1. Introduction

In recent decades, changes in the global context have been frequent [

1]. There are many reasons for this: natural disasters, pandemics, terrorism, wars, cyber-attacks, etc. [

2]. These circumstances change the context that affects disruptions and interruptions in the development of supply chains [

1]. One of the circumstances that has changed the global context and caused disruptions and interruptions to global supply chains is the COVID-19 pandemic. [

3]. This happened in late 2019 and early 2020. The pandemic completely surprised global market participants and the reactions were belated, panicky and radical, in such a way that at one point the movement of passengers and goods was completely banned. Countries around the world are increasingly accepting increasing security measures: including closing borders, closing airports, imposing travel restrictions, restricting movement, self-isolation or quarantine of the diseased. The world was completely unprepared for this situation [

4]. There has been a disruption and imbalance between global supply and demand, which has caused major financial losses for global market participants, as well as countries. Based on the World Bank analysis the significant potential impact of COVID-19 is assessed on GDP - Gross Domestic Product and trade the shock as underutilization of labor and capital, an increase in international trade costs, a drop in travel services, and a redirection of demand away from activities that require proximity between people. Global GDP is expected to decline by 2.09%, while developing countries’ GDP is expected to decline by 2.49% and high-income countries by 1.84%. The declines are 3,86% below the benchmark for the world, in an amplified pandemic scenario in which containment is assumed to take longer and which now seems more likely [

5]. After a decade of uninterrupted growth, the global economy came to a sudden halt because of the COVID-19 pandemic. The question now is not whether there will be a global recession but how deep it will be and how quickly countries can overcome the health crisis and pave the way for economic recovery. All of this has contributed to a decline in the quality of life of citizens around the world [

6].

In its essence, sustainability is a mechanism for better risk management, one of which includes disruptions in supply chains. The supply chain crisis has been present for several years, since the beginning of the COVID-19 pandemic, and in parallel, the EU, as well as numerous other countries, are in an energy crisis that was largely caused by the start of the war in Ukraine in 2022. The rise in the prices of oil and gas and other energy sources is at the same time a response to the increased demand for these energy sources due to faster economic growth, reduced supply and depleted stocks.

Food supply chains were also disrupted by the start of the war in Ukraine in 2022. It is known that Ukraine is the third producer and exporter of wheat in the world. Ukraine had stopped exporting wheat because it had no choice [

7]. However, other countries have also stopped or limited deliveries. So, India banned the export of wheat. Another 26 countries have restricted wheat exports to ensure sufficient supplies for themselves. All this has influenced the large increase in wheat prices on the global market and threatened the poorest parts of the world. India's announcement of the ban alone caused wheat prices to rise by 6% on the global market. They started talking about the need to reach a Global Agreement that would regulate that in such situations, countries with a surplus should help those in need [

8]. The fact that a successful global protection system or surplus-sharing agreement has never existed is no reason for its existence soon.

This problem is not unique to food. The same thing happened with vaccines during the COVID-19 pandemic. Some countries were receiving and buying more vaccines than they needed to protect themselves from possible future shortages. This situation also explains some of the existing global imbalances and inequalities in access to strategic resources and products. It is a phenomenon of “stockpiling psychology” that is a consequence of distrust in the functioning of the system [

9]. There is a solution here, and that is to build a system that can be trusted. Such efforts have succeeded in India, where a national public food distribution system was established in 1992, which evolved into the Food Security Act in 2013. It is a sophisticated system of minimum food guarantees that has been in place for more than three decades.

It was soon realized that the disruption of supply chains could not last long because it would have significant negative consequences for the global economy, affecting all sectors of the economy, all parts of the world [

10]. In a short time, agreements were established at the international level on how to control the movement of goods so that supply chains can continue to operate under difficult conditions and still ensure the flow of goods, people and money [

11]. However, the damage has already been done [

12]. It took a long time for supply chains to normalize. There was also a change in some quality management concepts, such as JiT – Just in Time and Customer focus [

13]. These concepts still exist, but they began to be interpreted more flexibly, to adapt to the changed context. Intensive thinking began about what to do to avoid a similar situation and prevent major damage due to disruption of supply chains in future crises.

The subject of this paper is research and identification of ways to solve this problem and help global market participants prepare for future crisis situations that will certainly occur. As a result of this research, three models have been defined, the design and application of which should increase the resilience of individual organizations, countries and the global community from the harmful impact of crises that will cause disruptions or interruptions in supply chains in the future. The authors have built and propose the application of three models: 1) a model for individual organizations, 2) a model for national economies or countries and 3) a global model. They have also developed the requirements of these three models, which must be met for the models to function and generate positive effects. The results of this research are important because they can help global market participants to be prepared for future disruptions or interruptions in supply chains, which will certainly occur, and in this way reduce the damage that will occur and preserve the necessary level of quality of life of citizens from complete erosion.

In the research whose results are presented in this paper, a working hypothesis was set: "The full application of the model for preventing the impact of supply chain disruptions in future crises contributes to strengthening the resilience of individual organizations, states and the global community, reduces damage and contributes to preserving the quality of life of citizens."

This paper is structured in such a way that the Introduction is followed by chapter 2 Material and methods, in which the application of the scientific method of cognition is stated and clarified. In chapter 3, entitled Case studies, three case studies are analyzed that resulted in disruptions in supply chains, namely: 1) pandemic COVID-19, 2) stranding of the vessel Ever Given in the Suez Canal and 3) the war in Ukraine. Chapter 4 provides a graphic presentation and analysis of a modern approach to the supply chain, which is important for understanding this research, because the main object of disruption or interruption due to a change in context is the supply chain. Chapter 5 is, next to chapter 4, the main chapter in this paper because it presents the results of the research, which are three original models with a system of indicators: 1) a model for individual organizations, 2) a model for national economies, or states, and 3) a global model. Chapter 6 is the Discussion in which the conclusion of this research is drawn. At the end of the paper are References, which list the sources used in this research and the preparation of this paper.

2. Materials and Methods

In conducting this research, scientific methods of cognition were applied. The analysis method was applied when analysing the context that in the recent past caused disruptions and interruptions in the development of supply chains, such as cases of the COVID-19 pandemic, stranding of the vessel Ever Given in the Suez Canal and war in Ukraine. Further to this analysis, the case study method was applied to show, on real examples from the past, the negative impact of the unpreparedness of the management systems of individual organizations, states and the global community in a context that causes disruptions or interruptions in the development of supply chains. The comparative method was applied in the comparison of individual requirements in three different models that are researched in this paper. The synthesis method was applied when drawing conclusions for each individual model. The induction method was also applied when developing the model, because the model is developed from an individual organization, through the national economy, that is, the state, to a global model. The models presented in the paper are the original work of the authors.

3. Case Studies

3.1. Pandemic COVID-19

In the period from late 2019 to mid-2022, there was a significant change in the circumstances of the context in which global supply chains operate. In late 2019 and early 2020, the Corona virus (COVID-19) pandemic took hold [

14]. The virus spread rapidly around the world, and scientists and health professionals did not have enough knowledge and understanding at the time about how to effectively combat the pandemic. Different countries and regions of the world took different approaches, from completely closing state borders and interrupting the movement of people and goods, to situations where almost nothing was done. However, restricting the movement of people and goods significantly disrupted the stability of supply chains at the global level, due to the closure or significant reduction in seaport traffic. The closure or significant reduction in seaport traffic, especially in China, but also elsewhere, due to [

15]:

The lack of workers in all logistics processes, due to illness or isolation;

The closure of state borders and significantly restricting the movement of people and goods;

The application of stricter procedures in the movement of people and goods.

The consequences that arose because of the above-mentioned circumstances and the change in context were manifested at the global level as:

Reduction of production;

Shortages of certain products;

Repurposing of production in favor of necessary funds and medical equipment needed in the fight against the pandemic;

Shortages of shipping containers that remained in blocked ports;

Shortages of shipping capacities;

Growth in maritime and other freight rates;

Growth in prices, i.e. inflation;

Disruption of the balance between supply and demand on a global level.

