1. Introduction

Climate change poses a significant global challenge, threatening ecosystems, economies, and societies alike. In response, the 2015 Paris Agreement set the target to limit global warming to 1.5 °C, aiming to mitigate the risks of extreme weather events and irreversible tipping points [

1]. This goal necessitates coordinated and effective actions at both national and international levels. The European Union (EU) has positioned itself as a global leader in climate action, with its European Climate Law mandating a reduction in greenhouse gas emissions by at least 55 % by 2030 compared to 1990 levels [

1]. This commitment underscores the EU’s pursuit of climate neutrality by 2050 as part of its broader Green Deal agenda [

1]. Germany, as the world’s third-largest economy and the largest in the EU (by gross domestic product) [

2], has historically contributed approximately five percent of global warming-related emissions since industrialization [

3] and therefore bears particular responsibility for climate action. Consequently, Germany has responded by committing to ambitious greenhouse gas emission reductions of 65 % through its Federal Climate Action Act [

4]. This effort aligns closely with the EU’s broader objectives.

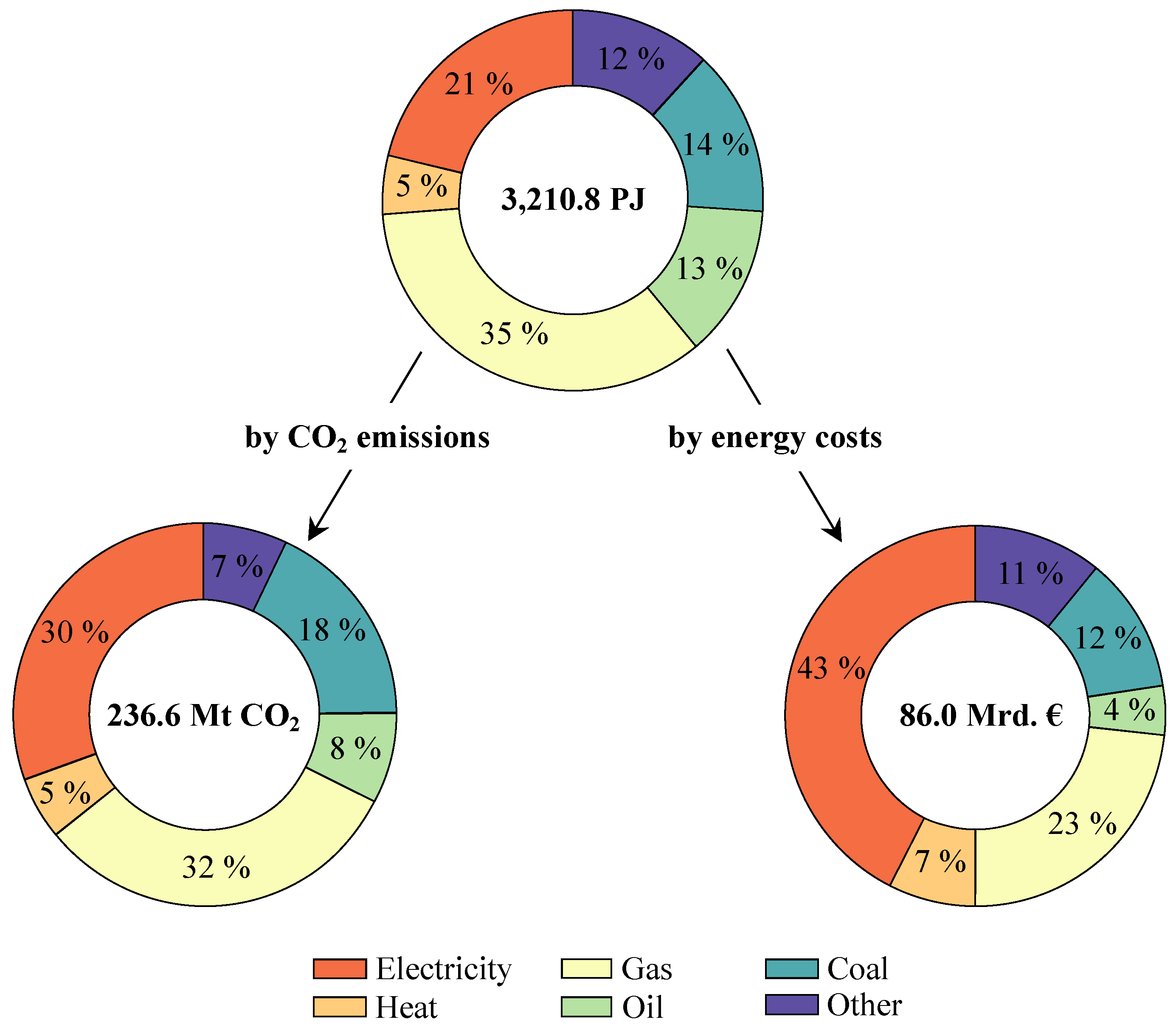

Central to these efforts is the industrial sector, a cornerstone of the EU and Germany’s green transitions. In Germany, it is the second-largest source of energy-related greenhouse gases, with manufacturing ranking second among emitting economic sectors. Additionally, it is the largest electricity consumer, accounting for 42.9 % of net electricity demand in Germany [

5]. Energy use in the German manufacturing industry is directly tied to

emissions and energy costs, with electricity playing a particularly significant role (see

Figure 1). Improving energy efficiency in this sector is essential not only for meeting climate targets but also for strengthening industrial competitiveness by reducing costs.

This dual advantage aligns with the EU’s "Energy Efficiency First" principle, which prioritizes efficient energy use as a key strategy for advancing the green transition [

7]. Globally, industrial enterprises are recognizing the importance of energy efficiency. Surveys reveal that the majority of companies are already investing in energy efficiency or plan to do so in the near future, with many committed to increasing their investments significantly over the coming years [

8]. However, substantial untapped efficiency potentials remain, particularly in manufacturing [

9]. The barriers to progress often include a lack of awareness about appropriate measures, a shortage of digital skills, and limited access to expert consulting resources [

8].

Expert systems (ESs) emerge as a promising solution to these challenges, leveraging embedded domain knowledge and automated data analysis to identify energy efficiency opportunities [

10]. They enable resource-efficient identification of improvement potential, reduce the dependency on specialized human expertise, and provide actionable recommendations through transparent and explainable reasoning [

11]. Furthermore, such systems can serve as tools for knowledge transfer, helping to bridge gaps in workforce expertise and support the training of future specialists. Despite these advantages, the development of ESs for energy efficiency remains largely unsystematic, which can complicate or even entirely inhibit their advancement [

11].

Following a literature review, which addresses the question of how ESs are developed to improve energy efficiency in industrial applications, the authors conclude that there is no universally applicable methodology. Existing solutions are often tailored to specific applications, limiting their scalability and generalizability across different manufacturing contexts [

11]. Of the 62 publications examined in depth, only [

12,

13,

14] indicated specified corresponding development procedures. Ref. [

13] pursues an incremental development model exclusively for the computational implementation of an ES. Ref. [

14] bases the entire development of their ES on a design science method. The methodology described therein comprises three phases: Conceptualization, tool development, and application and validation. In the conception phase, the influencing factors are selected and the calculation rules are defined and iteratively refined. This is followed by the computational implementation in the tool development phase. Finally, the ES is validated both qualitatively and quantitatively. However, the methodology of ref. [

14] is limited to the field of building commissioning. Ref. [

12] transfers the approach from ref. [

14] to manufacturing. This includes the identification of relevant consumers and controllable parameters, the collection of measurement data, the development of machine learning (ML) models and simulation models, the definition of indicators for the energy performance indicators (EnPIs), the formulation of a rule base and finally the integration of all subsystems. Based on ref. [

14], both application and validation were carried out, allowing further refinements to be made. In addition, personas with the necessary capabilities were described for each development step in ref. [

12]. However, it is limited exclusively to the consideration of a single machine and requires the time-consuming development of an analytical simulation model as a core element.

The lack of a universally applicable methodology for developing ESs hinders broader adoption and increases initial implementation costs, posing a barrier to their widespread deployment. To address these gaps, this paper presents a holistic framework for developing ESs that systematically identify and assess energy efficiency potentials in manufacturing.

The remainder of this work is organized as follows:

Section 2 provides the theoretical foundation by outlining key concepts in energy management, knowledge management, and ESs. In

Section 3, the multi-phase framework for systematic development of ESs is presented.

