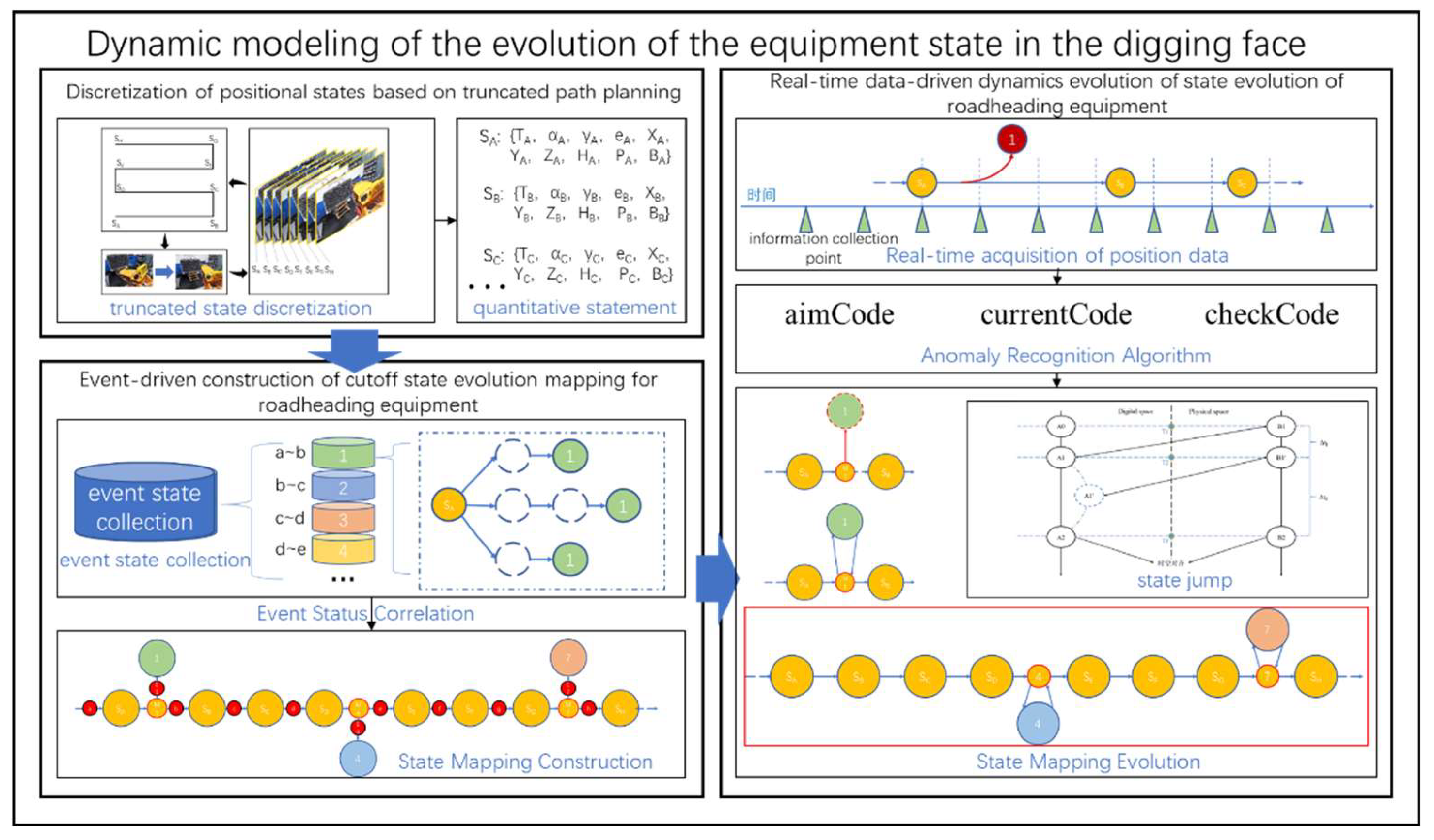

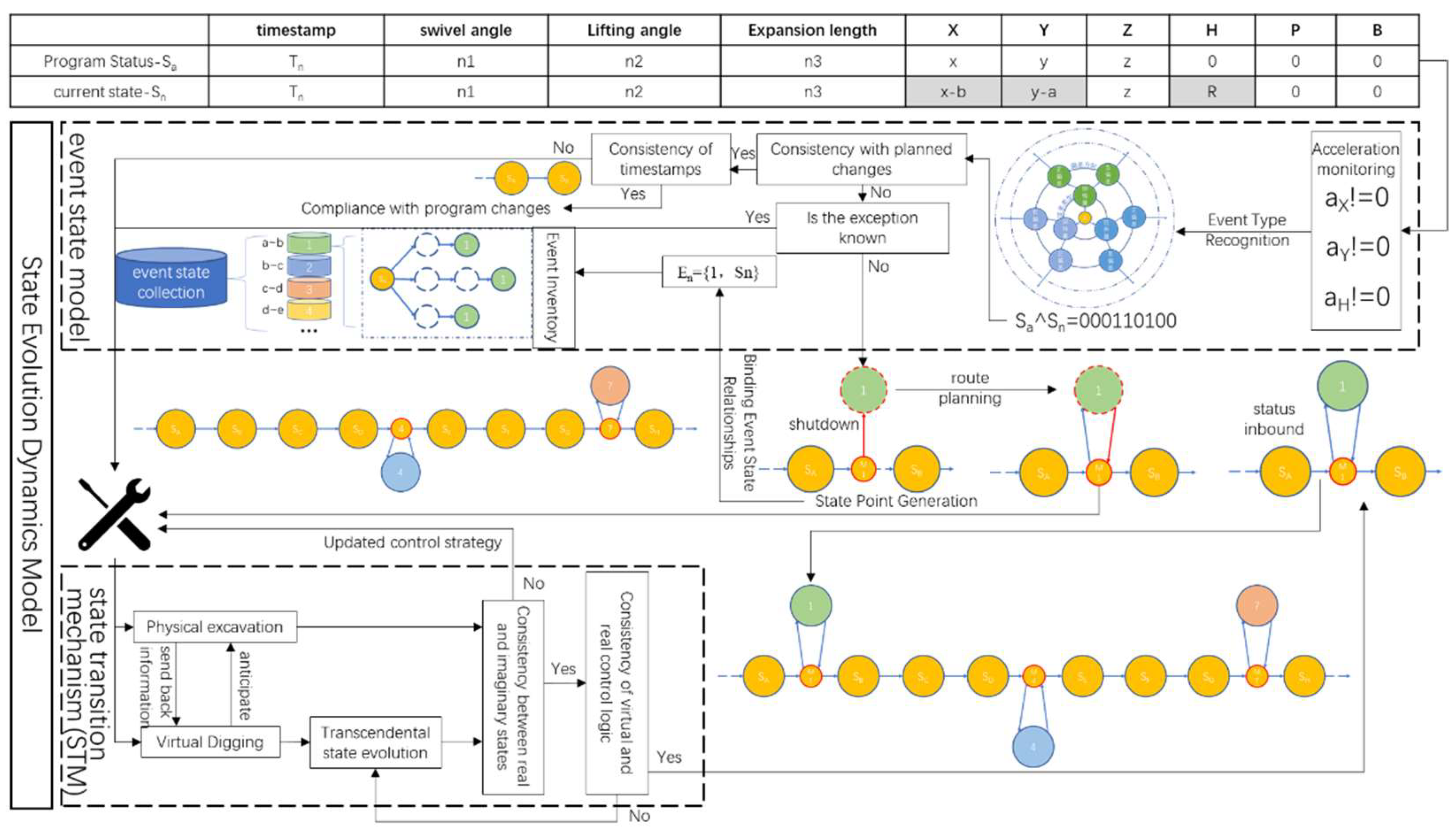

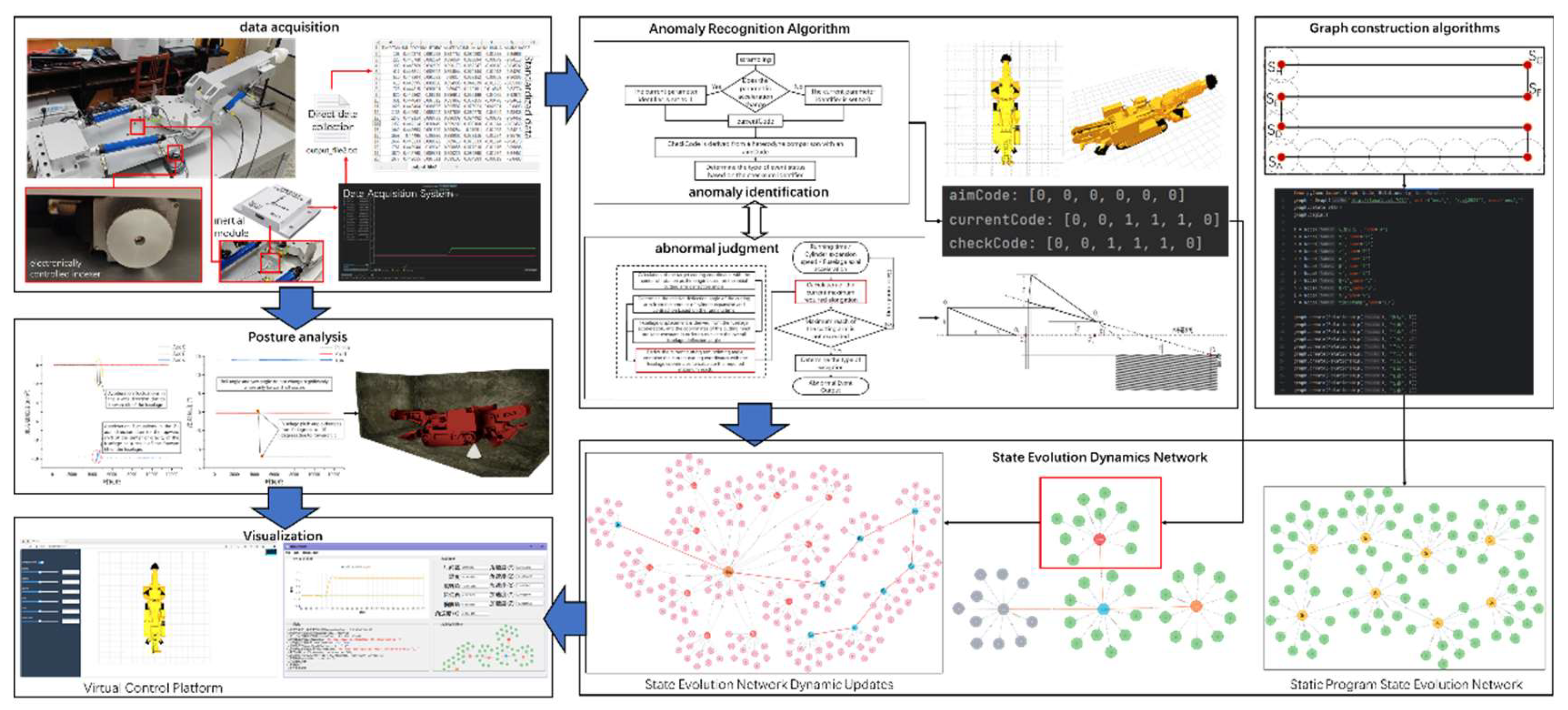

2.4.1. Anomaly Recognition Algorithm

The basis of model operation lies in the ability to identify anomalous states; how to identify event state types has been discussed above, and state identification, i.e., the method of identifying event state types, is critical to the endogenous evolution of the model's dynamics.