3.2. Stranding of the Vessel Ever Given in the Suez Canal

Another circumstance in the mentioned period with a significant impact on the change of context is the blockade of the Suez Canal as one of the most frequent maritime routes for the transport of goods in the world [

16]. In March 2021, the container ship of the Japanese company Shoei Kisen, Ever Given, 400 meters long, 59 meters wide and with a draft of 14.5 meters, blocked the Suez Canal. The ship belongs to the class of the largest cargo ships in the world. At one point, more than 300 ships were waiting to enter the canal. They had the option of going around Africa on their way to Europe, or Asia, which is about 9,000 km longer. Namely, the Suez Canal shortens the travel time by about 10 days, which saves money and shortens the transport time, although the average price of passage through the Suez Canal is about 250 thousand US

$. The Suez Canal is 193 km long and connects the Mediterranean and Red Seas and is also the shortest waterway between Asia and Europe. More than 18,000 ships pass through the Suez Canal annually. In the six days of the blockade, according to some estimates, the damage to the world economy was between 6 and 10 billion US

$. It is also estimated that suppliers of car parts in Europe suffered the most damage. Namely, the management of supply chains by applying the JiT - Just in Time (Just in Time) quality concept, which was not possible to fulfill under these circumstances. The Suez Canal Authority requested more than US

$ 900 million in compensation for the unblocking operation and other losses. This amount was later reduced to US

$ 550 million. Due to the above circumstances and changes in the context, the following consequences have manifested themselves on a global level:

Extension of the journey from Asia to Europe and vice versa, up to 10 days;

A standstill in shipping traffic, hundreds of ships were waiting to pass through the canal;

Increased time spent on goods being transported, delays in raw materials and spare parts for the production of finished products;

Failure to fulfill contractual obligations to customers regarding delivery time;

Poor quality costs for numerous participants in supply chains;

Reaction of a sense of insecurity, - price increases, i.e. inflation;

Disruption of the balance between supply and demand on a global level.

3.3. The War in Ukraine

The third circumstance in the mentioned period, which significantly influenced the change in the context in which global supply chains take place, is Russia's military aggression against Ukraine, in the first half of 2022, precisely when the COVID-19 pandemic began to subside more seriously and when it almost did not represent a serious obstacle to the movement of people and goods, since many countries began to lift most of the restrictive measures [

17]. This circumstance further disrupted the development of global supply chains, and the disruption was manifested through:

Creation of a sense of insecurity, which is not good for the economy;

Interruption of certain supply chains, namely of strategic goods such as grain;

Abandonment of the usual directions of development of supply chains;

Shortages of strategic goods such as food, oil, gas, etc.;

Large migrations of people and social problems;

Increase in the costs of caring for refugees in numerous countries and appropriate logistics;

Increase in input costs in production processes (increase in energy prices, etc.);

Price growth, i.e. inflation;

Finding new directions for development of supply chains;

Abandoning the concept of the only (dominant) supplier, i.e. customer;

Abandoning the previous ones and creating new political and economic alliances;

New bloc division of the world;

New geopolitical division of the world;

Redistribution of financial resources due to the need to strengthen the defense sector;

Redefining the understanding of sovereignty;

Violation of international rules and principles;

Violation of the balance between supply and demand on a global level.

4. A Modern Approach to the Supply Chain

There are many definitions of supply chain. Many of them are defined in international standards such as ISO – International Organization for Standardization, standards. International standards are an important part of the knowledge base in all fields. They are based on science, research and collaboration, and many years of experience. Behind them is a lot of extensive international cooperation, and thus have a great impact on international activities. In the following, there are performed supply chain information searches on tens of thousands of international standards. The topic of the supply chain is addressed in various aspects in a total of 2,062 standards. The concept of the supply chain is also defined in many standards. Many of them are case-specific, but only a few are listed here.

ISO 28001:2007 - Clause 3.24: SC linked set of resources and processes that upon placement of a purchase order begins with the sourcing of raw material and extends through the manufacturing, processing, handling and delivery of goods and related services to the purchaser. Note: The supply chain may include vendors, manufacturing facilities, logistics providers, internal distribution centers, distributors, wholesalers and other entities involved in the manufacturing, processing, handling and delivery of the goods and their related services [

18].

ISO 22136:2017: SC is a system of organizations, people, activities, information and resources involved in transforming materials and knowledge in a product or a service for the customer [

19].

ISO 10377:2013: SC is a network that designs, manufactures, imports, distributes and sells a product [

20].

Some supply chain definitions explicitly mention logistics processes. This is how ISO 13065:2015 - Clause 3.47states: SC is a linked set of resources and processes that begins with the sourcing of raw material and extends through transport and storage of products to the end user [

21].

ISO 20333:2017: SC is a linked set of resources and processes that begins with the sourcing of raw material and extends through the delivery of products or services to the end user across the modes of transport [

22].

ISO 22300:2021, Clause 3.1.271: SC is a two-way relationship of organizations, people, processes, logistics, information, technology and resources engaged in activities and creating value from the sourcing of materials through the delivery of products or services [

23].

Based on them, it can be concluded that the supply chain consists of the flow of goods, services and information from suppliers, through transport, manufacturers, distributors, retailers to the final customer. The supply chain is a complex system of integration of suppliers, manufacturers, distributors and wholesalers and retailers, for the purpose of production and distribution of goods/services with the aim of balancing supply and demand. The ideal situation is when supply and demand are in complete balance. However, in practice, the supply and demand of a product or service is usually in a certain imbalance, which affects price changes.

The stability of supply chains is one of the key factors that allows achieving a balance between supply and demand at some point in time. In these circumstances, supply chains can perform their basic task, which is the production and distribution of goods to the market, in such a way as to ensure [

24]:

The right product,

The right customer,

The right quantity,

The right condition,

The right place,

The right time,

The right cost.

If there is a disruption of stability in the development of supply chains, the realization of these tasks is not entirely possible, which causes a disruption in the market with all the negative consequences. Supply chain management is complex and therefore requires trained people who will be able to manage this complex phenomenon with their competences.

