1. Introduction

Considered as natural composite materials, superdeuterate aluminum-silicon alloys have a soft and ductile aluminum matrix with hard and wear-resistant silicon crystals located in it. These qualities combined with their relatively low weight make them indispensable materials in various engineering industries. Usually, primary silicon crystals crystallize in a rough irregular shape and with dimensions of 80-150 µm, this has a large cutting effect on the eutectic matrix and worsens their mechanical properties [

1,

2,

3,

4,

5]. The coarse needle-shaped silicon crystals in the composition of the eutectic also have a cutting effect [

6,

7,

8]. To improve mechanical properties, these alloys are usually subjected to a modification treatment that changes the morphology of the acicular silicon in the composition of the eutectic, and in the case of the primary separated silicon crystals, the aim is to reduce the size and give it a regular shape [

9,

10,

11,

12,

13,

14]. For modifiers of primary silicon crystals in the structure of superdeutectic Al-Si alloys, modifiers of the second generation are used. Classical modifiers for this type of alloys are phosphorus and sulfur [

15,

16,

17,

18,

19,

20,

21]. They form intermetallics (AlP and AlS) with a crystal lattice, identical in type and with parameters close to that of silicon crystals [

22,

23,

24,

25]. Distributed in the melt in a finely dispersed to colloidal-dispersed state, they become independent centers of crystallization. Of scientific interest is the complex modification of the microstructure of supradeutectic aluminum-silicon alloys with the introduction of modifiers of I and II types. It has been proven that the modifying effect of phosphorus (P) [

26,

27,

28] on primary silicon crystals is not only through the AlP compound, but also through the formation of solutions and their adsorption at the grain boundaries [

29,

30,

31,

32,

33]. Considering that modifiers most often have a dual effect [

34,

35] phosphorus could also be adsorbed on the grain boundaries of the alpha phase, thus preventing them from growing, i.e. it has an impact on the structure as a first-order modifier. With a residual phosphorus content of 0.05% in the composition of the alloys, they are overmodified and no modified structure is observed, but on the contrary, the structure is like that of an unmodified alloy and, accordingly, the properties of the alloys are deteriorated [

36,

37,

38,

39].

Iron is a harmful impurity element in the alloys of the Al–Si system. It forms intermetallic compounds that significantly reduce the mechanical properties of the alloy. The effect of beryllium (Be), as a modifying element, is associated with its interaction with iron-containing compounds, by a mechanism similar to manganese (Mn) [

40,

41], it gives a more rounded and compact shape to the iron-containing phases and thus increases the mechanical properties [

42,

43].

The positive influence of the modifier Al-Ti5-B1 on the mechanical properties of superdeuterium-silicon alloys is also known. The results of a number of studies [

44,

45] show that the Al-Ti5-B1 alloy modifies mainly the primary separated silicon in the alloy. The modification can improve the wear resistance of the alloy and also proves that the effect of combined modification is better than that of modification with a single modifier [

46]. The mechanism of modification with Al-Ti5-B1 is that Al3Ti and TiB2 belong to a heterogeneous core [

47].

The aim of the present work is to investigate the influence of various modifiers (P, Be) and their combination (P, Be, Ti, B) on the microstructure and mechanical properties (microhardness of the α-phase) of non-standardized piston hypereutectic alloys.

2. Materials and Methods

The object of the present study are the superdeutectic aluminum-silicon alloys AlSi18Cu3CrMn and AlSi18Cu5Mg with chemical composition indicated in

Table 1. For the modification of the AlSi18Cu5Mg alloy with beryllium, beryllium bronze CuCo1Ni1Be with different concentrations (0.005, 0.007 and 0.01 wt%) was used. The alloy was also modified with the classical modifier for this type of alloys, phosphorus, in an amount of 0.4 wt%, introduced by CuP10 ligature. As well as with titanium with a concentration of 0.015 wt% and boron with a concentration of 0.003 wt%, introduced by AlTi5B1 ligature. The AlSi18Cu3CrMn alloy is modified with phosphorus, as well as a combination of P (0.04 wt%), Ti (0.015 wt%), B (0.003 wt%) and Be (0.005 and 0.007 wt%), respectively, introduced into the melt, as in the AlSi18Cu5Mg alloy.

The studied alloys were melted in an electric resistance laboratory furnace with a graphite crucible under a layer of covering-refining flux 0.5 wt% of the amount of the batch material. They were degassed by blowing with argon for 3min. at a temperature of 760°C. In all experiments, the modification with phosphorus was carried out at an alloy temperature of 850°C, the casting of the test bodies was also at the same temperature for all experiments (760°C). The temperature of the metal equipment used was 210°C for all experiments. Test bodies were cast, which were subjected to heat treatment, quenching and artificial aging (T6). The heat treatment was carried out in a chamber furnace at a temperature of 510-515°C, holding for 6h and 30min, quenching in water at a temperature of 50°C and artificial aging at 330°C for 8h and at 210°C for 16h. Cooling in still air follows. Microsections were prepared from the test specimens for microstructural analysis. Metallographic microsections were prepared for microstructural analysis to study the microstructure of the investigated alloys. The samples were wet ground on sandpapers with numbers: 240, 320, 400, 600, 800 and 1000. After grinding, they were mechanically polished with diamond paste and lubricant. The microstructure of the samples was developed with Keller’s reagent (1 part HF, 1.5 part HCl, 2.5 part HNO3, 95 part H2O). The study was carried out on a Leica DM ILM microscope with the help of software and a module for grain measurement and phase analysis. The microhardness of the α-phase was measured with a Vickers Hardness Tester HV-1000. The measurement was carried out with a load of 50 grams and a holding time of 10 seconds.

