1. Introduction to Bioinspired Soft Machines

Soft machines stand at the forefront of technological innovation, aiming to replicate the remarkable capabilities of biological systems in artificial machines. By mimicking the flexibility and adaptability observed in nature, soft machines have the potential to revolutionize various industries and applications [

1]. Bioinspired materials play a key role in this field, offering unique properties that enable robots to interact safely and effectively with their environment. The significance of bioinspired materials in soft machines lies in their ability to infuse robots with characteristics parallel to living organisms [

2]. These materials are carefully selected to mimic the mechanical properties of biological tissues, allowing soft machines to move with agility, conform to different surfaces, and interact delicately with objects and living beings [

3]. Through bioinspired design principles, researchers aim to create robots that can navigate complex environments with ease and perform tasks that were once reserved for living creatures [

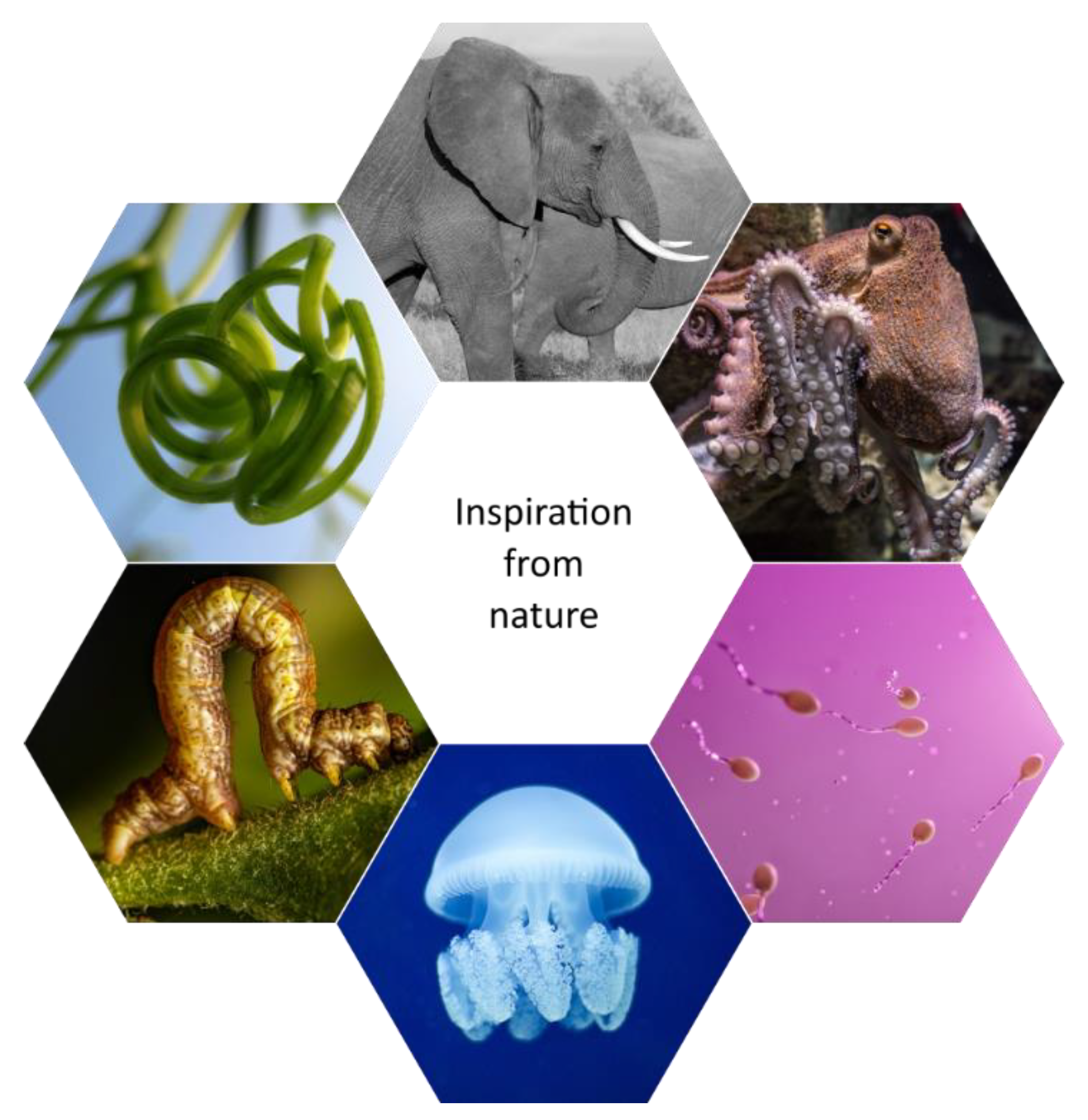

4]. The three most important characteristics of soft machines are their flexibility, adaptability, and resilience in their motion, enabling them to navigate complex environments, interact safely with humans, and perform delicate tasks with precision as inspired from different scale body parts in animal kingdom shown in

Figure 1.

Research in bioinspired soft machines focuses on material selection, actuation mechanisms, and mechanical design to enhance the performance and adaptability of robots. By drawing inspiration from nature's blueprints, scientists are pushing the boundaries of robot capabilities, paving the way for machines that can efficiently integrate into natural environments and interact harmoniously with humans [

5]. The exploration of bioinspired soft machines opens up possibilities for creating machines that not only mimic biological systems but also surpass them in certain aspects. By harnessing the power of bioinspired materials, researchers are unlocking new avenues for innovation in robotics, leading to a future where soft machines can navigate unpredictable environments efficiently [

6].

2. Understanding Biological Inspiration

Nature has long served as a source of inspiration for human innovation, and in the realm of soft machines, the study of biological systems has proven particularly fruitful. One of the most captivating aspects of biology is how animals exploit soft structures to navigate their environments with remarkable proficiency and adaptability [

7]. Understanding these biological inspirations not only sheds light on the fine details of natural systems but also provides valuable insights for the design and development of soft robotic technologies [

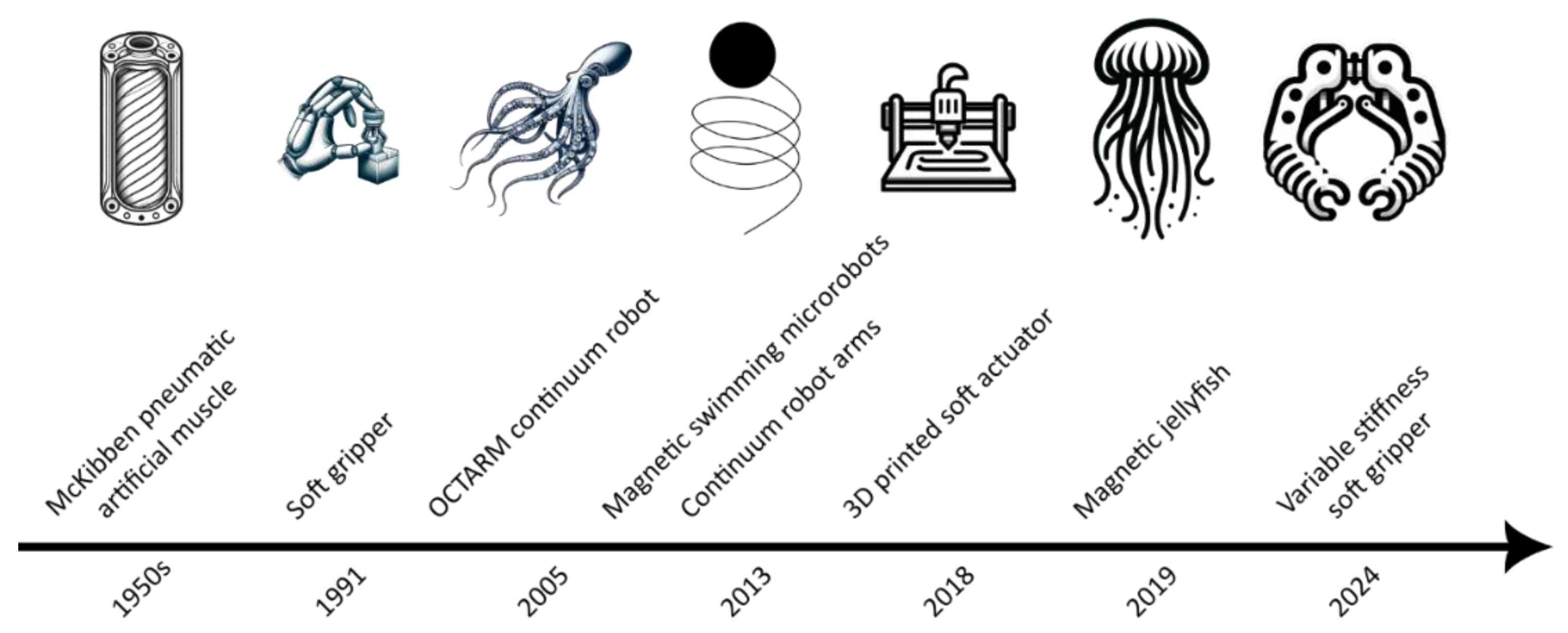

8]. As shown in

Figure 2, the timeline for the bioinspired soft machines encompasses the evolution of soft machines from its inception, highlighting key milestones where interdisciplinary efforts in biology, materials science, and engineering have converged to shape the field. Through exploration of nature's elegant solutions and ongoing advancements in bioinspired materials, the narrative traces the trajectory towards designing robots that mimic the adaptability and versatility found in natural organisms. This timeline underscores the collaborative efforts driving innovation in soft machines, leading to robots integrating into complex environments, having the potential to offer transformative solutions to societal challenges.

Animals ranging from cephalopods to mammals leverage the inherent flexibility and dexterity of soft structures to achieve a diverse array of movements and tasks. For instance, the octopus is a creature renowned for its ability to contort its body and manipulate objects with astonishing agility. The octopus achieves such feats through the coordination of its soft, muscular tentacles, which exhibit a level of flexibility and responsiveness unparalleled in the realm of robotics [

9]. By mimicking the mechanics of these tentacles, engineers have developed soft robotic arms capable of navigating confined spaces and delicately manipulating objects with a finesse reminiscent of their biological counterparts [

10].

Similarly, the elephant provides another compelling example of nature's ingenuity in soft locomotion. Despite its massive size, the elephant possesses a trunk endowed with a remarkable degree of flexibility and strength. This multifunctional trunk serves as both a sensory organ and a versatile tool for grasping and manipulating objects in its environment [

11]. By emulating the structural properties and functionalities of the elephant trunk, researchers have created soft robotic grippers capable of gripping objects of various shapes and sizes with remarkable precision and efficiency [

12,

13].

These examples underscore the remarkable adaptability and efficiency of soft structures in biological systems, providing inspiration for the design and development of innovative soft robotic technologies. By studying and emulating nature's solutions to complex challenges, researchers can unlock new avenues for enhancing the capabilities of soft machines in a wide range of applications, from healthcare to manufacturing to exploration [

14]. The survey of biological inspirations for soft machines offers a wealth of insights into the remarkable capabilities of natural systems. By drawing inspiration from creatures such as the octopus and the elephant, researchers can develop soft robotic technologies that not only emulate the agility and adaptability of their biological counterparts but also push the boundaries of what is possible in the field of robotics. Our understanding of biology will continue to grow, and so will our ability to harness nature's ingenuity to drive innovation in soft machines [

15].

3. Materials Selection in Soft Machines

The choice of materials is paramount in the design and development of soft machines, as it directly influences their performance, functionality, and potential applications [

16,

17]. Unlike traditional rigid robots, soft machines rely on pliable materials that can deform and adapt to their environment, enabling them to navigate complex and dynamic settings with ease [

18]. In this section, the importance of materials selection in soft machines is explored, highlighting various types of soft materials, and discussing key considerations for material properties.

