Introduction

Sericulture is an agro-based industry that involves the rearing of silkworms for the production of raw silk, which is the yarn obtained from cocoons spun by certain species of insects. The major activities of sericulture include food-plant cultivation to feed the silkworms, which spin silk cocoons, and reeling the cocoons to unwind the silk filament for value-added benefits. Like all other crops, seasonal factors play a pivotal role in determining the productivity and quality of raw silk. Weather conditions in different seasons impact sericulture (silk production) by affecting the growth and development of mulberry plants, the primary food source for silkworms. Fluctuations in temperature, precipitation patterns, and extreme weather events can lead to reduced silk production, lower-quality cocoons, and increased pest and disease outbreaks. Since silkworms are cold-blooded animals, they are highly sensitive to temperature changes and require specific climatic conditions for optimal silk production (Rahmatulla, 2012). Optimal conditions for silkworm rearing include temperatures between 23–28°C and relative humidity of 70–80%, ensuring high cocoon yield and superior filament quality. However, extreme heat and excessive humidity during summers and monsoons adversely affect cocoon production, leading to thinner shells, irregular shapes, and reduced filament lengths, ultimately compromising reeling efficiency (Rahmatulla, 2012).

In India, different states have distinct crop schedules based on their climatic suitability. For this study considering the oldest sericulture state that is West Bengal, particularly the Murshidabad region, where silk production is documented to have started as early as the 13th century. In West Bengal, sericulture districts cultivate up to seven crops annually, with five being major crops (Sericulture West Bengal, seriwb.gov.in). The state experiences a transitional climate, ranging from tropical wet-dry conditions in the south to humid subtropical conditions in the north. To maintain silk quality and production, the introduction of more resilient and high-yielding silkworm breeds has been implemented. Traditional Nistari breeds have been enhanced through hybridization, leading to the development of better-performing multi × multi hybrids such as N × MCon4 and MCon1 × MCon4, as well as bivoltine hybrids like Sk6 × Sk7 and BHP DH. Further advancements have led to multi-bi cross hybrids such as N × SK6 × SK7 and MCon4 × BCon4, which combine the high silk quality of bivoltine strains with the resilience of multivoltine varieties, ensuring better adaptability to fluctuating environmental conditions (Dayananda, 2012). According to the 2023–24 State Government report, Nistari (multivoltine), Sk6 × Sk7 (bivoltine), and N × SK6 × SK7 (crossbreed) are the most popular breeds among farmers due to their superior performance. These technological and biological advancements have led to better-quality cocoons and increased silk production (Chakraborty, 2020).

Regarding the reeling sector, West Bengal's sericulture remains decentralized but is transitioning from traditional reeling methods, such as Katghai and Ghosh Basin, to modern technologies like Multi-End Reeling Machines (MRM) and Automatic Reeling Machines (ARM). In 2023–24, twelve MRMs were established, along with one ARM in Malda and Murshidabad districts. This displays the interest of people in the adaptation of new technology. These innovations have enhanced efficiency, uniformity, and productivity while reducing manual inconsistencies (Alim, 2016). However, these new technologies require substantial investment and high-quality raw materials to ensure profitable and efficient production.

Assessing the suitability and understanding variations of locally produced mulberry cocoons for advanced machines has become imperative. MRM units require high-quality cocoons, and their efficiency is influenced by several factors, including operator skill level, the number of ends per thread, raw material characteristics, and machine maintenance (D. Chattopadhyay, 2018). Filament length, non-broken filament length (NBFL), and single-fiber denier are critical parameters that directly impact reeling speed, production efficiency, and yarn uniformity. Studies suggest that maintaining minimum reeling speeds of 100 m/min for MRMs and 200 m/min for ARMs is crucial for economic viability (International Sericulture Research Institute, 2017; Ramesh et al., 2019).

Research indicates that the NBFL for popular crossbreed hybrid, bivoltine, and Nistari cocoons ranges between 450–800 m, 350–900 m, and 250–450 m, respectively (Silk Board Research Report, 2022). Given the direct correlation between NBFL and reeling speed, optimizing cocoon characteristics is essential for maximizing the efficiency of MRM units.

This study aims to comprehensively assess the filament length, NBFL, and single filament denier of locally produced mulberry cocoons and cocoons procured from other states to evaluate their suitability for MRM reeling. By optimizing reeling parameters such as winding speed, the number of cocoons per end, basin water temperature, and croissure length, this research seeks to enhance productivity and reduce silk production costs. Ultimately, this study intends to address the technological and biological challenges facing the sericulture sector, thereby supporting its sustainable growth in West Bengal. So in terms of raw material Filament length and NBFL becomes important characteristics to determine the speed of Reeling machine and its production as well as evenness of the yarn. Optimizing these parameters is essential for improving the profitability of MRM units and reducing the cost of silk production (D. Chattopadhyay, 2018).