3. Results

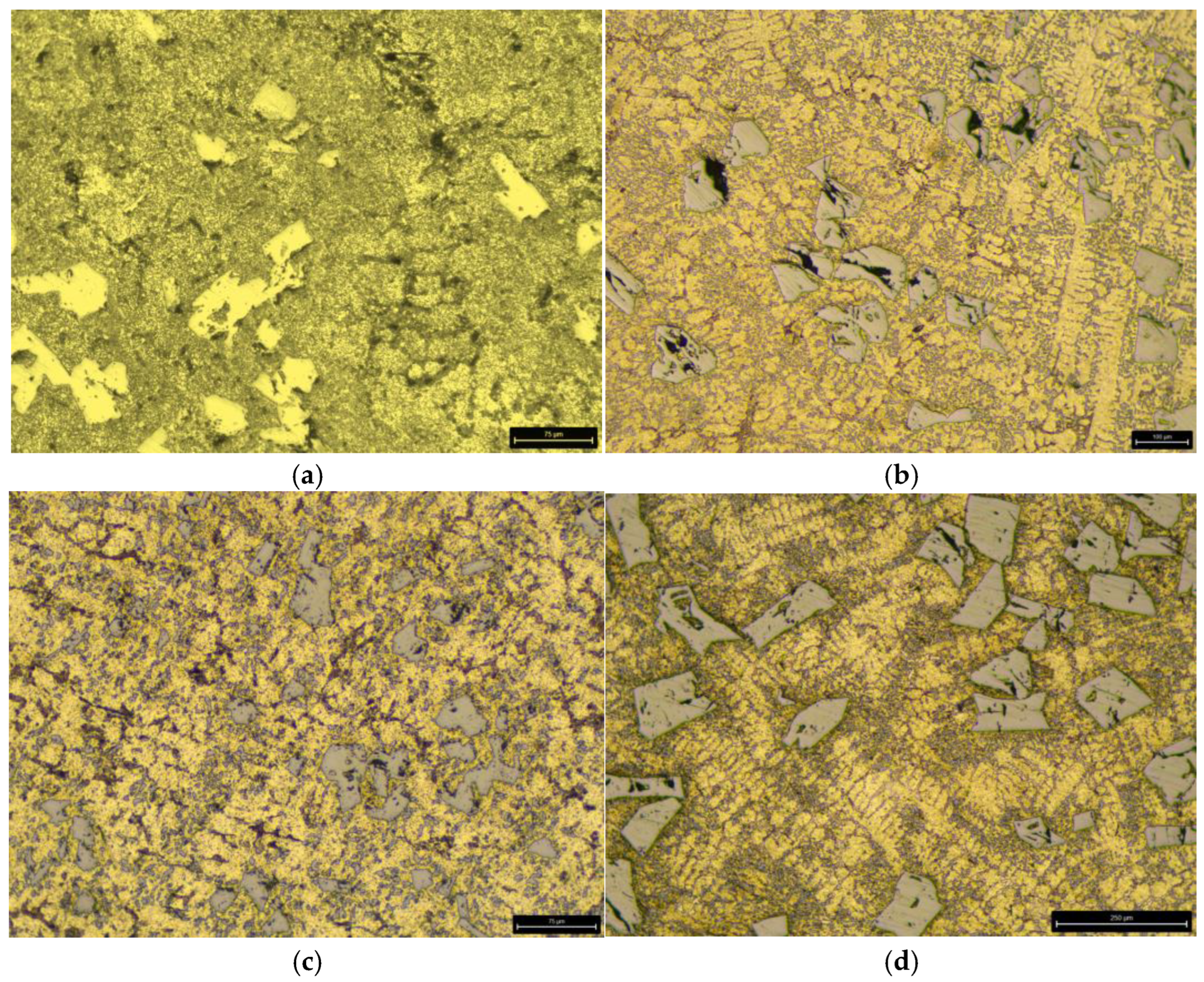

In the first part of the study, the goal was to determine the optimal content of the alloying element beryllium. For this purpose, the indicated modifier was used in concentrations of 0.005, 0.007 and 0.01 wt%, introduced into the AlSi18Cu5Mg alloy. After casting and modification, the alloy was subjected to heat treatment (T6) with parameters of the artificial aging regime of 330°C/12h. In the microstructural analysis of the AlSi18Cu5Mg alloy modified with Be at a concentration of 0.005% (

Figure 1 a), the sizes of the primary silicon crystals and the silicon crystals in the composition of the eutectic were measured. The measured and calculated conditional average diameter of the primary silicon crystals is in the range of 60-70 µm. A certain amount of unmodified silicon crystals, which are 100 µm in size and have an irregular shape, are also observed. The beryllium modifier has also influenced the shape of the α phase in the composition of the eutectic of the alloy, which is in the form of well-formed dendrites. The eutectic silicon crystals are 10-30 µm in size. The modification coefficient of the Be modifier at a concentration of 0.005% for the studied alloy is K=67%. The measured microhardness of the α-phase is 90 µHV