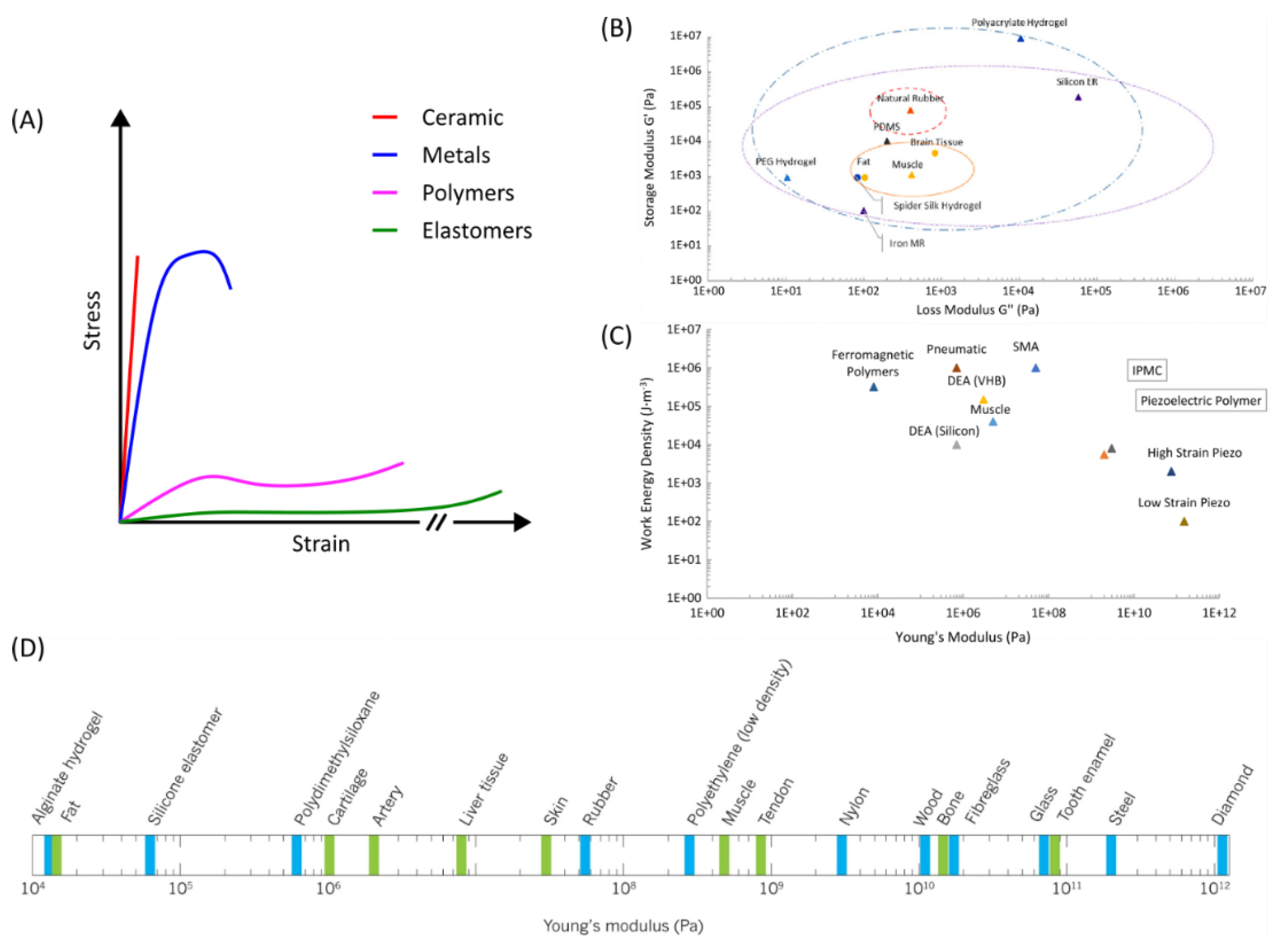

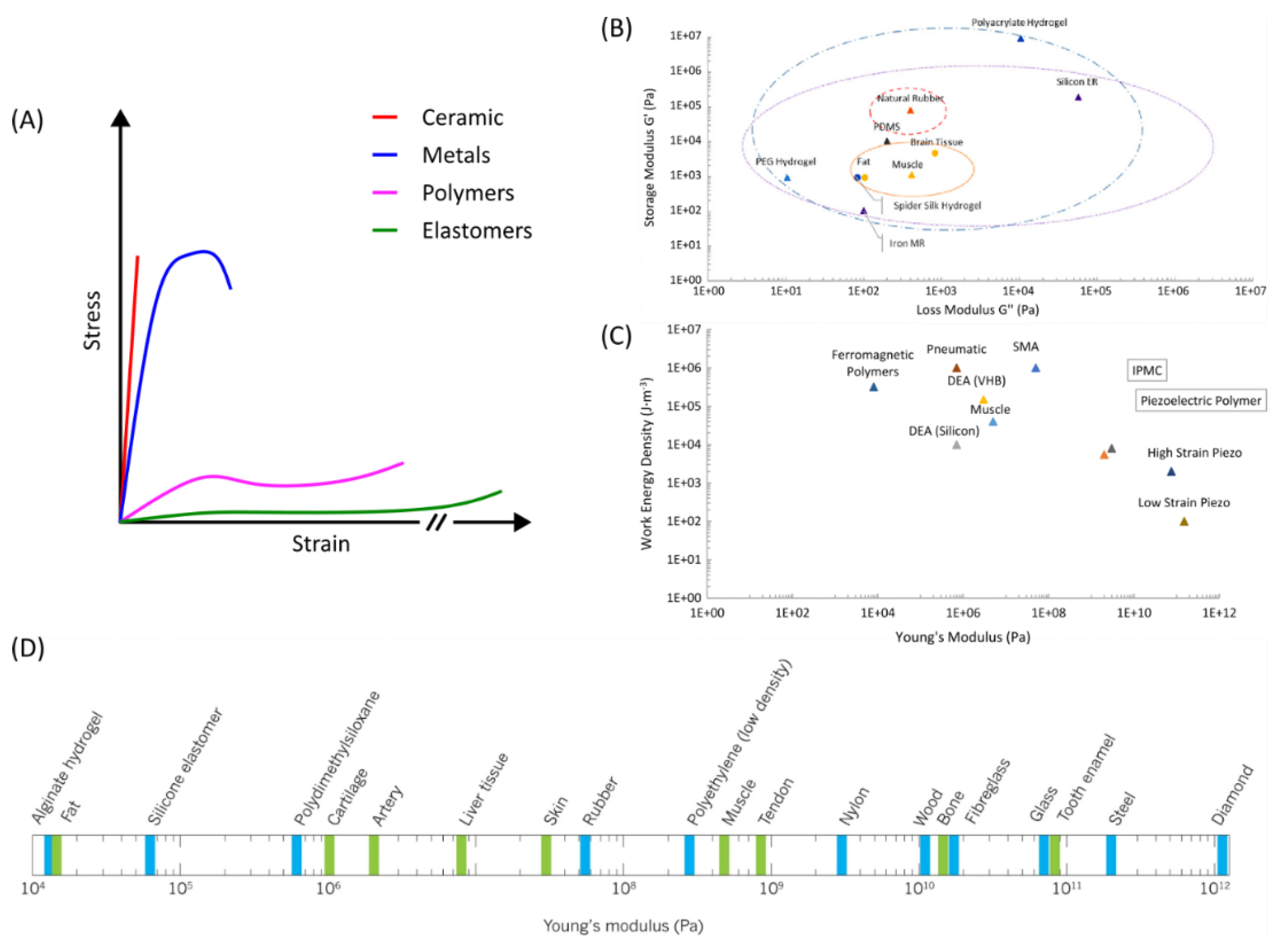

Unlike rigid materials commonly used in traditional robotics, soft materials possess unique mechanical properties such as flexibility, elasticity, and compliance, allowing soft machines to interact safely and effectively with their surroundings as depicted in

Figure 3 [

19]. The choice of materials influences not only the mechanical behavior of soft machines but also factors such as weight, cost, and manufacturability [

20]. A diverse array of soft materials is available for use in soft machines, each offering distinct advantages and limitations. Elastomers, such as silicone rubbers and polyurethanes, are commonly used in soft machines due to their excellent elasticity and durability [

21]. These materials can undergo large deformations without permanent damage, making them well-suited for applications requiring compliant and stretchable structures [

22].

Hydrogels represent another class of soft materials with unique properties, including high water content and tunable mechanical properties [

24]. Hydrogels exhibit similarities to biological tissues, making them suitable for applications such as biomedical devices and soft actuators [

25]. Shape-memory polymers, on the other hand, offer the ability to recover their original shape upon exposure to external stimuli, enabling programmable and reversible deformations in soft robotic systems [

26]. When selecting materials for soft machines, several key considerations must be taken into account to ensure optimal performance and functionality [

27]. Flexibility is a critical property, allowing soft machines to deform and conform to their environment while maintaining structural integrity (

Figure 3A). Choosing viscoelastic materials allows soft machines to dissipate energy and maintain stable motion during dynamical loading. The viscoelastic behavior is often described in terms of the storage and loss modulii (

Figure 3B). Durability is also essential, particularly in applications subject to repeated or prolonged mechanical stresses [

28]. Another important metric is the work energy density of materials. The higher the energy density of the actuator the less volume needed to meet the design objective. There seems to be a trade-off between stiffness with the energy density of materials as seen in

Figure 3C. Stiffer materials tend to have higher energy densities but are less compliant. To achieve compliance matching, materials with similar Young’s Modulus as some soft biological material can be considered (

Figure 3D). Biological cells and tissue itself can also be used directly as materials for soft machines [

29,

30]. Considerations such as biocompatibility are crucial for applications involving interaction with biological systems, ensuring compatibility and safety [

31]. Therefore, materials selection plays a central role in the design and development of soft machines, influencing their mechanical behavior, functionality, and potential applications [

32].

Table 1 gives key aspects of bioinspired materials used in soft machines.

Considering factors such as flexibility, durability, and biocompatibility, the unique properties of soft materials can be harnessed to create innovative and versatile soft robotic systems capable of addressing a wide range of challenges across various domains [

33].

Table 2 further exemplifies the practical application of these principles, showcasing a range of bio-inspired products currently available in the market. This selection highlights the diverse and innovative ways in which bioinspired materials are being utilized across various industries.

4. Actuation Mechanisms in Bioinspired Soft Machines

Soft machines, inspired by the capabilities of biological systems, has witnessed significant advancements in actuation mechanisms, enabling robots to exhibit lifelike movements and behaviors [

41]. In this section, an overview of different actuation methods used in soft machines is provided, bioinspired actuation mechanisms are examined, and the advantages and challenges associated with each approach are discussed.

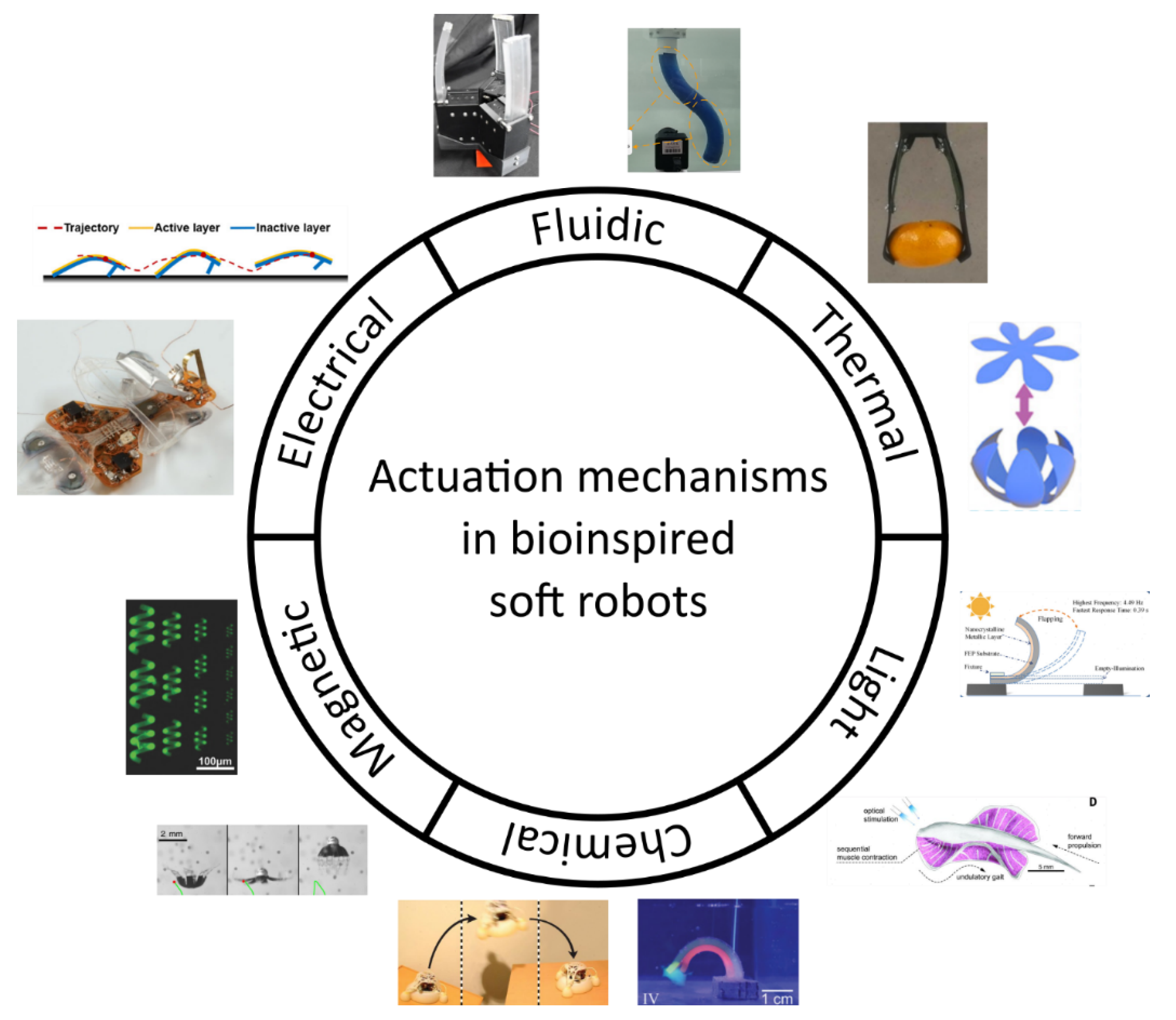

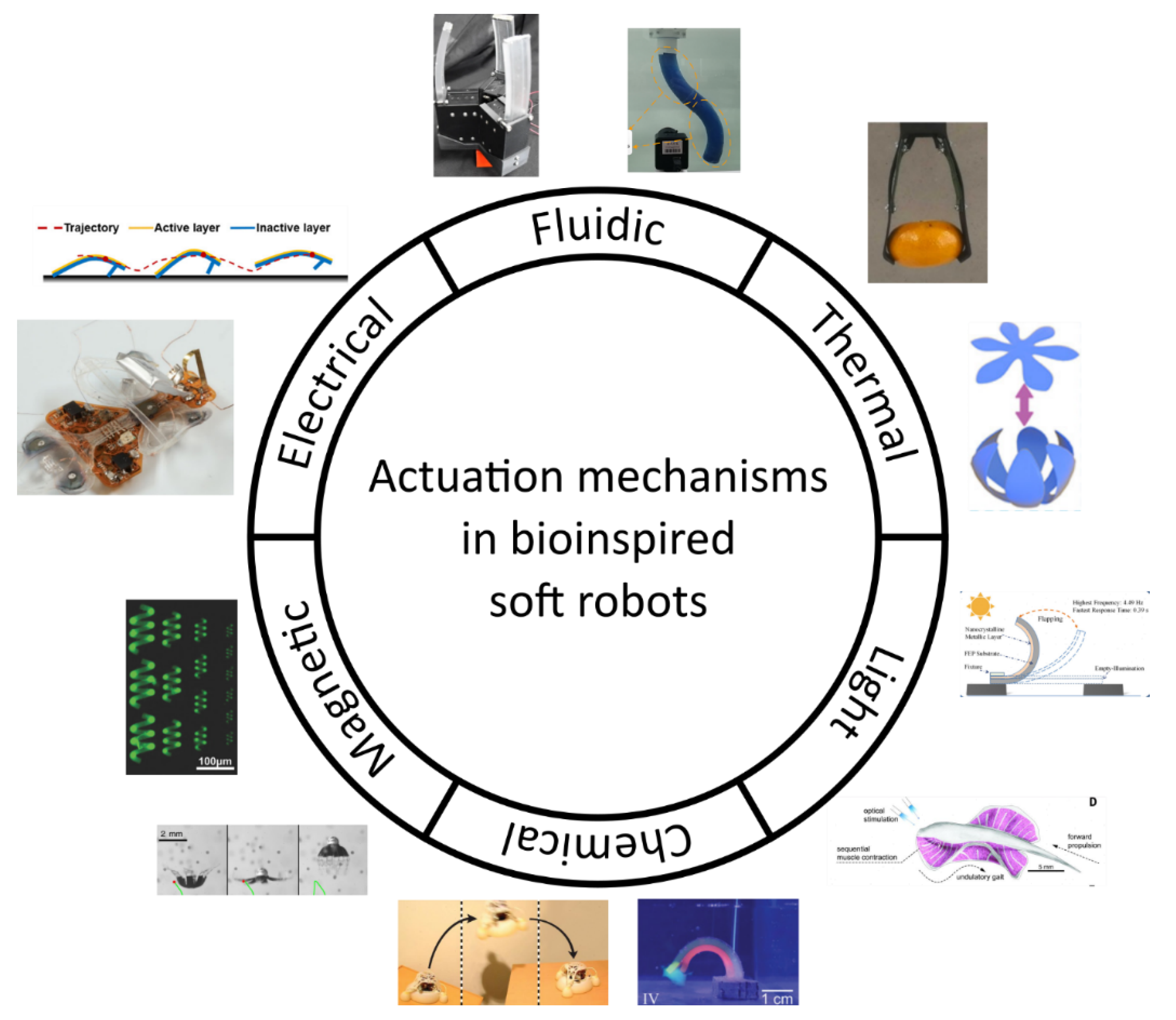

Soft machines utilize a variety of stimuli or actuation methods (

Figure 4), each offering unique advantages and challenges. Pneumatic actuation relies on the use of pressurized air or gas to deform soft structures, enabling smooth and versatile movements [