Material and Method

A sample of 1 kg of cocoons was procured for each popular bivoltine and Multi x Bi hybrid across five major seasons in West Bengal and the north-eastern region of India. The single cocoon weight, single shell weight, and shell ratio were measured. These samples were further analysed using the standard single cocoon reeling analysis to determine filament length, non-broken filament length, reelability, renditta, and silk recovery.

Drying of Cocoons:

The cocoons were stifled and dried using a hot air dryer following a standard procedure. The drying process began at 115°C for 1 hour, with the temperature gradually reduced by 15°C each hour, following the profile: 115°C → 100°C → 85°C → 70°C → 55°C. After reaching 55°C, the cocoons were allowed to cool for 30 minutes before being removed from the chamber.

Cocoon Sorting and Preparation for Reeling Analysis

The cocoons were sorted to identify defective ones in the lot. A random sample of 200 cocoons was selected for single cocoon reeling analysis, while another 300 cocoons were chosen for evaluating other reeling parameters.

Cocoon Cooking Process

The selected cocoons were cooked using a two-pan cooking mechanism based on the low-high-low temperature principle. The process lasted 8–12 minutes, ensuring the optimal cooking of the cocoons. The cocoons were brushed in the same pan at the same temperature to group the filament ends for reeling.

Single Cocoon Reeling Analysis

Cooked cocoons were reeled individually using an éprouvette until the filament end. The total filament length and the number of breaks were recorded. For this analysis, the average of 5 cocoons was used.

The calculations were as follows:

Reeling analysis

A sample of 300 cocoons was reeled by a skilled reeler using a multi-end reeling machine operating at a speed of 100 meters per minute. The reeling basin temperature was maintained at 40–45°C, with a croissure length of 8 cm. Eight cocoons per end were used, with two ends being reeled simultaneously. The number of castings and carryovers was recorded for further calculations of reeling efficiency and performance.

Statistical analysis:

Based on 200 readings for FL and NBFL, the mean, median, mode, standard deviation, and skewness have been calculated in Excel using standard formulas

Result and Discussion

Data was collected from 200 bivoltine and multi-bi hybrid cocoons for each season across two years from the north-eastern region of India. The grouped frequency distributions for FL and NBFL are analysed to understand their behaviour across seasons. These parameters are critical indicators of cocoon quality, as they influence silk yield, reeling efficiency, and the overall economic feasibility of silk production. The shell ratio, filament length, and NBFL variations between favourable and unfavourable seasons reveal the sensitivity of cocoon quality to environmental factors. (D. Chattopadhyay, 2018)

Shell Ratio and Filament Length Analysis

The shell ratio, defined as the ratio of shell weight to green cocoon weight, is an essential parameter for estimating raw silk content in cocoons. A higher shell ratio indicates a greater silk yield relative to the size of the pupa. This ratio is consistently higher in bivoltine cocoons during favourable seasons, highlighting their superior raw silk potential. However, it decreases significantly during unfavourable seasons due to stress-induced reduction in silk deposition.