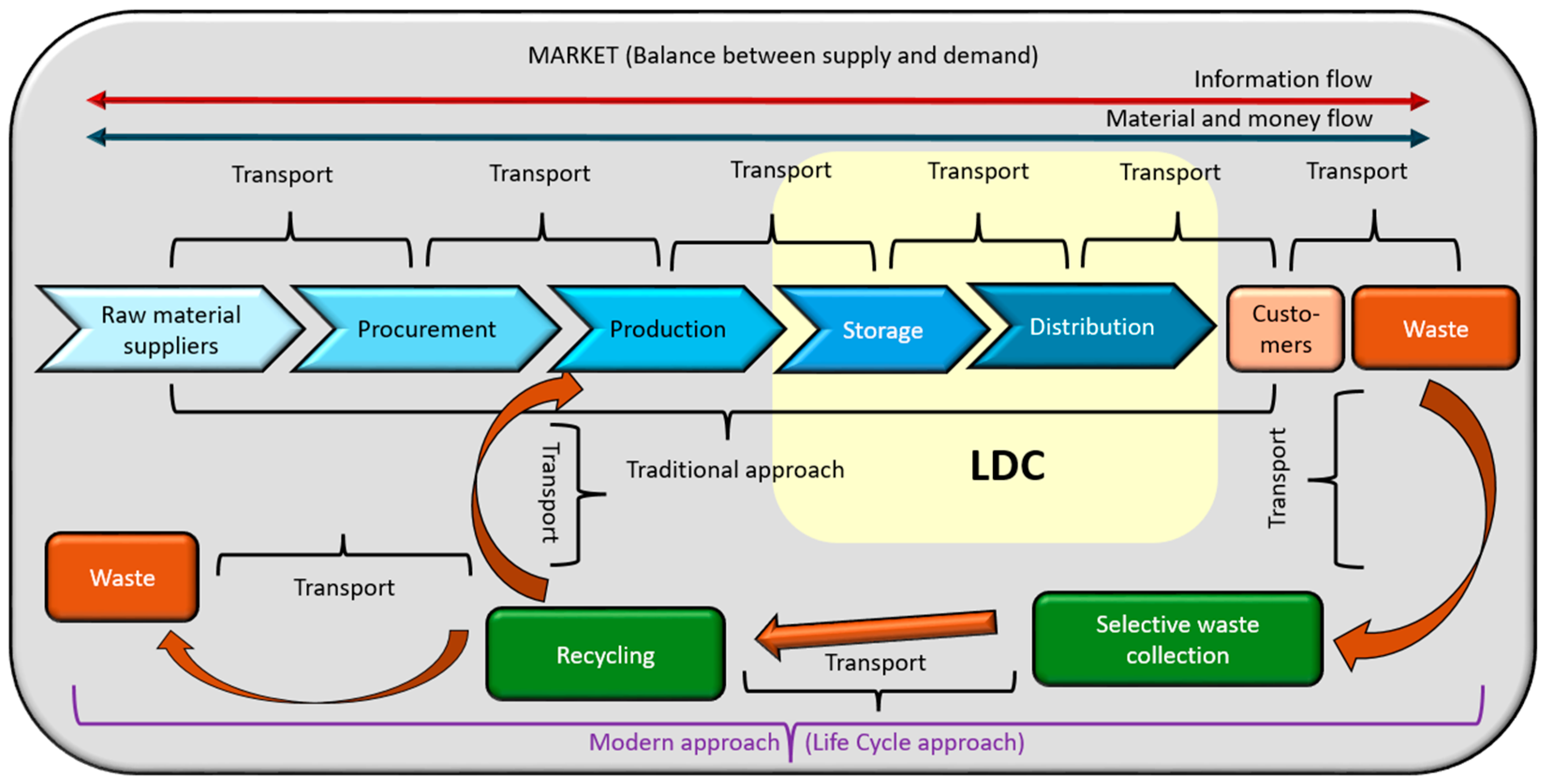

While traditional logistics is based primarily on warehousing and transportation activities, the supply chain also involves the flow of information between numerous participants, such as raw material suppliers, transport organizations, product manufacturers or service providers, product distributors, and retail chains that enable the product to reach the end customer and become an object of consumption. To understand the phenomenon of the supply chain as a complex structure of numerous participants, it is necessary to apply a modern approach to the supply chain, as shown in

Figure 1.

Traditional models, processes, and practices are no longer fit for purpose and companies are re-examining the factors that enable supply chains: for example, business models, stakeholders’ roles, technology and information systems, and complementary capabilities and processes [

25] The following are characteristic of the modern approach to the supply chain:

- -

numerous participants with different interests and levels of quality culture and organization,

- -

feedback, the supply chain does not end with the consumption of a product or service by the customer,

- -

transformation of the so-called linear economy into a circular economy,

- -

the supply chain cannot operate without logistics,

- -

the flow of information and materials is two-way and includes all participants in the supply chain,

- -

understanding the product throughout its life cycle.

Logistic distribution centers (LDC) are especially highlighted in

Figure 1 to emphasize their position and the strategic role of in supply chains, which is the connection of production and the market, that is, end users and consumption.

From a business perspective, companies are increasingly held accountable for the sustainable performance of the whole supply chain by a raft of stakeholders. Thus, the sustainable supply chain can be conceptualized as operating within economic and environmental contexts that must co-exist [

26].

Global supply chains are networks that can span across multiple continents and countries for the purpose of sourcing and supplying goods and services. Global supply chains involve the flow of information, processes and resources across the globe [

27]. The idea is that global supply chains utilize low-cost country sourcing and refers to the procurement of products and services from countries with lower labour rates and reduced production costs than that of the home country. There are both positives and negatives with global supply chains and the total cost should always be related to the real costs.

The outsourcing process has caused the emergence of another process, and that is the extension of the supply chains. The initial phase of supply chains, such as the procurement of raw materials for production, began many times in remote markets around the world, where, on the one hand, raw materials were available and on the other hand competitive in price. The same applies to other resources such as human resources, i.e. labour.

Supply chain as shown in

Figure 1, is a complex structure of numerous participants, economic entities in various sectors of the economy and activities. Each of these entities has a certain achieved level of quality of the management system, which is different. At the same time, each of them affects the result and quality of supply chain. In addition, supply chain can be disrupted or interrupted by poor implementation by any of these participants and at any stage of supply chain, from raw material extraction to retail and waste management. For this reason, it is necessary to regulate the system to increase the resilience of supply chains from the negative impacts of disruptions and interruptions of supply chains in future crises.

5. Results

Disruptions and interruptions in supply chains cause problems at three levels. The first level of the problem is the micro level, or the level of an individual organization that is a market participant. The second, higher level, is the level of the national economy or state. The third, highest level of the problem occurs at the global level. Each level of the problem manifests its impact on a specific group of people, as shown in

Table 1.

Long-term disruptions or interruptions in supply chains, especially global ones, cause numerous problems in the economy, the sphere of social infrastructure development and have negative consequences for society.

Table 1 lists the types of individual possible impacts for each level of the problem, as well as the groups that could be affected by the consequences.

Particularly significant problems arise at all levels if there are disruptions or interruptions in the supply chains of strategic products such as food, medicines and medical equipment, and energy. The beginning of the war in Ukraine and the Middle East are examples of disruptions in the development of supply chains precisely for strategic products, and the impact of such disruptions includes all the groups listed in

Table 1 [

7].

The balance of supply and demand, both in the global and national markets, is affected by several circumstances. Without delving far into the past, since the beginning of the 21st century there have been several circumstances that have significantly influenced the change in context and, consequently, disruptions in the development of supply chains. The terrorist attack in New York in 2001, the emergence of a mysterious disease called SARS in 2002 - 2004, the war in Iraq in 2003, the economic crisis in 2008 and the eruption of the Ejafjalajokull volcano in Iceland in 2010, the pandemic of the corona virus (COVID-19) in 2019 - 2022 marked as a new respiratory disease. The change of context in recent times was also influenced by other circumstances, which caused significant disruptions in the development of global supply chains, namely the blockade of the Suez Canal due to the stranding of the ship Ever Given in 2021 and the war in Ukraine that began in 2022. The above circumstances, each in its own way, influenced the change of context, which resulted in a new view of the development of supply chains, reversed processes compared to the period 40 or 50 years ago, and the need for a more flexible interpretation of some quality concepts.

As a result, supply chain resilience has become a vital strategic priority for governments and businesses, to minimize disruptions and maintain business continuity in volatile conditions [

28]. Supply chain resilience is increasingly recognized as a foundation for economic stability, growth, development, and sustainability, particularly in regions where political instability, economic dependencies, and infrastructural disparities create unique vulnerabilities [

29]. Supply chain resilience refers to the ability of a supply chain to anticipate, adapt to, and recover from disruptions, and to maintain operational continuity. The increasing complexity of global supply chains and the complexity of logistics subsystems and systems means that disruptions in one area could have global consequences.

Despite changing contexts and disruptions in supply chains, customers and other stakeholders are finding it difficult to abandon their usual demands for product and service quality. This is a significant problem that governments in all countries need to address.

What we can certainly count on is that circumstances will once again arise that will affect a change in the context that will affect disruptions or interruptions in supply chains. New crises will appear cyclically as before, but in shorter time intervals [

30,

31].

Future crises cannot be prevented, especially not at the micro level of an individual organization or at the level of the national economy or state. Equally, the global community has shown that it is often unable to successfully resolve conflicts, especially prevent war conflicts or stop them in a short time. For this reason, the authors of this paper have developed three models for preventing the impact of supply chain disruptions in future crises, which represent a new philosophical approach to supply chains, and which aim to; 1) proactive action, 2) focus on prevention, 3) development of awareness and 4) creation of assumptions for automatic reaction. These are quality models: 1) for individual organizations; 2) for national economies or states and 3) global model.

5.1. Quality Models for Preventing the Impact of Supply Chain Disruptions in Future Crises

All three models presented below have four groups of requirements: 1) Methods, 2) Measures, 3) Quality tools and 4) Indicators. They also have a narrower and broader context and function on the principle of the PDCA cycle or the Deming cycle.

