Submitted:

03 March 2025

Posted:

04 March 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Flexible Glass in Egyptian and Roman Tales

1.2. Legend of Non-Breakable Glass in the Middle Age

2. Recent History of Flexible Glass

- -

- Asahi Glass Co. (AGC) (Japan): Innovated ultra-thin glass for next-generation displays, including foldable screens.

- -

- Central Glass Co., Ltd. (Japan): Specializes in ultra-thin glass for solar panels and electronics.

- -

- Corning Inc. (USA): Renowned for its Gorilla Glass, Corning has expanded into ultra-thin glass for foldable devices and flexible electronics applications.

- -

- Emerge Glass (India): A key player in the South Asian market, offering specialized ultra-thin glass products.

- -

- Luoyang Glass Co., Ltd. (China): Focuses on ultra-thin glass for various industrial applications.

- -

- Nippon Electric Glass Co., Ltd., NEG (Japan): Produces ultra-thin glass for touchscreens and advanced display technologies.

- -

- Nippon Sheet Glass Co., Ltd., NSG (Japan): Produces ultra-thin UFF and Glanova glasses widely used in the automobile industry and in the liquid crystal industry.

- -

- Schott AG (Germany): Offers products such as the ultra-thin Schott AS 87 Eco, designed for use in consumer electronics, particularly in smartphones and wearable devices.

- -

- Xinyi Glass Holdings (Hong Kong): Supplies ultra-thin glass for electronics and the solar energy industry.

