Introduction

The four elements of nature, namely water, light, heat, and nutrients, are required for the germination, development, and maturation of agricultural crops. Therefore, when sowing, it is necessary to achieve an even distribution of seeds on the field surface and the placement of seedlings at a certain density. One of the main measures in the process of growing agricultural crops is sowing. Seed sowing is a determining factor in productivity [

1].

The main agrotechnical requirements for sowing are as follows, ie sowing rate, even distribution over the feeding area and sowing to the specified depth. Therefore, one of the important tasks is to improve the working parts of sowing machines and create new types.

In the history of the development of agricultural machinery, the sowing of seeds of vegetable crops was carried out by additional equipment of grain sowing units. To date, units for sowing the seeds of vegetable crops are being produced on a large scale.

The main working part that determines the quality of sowing is the sowing apparatus. Therefore, it is important to modernize planting equipment and create new designs and research them. In the design of sowing machines and the creation of their construction, first of all, the characteristics of the seeds are taken into account. This is because the sowing apparatus interacts and communicates directly with the seeds.

In order to obtain a high yield and quality product, the selected sowing machine must meet the following requirements, namely, even distribution of seeds, uncomplicated design, ease of adjusting the sowing rate, low damage to seeds, etc. [

2,

3].

Methodology

When developing the design of the planting apparatus for small-seeded vegetable crops, it is necessary to take into account the above requirements.

To assess the sowing quality of sowing machines, the indicators can be considered as the even distribution and granulation of seeds from the sowing apparatus across the sowing zone.

GOST 31345-2017 «Agricultural machinery. Seyalki traktornye. According to the interstate standard “Methods of testing” [

4,

5], the distribution of seeds in rows (sowing step) is studied in precision and dotted sowing machines. It was noted that the equal distribution of seeds is carried out in special standards. In this case, the distances between the sown seeds are determined by recording (measuring).

In the above-mentioned method, it is stated that the error of the measurement range should not exceed ± 0.5 cm. The distance between seeds in a row, the standard deviation, the coefficient of variation and the number of seeds (in the cell) should not exceed or decrease from the values specified in the TZ.

In determining the even distribution of seeds, the distance between the centers of two adjacent seeds is measured. The granulation of the seeds is also done by simultaneous counting. The degree of accuracy of the sowing apparatus is expressed as follows

This Чur - the number of cells in which the seeds fall according to the established sowing rate; Чum- total number of cells.

The main working body in disc sowing machines is the sowing disc. Typically, there are slots on the outer surface or side of the planting discs. In mechanical sowing machines, the cells are filled with seeds, and as a result of the rotational movement of the disk, the seeds fall out of the hole into the planting zone.