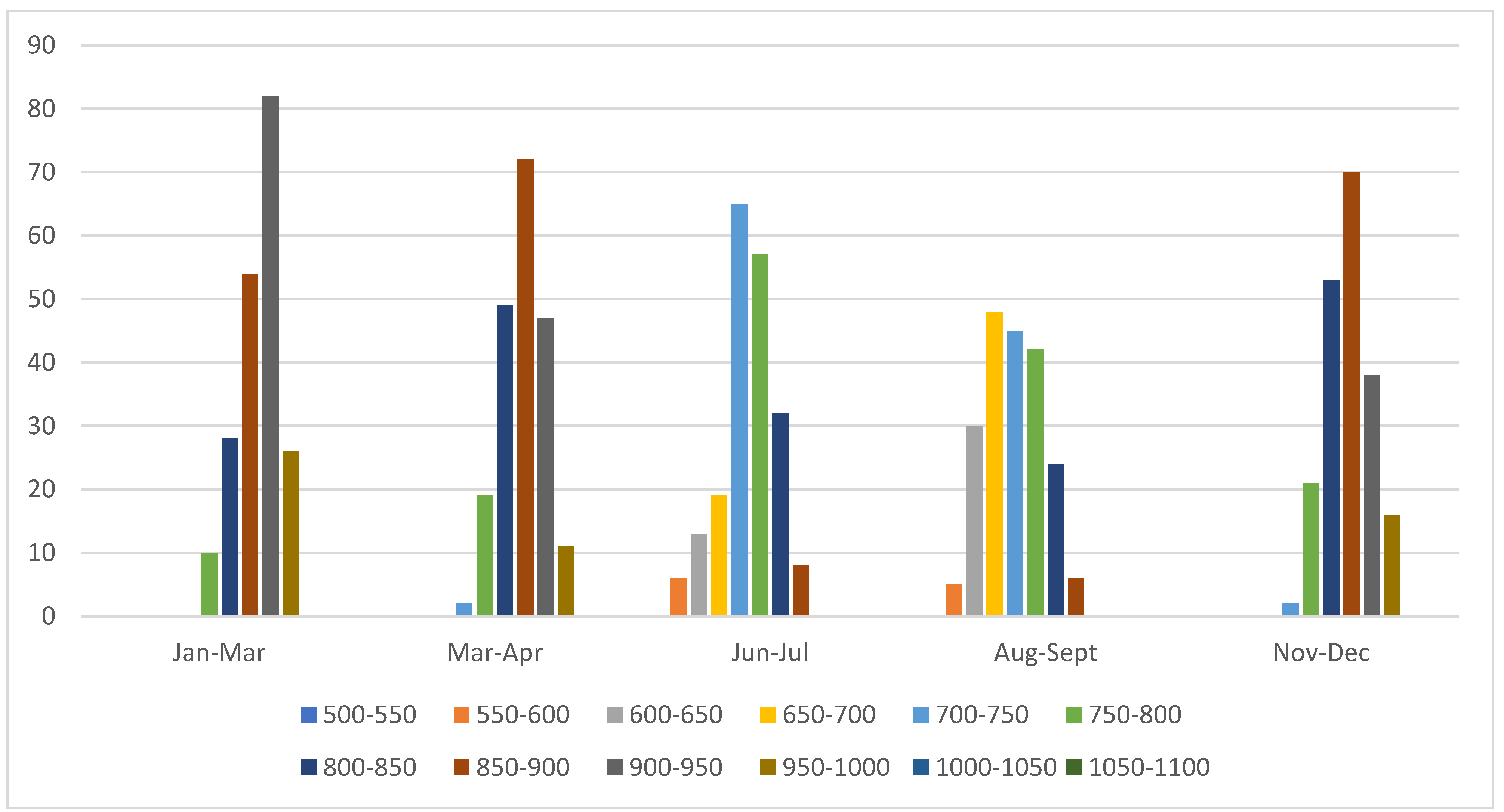

Filament length (FL) in bivoltine cocoons ranges from 750 to 1000 meters during favourable seasons such as January–March, March–April, and November–December. The mean FL for these seasons is 897 m, 869 m, and 867 m, respectively, with the highest frequencies observed in the ranges 900–950 m (82 cocoons), 850–900 m (72 cocoons), and 850–900 m (70 cocoons). In contrast, during unfavourable seasons such as June–July and August–September, the FL decreases and shifts to a range of 550–900 meters, with mean values of 746 m and 721 m, and the highest frequencies in the ranges 700–750 m (65 cocoons) and 650–700 m (48 cocoons).