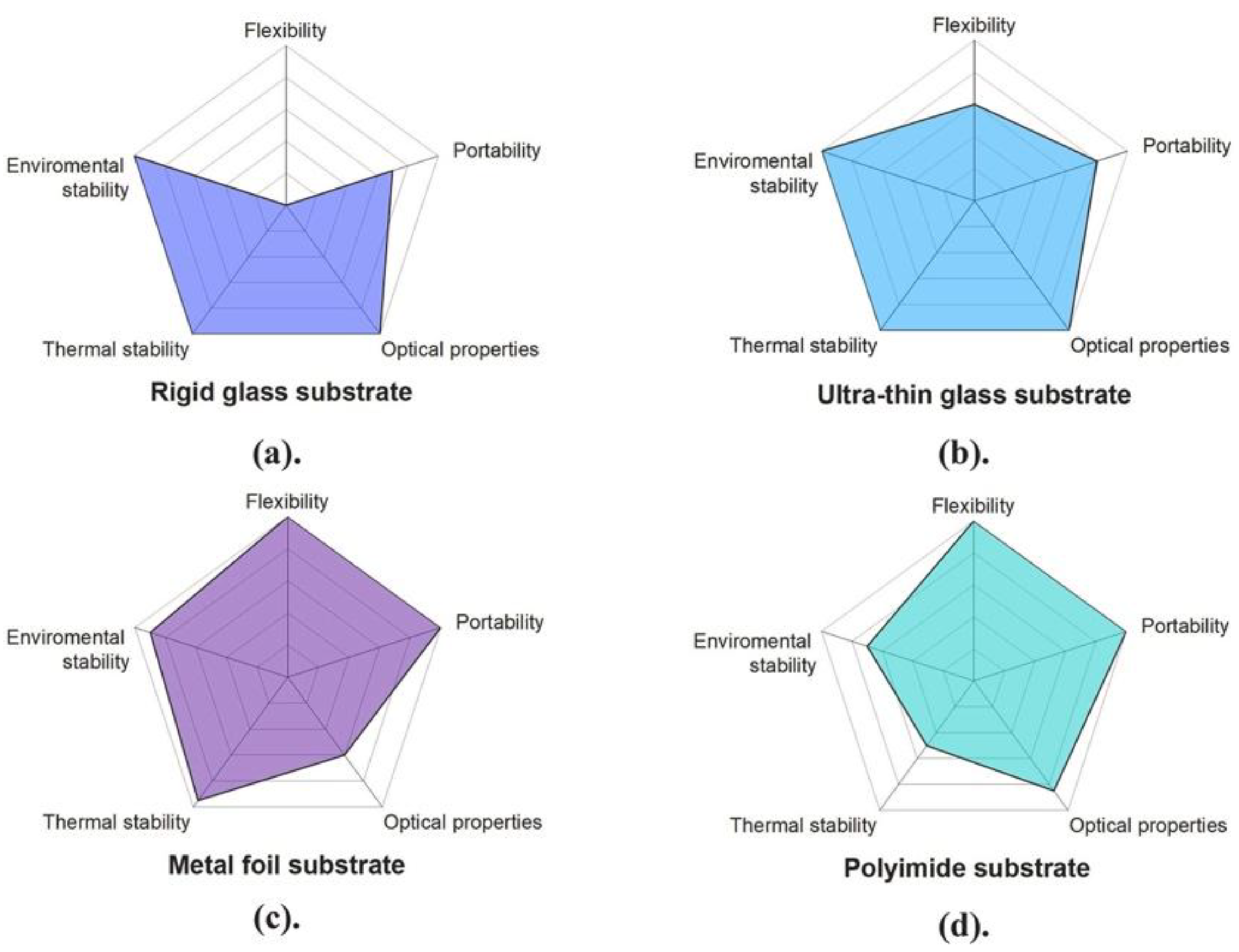

3. Photonic Applications of Flexible Glasses

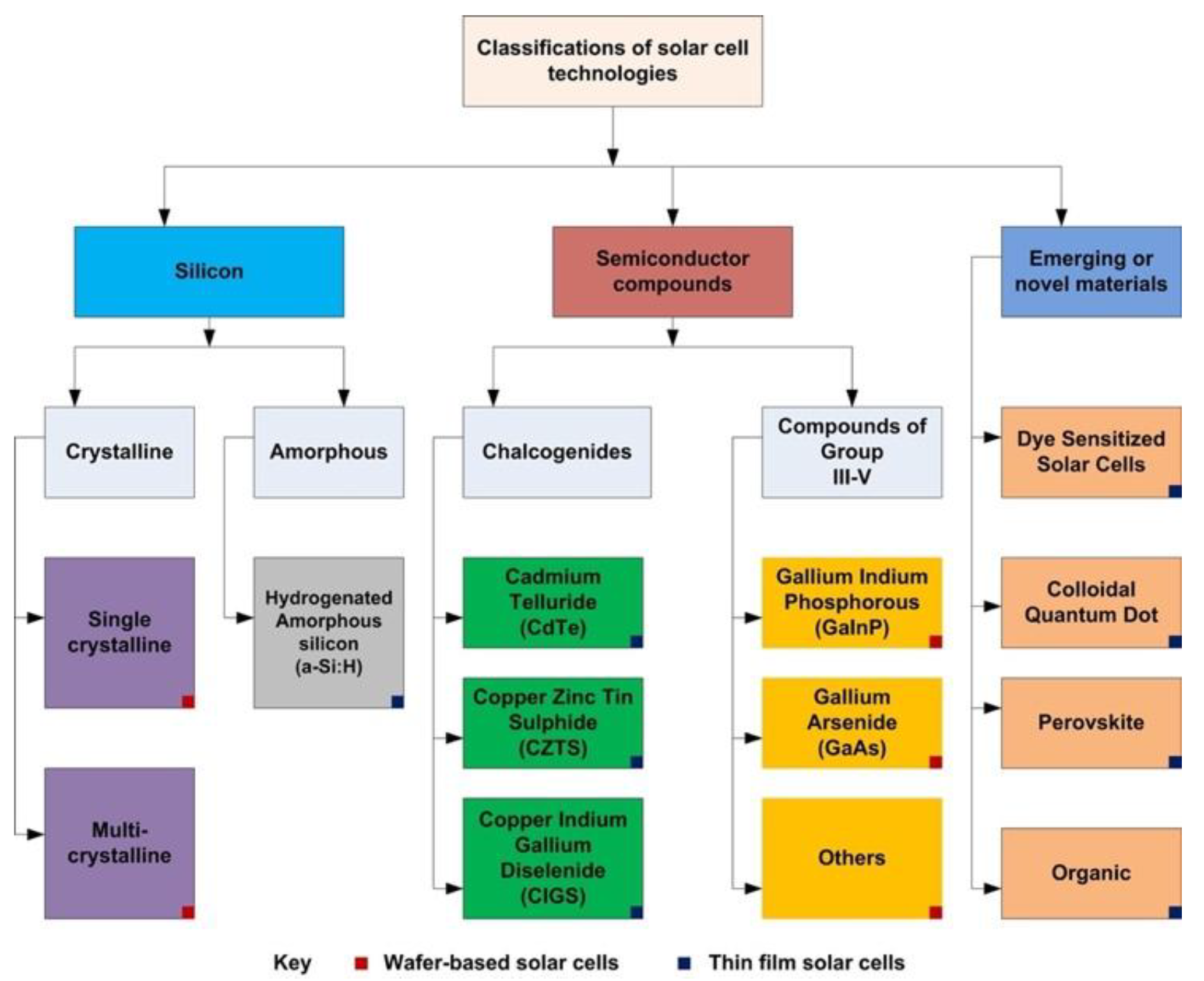

3.1. Flexible Solar Photovoltaic Systems

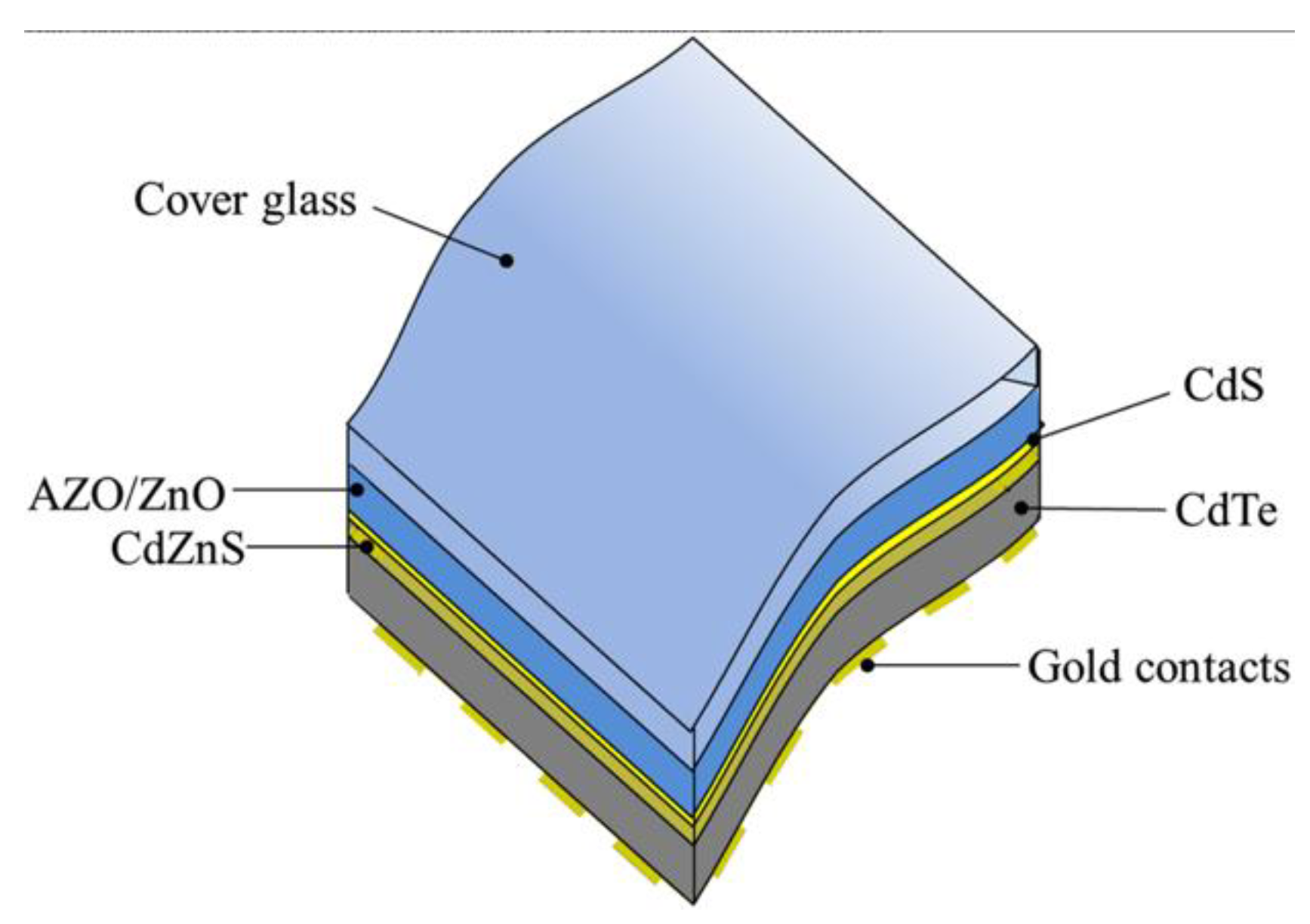

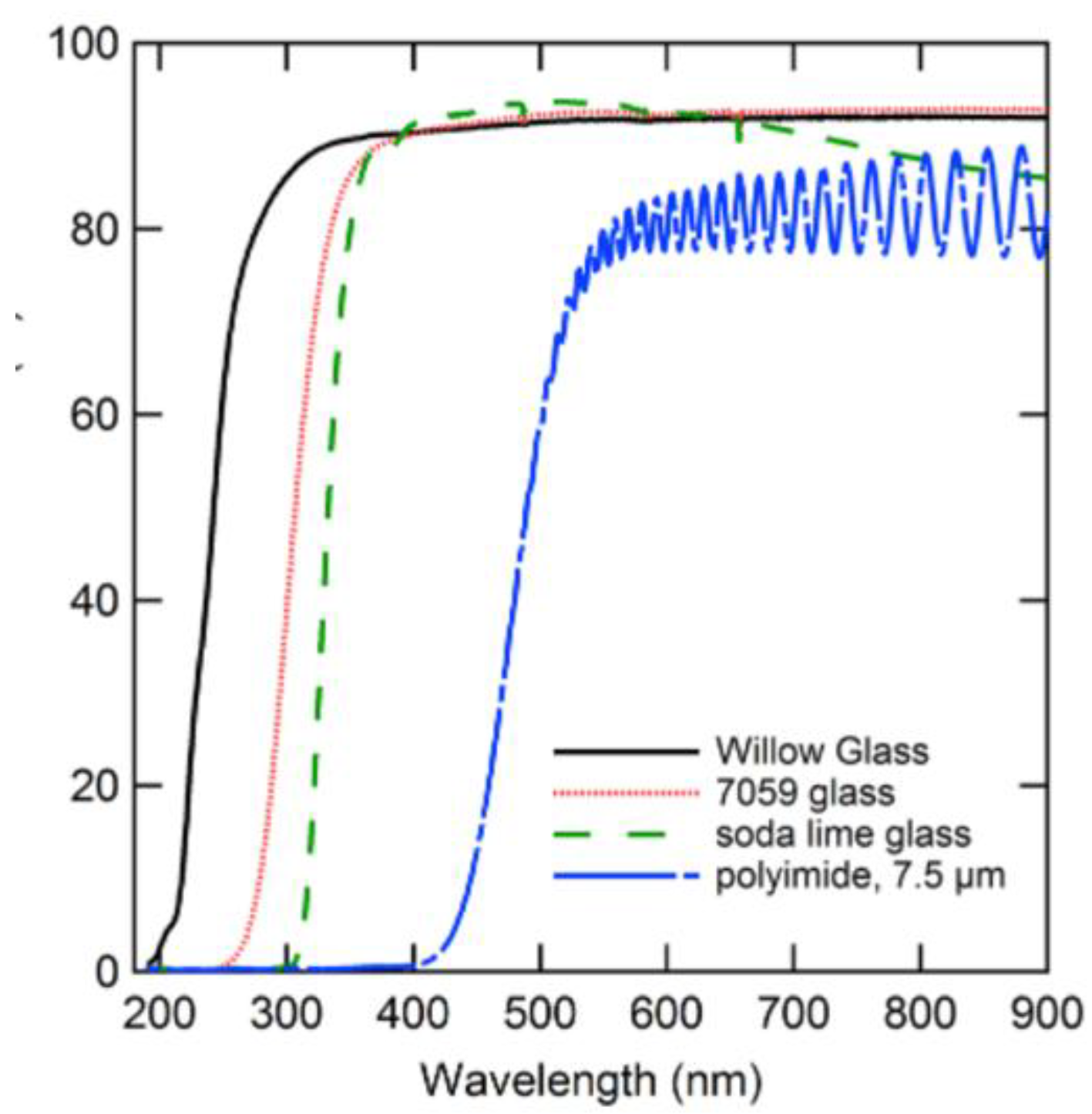

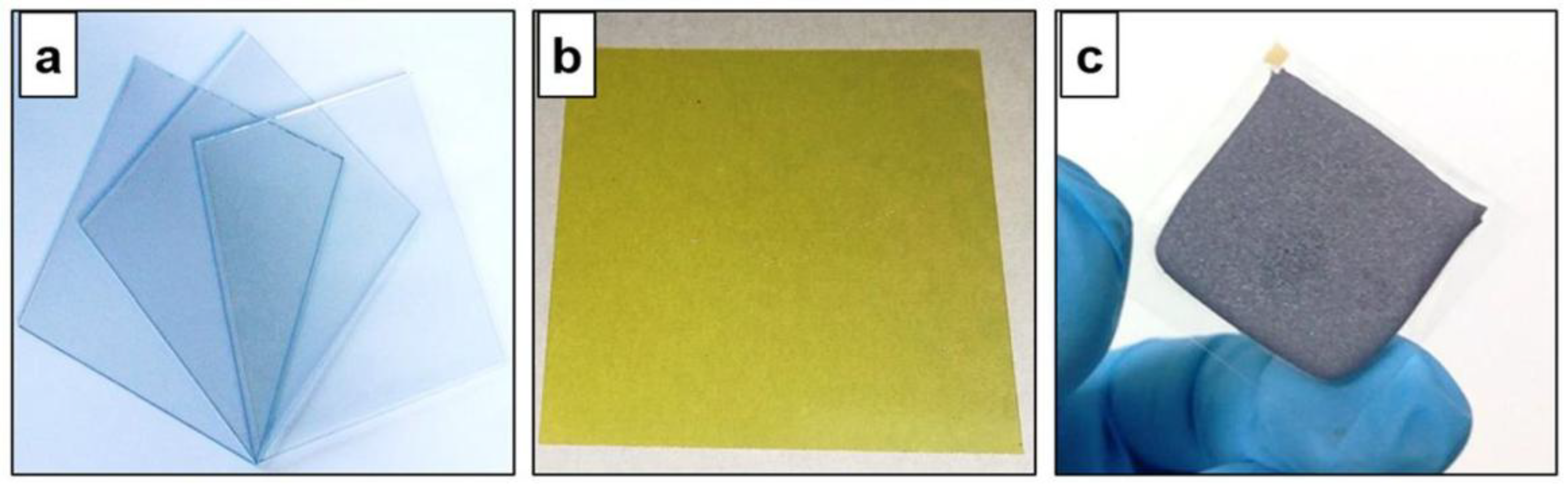

3.1.1. CdTe Solar Cells onto UTG Substrates

3.1.2. CIGS and Perovskite Solar Cells onto Flexible Glass Substrates

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

| 1 | In Italic in the book by Wallace-Dunlop [5]. She also inserted the footnote ‘This is surely the first attempt at describing flexible glass.’ |

References

- Varshneya, A.K.; Macrelli, G.; Yoshida, S.; Kim, S.H.; Ogrinc, A.L.; Mauro, J.C. Indentation and abrasion in glass products: lessons learned and yet to be learned. Int. J. Appl. Glass Sci. 2022, 13, 308–337. [Google Scholar] [CrossRef]

- Macrelli, G.; Varshneya, A.K.; Mauro, J.C. Ultra-thin glass as a substrate for flexible photonics. Opt. Mater. 2020, 106, 109994. [Google Scholar] [CrossRef]

- Pliny the Elder, Natural History 36.LXVI.195. https://penelope.uchicago.edu/Thayer/L/Roman/Texts/Pliny_the_Elder/36*.html.

- Caius Petronius Arbiter, Satiricon Liber. LI. https://www.thelatinlibrary.com/petronius1.html.

- Wallace-Dunlop, M.A. Glass in the Old World. Field & Tuer: London, U.K., 1883.

- Gardiner, J.H. Rustless steel and flexible glass 5000 years ago? Nature 1926, 117, 791. [Google Scholar] [CrossRef]

- Lattermann, G. The malleable glass of the ancients. E-Plastory 2017, N. 6.

- Lucchini, F. Aleardino’s glass. Art History 2013, 36, 498–517. [Google Scholar] [CrossRef]

- Righini, G.C.; Krzak, J.; Lukowiak, A.; Macrelli, G.; Varas, S.; Ferrari, M. From flexible electronics to flexible photonics: a brief overview. Opt. Mater. 2021, 115, 111011. [Google Scholar] [CrossRef]

- Koden, M. OLED Displays and Lighting. John Wiley & Sons: New York, USA, 2016.

- Hong, G.; Gan, X.; Leonhardt, C.; Zhang, Z.; Seibert, J.; Busch, J.M.; Brase, S. A brief history of OLEDS – Emitter Developments and Industry Milestones. Adv. Mater. 2021, 33, 2005630. [Google Scholar] [CrossRef]

- OLED history: A ‘guided tour’ of OLED highlights from invention to application. https://www.oled-info.com/history (Accessed on 15 January 2025).

- UFF™ and glanova® - Thin Glass Manufacturing Technology and Material Development Capabilities. https://100th.nsg.com/story/12/ (Accessed on 15 January 2025).

- https://hpm.nsg.com/en/products/glanova/index.html (Accessed on 15 January 2025).

- Auch, M.D.J.; Soo, O.K.; Ewald, G.; Soo-Jin, C. Ultrathin glass for flexible OLED application. Thin Solid Films 2002, 417, 47–50. [Google Scholar] [CrossRef]