Section 4 covers a software tool to facilitate its realization. To demonstrate the proposed methodology, a case study in a metalworking production line within the ETA Factory is provided in

Section 5. Finally,

Section 6 summarizes the main findings, discusses the contributions of this work, and outlines possible paths for future research.

2. Fundamentals

This section outlines the fundamentals of energy management, knowledge management and ESs, forming the foundation for understanding their role in the continuous improvement of energy efficiency in industry.

2.1. Energy Management

The German Energy Efficiency Act (EnEfG) is a regulatory effort to reach climate targets at a national level [

15]. The core objective of this legislation is to establish a framework that encourages companies to systematically track, analyze, and continuously improve their energy use. According to § 8 of the EnEfG, all German companies, regardless of size, with an average total final energy consumption exceeding 7.5 GWh over the last three completed calendar years are required to implement an energy management system (EnMS) in accordance with DIN EN ISO 50001:2018 or an environmental management system (EMS) based on the Eco-Management and Audit Scheme (EMAS) [

15]. An EMS under EMAS aims to reduce the overall environmental impact of an organization [

16]. In contrast, DIN EN ISO 50001 focuses solely on energy as a resource [

17], which is why it constitutes the primary focus of the following sections.

Energy management refers to the overarching process of coordinating energy procurement, conversion, distribution, storage, and application to meet usage requirements while considering ecological and economic objectives [

18]. EnMSs are based on the concept of energy management and support measures for efficient energy usage at both the organizational and macroeconomic levels [

18]. They provide a structured framework for establishing energy objectives, as well as policies and processes to achieve them [

18].

DIN EN ISO 50001 is based on a globally applicable standard and aims to enable organizations to establish systems and processes for improving energy performance [

17]. Energy performance refers to measurable outcomes related to energy efficiency, energy use, and energy consumption [

17]. The iterative cycle of Plan-Do-Check-Act (PDCA) offers a structured approach for improving energy performance. In the planning phase (Plan), the organizational context is analyzed and an energy policy is established, along with the definition of significant energy uses (SEUs), energy performance indicators (EnPIs), and energy baselines (EnBs). EnPIs are used to quantify energy performance, while EnBs serve as reference points for assessing changes in energy performance and calculating energy savings over a reporting period. Furthermore, targets and action plans are formulated during the planning phase to improve energy performance in line with the energy policy. In the implementation phase (Do), the planned measures are executed, processes and maintenance activities are managed, and competencies are ensured. The evaluation phase (Check) involves monitoring, measuring, and analyzing energy performance, as well as conducting internal audits and management reviews. Finally, in the action phase (Act), measures are taken to eliminate deviations and to continuously improve energy performance and the EnMS [

17].

2.2. Knowledge Management

In the context of a continuous energy improvement process, the targeted use of knowledge as a resource represents a crucial element, the lack of which is one of the major barriers to increasing energy efficiency in companies [

8]. The concept of knowledge is hierarchically based on symbols, data and information [

19]. At the lowest level are symbols, which are incoherent, smallest data elements that consist of letters, numbers or special characters and can be represented as character or pulse sequences [

19]. When individual symbols or sequences of symbols are structured through syntax, they form data [

19]. However, at this level, data still lacks a specific purpose. Information emerges when data is enriched with semantics, establishing a connection to reality [

19]. Finally, knowledge is generated from information when it is pragmatically organized to serve a specific purpose [

19]. Through decisions, knowledge can ultimately enable actions to solve problems [

20].

Knowledge is typically categorized by two key distinctions: implicit versus explicit knowledge [

20] and private versus collective knowledge [

21]. Both pairs of concepts are closely connected. Implicit knowledge is the knowledge that is stored in individuals (embodied knowledge) and is based on experiences, perceptions and values. It is inherently subjective and difficult to formalize or transfer. For instance, implicit knowledge can express itself as intuition. Explicit knowledge, in contrast, is systematically organized and stored externally in media (disembodied knowledge). It can be articulated, processed electronically, and shared. Patents are an example of explicit knowledge. For knowledge to be available to organizations and usable beyond individual persons or groups, it needs to exist in explicit form [

20]. Private knowledge is accessible only to individuals, whereas collective knowledge is available to multiple people simultaneously. Implicit knowledge can be collective if it is shared among multiple individuals. Explicit knowledge, on the other hand, can be private if it is restricted or encrypted, making it accessible only to specific individuals [

21].

Knowledge management addresses how the resource of knowledge can be utilized to achieve organizational objectives. This includes shaping, utilizing, directing, and developing the organizational knowledge base [

20]. This leads to the task of knowledge management to establish the necessary infrastructural and organizational conditions. Given the increasing complexity of the environment and the fluctuation of human knowledge carriers, the use of information and communication technologies is essential to support and preserve the organizational knowledge base.

2.3. Expert Systems

A significant digital knowledge carrier within the field of artificial intelligence are ESs [

22]. ESs, also referred to as knowledge-based systems or inference-based programs, are computer programs designed to use the knowledge of a narrowly defined domain to assist in decision-making or problem-solving [

22,

23]. The stored knowledge consists of facts and information, as well as their connections to potential solution approaches [

24]. Unlike electronic documentation or databases, the knowledge in ESs is not merely represented through relationships between elements but is explicitly stored within a knowledge base [

21]. Additionally, ESs are characterized by their ability to both store and represent knowledge, as well as to apply it to new problems, functioning as tools for knowledge processing [

23].

In contrast to conventional programs, ESs simulate human thinking [

23]. They formalize human knowledge, represent it in the computer, and manipulate it according to problem-solving strategies [

25]. The separation of knowledge and problem-solving strategies is a key feature of ESs, which can be implemented through rule-based and object-oriented programming styles [

23]. Another distinguishing feature is the ease of prototyping in ESs. This means that even early versions of these programs with an incomplete knowledge base are functional and can be incrementally expanded or updated with minimal effort. Furthermore, ESs are often differentiated from conventional data processing applications by their focus on specialized tasks of highly skilled professionals such as technicians and engineers [

24].

The structure of ESs consists of several program modules that are connected through different relationships. The functional separation between expert knowledge and problem-solving strategies is also reflected in their architecture [