50/10. The structure of the AlSi18Cu5Mg alloy modified with Be in a concentration of 0.007% is shown in

Figure 1 b. The primary silicon crystals in the structure of the thus modified alloy are in the range of 50-70 µm. A small amount of unmodified silicon crystals is also observed, which are 90-95 µm in size. The calculated modification coefficient when using Be in a concentration of 0.007% is K=80%. In the composition of the eutectic, an α phase is again observed, which is in the form of well-formed dendrites, which, however, are more finely divided than when modifying the same alloy with 0.005% Be. This is the reason why finely divided silicon crystals are also observed in the composition of the eutectic, which are 4-23 µm in size, but silicon crystals with sizes of 4-10 µm predominate. And the measured microhardness of the α-phase is 90 µHV

50/10.

When modifying the AlSi18Cu5Mg alloy with beryllium at a concentration of 0.01%, a negligible amount of modified primary silicon crystals is observed. The main amount of primary silicon crystals in the alloy structure are of rough irregular shape and large sizes (

Figure 1 c). The measured and calculated conditional average diameter is in the range of 95-110 µm. The most likely reason for the structure thus obtained is overmodification of the alloy. For superdeutectic aluminum-silicon alloys, it is characteristic that when the amount of the modifier used increases, overmodification of the alloy occurs. The primary silicon crystals in the structure of the overmodified alloys are larger in size than in the unmodified alloys. The modification coefficient of beryllium at a concentration of 0.01% on the structure of the studied alloy was calculated and it has a value of K=38%. The silicon crystals in the composition of the eutectic have sizes, as in all experiments, 10-30 µm. The microhardness of the α-phase is 80.6 µHV

50/10

The highest coefficient of modifying effect is at a beryllium concentration of 0.007%, and then 0.005%. In the next stage of the study, the classical modifier phosphorus in a concentration of 0.004%, as well as titanium (0.015%) and boron (0.003%) were added to the modified alloy with the described concentrations. The cast test bodies were subjected to heat treatment (T6) with parameters of the artificial aging regime of 330°C/8h and 210°C/16h.

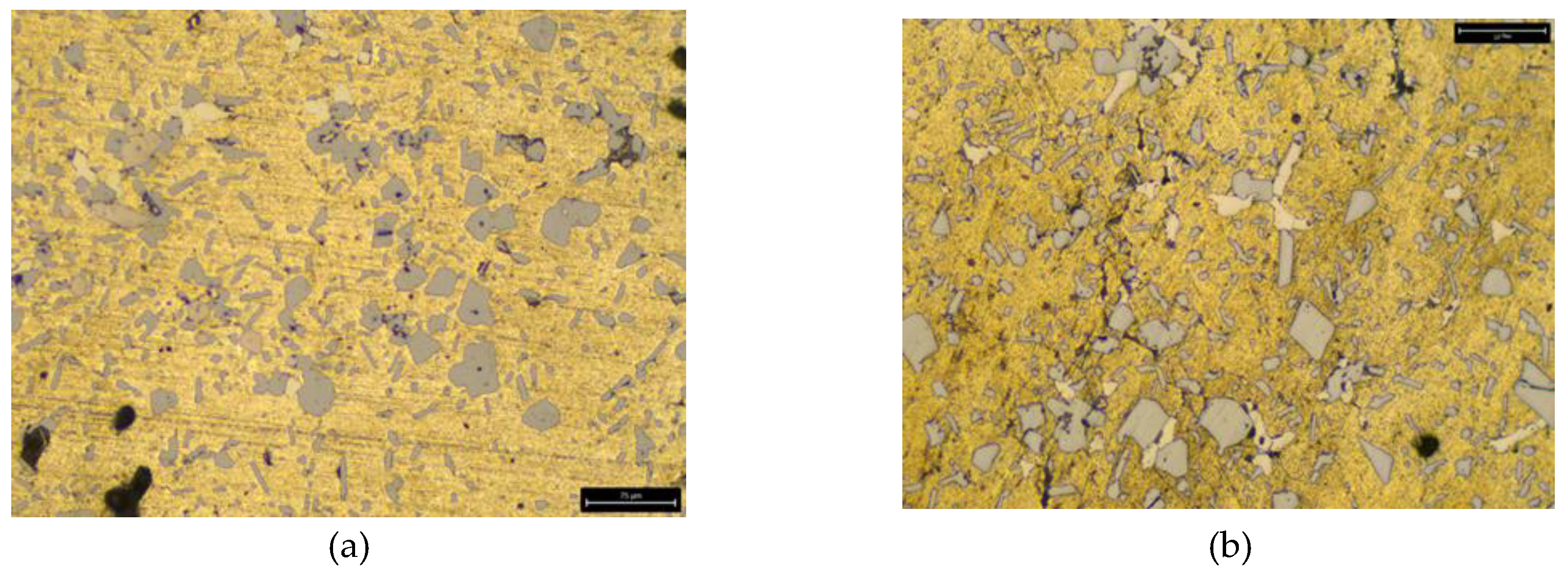

The microstructure of the AlSi18Cu5Mg alloy modified with 0.007% Be; 0.015% Ti; 0.003% B; 0.04% P and subjected to quenching and artificial aging at a temperature of 330°C for 8h is shown in

Figure 2 (a). The structure of the alloy consists of primary silicon crystals, which are crushed and evenly distributed in the alloy structure. Most crystals are irregular in shape and their sizes vary in the range of 34.10-45.62 µm. The silicon crystals in the composition of the eutectic are in the form of plates, arranged side by side and their sizes are in the range of 1.5-7.46 µm, but Si grains with a rounded shape and sizes below 1 µm are also observed. The measured and calculated microhardness of the α-phase is 98 µHV

50/10.