- Guenther, E.; Kumar, R.S.; Zhu, F.; Low, H.Y.; Ong, K.S.; Auch, M.D.J.; Zhang, K.; Chua, S.-J. Building blocks for ultrathin flexible organic electroluminescent devices. In Kafafi, Z.H., Editor, Organic Light-Emitting Materials and Devices V, vol. 4464, 23-33. SPIE: Bellingham, USA, 2002.

- Plichta, A.; Weber, A.; Habeck, A. Ultra Thin Flexible Glass Substrates. MRS Online Proc. Library 2003, 769, 91. [Google Scholar] [CrossRef]

- Ong, K.S.; Hu, J.; Shrestha, R.; Zhu, F.; Chua, S.J. Flexible polymer light emitting devices using polymer-reinforced ultrathin glass. Thin Solid Films 2005, 477, 32–37. [Google Scholar] [CrossRef]

- Gardiner, B. Glass Works: How Corning Created the Ultrathin, Ultrastrong Material of the Future. Wired, 24 September 2012. https://www.wired.com/2012/09/ff-corning-gorilla-glass/ (accessed on January 23, 2025).

- https://www.corning.com/gorillaglass/worldwide/en.html (accessed on January 23, 2025).

- Garner, S.M. , Editor, Flexible Glass Enabling Thin, Lightweight, and Flexible Electronics. Wiley: Hoboken, NJ, USA, 2017.

- https://www.agc-yourglass.com/sites/default/files/agc_docs/Falcon_0420_EN.pdf (accessed on 30 January 2025).

- https://www.corning.com/microsites/csm/gorillaglass/PI_Sheets/2020/Corning Gorilla Glass 6_PI Sheet.pdf (accessed on 30 January 2025).

- https://www.corning.com/media/worldwide/Innovation/documents/WillowGlass/Corning Willow Glass Fact Sheets_August2019.pdf (accessed on 30 January 2025).

- https://www.neg.co.jp/en/assets/file/product/dp/en-g-leaf.pdf (accessed on 7 February 2025).

- https://hpm.nsg.com/en/products/glanova/index.html (accessed on 7 February 2025).

- https://www.schott.com/en-gb/products/as-87-neo-p1000312/technical-details (accessed on 7 February 2025).

- https://www.schott.com/en-gb/products/d-263-p1000318/downloads; https://www.schott.com/en-gb/products/d-263-p1000318/technical-details. (accessed on 7 February 2025).

- Hu, J.J.; Li, L.; Lin, H.; Zhang, P.; Zhou, W.; Ma, Z. Flexible integrated photonics: where materials, mechanics and optics meet. Opt. Mater. Express, 2013, 3, 1313–1331. [Google Scholar] [CrossRef]

- Li, H.; Cao, Y.; Wang, Z.; Feng, X. Flexible and stretchable inorganic optoelectronics. Opt. Mater. Express, 2019, 9, 4023–4049. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, D. , Editors, Inorganic Flexible Optoelectronics. Wiley: Weinheim, Germany, 2019.

- Ray, K.A. Flexible Solar Cell Arrays for Increased Space Power, IEEE Trans. AES 1967, AES-3, 107-115. [CrossRef]

- Gupta, R.K.; Ngujen, T.A. , Editors, Smart and Flexible Energy devices. CRC Press: Boca Raton, FL, USA, 2022.

- Cairns, D.R.; Broer, D.J.; Crawford, G.P. , Editors, Flexible Flat Panel Displays. Wiley (second edition): Weinheim, Germany, 2023.

