Submitted:

27 February 2025

Posted:

28 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials, Plasmids, and Enzyme

2.2. Expression and Purification of Enzymes

2.3. Estimation of Esterase Activity and Protein Concentration

2.4. Evaluating Enzyme Performance on a Small Scale on Different Powder and Films

2.5. Evaluation of Different Reaction Variables for PET Hydrolysis

2.6. Evaluating Enzyme Performance in 10 mL (Without pH Control) and 1L Bioreactor (pH Control)

2.7. Production of LCCICCG in the Bioreactor and PET Hydrolysis

2.8. Depolymerization of Mixed PET Waste Using LCCICCG in 1L

2.9. Advanced Analysis

2.9.1. High-Performance Liquid Chromatography (HPLC)

2.9.2. Nuclear Magnetic Resonance (NMR)

2.9.3. Differential scanning Calorimetry (DSC) Analysis of PET Materials

3. Results and Discussion

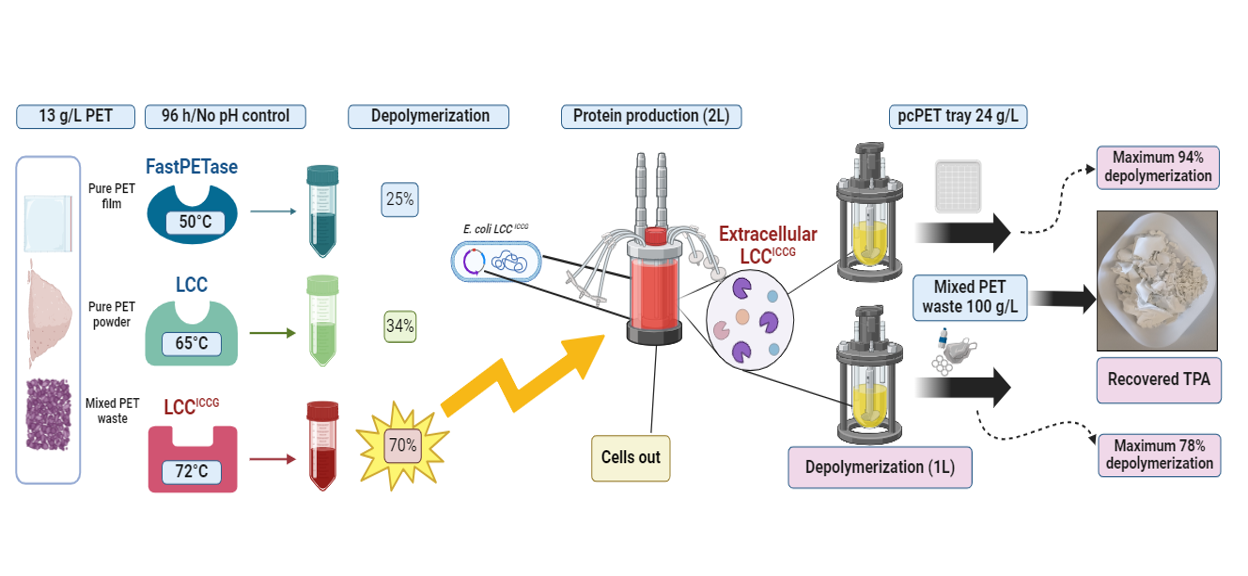

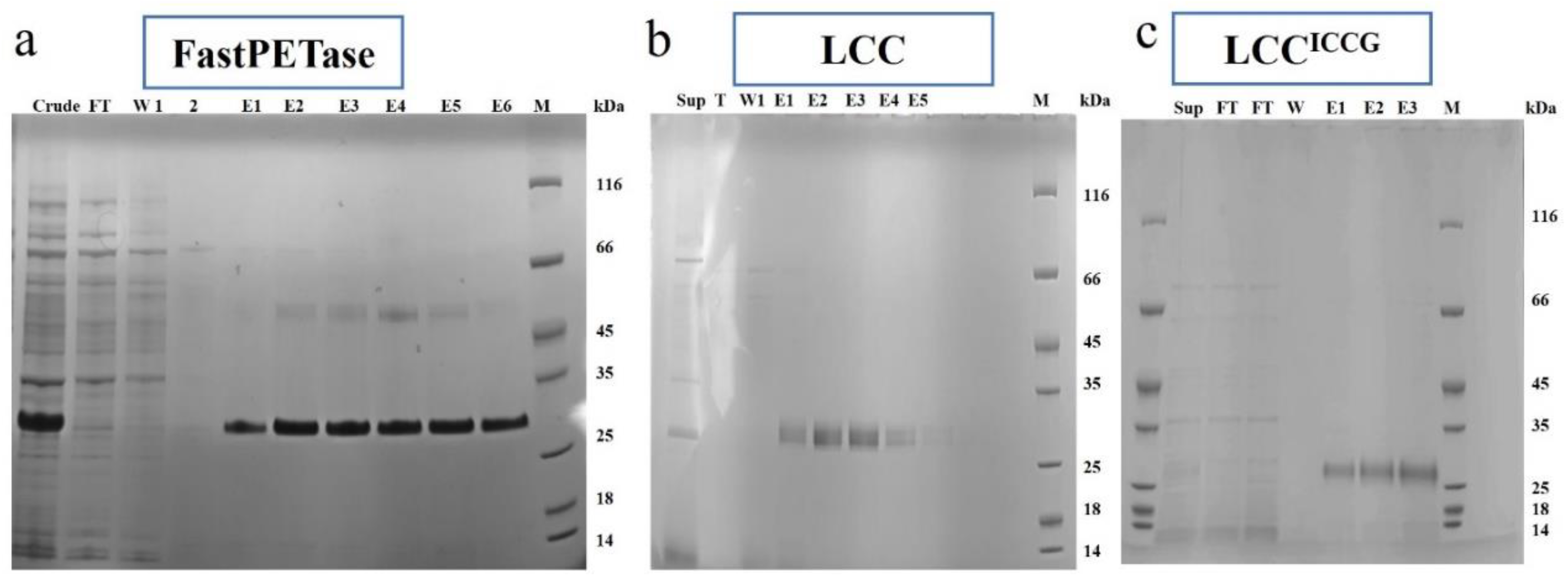

3.1. Expression, Production, and Purification of FastPETase, and LCC, LCCICCG

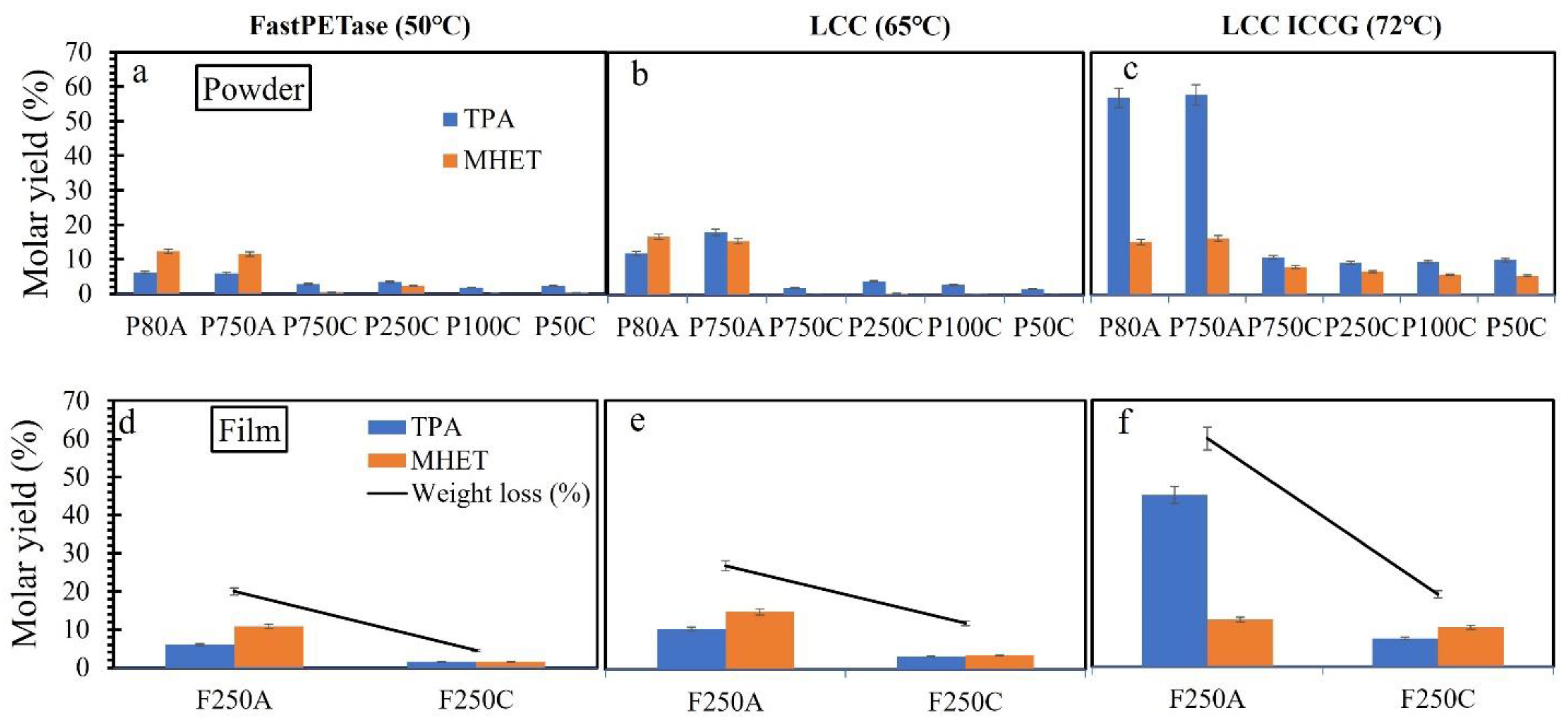

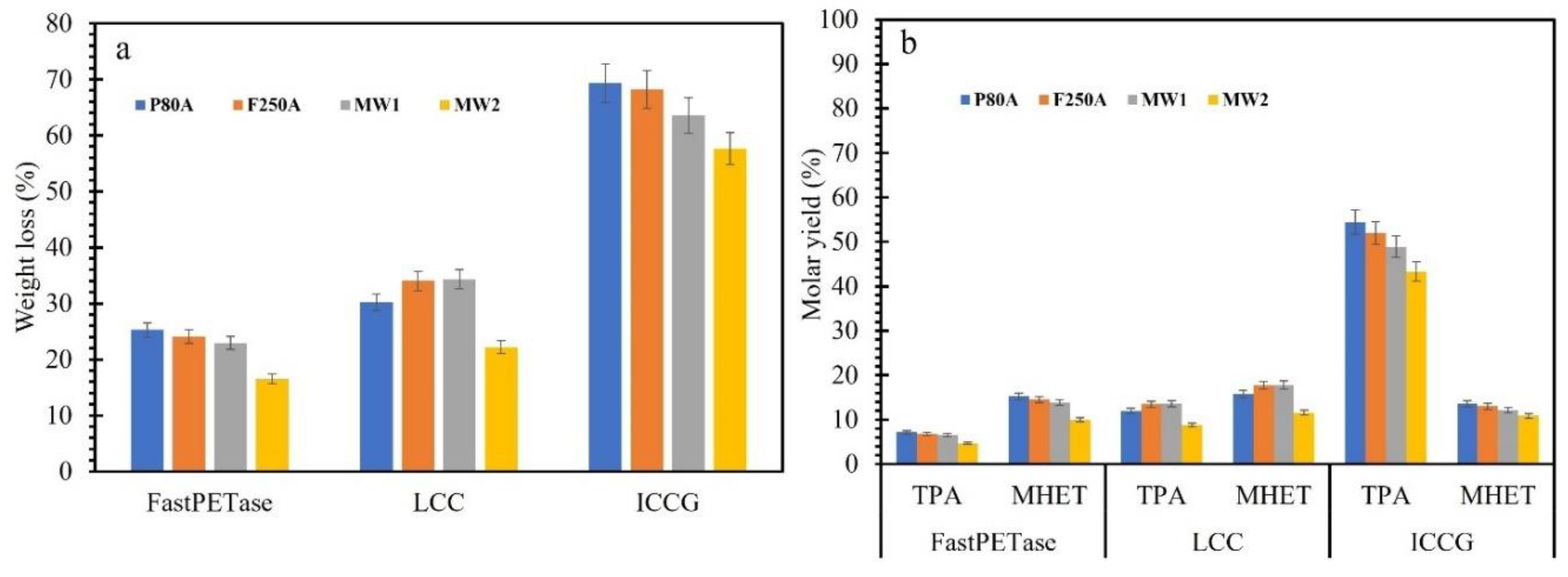