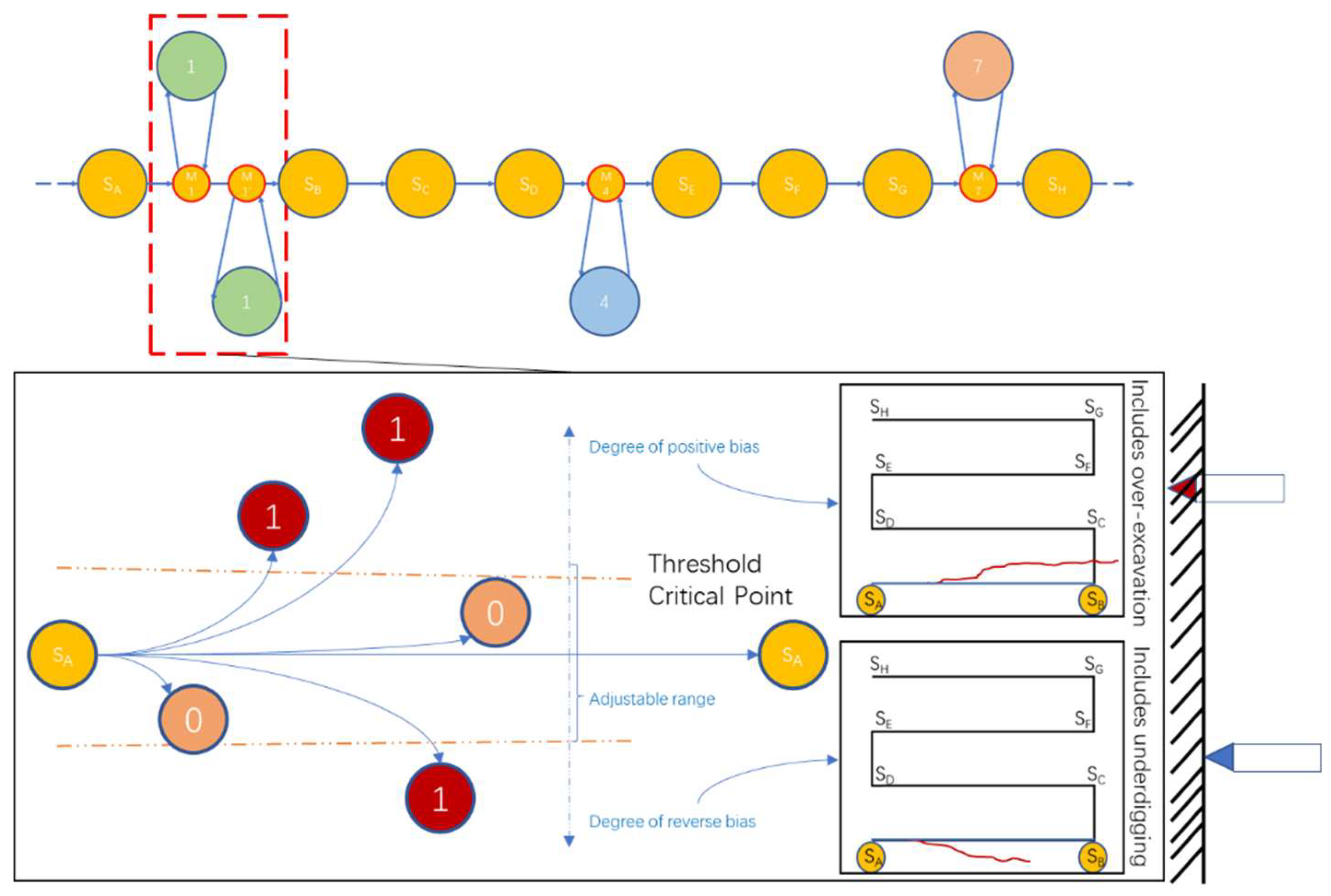

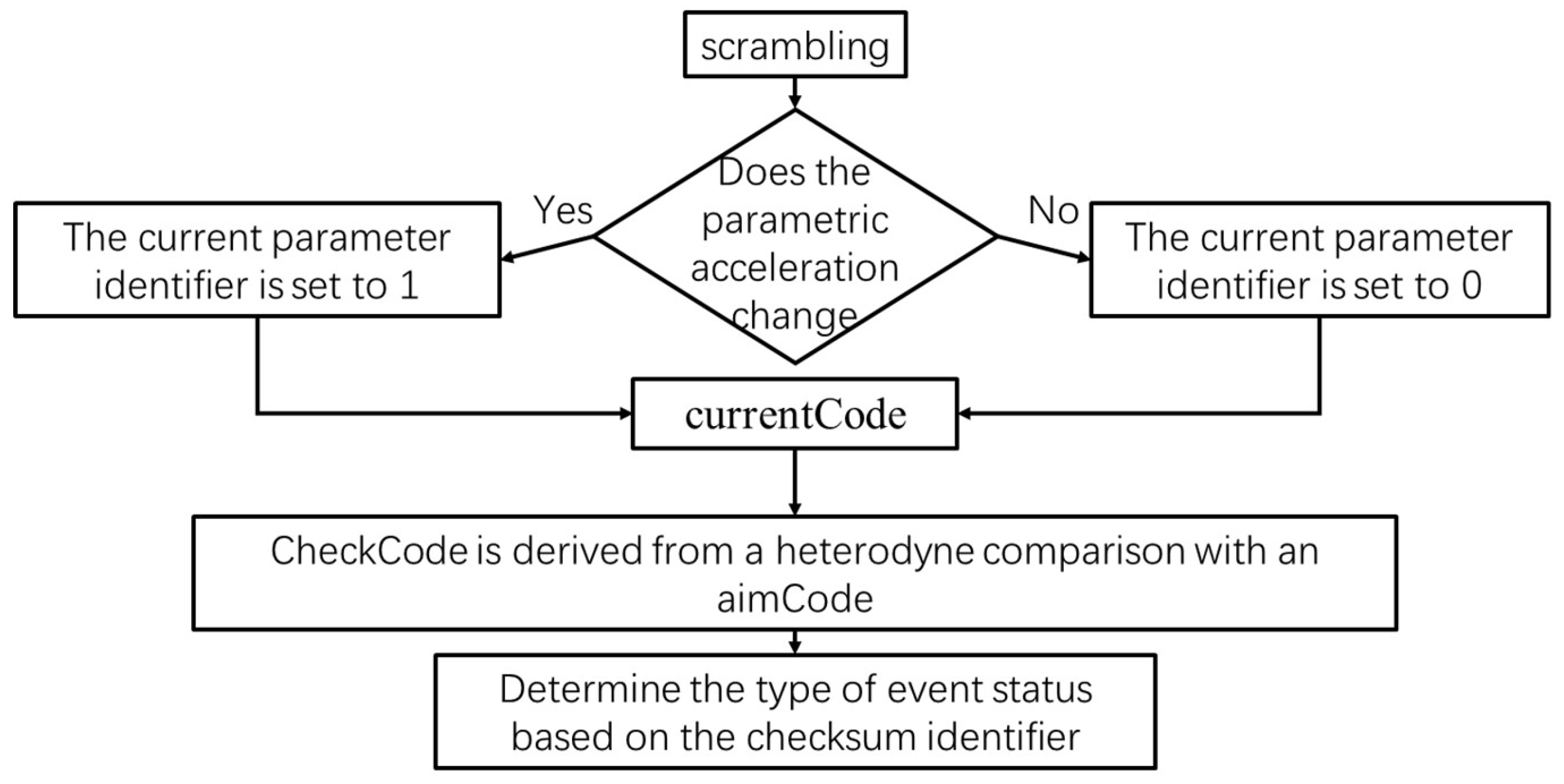

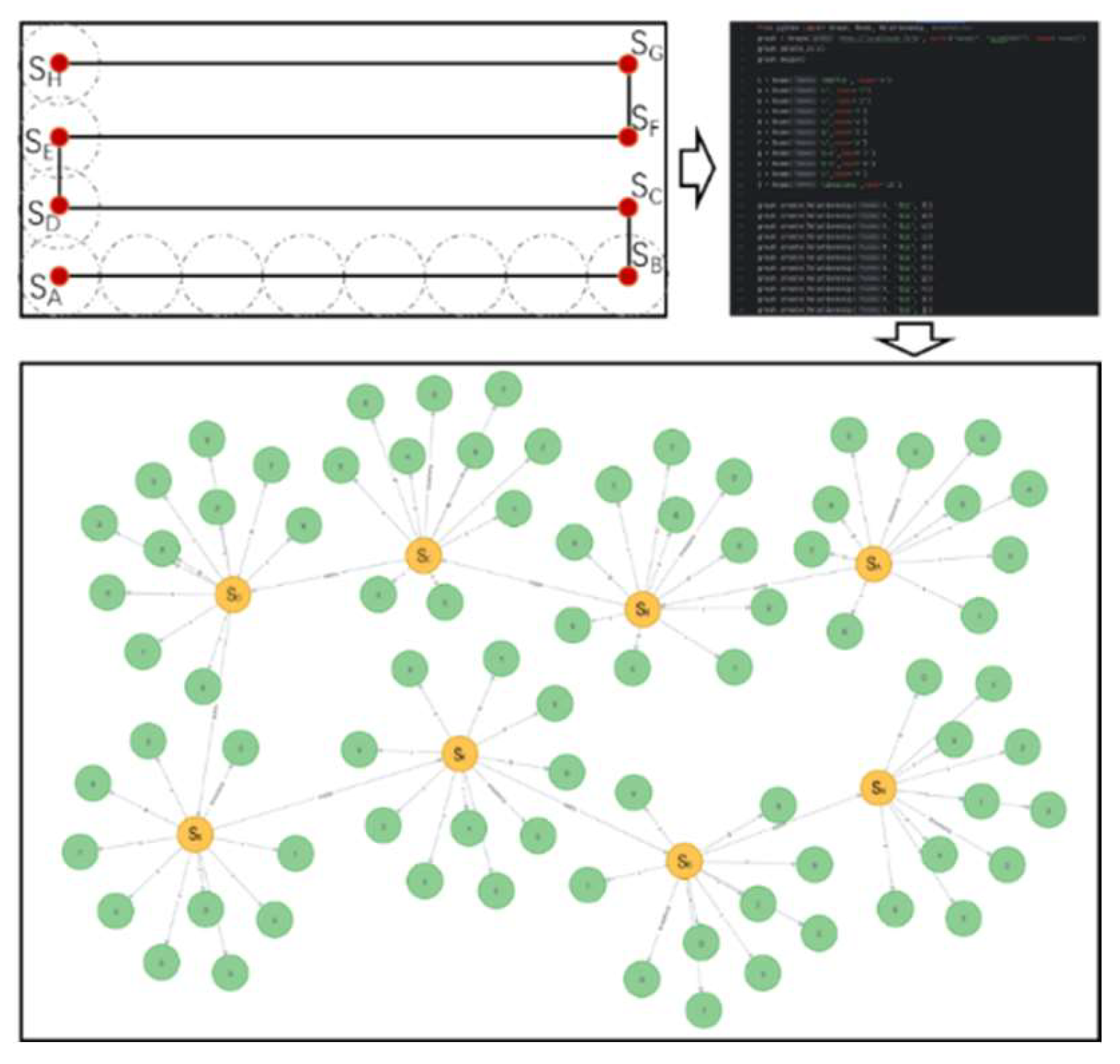

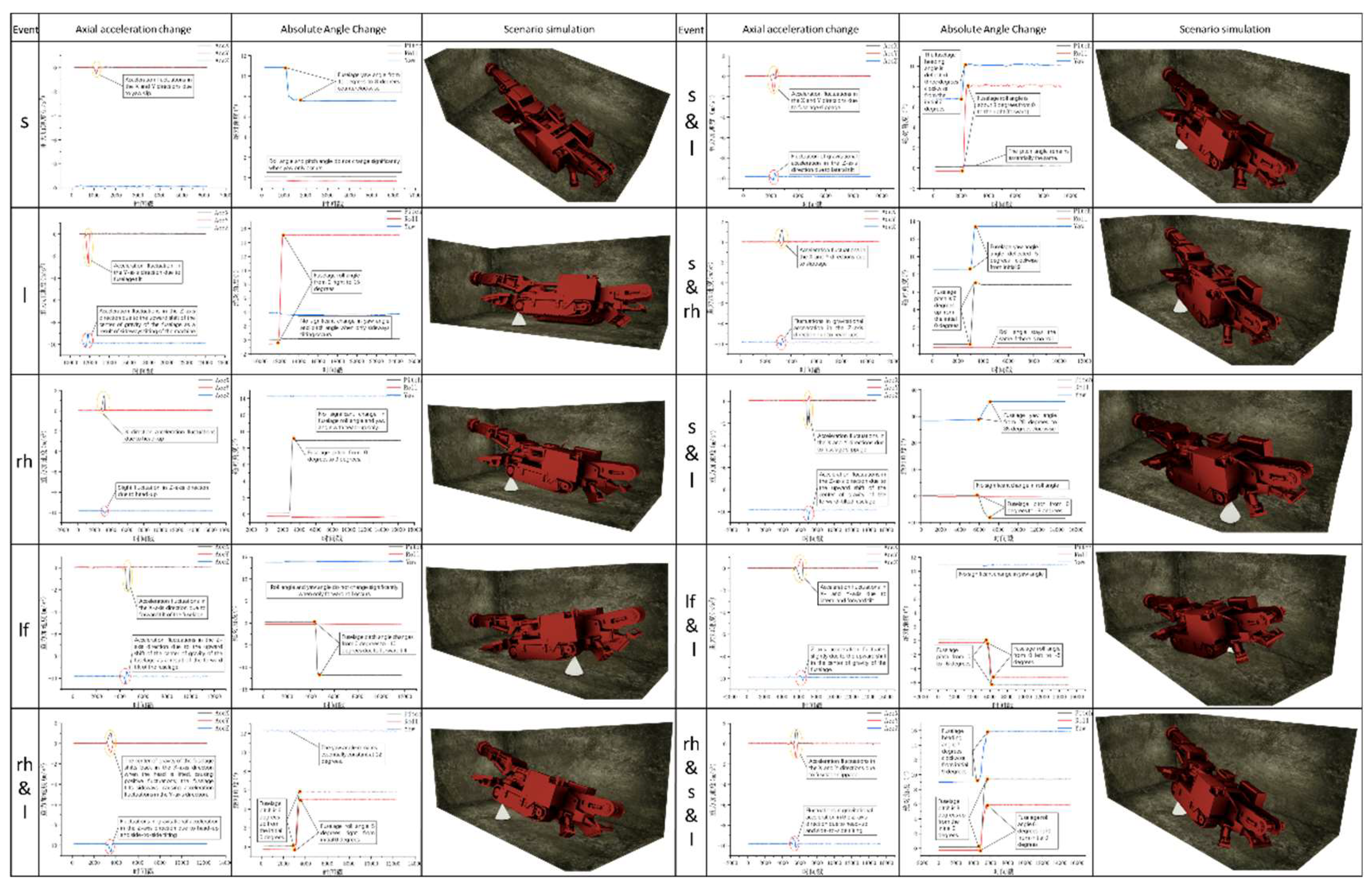

The state identification algorithm is shown in

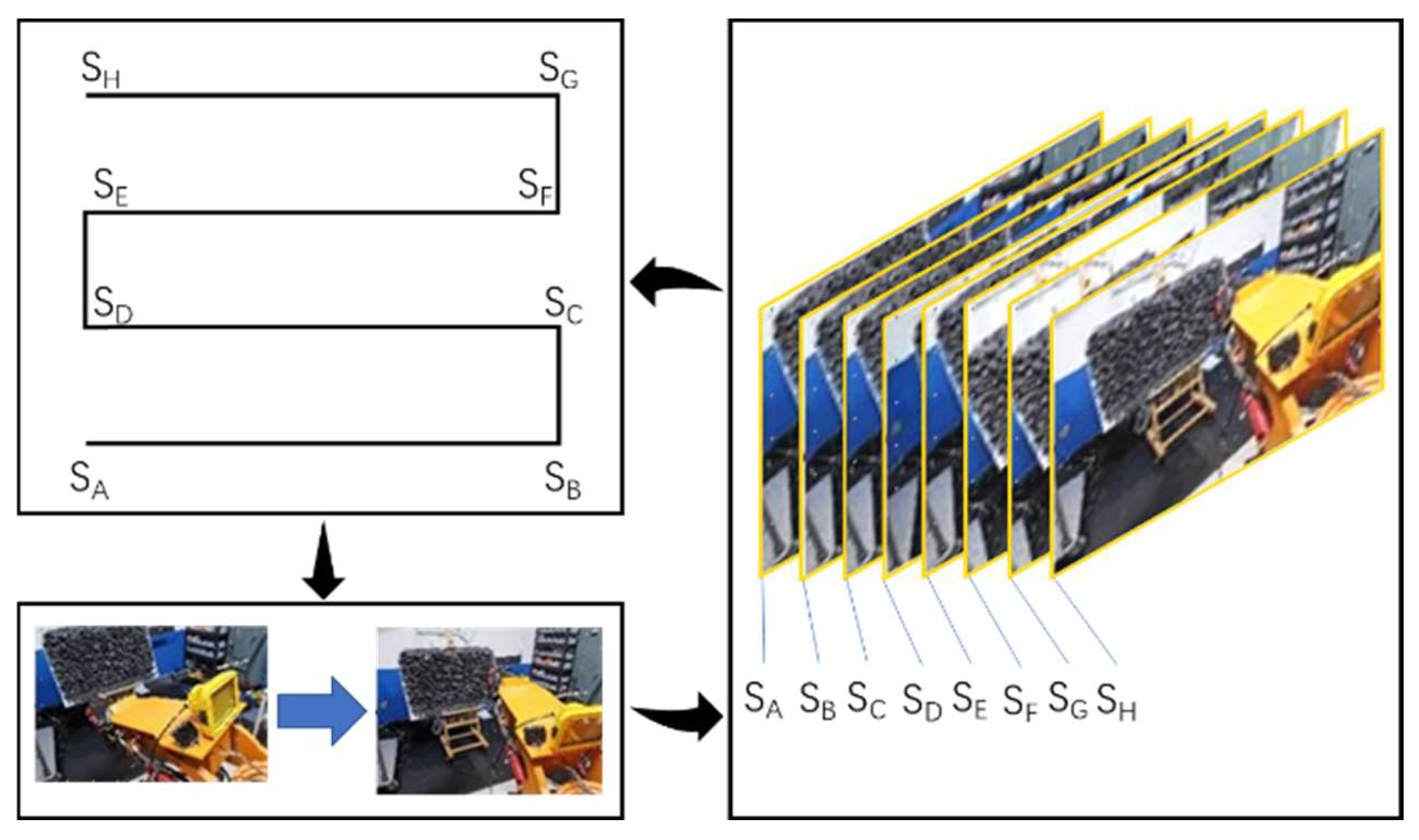

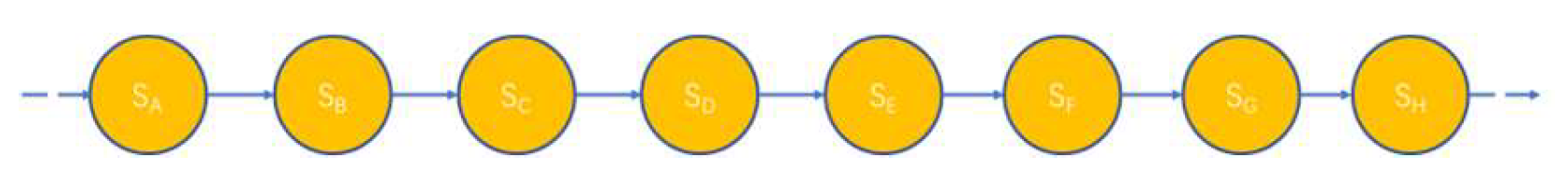

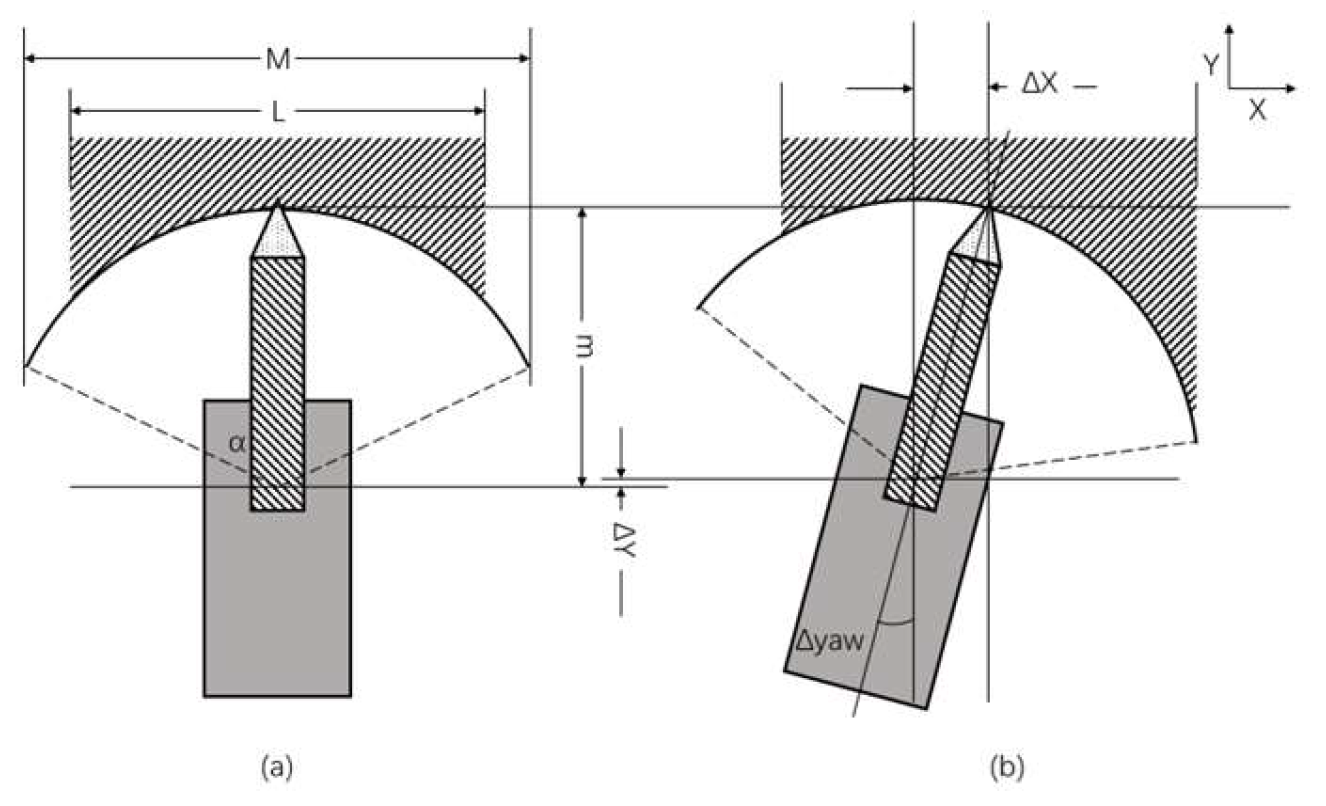

Figure 10. The anomaly type recognition algorithm consists of three state identifiers: aimCode, currentCode, and checkCode, which are consistently judged through an iso-or relationship. A 0 or 1 in these identifiers represents a change in the acceleration of a parameter at the current timestamp, with a change being a 1 and no change being a 0. The aimCode represents an airframe control command event at the current timestamp. For example, during the process of cutting operation from state S

A to S

B, the system needs to adjust the motion mode, stop slewing and start lifting the cutting arm, and the overall body position remains unchanged. Taking the case of not considering the cutting arm extension and retraction as an example, the system command event identifier at S

B should be T110000000, T stands for the time stamp of the system command, and the numbers from the left to the right represent the platform slewing acceleration, the cutting arm lifting angle acceleration, the cutting arm retraction and retraction, the spatial coordinates of X, Y and Z, the fuselage yaw angle H acceleration, the fuselage pitch angle P acceleration, and the fuselage roll angle B acceleration. The other parameters are 0 if they are unchanged, the rotary platform rotary angle acceleration becomes negative when the slewing stops, and the cutter arm lifting angle acceleration increases suddenly when the lifting starts. As shown in