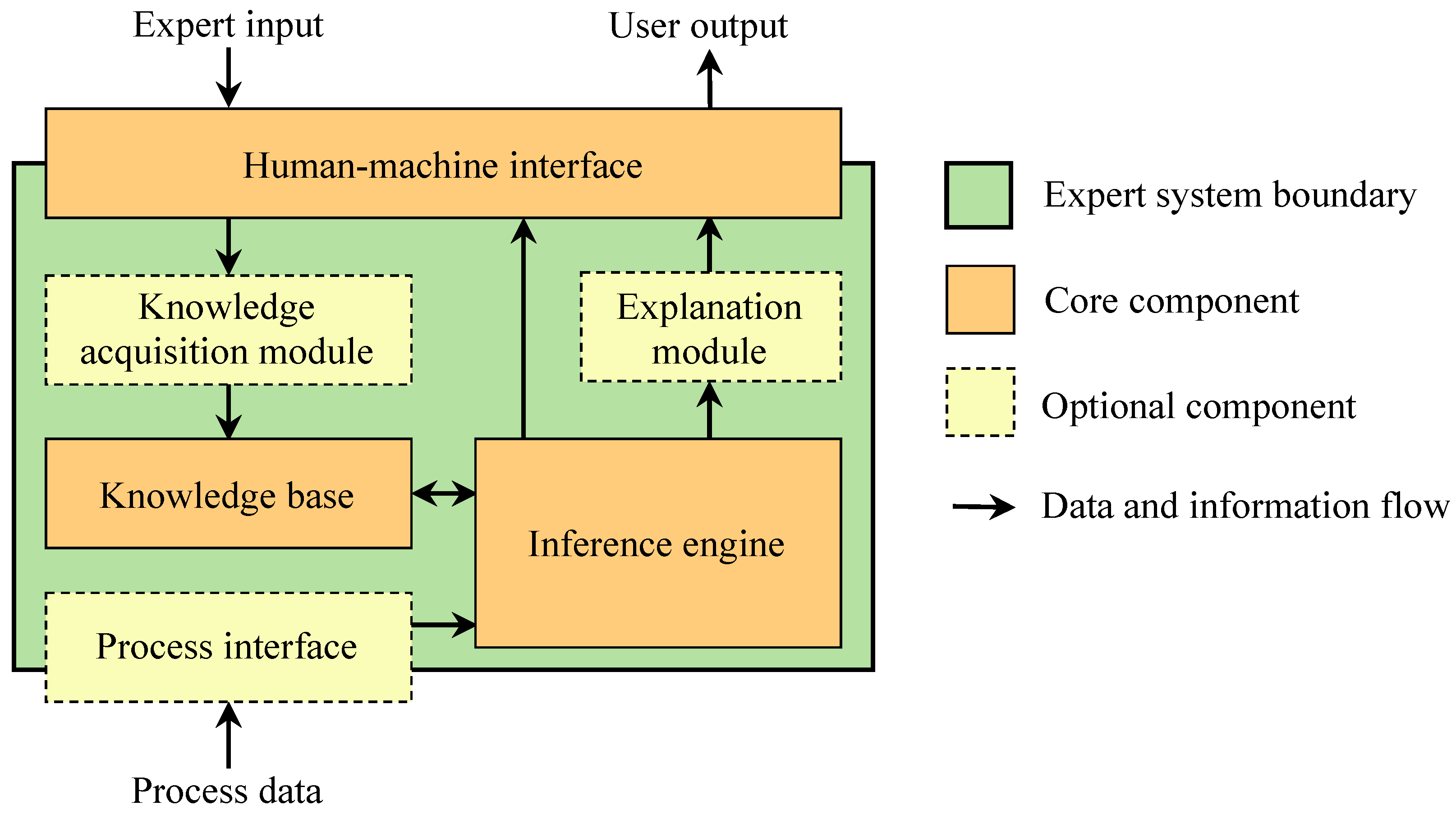

23]. In general, ESs can be divided into the following components, as shown in

Figure 2:

-

The

knowledge base encompasses an explicit representation of knowledge used for problem-solving [

26]. It can be divided into different parts [

23,

27]:

- –

Domain-specific knowledge covers general knowledge about a specific field, which is independent of a specific problem. Ref. [

13] refers to this part as the system’s long-term memory.

- –

Case-specific knowledge corresponds to problem-specific facts, data and parameters. Ref. [

13] refers to this part as the system’s short-term memory.

- –

Intermediate and final results are ultimately derived knowledge that arises within problem-solving processes.

The

inference engine is responsible for interpreting and applying knowledge to gain insights or solve problems [

23]. This component simulates human decision-making [

13].

The

human-machine interface serves as the communication environment between humans (experts and other users) and the ES [

13].

The

process interface connects the ES to other technical systems, enabling unidirectional or bidirectional data transfer [

27]. Other technical systems can be, for example, sensors or programmable logic controllers [

12].

The

knowledge acquisition module enables experts to enrich the ES with new knowledge or to modify existing knowledge [

13].

The

explanation module ensures transparency in the decision-making process of the ES. This helps to make the solutions found comprehensible and verifiable, thus increasing their acceptance. Moreover, it provides benefits in terms of knowledge transfer and distribution within knowledge management [

23].

Figure 2.

Expert system architecture. Illustration from [

28] based on [

11]. .

Figure 2.

Expert system architecture. Illustration from [

28] based on [

11]. .

3. Methodology

This section describes the methodology for systematically developing an ES aimed at improving energy efficiency. It builds on the premise that individual application scenarios differ primarily in their knowledge content, while knowledge representations and problem-solving strategies remain similar [

23]. The conceptual framework is based on the Design Science Research (DSR) paradigm, as described by ref. [

29] and adapted by refs. [

12,

14] for ES development. DSR aims to expand the capabilities of individuals and organizations by creating innovative artifacts. These artifacts are structured entities that range from software, formal logic, and mathematical models to informal descriptions in natural language [

29]. Furthermore, DSR provides insights into how artifacts can be purposefully designed through human action to achieve specific objectives [

30].

3.1. Environment

Following DSR, the development of ESs is based on its environment, which comprises people, organizational and technical systems, as well as problems and opportunities. The people taking on a key role in this environment are represented as personas, a concept borrowed from the field of software development [

31]. These personas embody specific knowledge and skills that are characteristic of their respective professions.

Among them are machine operators, who are directly involved in manufacturing processes. Their practical expertise is crucial for ensuring the feasibility and applicability of proposed optimizations in real-world production environments. Energy managers, another key group, evaluate manufacturing processes from an energy perspective, analyze energy usage, and identify inefficiencies requiring improvement. Collaborating closely with both machine operators and energy managers are knowledge engineers, who are responsible for collecting, structuring, and representing the required expertise in a form usable by the ES. Data scientists are the fourth persona in this environment, providing data-based models and algorithms. These tools enable the automated analysis of energy and process data, facilitating the generation of new insights. The insights that are to be extracted from the data are given by the energy managers.

Table 1 provides an overview of the personas involved:

The organizational systems within which the ES is being developed are manufacturing companies that are faced with the challenge of making their production more energy-efficient. This requires practicable solutions that can be implemented without high investments. Furthermore, ESs can complement existing EnMSs, enhancing their effectiveness and scope.