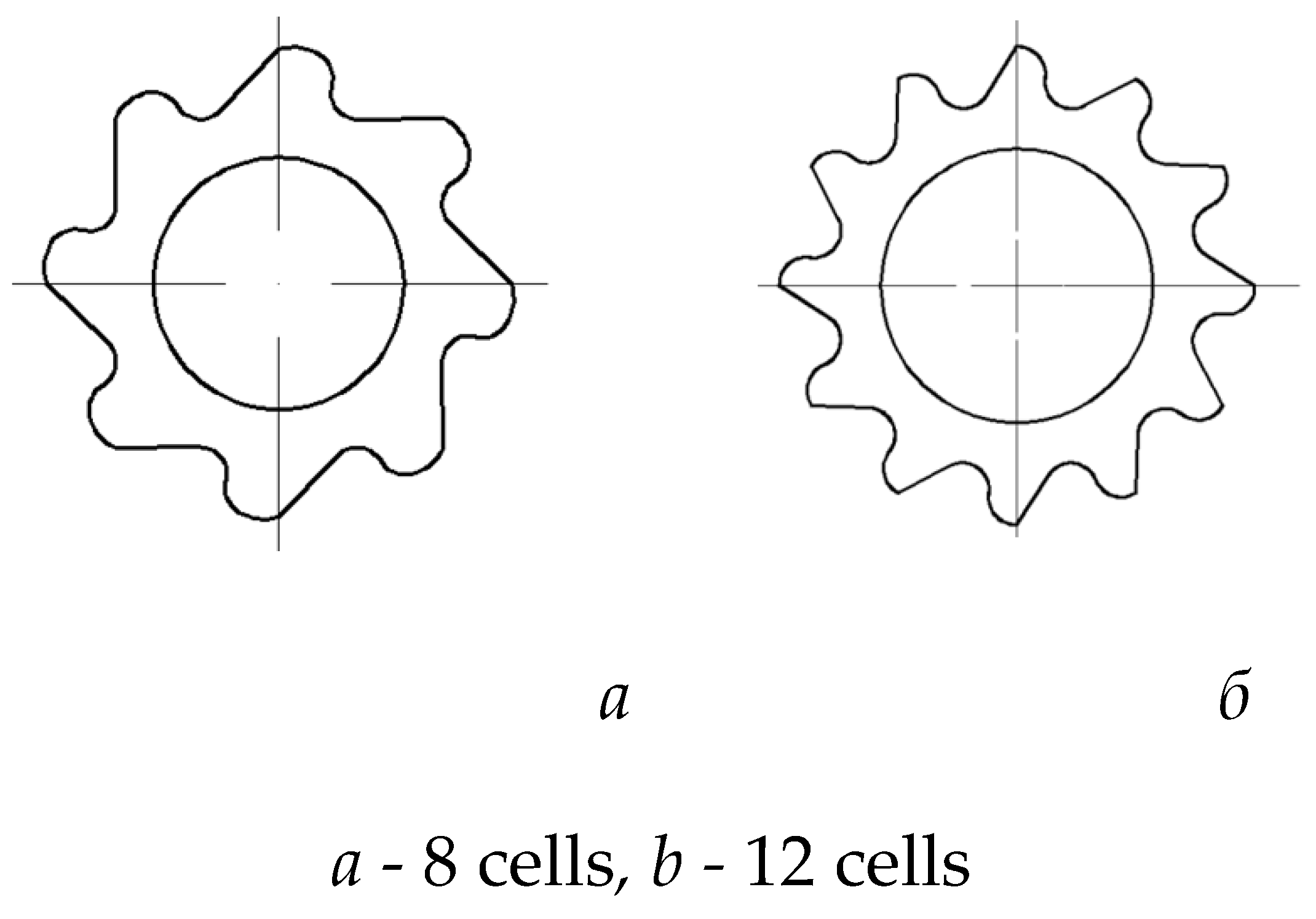

The geometrical dimensions of the cellular disk of the planting apparatus have been studied in theoretical studies, according to which it is recommended that the cellular disc be 30 mm in diameter and 3 mm thick. For this reason, in experimental studies, the number of cells with a diameter of 30 mm and a thickness of 3 mm was chosen as 8 and 12 (

Figure 1).