5.1.1. Quality Model for Individual Organizations

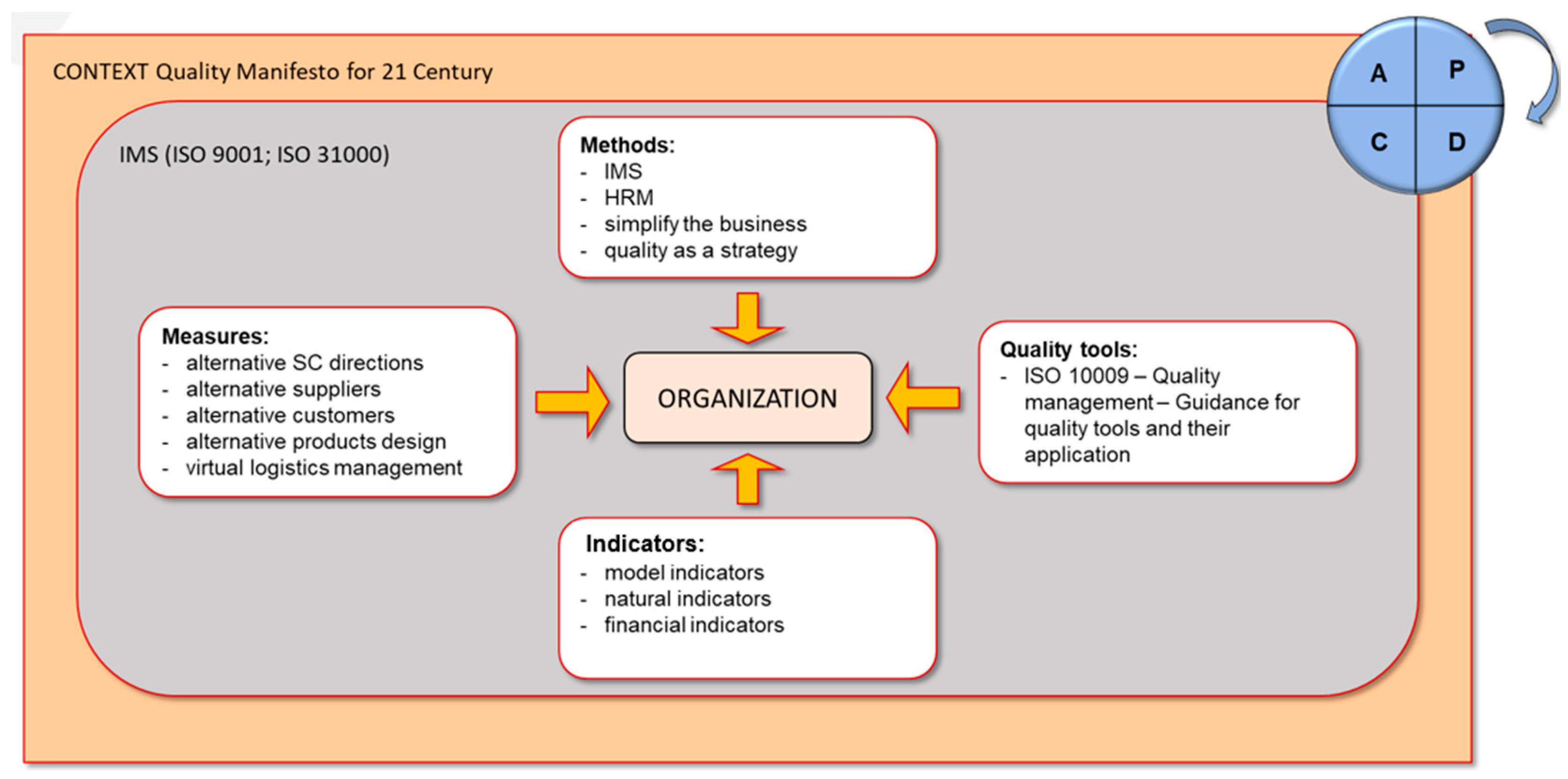

In the model for individual organizations, it is necessary, as shown in

Figure 2, fulfill the following requirements in order for the organization to gain resistance to disruptions in the development of supply chains, which will be caused by future crises:

IMS – Integrated Management System – regardless of the level of management knowledge, each management system is structured in layers. This means that it contains elements of multiple management systems (quality, environment, safety, social responsibility, etc.). An integrated management system does not necessarily need to be certified as such. But it does exist. For this reason, management at all levels of management should have the competence to manage an integrated system. To reach the stage of being managed, the system needs to be built, documented, implemented, and staff trained to manage this complex structure.

HRM – Human Resource Management – it is important that managers at all levels, business process managers, and operational staff are adequately trained in managing the IMS, as well as managing supply chains in conditions of disruption or interruption, i.e. in a crisis. It is essential that they can recognize indicators that indicate an approaching crisis and to take appropriate actions accordingly to mitigate the consequences.

Simplify the business – should be one of the fundamental principles of management at all levels of the organization. Written procedures, work instructions, process documentation, rulebooks, etc. should be as simple as possible. Simplification and simplicity should be strived for as much as possible. Management problems should be solved at the lowest level of management at which they can be solved.

Quality as a strategy – strategy as the main plan, the main path to follow, the main method for achieving the vision and implementing the mission of the organization should be quality. This implies a higher degree of materialization of the principles of quality management in each subsequent process cycle [

32].

Alternative supply chain directions – it is necessary to continuously work on finding and establishing alternative routes of supply chains that could be activated in case of disruption or interruption of the usual routes of supply chains [

33].

Alternative suppliers – it is necessary to continuously work on finding and establishing partnerships with multiple suppliers for the same product, if possible. They should be ordered from time to time and good partnerships should be developed so that they can be fully activated in the event of disruption or interruption of the usual supply chains. This is because dominant dependence on a single supplier, especially when it comes to strategic products (food, medicines and medical equipment, energy sources), represents a great risk [

34].

Alternative customers – the same logic applies as with Alternative suppliers. Dominant dependence on a single buyer of a product poses a major risk to the organization.

Alternative product design – should strive to develop alternative production and products that the organization can continue to market in the event of a disruption or interruption of the supply chain for the usual dominant product. The market should be prepared for such a situation.

Virtual logistics management – a new approach to logistics management, the essence of which is that it is not necessary to have physically full warehouses of raw materials and semi-finished products to ensure production in case of disruptions or interruptions of supply chains. It is necessary to develop a system of information on where the necessary raw materials and semi-finished products are located, under what conditions and in what time frame they can be procured, and in which directions the supply chains can take place in the part related to their procurement. Information should be regularly updated and available to decision makers in the organization [

35].

Application of Quality tools is necessary in the management system. The problems that arise in business are complex and cannot be solved unambiguously. This is also the case with problems of disruption or interruption of supply chains. Since each organization is a special entity and has some peculiarities, it is not appropriate to prescribe to the organization which and how many quality tools should be used in solving problems in the case of disruptions in the development of supply chains. For this reason, it is left to the organization's management and experts to choose which and how many quality tools they will use in solving certain problems. That is why the "Quality toolbox" was formed, shown in

Table 2, which contains 16 groups with a total of 65 quality tools. Quality toolbox consists of quality tools brought by the international standard ISO 10009:2024 Quality management – Guidance for quality tools and their application [

36].

This document provides a brief description of each of the selected quality tools to assist the user in determining whether the tool has beneficial application in a particular context. The document also provides instruction on how the tool can be used [

36].

The “Indicators” are divided into three groups: 1) model indicators, characteristic of this model that refers to individual organizations, 2) natural indicators and 3) financial indicators. In each group of indicators, as shown in

Table 3, several indicators are listed, then the "Method of calculation", their "Interpretation" or meaning and the necessary "Reaction" of the organization's management now when a certain indicator reaches a certain value. By developing such a system of indicators, the organization is ready to react, which means making the necessary decisions to mitigate the negative consequences of disruptions or interruptions in the development of supply chains. Automation of action is achieved.

The system can be developed in a way that monitors the movement of each of these indicators, which is important for anticipatory crisis management because events are actively monitored, and the arrival of a crisis is predicted.

The IMS phenomenon has already been explained previously. It represents a narrower context when it comes to individual organization. This is the fact that essentially determines the direction of the administration. Integration can consist of elements of different management systems. In

Figure 2 is an example of the integration of two management systems ISO 9001 -

Quality management system - Requirements and ISO 31000 -

Risk management - Guidelines, but numerous other combinations and IMS structures are also possible.

The wider context of the model shown in

Figure 2 presents the

Quality Manifesto for the 21st century. It is a document adopted by IAQ - International Academy for Quality. Its acceptance is proof of commitment to "Leadership through Quality" at all levels, from the individual organization to the global level. It is based on these ten principles [

37]:

Deepen our art and science: deepening the profound knowledge of quality sciences and widening the art of its application into all spheres of endeavor for the benefit of humanity.

Do no harm: embedding the idea that not causing harm and doing good for society and the ecology of the planet are not limiting conditions of quality applications but are integral to framing improvement objectives at the highest levels.