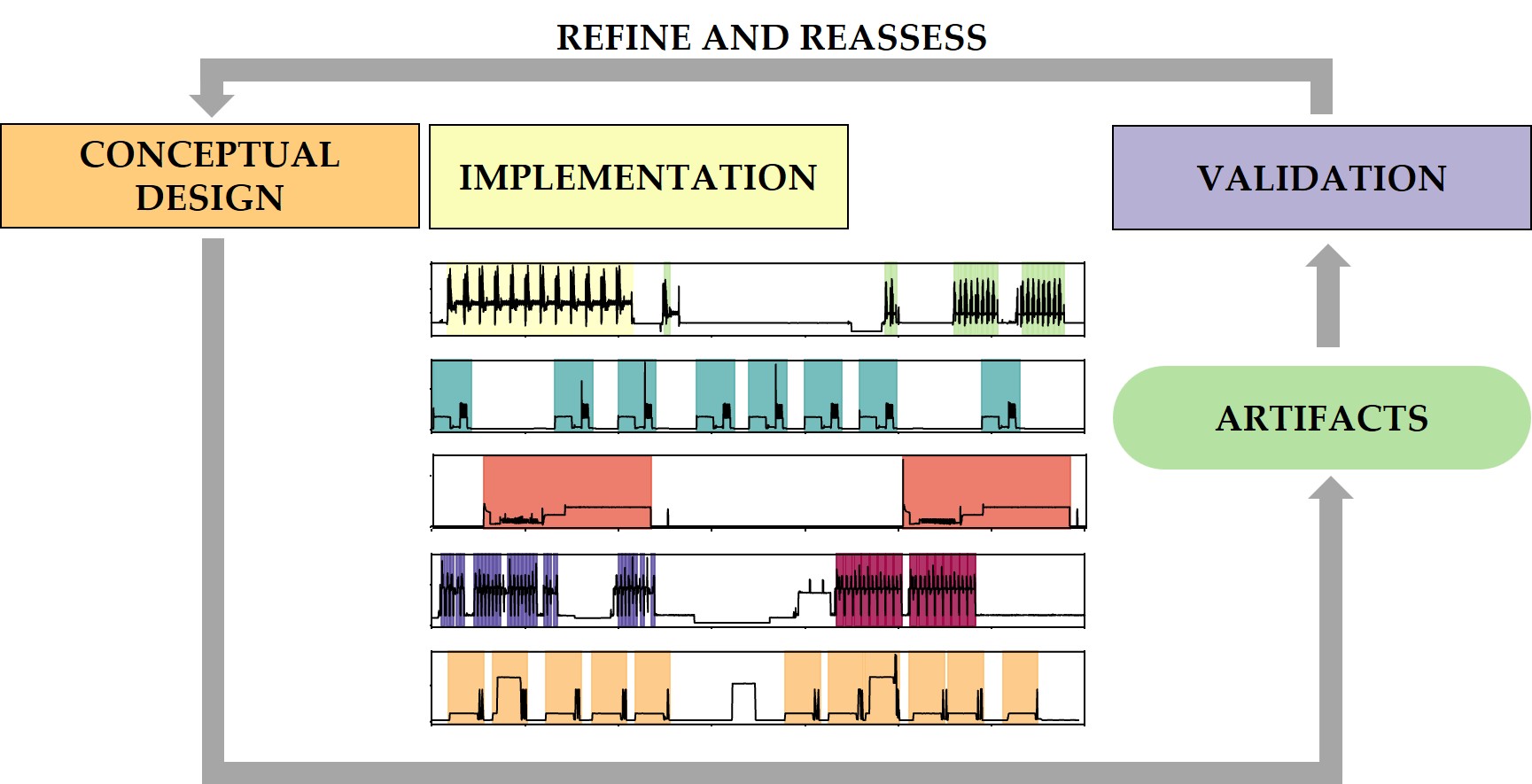

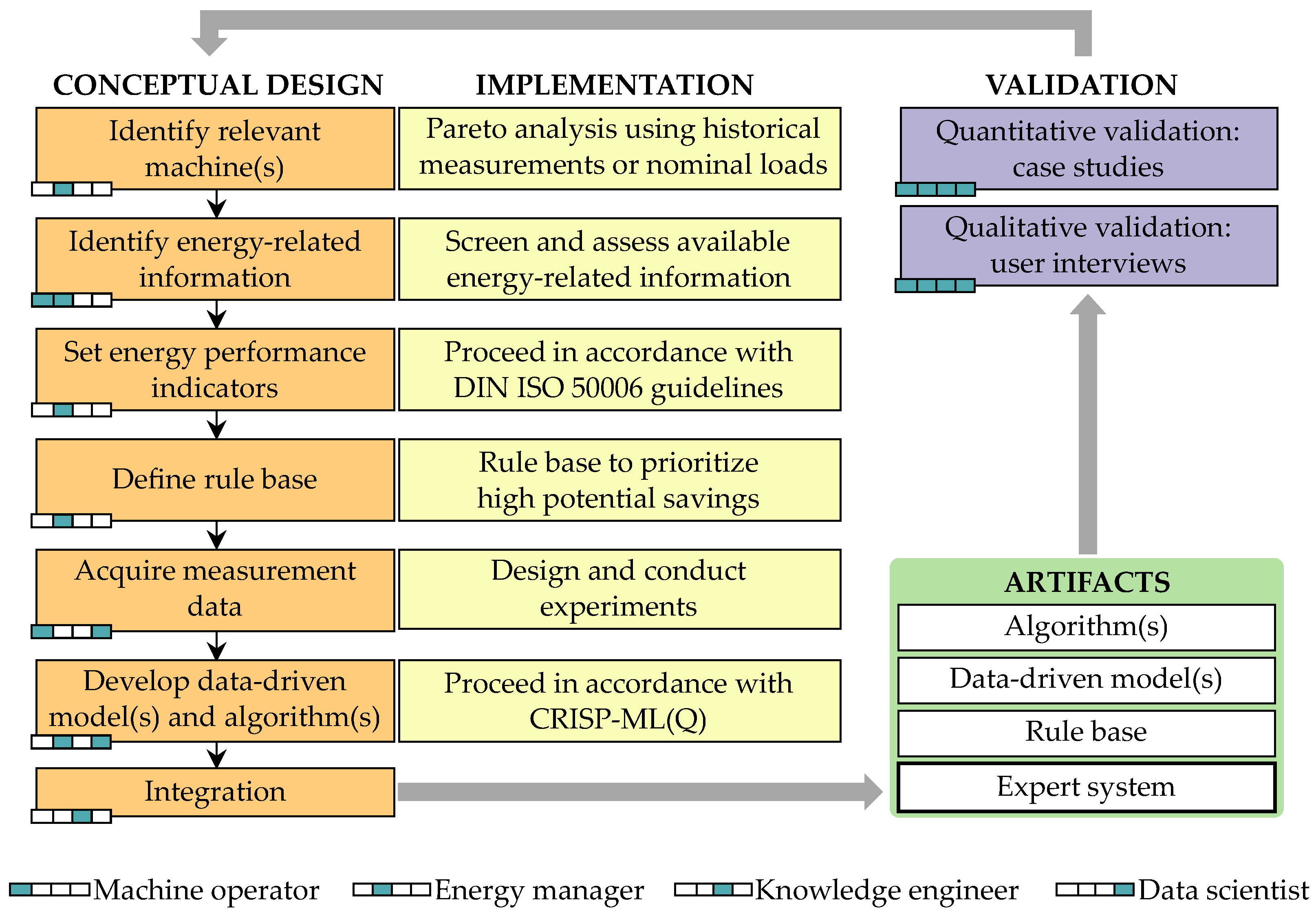

3.2. Methodological Framework

The methodology for developing ESs follows a multi-phase approach consisting of conceptual design, implementation, and validation. The first two phases are carried out concurrently. The conceptual design focuses on defining the foundational steps required for creating the ES, establishing its structure, and identifying key objectives. Simultaneously, the implementation translates these conceptual elements into practice by detailing the procedures, tools, and methods necessary for their realization.

The methodology begins with the identification and prioritization of relevant machines that contribute to SEUs within the manufacturing company. Methods such as Pareto analysis or the energy portfolio can be applied, utilizing historical measurements or nominal load data to determine machines with the highest energy demand [

32]. Subsequently, energy-related information is identified to assess energy performance. This information is determined, among other factors, by the defined system boundary (e.g. a single machine or multiple machines) and may include machine states [

33], processes [

10], processing cycles [

34] or controllable variables [

12]. Following this, EnPIs are established to quantify changes in energy performance [

35]. To replicate the decision-making behavior of human experts, a heuristic rule base is created using the EnPIs. The rule base should be designed to identify areas with the highest potential energy savings. For practical implementation, the use of fuzzy logic is recommended [

12]. This approach assumes that human experts often make decisions without precisely quantified information and thus accommodates conditions or conclusions that may be partially true or false [

36]. The rules are typically structured as IF-THEN statements, where the IF part represents the causes (antecedent) and the THEN part the effects (consequent) [

12,

13]. To automate the extraction of energy-related information, measurement data must be systematically collected for the development of ML models or algorithms. This development process can follow the CRoss-IndustryStandard Process model for the development of Machine Learning applications with Quality assurance methodology (CRISP-ML(Q)) [

37]. The preceding steps yield algorithms, data-driven models, and a rule base, which are integrated into the complete ES together with the expert knowledge by the knowledge engineer in the final step.

During the

validation, all artifacts, including the overall ES, are validated through quantitative case studies and qualitative user interviews. This ensures that the ES fulfills practical requirements. Where necessary, the artifacts are refined and reassessed based on feedback or newly identified issues. The various steps in the methodology are supported by the personas presented in

Table 1, as illustrated in

Figure 3.

4. Computational Implementation

In addition to the lack of a universally applicable methodology for developing ESs, ref. [

11] pointed out that computational implementation is highly heterogeneous and uses a wide variety of programs and programming languages. For this reason, ref. [

28] provide the Expert System Shell for Energy Efficiency (ESS4EE), which is available on GitHub [

38], and supports the software implementation according to the methodology presented in this paper. Thus, developers of ESs do not have to build the logic or representation structures from the ground up [

28].