The structure of the AlSi18Cu5Mg alloy modified with Be in a concentration of 0.005%; 0.015% Ti; 0.003% B; 0.04% P after T6 with artificial aging at 330°/8h (

Figure 2 (b)) is made up of primary silicon crystals in the range of 54-88 µm. A small amount of unmodified silicon crystals is also observed, which are 96-115 µm in size. The main amount of primary silicon crystals are in the form of plates, but there are also those with an irregular shape. In the composition of the eutectic, the α phase is in the form of well-formed dendrites, which, however, are more finely divided and have sizes in the range of 1-10 µm, but equiaxed silicon crystals with sizes of about 1 µm prevail. The measured microhardness of the α-phase of the thus modified alloy is 90 µHV

50/10.

In the structure of the AlSi18Cu5Mg alloy modified with 0.007% Be; 0.015% Ti; 0.003% B; 0.04% P, quenched and aged at 210°C for 16h (

Figure 2 c), the primary silicon crystals are highly refined, irregularly shaped and again evenly distributed in the alloy structure. Their sizes vary in the range of 21.5 – 36µm. The silicon crystals in the composition of the eutectic are also highly refined. They represent a string of small silicon crystals arranged next to each other, which are no longer than 1-4.55 µm in length, but silicon crystals with sizes below 1 µm predominate. The measured microhardness of the α-phase is 100 µHV

50/10.

The microstructure of the AlSi18Cu5Mg alloy modified with 0.005% Be; 0.015% Ti; 0.003% B; 0.04% P quenched and aged at 210°C for 16 h (

Figure 2 (c)) consists of uniformly distributed primary silicon crystals. Plate-like crystals and single primary silicon crystals with irregular shape predominate. The conditional average diameter of the primary silicon crystals in the structure of the alloy during this heat treatment is larger than in the previous one and varies in the range of 66-120 µm. The silicon crystals in the composition of the eutectic, which also has a dendritic structure, are in the form of plates and their sizes are in the range of 8-13 µm. The microhardness of the α-phase is 110 µHV

50/10.

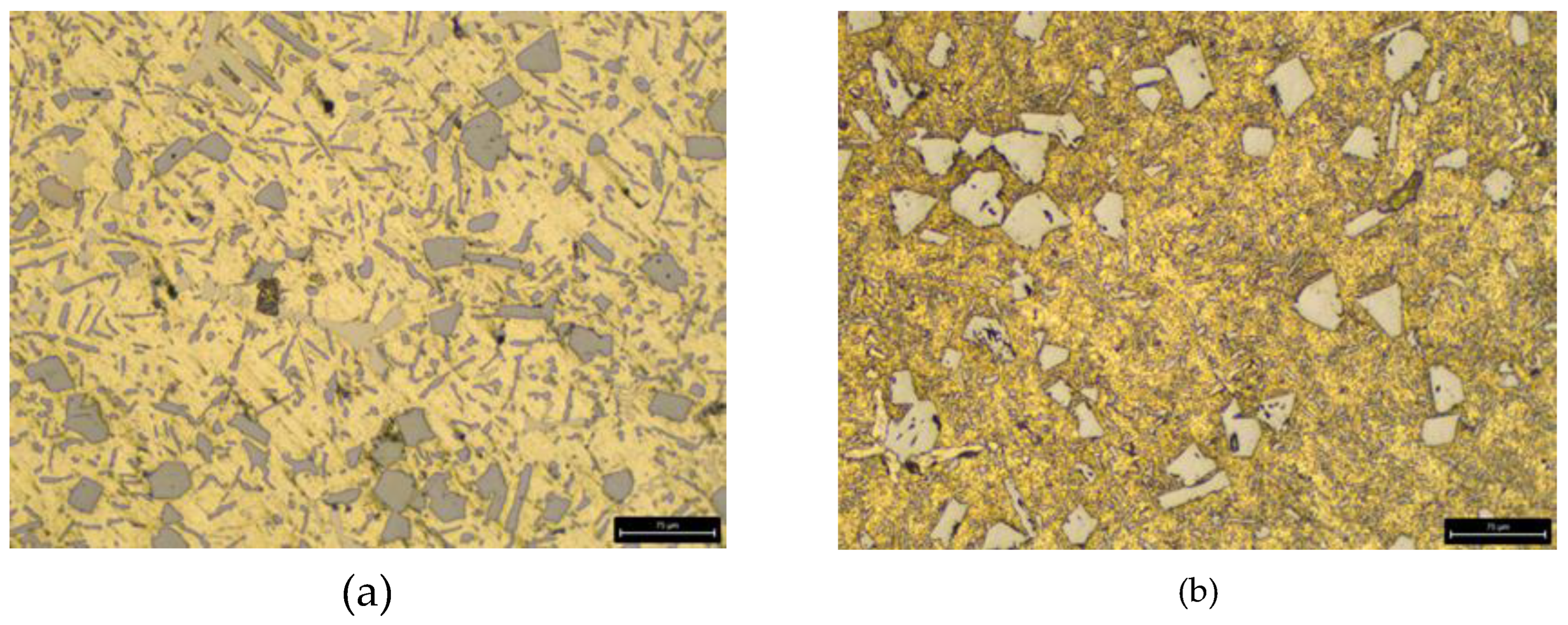

The microstructure of the AlSi18Cu3CrMn alloy modified with the modifiers P – 0.04%; Ti - 0.015%; B – 0.003% and Be – 0.007% after heat treatment regime T6 with artificial aging at 210°C for 16h, consists of eutectic and separated primary silicon crystals. The primary silicon crystals are highly crushed with sizes of 31μm (