42]. Additionally, pneumatic networks represent another bioinspired approach to actuation, mimicking the distributed network of muscles and tendons found in biological organisms. By embedding channels within soft structures and selectively pressurizing them, soft machines can achieve complex movements and deformations, reminiscent of natural locomotion [

43]. Hydraulic actuation, similar in principle to pneumatic actuation, uses pressurized liquid instead of gas, offering increased power and precision in certain applications [

44]. Electric actuation, on the other hand, involves the use of electrically driven components such as shape-memory alloys or electroactive polymers to induce deformations in soft materials, providing precise control and responsiveness [

45]. Muscle-like actuators, for example, emulate the contractile properties of biological muscles, enabling soft machines to exhibit dynamic and adaptive movements [

46]. These actuators can be fabricated using materials such as dielectric elastomers or pneumatic artificial muscles, offering a high degree of compliance and controllability [

47]. Magnetic actuation involves the use of magnetic fields and gradients to manipulate hard or soft magnetic materials [

48]. Thermally responsive actuators include those activated by infrared (IR), NIR, thermal radiation, and Joule heating. Light-responsive materials are based on photochromic molecules which capture optical signals and convert them into different property modifications. Chemical based actuators utilize different chemical reactions to either produce energy or phase change which actuates the robot [

49].

Examples of some soft robots based on these actuation methods are given in

Figure 5. Each actuation method in soft machines offers distinct advantages and faces unique challenges. Pneumatic actuation, for instance, provides excellent compliance and adaptability but may suffer from limited power and response time. Hydraulic actuation offers increased power and precision but may be constrained by the complexity of fluid management systems. Electric actuation provides precise control and responsiveness but may require complex electronic components and power sources [

50]. Magnetic actuation provides remote actuation abilities and excellent controllability but suffers from low actuation forces [

51]. Thermal actuation provides a safe trigger but can be slow. Light actuation is advantageous in terms of its remote nature, but it requires a direct line of sight with the actuator. Chemical actuation can provide strong actuation forces but suffers from low controllability [

49].

Bioinspired actuation mechanisms offer the potential for soft machines to emulate natural movements and behaviors convincingly, but they also present challenges in terms of scalability, efficiency, and control. Overcoming these challenges requires interdisciplinary collaboration and innovative approaches that leverage insights from biology, materials science, and engineering [

64]. By drawing inspiration from biological systems and exploring innovative actuation methods, researchers and engineers can unlock new possibilities for soft machines, enabling robots to exhibit lifelike movements and behaviors in a wide range of applications [

65].

5. Mechanical Design for Adaptive Functionality

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn. In the realm of soft machines, mechanical design plays a pivotal role in enabling robots to achieve adaptive functionality, mimicking the versatility and resilience observed in natural organisms [

66]. The significance of mechanical design in soft machines is explored in this section. Flexible and reconfigurable designs inspired by nature are also discussed, and case studies showcasing bioinspired mechanical innovations are presented.

Unlike traditional rigid robots, which are constrained by fixed geometries and limited degrees of freedom, soft machines possess inherent flexibility and deformability, allowing them to navigate complex environments and perform a wide range of tasks. Organisms ranging from plants to animals exhibit remarkable adaptability and resilience, achieved through ingenious mechanical structures and mechanisms [

67]. By emulating the principles underlying natural systems, engineers can develop soft machines capable of adapting to diverse tasks and environments with ease [

68]. The mechanical design of soft machines must therefore prioritize characteristics such as compliance, resilience, and adaptability to enable robust and versatile functionality [

69,

70].

Few key points for mechanical design for adaptive functionality are as follows:

Design Inspiration: Bioinspired designs to achieve lifelike movements. By mimicking nature's mechanics, soft machines can adapt to their environment and manipulate objects effectively [

23]. For example, bioinspired Fluid-Filled Soft Linear Actuator: A novel fluidic actuator inspired by marine worms has been developed, combining pneumatic and hydraulic principles to create a unique fluidic transmission mechanism. This innovative design aims to enhance soft machines with increased stretch ability and output forces [

71]. Soft grippers, inspired by the dexterity of octopus tentacles and human hands, employ flexible and compliant structures to grasp objects of varying shapes and sizes with precision and versatility [

72]. These grippers leverage principles such as differential stiffness and under-actuation to achieve robust and adaptive grasping capabilities, enabling applications in fields such as manufacturing, healthcare, and exploration [

73]. Similarly, locomotion mechanisms in soft machines draw inspiration from the diverse modes of movement observed in nature, ranging from crawling and slithering to swimming and flying [

74]. Bioinspired designs such as soft robotic worms and snake-like robots utilize segmented and undulating bodies to navigate complex terrains and confined spaces, mirroring the locomotive strategies of their biological counterparts [

75].

Materials for Soft machines: The integration of bioinspired materials and approaches in soft machines enables robots to acquire life-like abilities, self-repair, self-feed, adapt, and biodegrade. For example, the structure of plant tendrils, which can curl and wrap around objects to support climbing, inspires the design of flexible gripping mechanisms in soft machines [

68]. Advances in materials science play a crucial role in pushing the boundaries of biomimetic robotics [

3]. Understanding the mechanical properties of natural materials guides the successful development of soft robotic systems [

76].

Biology to autonomous Soft machines: Research explores the bioinspired aspects of soft machines, focusing on actuation, sensing, and system integration. The trend is towards closed-loop systems and embodiment to achieve autonomous soft machines [

6].

The continued advancement of bioinspired mechanical designs holds promise for the development of soft machines technologies that can truly integrate and interact with the natural world [

77].

6. Embodied Intelligence in Bioinspired Soft Machines

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

Embodied intelligence lies at the heart of bioinspired soft machines, leveraging the inherent properties of soft materials to achieve adaptive and versatile behaviors [

78,

79,

80]. In this section, the concept of embodied intelligence, its relevance in soft machines, and the unique contributions of soft materials to this paradigm shift are discussed. Furthermore, the advantages of embodied intelligence over traditional algorithmic approaches in robotics are highlighted.

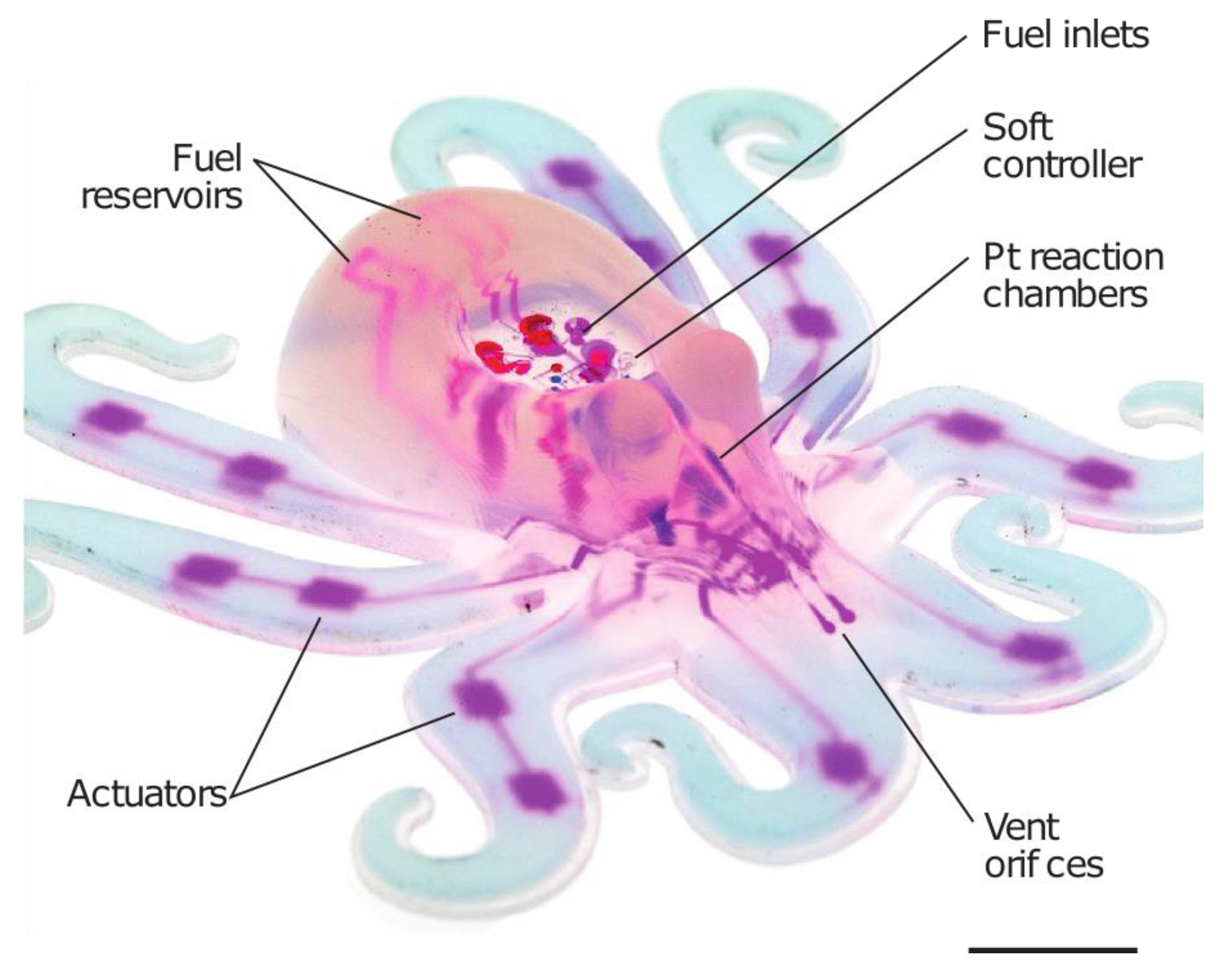

Figure 6.

Soft Materials and Embodied Intelligence in Soft machines inspired from Octopus realized with microfluidic actuation: This figure highlights the contributions, relevance, and advantages of soft materials in embodied intelligence within soft machines, using the octopus as a prime example. Soft materials enable robots to achieve complex and adaptable movements, akin to the dexterity and versatility observed in the octopus. This illustration underscores the pivotal role of soft materials in enhancing the functionality and efficiency of soft robotic systems, paving the way for innovative applications across various domains. Reproduced with permission [

81]. Copyright 2016, Springer Nature Limited. Scale bar: 10mm.

Figure 6.

Soft Materials and Embodied Intelligence in Soft machines inspired from Octopus realized with microfluidic actuation: This figure highlights the contributions, relevance, and advantages of soft materials in embodied intelligence within soft machines, using the octopus as a prime example. Soft materials enable robots to achieve complex and adaptable movements, akin to the dexterity and versatility observed in the octopus. This illustration underscores the pivotal role of soft materials in enhancing the functionality and efficiency of soft robotic systems, paving the way for innovative applications across various domains. Reproduced with permission [

81]. Copyright 2016, Springer Nature Limited. Scale bar: 10mm.

Embodied intelligence refers to the integration of perception, action, and cognition within the physical body of a robotic system, enabling it to interact with its environment in a dynamic and adaptive manner [

23,

82]. Traditional robots often rely on centralized control architectures and explicit programming to execute tasks, which can be computationally intensive and brittle in the face of uncertainty and variability. In contrast, embodied intelligent systems leverage the intrinsic capabilities of their bodies and the principles of self-organization to generate robust and adaptive behaviors without the need for explicit instructions. Unlike traditional robots, which rely heavily on pre-programmed algorithms to execute specific tasks, embodied intelligent systems derive their behaviors from the interactions between their bodies, sensors, and surroundings. This approach mirrors the decentralized and emergent nature of intelligence observed in biological organisms, allowing soft machines to exhibit lifelike movements and behaviors without the need for complex computation [

83,

84]. It also allows soft machines to navigate unpredictable environments, interact with complex objects, and learn from experience in a manner that closely resembles biological organisms [

85,

86]. Therefore, the intrinsic properties of soft materials play a crucial role in enabling embodied intelligence in bioinspired soft machines [

87]. The integration of embodied intelligence simplifies principles for robot control by focusing on control parameters, albeit introducing complexities in robot design [

88]. As shown in

Figure 6, by exploiting these properties, soft machines can exhibit a form of "embodied cognition," where their physical bodies serve as a substrate for intelligence, enabling them to perceive, process, and respond to sensory stimuli in real time [

89]. In all such examples, soft bodyware is essential for obtaining emergent behaviors from external interactions, highlighting the interconnected nature of embodied intelligence and soft machines [

88].