3.2. Enzymatic Depolymerization of Different Powders and Films in Small-Scale

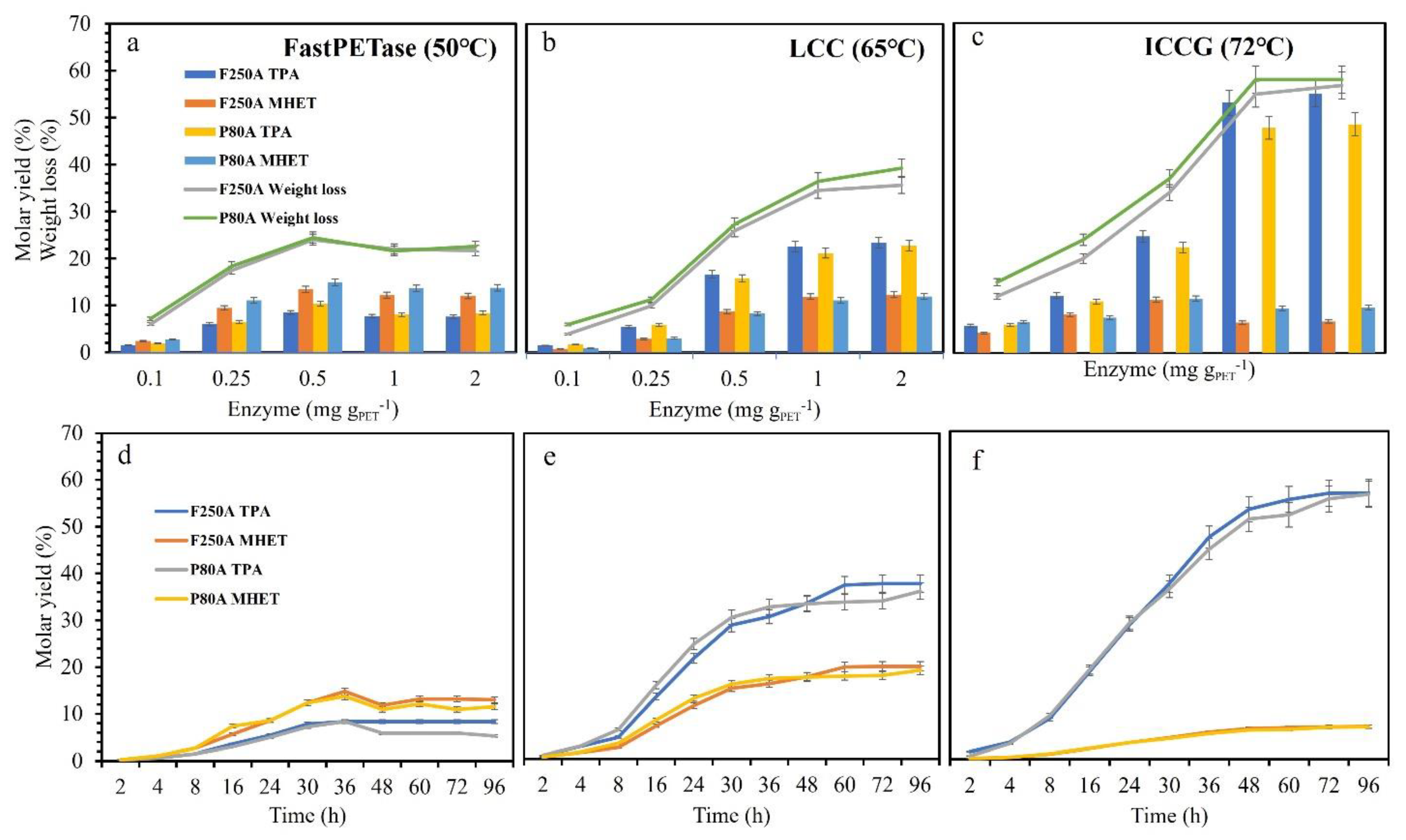

2.3. Optimization of Different Parameters for Enzymatic PET Hydrolysis

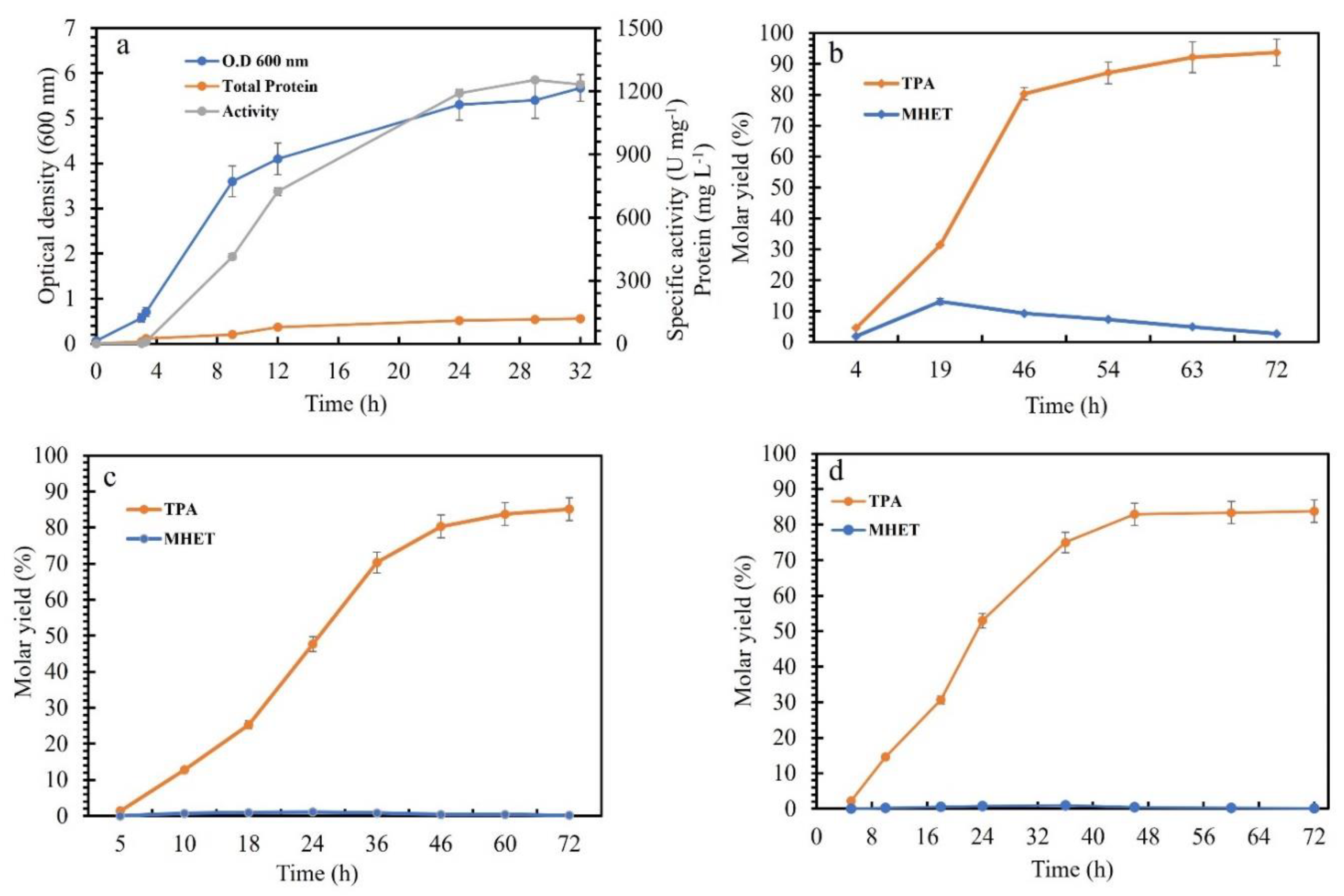

2.4. PET Depolymerization in 10 mL

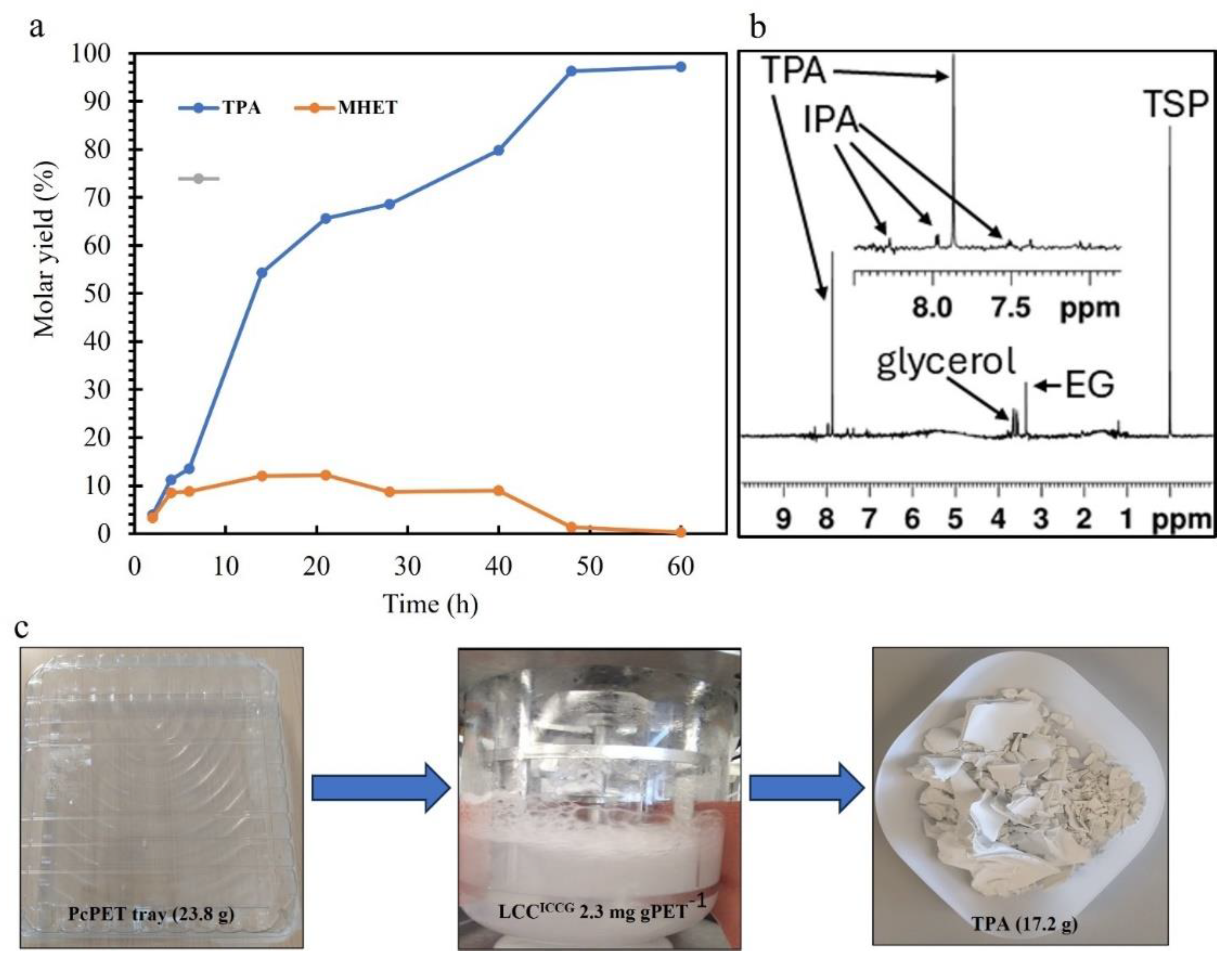

2.5. Depolymerization of Different PET Substrates Using Crude LCCICCG in a Bioreactor (1L)

