by size zip tack to body front fly tostitch. In developing the alternative solutions, the researchers have developed a proposed models and experimented with different scenarios and come up with the following optimal solutions by selecting the best developed model. In today's highly competitive global environment, people are faced with many difficult decisions, such as allocating financial resources, building facilities, managing inventories, determining product mix strategies, and more. Simulation modeling a decision problem in Arena tells us; what performance measures can expect using a certain strategy (allen, 2012).

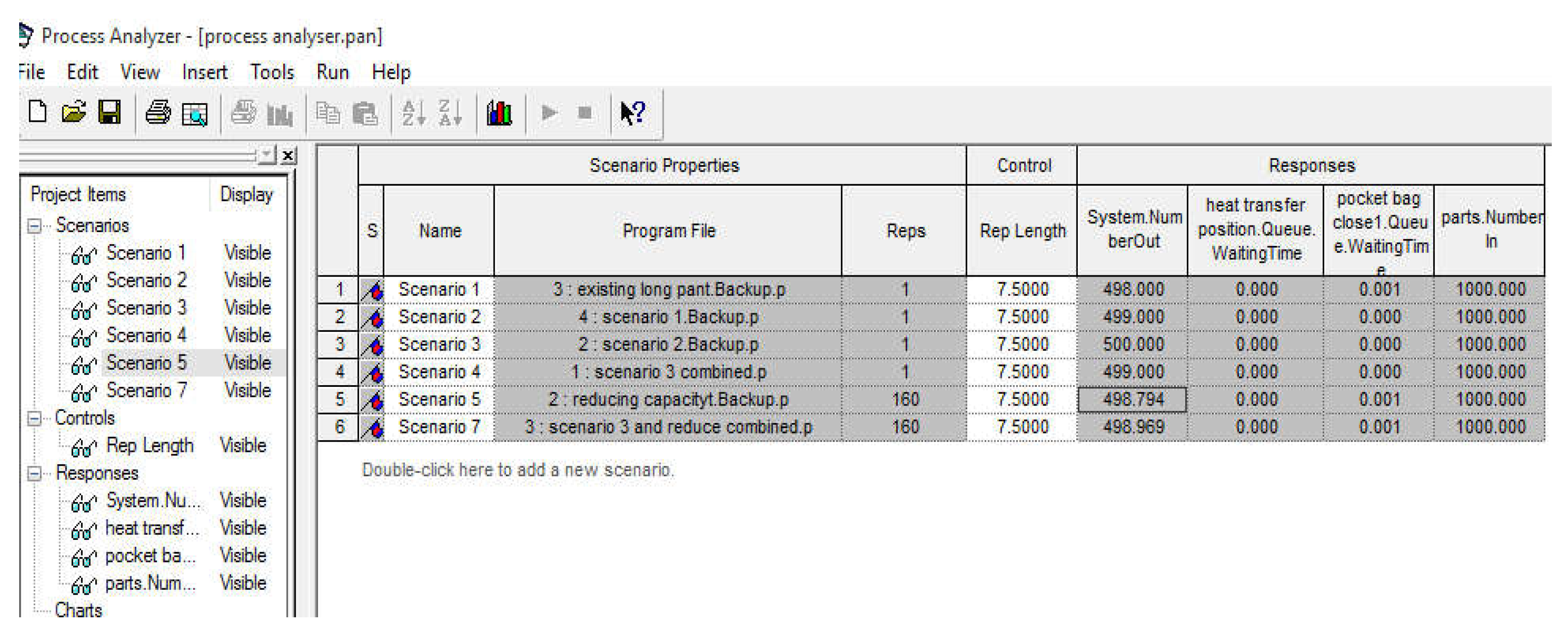

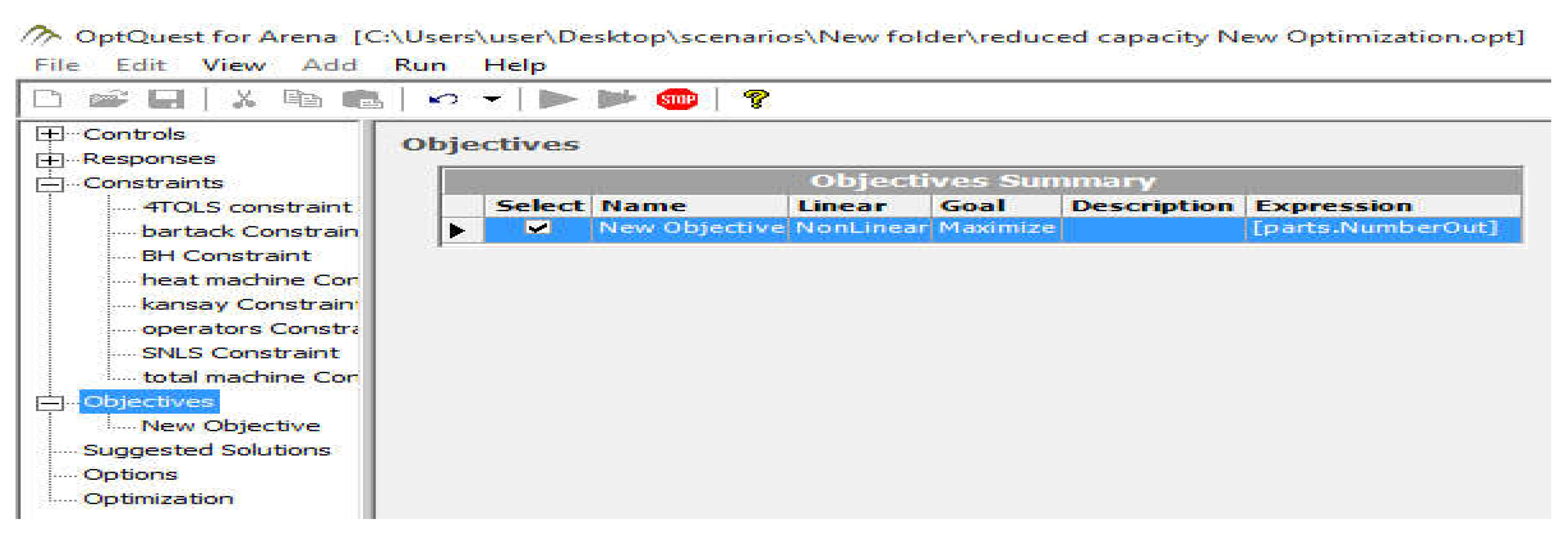

5.1. OPT QUEST

A strategy can be defined as a certain set of values for the controls the resources that can the model developers could have been controlled. Others words for strategy include scenario and solution refers to the control values the inputs to the arena simulation modelling. not to the resulting values of the performance measures like responses or the outputs from the developed model.in this case Opt Quest enhances the Arena by automating the search for an optimal solution by alternating different scenarios by controlling the resources and gives as different responses from a set of replications.

Opt Quest analyzes the results of the simulation and uses its intelligent search procedures to generate a new potential solution, and its ultimate goal is to find the solution that to maximizes or minimizes the value of the model’s objective. Opt Quest for Arena has three major elements and these are constraints, controls and objective that can be optimized.

Controls: - Are variables or resources that can be meaningfully manipulated to affect the performance measurement of a simulated production system.