Extend our scope: extending the application of quality to all geographies, sectors, functional domains, as well as supporting smaller enterprises.

Go beyond business: developing beyond major corporate applications to cause intense shifts in management of education, health care, environment, and government.

Serve our customers: emboldening all organizational leaders to forever commit to the precedence of satisfying the needs of their customers-patients-students-citizens as their principal objective.

Build strategy the quality way: sensitizing managers to the way vision and objectives must be established, not only to avoid an organization’s internal weaknesses and vulnerabilities and assure harmony with strengths and opportunities, but also in service to all its stakeholders.

Involve everyone: stimulating the universal involvement of all individuals in an organization, creating ownership and capabilities for assuring the quality of their own work and in making improvements endlessly.

Create trust and happiness: encouraging organizations to create an environment wherein all employees gain security through their experience of prosperity, happiness, trust, and inner confidence through their rising abilities and self-respect.

Bring data into daily conversation: rendering, in an age of data profusion, everyone from board members to frontline associates skillful in generating and interpreting data for applications in control, improvement, and daily conversation.

Embrace the new technologies: weaving quality seamlessly into emerging digital, biological, materials and other advanced technologies.

IAQ published this document in 2021 as a Manifesto that represents a global framework for action today and in the future, in which the possibilities of action and individual organizations are found in achieving goals, implementing policies, strategies and realizing visions and missions.

PDCA (Plan – Do – Check – Act) cycle or Deming circle, as shown in

Figure 2, represents one of the important management principles and is an integral part of all three models presented in this paper. Its application guarantees dynamism in management and is a prerequisite for the organization's proactive action [

38].

Application of the model shown in

Figure 2 is in the function of creating the resilience of the management system of an individual organization to make it as less vulnerable as possible in future crises, which will cause disruptions or interruptions in the development of supply chains. This has significant financial, social and political positive implications, both for the specific organization and for the local community in which it is located and operates.

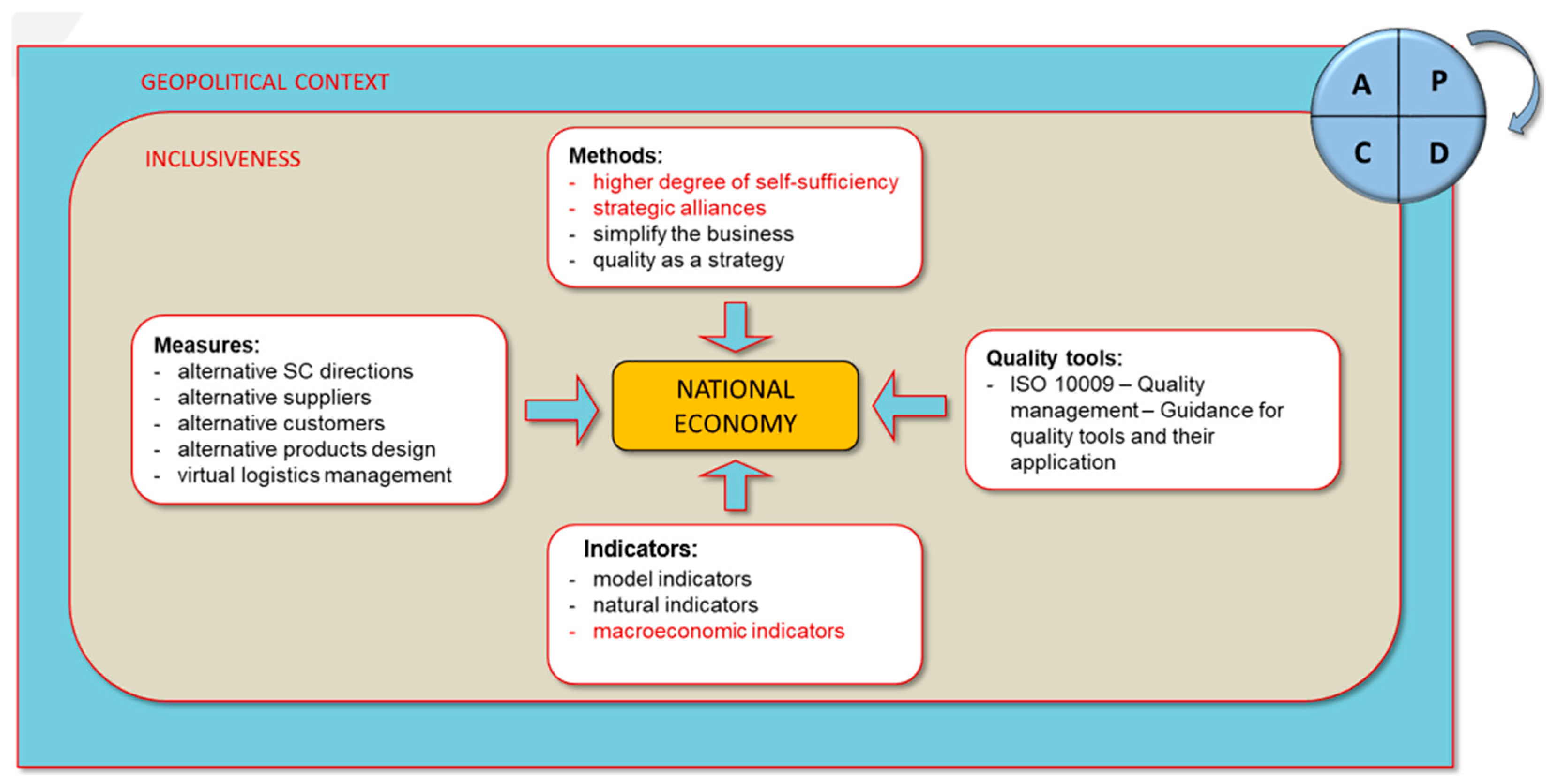

5.1.2. Quality Model for National Economy

In the model for national economies or states shown in

Figure 3, red text indicates the requirements of the model that differ from the model for individual organizations shown in

Figure 2. In the model for national economies, that is, states, it is necessary to fulfill the following requirements to gain resistance to disruptions in the development of supply chains, which will be caused by future crises:

Higher degree of self-sufficiency – it is important for each country to strive for the highest possible level of satisfaction of its own needs for certain types of products, primarily food and energy, but also other vital products. Due to numerous reasons such as economic, natural, historical, geographical, etc., it is not possible for individual countries to be self-sufficient in these and other types of products, but it is necessary to try to make maximum use of existing natural, production and other resources. In situations of disruption or interruption in supply chains, countries that have a higher degree of self-sufficiency of strategic products are in a better position. In extreme cases, this also becomes a question of sovereignty. The strategies and policies of the governments of individual countries should be directed towards the highest possible degree of self-sufficiency in production and services, even though this does not always mean optimization from the point of view of financial results. Countries with the ability to satisfy their needs for products and services to a higher degree are more resistant to the impact of the crisis and disruptions in the development of supply chains. Excessive dependence on imported products and services in crisis situations will negatively affect the economy.

Strategic alliances – no country, regardless of its size and availability of natural and other resources, can solve all problems on its own in crisis situations. For this reason, it is desirable for each country to create economic, political, defense and other alliances with other countries, based on equality, mutual respect and cooperation in achieving common interests. In times of crisis and disruption in supply chains, countries within individual alliances will cooperate to mitigate the negative consequences of the crisis. An example is the joint procurement of vaccines during the COVID-19 pandemic, which was carried out by the EU for its member states.

The remaining two requirements within the "Methods" group are the same as in the previous model for individual organizations, with application to the national economy, i.e. the state.

In this group of requirements, there are the same requirements as in the previous model for individual organizations, with the difference that care must be taken to apply it in a manner appropriate for the national economy, that is, the state.

In this model, the group of requirements "Quality tools" includes the requirements for the application of quality tools as in the previous model for individual organizations, while respecting the specifics related to their application when making decisions at the level of the three levers of power in a country, namely: executive, legislative and judicial power. "Quality tools" are in the "Quality toolbox", as shown in

Table 2.

In this group of requirements, the first two requirements refer, as in the previous model for individual organizations, to model indicators and natural indicators. However, these are completely different indicators, as shown in

Table 3.