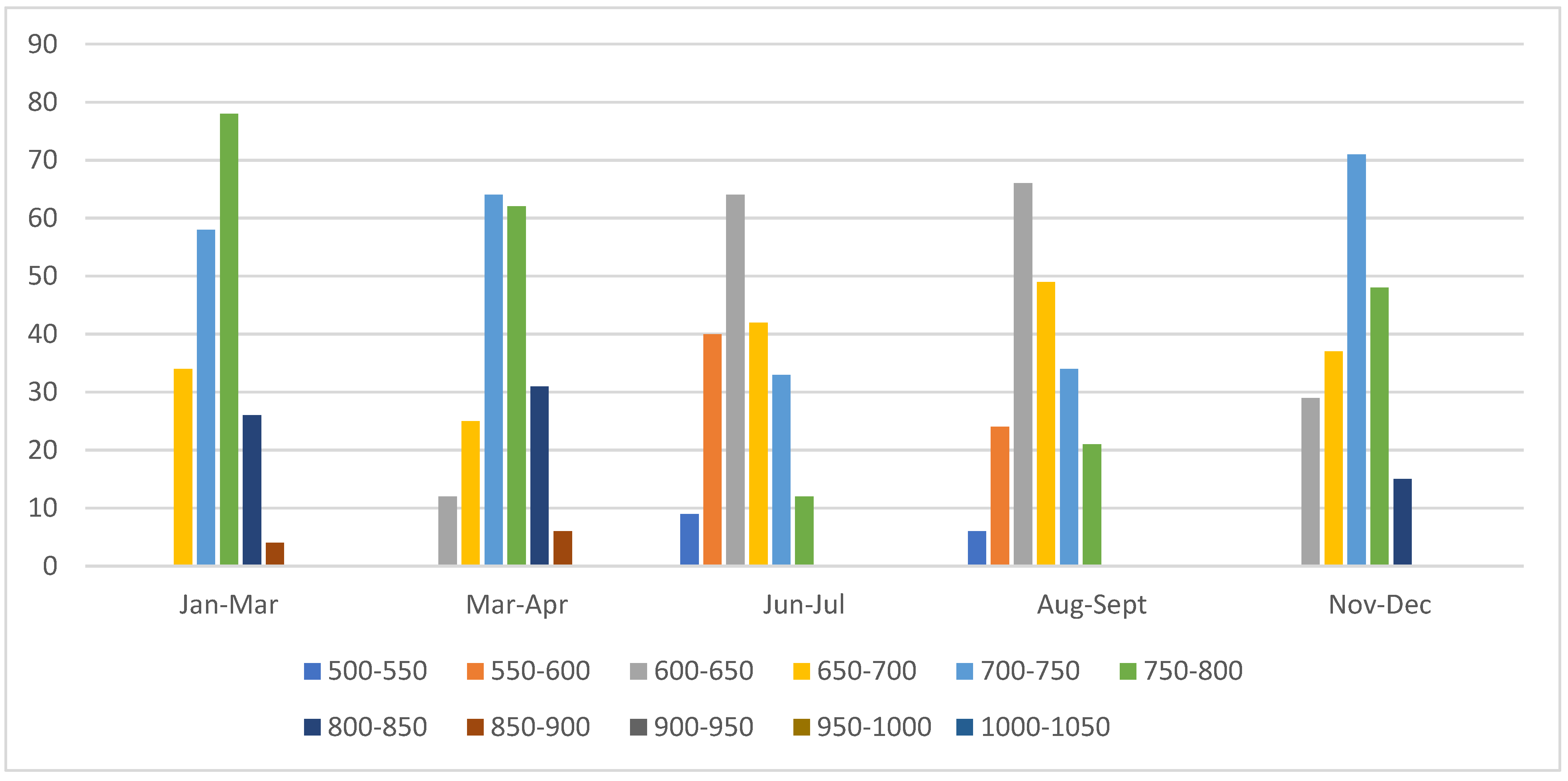

For multi-bi hybrids, FL ranges between 650 and 900 meters during favourable seasons, with mean values of 752 m, 748 m, and 721 m, with the highest frequencies observed in the ranges 750–800 m (78 cocoons), 700–750 m (64 cocoons), and 700–750 m (71 cocoons). In unfavourable seasons, the FL reduces to a range of 500–800 meters, with mean values of 647 m and 661 m, and the highest frequencies in the ranges 600–650 m (64 cocoons) and 600–650 m (60 cocoons). These observations indicate that while multi-bi hybrids are less sensitive to seasonal changes compared to bivoltine cocoons, they also experience a decline in filament quality during unfavourable periods.

Figure 1.

Filament legth distribution of bivoltine cocoons in different seasons.

Figure 1.

Filament legth distribution of bivoltine cocoons in different seasons.

Figure 2.

Filament legth distribution of multi-bi hybrid cocoons in different seasons.

Figure 2.

Filament legth distribution of multi-bi hybrid cocoons in different seasons.