Constraints: - Are relationships among controls like resources that can we use in the production line and that expected to give us, a responses of the outputs like number of resources in its appropriate amount and type in the production lines.

Objective: - and the last element of an opt quest a response or an expression used to represent the model's objective, such as minimizing queues or maximizing outputs that can be generated from the simulated model run like waiting time in each resources, WIP and cycle time of the production system.

5.1.1. Control Resources

Controls: - Are variables or resources that can be meaningfully manipulated to affect the performance of a simulated system. The resources that have a bottleneck in the production line are quality checker 1, quality checker 2, trimmers, sleeve hemming machines and operators, shoulder attach machines and operators, or those which have high number in queue and have high waiting time in queue are the controls in the simulation model.

5.1.2. Responses

Responses: - are the performance measurements of the resources when they have different alternatives declared or when the controls vary then, measure the queue waiting number and queue waiting time, resources utilization etc.

5.1.3. Constraints

Constraints: - Are relationships among controls and/or responses. For example, a constraint might ensure that the total amount of machines allocated among various operations exceed a specified amount, or at most one machine from a certain group can be selected. So, from these constraints table the sleeve hemming operation needs at least one machine to perform the operation and the number of machines that in the line must be below fifteen machines and the operators assigned for the line a maximum of nineteen in each of the production lines.