- Zhao, Z.; Liu, K.; Liu, Y.; Guo, Y.; Liu, Y. Intrinsically flexible displays: key materials and devices. Nat. Sci. Rev. 2022, 9, nwac090. [Google Scholar] [CrossRef]

- Kong, B.; Lee, J.-y.; Jo, H.-h.; Chowdhury, D. Ultrathin Glass Processing Technologies for Bendable OLED Taillight: Innovative Ultrathin Glass Solutions for OLED Lighting Application. IEEE Electron Dev. Mag. 2024, 2, 44–50. [Google Scholar] [CrossRef]

- Li, L.; Lin, H.; Michon, J.; Geiger, S.; Li, J.; Zheng, H.; Huang, Y.; Yadav, A.; Richardson, K.A.; Gu, T.; Hu, J.J. Mechanically Flexible Integrated Photonic Systems for Sensing and Communications. ECS Trans. 2017, 77, 37. [Google Scholar] [CrossRef]

- Sayginer, O.; Iacob, E.; Varas, S. , Szczurek, A.; Ferrari, M.; Lukowiak, A.; Righini, G.C.; Bursi, O.S.; Chiasera, A. Design, fabrication and assessment of an optomechanical sensor for pressure and vibration detection using flexible glass multilayers. Opt. Mater. 2021, 115, 111023. [CrossRef]

- Zuo, H.; Yu, S.; Hu, J.J. Low loss, flexible single-mode polymer photonics. Opt. Express 2019, 27, 11152–11159. [Google Scholar] [CrossRef]

- Serpe, M.J.; Kang, Y.; Zhang, Q.M. , Editors, Photonic Materials for Sensing, Biosensing and Display Devices. Springer International Publishing: Cham, Switzerland, 2016.

- Takei, K. , Editor, Flexible and Stretchable Medical Devices. (2018). Wiley: Weinheim, Germany, 2018.

- Zhang, C.; Zhao, Y.S. Flexible Photonic Materials and Devices: Synthetic Strategies, Sensing Properties, and Wearable Applications. Adv. Mater. 2024, 2415856. [Google Scholar] [CrossRef]

- Enrichi, F.; Righini, G.C. , Editors, Solar Cells and Light Management. Elsevier: Amsterdam, Netherlands, 2020.

- Ibn-Mohammed, T.; Koh, S.C.L. , Reaney, I. M.; Acquaye, A., Schileo, G., Mustapha, K.B.; Greenough, R. Perovskite solar cells: An integrated hybrid lifecycle assessment and review in comparison with other photovoltaic technologies, Renew. Sust. Energ. Rev. 2017, 80, 1321–1344. [Google Scholar] [CrossRef]

- Brown, C.R.; Eperon, G.E.; Whiteside, V.R.; Sellers, I.R. Potential of High-Stability Perovskite Solar Cells for Low-Intensity–Low-Temperature (LILT) Outer Planetary Space Missions. ACS Appl. Energy Mater. 2019, 2, 814–821. [Google Scholar] [CrossRef]

- Li, J.; Aierken, A.; Liu, Y. ; Zhuang,Y.; Yang, X.; Mo, J.H.; Fan, R.K.; Chen, Q.Y.; Zhang, S.Y.; Huang, Y.M.; Zhang, Q. A Brief Review of High Efficiency III-V Solar Cells for Space Application. Front. Phys. 2021, 8, 631925. [CrossRef]

- Verduci, R.; Romano, V.; Brunetti, G. , Nia, N.Y.; Di Carlo, A.; D'Angelo, G.; Ciminelli, C. Solar Energy in Space Applications: Review and Technology Perspectives. Adv. Energy Mater. 2022, 12, 2200125. [Google Scholar] [CrossRef]

- Pessoa, R.S.; Amorim Fraga, M. Recent Advances in Solar Cells for Aerospace Applications: Materials and Technologies. J. Aerosp. Technol. Manag. 2023, 15. [Google Scholar] [CrossRef]

- Angmo, D.; Yan, S.; Liang, D. , Scully, A.D.; Chesman, A.S.R.; Kellam, M.; Duffy, N.W.; Carter, N.; Chantler, R., Chen, C.; Gao, M. Toward Rollable Printed Perovskite Solar Cells for Deployment in Low-Earth Orbit Space Applications. ACS Appl. Energy Mater. 2024, 7, 1777–1791. [Google Scholar] [CrossRef]

- Li, Y.; Kamaraj, K.; Silori, Y.; Zhao, H. , Arneson, C.; Liu, B.; Ogilvie, J.; Forrest, S.R. Radiation hardness of organic photovoltaics. Joule, 2025, 101800. [CrossRef]

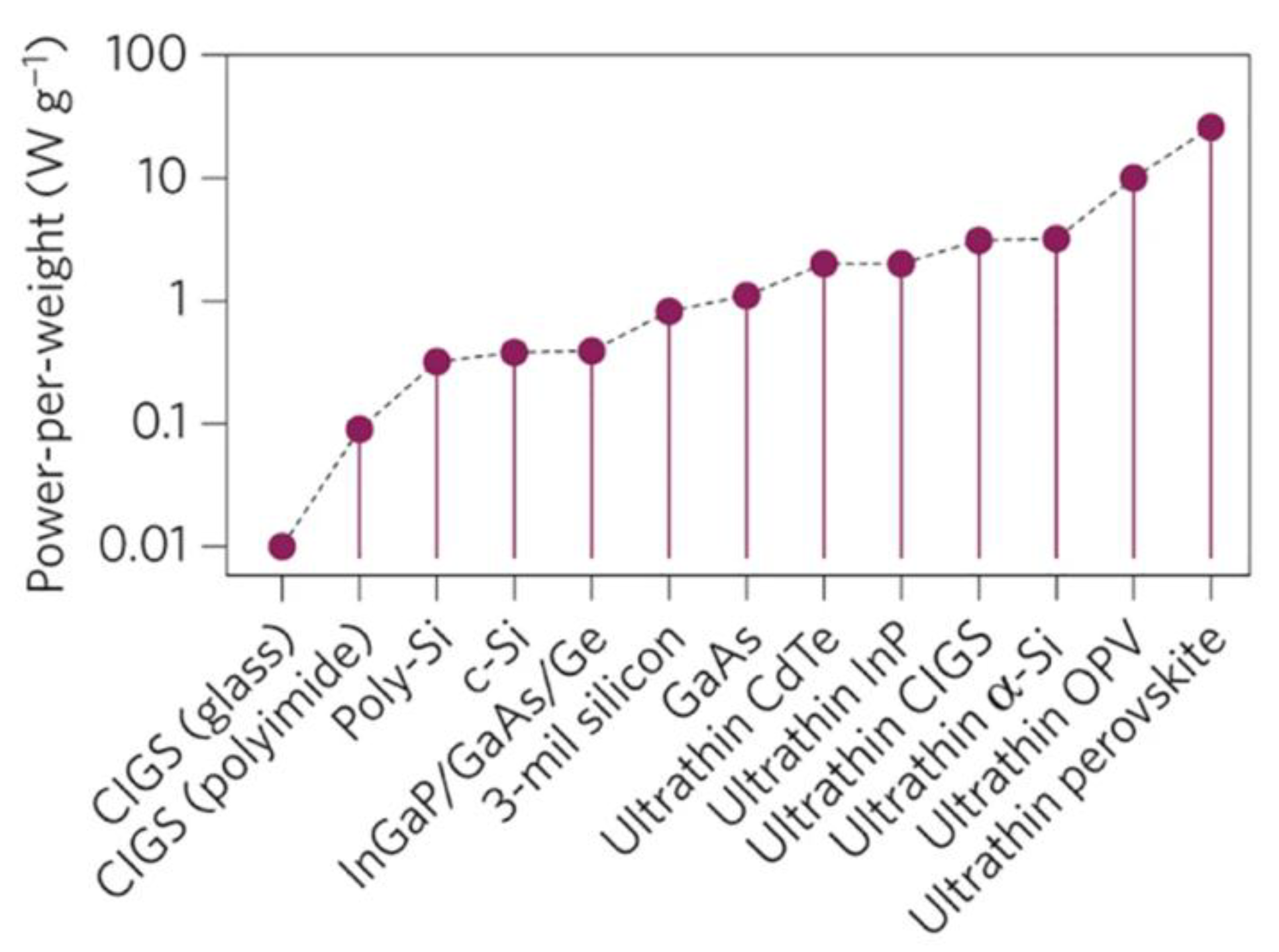

- Kaltenbrunner, M.; Adam, G.; Głowacki, E.; Drack, M.; Schwödiauer, R.; Leonat, L.; Apaydin, D.H.; Groiss, H.; Scharber, M.K.; White, M.S.; Sariciftci, N.S.; Bauer, S. Flexible high power-per-weight perovskite solar cells with chromium oxide–metal contacts for improved stability in air. Nature Mater. 2015, 14, 1032–1039. [Google Scholar] [CrossRef]

- Ahmad, N.I.; Kar, Y.B.; Doroody, C.; Kiong, T.S.; Rahman, K.S. , Harif, M.N.; Amin, N. A comprehensive review of flexible cadmium telluride solar cells with back surface field layer. Heliyon 2023, 9, e21622. [Google Scholar] [CrossRef]

- Haynes, G.A. Effect of radiation on cerium-doped solar-cell cover glass. NASA Techn. Note 1970, TN D-6024. https://ntrs.nasa.gov/api/citations/19710002803/downloads/19710002803.pdf.