Non-Broken Filament Length (NBFL) Analysis

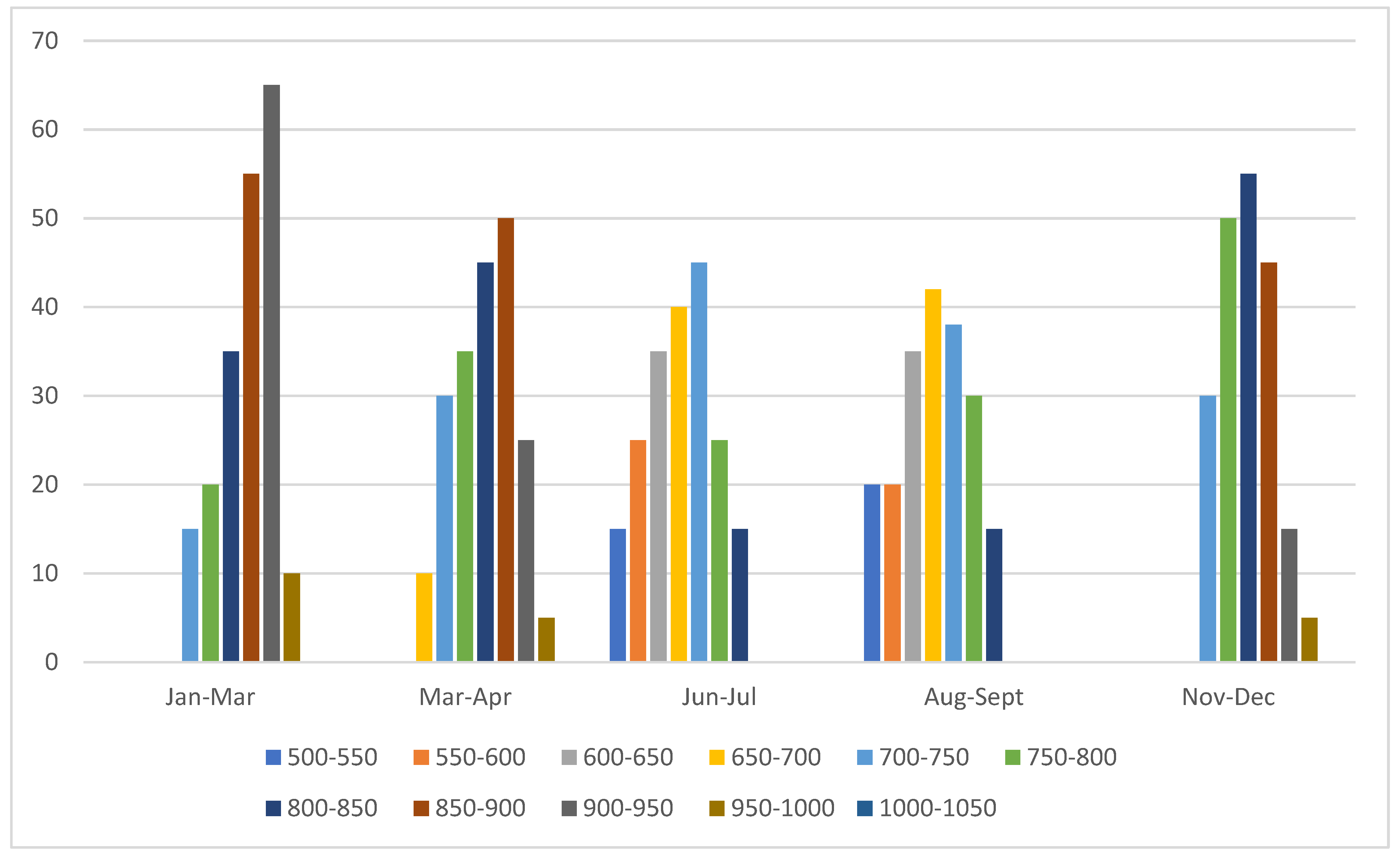

Non-broken filament length (NBFL) is another crucial parameter, as it directly affects reeling efficiency and silk quality. In favourable seasons, NBFL for bivoltine cocoons ranges between 700 and 1000 meters, with mean values of 866 m, 823 m, and 820 m, and mode values of 908 m, 858 m, and 817 m. During unfavourable seasons, the NBFL decreases significantly, ranging between 500 and 850 meters, with mean values of 678 m and 677 m, and mode values of 626 m and 636 m. This reduction highlights the challenges of maintaining quality if raw silk yarn and productivity during unfavourable climatic conditions.