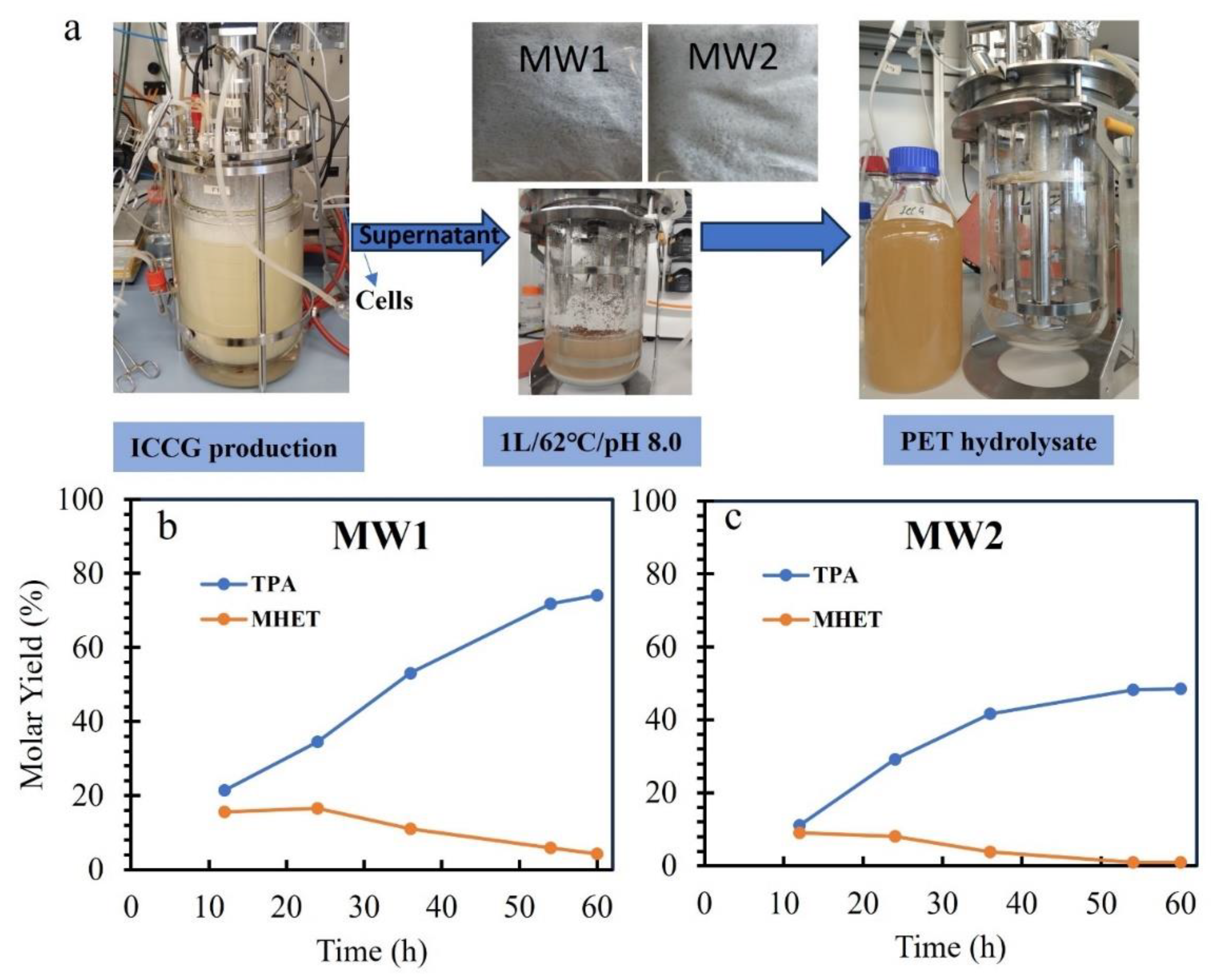

2.6. Mixed PET Waste Depolymerization

4. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tournier, V.; Duquesne, S.; Guillamot, F.; Cramail, H.; Taton, D.; Marty, A.; André, I. Enzymes’ Power for Plastics Degradation. Chemical Reviews 2023, 123. [Google Scholar] [CrossRef]