The third group is macroeconomic indicators, which refers to the macroeconomic framework of the concrete national economy, that is, the state. Following the movement of the "National macroeconomic indicators" listed in

Table 3, it is possible to timely see macroeconomic developments, trends and predict the arrival of a crisis. The system should be built in such a way that it implies automatic action upon reaching the values of the indicators shown in

Table 3.

Inclusiveness in this model represents the inclusiveness of public administration bodies, that is, of state institutions that should serve citizens to a greater extent and be directed towards meeting the demands of citizens in solving their life situations, and of economic entities, to facilitate entrepreneurial activities [

39,

40,

41]. If the institutions of the state are directed to a greater extent as a service to citizens and the economy, in that case, both citizens and the economy will more easily overcome the period of crisis due to disruptions in the development of supply chains. One of the possible solutions that works in the practice of many member states of the EU is transformation public administration with CAF - Common Assessment Framework [

40].

The CAF is the European Common Assessment Framework for better quality in public administration. The CAF improves public sector organizations through self-assessment and contributes to good governance. The basic idea of the CAF is that every public sector organization has to achieve excellent results an impacts of the benefit of customers, citizens and society, such as “quick and correct business licenses,” “supply with clean water,” “well educated students,” “high life quality through public health services,” “well-understood information on the organization website,” “a comprehensive citizens service,” “sustainably managed infrastructure,” or “high motivated employees” and “satisfied customers” [

40]. Countries that do not have a public administration organized according to CAF principles are not sufficiently focused on citizens and the economy, but rather on the ruling elites, and are less resilient to disruptions in supply chains and crises in general [

39].

In this model, as a broader context than the impact on the national economy, or the state, the geopolitical context should be continuously monitored and understood. In recent years and months, significant changes have been taking place in the geopolitical context that will certainly affect the development of supply chains. No country, regardless of its size and economic strength, can ensure stability and a greater degree of resilience without understanding the geopolitical context and adapting to changes in that context. This is especially important for small countries that cannot significantly influence the geopolitical context, but instead must monitor it, understand it well and make adjustments that will make them capable of operating and developing in a changed geopolitical context.

PDCA (Plan – Do – Check – Act) cycle or Deming circle, as shown in

Figure 3, as in the previous model for individual organizations, also in this model represents one of the important management principles and is an integral part of the model for national economies, that is, states.

Application of the model shown in

Figure 3 is in the function of creating the resilience of the management system of the national economy, i.e. the state, to make it as less vulnerable as possible in future crises, which will cause disruptions or interruptions in the development of supply chains. This has significant financial, social and political positive implications, both for the concrete national economy, that is, for the state, its allies and partners, and for its citizens.

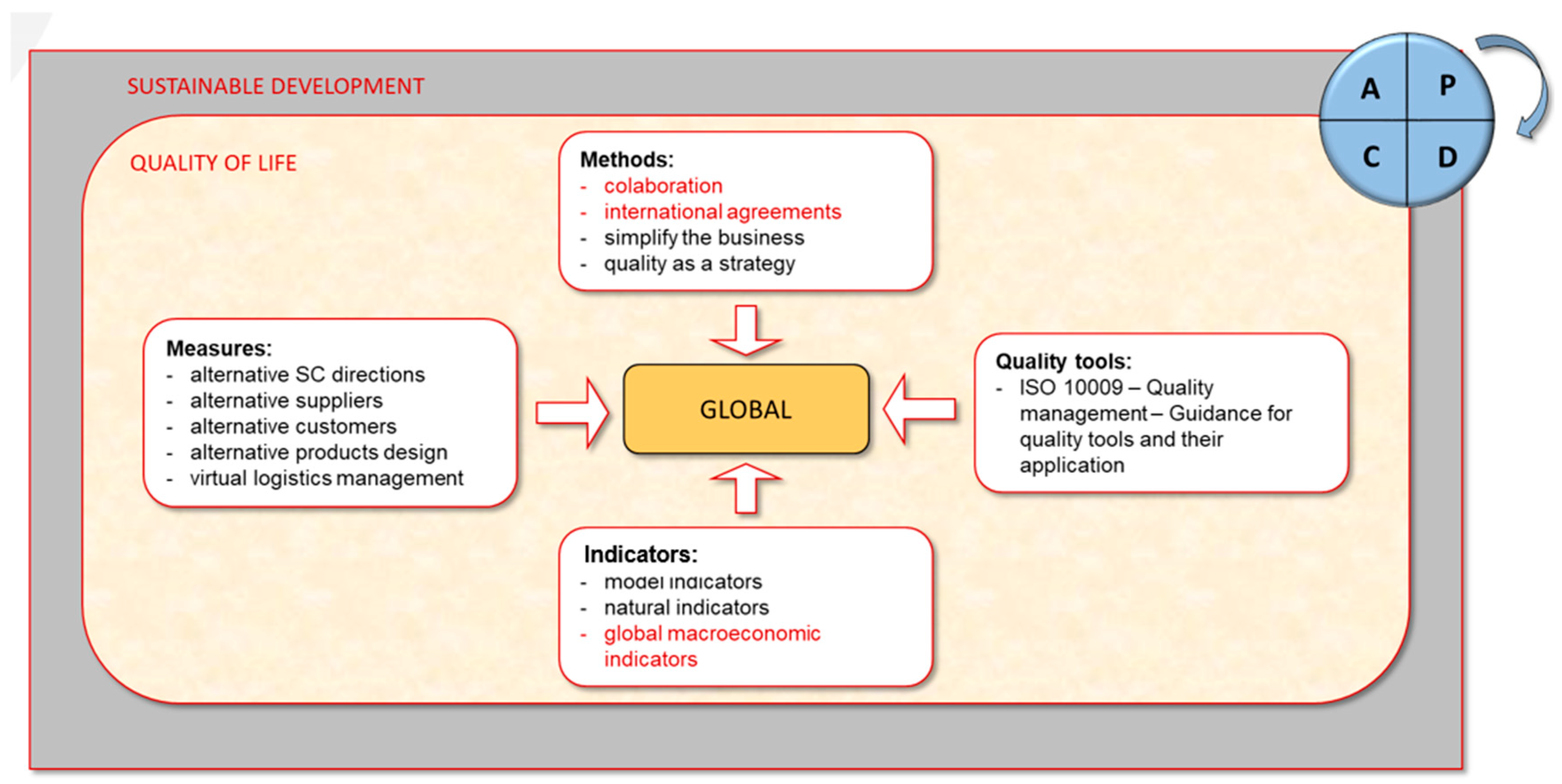

5.1.3. Global Model

In the Global Model shown in

Figure 4, requirements that differ from the previous two models shown in

Figure 2 and

Figure 3 are highlighted in red text. With the global model, the following requirements shown in

Figure 4, so that the entire human community, that is, the global economy, would gain resistance to disruptions in the development of supply chains, which will be caused by future crises:

Collaboration – global economic, political, social stability should be the goal of all people on the planet. However, the world is characterized by numerous imbalances and opposites: 1) rich and poor, 2) educated and uneducated, 3) healthy and those who do not have quality health care, 4) who can defend themselves and who cannot, etc. These imbalances can only be mitigated by collaboration. However, almost as a rule partial interest of groups or individuals disturb this balance. Decision makers at the global level should cooperate for the benefit of all citizens of the world. In this way, the world becomes more resilient to the adverse consequences caused by disruptions or interruptions in supply chains. A good example is the period of the COVID-19 pandemic from 2019 – 2022. Although there were examples of some countries trying to secure a vaccine for their own needs at the expense of others, it was soon realized that the pandemic is a global problem, and that global problems require global solutions. The pandemic could not have ended without collaboration because the virus needed to be eradicated in all parts of the world to be globally eradicated and for the pandemic to end [

42].

International agreements – collaboration is established and institutionalized through various international agreements. For decades, there have been certain alliances in the world based on international agreements, such as the UN - United Nations, NATO - North Atlantic Treaty Organization, EU - European Union, OPEC - Organization of the Petroleum Exporting Countries and many others, however, this does not mean that the problem will be successfully solved. On the contrary, witness that despite the existence and operation of the UN and NATO, wars are being waged somewhere in the world every day with great human casualties, destruction of infrastructure and destruction of the environment. However, international agreements are still important to have generally accepted rules in international relations, which put all subjects of global society on an equal footing. This also applies to the mitigation of harmful consequences due to disruptions or interruptions in the development of supply chains [

43].