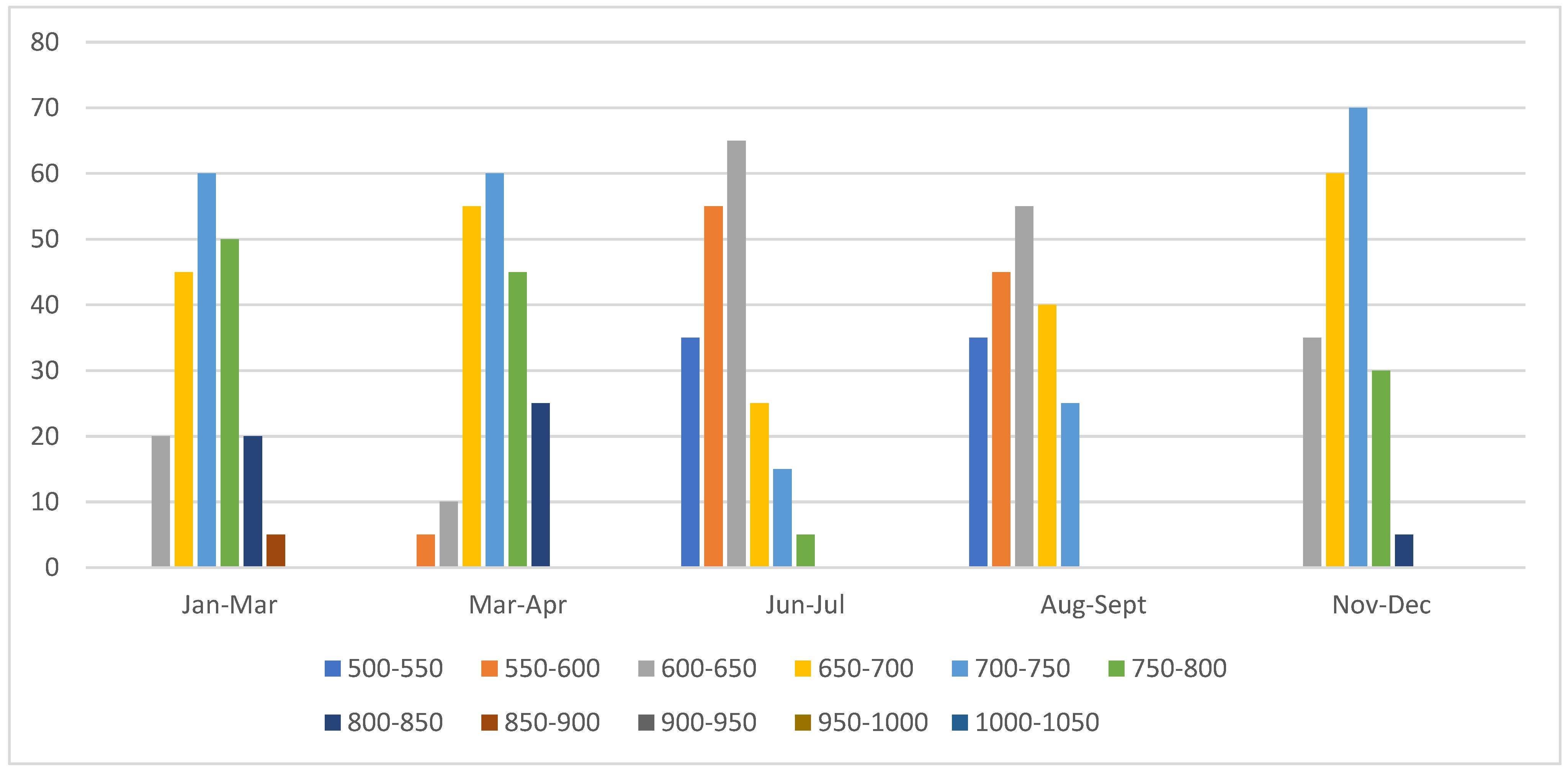

Similarly, for multi-bi hybrids, NBFL during favourable seasons ranges between 600 and 900 meters, with mean values of 730 m, 726 m, and 703 m, and mode values of 730 m, 713 m, and 710 m. In unfavourable seasons, the NBFL drops to a range of 500–800 meters, with mean values of 611 m and 619 m, and mode values of 610 m and 620 m. These results show that while multi-bi hybrids exhibit better stability compared to bivoltine cocoons, they are not entirely immune to environmental stress.

Impact of Seasonal Variations

Seasonal changes have a pronounced effect on cocoon quality, particularly for bivoltine silkworms, which are more delicate and sensitive to environmental fluctuations. The shell ratio, filament length, and NBFL all decrease during unfavourable seasons, resulting in poorer reeling performance. Reelability, defined as the percentage of reelable cocoons out of 100, drops from 80% in favourable seasons to 60% in unfavourable seasons for bivoltine cocoons. Multi-bi hybrids show a smaller decline, with reelability decreasing from 76% to 68%. Raw silk recovery follows a similar trend, remaining above 80% in favourable seasons but dropping below 60% in unfavourable periods for both types.

Figure 3.

NBFL distribution of bivoltine cocoons in different seasons.

Figure 3.

NBFL distribution of bivoltine cocoons in different seasons.

Figure 4.

NBFL distribution of multi-bi hybrid cocoons in different seasons .

Figure 4.

NBFL distribution of multi-bi hybrid cocoons in different seasons .

Statistical Analysis

Based on data obtained from single cocoon reeling analysis, key statistical measures, including the mean, median, mode, standard deviation (SD), and skewness, were computed for filament length (FL) and non-broken filament length (NBFL). These statistical parameters provide insights into the variability and distribution of filament characteristics among different silkworm cocoon types.

The results of these calculations are summarized in

Table 1 and

Table 2 for bivoltine silkworm cocoons, while

Table 3 and

Table 4 present the same parameters for multi-bi hybrid silkworm cocoons. Additionally, the cocoon characteristics, assessed prior to the reeling analysis, are displayed in

Table 5 and

Table 6.

A detailed examination of skewness, a measure of asymmetry in data distribution, reveals notable patterns. For bivoltine cocoons, skewness values are predominantly negative in all seasons except for the November–December period, suggesting a tendency towards shorter filament lengths. This indicates that, under most conditions, the filament length distribution is skewed towards lower values. Conversely, multi-bi hybrid cocoons exhibit mostly positive skewness, except in the January–March and March–April periods, where skewness values are near zero, suggesting a more symmetrical distribution of filament lengths in these seasons.

These observed trends indicate that unfavorable environmental conditions disproportionately affect bivoltine cocoons, reducing their quality and filament characteristics to levels comparable to those of multi-bi hybrid cocoons. This suggests that bivoltine varieties may be more sensitive to seasonal variations, whereas multi-bi hybrids demonstrate a relatively stable performance across different seasons.

The findings highlight the importance of season-specific management strategies to mitigate the impact of environmental factors on filament characteristics, particularly for bivoltine silkworms, to ensure optimal cocoon quality and reeling efficiency.

NBFL is a crucial parameter for determining the optimal reeling machine speed, directly influencing production rates while maintaining the desired silk yarn quality. For instance, in producing 20–22 denier silk yarn, the reeling process typically requires 10 cocoons per end. Maintaining consistent feeding of these cocoons is critical to achieving uniform quality and high efficiency. Skilled reeling workers play an essential role in managing this process, as their ability to sustain consistent feeding directly correlates with reeling performance.

The relationship between NBFL, feeding rate, and reeling speed is mathematically expressed as:

Performance data for bivoltine hybrids (Sk6 x Sk7) and multi-bi hybrids (NxSk6 x Sk7) across different seasons highlight the influence of NBFL on reeling speed:

Table 7.

Reeling Speed with respect to NBFL.

Table 7.