- Arnal, G.; Anglade, J.; Gavalda, S.; Tournier, V.; Chabot, N.; Bornscheuer, U.T.; Weber, G.; Marty, A. Assessment of Four Engineered PET Degrading Enzymes Considering Large-Scale Industrial Applications. ACS Catalysis 2023, 13, 13156–13166. [Google Scholar] [CrossRef]

- Zhang, S.; Li, M.; Zuo, Z.; Niu, Z. Recent Advances in Plastic Recycling and Upgrading under Mild Conditions. Green Chemistry 2023, 25, 6949–6970. [Google Scholar] [CrossRef]

- Gibb, B.C. Plastics Are Forever. Nature Chemistry 2019, 11, 394–395. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Wang, J.; Jiao, L.; Song, Y.; Li, C.; Hu, C. Easily Recoverable and Reusable P-Toluenesulfonic Acid for Faster Hydrolysis of Waste Polyethylene Terephthalate. Green Chemistry 2022, 24, 1362–1372. [Google Scholar] [CrossRef]

- Raheem, A.B.; Noor, Z.Z.; Hassan, A.; Abd Hamid, M.K.; Samsudin, S.A.; Sabeen, A.H. Current Developments in Chemical Recycling of Post-Consumer Polyethylene Terephthalate Wastes for New Materials Production: A Review. Journal of Cleaner Production 2019, 225, 1052–1064. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and Chemical Recycling of Solid Plastic Waste. Waste Management 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Hu, Q.; Zhang, Y.; Guo, H.; Wu, Y.; Sun, M.; Zhu, X.; Zhang, J.; Gong, S.; Liu, P.; Niu, Z. Depolymerization of Polyesters by a Binuclear Catalyst for Plastic Recycling. Nature Sustainability 2023, 6, 965–973. [Google Scholar] [CrossRef]

- Li, M.; Zhang, S. Tandem Chemical Depolymerization and Photoreforming of Waste PET Plastic to High-Value-Added Chemicals. ACS catalysis 2024, 14, 2949–2958. [Google Scholar] [CrossRef]

- Niu, Z.; Zhang, S.; Xue, Y.; Wu, Y.; Zhang, Y.-X.; Tan, T. PET Recycling under Mild Conditions Via Substituent-Modulated Intramolecular Hydrolysis. Chemical science 2023, 14, 6558–6563. [Google Scholar] [CrossRef]

- Jaime-Azuara, A.; Thomas Helmer Pedersen; Wimmer, R. Process Optimization by NMR-Assisted Investigation of Chemical Pathways during Depolymerization of PET in Subcritical Water. Green Chemistry 2023, 25, 2711–2722. [Google Scholar] [CrossRef]

- Cui, Y.; Chen, Y.; Liu, X.; Dong, S.; Tian, Y.; Qiao, Y.; Mitra, R.; Han, J.; Li, C.; Han, X.; Liu, W.; Chen, Q.; Wei, W.; Wang, X.; Du, W.; Tang, S.; Xiang, H.; Liu, H.; Liang, Y.; Houk, K.N. Computational Redesign of a PETase for Plastic Biodegradation under Ambient Condition by the GRAPE Strategy. ACS Catalysis 2021, 11, 1340–1350. [Google Scholar] [CrossRef]

- Bell, E.L.; Smithson, R.; Kilbride, S.; Foster, J.; Hardy, F.J.; Ramachandran, S.; Tedstone, A.A.; Haigh, S.J.; Garforth, A.A.; Day, P.J.R.; Levy, C.; Shaver, M.P.; Green, A.P. Directed Evolution of an Efficient and Thermostable PET Depolymerase. Nature Catalysis 2022, 5, 673–681. [Google Scholar] [CrossRef]

- Pfaff, L.; Gao, J.; Li, Z.; Jäckering, A.; Weber, G.; Mičan, J.; Chen, Y.; Dong, W.; Han, X.; Feiler, C.; Ao, Y.; Christoffel; Bednář, D. ; Palm, G.J.; Lammers, M.; Jiřı́ Damborský; Strodel, B.; Liu, W.; Bornscheuer, U.T.; Wei, R. Multiple Substrate Binding Mode-Guided Engineering of a Thermophilic PET Hydrolase. ACS Catalysis 2022, 12, 9790–9800. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Liu, W.; Huang, J.-W.; Ma, J.; Zheng, Y.; Ko, T.-P.; Xu, L.; Cheng, Y.-S.; Chen, C.-C.; Guo, R.-T. Structural Insight into Catalytic Mechanism of PET Hydrolase. Nature Communications 2017, 8. [Google Scholar] [CrossRef]

- Yoshida, S.; Hiraga, K.; Takehana, T.; Taniguchi, I.; Yamaji, H.; Maeda, Y.; Toyohara, K.; Miyamoto, K.; Kimura, Y.; Oda, K. A Bacterium That Degrades and Assimilates Poly(Ethylene Terephthalate). Science 2016, 351, 1196–1199. [Google Scholar] [CrossRef]

- Lu, H.; Diaz, D.J.; Czarnecki, N.J.; Zhu, C.; Kim, W.; Shroff, R.; Acosta, D.J.; Alexander, B.R.; Cole, H.O.; Zhang, Y.; Lynd, N.A.; Ellington, A.D.; Alper, H.S. Machine Learning-Aided Engineering of Hydrolases for PET Depolymerization. Nature 2022, 604, 662–667. [Google Scholar] [CrossRef]