Figure 3(a)). The silicon crystals in the composition of the eutectic are plates, which in the observed field of the micrograph are needle-shaped and linear sizes from 3 to 7μm. The macrohardness of the α-phase is 147 µHV

50/10.

The microstructure of the samples of the AlSi18Cu3CrMn alloy modified with 0.007% Be; 0.015% Ti; 0.003% B and 0.04% P, subjected to the T6 heat treatment regime (artificial aging at 330°C/8h) consists of primary silicon crystals in the form of polygons, located in a granular eutectic. The measured and calculated conditional average diameter of the primary silicon crystals is 25 µm. The silicon crystals in the eutectic of the alloy are evenly distributed and have a strongly rounded shape, their sizes vary in the range of 7-13 µm. The thus treated weld possesses an α-phase with macrohardness 120,5 µHV50/10.

A metallographic analysis of the AlSi18Cu3CrMn alloy modified only with phosphorus and subjected to T6 heat treatment with artificial aging regimes of 210°/16h and 330°/8h was also carried out. The microstructure of the AlSi18Cu3CrMn alloy subjected to quenching and artificial aging at a temperature of 210°C and a holding time at this temperature of 16h is shown in

Figure 3 (a). The results of the microstructural analysis show that the main amount of primary silicon crystals are in the shape of polygons with straight walls and sizes in the range of 27-40 µm. The silicon crystals in the composition of the eutectic of the thus heat-treated alloy are in the range of 7-26 µm, the shape of the majority of the crystals is elongated “needle-shaped”, but a part of them have rounded their shape. The thus treated weld has an α-phase with macrohardness 140 µHV

50/10. In the heat-treated alloy by quenching and artificial aging at a temperature of 330°C and holding for 8 hours, the size of the primary silicon crystals in the structure of the alloy is in the range of 24 - 28 µm. Almost all crystals are of regular shape. The eutectic silicon of the alloy heat-treated in this way has dimensions of 15-18 µm, has the shape of “needles” in the plane of the section with many adhering small silicon crystals. The alloy thus treated has an α-phase with macrohardness 112 µHV

50/10.

4. Discussion

In the studies conducted on the two hypereutectic aluminum-silicon alloys AlSi18Cu5Mg and AlSi18Cu3CrMn, it was found that heat treatment has a positive effect on both the primary silicon crystals and the eutectic silicon of the studied compositions [

48]. The artificial aging regimes show that at a lower temperature and a longer holding time, the precipitated phases have passed into an intermediate state, in which they simultaneously remained small in size, but have not destroyed the coherent bonds with the α-solid solution, which is judged by the results of the measured microhardness.

In both alloys modified with beryllium, phosphorus, titanium and boron in a concentration of 0.007% after heat treatment, the lowest values of primary silicon crystals and silicon crystals in the composition of the eutectic were measured from all experiments conducted. The studies establish the optimal amount of beryllium as a modifier in the two hypereutectic piston alloys.

In the case of AlSi18Cu5Mg alloy modified with beryllium at a concentration of 0.01% after heat treatment, the measured macrohardness is comparable to that of the other studied compositions, but the coefficient of modifying effect is low, the free silicon crystals are irregular in shape and large in size. This is typical of the overmodified compositions, which, with a larger amount of the introduced modifier, neutralize its modifying effect.

Beryllium has the second most effective modification coefficient of primary silicon crystals at a relatively low concentration (K=73% at a Be content of 0.005%) [

49]. In addition, beryllium does not affect the corrosion resistance of aluminum-silicon alloys. Eutectic silicon crystallizes between the branches of the α-phase in the composition of the eutectic. In order to reduce the cutting effect of the silicon crystals in the composition of the eutectic, the α-phase must be modified so that the distances between its branches are reduced and do not allow (eutectic silicon) to grow. In this way, small-sized spheroidal eutectic silicon crystals are obtained. Titanium and boron have been used to modify the α-phase in the structure of aluminum-silicon alloys. The combination of Ti and Be in minimal concentrations has a positive effect on the structure of silumins after T6 heat treatment. Their influence consists in increasing the concentration of point defects at the grain boundaries, thus accelerating the diffusion processes of alloying element atoms during aging, which stimulates the earlier formation of metastable and stable phase separation [

50]. The positive results of the indicated studies are a starting point in the study of the complex modification treatment of hypereutectic aluminum-silicon alloys. The object of interest is the study of the strengthening phases in the alloys, given the fact that the alloy (AlSi18Cu3CrMn) modified with a smaller amount of copper, but excluding magnesium (a highly diffusive mobile element) in its composition, has a much higher microhardness of the α phase.