Other requirements from the "Methods" group in the global model shown in

Figure 4 are the same as in the previous two models, with a note that they need to be interpreted and implemented because it is a global model.

This group of requirements in the global model is identical to the previous two models, with the difference that they should be adapted and understood from the point of view of contributing to the prevention of damage due to disruptions or interruptions of global supply chains. The fundamental interest should be to ensure the functioning of global supply chains in all circumstances, especially when it comes to strategic products such as food, water, medicines and medical equipment, energy sources, etc. This should be considered by international organizations and global decision-makers, since they have a dominant influence on changing the global context and have the resources to find global solutions.

In this model, the group of requirements "Quality tools" includes the requirements for the application of "Quality tools" as in the previous two models, while respecting the specifics related to their application in decision-making at the global level, which means that they should be used by experts in international organizations and decision-makers with global impact. "Quality tools" are in the "Quality toolbox", as shown in

Table 2.

In the "Indicators" global model, "Model indicators" and "Natural indicators" are provided, as in the previous two models, with the difference that they have a completely different "Method of calculation" and "Interpretation", as well as the provided "Reaction". These are indicators characteristic of the global economy and are related to stock exchange commodities such as oil, gas, gold, as shown in

Table 4. It should be emphasized that the price of oil and the price of gold move in the same direction in the long term. These goods could be supplemented with other stock exchange goods such as wheat, some ores, etc. A characteristic of stock exchange commodities is that their price, and that means availability, largely depends on the global context, that is, on the stability of global supply chains that form global supply and demand. These goods respond promptly to changes in the global context and disruptions in supply chains.

"Natural indicators" are also provided for goods that are traded on stock exchanges, and which represent an input in almost all production and services, either directly or indirectly, namely oil. The price of oil is subject to frequent fluctuations due to several factors, including: 1) supply and demand dynamics, 2) geopolitical events, 3) weather conditions and 4) economic indicators.

As for “Global macroeconomic indicators”, it is an indicator specific to the global market and the global economy. The “Inflation rate” indicator was chosen, which refers to economies with a large impact on the global market, such as the USA, Japan, EU, China, because the inflation rate in these countries has a dominant effect on average global inflation. And the “Inflation rate” indicator reflects the degree of imbalance between global supply and demand. For every 10-percentage point increase in the price of oil, inflation in an average country will rise between 0.4 and 0.6%, depending on how much its economy relies on oil derivatives. If the average inflation is around 3.7%, 0.5% of inflation is added to that for every 10% increase in the price of oil (15% growth price of oil = 1.5 x 0.5 = 0.75 + 3.7 = 4.45), as shown in

Table 4.

The global strategic goal should be "Quality of life" for all the inhabitants of planet Earth. This is the narrower context of the global model. Quality of life consists of numerous factors: health, environment, material well-being, safety, equality, information, level of democracy, etc. This strategic goal determines the need for continuous development of global supply chains. "Quality of life" is threatened if supply chains are disrupted or interrupted.

Sustainable development in the global model appears as a broader context. In addition to referring to the entire planet Earth, it also includes the part of the universe close to the Earth. The application of the principle of sustainable development is of great importance for the smooth development of supply chains. Weather problems around the world, which are attributed to climate change, can significantly disrupt the development of supply chains or lead to their interruption. This in a way that they destroy natural resources, infrastructure, communications, agricultural products, and human lives. They cause an imbalance between global supply and demand with all the negative consequences for the quality of life on planet Earth [

44].

PDCA (Plan – Do – Check – Act) cycle or Deming circle, as shown in

Figure 4, as in the previous two models, represents one of the important management principles in this model and is an integral part of the global model.

Application of the model shown in

Figure 4 is in the function of creating the resilience of the global economic system, to make it as less vulnerable as possible in future crises, which will cause disruptions or interruptions in the development of global supply chains.

6. Discussion

Circumstances that influence the change of context that causes disruptions or interruptions in supply chains are almost every day. Often their intensity is such that it causes crises. It is certain that such circumstances, disruptions or interruptions in supply chains and crises will occur in the future. Responsible management in organizations, responsible governments in countries, responsible international organizations and decision-makers with global influence should prepare their management systems in a way that they are exposed to the impact of future crises to the smallest extent possible. This also means that systems should be more resilient to future crises.

Quality models for preventing the impact of supply chain disruptions and interruptions in future crises, presented in this paper as: 1) a model for individual organizations, 2) a model for national economies, i.e. states and 3) a global model, are structured in such a way that they contain: 1) methods that should be applied, 2) measures that should be adopted and implemented, 3) quality tools that can and should be applied in solving problems in business and 4) a system of indicators that warns of the presence of a crisis. The development and implementation of these models as an integral part of the management system of an organization, state or global society brings significant advantages such as:

All of this aims to prevent major financial and other damage, both to individual organizations, countries, and the global community. The full implementation of these models will make organizations, countries, and the global community more resilient to disruptions or interruptions in supply chains in future crises and will contribute to preserving the quality of life of citizens.

The results of the research presented in this paper show that the full application of the model for preventing the impact of supply chain disruptions in future crises contributes to strengthening the resilience of individual organizations, states and the global community, reduces damage and contributes to preserving the quality of life of citizens. This is since the implementation and application of the presented models enables business processes to be managed, and not to take place spontaneously.

The application of the presented models, which implies the fulfillment of all requirements from the four groups of requirements in each model, will make the management systems of individual organizations, national economies or states and the global community, aware of the approach of crises, prepared to make decisions that will be prepared in advance, more resistant to disruptions and interruptions of supply chains than they have been so far, without the application of the models presented in this paper.

This paper has theoretical and practical significance and contribution. Theoretically, it consists in developing three quality models for preventing the impact of supply chain disruptions in future crises and defining four groups of requirements that need to be met in order for management systems at the level of an individual organization, a national economy or a state and at a global level to be more resilient to the consequences that will arise in future crises due to disruptions or interruptions in supply chains. Also, a system of quantified indicators has been developed, which enables decision-makers at all three levels of the model to make decisions that will be based on facts, which is one of the principles of quality management.

The practical significance and contribution is that, if the methodology described in all three models is followed and indicators are applied, the management system at all three levels can be strengthened in practice and made more resilient to the harmful impact of disruptions in supply chains in future crises, which should result in significant financial savings and prevention of erosion of the quality of life of citizens.

Further research and development of the presented models should be continued in the direction of further development of methods, definition of additional measures and development of indicator systems. The indicator system can be further developed and improved in such a way that, in addition to the quantification of indicators which implies automaticity of reaction, their quantification is established which enables monitoring of trends, which would be a significant contribution to anticipatory crisis management. In this way, surprises of any kind would be avoided, which was characteristic of the period of the COVID-19 pandemic, when disruptions and interruptions in supply chains, both in individual organizations and countries and at the global level, represented a surprise for all participants in the global market, with a significant negative impact on the quality of life of all people on the planet.

Author Contributions

Conceptualization, M.D. and G.B.; methodology, M.D; software, I.Š; validation, M.D.; formal analysis, M.D. and S.P.; investigation, M.D.; resources, S.P. and I.Š.; data curation, I.Š.; writing—original draft preparation, M.D.; writing—review and editing, M.D.; visualization, M.D.; supervision, G.B.; project administration, M.D. and G.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was paid by the University North, Varaždin - Koprivnica, Croatia.