The main advantage of soft materials for embodied intelligence in soft machines is the adaptability. Soft machines with embodied intelligence can think autonomously based on sensory inputs, enabling human-like interactions with the environment and enhancing adaptability in complex and changing geometries. By mimicking the neural networks of living organisms, these robots can exhibit complex behaviors, learn from interactions, and adapt to changing conditions autonomously [

90]. Embodied intelligence allows soft machines to navigate and interact with their environment more naturally, making them suitable for tasks like assisting surgeons or search and rescue operations in disaster areas. They excel in adapting and responding to dynamic environments, offering advantages over rigid robotic systems that struggle in complex or changing terrains [

86].

Embodied intelligence represents a paradigm shift in robotics, where the physical properties of soft materials are harnessed to imbue robots with adaptive and versatile behaviors. As shown in

Table 3, soft machines are much better equipped for adaptability and compliance compared to conventional hard robots. The continued exploration of embodied intelligence holds promise for the development of soft machines technologies that can seamlessly integrate into and interact with the natural world, opening up new possibilities for applications in fields such as healthcare, exploration, and beyond.

7. Applications and Future Directions of Bioinspired Soft Machines

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

Bioinspired soft machines have emerged as a ground-breaking field with diverse applications, promising transformative advancements across various domains [

91]. An overview of current applications is provided in this section, potential future directions and advancements are discussed, ethical considerations and societal impacts associated with bioinspired soft machines are also addressed.

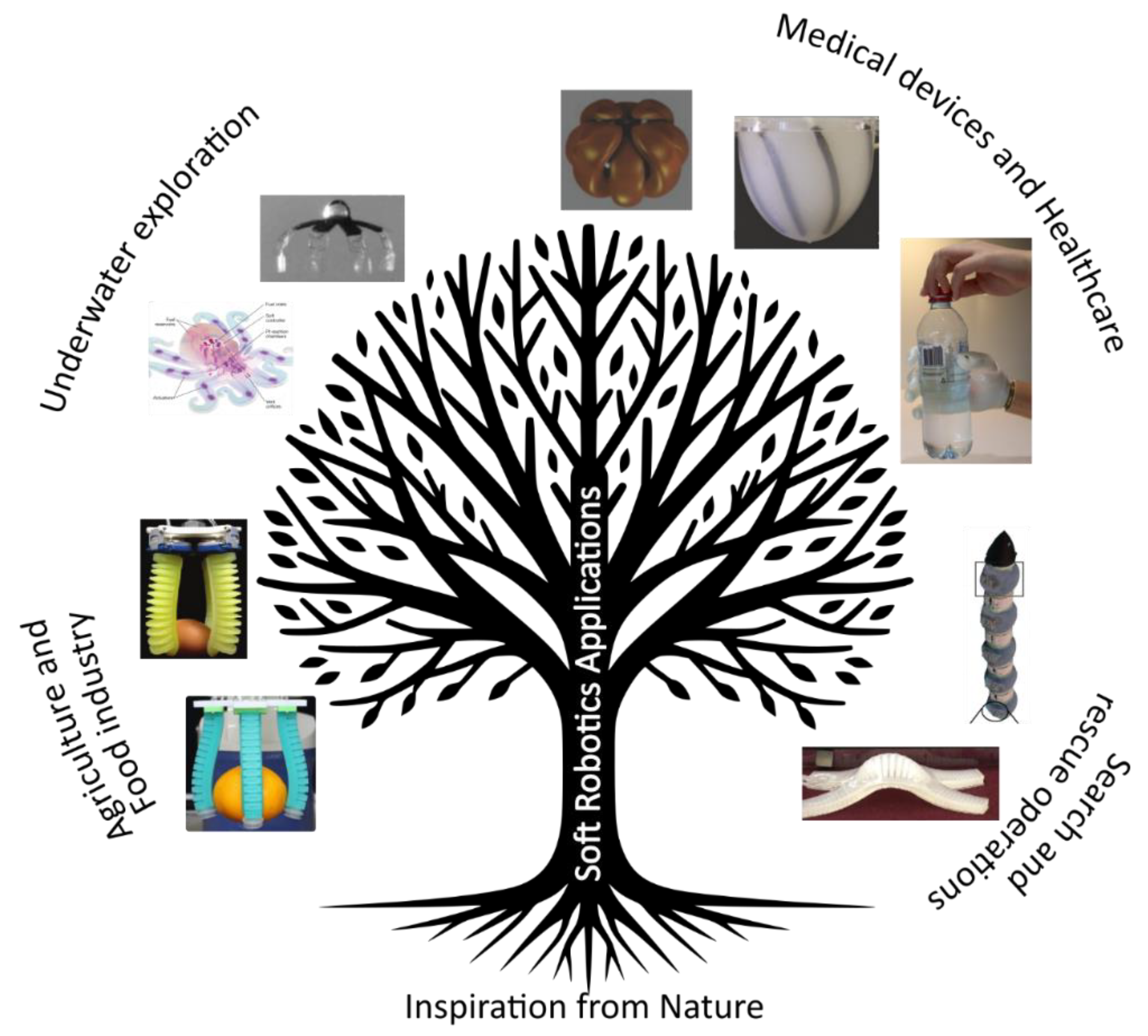

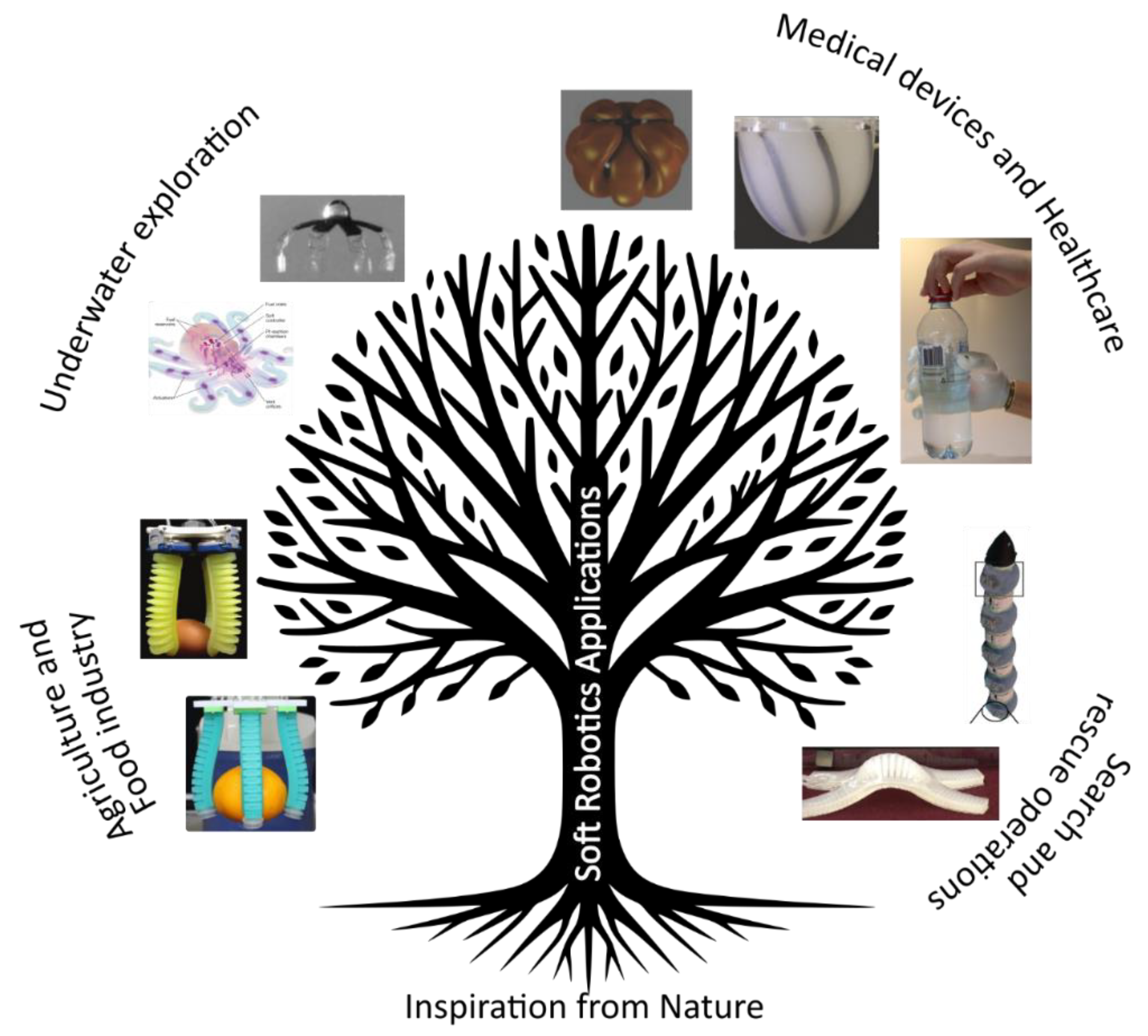

Figure 7.

Nature-Inspired Soft Robot Applications: This figure depicts the diverse applications of nature-inspired soft machines across agriculture, underwater exploration, medical health, and search and rescue operations. Examples include agricultural robots mimicking human hands for delicate crop handling (Reproduced with permission [

92]. Copyright 2020, Elsevier Ltd. Reproduced with permission [

93]. Copyright 2018, Springer Nature Limited), underwater robots inspired by jellyfish and octopus propulsion for efficient marine exploration (Reproduced with permission [

81]. Copyright 2016, Springer Nature Limited. Reproduced with permission [

60]. Copyright 2019, American Association for the Advancement of Science.), soft medical robots replicating the movement of muscles for minimally invasive surgeries (Reproduced with permission [

94]. Copyright 2014, Wiley. Reproduced with permission [

95]. Copyright 2014, Wiley. Reproduced with permission [

96]. Copyright 2020, Public Library of Science.), and resilient soft machines inspired by snakes and worms for navigating complex terrain during search and rescue missions (Reproduced with permission [

97]. Copyright 2023, Springer Nature Limited. Reproduced with permission [

98]. Copyright 2011, National Academy of Sciences).

Figure 7.

Nature-Inspired Soft Robot Applications: This figure depicts the diverse applications of nature-inspired soft machines across agriculture, underwater exploration, medical health, and search and rescue operations. Examples include agricultural robots mimicking human hands for delicate crop handling (Reproduced with permission [

92]. Copyright 2020, Elsevier Ltd. Reproduced with permission [

93]. Copyright 2018, Springer Nature Limited), underwater robots inspired by jellyfish and octopus propulsion for efficient marine exploration (Reproduced with permission [

81]. Copyright 2016, Springer Nature Limited. Reproduced with permission [

60]. Copyright 2019, American Association for the Advancement of Science.), soft medical robots replicating the movement of muscles for minimally invasive surgeries (Reproduced with permission [

94]. Copyright 2014, Wiley. Reproduced with permission [

95]. Copyright 2014, Wiley. Reproduced with permission [

96]. Copyright 2020, Public Library of Science.), and resilient soft machines inspired by snakes and worms for navigating complex terrain during search and rescue missions (Reproduced with permission [

97]. Copyright 2023, Springer Nature Limited. Reproduced with permission [

98]. Copyright 2011, National Academy of Sciences).

Bioinspired soft machines hold great promise for addressing a wide range of challenges and advancing technological innovation. By leveraging insights from biology and embracing interdisciplinary collaboration, researchers and engineers can continue to push the boundaries of what is possible in soft machines, unlocking new opportunities for applications and addressing ethical considerations and societal impacts along the way. As we embark on this journey towards a future shaped by bioinspired soft machines, it is imperative to remain mindful of our responsibilities and ensure that these technologies serve the common good and contribute to the well-being of society [

99,

100].

7.1. Current Applications

As shown in

Figure 7, bioinspired soft machines are already making significant contributions to fields such as healthcare, search and rescue, and exploration [

101]. In healthcare, soft machines offer minimally invasive solutions for surgical procedures, enabling precise and gentle interventions with reduced risk to patients [

102,

103]. Soft machines are being explored for applications such as targeted drug delivery, and prosthetics due to their flexibility and biocompatibility [

104]. Soft robotic exosuits and prosthetics provide personalized assistance and rehabilitation for individuals with mobility impairments, enhancing their quality of life and independence [

105]. In search and rescue operations, bioinspired soft machines can navigate confined spaces and complex terrain with agility, aiding in disaster response efforts and saving lives [

106]. Their adaptability and ability to navigate complex terrains can be crucial for locating and assisting individuals in disaster scenarios [

104]. In environmental exploration, bioinspired soft machines can navigate challenging terrains, monitor ecosystems, and collect data in ways that traditional rigid robots cannot. Their flexibility and adaptability make them ideal for exploring remote or hazardous environments [

107]. Furthermore, soft robotic grippers and manipulators find applications in manufacturing and assembly, offering flexible and adaptable solutions for handling delicate objects and performing intricate tasks [

108].

7.2. Future Directions and Advancements

The future of bioinspired soft machines holds immense potential for further innovation and advancement. One promising direction is the development of autonomous soft machines capable of self-repair and self-reconfiguration, enabling adaptive responses to changing environments and unforeseen challenges [

109]. Integrating advanced sensing and artificial intelligence technologies into soft machines will enhance their perception, decision-making, and interaction capabilities, paving the way for intelligent and autonomous systems with human-like cognition [

110]. Additionally, advances in materials science and fabrication techniques will enable the creation of soft machines with enhanced performance, durability, and biocompatibility, opening up new possibilities for applications in healthcare, wearable technology, and human-robot interaction [

111]. For example, the integration of self-healing materials in soft machines is a groundbreaking innovation that enables robots to repair damage autonomously. Inspired by biological systems that can regenerate and heal, self-healing soft machines have the potential to enhance durability and longevity in various applications [

112,

113].