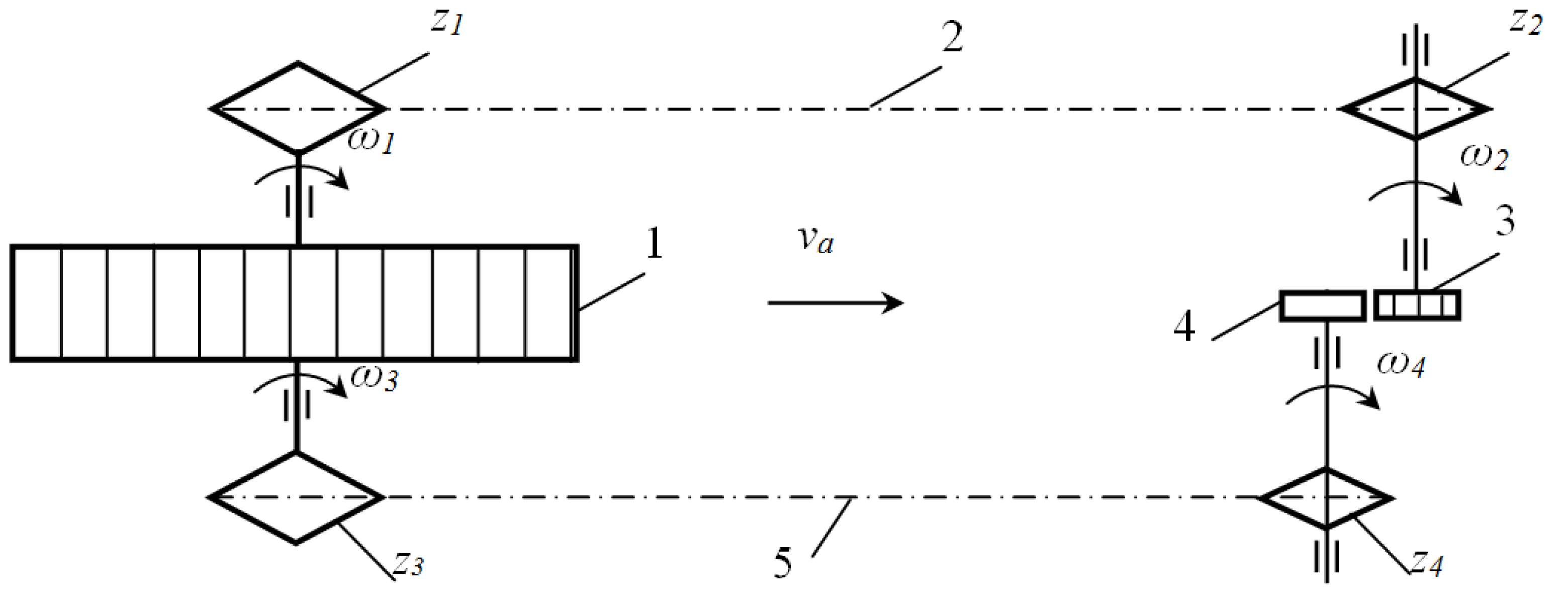

The diameter of the seed roller was assumed to be equal to the diameter of the cellular disc (

Figure 2).

In mechanical planters, the movement of the working parts is usually transmitted through the support wheels. The movement of both the cellular disk and the rotating roller of the recommended planting apparatus is transmitted from the base wheel by means of a chain drive. The kinematic scheme of the transmission mechanism of this sowing apparatus is shown in

Figure 1.

Result and Discussion

According to the kinematic scheme shown in

Figure 3, the leading joint is the base wheel 1. The movement of the cell disc 3 and the reciprocating roller 4 is transmitted from the base wheel 1 through the chain drive 2 and 5, respectively. Here, the slot disc 3 and the return roller 4 perform a rotational motion in the same direction.

In the process of sowing the seeds, the sowing machine moves one by one and quickly. As a result of this and speed, the base wheel performs a rotational motion. We express the angular velocity of the base wheel as follows

This va - speed of movement of the sowing machine or linear speed of the base wheel, m / s; Rг – radius of the base wheel, m.

We express the number of revolutions of the base wheel as follows

We express the number of revolutions of the cellular disk as follows, taking into account the execution of the technological process

where

l - distance between the seeds in the row, m;

z - number of cells on the floppy disk.

We determine the number of revolutions of the return roller by the following condition, based on the technological process

The reason for the inclusion of this condition is that the return roller must have time to remove the seeds that are outside the disc compartment and they must not be pinched in the groove.

We implement numerical solutions of the above expressions. According to the agro-technical requirements developed by the Scientific Research Institute of Agricultural Mechanization, the scheme of sowing onion seeds is as follows, ie

,

,

ёки

[

6,

7].