- Sulaiman, S.; Yamato, S.; Kanaya, E.; Kim, J.-J.; Koga, Y.; Takano, K.; Kanaya, S. Isolation of a Novel Cutinase Homolog with Polyethylene Terephthalate-Degrading Activity from Leaf-Branch Compost by Using a Metagenomic Approach. Applied and Environmental Microbiology 2011, 78, 1556–1562. [Google Scholar] [CrossRef]

- Tournier, V.; Topham, C.M.; Gilles, A.; David, B.; Folgoas, C.; Moya-Leclair, E.; Kamionka, E.; Desrousseaux, M.-L. .; Texier, H.; Gavalda, S.; Cot, M.; Guémard, E.; Dalibey, M.; Nomme, J.; Cioci, G.; Barbe, S.; Chateau, M.; André, I.; Duquesne, S.; Marty, A. An Engineered PET Depolymerase to Break down and Recycle Plastic Bottles. Nature 2020, 580, 216–219. [Google Scholar] [CrossRef]

- Kawai, F.; Kawabata, T.; Oda, M. Current State and Perspectives Related to the Polyethylene Terephthalate Hydrolases Available for Biorecycling. ACS Sustainable Chemistry & Engineering 2020, 8, 8894–8908. [Google Scholar] [CrossRef]

- Erickson, E.; Gado, J.E. ; Luisana Avilán; Bratti, F.; Brizendine, R.K.; Cox, P.A.; Gill, R.; Graham, R.; Kim, D.-J.; Gerhard König; Michener, W.K.; Saroj Poudel; Ramirez, K.J.; Shakespeare, T.J.; Zahn, M.; Boyd, E.S.; Payne, C.M.; DuBois, J.L.; Pickford, A.; Beckham, G.T. Sourcing Thermotolerant Poly(Ethylene Terephthalate) Hydrolase Scaffolds from Natural Diversity. Nature Communications 2022, 13. [Google Scholar] [CrossRef]

- Singh, A.; Rorrer, N.A.; Nicholson, S.R.; Erickson, E.; DesVeaux, J.S.; Avelino, A.F.T.; Lamers, P.; Bhatt, A.; Zhang, Y.; Avery, G.; Tao, L.; Pickford, A.R.; Carpenter, A.C.; McGeehan, J.E.; Beckham, G.T. Techno-Economic, Life-Cycle, and Socioeconomic Impact Analysis of Enzymatic Recycling of Poly(Ethylene Terephthalate). Joule 2021, 5, 2479–2503. [Google Scholar] [CrossRef]

- Kumar, V.; Pellis, A.; Wimmer, R.; Vladimir Popok; de, J. ; Varrone, C. Efficient Depolymerization of Poly(Ethylene 2,5-Furanoate) Using Polyester Hydrolases. ACS Sustainable Chemistry & Engineering 2024, 12, 9658–9668. [Google Scholar] [CrossRef]

- Ribitsch, D.; Acero, E.H.; Greimel, K.; Eiteljoerg, I.; Trotscha, E.; Freddi, G.; Schwab, H.; Guebitz, G.M. Characterization of a New Cutinase FromThermobifida Albafor PET-Surface Hydrolysis. Biocatalysis and Biotransformation 2011, 30, 2–9. [Google Scholar] [CrossRef]

- Bradford, M.M. A Rapid and Sensitive Method for the Quantitation of Microgram Quantities of Protein Utilizing the Principle of Protein-Dye Binding. Analytical Biochemistry 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Li, R.; Greenchem; Ismail, M.; Abouhmad, A.; Warlin, N.; Pyo, S.-H.; Örn, O.; Al-Rudainy, B.; Tullberg, C.; Zhang, B.; Hatti-Kaul, R. Cite This: Green Chem. 2024, 26, 3863. [CrossRef]

- Su, L.; Woodard, R.W.; Chen, J.; Wu, J. Extracellular Location of Thermobifida Fusca Cutinase Expressed in Escherichia Coli BL21(DE3) without Mediation of a Signal Peptide. Applied and Environmental Microbiology 2013, 79, 4192–4198. [Google Scholar] [CrossRef] [PubMed]

- Lizhu Aer; Qin, H.; Wo, P.; Feng, J.; Tang, L. Signal Peptide Independent Secretion of Bifunctional Dual-Hydrolase to Enhance the Bio-Depolymerization of Polyethylene Terephthalate. Bioresource Technology 2024, 391, 129884–129884. [CrossRef]

- Taniguchi, I.; Yoshida, S.; Hiraga, K.; Miyamoto, K.; Kimura, Y.; Oda, K. Biodegradation of PET: Current Status and Application Aspects. ACS Catalysis 2019, 9, 4089–4105. [Google Scholar] [CrossRef]

- Tarazona, N.A.; Wei, R.; Brott, S.; Pfaff, L.; Bornscheuer, U.T.; Lendlein, A.; Rainhard Machatschek. Rapid Depolymerization of Poly(Ethylene Terephthalate) Thin Films by a Dual-Enzyme System and Its Impact on Material Properties. Chem catalysis 2022, 2, 3573–3589. [Google Scholar] [CrossRef]

- Thomsen, T.B.; Hunt, C.J.; Meyer, A.S. Influence of Substrate Crystallinity and Glass Transition Temperature on Enzymatic Degradation of Polyethylene Terephthalate (PET). New Biotechnology 2022, 69, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Pasula, R.R.; Lim, S.; Ghadessy, F.J.; Sana, B. The Influences of Substrates’ Physical Properties on Enzymatic PET Hydrolysis: Implications for PET Hydrolase Engineering. Engineering Biology 2022, 6, 17–22. [Google Scholar] [CrossRef]