Reeling Speed with respect to NBFL.

| Speed (MPM) N=10 |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Sk6 x Sk7 |

104 |

99 |

81 |

81 |

98 |

| NxSk6xSk7 |

88 |

87 |

73 |

74 |

84 |

| Speed (MPM) N=08 |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Sk6 x Sk7 |

130 |

123 |

102 |

102 |

123 |

| NxSk6xSk7 |

110 |

109 |

92 |

93 |

105 |

According to the Reeling and Testing Manual by Yong-Woo Lee, a skilled reeling worker can consistently feed 12–14 cocoon ends per minute, which serves as a benchmark for reeling speed calculations under standard conditions. This benchmark enables reeling units to optimize their operations for both bivoltine and multi-bi hybrid cocoons.

Conclusion

NBFL is the most important quality characteristic of reeling cocoons, as it helps predict the achievable production speed. The NBFL value depends on the breed of the silkworm—bivoltine silkworms have a higher filament length (FL), resulting in higher NBFL if the number of breaks is minimal. In contrast, the multi-bi hybrid has a lower NBFL.

Seasons with temperatures below 30°C and relative humidity (RH) around 70% or lower are favorable for silkworm health. Temperatures above this threshold start to negatively impact silkworm health and silk gland function, leading to higher mortality, reduced FL, and lower crystallinity. High humidity during spinning also affects silk quality.

A lower NBFL means more frequent breaks, requiring additional feedings within the same period. For bivoltine cocoons, the highest frequency range for NBFL is above 800 meters during January–February and November–December. This indicates that during favorable seasons, a reeler can achieve an approximate production speed of 100 meters per minute (mpm), whereas in unfavorable seasons, it may drop to around 80 mpm, leading to a 20% production loss due to raw material quality.

For multi-bi hybrids, production is lower in the January–February, March–April, and November–December crops, while in the remaining two seasons, the NBFL value is almost at par. This allows reelers to select raw materials based on price and demand.

This alignment ensures consistent silk quality and efficiency, even under variable seasonal conditions. The adoption of such optimized reeling practices is vital for sustaining the competitiveness of the silk reeling industry in the northeastern region.

Conflicts of Interest

No potential conflict of interest was reported by the authors.

References

- Alim, K. (2016). Technological advancements in silk reeling: A case study of modernization in sericulture. Journal of Sericulture Research, 12(3), 45–58.

- Alim, M. A., Hossain, M. S., & Islam, M. S. (2016). Study on comparative reeling performance of multi-end reeling machine and cottage basin reeling machine for qualitative and quantitative improvement of raw silk production. Elixir Applied Chemistry, 95, 41180–41183.

- Akahane, T., & Tsubouchi, K. (1994). Reelability and water content of cocoon layer during the spinning stage. Journal of Sericultural Science of Japan, 63(3), 229–234.

- Akash, C., Kunal, S., Majumdar, M., & Kumar, V. (2020). Studies on performances of bivoltine hybrids SK6 × SK7 and its reciprocal crosses during April crop in West Bengal. International Journal of Advanced Research in Biological Sciences, 7(6), 134–140.

- ASTM International. (2015). ASTM D1776/1776M: Standard practice for conditioning and testing of textiles (pp. 418–422). ASTM International.

- Chakraborty, S. (2020). Sericulture development in West Bengal: Recent trends and challenges. West Bengal State Government Report, 2023–24.

- Chattopadhyay, D. (2018). Reeling efficiency and cocoon quality assessment in modern silk production units. Indian Journal of Sericulture, 19(2), 102–117.

- Chattopadhyay, D., Munshi, R., & Chakravorty, D. (2018). Studies on the distribution of filament length and non-broken filament length for tropical tasar and muga silk cocoons vis-à-vis mulberry silk cocoons. The Journal of the Textile Institute, 109(2), 1–6. [CrossRef]

- Chattopadhyay, R., Das, S., Gulrajani, M. L., & Sen, K. (1997). A study on the progressive change in characteristics of the bave (filament) along its length in mulberry and tasar cocoons. Sericologia, 37(2), 263–270.

- Dayananda, R. (2012). Hybridization in silkworm breeding: Enhancing quality and resilience in sericulture. International Journal of Sericulture Studies, 9(4), 55–73.

- Dayananda, R., Kulkarni, S. B., Rao, P. R. M., Gopinath, O. K., & Nirmal Kumar, S. (2011). Evaluation and selection of superior bivoltine hybrids of the silkworm Bombyx mori L. for tropics through large-scale in-house testing. International Journal of Plant, Animal and Environmental Sciences, 1(3), 16–22.

- Gowda, B. N., & Reddy, N. M. (2007). Influence of different environmental conditions on cocoon parameters and their effects on reeling performance of bivoltine hybrids of silkworm, Bombyx mori L. International Journal of Industrial Entomology, 14(1), 15–21.

- International Sericulture Research Institute. (2017). Advancements in reeling technology: The role of automation in silk production. ISRI Technical Bulletin, 15(1), 78–92.