5.1.4. Objectives

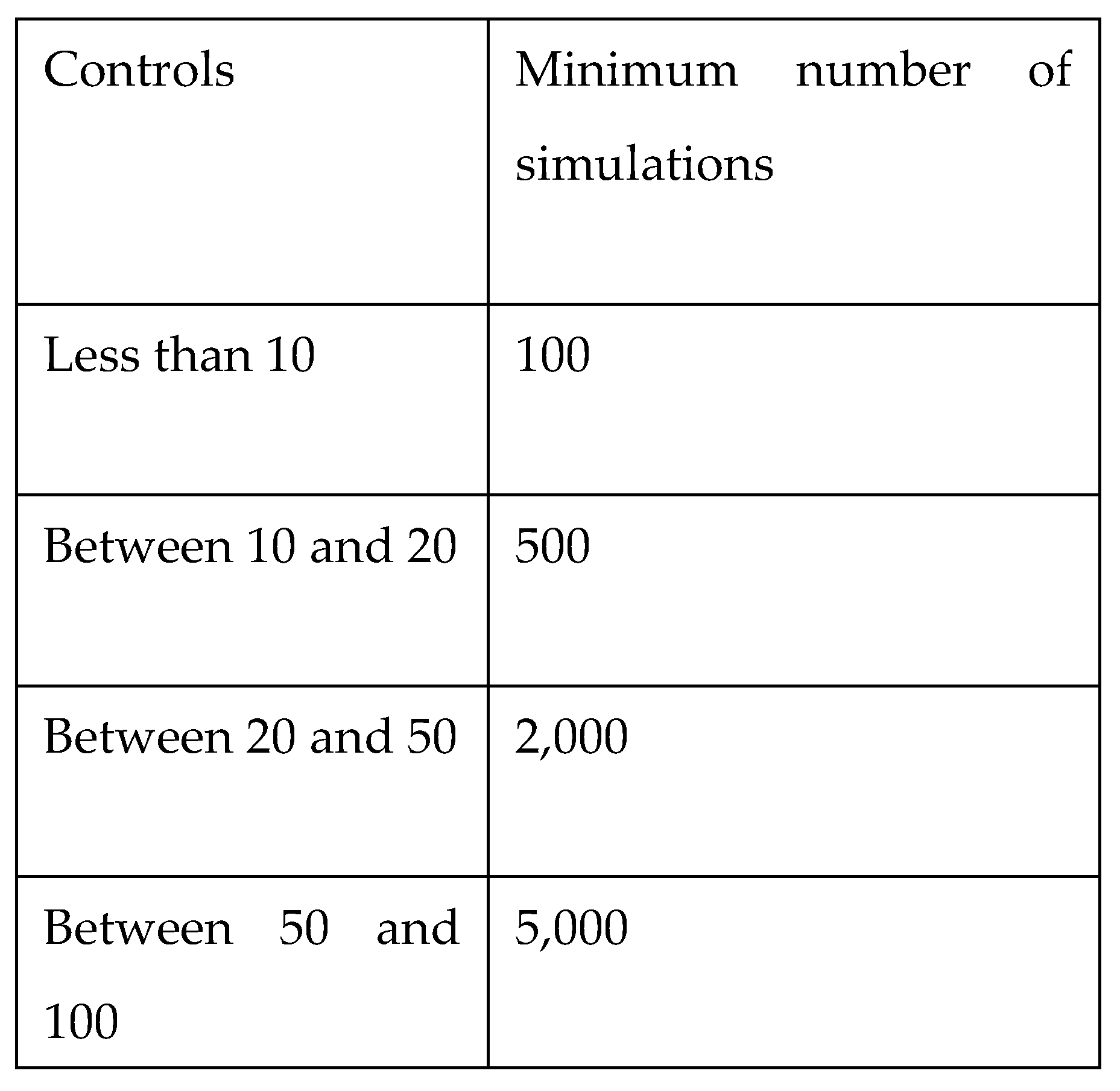

Objective: - it is an expression or a response used to represent the model's objective, such as minimizing queues waiting time, queue waiting number in the bottlenecks or maximizing outputs. According to (allen, 2012) the number of simulations for the opt quest are 2000 because there are 38 controls and the best solution is set at the first row in the grid will be the best solution. The simulation column identifies the simulation that generated that solution. For this research the first row shows simulation 1, the best solution is found at the 1st simulation. The number of controls greatly affects Opt Quest’s performance. Opt Quest has no physical limit on the number of controls you can use in any given problem. However, the performance might deteriorate if you use more than 100 controls.

Also, as the number of controls increases, you need more simulations to find high-quality solutions. General guidelines for the minimum number of simulations required for a given number of controls in a problem are:

Table 6.

simulation number.

Table 6.

simulation number.

Figure 9.

best simulation number From the result of the opt quest the optimal solution is in simulation 1 and the researchers have developed a model to represent the real manufacturing system and it produces 498.

Figure 9.

best simulation number From the result of the opt quest the optimal solution is in simulation 1 and the researchers have developed a model to represent the real manufacturing system and it produces 498.

Figure 10.

optimized model This model is developed based on the opt quest output by reducing one operator in the pocket bag close and one 4TOL machine from it.

Figure 10.

optimized model This model is developed based on the opt quest output by reducing one operator in the pocket bag close and one 4TOL machine from it.

6. Conclusion

In this research, the simulation modeling and optimal line balancing of the long pant sewing line is carried out by using arena 14 version. Based on the simulation model run, results the operations that have high queue length and high resource utilization are facing serging, pocket positioning, size by size zip tack to body and front fly topstitch and a resources which have been low utilizations or below 50% utilizations are like BH machine, manual operator2, helper a2, and heat machine are idle operations in the production lines of the long pant model. And the operations that have high waiting time are bottlenecks for the production lines. identified bottlenecks are eliminated or minimized using sharing and adding of the existing resources (operators and machines) in order to optimize the resources as much as possible.

Finally, a new model has developed by using opt quest model of arena with different types of scenarios by considering the constraints of the resources and controls and responses of the results. Therefore, the production system produces 498 long pants and by reducing one operator and one 4TOL machine.

The researchers have identified the main bottle necks which have high work in process and low work in process, high queue length, low and high utilized resource specially the operators and the machines that allocated in the assembly lines. Based on the research findings the researcher will implement the model in the production areas and will have analyzed different alternatives to enhance the productivity of the company with integrating with different line balancing methods.