- Brizendine, R.K.; Erickson, E.; Haugen, S.J.; Ramirez, K.J.; Miscall, J.; Salvachúa, D.; Pickford, A.R.; Sobkowicz, M.J.; McGeehan, J.E.; Beckham, G.T. Particle Size Reduction of Poly(Ethylene Terephthalate) Increases the Rate of Enzymatic Depolymerization but Does Not Increase the Overall Conversion Extent. ACS Sustainable Chemistry & Engineering 2022, 10, 9131–9140. [Google Scholar] [CrossRef]

- Barth, M.; Honak, A.; Oeser, T.; Wei, R.; Belisário-Ferrari, M.R.; Then, J.; Schmidt, J.; Zimmermann, W. A Dual Enzyme System Composed of a Polyester Hydrolase and a Carboxylesterase Enhances the Biocatalytic Degradation of Polyethylene Terephthalate Films. Biotechnology Journal 2016, 11, 1082–1087. [Google Scholar] [CrossRef] [PubMed]

- Knott, B.C.; Erickson, E.; Allen, M.D.; Gado, J.E.; Graham, R.; Kearns, F.L.; Pardo, I.; Topuzlu, E.; Anderson, J.J.; Austin, H.P.; Dominick, G.; Johnson, C.W.; Rorrer, N.A.; Szostkiewicz, C.J.; Copié, V.; Payne, C.M.; Woodcock, H.L.; Donohoe, B.S.; Beckham, G.T.; McGeehan, J.E. Characterization and Engineering of a Two-Enzyme System for Plastics Depolymerization. Proceedings of the National Academy of Sciences of the United States of America 2020, 117, 25476–25485. [Google Scholar] [CrossRef] [PubMed]

- Ya-Hue Valerie, Soong; Abid, U.; Chang, A.C.; Ayafor, C.; Patel, A.; Qin, J.; Xu, J.; Lawton, C.; Wong, H.; Sobkowicz, M.J.; Xie, D. Ya-Hue Valerie Soong; Abid, U.; Chang, A.C.; Ayafor, C.; Patel, A.; Qin, J.; Xu, J.; Lawton, C.; Wong, H.; Sobkowicz, M.J.; Xie, D. Enzyme Selection, Optimization, and Production toward Biodegradation of Post-Consumer Poly(Ethylene Terephthalate) at Scale. Biotechnology Journal 2023. [Google Scholar] [CrossRef]

- de Castro, A.M.; Carniel, A.; Nicomedes Junior, J.; da Conceição Gomes, A.; Valoni, É. Screening of Commercial Enzymes for Poly(Ethylene Terephthalate) (PET) Hydrolysis and Synergy Studies on Different Substrate Sources. Journal of Industrial Microbiology and Biotechnology 2017, 44, 835–844. [Google Scholar] [CrossRef]

- Castro, A.M. de; Carniel, A.; Stahelin, D.; Chinelatto Junior, L.S.; Honorato, H. de A.; de Menezes, S.M.C. High-Fold Improvement of Assorted Post-Consumer Poly(Ethylene Terephthalate) (PET) Packages Hydrolysis Using Humicola Insolens Cutinase as a Single Biocatalyst. Process Biochemistry 2019, 81, 85–91. [Google Scholar] [CrossRef]

- Oh, Y.-R.; Jang, Y.-A.; Song, J.K.; Eom, G.T. Secretory Production of an Engineered Cutinase in Bacillus Subtilis for Efficient Biocatalytic Depolymerization of Polyethylene Terephthalate. Bioprocess and Biosystems Engineering 2022, 45, 711–720. [Google Scholar] [CrossRef]

- Rezazadeh, A.; Thomsen, K.; Gavala, H.N.; Skiadas, I.V.; Fosbøl, P.L. Solubility and Freezing Points of Disodium Terephthalate in Water–Ethylene Glycol Mixtures. Journal of Chemical & Engineering Data 2021, 66, 2143–2152. [Google Scholar] [CrossRef]

- Chen, C.-C.; Li, X.; Min, J.; Zeng, Z.; Ning, Z.; He, H.; Long, X.; Niu, D.; Peng, R.; Liu, X.; Yang, Y.; Huang, J.-W.; Guo, R.-T. Complete Decomposition of Poly(Ethylene Terephthalate) by Crude PET Hydrolytic Enzyme Produced in Pichia Pastoris. Chemical Engineering Journal 2023, 148418–148418. [Google Scholar] [CrossRef]

- Fritzsche, S.; Holger Hübner; Oldiges, M. ; Castiglione, K. Comparative Evaluation of the Extracellular Production of a Polyethylene Terephthalate Degrading Cutinase by Corynebacterium Glutamicum and Leaky Escherichia Coli in Batch and Fed-Batch Processes. Microbial Cell Factories 2024, 23. [Google Scholar] [CrossRef]

| Sample Code | Sample name | Size or thickness (mm) | Xc (%) |

|---|---|---|---|

| P80A | PET powder cryo-milled | 0.08 | 9.3 |

| P750A | PET powder | 0.75 | 16.6 |

| P750C | PET powder | 0.75 | 37.7 |

| P250C | PET powder | 0.25 | 42.6 |

| P100C | PET powder | 0.1 | 39.1 |

| P750C | PET powder | 0.05 | 37.7 |

| F250A | PET film (Amorphous) | 0.25 | 0.6 |

| F250C | PET film (Crystalline Film) Goodfellow | 0.25 | 35.1 |

| MW1 | PET trays (real waste, origin Spain) cryo-milled at < 500 microns | <0.5 | 15.9 |

| MW2 | PET Bottle (real waste, origin: Spain) cryo-milled at > 500 microns | <0.5 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).