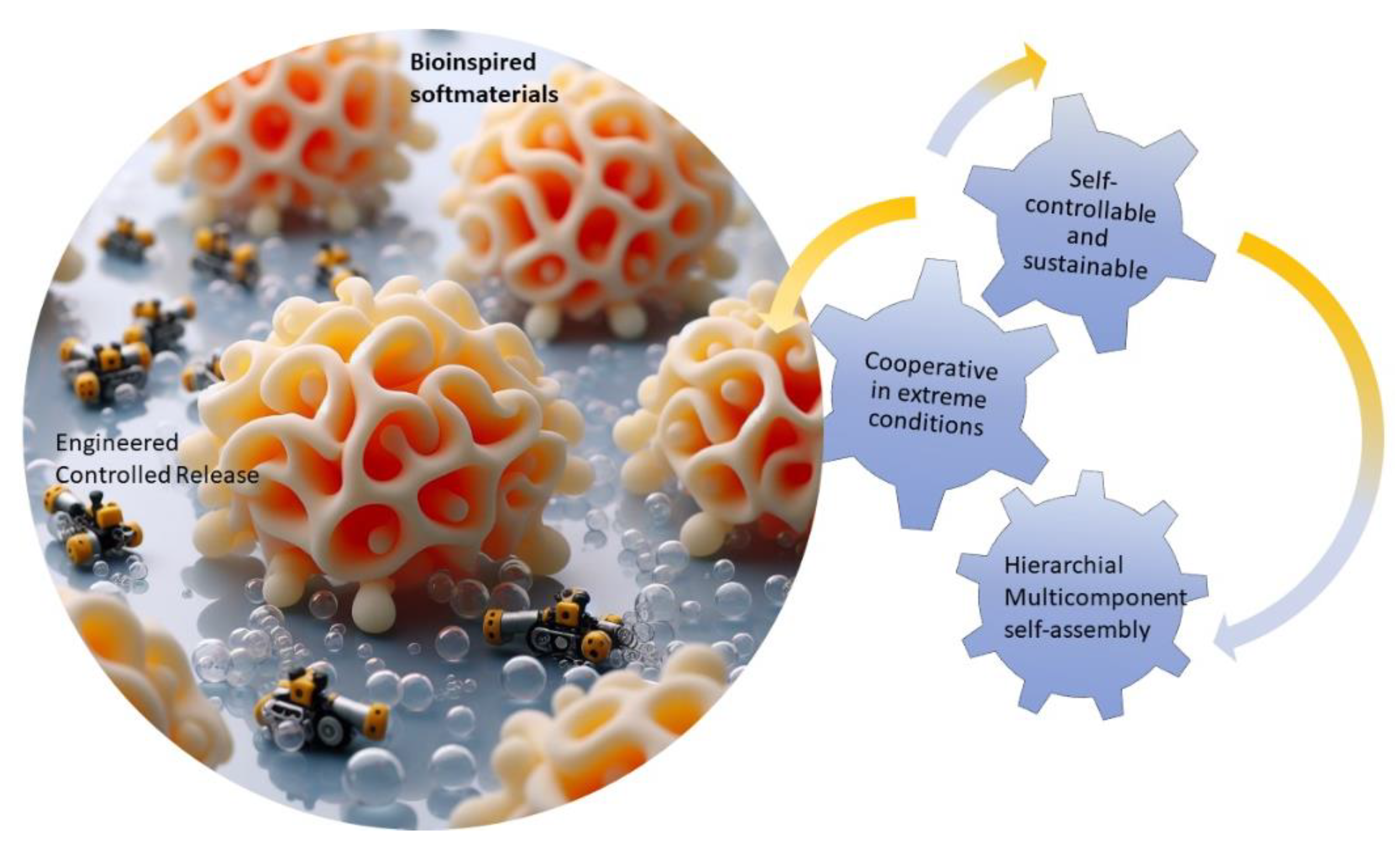

These futuristic machines can also be autonomous, sustainable bio-inspired robots that can mimic artificial organs. Non-experts could effortlessly utilize these machines capable of computing, sensing, and moving autonomously using embodies intelligence. A potential example is depicted in

Figure 8 where self-controllable small-scale robots cooperate and, if needed, perform a self-assembly to give a coordinated response for a specific task, for example-controlled drug release in a difficult to reach place in the human body. These robots have the potential to outperform traditional counterparts, harness energy sustainably, and operate effectively in challenging environments [

104,

114]. As soft robotic technologies mature, there is a growing trend towards commercialization. Concepts developed in academia are transitioning into commercial enterprises, broadening the adoption of soft robotic systems across industries like food processing and industrial automation [

104,

115].

This convergence between materials and machines is a paradigm shift, where the soft body integrates all components necessary for actuation, sensing, and computation, while the "soft brain" handles software aspects, controlling the device and reasoning about the world and task goals [

85,

116]. To realize their true potential, extreme body compliance is essential, enabling tasks like inspecting pipes with complex geometries or performing laparoscopic surgery. Moreover, soft machines must contend with uncertainty, navigating rocky terrains or grasping unknown objects. For autonomy, proprioceptive localization is crucial, enabling soft machines to operate independently. Utilizing biologically inspired artificial intelligence, these soft machines promise to revolutionize various industries like healthcare and exploration, by offering adaptive, versatile, and user-friendly solutions [

116].

8. Ethical Considerations and Societal Impacts

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

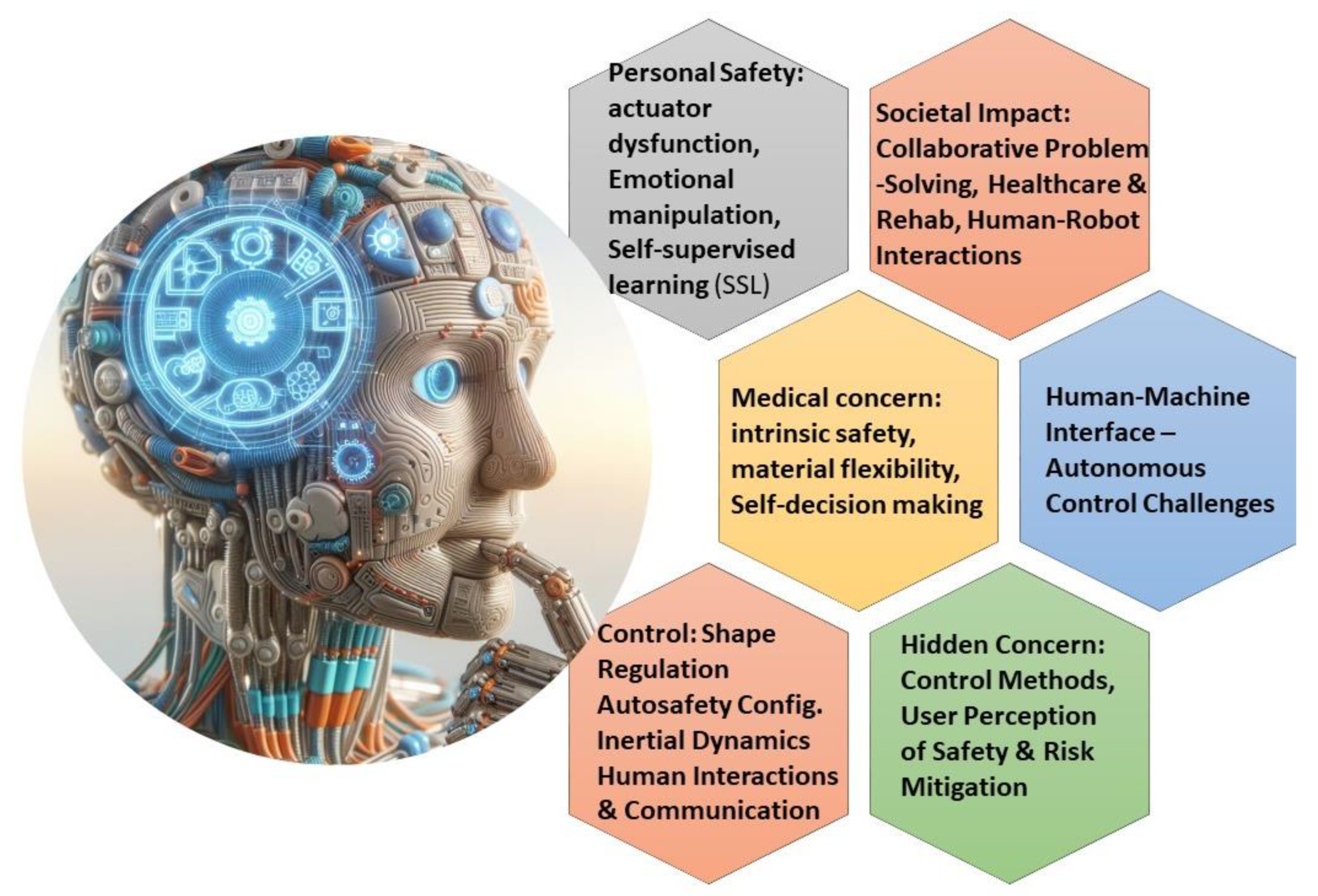

As bioinspired soft machines continue to evolve, it is essential to address ethical considerations and societal impacts associated with their development and deployment. Ethical considerations include issues such as privacy, autonomy, and safety, particularly in applications involving human-robot interaction and healthcare as shown in

Figure 9 [

117]. Ensuring transparency and accountability in the design, development, and deployment of soft machines is crucial to mitigate potential risks and ensure ethical standards are upheld [

118]. Furthermore, addressing societal impacts involves considerations such as job displacement, economic inequality, and access to technology, as the widespread adoption of soft machines may reshape labor markets and social dynamics. Collaborative efforts involving stakeholders from diverse backgrounds will be essential to navigate these ethical and societal challenges and ensure that bioinspired soft machines benefits humanity as a whole [

119]. Projects like the Horizon2020 EU initiative focusing on soft actuated heart development highlight the importance of addressing ethical concerns in medical applications [

104,

120]. Biohybrid systems that combine living cells or tissues with synthetic materials to open up new possibilities for applications in healthcare, environmental monitoring, etc. raise other ethical concerns [

121,

122]. Another ethical concern could come with the development of soft machines to function as artificial organs which could offer solutions to millions of people awaiting transplants worldwide [

104,

123]. The potential for soft machines to contribute to artificial organs is significant given the global shortage of organ donors.

In the ever-evolving landscape of technology and safety standards, the integration of Artificial Intelligence (AI), Machine Learning (ML), and Quantitative Structure-Activity Relationship (QSAR) techniques help in the evaluation of material safety for soft machines [

124,

125]. This forward-looking approach not only ensures meticulous scrutiny of potential hazards but also enables swift identification and mitigation of risks. Moreover, the expanding field of digitalized toxicology adds another layer of sophistication to safety analysis methodologies, empowering stakeholders to proactively address safety concerns with precision and efficiency [

126]. As we embrace these new approach methodologies (NAMs), the future of ensuring the safety of soft machines is propelled towards a realm of heightened reliability and transparency, safeguarding both users and the wider community [

127,

128].

9. Conclusions

The journey through the realm of bioinspired soft machines has unveiled a world of innovation, where the convergence of biology, materials science, and engineering has given rise to transformative technologies. The adaptability and versatility of soft machines, inspired by the elegant solutions found in nature, has been highlighted. By harnessing the intrinsic properties of soft materials, researchers have unlocked new possibilities for creating robots that integrate into and interact with the natural world. These materials, with their unique mechanical properties and functionalities, serve as the building blocks for creating soft machines with adaptive capabilities. By continuing to advance this field, new materials and fabrication techniques can be developed, enabling breakthroughs in healthcare, exploration, manufacturing, and beyond. A wide range of actuation principles have been developed for powering the soft machines. Taking inspiration from nature, embodied intelligence has also been integrated into the soft machines for a decentralized and autonomous decision-making of soft machines. Several application scenarios found in the state of the art and many more can be developed as the field progresses have been discussed. Some ethical considerations when dealing with soft machines and efforts to tackle them have also been mentioned.

Cross-disciplinary collaboration between researchers, engineers, biologists, and other stakeholders is crucial for bridging the gap between biology and technology, facilitating the exchange of ideas and expertise, and accelerating the pace of innovation. Moreover, advancing innovation will push the boundaries of what is possible in soft machines and unlock new opportunities for addressing societal challenges.

Bioinspired soft machines offer a glimpse into a future where robots blend with the natural world, offering solutions to some of humanity's most pressing challenges. By continuing to explore nature, harnessing the potential of bioinspired materials, and taking a multi-disciplinary route, we can unlock new possibilities for advancing soft machines and shaping a future where bioinspired robots will be used for the most crucial and needed applications.

Author Contributions

Conceptualization, A.V.S., M.H.D.A., and M.S.; methodology, A.V.S. and M.H.D.A.; software, A.V.S. and M.H.D.A.; investigation, A.V.S. and M.H.D.A.; resources, A.V.S., P.L., S.K.S., M.S.; data curation, A.V.S., M.H.D.A., A.K.D., P.L., S.K.S., S.R.M., and M.S.; writing—original draft preparation, A.V.S. and M.H.D.A.; writing—review and editing, A.V.S., M.H.D.A., A.K.D., P.L., S.K.S., S.R.M., and M.S.; supervision, A.V.S., M.H.D.A., and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

M.H.D.A is now with the MAPWORMS project which has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement N° 101046846.

Data Availability Statement

The data supporting the findings of this study are available upon a reasonable request.

Acknowledgments

We utilized some AI tools to enhance various aspects of our paper. Connected Papers and Perplexity AI streamlined our literature search, identifying key articles and synthesizing complex information. Biorender, coupled with Microsoft Designer, permitted us to create visually engaging graphics and illustrations. Additionally, Quillbot improved the readability and coherence of our final drafts by identifying and rectifying grammatical errors and stylistic inconsistencies.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| ER |

Electrorheological |

| MR |

Magnetirheological |

| SMA |

Shape Memory Alloy |

| IPMC |

Ionic Polymer-metal composite |

| DEA |

Dielectric Elastomer |

| AI |

Artificial Intelligence |

| ML |

Machine Learning |

| QSAR |

Quantitative Structure-Activity Relationship |

| NAM |

New Approach Methodology |

References

- Cianchetti, M.; Laschi, C.; Menciassi, A.; Dario, P. Biomedical applications of soft robotics. Nature Reviews Materials 2018, 3, 143-153. [CrossRef]

- Gariya, N.; Kumar, P. A review on soft materials utilized for the manufacturing of soft robots. Materials Today: Proceedings 2021, 46, 11177-11181. [CrossRef]

- Laschi, C.; Mazzolai, B. Bioinspired materials and approaches for soft robotics. MRS Bulletin 2021, 46, 345-349. [CrossRef]

- Feinberg, A.W. Biological Soft Robotics. Annual Review of Biomedical Engineering 2015, 17, 243-265. [CrossRef]

- Consumi, V.; Lindenroth, L.; Merlin, J.; Stoyanov, D.; Stilli, A. Design and Evaluation of the SoftSCREEN Capsule for Colonoscopy. IEEE Robotics and Automation Letters 2023, 8, 1659-1666. [CrossRef]

- Ren, L.; Li, B.; Wei, G.; Wang, K.; Song, Z.; Wei, Y.; Ren, L.; Liu, Q. Biology and bioinspiration of soft robotics: Actuation, sensing, and system integration. iScience 2021, 24, 103075. [CrossRef]

- Alici, G. Robotics—Soft Robotics. In Encyclopedia of Biomedical Engineering, Narayan, R., Ed.; Elsevier: Oxford, 2019; pp. 652-659.