- Yang, G.; Cho, E.W.; Hwang, Y.J.; Min, B.K.; Kang, Y.; Kim, D.; Kim, J. Radiation-Hard and Ultralightweight Polycrystalline Cadmium Telluride Thin-Film Solar Cells for Space Applications. Energy Technol. 2016, 4, 1463. [Google Scholar] [CrossRef]

- Lamb, D.A.; Underwood, C.I.; Barrioz, V.; Gwilliam, S.; Hall, J.; Baker, M.A.; Irvine, S.J.C. Proton irradiation of CdTe thin film photovoltaics deposited on cerium-doped space glass. Prog. Photovolt. Res. Appl. 2017, 25, 1059–1067. [Google Scholar] [CrossRef]

- https://www.excelitas.com/file-download/download/public/58456?filename=Qioptiq_Space-Qualified_Cover_Glass_Datasheet.pdf. (accessed on 6 February 2025).

- Lamb, D.A.; Irvine, S.J.C.; Baker, M.A.; Underwood, C.; Mardhani, S. Thin film cadmium telluride solar cells on ultra-thin glass in low earth orbit–3 years of performance data on the AlSat-1N CubeSat mission. Prog. Photovolt. 2021, 29, 1000–1007. [Google Scholar] [CrossRef]

- Bonnet, D.; Henrichs, B.; Richter, H. High-rate deposition of high-quality CdTe films for high-efficiency solar cells. In The Conference Record of the Twenty-Second IEEE Photovoltaic Specialists Conference, Las Vegas, USA, 1991, vol.2, 1165-1168. [CrossRef]

- Romeo, A.; Artegiani, E. CdTe-Based Thin Film Solar Cells: Past, Present and Future. Energies 2021, 14, 1684. [Google Scholar] [CrossRef]

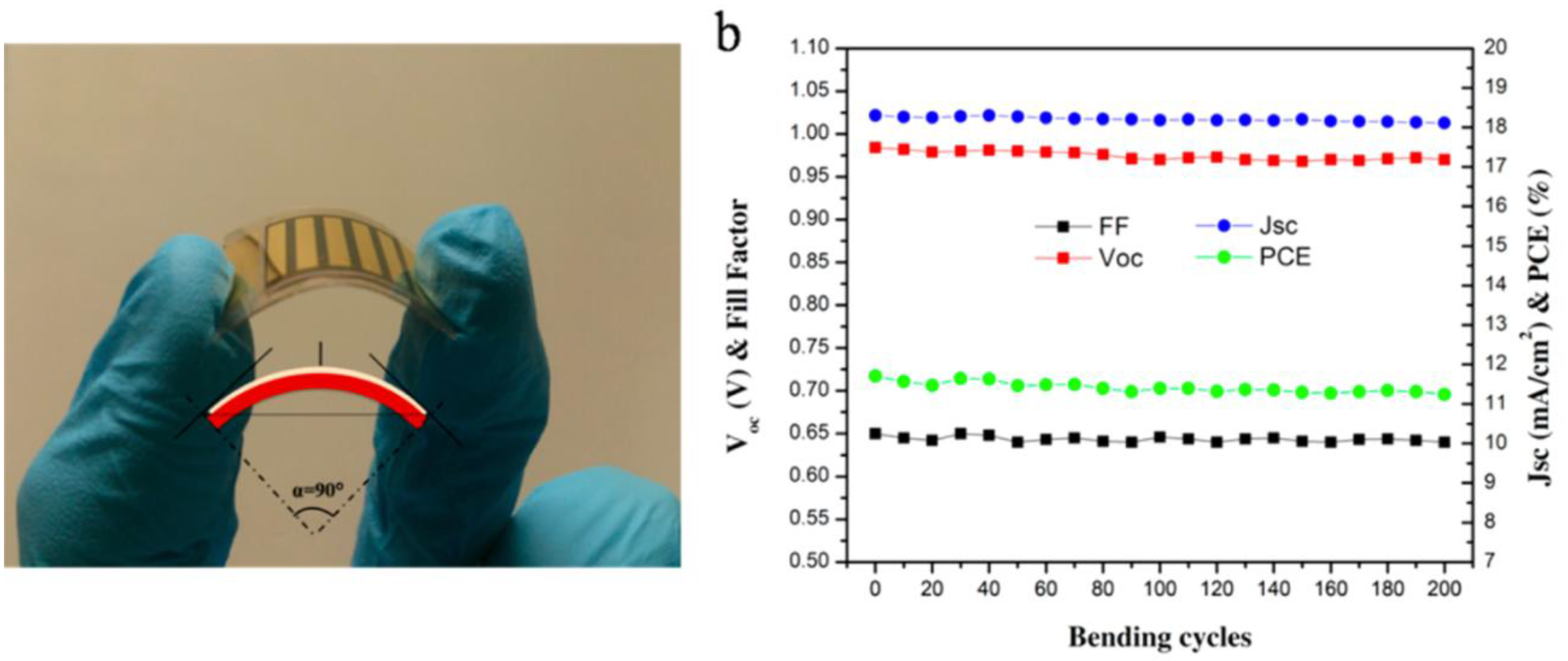

- Teloeken, A.; Lamb, D.; Dunlop, T.; Irvine, S. Effect of bending test on the performance of CdTe solar cells on flexible ultra-thin glass produced by MOCVD. Sol. Energy Mater. Sol. Cells 2020, 211, 110552. [Google Scholar] [CrossRef]

- Rance, W.L.; Burst, J.M.; Meysing, D.M.; Wolden, C.A.; Reese, M.O.; Gessert, T.A.; Metzger, W.K.; Garner, S.; Cimo, P.; Barnes, T.M. 14%-efficient flexible CdTe solar cells on ultra-thin glass substrates, Appl. Phys. Lett. 2014, 104, 827. [Google Scholar] [CrossRef]

- Mahabaduge, H.P.; Rance, W.L.; Burst, J.M.; Reese, M.O.; Meysing, D.M. , Wolden, C.A.; Li, J.; Beach, D.; Gessert, T.A.; Metzger, W.K.; Garner, S.; Barnes, T. M. High-efficiency, flexible CdTe solar cells on ultra-thin glass substrates. Appl. Phys. Lett. 2015, 106, 133501. [Google Scholar] [CrossRef]

- Liyanage, G.K.; Grice, C.R.; Phillips, A.B.; Song, Z.; Watthage, S.C.; Franzer, N.D.; Garner, S.; Yan, Y.; Heben, M.J. RF-sputtered Cd2SnO4 for flexible glass CdTe solar cells. In IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, USA, 2016, pp. 0450-0453. [CrossRef]

- Doroody, C.; Rahman, K.; Abdullah, S.; Harif, M.; Rosly, H.; Tiong, S.; Amin, N. Temperature difference in close-spaced sublimation (CSS) growth of CdTe thin film on ultra-thin glass substrate. Results Phys. 2020, 18, 103213. [Google Scholar] [CrossRef]

- Amin, N.; Karim, M.R.; ALOthman, Z.A. An In-Depth Analysis of CdTe Thin-Film Deposition on Ultra-Thin Glass Substrates via Close-Spaced Sublimation (CSS). Coatings 2022, 12, 589. [Google Scholar] [CrossRef]

- Ahmad, N.I.; Kar, Y.B.; Doroody, C.; Kiong, T.S.; Rahman, K.S.; Harif, M.N.; Amin, N. A comprehensive review of flexible cadmium telluride solar cells with back surface field layer. Heliyon 2023, 9, e21622. [Google Scholar] [CrossRef]

- Jamarkattel, M. K.; Abbas, A.; Mathew, X.; Neupane, S.; Bastola, E.; Li, D. B.; Seibert, S.; Patel, A.P.; Song, Z.; Liu, X.; Walls, J.M.; Garner, S.M.; Phillips, A.B.; Ellingson, R.J.; Yan, Y.; Heben, M. J. 17.2% Efficient CdSexTe1− x solar cell with (InxGa1− x)2O3 emitter on lightweight and flexible glass. Appl. Phys. Lett. 2024, 124, 080601. [Google Scholar] [CrossRef]

- Huang, K.; Wu, Q.; Liu, X. Picosecond pulsed laser scribing of Cd2SnO4-based CdTe thin-film solar cells on flexible glass. Solar Energy 2024, 283, 112999. [Google Scholar] [CrossRef]

- Keller, J.; Kiselman, K.; Donzel-Gargand, O.; Martin, N.M.; Babucci, M.; Lundberg, O.; Wallin, E.; Stolt, L.; Edoff, M. . High-concentration silver alloying and steep back-contact gallium grading enabling copper indium gallium selenide solar cell with 23.6% efficiency. Nat. Energy 2024, 9, 467–478. [CrossRef]