5. Conclusions

The investigated possibility of complex modification of the complex-alloyed hypereutectic aluminum-silicon alloys by using modifiers of I and II type (P, Ti, B and Be) shows a positive influence on the two studied compositions. The concentration of the indicated modifiers in the composition of the alloy has been optimized.

The obtained results of the AlSi18Cu5Mg and AlSi18Cu3CrMn alloys complexly modified (P, Ti, B and Be in a concentration of 0.007 wt%) in the microstructural analysis (modified silicon crystals evenly distributed in the studied metallographic section) and the microhardness of the α-phase are a prerequisite for improving the mechanical and operational properties of the studied alloys.

Author Contributions

All authors declare equal contribution to this manuscript.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Written informed consent has been obtained from the patient(s) to publish this paper.

Acknowledgments

The authors would like to thank the Research and Development Sector at the Technical University of Sofia for the financial support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- A, O.O. Joseph, P.A. Olubambi, Olakunle O. Joseph, B.M. Edun, J.O. Okeniyi and O.P. Abioye –“Effects of Alloying on Aluminium-Silicon Alloys” – A Review, IOP Conference Series: Materials Science and Engineering, Volume 1107, nternational Conference on Engineering for Sustainable World (ICESW 2020) 10th-14th 20, Ota, Nigeria, DOI10. 20 August 1088. [Google Scholar]

- Anastasiya, D. Shlyaptseva, Igor A. Petrov, Alexandr P. Ryakhovsky, Elena V. Medvedeva and Victor V. Tcherdyntsev – “Complex Structure Modification and Improvement of Properties of Aluminium Casting Alloys with Various Silicon Content. Metals 2021, 11, 1946. [Google Scholar] [CrossRef]

- M. D. Hanna, Shu-Zu Lu, A. Hellawell Author – “Modification in the aluminum silicon system. Metallurgical Transactions 1984, 15, 459–469. [Google Scholar] [CrossRef]

- Q. C. Jiang a, C.L. Xu a, M. Lu b, H.Y. Wang a – “Effect of new Al–P–Ti–TiC–Y modifier on primary silicon in hypereutectic Al–Si alloys. Materials Letters 2005, 59, 624–628. [Google Scholar] [CrossRef]

- N. Tenekedjiev &J. E. Gruzleski “Hypereutectic Aluminium-Silicon Casting Alloys—A Review. Cast Metals 1990, 3, 96–105. [Google Scholar] [CrossRef]

- Stuart D McDonald, Kazuhiro Nogita, Arne K Dahle – „Eutectic nucleation in Al–Si alloys. Acta Materialia 2004, 52, 4273–4280. [CrossRef]

- D.K. O: Dwivedi – “Adhesive wear behaviour of cast aluminium–silicon alloys, 1980.

- 20 May 2517; 31. [CrossRef]

- M. G. Mueller, M. Fornabaio, G. Žagar, A. Mortensen – “Microscopic strength of silicon particles in an aluminium–silicon alloy. Acta Materialia 2016, 105, 165–175. [Google Scholar] [CrossRef]

- M. Elmadagli, T. Perry, A.T. Alpas – “A parametric study of the relationship between microstructure and wear resistance of Al–Si alloys. Wear 2007, 262, 79–92. [Google Scholar] [CrossRef]

- Maria Ganchenkova, Risto M. 2010. [CrossRef]

- D. L Zhang, L.H Zheng, D.H StJohn – “Effect of a short solution treatment time on microstructure and mechanical properties of modified Al–7wt.%Si–0.3wt.%Mg alloy. Journal of Light Metals 2002, 2, 27–36. [Google Scholar] [CrossRef]

- J. Lian, B. J. Lian, B. [CrossRef]

- G. Timelli, F. Bonollo, „The influence of Cr content on the microstructure and mechanical properties of AlSi9Cu3(Fe) die-casting alloys. Materials Science and Engineering: A 2010, 528, 273–282. [Google Scholar] [CrossRef]

- Porawit Jiandon, Sukangkana Talangkun – “Microstructural Modification Hardness and Surface Roughness of Hypereutectic Al-Si Alloys by a Combination of Bismuth and Phosphorus. Crystals 2022, 12, 1026. [CrossRef]

- Bo Dang, Zeng-yun Jian, Jun-feng Xu, Fang-e Chang, Man Zhu – “Effect of phosphorus and heat treatment on microstructure of Al-25%Si alloy. Research & Development 2017, 14, 10–15. [CrossRef]

- Xiaolu Hong, Dahui Chen, Ying Xu, Honglei Zhu, Jiang Zhang, Yongqiang Liu, Yingjiang Peng, Linchong Hou – “Effect of Different Phosphorus Modifiers on Microstructure and Properties for Al-Si Alloy”, IOP Conference Series: Earth and Environmental Science, Volume 692, 2, DOI 10. 1088.