- Roh, Y.; Lee, Y.; Lim, D.; Gong, D.; Hwang, S.; Kang, M.; Kim, D.; Cho, J.; Kwon, G.; Kang, D.; et al. Nature's Blueprint in Bioinspired Materials for Robotics. Advanced Functional Materials n/a, 2306079. [CrossRef]

- Ye, T.; Wang, Y.; Xu, S.; Wang, Y.; Li, J. Modeling and motion control of an octopus-like flexible manipulator actuated by shape memory alloy wires. Journal of Intelligent Material Systems and Structures 2021, 33, 3-16. [CrossRef]

- Calisti, M.; Giorelli, M.; Levy, G.; Mazzolai, B.; Hochner, B.; Laschi, C.; Dario, P. An octopus-bioinspired solution to movement and manipulation for soft robots. Bioinspiration & biomimetics 2011, 6, 036002.

- Kumar, S.R.S. How elephant's flexible trunk can improve robots. Hindustan Times 25/07/2022 2022.

- Tang, C. Soft robotic gripper modeled after an elephant’s trunk. 2020.

- Leanza, S.; Lu-Yang, J.; Kaczmarski, B.; Wu, S.; Kuhl, E.; Zhao, R.R. Elephant Trunk Inspired Multimodal Deformations and Movements of Soft Robotic Arms. Advanced Functional Materials 2024, 2400396.

- Ashuri, T.; Armani, A.; Jalilzadeh Hamidi, R.; Reasnor, T.; Ahmadi, S.; Iqbal, K. Biomedical soft robots: Current status and perspective. Biomed Eng Lett 2020, 10, 369-385. [CrossRef]

- Banerjee, H.; Tse, Z. Soft robotics with compliance and adaptation for biomedical applications and forthcoming challenges. International Journal of Robotics and Automation 2018, 33. [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467-475. [CrossRef]

- Laschi, C.; Mazzolai, B.; Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Science Robotics 2016, 1, eaah3690. [CrossRef]

- Truby, R.L. Designing Soft Robots as Robotic Materials. Accounts of Materials Research 2021, 2, 854-857. [CrossRef]

- Hegde, C.; Su, J.; Tan, J.M.R.; He, K.; Chen, X.; Magdassi, S. Sensing in Soft Robotics. ACS Nano 2023, 17, 15277-15307. [CrossRef]

- Ang, B.W.K.; Yeow, C.-H.; Lim, J.H. A Critical Review on Factors Affecting the User Adoption of Wearable and Soft Robotics. Sensors 2023, 23, 3263.

- Wang, Y.; Gregory, C.; Minor, M.A. Improving Mechanical Properties of Molded Silicone Rubber for Soft Robotics Through Fabric Compositing. Soft Robotics 2018, 5, 272-290. [CrossRef]

- Marchese, A.D.; Katzschmann, R.K.; Rus, D. A Recipe for Soft Fluidic Elastomer Robots. Soft Robot 2015, 2, 7-25. [CrossRef]

- Coyle, S.; Majidi, C.; LeDuc, P.; Hsia, K.J. Bio-inspired soft robotics: Material selection, actuation, and design. Extreme Mechanics Letters 2018, 22, 51-59. [CrossRef]

- Khandan, A.; Jazayeri, H.; Fahmy, M.D.; Razavi, M. Hydrogels: Types, structure, properties, and applications. Biomat Tiss Eng 2017, 4, 143-169.

- Deligkaris, K.; Tadele, T.S.; Olthuis, W.; van den Berg, A. Hydrogel-based devices for biomedical applications. Sensors and Actuators B: Chemical 2010, 147, 765-774. [CrossRef]

- Schönfeld, D.; Chalissery, D.; Wenz, F.; Specht, M.; Eberl, C.; Pretsch, T. Actuating Shape Memory Polymer for Thermoresponsive Soft Robotic Gripper and Programmable Materials. Molecules 2021, 26, 522.

- Boyraz, P.; Runge, G.; Raatz, A. An overview of novel actuators for soft robotics. In Proceedings of the Actuators, 2018; p. 48.

- Bilodeau, R.A.; Kramer, R.K. Self-Healing and Damage Resilience for Soft Robotics: A Review. Frontiers in Robotics and AI 2017, 4. [CrossRef]

- Singh, A.V.; Ansari, M.H.D.; Mahajan, M.; Srivastava, S.; Kashyap, S.; Dwivedi, P.; Pandit, V.; Katha, U. Sperm Cell Driven Microrobots-Emerging Opportunities and Challenges for Biologically Inspired Robotic Design. Micromachines (Basel) 2020, 11. [CrossRef]

- Singh, A.V.; Dad Ansari, M.H.; Dayan, C.B.; Giltinan, J.; Wang, S.; Yu, Y.; Kishore, V.; Laux, P.; Luch, A.; Sitti, M. Multifunctional magnetic hairbot for untethered osteogenesis, ultrasound contrast imaging and drug delivery. Biomaterials 2019, 219, 119394. [CrossRef]

- Li, S.; Bai, H.; Shepherd, R.F.; Zhao, H. Bio-inspired design and additive manufacturing of soft materials, machines, robots, and haptic interfaces. Angewandte Chemie International Edition 2019, 58, 11182-11204.

- Singh, A.V.; Ansari, M.H.D.; Laux, P.; Luch, A. Micro-nanorobots: Important considerations when developing novel drug delivery platforms. Expert Opinion on Drug Delivery 2019, 16, 1259-1275. [CrossRef]

- C., J. Soft Material Characterization for Robotic Applications. SOFT ROBOTICS 2015, Volume 2. [CrossRef]

- Jiang, H.Y.; Kelch, S.; Lendlein, A. Polymers Move in Response to Light. Advanced Materials 2006, 18, 1471-1475. [CrossRef]

- Meng, Q.; Hu, J.; Ho, K.; Ji, F.; Chen, S. The Shape Memory Properties of Biodegradable Chitosan/Poly(l-lactide) Composites. Journal of Polymers and the Environment 2009, 17, 212-224. [CrossRef]

- Zhang, Y.-F.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Advanced Functional Materials 2019, 29, 1806698. [CrossRef]

- Yang, J.; Cao, P.; Gao, K.; Ding, C.; Chen, S.; Zhang, X.; Wang, T.; Wang, Q.; Zhang, Y. Thermal Tunable Tribological Behavior of Shape Memory Biphenyl Epoxy Resin. Coatings 2023, 13. [CrossRef]

- Capadona, J.R.; Shanmuganathan, K.; Tyler, D.J.; Rowan, S.J.; Weder, C. Stimuli-Responsive Polymer Nanocomposites Inspired by the Sea Cucumber Dermis. Science 2008, 319, 1370-1374. [CrossRef]

- Trotter, J.A.; Tipper, J.; Lyons-Levy, G.; Chino, K.; Heuer, A.H.; Liu, Z.; Mrksich, M.; Hodneland, C.; Dillmore, W.S.; Koob, T.J.; et al. Towards a fibrous composite with dynamically controlled stiffness: Lessons from echinoderms. Biochemical Society Transactions 2000, 28, 357-362. [CrossRef]

- Rokaya, D.; Skallevold, H.E.; Srimaneepong, V.; Marya, A.; Shah, P.K.; Khurshid, Z.; Zafar, M.S.; Sapkota, J. Shape Memory Polymeric Materials for Biomedical Applications: An Update. Journal of Composites Science 2023, 7. [CrossRef]

- Yasa, O.; Toshimitsu, Y.; Michelis, M.Y.; Jones, L.S.; Filippi, M.; Buchner, T.; Katzschmann, R.K. An overview of soft robotics. Annual Review of Control, Robotics, and Autonomous Systems 2023, 6, 1-29.

- Huang, W.; Xiao, J.; Xu, Z. A variable structure pneumatic soft robot. Scientific Reports 2020, 10, 18778. [CrossRef]

- Su, H.; Hou, X.; Zhang, X.; Qi, W.; Cai, S.; Xiong, X.; Guo, J. Pneumatic Soft Robots: Challenges and Benefits. Actuators 2022, 11, 92.

- Pawar, P.B. Industrial Hydraulics and Pneumatics; Sankalp Publication: 2020.

- Ankit; Ho, T.Y.K.; Nirmal, A.; Kulkarni, M.R.; Accoto, D.; Mathews, N. Soft actuator materials for electrically driven haptic interfaces. Advanced Intelligent Systems 2022, 4, 2100061.

- Higueras-Ruiz, D.R.; Nishikawa, K.; Feigenbaum, H.; Shafer, M. What is an artificial muscle? A comparison of soft actuators to biological muscles. Bioinspiration & biomimetics 2021, 17, 011001.

- Ramdya, P.; Ijspeert, A.J. The neuromechanics of animal locomotion: From biology to robotics and back. Science Robotics 2023, 8, eadg0279.

- Ansari, M.H.D.; Iacovacci, V.; Pane, S.; Ourak, M.; Borghesan, G.; Tamadon, I.; Vander Poorten, E.; Menciassi, A. 3D Printing of Small-Scale Soft Robots with Programmable Magnetization. Advanced Functional Materials 2023, 33, 2211918. [CrossRef]

- El-Atab, N.; Mishra, R.B.; Al-Modaf, F.; Joharji, L.; Alsharif, A.A.; Alamoudi, H.; Diaz, M.; Qaiser, N.; Hussain, M.M. Soft Actuators for Soft Robotic Applications: A Review. Advanced Intelligent Systems 2020, 2, 2000128. [CrossRef]

- Li, M.; Pal, A.; Aghakhani, A.; Pena-Francesch, A.; Sitti, M. Soft actuators for real-world applications. Nat Rev Mater 2022, 7, 235-249. [CrossRef]

- Ansari, M.H.; Ha, X.T.; Ourak, M.; Borghesan, G.; Iacovacci, V.; Vander Poorten, E.; Menciassi, A. Characterization of a 3D Printed Endovascular Magnetic Catheter. Actuators 2023, 12. [CrossRef]

- Lee, J.-H.; Chung, Y.S.; Rodrigue, H. Long Shape Memory Alloy Tendon-based Soft Robotic Actuators and Implementation as a Soft Gripper. Scientific Reports 2019, 9, 11251. [CrossRef]

- Xie, Q.; Wang, T.; Yao, S.; Zhu, Z.; Tan, N.; Zhu, S. Design and modeling of a hydraulic soft actuator with three degrees of freedom. Smart Materials and Structures 2020, 29, 125017. [CrossRef]

- Lalegani Dezaki, M.; Bodaghi, M.; Serjouei, A.; Afazov, S.; Zolfagharian, A. Adaptive reversible composite-based shape memory alloy soft actuators. Sensors and Actuators A: Physical 2022, 345, 113779. [CrossRef]

- Yang, Y.; Pei, Z.; Li, Z.; Wei, Y.; Ji, Y. Making and Remaking Dynamic 3D Structures by Shining Light on Flat Liquid Crystalline Vitrimer Films without a Mold. Journal of the American Chemical Society 2016, 138, 2118-2121. [CrossRef]

- Dong, X.; Xu, J.; Xu, X.; Dai, S.; Zhou, X.; Ma, C.; Cheng, G.; Yuan, N.; Ding, J. Sunlight-Driven Continuous Flapping-Wing Motion. ACS Applied Materials & Interfaces 2020, 12, 6460-6470. [CrossRef]

- Park, S.-J.; Gazzola, M.; Park, K.S.; Park, S.; Di Santo, V.; Blevins, E.L.; Lind, J.U.; Campbell, P.H.; Dauth, S.; Capulli, A.K.; et al. Phototactic guidance of a tissue-engineered soft-robotic ray. Science 2016, 353, 158. [CrossRef]

- Fusi, G.; Del Giudice, D.; Skarsetz, O.; Di Stefano, S.; Walther, A. Autonomous Soft Robots Empowered by Chemical Reaction Networks. Advanced Materials 2023, 35, 2209870. [CrossRef]

- Bartlett, N.W.; Tolley, M.T.; Overvelde, J.T.B.; Weaver, J.C.; Mosadegh, B.; Bertoldi, K.; Whitesides, G.M.; Wood, R.J. A 3D-printed, functionally graded soft robot powered by combustion. Science 2015, 349, 161-165. [CrossRef]

- Ren, Z.; Hu, W.; Dong, X.; Sitti, M. Multi-functional soft-bodied jellyfish-like swimming. Nature Communications 2019, 10, 2703. [CrossRef]

- Wang, X.; Qin, X.-H.; Hu, C.; Terzopoulou, A.; Chen, X.-Z.; Huang, T.-Y.; Maniura-Weber, K.; Pané, S.; Nelson, B.J. 3D Printed Enzymatically Biodegradable Soft Helical Microswimmers. Advanced Functional Materials 2018, 28, 1804107. [CrossRef]

- Ji, X.; Liu, X.; Cacucciolo, V.; Imboden, M.; Civet, Y.; El Haitami, A.; Cantin, S.; Perriard, Y.; Shea, H. An autonomous untethered fast soft robotic insect driven by low-voltage dielectric elastomer actuators. Science Robotics 2019, 4, eaaz6451. [CrossRef]

- Wu, Y.; Yim, J.K.; Liang, J.; Shao, Z.; Qi, M.; Zhong, J.; Luo, Z.; Yan, X.; Zhang, M.; Wang, X.; et al. Insect-scale fast moving and ultrarobust soft robot. Science Robotics 2019, 4, eaax1594. [CrossRef]

- Ahmed, F.; Waqas, M.; Jawed, B.; Soomro, A.M.; Kumar, S.; Hina, A.; Khan, U.; Kim, K.H.; Choi, K.H. Decade of bio-inspired soft robots: A review. Smart Materials and Structures 2022, 31, 073002. [CrossRef]

- Roche, E.T.; Wohlfarth, R.; Overvelde, J.T.; Vasilyev, N.V.; Pigula, F.A.; Mooney, D.J.; Bertoldi, K.; Walsh, C.J. A bioinspired soft actuated material. Adv. Mater 2014, 26, 1200-1206.