- Friedlmeier, T.M.; Jackson, P.; Bauer, A.; Hariskos, D.; Kiowski, O.; Wuerz, R.; Powalla, M. Improved Photocurrent in Cu(In,Ga)Se2 Solar Cells: From 20.8% to 21.7% Efficiency with CdS Buffer and 21.0% Cd-Free. IEEE J. Photovolt. 2015, 5, 1487–1491. [Google Scholar] [CrossRef]

- Dursch, H.W. CdS/CuInSe2 solar cells with Ti foil substrate, U.S. Patent 4, 703, 131 1987. [Google Scholar]

- Başol, B.M.; Kapur, V.K.; Halani, A.; Leidholm, C. Copper indium diselenide thin film solar cells fabricated on flexible foil substrates. Sol. Energ Mater. and Sol. Cells 1993, 29, 163–173. [Google Scholar] [CrossRef]

- Ishizuka, S.; Yamada, A.; Matsubara, K.; Fons, P.; Sakurai, K.; Niki, S. Development of high-efficiency Cu(InGa)Se2 solar cells: A study of alkali doping effect on CIS, CIGS and CGS using alkali-silicate glass thin layers. Curr. Appl. Phys. 2010, 10, S154–S156. [Google Scholar] [CrossRef]

- Badgujar, A.C.; Madhuri, K.; Garner, S.; Dhage, S.R.; Joshi, S.V. Non-vacuum route for CIGS thin film absorber on flexible glass substrates. In IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 2015, 1-4. [CrossRef]

- Gerthoffer, A.; Roux, F.; Emieux, F.; Faucherand, P.; Fournier, H.; Grenet, L. , Perraud, S. CIGS solar cells on flexible ultra-thin substrates: Characterization and bending test. Thin Solid Films 2015, 592 A, 99–104. [CrossRef]

- Gerthoffer, A.; Poulain, C.; Roux, F.; Emieux, F.; Grenet, L.; Perraud, S. CIGS solar cells on ultra-thin glass substrates: Determination of mechanical properties by nanoindentation and application to bending-induced strain calculation. Sol. En. Mater. Sol. Cells. 2017, 166, 254–61. [Google Scholar] [CrossRef]

- Chen, J.; Shen, H.; Zhai, Z.; Liu, F.; Zhu, Z.; Luo, M. Performance and stability enhancement of Cu(InGa)Se2 solar cells on ultrathin glass by potassium incorporation. Mater. Lett. 2020, 271, 127749. [Google Scholar] [CrossRef]

- Kim, D.; Shin, S.S.; Lee, S.M.; Cho, J.S.; Yun, J.H.; Lee, H.S.; Park, J.H. (2020). Flexible and semi-transparent ultra-thin CIGSe solar cells prepared on ultra-thin glass substrate: a key to flexible bifacial photovoltaic applications. Adv. Funct. Mater. 2020, 30, 2001775. [CrossRef]

- Amare, A.M.; Hwang, I.; Jeong, I.; Park, J.H.; An, J.G.; Song, S.; Eo, Y.-J.; Cho, A.; Cho, J.-S.; Ahn, S. K.; Ahn, S.; Gwak, J.; Rehan, M.; Park, H.-W.; Jae, H.Y.; Jae, H.Y.; Kim, K.; Shin, D. High-Efficiency Cadmium-Free Cu(In,Ga)Se2 Flexible Thin-Film Solar Cells on Ultra-Thin Glass as a Novel Substrate. Available at SSRN, 2024. [CrossRef]

- Hamtaei, S.; Debot, A.; Scaffidi, R.; Brammertz, G.; Cariou, E.; Garner, S. M.; Aguirre, A.; Poortman, J. ; Dale,P.J.; Vermang, B. Fabrication of bendable and narrow bandgap Cu (In, Ga)(S, Se)2 for tandem photovoltaics. Commun. Mater. 2025, 6, 2. [CrossRef]

- Nia, N.Y.; Saranin, D.; Palma, A.L.; Di Carlo, A. Perovskite solar cell. In Enrichi, F.; Righini, G.C., Editors, Solar Cells and Light Management. Elsevier: Amsterdam, Netherlands, 2020; pp. 163–228. [Google Scholar] [CrossRef]

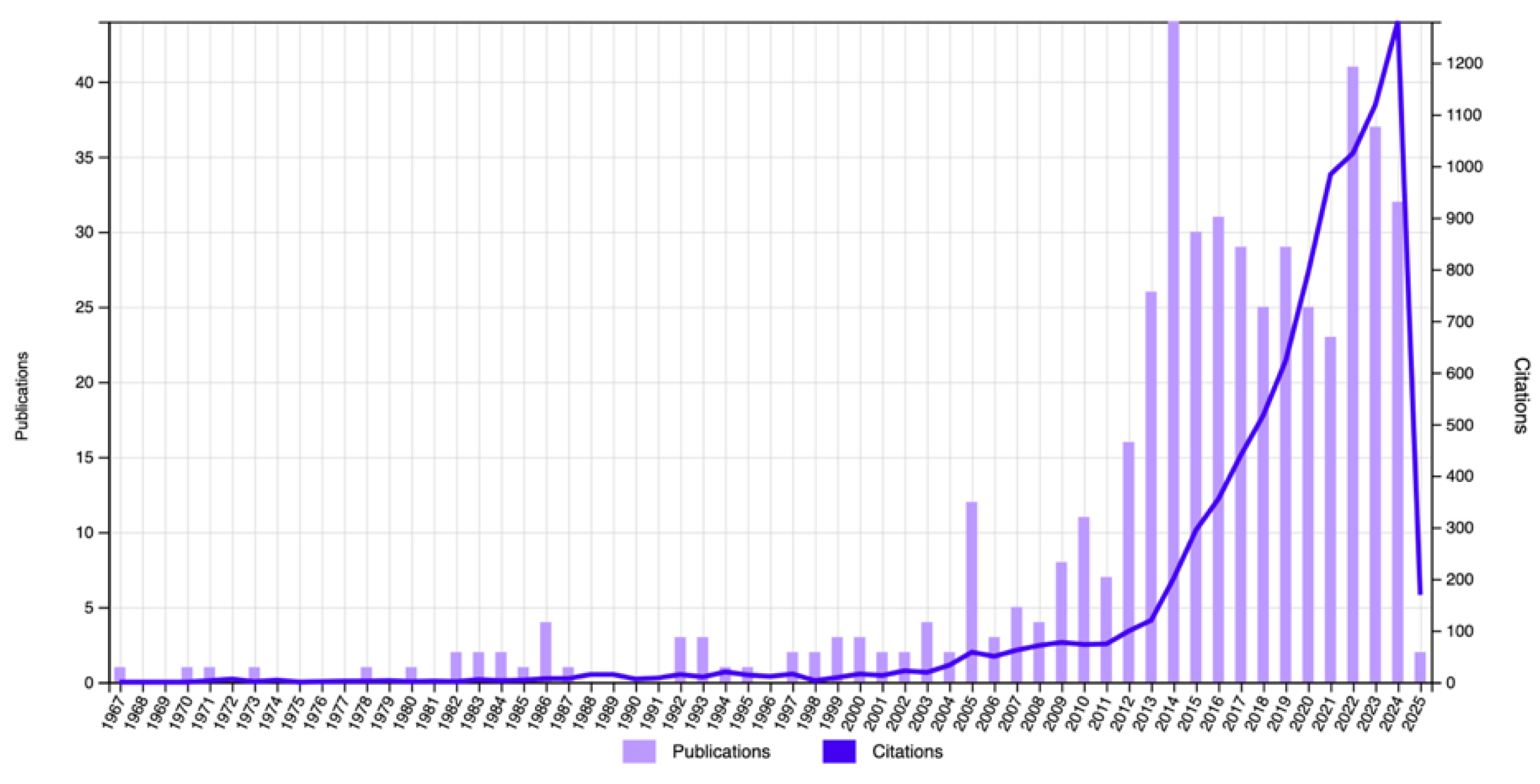

- Harito, C.; Abrori, S.A.; Khalil, M.; Yuliarto, B.; Erten-Ela, S. Current progress of perovskite solar cells stability with bibliometric study. Curr. Opin. Colloid Interface Sci. 2024, 74, 101862. [Google Scholar]

- https://doi.org/10.1016/j.cocis.2024.101862.