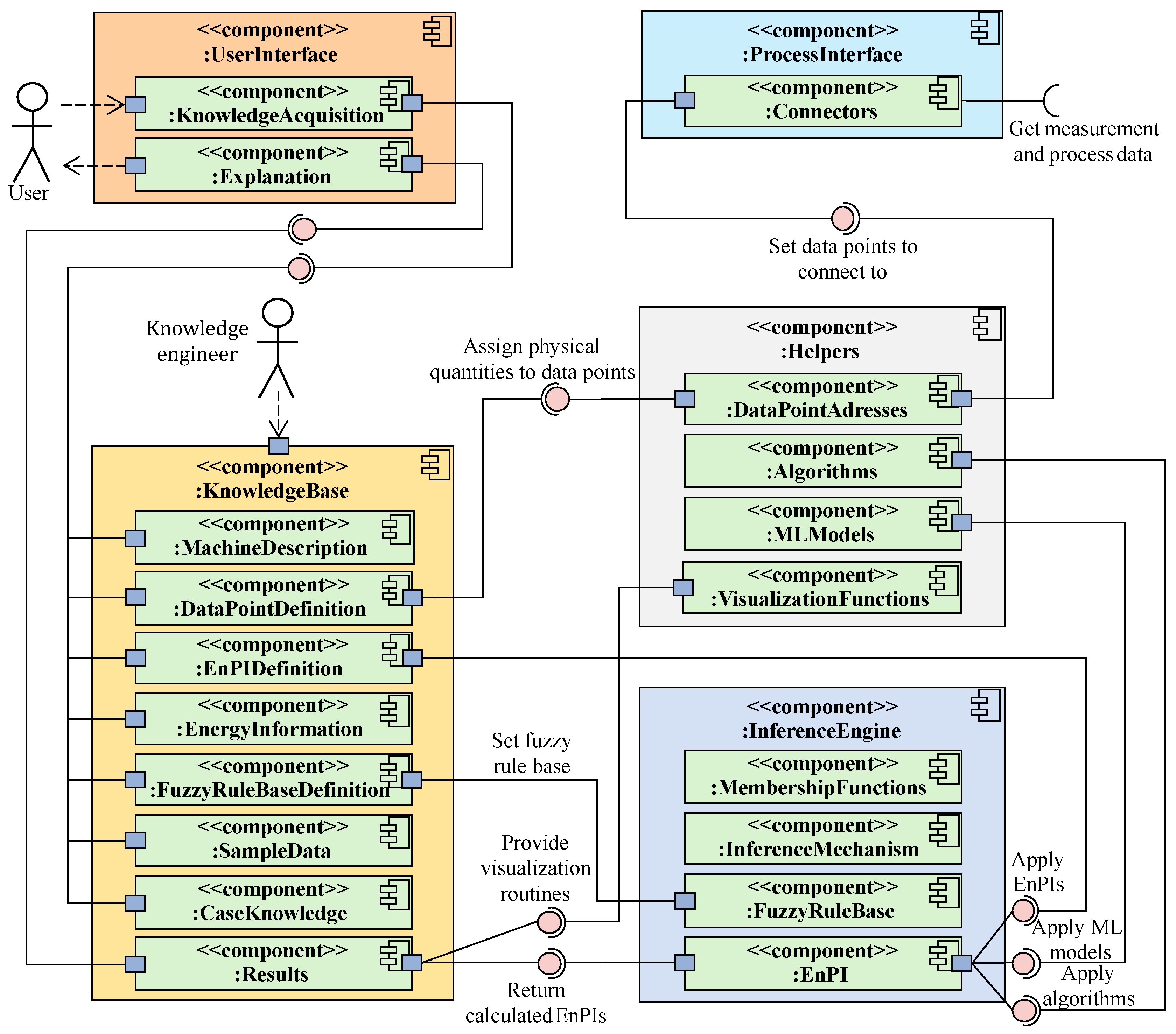

Implemented in Python within Jupyter Notebook [

39], ESS4EE employs a modular software architecture, as depicted in

Figure 4, which ensures adaptability to diverse manufacturing settings, scalability for varying industrial complexities, and integration with external systems.

The system architecture comprises key modules for knowledge management, data handling, and decision-making. The KnowledgeBase stores expert knowledge, including machine descriptions, EnPI definitions, and energy information. This knowledge can be enriched or modified by users through the UserInterface. The ProcessInterface enables access to historical and live data from power meters and programmable logic controllers, while the Helpers module supports algorithm integration, address mapping, and data visualization. At its core, the InferenceEngine applies fuzzy logic using membership functions, an inference mechanism, and a rule base. Finally, results of the ES are presented with visualizations, and the explanation component enhances interpretability, ensuring actionable insights for users.

5. Application

This section demonstrates the practical application of the methodology described in

Section 3 by developing an ES for a representative process chain from the metalworking industry. The scenario is set within the ETA Factory, a full-scale model factory at the Technical University of Darmstadt. The factory’s primary production line focuses on manufacturing hydraulic control discs and comprises five machines executing seven distinct production processes [

40,

41]. In this case study, the personas are represented by the authors of this paper, whereby, just as in industrial practice, a single author can also embody multiple personas.

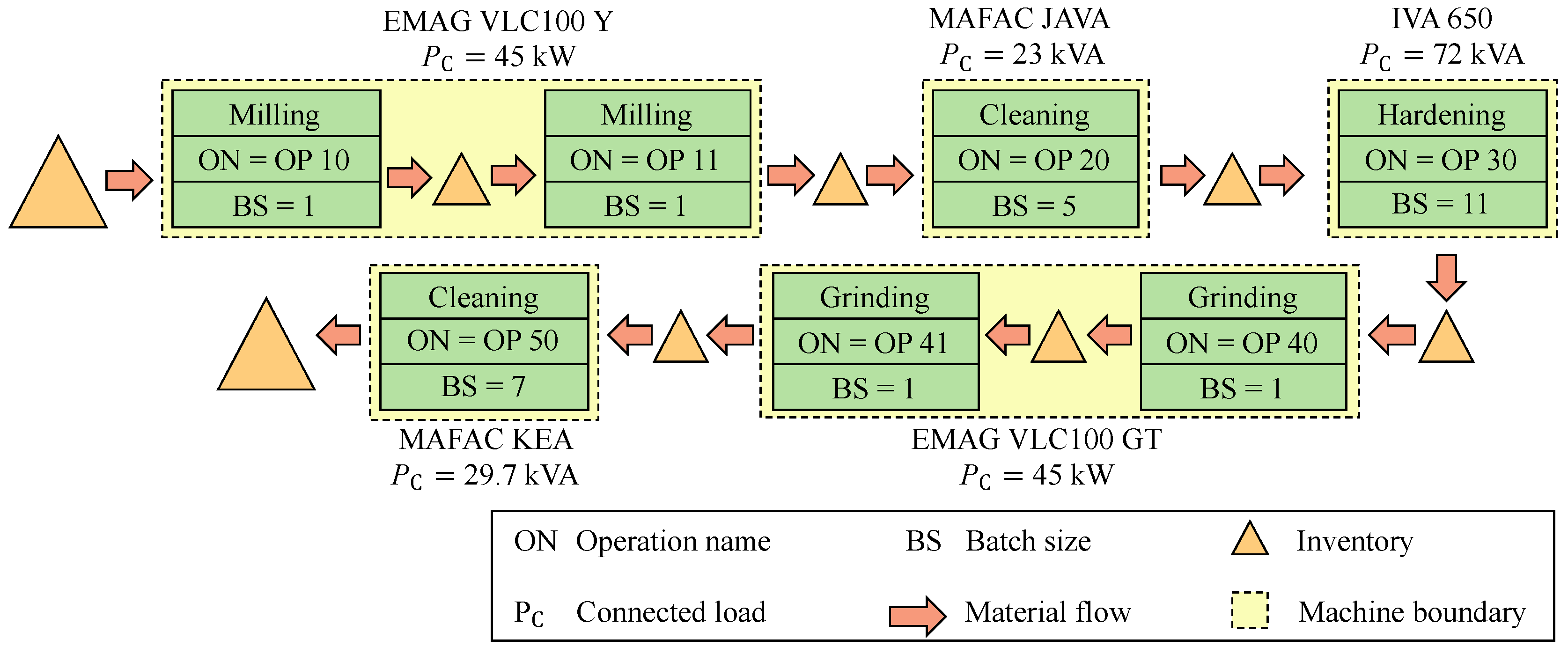

The process begins with machining blanks in the

EMAG VLC100 Y turning and milling center in two milling operations. This is followed by an intermediate water-based cleaning step in the

MAFAC JAVA cleaning machine. The parts then undergo a hardening process in the

IVA RH 655 gas nitriding furnace. Subsequently, two grinding operations are carried out on the

EMAG VLC100 GT grinding machine. Finally, the process concludes with water-based final cleaning in the

MAFAC KEA cleaning machine [

42]. An overview of the production line is presented in

Figure 5.