- Stella, F.; Hughes, J. The science of soft robot design: A review of motivations, methods and enabling technologies. Front Robot AI 2022, 9, 1059026. [CrossRef]

- Fratzl, P.; Jacobs, K.; Möller, M.; Scheibel, T.; Sternberg, K. Inspired by Nature.

- Lee, J.; Calvo, P. Enacting Plant-Inspired Robotics. Front Neurorobot 2021, 15, 772012. [CrossRef]

- Stella, F.; Hughes, J. The science of soft robot design: A review of motivations, methods and enabling technologies. Frontiers in Robotics and AI 2023, 9. [CrossRef]

- Wang, H.; Totaro, M.; Beccai, L. Toward Perceptive Soft Robots: Progress and Challenges. Advanced Science 2018, 5, 1800541. [CrossRef]

- Ang, B.W.; Yeow, C.-H.; Lim, J.H. A Critical Review on Factors Affecting the User Adoption of Wearable and Soft Robotics. Sensors 2023, 23. [CrossRef]

- Manti, M.; Hassan, T.; Passetti, G.; NicolòD’Elia; Laschi, C.; Cianchetti, M. A Bioinspired Soft Robotic Gripper for Adaptable and Effective Grasping. Soft Robotics 2015, 2. [CrossRef]

- Zhou, L.; Ren, L.; Chen, Y.; Niu, S.; Han, Z.; Ren, L. Bio-Inspired Soft Grippers Based on Impactive Gripping. Advanced Science 2021, 8, 2002017. [CrossRef]

- Ijspeert, A.J. Biorobotics: Using robots to emulate and investigate agile locomotion. Science 2014, 346, 196-203. [CrossRef]

- Calisti, M.; Picardi, G.; Laschi, C. Fundamentals of soft robot locomotion. Journal of The Royal Society Interface 2017, 14, 20170101. [CrossRef]

- Roh, Y.; Lee, Y.; Lim, D.; Gong, D.; Hwang, S.; Kang, M.; Kim, D.; Cho, J.; Kwon, G.; Kang, D.; et al. Nature's Blueprint in Bioinspired Materials for Robotics. Advanced Functional Materials 2023, n/a, 2306079. [CrossRef]

- Trivedi, D.; Rahn, C.D.; Kier, W.M.; Walker, I.D. Soft robotics: Biological inspiration, state of the art, and future research. Applied bionics and biomechanics 2008, 5, 99-117.

- Cianchetti, M. Embodied Intelligence in Soft Robotics Through Hardware Multifunctionality. Frontiers in Robotics and AI 2021, 8. [CrossRef]

- Sun, J.; Lerner, E.; Tighe, B.; Middlemist, C.; Zhao, J. Embedded shape morphing for morphologically adaptive robots. Nature Communications 2023, 14, 6023. [CrossRef]

- Laschi, C.; Mazzolai, B. Lessons from animals and plants: The symbiosis of morphological computation and soft robotics. IEEE Robotics & Automation Magazine 2016, 23, 107-114.

- Wehner, M.; Truby, R.L.; Fitzgerald, D.J.; Mosadegh, B.; Whitesides, G.M.; Lewis, J.A.; Wood, R.J. An integrated design and fabrication strategy for entirely soft, autonomous robots. Nature 2016, 536, 451-455. [CrossRef]

- Cangelosi, A.; Bongard, J.; Fischer, M.H.; Nolfi, S. Embodied intelligence. Springer handbook of computational intelligence 2015, 697-714.

- Floreano, D.; Mondada, F.; Perez-Uribe, A.; Roggen, D. Evolution of embodied intelligence. In Proceedings of the Embodied Artificial Intelligence: International Seminar, Dagstuhl Castle, Germany, July 7-11, 2003. Revised Papers, 2004; pp. 293-311.

- Sitti, M. Physical intelligence as a new paradigm. Extreme Mechanics Letters 2021, 46, 101340. [CrossRef]

- Harvey, K. Embodied Intelligence through Coordination Dynamics in the Brain-Body Complex. International Journal of Basic & Applied Sciences 2019, 3, 37-54.

- Tauber, F.; Desmulliez, M.; Piccin, O.; Stokes, A.A. Perspective for soft robotics: The field’s past and future. Bioinspiration & Biomimetics 2023, 18, 035001. [CrossRef]

- Mengaldo, G.; Renda, F.; Brunton, S.L.; Bächer, M.; Calisti, M.; Duriez, C.; Chirikjian, G.S.; Laschi, C. A concise guide to modelling the physics of embodied intelligence in soft robotics. Nature Reviews Physics 2022, 4, 595-610. [CrossRef]

- Laschi, C. Embodied Intelligence in soft robotics: Joys and sorrows. IOP Conference Series: Materials Science and Engineering 2022, 1261, 012002. [CrossRef]

- Lara, B.; Astorga, D.; Mendoza-Bock, E.; Pardo, M.; Escobar, E.; Ciria, A. Embodied Cognitive Robotics and the learning of sensorimotor schemes. Adaptive Behavior 2018, 26, 225-238. [CrossRef]

- Polykretis, I.; Supic, L.; Danielescu, A. Bioinspired smooth neuromorphic control for robotic arms. Neuromorphic Computing and Engineering 2023, 3, 014013. [CrossRef]

- Hartmann, F.; Baumgartner, M.; Kaltenbrunner, M. Becoming Sustainable, The New Frontier in Soft Robotics. Advanced Materials 2021, 33, 2004413. [CrossRef]

- Wang, Z.; Or, K.; Hirai, S. A dual-mode soft gripper for food packaging. Robotics and Autonomous Systems 2020, 125, 103427. [CrossRef]

- Hao, Y.; Gong, Z.; Xie, Z.; Guan, S.; Yang, X.; Wang, T.; Wen, L. A Soft Bionic Gripper with Variable Effective Length. Journal of Bionic Engineering 2018, 15, 220-235. [CrossRef]

- Fusco, S.; Sakar, M.S.; Kennedy, S.; Peters, C.; Bottani, R.; Starsich, F.; Mao, A.; Sotiriou, G.A.; Pané, S.; Pratsinis, S.E.; et al. An Integrated Microrobotic Platform for On-Demand, Targeted Therapeutic Interventions. Advanced Materials 2014, 26, 952-957. [CrossRef]

- Roche, E.T.; Wohlfarth, R.; Overvelde, J.T.B.; Vasilyev, N.V.; Pigula, F.A.; Mooney, D.J.; Bertoldi, K.; Walsh, C.J. A Bioinspired Soft Actuated Material. Advanced Materials 2014, 26, 1200-1206. [CrossRef]

- Mohammadi, A.; Lavranos, J.; Zhou, H.; Mutlu, R.; Alici, G.; Tan, Y.; Choong, P.; Oetomo, D. A practical 3D-printed soft robotic prosthetic hand with multi-articulating capabilities. PLoS ONE 2020, 15, e0232766.

- Das, R.; Babu, S.P.M.; Visentin, F.; Palagi, S.; Mazzolai, B. An earthworm-like modular soft robot for locomotion in multi-terrain environments. Scientific Reports 2023, 13, 1571. [CrossRef]

- Shepherd, R.F.; Ilievski, F.; Choi, W.; Morin, S.A.; Stokes, A.A.; Mazzeo, A.D.; Chen, X.; Wang, M.; Whitesides, G.M. Multigait soft robot. Proceedings of the National Academy of Sciences 2011, 108, 20400-20403. [CrossRef]

- Hammond, M.; Cichella, V.; Lamuta, C. Bioinspired Soft Robotics: State of the Art, Challenges, and Future Directions. Current Robotics Reports 2023, 4, 65-80. [CrossRef]

- Biological Robots: Perspectives on an Emerging Interdisciplinary Field. Soft Robotics 2023, 10, 674-686. [CrossRef]

- Isaka, K.; Tsumura, K.; Watanabe, T.; Toyama, W.; Sugesawa, M.; Yamada, Y.; Yoshida, H.; Nakamura, T. Development of underwater drilling robot based on earthworm locomotion. Ieee Access 2019, 7, 103127-103141.

- Zhu, J.; Lyu, L.; Xu, Y.; Liang, H.; Zhang, X.; Ding, H.; Wu, Z. Intelligent soft surgical robots for next-generation minimally invasive surgery. Advanced Intelligent Systems 2021, 3, 2100011.

- Tse, Z.; Chen, Y.; Hovet, S.; Monfaredi, R.; Xu, S.; Wood, B.; Cleary, K. Soft Robotics in Medical Applications. Journal of Medical Robotics Research 2018, 03. [CrossRef]

- Tauber, F.J.; Slesarenko, V. Early career scientists converse on the future of soft robotics. Front Robot AI 2023, 10, 1129827. [CrossRef]

- Pan, M.; Yuan, C.; Liang, X.; Dong, T.; Liu, T.; Zhang, J.; Zou, J.; Yang, H.; Bowen, C. Soft Actuators and Robotic Devices for Rehabilitation and Assistance. Advanced Intelligent Systems 2022, 4, 2100140. [CrossRef]

- Delmerico, J.; Mintchev, S.; Giusti, A.; Gromov, B.; Melo, K.; Horvat, T.; Cadena, C.; Hutter, M.; Ijspeert, A.; Floreano, D.; et al. The current state and future outlook of rescue robotics. Journal of Field Robotics 2019, 36, 1171-1191. [CrossRef]

- Aracri, S.; Giorgio-Serchi, F.; Suaria, G.; Sayed, M.E.; Nemitz, M.P.; Mahon, S.; Stokes, A.A. Soft robots for ocean exploration and offshore operations: A perspective. Soft Robotics 2021, 8, 625-639.

- Hughes, J.; Culha, U.; Giardina, F.; Guenther, F.; Rosendo, A.; Iida, F. Soft manipulators and grippers: A review. Frontiers in Robotics and AI 2016, 3, 69.

- Wegener, K.; Damm, O.; Harst, S.; Ihlenfeldt, S.; Monostori, L.; Teti, R.; Wertheim, R.; Byrne, G. Biologicalisation in manufacturing–Current state and future trends. CIRP Annals 2023.

- Gao, S.; Dai, Y.; Nathan, A. Tactile and Vision Perception for Intelligent Humanoids. Advanced Intelligent Systems 2022, 4, 2100074. [CrossRef]

- Xiong, J.; Chen, J.; Lee, P.S. Functional Fibers and Fabrics for Soft Robotics, Wearables, and Human–Robot Interface. Advanced Materials 2021, 33, 2002640. [CrossRef]

- Islam, M.A.; Talukder, L.; Al, M.F.; Sarker, S.K.; Muyeen, S.M.; Das, P.; Hasan, M.M.; Das, S.K.; Islam, M.M.; Islam, M.R.; et al. A review on self-healing featured soft robotics. Frontiers in Robotics and AI 2023, 10. [CrossRef]

- Roels, E.; Terryn, S.; Iida, F.; Bosman, A.; Norvez, S.; Clemens, F.; Van Assche, G.; Vanderborght, B.; Brancart, J. Processing of Self-Healing Polymers for Soft Robotics. Advanced materials (Deerfield Beach, Fla.) 2021, 34, e2104798. [CrossRef]

- Horvath, M.A.; Hu, L.; Mueller, T.; Hochstein, J.; Rosalia, L.; Hibbert, K.A.; Hardin, C.C.; Roche, E.T. An organosynthetic soft robotic respiratory simulator. APL bioengineering 2020, 4.

- Duggal, A.S.; Malik, P.K.; Gehlot, A.; Singh, R.; Gaba, G.S.; Masud, M.; Al-Amri, J.F. A sequential roadmap to Industry 6.0: Exploring future manufacturing trends. Iet Communications 2022, 16, 521-531.

- Berrueta, T.A.; Murphey, T.D.; Truby, R.L. Materializing Autonomy in Soft Robots across Scales. Advanced Intelligent Systems 2024, 6, 2300111. [CrossRef]

- Potter, K.; Oloyede, J.; f, o. The Evolution of Robotics: Advancements, Impacts, and Ethical Considerations. Science Robotics 2024.

- Wachter, S.; Mittelstadt, B.; Floridi, L. Transparent, Explainable, and Accountable AI for Robotics. Science Robotics 2017, 2. [CrossRef]

- Daniel, S. The Impact of Artificial Intelligence on Employment and Workforce Dynamics in Contemporary Society Author(s). 2023.

- Elendu, C.; Amaechi, D.C.; Elendu, T.C.; Jingwa, K.A.; Okoye, O.K.; John Okah, M.; Ladele, J.A.; Farah, A.H.; Alimi, H.A. Ethical implications of AI and robotics in healthcare: A review. Medicine (Baltimore) 2023, 102, e36671. [CrossRef]

- Lin, Z.; Jiang, T.; Shang, J. The emerging technology of biohybrid micro-robots: A review. Bio-Design and Manufacturing 2022, 5, 107-132. [CrossRef]

- Mousa, M.; Soliman, M.; Saleh, M.; Radwan, A. Biohybrid Soft Robots, E-Skin, and Bioimpedance Potential to Build Up Their Applications: A Review. IEEE Access 2020, 8, 184524-184539. [CrossRef]

- Sohn, S.; Buskirk, M.V.; Buckenmeyer, M.J.; Londono, R.; Faulk, D. Whole organ engineering: Approaches, challenges, and future directions. Applied Sciences 2020, 10, 4277.