- Ozen Gursoy, Giulio Timelli – “Lanthanides: a focused review of eutectic modification in hypoeutectic Al–Si alloys. Journal of Materials Research and Technology 2020, 9, 8652–8666. [CrossRef]

- Y Wang, Y Xiong – “Effects of beryllium in Al–Si–Mg–Ti cast alloy. Materials Science and Engineering: A 2000, 280, 124–127. [CrossRef]

- Y Wang, Y Xiong – “Effects of beryllium in Al–Si–Mg–Ti cast alloy. Materials Science and Engineering: A 2000, 280, 124–127. [CrossRef]

- I. Averkin, B. N. Korchunov, S. P. Nikanorov, V. N. Osipov – “The effect of strontium on the mechanical properties of aluminum–silicon alloy. Technical Physics Letters 2016, 42, 201–203. [Google Scholar] [CrossRef]

- S. Mahanty, Gouthama – “Surface modification of Al–Si alloy by excimer laser pulse processing. Materials Chemistry and Physics 2016, 173, 192–199. [Google Scholar] [CrossRef]

- C. L. Xu, Y. F. Yang, H. Y. Wang & Q. C. Jiang – “Effects of modification and heat-treatment on the abrasive wear behavior of hypereutectic Al–Si alloys. Journal of Materials Science 2007, 42, 6331–6338. [Google Scholar] [CrossRef]

- Anna Zykova, Lyudmila Kazantsev, Natalya Popova, Alexander Vorozhtsov, Irina Kurzina – “Influence of Modifying Mixtures on Si Crystal Formation in Al-7%Si Alloy. Metals 2018, 8, 98. [CrossRef]

- Talib abdulameer Jasim – “Review on the Mechanisms of Modification Al-Si alloys”, Journal of University of Babylon for Engineering Sciences, Vol. (27), No. (1): 2019.

- R. S. 20 June 2250; 2.

- Stuart, D. McDonald, Kazuhiro Nogita, Arne K. Dahle – “Eutectic grain size and strontium concentration in hypoeutectic aluminium–silicon alloys. Journal of Alloys and Compounds 2006, 422, 184–191. [Google Scholar] [CrossRef]

- P. V.Chandra Sekhar Rao, A.Satya Devib, K.G.Basava Kumarc – “Influence of Melt Treatments on Dry Sliding Wear Behavior of Hypereutectic Al-15Si-4Cu Cast Alloys. Jordan Journal of Mechanical and Industrial Engineering 2012, 6, 55–61. [Google Scholar]

- Abdollahi, A. , Gruzleski, J.E – “An evaluation of calcium as a eutectic modifier in A357 alloy(Article). International Journal of Cast Metals Research 1998, 11, 145–155. [Google Scholar] [CrossRef]

- K Nogita, A. K Dahle – “Eutectic solidification in hypoeutectic Al–Si alloys: electron backscatter diffraction analysis. Materials Characterization 2001, 46, 305–310. [Google Scholar] [CrossRef]

- Sathyapal Hegde, K. Narayan Prabhu – “Modification of eutectic silicon in Al–Si alloys. Journal of Materials Science 2008, 43, 3009–3027. [Google Scholar] [CrossRef]

- Kazuhiro Nogita, Stuart D. McDonald, Katsuhiro Tsujimoto, Kazuhiro Yasuda, Arne K. Dahle – “Aluminium phosphide as a eutectic grain nucleus in hypoeutectic Al-Si alloys. Journal of Electron Microscopy 2004, 53, 361–369. [Google Scholar] [CrossRef]

- Barrirero, Jenifer – “Eutectic Modification of Al-Si Casting Alloys”, Linkopings Universitet (Sweden). ProQuest Dissertation, s & Theses, 2019. 27764720. [CrossRef]

- Chunyu Li, Fang Liu, Jiaqi Yin, Fuxiao Yu, Dongpu Zheng, Hairong Qiao, Yuanjie He, Qichi Le – “Effect of P modification on the banded structure and mechanical properties in direct-chill casting Al-16. 5Si-3Cu-0.6Mg-0.1Zr alloys. Journal of Alloys and Compounds 2024, 1002, 175167. [Google Scholar] [CrossRef]

- J. H. Jeon, J.H. Shin, D.H. Bae – “Si phase modification on the elevated temperature mechanical properties of Al-Si hypereutectic alloys. Materials Science and Engineering: A 2019, 748, 367–370. [Google Scholar] [CrossRef]

- Cleiton Luiz Pereira, Leonardo Fernandes Gomes, Amauri Garcia, José Eduardo Spinelli – “Comparing the roles of Sb and Bi on microstructures and application properties of the Al-15% Si alloy. Journal of Alloys and Compounds 2021, 878, 160343. [CrossRef]

- Felipe Bertelli, Emmanuelle S. Freitas, Noé Cheung, Maria A. Arenas, Ana Conde, Juan de Damborenea, Amauri Garcia – “Microstructure, tensile properties and wear resistance correlations on directionally solidified Al-Sn-(Cu; Si) alloys. Journal of Alloys and Compounds 2017, 695, 3621–3631. [Google Scholar] [CrossRef]

- Wang, J. , Ren, Z., Yang, W., Xia, F., Duan, H., Guo, Y., Gao, X. Effect of ultrasonic and different modification treatments on the microstructure of cast Al-Si-Cu-Mg-Ni alloy. Philosophical Magazine 2021, 101, 1750–1764. [Google Scholar] [CrossRef]

- H A Hussein, M j kahdim and A A Atiyah – “Modification and Refinement of Al-23Si Alloy Processed by Addition of Nano-Metal-Phosphate”, IOP Conference Series: Materials Science and Engineering, Volume 881, 3rd International Conference on Sustainable Engineering Techniques (ICSET 2020) , Baghdad, Iraq, DOI 10. 15 April 1088.