5.1. Relevant Machines and Energy-Related Information

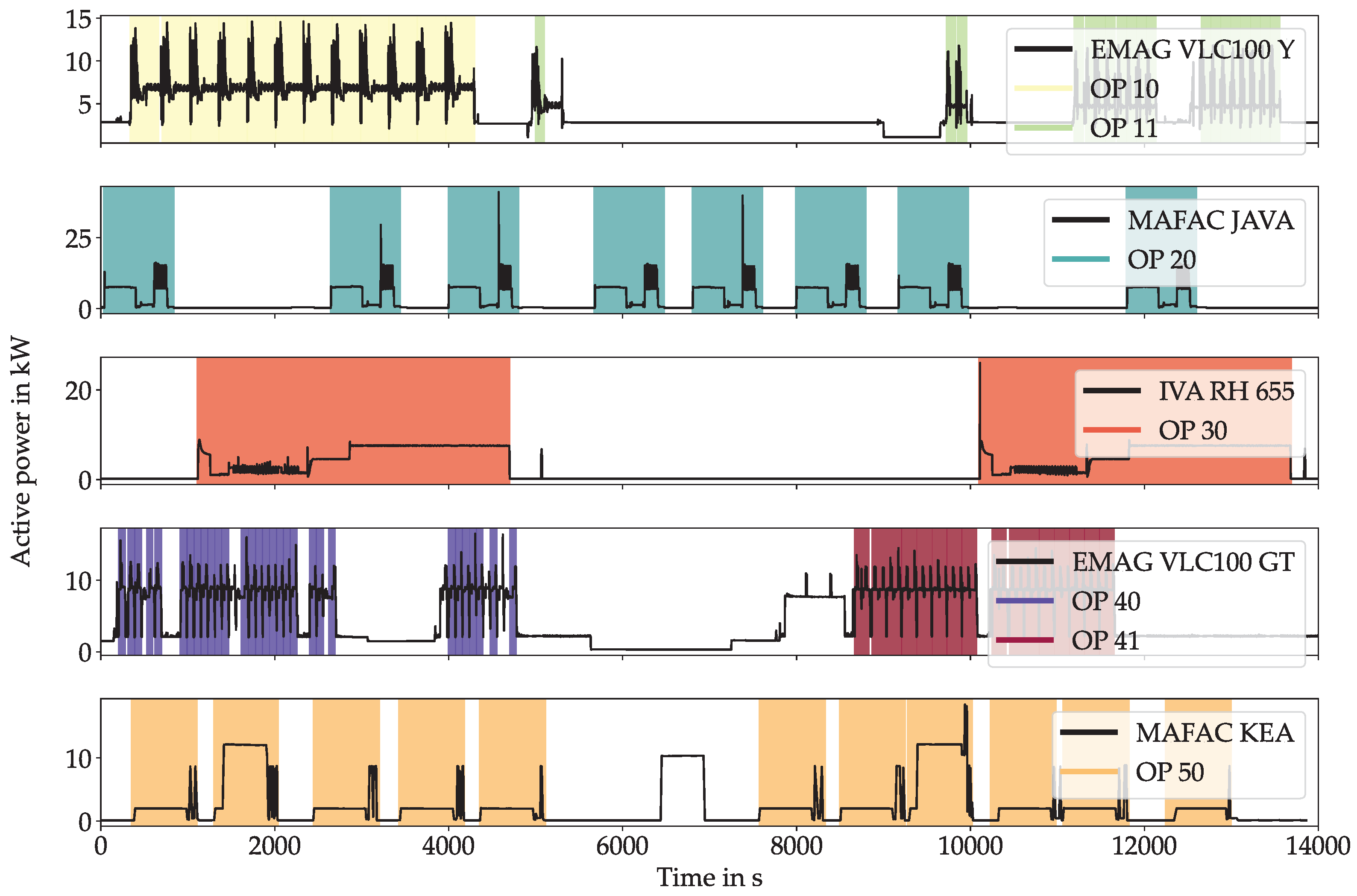

The described production line accounted for approximately 72 % of the total energy demand of the ETA factory in a representative period and thus represents the SEU. Therefore, the ES is developed for this production line. Other systems, such as supply equipment, are excluded from consideration since the machines themselves account for the majority of the electrical demand.

To assess energy performance at the line level for all machines, machining cycles are identified as energy-relevant information. Machining cycles refer to cyclically recurring manufacturing operations performed in the productive, value-adding state

working of a machine [

44]. In addition to this productive state, machines also have the unproductive, no value adding states

off,

standby,

operational, and

powering up/down [

45]. The productive state typically has the highest average power and energy demand [

44].

5.2. Energy Performance Indicators and Rule Base

Using machining cycles, EnPIs can be calculated to quantify unproductive time and energy shares, as well as energy differences between jobs. To describe the share of unproductive time, the non-production time factor

of a machine

m is employed, which represents the ratio of unproductive time

to the total observation period

[

46]:

The non-production energy factor

, defined as the ratio of unproductive energy demand

to the total energy demand

, quantifies the share of energy that does not contribute to value creation [

46]:

For both and , values close to 0 indicate a high productive share, while values close to 1 point to significant improvement potential.

To assess the potential for minimizing unproductive time, the minimum interruption-free unproductive time

and the maximum interruption-free unproductive time

across all non-productive time intervals

of a machine

m are identified. Subsequently the non-productive time ratio

is determined as the quotient of these values:

A value close to 1 indicates that the unproductive time intervals are almost evenly distributed, while a value close to 0 suggests that at least one unproductive time interval could potentially be shortened.

Additionally, the number of jobs

can be directly determined using machining cycles. The productive state can be characterized by the average energy per job

, the average energy per part of a job

and the energetic variance of a job

:

These EnPIs are subsequently normalized to values between 0 and 1 to serve as inputs for determining three output variables. The first output variable is the priority number for reducing unproductive energy share . The other two output variables are the priority number for reducing the unproductive time share and the priority number for minimizing productive energy . Analogous to the input variables, the output variables range between 0 and 1, with higher values indicating greater priority.

The inference of the output from the input variables is defined through a fuzzy rule base, partially presented in

Table 2. This involves first assigning membership functions to input and output variables. The selection of the membership function and its linguistic division, as in the following implementation in

very low,

low,

medium,

high,

very high, can be carried out by applying expert knowledge. The output variables are computed using Mamdani inference [

47]. For details on the specific selection of membership functions and the complete rule base comprising 45 rules, we refer to the implementation of this ES [

48].

Regarding the logic, the is based on the assumption that the can be reduced in particular if both this share and the are high. The rules for are designed to identify significant potential when higher values of are combined with lower values of . The final part of the rule base integrates the EnPIs , , and , where higher combined values indicate a potential optimization of the value-adding energy share.

5.3. Data Acquisition and Algorithm Development

To automatically extract energy-relevant information, i.e., machining cycles, and validate the ES, measurement data is acquired in the next step. This data consists of electrical active power, measured at the main power supply of the machines using the metering devices Janitza UMG 604 [

49] and transmitted at a sampling rate of 1 Hz via Modbus TCP. These measurements were recorded as part of the project KI4ETA (grant agreement No. 03EN2053A) and are available online [

6].

To detect the machining cycles, the algorithm from ref. [

34] was modified and extended. The algorithm identifies machining cycles by detecting recurring patterns, known as motifs, within time-series data. Users define representative sample patterns by specifying start and end indices, similarity thresholds, and job labels. The algorithm compares these patterns against the data using a pre-check step that evaluates statistical properties, such as mean and standard deviation, to ensure a high degree of similarity before conducting a full comparison. Once a match is detected, the algorithm calculates the energy of the pattern, based on the sum of squared deviations from the mean, to filter out noise and prioritize significant motifs. Overlapping motifs are resolved by selecting those with higher energy, ensuring non-redundant detection. Finally, the detected motifs are assigned to jobs, providing a structured output that maps machining cycles to their corresponding segments in the time-series data [

48].

5.4. Integration and Validation

During the previously outlined development steps, the individual artifacts are tested, validated, and refined as necessary. The final step involves integrating these artifacts into a comprehensive ES according to the schema shown in

Figure 4, which needs to be applied and validated. This subsection describes the quantitative validation of the implemented ES [

48] using the aforementioned measurement data [

6].

After the user specifies the case-specific knowledge, i.e. the start and end indices of representative machining cycles, via the

UserInterface, the ES identifies additional similar machining cycles and visualizes them along with the measurement data (see

Figure 6). Subsequently, the defined EnPIs and the derived priority numbers are calculated. The results for this application are listed in

Table 3.