- Singh, A.V.; Varma, M.; Rai, M.; Pratap Singh, S.; Bansod, G.; Laux, P.; Luch, A. Advancing Predictive Risk Assessment of Chemicals via Integrating Machine Learning, Computational Modeling, and Chemical/Nano-Quantitative Structure-Activity Relationship Approaches. Advanced Intelligent Systems 2024, n/a, 2300366. [CrossRef]

- Singh, A.V.; Shelar, A.; Rai, M.; Laux, P.; Thakur, M.; Dosnkyi, I.; Santomauro, G.; Singh, A.K.; Luch, A.; Patil, R.; et al. Harmonization Risks and Rewards: Nano-QSAR for Agricultural Nanomaterials. Journal of Agricultural and Food Chemistry 2024, 72, 2835-2852. [CrossRef]

- Singh, A.V.; Bansod, G.; Mahajan, M.; Dietrich, P.; Singh, S.P.; Rav, K.; Thissen, A.; Bharde, A.M.; Rothenstein, D.; Kulkarni, S.; et al. Digital Transformation in Toxicology: Improving Communication and Efficiency in Risk Assessment. ACS Omega 2023, 8, 21377-21390. [CrossRef]

- Rai, M.; Singh, A.V.; Paudel, N.; Kanase, A.; Falletta, E.; Kerkar, P.; Heyda, J.; Barghash, R.F.; Pratap Singh, S.; Soos, M. Herbal concoction Unveiled: A computational analysis of phytochemicals' pharmacokinetic and toxicological profiles using novel approach methodologies (NAMs). Current Research in Toxicology 2023, 5, 100118. [CrossRef]

- Singh, A.V.; Bansod, G.; Schumann, A.; Bierkandt, F.S.; Laux, P.; Nakhale, S.V.; Shelar, A.; Patil, R.; Luch, A. Analyzing Tattoo Pigments in a Laboratory Setting: Application of UV-Vis and FTIR Spectroscopy Methods supported with Chemometric Modelling. Researchsquare (Preprint) 2023. [CrossRef]

Figure 1.

Nature-Inspired Robotics Motion: Various biomimetic motions inspired by nature, including inchworm locomotion, jellyfish propulsion, earthworm peristalsis, octopus tentacle movements, sperm motility, elephant trunk manipulation, and earthworm burrowing. These bioinspired motions serve as inspiration for the design and development of robotic systems capable of navigating diverse environments with adaptability and efficiency.

Figure 1.

Nature-Inspired Robotics Motion: Various biomimetic motions inspired by nature, including inchworm locomotion, jellyfish propulsion, earthworm peristalsis, octopus tentacle movements, sperm motility, elephant trunk manipulation, and earthworm burrowing. These bioinspired motions serve as inspiration for the design and development of robotic systems capable of navigating diverse environments with adaptability and efficiency.

Figure 2.

Evolution of Soft machines: This figure illustrates the transformative journey of soft machines, from its conceptualization as an interdisciplinary field merging biology, materials science, and engineering, to the development of robots inspired by nature's elegant solutions.

Figure 2.

Evolution of Soft machines: This figure illustrates the transformative journey of soft machines, from its conceptualization as an interdisciplinary field merging biology, materials science, and engineering, to the development of robots inspired by nature's elegant solutions.

Figure 3.

Mechanical characteristics of Soft Materials in Soft machines: (A) Typical stress-strain curve plots depicting the mechanical behavior of various materials commonly used in soft machines, such as silicone elastomers, urethanes, hydrogels, braided fabrics, hydraulic fluids, and gases. Materials like ceramics and metals have an elastic modulus much higher than soft materials like polymers and elastomers. On the other hand, polymers and, especially, elastomers can withstand much higher strains and deform accordingly making them more compliant. (B) Approximation of Storage Modulus vs Loss Modulus of various organic and inorganic materials. Hydrogels (Blue line); Biological Tissue (yellow line); Natural Rubber (red line); Electrorheological (ER) And Magnetorheological (MR) Fluid Based Polymers (purple line); Materials that have been used in soft machines: Triangle; Hard Materials: Diamond. (C) Work Energy Density vs Young’s Modulus of established soft materials. Abbreviations: SMA — shape memory alloy, IPMC — ionic polymer-metal composite, DEA — dielectric elastomer. Reproduced with permission [

23]. Copyright 2018, Elsevier Ltd. (D) Understanding the Young's modulus of these soft components is crucial for designing and fabricating soft machines with desired mechanical properties, including flexibility, resilience, and responsiveness to external stimuli. Soft machines are composed primarily of materials with moduli comparable with those of soft biological materials which not only makes them compliant, but also leads to compliance matching. Reproduced with permission [

16]. Copyright 2015, Springer Nature Limited.

Figure 3.

Mechanical characteristics of Soft Materials in Soft machines: (A) Typical stress-strain curve plots depicting the mechanical behavior of various materials commonly used in soft machines, such as silicone elastomers, urethanes, hydrogels, braided fabrics, hydraulic fluids, and gases. Materials like ceramics and metals have an elastic modulus much higher than soft materials like polymers and elastomers. On the other hand, polymers and, especially, elastomers can withstand much higher strains and deform accordingly making them more compliant. (B) Approximation of Storage Modulus vs Loss Modulus of various organic and inorganic materials. Hydrogels (Blue line); Biological Tissue (yellow line); Natural Rubber (red line); Electrorheological (ER) And Magnetorheological (MR) Fluid Based Polymers (purple line); Materials that have been used in soft machines: Triangle; Hard Materials: Diamond. (C) Work Energy Density vs Young’s Modulus of established soft materials. Abbreviations: SMA — shape memory alloy, IPMC — ionic polymer-metal composite, DEA — dielectric elastomer. Reproduced with permission [

23]. Copyright 2018, Elsevier Ltd. (D) Understanding the Young's modulus of these soft components is crucial for designing and fabricating soft machines with desired mechanical properties, including flexibility, resilience, and responsiveness to external stimuli. Soft machines are composed primarily of materials with moduli comparable with those of soft biological materials which not only makes them compliant, but also leads to compliance matching. Reproduced with permission [

16]. Copyright 2015, Springer Nature Limited.

Figure 4.

Stimuli-responsive soft machines Inspired by Plant Motion: This figure illustrates stimuli-responsive soft machines inspired by plant motion, incorporating (clockwise, peripherally) hydraulic, pneumatic, electrical, and chemical stimuli-responsive mechanisms. (Centre) Mimicking the adaptive responses observed in plants to (A) environmental cues, these soft machines demonstrate versatile motion capabilities, enabling them to navigate and interact with their surroundings effectively. The integration of diverse stimuli-responsive systems: (B) humidity, (C) pH, (D) Temperature, (E) Light, (F) Magnetic fields, and (G) Electrical fields enhances the adaptability and functionality of these robots, promising advancements in fields such as agriculture, environmental monitoring, and soft machines research.

Figure 4.

Stimuli-responsive soft machines Inspired by Plant Motion: This figure illustrates stimuli-responsive soft machines inspired by plant motion, incorporating (clockwise, peripherally) hydraulic, pneumatic, electrical, and chemical stimuli-responsive mechanisms. (Centre) Mimicking the adaptive responses observed in plants to (A) environmental cues, these soft machines demonstrate versatile motion capabilities, enabling them to navigate and interact with their surroundings effectively. The integration of diverse stimuli-responsive systems: (B) humidity, (C) pH, (D) Temperature, (E) Light, (F) Magnetic fields, and (G) Electrical fields enhances the adaptability and functionality of these robots, promising advancements in fields such as agriculture, environmental monitoring, and soft machines research.

Figure 5.

Examples of common actuation mechanisms used in bioinspired soft machines.: Fluidic (pneumatic or hydraulic) (Reproduced with permission [

52]. Copyright 2019, Springer Nature Limited. Reproduced with permission [

53]. Copyright 2020, IOP Publishing), Thermal (Reproduced with permission [

54]. Copyright 2022, Elsevier Ltd. Reproduced with permission [

55]. Copyright 2016, ACS Publications.), Light (Reproduced with permission [

56]. Copyright 2020, ACS Publications. Reproduced with permission [

57]. Copyright 2016, American Association for the Advancement of Science.), Chemical (Reproduced with permission [

58]. Copyright 2023, Wiley. Reproduced with permission [

59]. Copyright 2015, American Association for the Advancement of Science.), Magnetic (Reproduced with permission [

60]. Copyright 2019, Springer Nature Limited. Reproduced with permission [

61]. Copyright 2018, Wiley.), and Electrical (Reproduced with permission [

62]. Copyright 2019, American Association for the Advancement of Science. Reproduced with permission [

63]. Copyright 2019, American Association for the Advancement of Science).

Figure 5.

Examples of common actuation mechanisms used in bioinspired soft machines.: Fluidic (pneumatic or hydraulic) (Reproduced with permission [

52]. Copyright 2019, Springer Nature Limited. Reproduced with permission [

53]. Copyright 2020, IOP Publishing), Thermal (Reproduced with permission [

54]. Copyright 2022, Elsevier Ltd. Reproduced with permission [

55]. Copyright 2016, ACS Publications.), Light (Reproduced with permission [

56]. Copyright 2020, ACS Publications. Reproduced with permission [

57]. Copyright 2016, American Association for the Advancement of Science.), Chemical (Reproduced with permission [

58]. Copyright 2023, Wiley. Reproduced with permission [

59]. Copyright 2015, American Association for the Advancement of Science.), Magnetic (Reproduced with permission [

60]. Copyright 2019, Springer Nature Limited. Reproduced with permission [

61]. Copyright 2018, Wiley.), and Electrical (Reproduced with permission [

62]. Copyright 2019, American Association for the Advancement of Science. Reproduced with permission [

63]. Copyright 2019, American Association for the Advancement of Science).

Figure 8.

Soft Robotic Swarm for targeted drug release: Self-controllable small-scale robots that can adapt and navigate a complex path to reach the target area and give a coordinated response for a specific task, for example-controlled drug release. If needed, self-assembly could be performed to improve the effectiveness of a coordinated response.

Figure 8.

Soft Robotic Swarm for targeted drug release: Self-controllable small-scale robots that can adapt and navigate a complex path to reach the target area and give a coordinated response for a specific task, for example-controlled drug release. If needed, self-assembly could be performed to improve the effectiveness of a coordinated response.

Figure 9.

Ethical Framework for Bioinspired Soft machines: The establishment of an ethical framework can guide the development and deployment of bioinspired soft machines. Addressing concerns including privacy, safety, and societal impact, this framework can ensure responsible innovation and adoption of these technologies, fostering ethical considerations throughout their lifecycle.

Figure 9.

Ethical Framework for Bioinspired Soft machines: The establishment of an ethical framework can guide the development and deployment of bioinspired soft machines. Addressing concerns including privacy, safety, and societal impact, this framework can ensure responsible innovation and adoption of these technologies, fostering ethical considerations throughout their lifecycle.

Table 1.

Comprehensive table outlining key aspects of bioinspired materials for soft machines.

Table 1.

Comprehensive table outlining key aspects of bioinspired materials for soft machines.

| Materials Type |

Applications Field |

Material Selection: Application |

Actuation Criteria: Application |

| Electroactive Polymers |

Soft Actuators |

Flexibility, Responsiveness, Durability |

Electrical Stimulation, Mechanical Deformation |

| Magnetic Soft Composites |

Soft machines |

Magnetic Responsiveness, Structural Integrity |

Magnetic Fields |

| Stimuli-Responsive Hydrogels and Liquid Crystal Elastomers |

Soft Actuators, Robotics |

Swelling Behavior, Mechanical Properties |

Various Stimuli (e.g., Temperature, pH) |

| Shape Memory Alloys |

Biomedical Devices |

Shape Recovery, Biocompatibility |

Thermal Activation |

| Chemical-Responsive Materials |

Adaptive Structures |

Chemical Sensitivity, Structural Adaptability |

Chemical Triggers |

Table 2.

Examples of Commercially Available Bio-Inspired Products and Their Applications.

Table 2.

Examples of Commercially Available Bio-Inspired Products and Their Applications.

| Company/Group Name |

Bioinspired Theme |

Product Name |

Usage |

Reference |

| Fusion Bionic |

Nano-scale Surface Texture |

Bio-inspired Nano Texture |

Surface applications in various fields like medical and aerospace |

[34] |

| GreenPod Labs |

Plant-Based Volatiles |

Packaging Sachets |

Sustainable packaging |

[35] |

| Intropic Materials |

Enzymatic Processes |

Plastic Degradation |

Plastic waste management |

[36] |

| Biohm |

Biomimicry |

Circular Construction |

Sustainable construction |

[37] |

| Terrapin Bright Green |

Biomimicry in Transportation |

Biomimicry-inspired Transportation Solutions |

Sustainable transportation systems |

[38] |

| TISSIUM |

Gecko Adhesion |

Surgical Adhesive |

Medical surgeries (Tissue reconstruction) |

[39] |

| SoftGripping |

Soft grippers |

GorillaFingers |

Pick and place |

[40] |

Table 3.

Embodied intelligence: Comparison of the capabilities of soft machines due to their embodied intelligence versus conventional hard robots. Authors’ opinion about how advantageous they are in terms of different characteristics is indicated using a star system where ⋆ is the lowest and ⋆⋆⋆ is the highest.

Table 3.

Embodied intelligence: Comparison of the capabilities of soft machines due to their embodied intelligence versus conventional hard robots. Authors’ opinion about how advantageous they are in terms of different characteristics is indicated using a star system where ⋆ is the lowest and ⋆⋆⋆ is the highest.

| Robot Characteristics |

Soft machines |

Conventional Hard Robotics |

| Compliance |

Able to bend and twist with high curvatures and exhibit unprecedented adaptation, sensitivity and agility. Soft materials are elastic and can deform and absorb much of the energy arising from a collision, so large Degrees of Freedom (DoF). |

Poor grasping power and mobility over soft surfaces. Hard materials perform single tasks efficiently, but often with limited compliance due to rigid links and joints. |

| Adaptability |

Soft machines can adapt their shape to the environment, enabling their use in confined spaces. |

Hard robots have limited adaptability due to rigid links and joints, restricting their use in confined spaces. |

| Materials Young Modulus |

Soft materials like skin or muscle tissue have a Young's Modulus ranging from 10^4 to 10^9 Pa. |

Hard materials like metals or hard plastics have a Young's Modulus ranging from 10^9 to 10^12 Pa. |

| Actuation force |

Soft structures are usually able to apply weak forces and torques. |

Conventional actuators can apply high forces and torques. |

Ease of integrating subsystems

|

Integrating sensing, actuation, computation, power storage, and communication into controllable soft-bodied material is difficult. Subsystems may move with respect to each other. |

Subsystems can be attached firmly to the body. |

| Ease of fabrication |