- Laura García, Christian Dietz, Antonio J. Criado and J.A. 14 July 2014. [CrossRef]

- Sinfield, R. , Harris, D.A “Effects of magnesium and iron contents and of heat-treatment variables on the mechanical properties of sodium-modified 7% si-0. 35% mg alloy. 20.

- Prince, N. Anyalebechi – “Effects of solidification rate, Fe, and Ca on the cast microstructure of aluminum alloy A356”, TMS Light Metals, Conference: TMS 2003At: San Diego, CAVolume: Light Metals 2003, edited by Paul N.

- S. S. Sreeja Kumari, R.M. Pillai, T.P.D Rajan, B.C. Pai – “Effects of individual and combined additions of Be, Mn, Ca and Sr on the solidification behaviour, structure and mechanical properties of Al–7Si–0.3Mg–0.8Fe alloy. Materials Science and Engineering: A 2007, 460–461, 561–573. [Google Scholar] [CrossRef]

- Mingfan Qi, Yonglin Kanga, Quanquan Qiu, Wenchuan Tanga Jingyuan, Li, Baoshun Li - Microstructures, mechanical properties, and corrosion behavior of novel high-thermal-conductivity hypoeutectic Al-Si alloys prepared by rheological high pressure die-casting and high pressure die-casting. Journal of Alloys and Compounds 2018, 749, 487–502.

- G.K. 2: Sigworth – “Modification of Aluminum-Silicon Alloys”, ASM Handboo Casting, Published: 2008, Page range, 2008. [CrossRef]

- C. Limmaneevichitr, W. Eidhed – “Fading mechanism of grain refinement of aluminum–silicon alloy with Al–Ti–B grain refiners. Materials Science and Engineering: A 2003, 349, 197–206. [Google Scholar] [CrossRef]

- 20 April; 4. [CrossRef]

- ,: Dochev, Ivan Panov, Desislava Dimova – “Investigation of the Influence of Heat Treatment on the Structure and Properties of Aluminum-Silicon Alloy AlSi18Cu3CrMn”, AIP Conference Proceedings 2449, 060020 (2022), Published Online, 01 September 2449. [CrossRef]

- G.B. Stroganov, B.A. G.B. Stroganov, B.A.Rotenberg and G.B.Gershman, Alloys of aluminum with silicon, M. 1977. [Google Scholar]

- 2021. [CrossRef]

Figure 1.

Microstructure of AlSi18Cu5Mg alloy modified with Be at concentrations of 0.005 (a), 0.007 (b) and 0.01 wt% (c). And subjected to heat treatment T6 with parameters of the artificial aging regime 330°/8h.

Figure 1.

Microstructure of AlSi18Cu5Mg alloy modified with Be at concentrations of 0.005 (a), 0.007 (b) and 0.01 wt% (c). And subjected to heat treatment T6 with parameters of the artificial aging regime 330°/8h.

Figure 2.

Microstructure of AlSi18Cu5Mg alloy modified with Be, Ti, B and P: (a) modified with Be in a concentration of 0.007 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h; (b) modified with Be in a concentration of 0.005 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h; (c) modified with Be in a concentration of 0.007 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 210°/16h; (d) modified with Be in a concentration of 0.005 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 210°/16h.

Figure 2.

Microstructure of AlSi18Cu5Mg alloy modified with Be, Ti, B and P: (a) modified with Be in a concentration of 0.007 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h; (b) modified with Be in a concentration of 0.005 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h; (c) modified with Be in a concentration of 0.007 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 210°/16h; (d) modified with Be in a concentration of 0.005 wt%, Ti 0,015 wt%, B 0,003 wt%, P 0,04 wt% and subjected to heat treatment T6 with parameters of the artificial aging mode 210°/16h.

Figure 3.

Microstructure of AlSi18Cu3CrMn alloy modified with Be 0,007 wt%, Ti 0,015 wt%, B 0.003 wt% and P 0,04 wt%: (a) subjected to heat treatment T6 with parameters of the artificial aging mode 210°/16h; (b) subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h.

Figure 3.

Microstructure of AlSi18Cu3CrMn alloy modified with Be 0,007 wt%, Ti 0,015 wt%, B 0.003 wt% and P 0,04 wt%: (a) subjected to heat treatment T6 with parameters of the artificial aging mode 210°/16h; (b) subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h.

Figure 4.

Microstructure of AlSi18Cu3CrMn alloy modified with P 0,04 wt%: (a) subjected to heat treatment T6 with parameters of the artificial aging mode 210°/12h; (b) subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h.

Figure 4.

Microstructure of AlSi18Cu3CrMn alloy modified with P 0,04 wt%: (a) subjected to heat treatment T6 with parameters of the artificial aging mode 210°/12h; (b) subjected to heat treatment T6 with parameters of the artificial aging mode 330°/8h.

Table 1.

Chemical composition of the studied alloys.

Table 1.

Chemical composition of the studied alloys.

| Alloys |

Si |

Cu |

Mg |

Mn |

Ni |

Al |

| AlSi18Cu3CrMn |

18,5 |

3,12 |

0,01 |

0,76 |

0,01 |

rest |

| AlSi18Cu5Mg. |

19,2 |

5,1 |

1,5 |

0,02 |

0,02 |

rest |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).