It can be seen from the sowing diagrams that the distance between the seeds in the row is l = 8 cm, the speed of movement of the sowing machine and in the range of va = (1 .... 2) m / s, the radius of the base wheel Rg = 0.2 m and the number of cells in the cell disk z = (4 … 12) pieces were received.

According to the results of the calculations, the number of revolutions of the base wheel will be in the range of

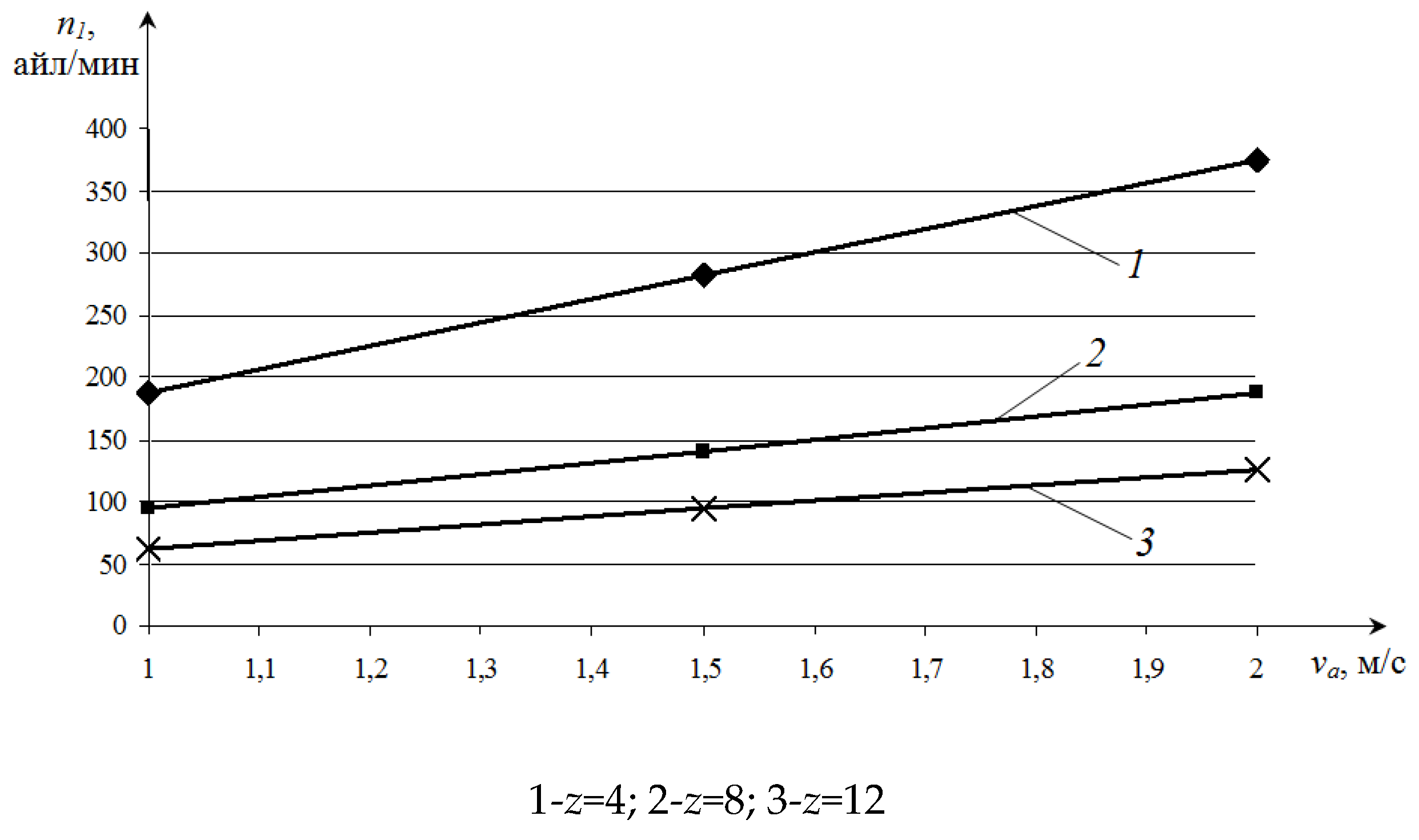

n1 = (47.8… 95.5) rpm according to the speed of movement of the sowing machine. The graph of the dependence of the number of cell disk rotations on the speed of movement of the sowing machine and the number of cells is shown in

Figure 4.

An analysis of the graphs in

Figure 4 shows that as the speed of movement of the sowing machine increases, the number of revolutions of the cell disk at any value of the number of cells should increase with a straight-line regularity.

That is, at a speed of 1 m / s, if the number of cells is 4, the number of revolutions of the cell disk is 187.5 ayl/m, if the number of cells is 8, 93.75 ayl/m, and if the number of cells is 12. It should be 62.5 ayl/m. If the speed of the sowing machine is increased by 1.5 m / s, then when the number of cells is 4, the number of revolutions of the cell disk is 281.25 ayl/m, when the number of cells is 8, 140,625 ayl/m, and when the number of cells is 12,93, As long as it should be 75 ayl/m.

If the speed of the sowing machine is chosen to be 2 m / s, then when the number of cells is 4, the number of revolutions of the cell disk is 375 ayl/m, when the number of cells is 8, it is 187.5 ayl/m, and when the number of cells is 12, it is 125 ayl/m. as long as it should be min.

Figure 5 shows a view of the cellular discs.