Figure 6 shows that the algorithm achieves results comparable to those of human experts in recognizing machining cycles. A simplified version of this algorithm achieved an accuracy of up to 94.3 % using different test data [

34]. Additionally, the rule base and the comprehensive ES identify energy efficiency potentials that could also have been detected by human experts. Accordingly, the ES yields values of

and

of 0.92 for the observation period. Consequently, the machine

EMAG VLC100 GT is the hotspot in the production line for energy efficiency potentials related to non-value-adding states, particularly regarding the reduction of non-productive energy and time shares. Potential improvement measures proposed by experts could include optimizing machine utilization and implementing shutdown management for auxiliary units during non-value-adding periods. Next, according to the results, the machine

EMAG VLC100 Y should also be analyzed for these measures. On the other hand, with

MAFAC JAVA, the priority would only focus on reducing the non-productive time, but not on lowering the non-productive energy share. Regarding the optimization of the value-adding energy during machining individual parts, the highest priority lies with

= 0.5. In this process, increasing the batch size would improve the specific energy demand per part. In the event that only one part can be processed per machining cycle, which is the case with the aforementioned machine tools, coupled with a high

, it would be expedient to investigate an optimization of the actual machining process.

In addition to the automated derivation of prioritized energy efficiency potentials from measurement data, the ES includes detailed descriptions of all relevant information and intermediate results that support these conclusions. Each component of the ES can be individually modified as needed, for example, when a new machine is added to the process chain, EnPIs are expanded, or the rule base is adjusted, without affecting the system’s structure or overall functionality.

6. Summary and Conclusions

This paper presents a holistic framework for systematically developing ESs to improve energy efficiency in manufacturing. While previous research has demonstrated the potential of ESs in this domain, their development remained largely unsystematic, application-specific, and difficult to generalize, limiting scalability and transferability. This work addresses these limitations by introducing a methodology, that enables structured development while remaining adaptable to different manufacturing environments.

The proposed methodology is based on DSR and consists of three phases: conceptual design, implementation, and validation. The conceptual design defines all essential steps required for the development of an ES, including the identification of energy-relevant machines and information, the definition of EnPIs, the creation of a rule base, data acquisition and analytics, as well as the overarching integration. Concurrently, the implementation describes the steps for realization and is supported by the ESS4EE. As a modular and customizable Python-based template, ESS4EE facilitates software implementation. Finally, in the validation, the entire ES is rigorously assessed through quantitative and qualitative studies and iteratively refined as needed.

To demonstrate the feasibility and effectiveness of the methodology, it is applied to a metalworking production line in the ETA Factory. The implemented ES, covering five manufacturing machines and seven jobs, automatically detects machining cycles, calculates defined EnPIs, and prioritizes energy efficiency potentials based on the obtained data. The results of this case study highlight significant optimization opportunities, particularly in reducing non-productive energy share and improving machine utilization. For example, the system identified that the EMAG VLC100 GT exhibited the highest priority for energy-saving measures, with non-productive energy and time shares of 37.15 % and 66.01 %, respectively. Based on these insights, targeted interventions such as optimized shutdown management and improved production scheduling can be implemented to achieve energy savings. This study illustrates the practical benefits of a systematic, ES-based approach to energy efficiency in manufacturing. By embedding expert knowledge into a reusable software framework, the need for continuous expert intervention is reduced, scalability is improved, and the application is automated and standardized across different industrial contexts.

While the presented framework provides a structured approach, future developments could focus on further optimizing the software implementation. This could be achieved by extending the built-in library of ML models and algorithms to support common energy data analytics by experts and by integrating a predefined selection of frequently used EnPIs, which would reduce the initial system configuration effort. Another promising direction for further research is the integration of Large Language Models. These models could act as automated knowledge engineers that help formalize expert knowledge into structured rule bases and extend the knowledge base under the supervision of experts to ensure continuous learning and adaptation. Furthermore, extending the assessment to include flexibility potentials would support efforts to achieve climate neutrality in the industrial sector.

Author Contributions

Conceptualization, B.I.; methodology, B.I.; formal analysis, B.I.; investigation, B.I.; resources, M.W.; data curation, B.I.; writing—original draft preparation, B.I.; writing—review and editing, B.I., R.Z., O.O., and M.W.; visualization, B.I.; software, B.I.; validation, B.I.;, M.W.; project administration, B.I.; funding acquisition, M.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the German Federal Ministry of Economic Affairs and Climate Action (BMWK) within the project KI4ETA (grant number 03EN2053A).

Data Availability Statement

The dataset used to create

Figure 1, which includes a breakdown of energy consumption, CO

2 factors, and cost factors by energy carrier for the manufacturing industry in Germany in 2023, as well as the measurement data of the machines for the reported use case shown in

Figure 6, can be found at [

6]. The ESS4EE described in

Section 4 is available at [

38]. The implementation of the ES presented in

Section 5 is available at [

48].

Acknowledgments

The authors gratefully acknowledge financial support from the German Federal Ministry of Economic Affairs and Climate Action (BMWK) and project supervision by the project management Jülich (PtJ).

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CRISP-ML(Q) |

CRoss-Industry Standard Process model for the development of |

| |

Machine Learning applications with Quality assurance methodology |

| DSR |

Design Science Research |

| EMAS |

Eco-Management and Audit Scheme |

| EMS |

Environmental management system |

| EnB |

Energy baseline |

| EnEfG |

Energy Efficiency Act |

| EnMS |

Energy management system |

| EnPI |

Energy performance indicator |

| ES |

Expert system |

| ESS |

Expert system shell |

| ESS4EE |

Expert System Shell for Energy Efficiency |

| EU |

European Union |

| MDPI |

Multidisciplinary Digital Publishing Institute |

| ML |

Machine Learning |

| PDCA |

Plan-Do-Check-Act |

| SEU |

Significant energy use |

References

- European Parliament, Council of the European Union. Regulation (EU) 2021/1119. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32021R1119 (accessed on 07.12.2024).

- Metreau, E.; Kouame, Y. GDP ranking. Available online: https://datacatalog.worldbank.org/search/dataset/0038130/gdp_ranking (accessed on 07.12.2024). [CrossRef]

- Gütschow, J.; Jeffery, L.; Gieseke, R.; Günther, A. The PRIMAP-hist national historical emissions time series (1850-2017). [CrossRef]

- Federal Office of Justice. Federal Climate Action Act: KSG. Available online: https://www.gesetze-im-internet.de/ksg/KSG.pdf (accessed on 08.02.2025).

- Energieeffizienz in Zahlen: Entwicklungen und Trends in Deutschland 2022. Available online: https://www.bmwk.de/Redaktion/DE/Publikationen/Energie/energieeffizienz-in-zahlen-2022.pdf?__blob=publicationFile&v=7 (accessed on 08.02.2025).

- Ioshchikhes, B. Supplementary Material | A holistic framework for developing expert systems to improve energy efficiency in manufacturing. Available online: https://tudatalib.ulb.tu-darmstadt.de/handle/tudatalib/4396.2 (accessed on 22.02.2025).

- European Parliament, Council of the European Union. Directive (EU) 2023/1791. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=OJ:JOL_2023_231_R_0001 (accessed on 08.02.2025).

- ABB Ltd. Accelerating Ambition: How global industry is speeding up investment in energy efficiency. Available online: https://www.energyefficiencymovement.com/wp-content/uploads/2022/04/ABB-Energy-Efficiency-Survey-Report-2022.pdf (accessed on 08.12.2024).

- International Energy Agency. Energy Efficiency 2024. Available online: https://www.iea.org/reports/energy-efficiency-2024 (accessed on 08.12.2024).

- Ioshchikhes, B.; Elserafi, G.; Weigold, M. An Expert System-Based Approach For Improving Energy Efficiency Of Chamber Cleaning Machines. In Proceedings of the Conference on Production Systems and Logistics (CPSL 2023); publish-Ing.: Offenburg, 2023. [CrossRef]

- Ioshchikhes, B.; Frank, M.; Weigold, M. A Systematic Review of Expert Systems for Improving Energy Efficiency in the Manufacturing Industry. Energies 2024, 17, 4780. [Google Scholar] [CrossRef]

- Ioshchikhes, B.; Frank, M.; Elserafi, G.; Magin, J.; Weigold, M. Developing Expert Systems for Improving Energy Efficiency in Manufacturing: A Case Study on Parts Cleaning. Energies 2024, 17, 3417. [Google Scholar] [CrossRef]

- Buccieri, G.P.; Balestieri, J.A.P.; Matelli, J.A. Energy efficiency in Brazilian industrial plants: knowledge management and applications through an expert system. JOURNAL OF THE BRAZILIAN SOCIETY OF MECHANICAL SCIENCES AND ENGINEERING 2020, 42. [Google Scholar] [CrossRef]

- Li, P.; Lu, Y.; Qian, Y.; Wang, Y.; Liang, W. An explanatory parametric model to predict comprehensive post-commissioning building performances. Building and Environment 2022, 213, 108897. [Google Scholar] [CrossRef]

- Bundesministerium der Justiz. Gesetz zur Steigerung der Energieeffizienz in Deutschland: (Energieeffizienzgesetz - EnEfG). Available online: https://www.gesetze-im-internet.de/enefg/BJNR1350B0023.html (accessed on 2024-12-11).