- Iizuka, E. (1980). Structure of silk yarn: Biological and physical aspects, mechanism of silk spinning. In A. Gopal (Trans.), D. Mahadevappa (Ed.), Tsuneda, Shinshu University (pp. 336–337). Matsumoto: Tsuneda.

- Lee, Y. (1999). Raw silk reeling: Reeling and testing manual (No. 136, p. 61). Food & Agriculture Organization of the United Nations.

- Naik, S. V., & Somashekar, T. H. (2008). Influence of temperature and humidity maintained during cocoon spinning on reeling performance and quality of raw silk of Indian bivoltine hybrid cocoons. Sericologia, 48(4), 379–389.

- Rahmatulla, V. (2012). Impact of climatic factors on silkworm rearing and cocoon production. Sericulture Science Review, 8(1), 33–49.

- Rahmathulla, V. K. (2012). Management of climatic factors for successful silkworm (Bombyx mori L.) crop and higher silk production: A review. Psyche: A Journal of Entomology.

- Ramesh, M., Patel, K., & Singh, A. (2019). Optimization of reeling speeds for sustainable silk production. Journal of Silk Technology, 14(2), 112–126.

- Sericulture West Bengal. (n.d.). Silk production in West Bengal: Crop schedules and climatic adaptation. Retrieved from http://www.seriwb.gov.in.

- Silk Board Research Report. (2022). Performance assessment of different silkworm breeds for enhanced cocoon quality. Central Silk Board, Government of India.

- Somashekar, T. H., & Kawakami, K. (2002). Manual on bivoltine silk reeling technology (pp. 42–58). Central Silk Technological Research Institute, Central Silk Board.

- Subhas, V., Naik, H., Hariraj, G., Takabayashi, C., Yoda, K., Nakajima, L., & Ishii, H. (2022). Cocoon testing: Manual of bivoltine silk reeling technology (pp. 10–22). Central Silk Technological Research Institute, Central Silk Board.

Table 1.

Bivoltine-Filament length.

Table 1.

Bivoltine-Filament length.

| |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Mean |

897 |

869 |

746 |

721 |

867 |

| Median |

905 |

871 |

748 |

719 |

823 |

| Mode |

917 |

874 |

743 |

693 |

857 |

| SD |

52.08 |

53.75 |

65.99 |

71.05 |

56.15 |

| Skewness |

-0.48 |

-0.10 |

-0.10 |

0.10 |

2.38 |

Table 2.

Bivoltine-Non Broken filament length.

Table 2.

Bivoltine-Non Broken filament length.

| |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Mean |

866 |

823 |

678 |

677 |

820 |

| Median |

877 |

828 |

681 |

680 |

818 |

| Mode |

908 |

858 |

710 |

682 |

817 |

| SD |

66.04 |

74.12 |

82.88 |

70.96 |

58.09 |

| Skewness |

-0.50 |

-0.21 |

-0.14 |

-0.12 |

0.09 |

Table 3.

Multi x Bi Hybrid-Filament length.

Table 3.

Multi x Bi Hybrid-Filament length.

| |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Mean |

752 |

748 |

647 |

661 |

721 |

| Median |

755 |

749 |

640 |

654 |

696 |

| Mode |

764 |

748 |

626 |

636 |

730 |

| SD |

49.20 |

58.07 |

63.35 |

58.52 |

56.96 |

| Skewness |

-0.19 |

-0.05 |

0.32 |

0.35 |

1.31 |

Table 4.

Multi x Bi Hybrid-Non broken filament length.

Table 4.

Multi x Bi Hybrid-Non broken filament length.

| |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Mean |

730 |

726 |

611 |

619 |

703 |

| Median |

729 |

725 |

608 |

618 |

654 |

| Mode |

730 |

713 |

610 |

620 |

710 |

| SD |

61.03 |

59.67 |

62.24 |

49.85 |

51.17 |

| Skewness |

0.04 |

0.06 |

0.17 |

0.03 |

2.83 |

Table 5.

Bivoltine cocoon characteristics.

Table 5.

Bivoltine cocoon characteristics.

| |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Single cocoon weight |

1.92 |

1.94 |

1.60 |

1.52 |

2.11 |

| Single shell weight |

0.37 |

0.36 |

0.26 |

0.23 |

0.41 |

| SR% |

19.36 |

18.35 |

16.02 |

15.45 |

19.52 |

| Denier |

2.13 |

2.19 |

1.95 |

1.89 |

2.22 |

| |

|

|

|

|

|

Table 6.

Multi Bi hybrid cocoon characterises.

Table 6.

Multi Bi hybrid cocoon characterises.

| |

Jan-Mar |

Mar-Apr |

Jun-Jul |

Aug-Sept |

Nov-Dec |

| Single cocoon weight |

1.79 |

1.72 |

1.51 |

1.46 |

1.84 |

| Single shell weight |

0.29 |

0.27 |

0.21 |

0.20 |

0.32 |

| SR% |

16.40 |

15.92 |

13.68 |

13.56 |

17.13 |

| Denier |

1.98 |

1.87 |

1.92 |

1.85 |

2.11 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).