Conclusion

Thus, according to the agro-technical requirements of the sowing machine, the number of cells for sowing onion seeds in rows at intervals of 8 cm is 8, and the transmission ratio is 0.75 when the speed of the sowing machine is 1.5 m / s, and the number of cells is 12 when the number of cells is 12. as long as the ratio is 1.02.

References

- Кoсимoв, А.А. ОБОСНОВАНИЕ КИНЕМАТИЧЕСКИХ ПАРАМЕТРОВ ЗУБЧАТОЙ ПЕРЕДАЧИ СО СЖАТЫМ ШКИВОМ. Вестник науки и твoрчества 2022, 2, 47–50. [Google Scholar]

- Djuraevich, D.A.; Maxsudovich, T.V.; Adixamjonovich, Q.A. The analysis of influence of parameters of chain transfer on change of force of deformation of the elastic element of the compound conducted asterisk. European science review 2016, 1–2, 159–160. [Google Scholar] [CrossRef]

- Turdaliev, V.M.; Igrashev, B.; Makhkamov, G.U.; Qosimov, A.A. Theoretical Research on the Flight of Onion Seeds under Discharge from the Seeding Unit.

- Umurzakov, A.K.; Turdaliev, V.M.; Khakimov, U.A. Low-Power Hydraulic Motor for Mobile Micropower Stations and Pumps. Russ. Engin. Res. 2022, 42, 791–793. [Google Scholar] [CrossRef]

- Mukhamedov, Z.; Turdaliev, V.M.; Kosimov, A.A. Kinematic Nonuniformity of the Rotation of a Toothed Belt Transmission with a Composite Pulley. Russ. Engin. Res. 2020, 40, 705–709. [Google Scholar] [CrossRef]

- Turdaliyev, V.M.; Kosimov, A.A.; Sheraliev, I.I. Determining the Tractional Resistance of a Seed Drill by Similarity Theory. Russ. Engin. Res. 2024, 44, 1537–1541. [Google Scholar] [CrossRef]

- Makhkamov, G.U.; Khakimov, U.A. Experimental Study of Micro-Hydropower Plants. Calculation of Water Wheel Efficiency. Russ. Engin. Res. 2023, 43, 1524–1527. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).