- Huang, S.; Qian, C.; Liu, X.; Zhang, L.; Meng, F.; Yan, Z.; Zhou, Y.; Du, J.; Ding, B.; Shi, J.; Han, A.; Zhao, W.; Yu, J.; Song, X.; Liu, Z.; Liu, W. A review on flexible solar cells. Sci. China Mater. 2024, 67, 2717–2736. [Google Scholar] [CrossRef]

- Aftab, S.; Hussain, S. , Kabir, F.; Aslam, M., Rajpar, A.H., Eds.; Al-Sehemi, A.G. Advances in flexible perovskite solar cells: A comprehensive review. Nano Energy 2024, 120, 109112. [Google Scholar] [CrossRef]

- Tavakoli, M.M.; Tsui, K.-H.; Zhang, Q.; He, J.; Yao, Y.; Li, D.; Fan, Z. Highly Efficient Flexible Perovskite Solar Cells with Antireflection and Self-Cleaning Nanostructures. ACS Nano 2015, 9, 10287–10295. [Google Scholar] [CrossRef]

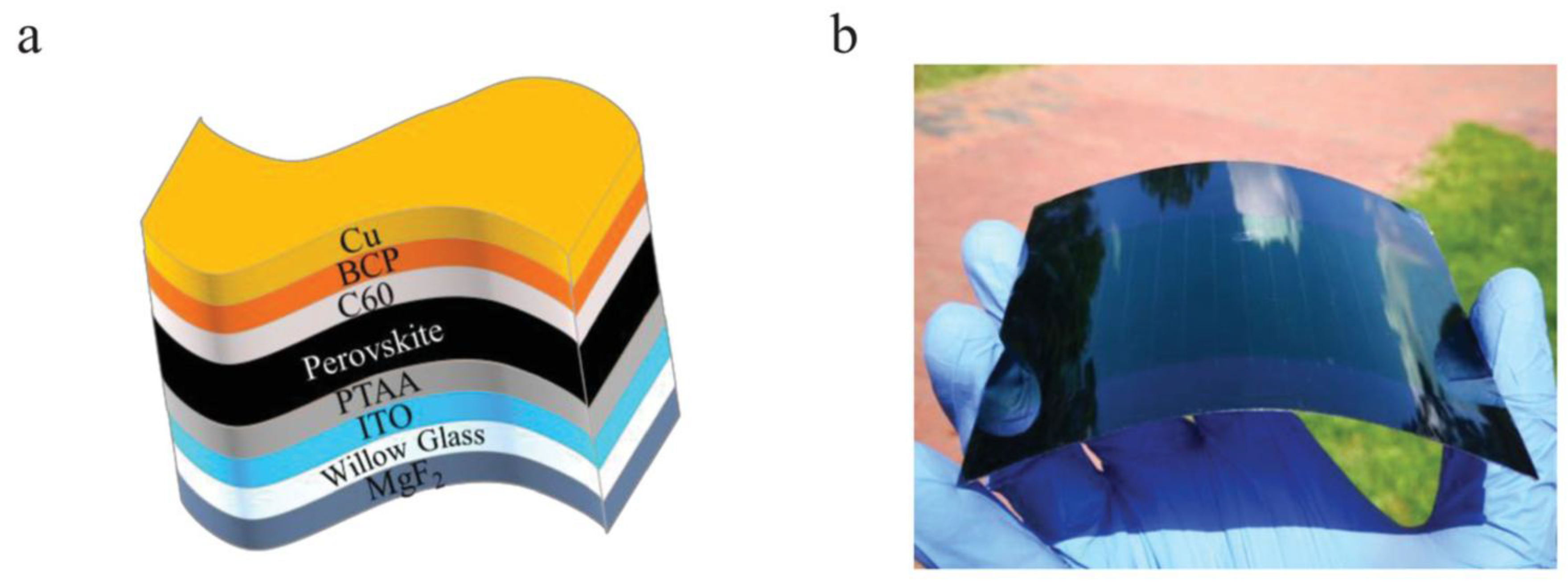

- Kaltenbrunner, M.; Adam, G.; Glowacki, E.D.; Drack, M.; Schwödiauer, R.; Leonat, L.; Apaydin, D.H.; Groiss, H.; Scharber, M.C.; White, M.S.; Sariciftci, N.S.; Bauer, S. Flexible high power-per-weight perovskite solar cells with chromium oxide–metal contacts for improved stability in air. Nat. Mater. 2015, 14, 1032–1041. [Google Scholar] [CrossRef]

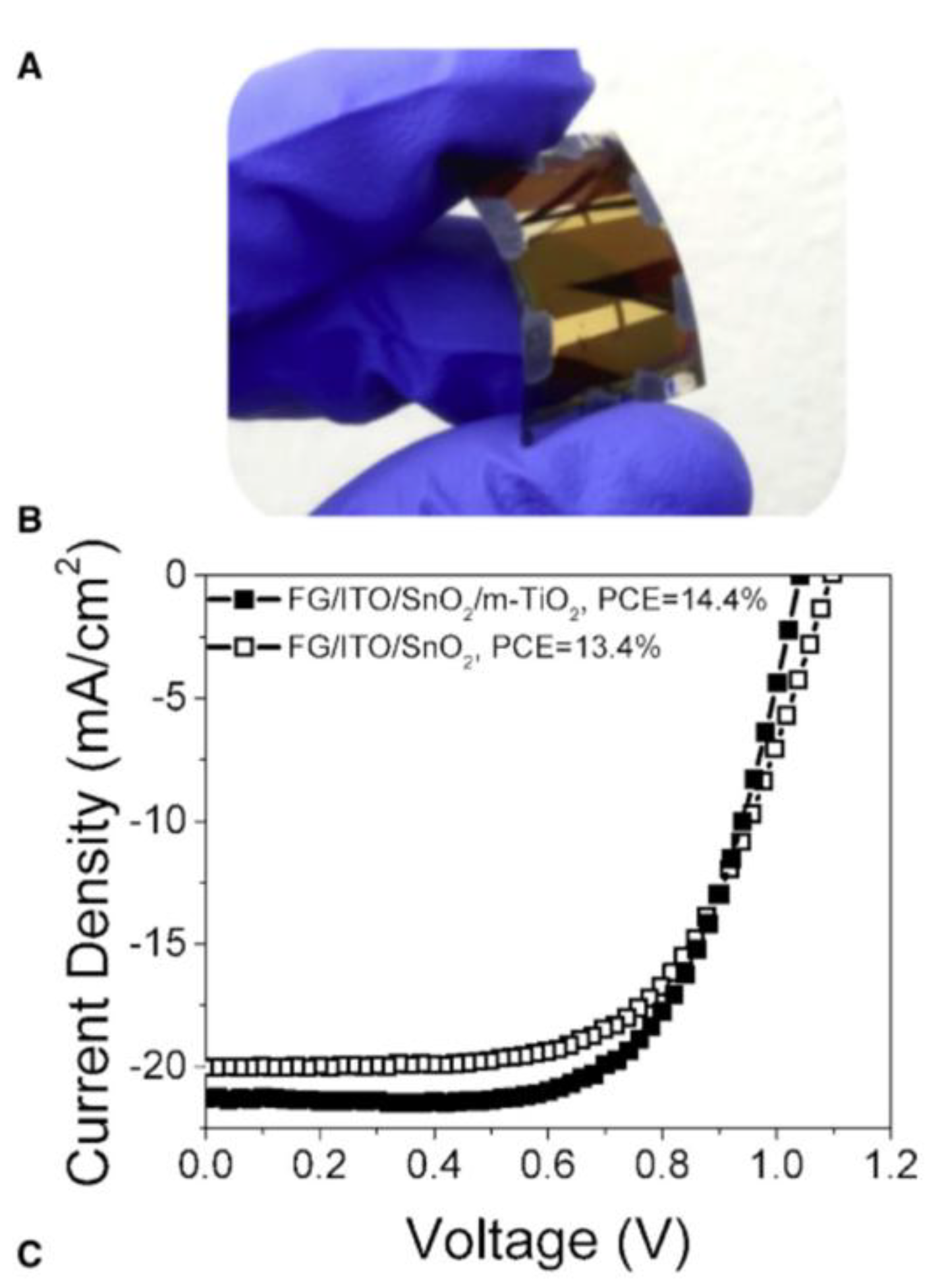

- Ballipinar, F.; Rastogi, A.C.; Garner, S.M.; Darling, S.B. Planar mixed halide perovskite-PCBM solar cells on flexible glass substrates processed at low temperature without ITO. IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 2016, pp. 1611-1616. [CrossRef]