Acknowledgments

The authors would like to thank IAQ-QiLTT (International Academy for Quality - Quality in logistics think tank) for their cooperation.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Grzybowska, K. Identification, and classification of global theoretical trends and supply chain development directions. Energies 2021, 14, 4414. [Google Scholar] [CrossRef]

- Mbonigaba, C.; Sujatha, S. Impact of global supply chain disruptions on business resilience: strategies for adapting to pandemics and geopolitical conflicts. Int. J. Adv. Trends Eng. Technol. (IJATET) 2024. Version 1. [Google Scholar] [CrossRef]

- Aljuneidi, T.; Bhat, S.H.; Boulaksil, Y. A comprehensive systematic review of the literature on the impact of the COVID-19 pandemic on supply chains. Supply Chain. Anal. 2023, 3. [Google Scholar] [CrossRef]

- Williams, B.A.; Jones, C.H.; Welch, V.; True, J.M. Outlook of pandemic preparedness in a post-COVID-19 world. npj Vaccines 2023. [Google Scholar]

- Maliszewska, M.; Mattoo, A.; Van der Mensbrugghe, D. The Potential Impact of COVID-19 on GDP and Trade, A Preliminary Assessment, World Bank Group, East Asia and the Pacific Region Office of the Chief Economist & Macroeconomics, Trade and Investment Global Practice. April 2020. [Google Scholar]

- Nshimirimana, D.A.; Kokonya, D.; Gitaka, J.; Wesonga, B.; Mativo, J.N.; Rukanikigitero, J.M.V. Impact of COVID-19 on health-related quality of life in the general population: A systematic review and meta-analysis. Plos Global Public Health 2023, 3, e0002137. [Google Scholar] [CrossRef]

- Devados, S.; Ridley, W. Impacts of the Russian invasion of Ukraine on the global wheat market. World Dev. 2024, 173. [Google Scholar] [CrossRef]

- Kim, D.; Steinbach, S.; Zurita, C. Deep trade agreements and agri-food global value chain integration. Food Policy 2024, 124. [Google Scholar] [CrossRef]

- To, B.C.N.; Nguyen, B.K.Q.; Nguyen, T.V.T. When the market got the first dose: Stock volatility and vaccination campaign in COVID-19 period. Heliyon 2023, 9. [Google Scholar] [CrossRef]

- Xu, Z.; Elomri, A.; Kerbache, L.; El Omri, A. Impacts of COVID-19 on Global Supply Chains: Facts and Perspectives. IEEE Eng. Manag. Rev. 2020, 48, 153–166. [Google Scholar] [CrossRef]

- Magableh, G.M. Supply Chains and the COVID-19 Pandemic: A Comprehensive Framework. Wiley 2021, 18, 363–382. [Google Scholar] [CrossRef]

- McKibbin, W.; Fernando, R. The global economic impacts of the COVID-19 pandemic. Econ. Model. 2023, 129. [Google Scholar] [CrossRef]

- Choi, T.Y.; Netland, T.H.; Sanders, N.; Sodhi, M.S.; Wagner, S.M. Just-in-time for supply chains in turbulent times. Prod. Oper. Manag. 2023. [Google Scholar] [CrossRef]

- Drljača, M.; Repnjak, P. Supply chains in the context of the COVID-19. In Proceedings of the International Scientific Conference “The Science and Development of Transport” (ZIRP 2020), Transformation of Transportation, University of Zagreb, Faculty of Transport and Traffic Sciences, Šibenik, Zagreb, Croatia (online), 29-30 September 2020; 2020; pp. 35–46. [Google Scholar]

- March, D.; Metcalfe, K.; Tintoré, J.; Godley, B.J. Tracking the global reduction of marine traffic during the COVID-19 pandemic. Nat. Commun. 2021, 12. [Google Scholar] [CrossRef] [PubMed]

- Gerson, A. Stranding of the Mega-Ship Ever Given in the Suez Canal: Causes, Consequences, and Lessons to Be Learned. In The Suez Canal: Past Lessons and Future Challenges; 2023; pp. 231–252. [Google Scholar] [CrossRef]

- Rssenfosse, d.G.; Murovana, T.; Uhlbach, W.-H. The effects of war on Ukrainian research. Humanit. Soc. Sci. Commun. 2023. [Google Scholar] [CrossRef]

-

ISO 28001:2007; Security management systems for the supply chain - best practices for implementing supply chain security, assessments and plans - Requirements and guidance.

-

ISO 22163:2023; Railway applications - Railway quality management system - ISO 9001:2015 and specific requirements for application in the railway sector.

-

ISO 10377:2013; Consumer product safety - Guidelines for suppliers.

-

ISO 13065:2015; Sustainability criteria for bioenergy.

-

ISO 20333:2017; Traditional Chinese medicine - Coding rules for Chinese medicines in supply chain management.

-

ISO 22300:2021; Security and resilience — Vocabulary.

- Swamidass, P.M. SEVEN “RIGHTS” OF LOGISTICS. In Encyclopedia of Production and Manufacturing Management; Swamidass, P.M., Ed.; Springer: New York, NY, 2000. [Google Scholar] [CrossRef]

- Sarkis, J.A. Strategic Decision Framework for Green Supply Chain Management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Vurro, C.; Russo, A.; Perrini, F. Shaping Sustainable Value Chains: Network Determinants of Supply Chain Governance Models. J. Bus. Ethics 2009, 90, 607–621. [Google Scholar] [CrossRef]

- Available online: https://www.cips.org/knowledge/procurement-topics-and-skills/supply-chain-management/global-supply-chains/ (accessed on 1 March 2025).

- Adeleye, R.A.; Oyeyemi, O.P.; Asuzu, O.F.; Awonuga, K.F.; Bello, B.G. Advanced analytics in supply chain resilience: a comparative review of African and USA practices. Int. J. Manag. Entrep. Res. 2024, 6, 296–306. [Google Scholar]

- Al-Balushi, Z.; Durugbo, C.M. Management strategies for supply risk dependencies: empirical evidence from the gulf region. Int. J. Phys. Distrib. Logist. Manag. 2020, 50, 457–481. [Google Scholar]

- Veil, S.R. Mindful Learning in Crisis Management. J. Bus. Commun. 2011, 48, 116–147. [Google Scholar] [CrossRef]

- Wolbers, J.; Kuipers, S.; Boin, A. A systematic review of 20 years of crisis and disaster research: Trends and progress. Wiley Online Library. 2021. [Google Scholar] [CrossRef]

- Drljača, M. 2nd IAQ World Quality Forum Future Impact of Quality. Quality as a global strategy; IAQ – International Academy for Quality: Bled, Slovenia, 2017. [Google Scholar]

- Lee, P.T.-W.; Song, Z. Exploring a new development direction of the Belt and Road Initiative in the transitional period towards the post-COVID-19 era. Transp. Res. Part E Logist. Transp. Rev. 2023, 172. [Google Scholar] [CrossRef] [PubMed]

- Gritz, A.; Wolff, G. Gas and energy security in Germany and central and Eastern Europe. Energy Policy 2024, 184. [Google Scholar] [CrossRef]

- Wong, E.Y.C.; Lee, P.T.Y. Virtual reality in transportation and logistics: A clustering analysis of studies from 2010 to 2023 and future directions. Comput. Hum. Behav. 2024, 153. [Google Scholar] [CrossRef]

-

ISO 10009:2024; Quality management – Guidance for quality tools and their application.

- Ramanathan, N(Ram).; Watson, G.H. IAQ - IAQ Position Paper: Revitalizing the Global Quality Manifesto. Available online: https://hksq.org/wp-content/uploads/2021/08/IAQ-Position-Paper-Revitalizing-the-Global-Quality-Manifesto-2021.pdf.

- Deming Institute. PDSA Cycle - The W. Edwards Deming Institute. (accessed on 1 March 2025).

- Acemogly, D.; Robinson, J.A. Why Nations Fail. Profile Books; Main edition (7 Feb. 2013).

-

Transforming Public Administration with CAF (20 years of Common Assessment Framework); Prorok, T., Parzer, P., Eds.; KDZ – Centre for Public Administration Research: Vienna, 2020; p. 15. [Google Scholar]

- Gwiżdż, A.; Wołowiec, T.; Grzesiak, A.; Orzeł, Z. Quality management in public administration. Legal and administrative regulations and effective process management. J. Mod. Sci. 2024, 57, 302–321. [Google Scholar] [CrossRef]

- Qian, X.; Ren, R.; Wang, Y.; Guo, Y.; Fang, J.; Wu, Z.-D.; Liu, P.-L.; Han, T.-R. Fighting against the common enemy of COVID-19: a practice of building a community with a shared future for mankind. Infect Dis Poverty 2020, 9, 34. [Google Scholar] [CrossRef]

- Goldschmidt, K.H.; Kumar, S. Humanitarian operations and crisis/disaster management: A retrospective review of the literature and framework for development. Int. J. Disaster Risk Reduct. 2016, 20, 1–13. [Google Scholar] [CrossRef]

- Kara, M.E.; Ghadge, A.; Bititci, U.S. Modelling the impact of climate change risk on supply chain performance. Int. J. Prod. Res. 2021, 59. Performance measurement and management in a VUCA world. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).