- European Parliament, Council of the European Union. Consolidated text: Regulation (EC) No 1221/2009. Available online: http://data.europa.eu/eli/reg/2009/1221/2023-07-12 (accessed on 02.01.2025).

- DIN Deutsches Institut für Normung e. V.. Energiemanagementsysteme – Anforderungen mit Anleitung zur Anwendung (ISO 50001:2018); Deutsche Fassung EN ISO 50001:2018, 2018.

- VDI Verein Deutscher Ingenieure e.V.. Energy management - Fundamentals, 04.2018.

- Agnar Aamodt.; Mads Nygård. Different roles and mutual dependencies of data, information, and knowledge — An AI perspective on their integration. Data & Knowledge Engineering 1995, 16, 191–222. [CrossRef]

- North, K. Wissensorientierte Unternehmensführung: Wertschöpfung durch Wissen, 5th ed.; Gabler Verlag: Wiesbaden, 2011. [Google Scholar] [CrossRef]

- Rehäuser, J.; Krcmar, H. Wissensmanagement im Unternehmen. In Wissensmanagement; Georg Schreyögg.; Peter Conrad., Eds.; De Gruyter: Berlin, Boston, 1996; pp. 1–40. [CrossRef]

- DeTore, A.W. An introduction to expert systems. Journal of insurance Medicine 1989, 21, 233–236. [Google Scholar]

- Puppe, F. Einführung in Expertensysteme, 2nd ed.; Studienreihe Informatik: New York; Springer: Berlin, 1991. [Google Scholar]

- Lutz, B.; Moldaschl, M. Expertensysteme und industrielle Facharbeit: ein Gutachten über denkbare qualifiktorische Auswirkungen von Expertensystemen in der fertigenden Industrie; erstellt im Auftrag der Enquete-Kommission "Technikfolgenabschätzung und -bewertung" des Deutschen Bundestages; Forschungsberichte aus dem Institut für Sozialwissenschaftliche Forschung e.V, Campus Verl.: Frankfurt am Main, 1989.

- Jackson, P. Introduction to Expert Systems, 3rd ed.; Addison-Wesley Longman Publishing Co., Inc: USA, 1998. [Google Scholar]

- Styczynski, Z.A.; Rudion, K.; Naumann, A. Einführung in Expertensysteme; Springer Berlin Heidelberg: Berlin, Heidelberg, 2017. [Google Scholar] [CrossRef]

- Wehking, K.H. Technisches Handbuch Logistik 2; Springer Berlin Heidelberg: Berlin, Heidelberg, 2020. [Google Scholar] [CrossRef]

- Ioshchikhes, B.; Frank, M.; Joseph, T.M.; Weigold, M. Improving Energy Efficiency in Manufacturing: A Novel Expert System Shell, 2024. [CrossRef]

- Hevner, A.; R, A.; March, S.; T, S.; Park.; Park, J.; Ram.; Sudha. Design Science in Information Systems Research. Management Information Systems Quarterly 2004, 28, 75–105. [CrossRef]

- vom Brocke, J.; Hevner, A.; Maedche, A. (Eds.) Design Science Research. Cases; Progress in IS, Springer International Publishing: Cham, 2020. [Google Scholar] [CrossRef]

- Ferreira, B.; Silva, W.; Barbosa, S.D.; Conte, T. Technique for representing requirements using personas: a controlled experiment. IET Software 2018, 12, 280–290. [Google Scholar] [CrossRef]

- Thiede, S. Energy efficiency in manufacturing systems: Zugl.: Braunschweig, Techn. Univ., Diss., 2011; Sustainable production, life cycle engineering and management, Springer: Berlin, 2011. [Google Scholar]

- Petruschke, L.; Elserafi, G.; Ioshchikhes, B.; Weigold, M. Machine learning based identification of energy efficiency measures for machine tools using load profiles and machine specific meta data. MM Science Journal 2021, 2021, 5061–5068. [Google Scholar] [CrossRef]

- Ioshchikhes, B.; Heller, P.; Weigold, M. Machining Cycle Detection Based Expert System for Improving Energy Efficiency in Manufacturing. In Sustainable Manufacturing as a Driver for Growth; Kohl, H., Seliger, G., Dietrich, F., Mur, S., Eds.; Lecture Notes in Mechanical Engineering, Springer Nature Switzerland: Cham, 2025; pp. 659–667. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung e.V.. Energiemanagementsysteme - Bewertung der Energieleistung anhand von Energieleistungskennzahlen und energetischen Ausgangsbasen (ISO 50006:2023), 14.06.2024.

- Liao, S.H. Expert system methodologies and applications—a decade review from 1995 to 2004. Expert Systems with Applications 2005, 28, 93–103. [Google Scholar] [CrossRef]

- Studer, S.; Bui, T.B.; Drescher, C.; Hanuschkin, A.; Winkler, L.; Peters, S.; Müller, K.R. Towards CRISP-ML(Q): A Machine Learning Process Model with Quality Assurance Methodology. Machine Learning and Knowledge Extraction 2021, 3, 392–413. [Google Scholar] [CrossRef]

- Ioshchikhes, B.; Yoldas, C.; Horn, L.; Asl, N.A.; Zimmer, L.; Wigandt, A. Expert System Shell for Energy Efficiency (ESS4EE). Available online: https://github.com/Borika95/ESS4EE (accessed on 14.02.2025).

- Kluyver, T.; Ragan-Kelley, B.; Pérez, F.; Granger, B.; Bussonnier, M.; Frederic, J.; Kelley, K.; Hamrick, J.; Grout, J.; Corlay, S.; et al. Jupyter Notebooks – a publishing format for reproducible computational workflows. In Proceedings of the Positioning and Power in Academic Publishing: Players, Agents and Agendas. IOS Press, 2016, pp. 87–90. [CrossRef]

- Abele, E.; Schneider, J.; Beck, M.; Maier, A. ETA - die Modell-Fabrik: Energieeffizienz weiter gedacht. Available online: http://tubiblio.ulb.tu-darmstadt.de/105750/ (accessed on 14.02.2025).

- Sossenheimer, J. Hybrides Energiemessstellenkonzept zum ganzheitlichen Energiemonitoring von Fertigungsmaschinen und Komponenten; Shaker Verlag, 2023.

- Walther, J. Hierarchical Electrical Load Forecasting of Industrial Production Systems in the Manufacturing Industry based on Deep Learning, 2022. [CrossRef]

- Erlach, K.; Westkämper, E. (Eds.) Energiewertstrom: Der Weg zur energieeffizienten Fabrik; Fraunhofer Verl.: Stuttgart, 2009. [Google Scholar]

- Seevers, J.P.; Jurczyk, K.; Meschede, H.; Hesselbach, J.; Sutherland, J.W. Automatic Detection of Manufacturing Equipment Cycles Using Time Series. Journal of Computing and Information Science in Engineering 2020, 20. [Google Scholar] [CrossRef]

- VDMA. Messvorschrift zur Bestimmung des Energie- und Medienbedarfs von Werkzeugmaschinen in der Serienfertigung: Verband Deutscher Maschinen- und Anlagenbau e.V., 04/2019.

- Dehning, P.; Blume, S.; Dér, A.; Flick, D.; Herrmann, C.; Thiede, S. Load profile analysis for reducing energy demands of production systems in non-production times. Applied Energy 2019, 237, 117–130. [Google Scholar] [CrossRef]

- Mamdani, E.H.; Assilian, S. An experiment in linguistic synthesis with a fuzzy logic controller. International Journal of Man-Machine Studies 1975, 7, 1–13. [Google Scholar] [CrossRef]

- Ioshchikhes, B. ES4EE_ETAFactory. Available online: https://github.com/Borika95/ES4EE_ETAFactory. https://doi.org/tba.

- POWER ANALYZER UMG 604-PRO. Available online: https://www.janitza.com/us/umg-604-pro.html (accessed on 23.01.2025).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).