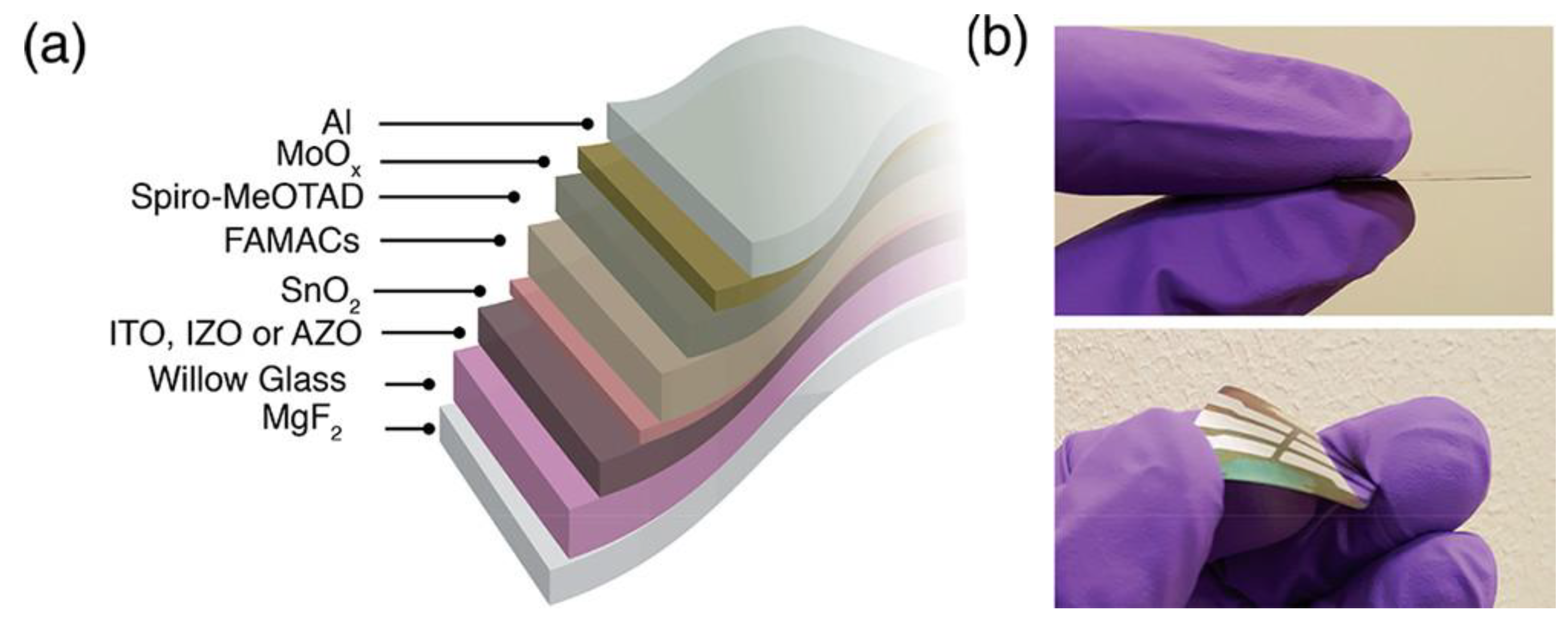

- Dou, B.; Miller, E.M.; Christians, J.A.; Sanehira, E.M.; Klein, T.R.; Barnes, F.S.; Shaheen, S.E.; Garner, S.M.; Ghosh, S.; Mallick, A.; Basak, D.; van Hest, M.F.A.M. High-Performance Flexible Perovskite Solar Cells on Ultrathin Glass: Implications of the TCO. J. Phys. Chem. Lett. 2017, 8, 4960–4966. [Google Scholar] [CrossRef]

- Dai, X.; Deng, Y.; Van Brackle, C.H.; Chen, S.; Rudd, P.N.; Xiao, X.; Lin, Y.; Chen, B.; Huang, J. Scalable Fabrication of Efficient Perovskite Solar Modules on Flexible Glass Substrates. Adv. Energy Mater. 2019, 10, 190 3108. [CrossRef]

- Castro-Hermosa, S.; Lucarelli, G.; Top, M.; Fahland, M.; Fahlteich, J.; Brown, T.M. Perovskite photovoltaics on roll-to-roll coated ultra-thin glass as flexible high-efficiency indoor power generators. Cell Rep. Phys. Sci. 2020, 1, 100045. [Google Scholar] [CrossRef]

- Tang, G.; Yan, F. Recent progress of flexible perovskite solar cells. Nano Today 2021, 39, 101155. [Google Scholar] [CrossRef]

- Goje, A.A.; Ludin, N.A.; Fahsyar, P.N.A.; Syafiq, U.; Chelvanathan, P.; Syakirin, A.D. Al-G.; Teridi, M.A.;· Ibrahim, M.A.; · Su’ait, M.S.; Sepeai, S.; Yasir, A.S.H.M. Review of flexible perovskite solar cells for indoor and outdoor applications. Ren. Sustain. Energy 2024, 13, 155–179. [Google Scholar] [CrossRef]

- Tian, R.; Zhou, S.; Meng, Y.; Liu, C.; Ge, Z. Material and device design of flexible perovskite solar cells for next-generation power supplies. Adv. Mater. 2024, 36, 202311473. [Google Scholar] [CrossRef]

- Keller, V. Storied Objects, Scientific Objects, and Renaissance Experiment: The Case of Malleable Glass. Renaissance Quarterly. 2017, 70, 594–632. [Google Scholar] [CrossRef]

| Brand name | Unit | AGC Falcon® [22] |

Corning Gorilla®6 [23] |

Corning Willow® [24] | NEG G-Leaf TM [25] |

NSG Glanova® [26] |

Schott AS87 eco [27] |

Schott D263® [28] |

|---|---|---|---|---|---|---|---|---|

| Glass type | Als | Alkali-Als | Alkaline earth BAls | Green Glass (As, Sb free) | Als | Als | Bs | |

| Minimum COTS | µm | 50 | 400 | 100 | 30 ± 10% | 330 | 75 | 30 |

| TL D65 | % | > 91.5 | ≥90.5 [600 µm] |

> 90 | 92 @λ=550 nm |

≥ 91 | ≥ 92 [330 µm] |

91.7 [300 µm] |

| Refractive index nd (@587.6 nm) |

1.515 ± 0.005 | 1.50 core 1.51 clad |

1.52 | 1.51 | 1.5044 ± 0.0015 | 1.5231 ± 0.0015 | ||

| PEC | (nm/cm)/MPa | 27.600 | 29.8 | 29 | 34.7 | |||

| Density | g/cm3 | ≈ 2.48 | 2.40 | 2.56 | 2.46 | 2.48 | 2.46 | 2.51 |

| Young’s modulus | GPa | ≈ 70 | 77 | 78.7 | 73 | 75.4 | 71.9 | 72.9 |

| Poisson’s ratio | ≈ 0.21 | 0.21 | 0.23 | 0.2 | 0.24 | 0.216 | 0.21 | |

| Shear modulus | GPa | ≈ 30 | 31.9 | |||||

| Hardness(bct) | Kgf/mm2 | KH 450 | VH 611 (200 g load) |

KH 588 (2000 g load) | VH 600 | VH 528 | KH 490 VH 560 |

KH 470 VH 510 |

| Hardness (act) | Kgf/mm2 | KH 546 | VH 678 (200 g load) |

VH 583 | KH 560 VH 630 |

|||

| CS | MPa | 600-800 | 1000 [330 µm] |

290 | ||||

| DOL | µm | 15-25 | ||||||

| Softening point | °C | ≈ 665 | 742 | 855 | 736 | |||

| Tg | °C | ≈ 575 | 554 | 598 | 557 | |||

| Strain point | °C | 725 | 508 | 577 | 529 | |||

| Annealing point | °C | 781 | 552 | 616 | 557 | |||

| CTE ×10-7 | /°C | ≈ 90 25-300°C |

75.2 0-300 °C |

31.7 0-300 °C |

91.8 50-350 °C |

92 20 – 300 °C |

||

| Thermal conductivity | W/(m×K) | ≈ 1.19 * | ||||||

| Dielectric constant | 5.3 (1 MHz, 25 °C) |

8.4 (1 MHz, 25 °C) | 6.7 (1MHz, 25 °C) |

|||||

| Notes | ♣ | ♦ | ♥ | |||||

| Suggested applications | See notes: | {A} | {B} | {C} | {D} | {E} | {F} | {G} |

| Solar Cell | Time (hrs) | η (%) | Jsc (mA/cm2) |

Voc (mV) | FF (%) | Rs (Ω cm2) |

Rshunt (Ω cm2) |

|---|---|---|---|---|---|---|---|

| A2 | 0 | 14.1 ± 0.3 | 25.4 | 747 | 74 | 2.4 | 3233 |

| 168 | 13.8 ± 0.3 | 24.7 | 745 | 75 | 2.4 | 3254 | |

| B2 | 0 | 14.1 ± 0.3 | 25.4 | 752 | 74 | 2.4 | 3627 |

| 168 | 14.2 ± 0.3 | 25.7 | 751 | 74 | 2.5 | 5122 |

| Specific Power (W g-1) | Area density(g/cm2) | Thickness (µm) | |||

| STC | 400 lx | 200 lx | |||

| FG-PSC | 0.58 | 1.4 x 10-3 | 0.7 x 10-3 | 251 | 100 |

| PET-PSC | 0.74 | 0.9 x 10-3 | 0.5 x 10-3 | 198 | 125 |

| Glass-PSC | 0.07 | 1.5 x 10-4 | 0.7 x 10-3 | 2,761 | 1,100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).