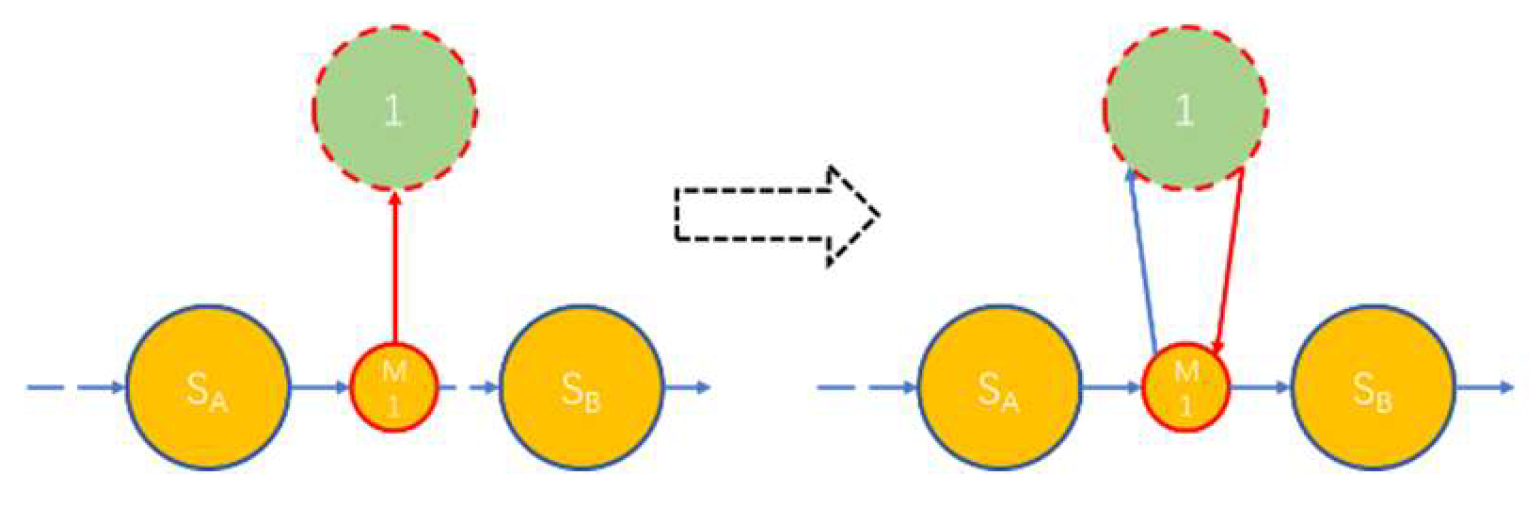

Figure 7, abnormal perturbations usually occur in non-system command bits. Under these conditions, when branch state node 1 is generated, the digging state should maintain the original operation state, i.e., the aimCode should be 000000000. if the current abnormality is the lifting angle abnormality, the corresponding acceleration of the lifting angle will change, i.e., the current state identification code currentCode is 010000000. Comparing aimCode and currentCode, we can get the specific variable of unplanned change, i.e. checkCode is 010000000. according to checkCode, we can determine the type of current event.

Before constructing the event triggering mechanism, it is crucial to clarify its role and the significance of its construction. The core objective of the mechanism is to ensure the synchronization of the virtual and real in the remote intelligent tunneling process. In the current synchronization scheme, the virtual control platform and the physical digging site synchronize their operations according to the instructions of the operation plan. If the digging site encounters disturbances that lead to unplanned changes in the operation status, the virtual-real synchronization that was originally maintained by synchronizing the operation instructions will be destroyed. The virtual tunneling scene needs to be adjusted according to the real data feedback from the physical tunneling site, but this process generates a time delay. If the virtual scene digging state is adjusted in real time according to the site data, the virtual digging scene will always lag behind the real digging site, which can not accurately reflect the current digging state, affecting the corrective decision-making of the remote intelligent digging system on digging anomalies. Event triggering mechanism identifies the disturbance event when it occurs and adjusts the virtual synchronization strategy.

When a change in the digging status is detected by acceleration comparison, the value of the specific parameter change is calculated and compared with the last two control instruction change nodes. If the established operation control instructions do not contain the current change, it means that the state change is caused by a disturbance event.

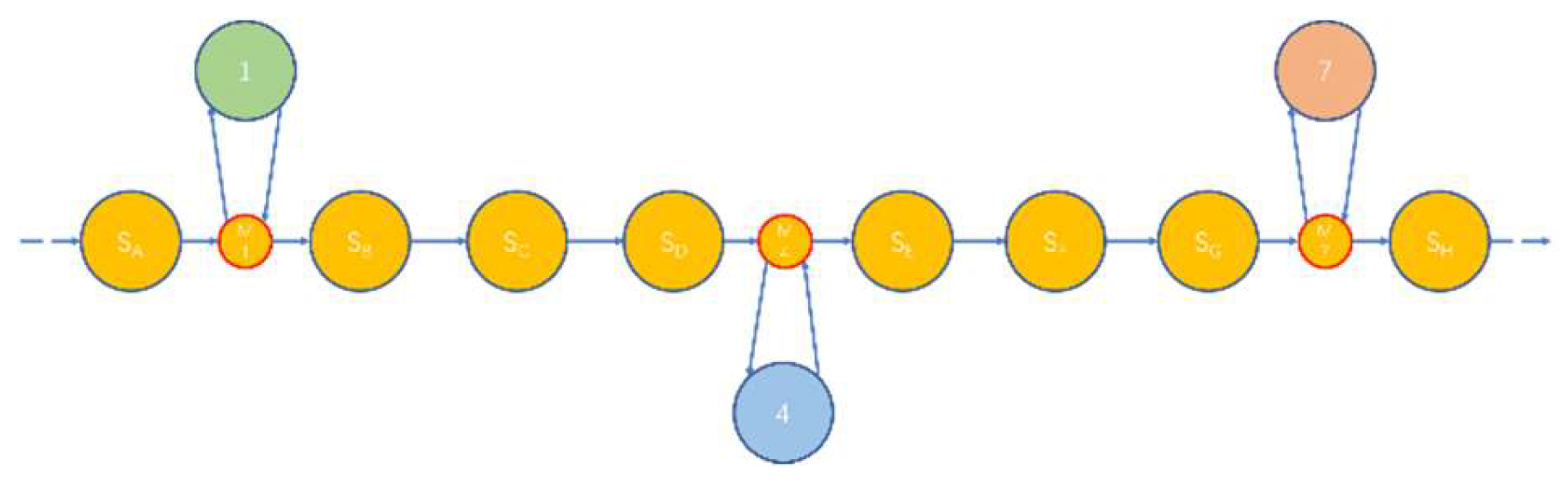

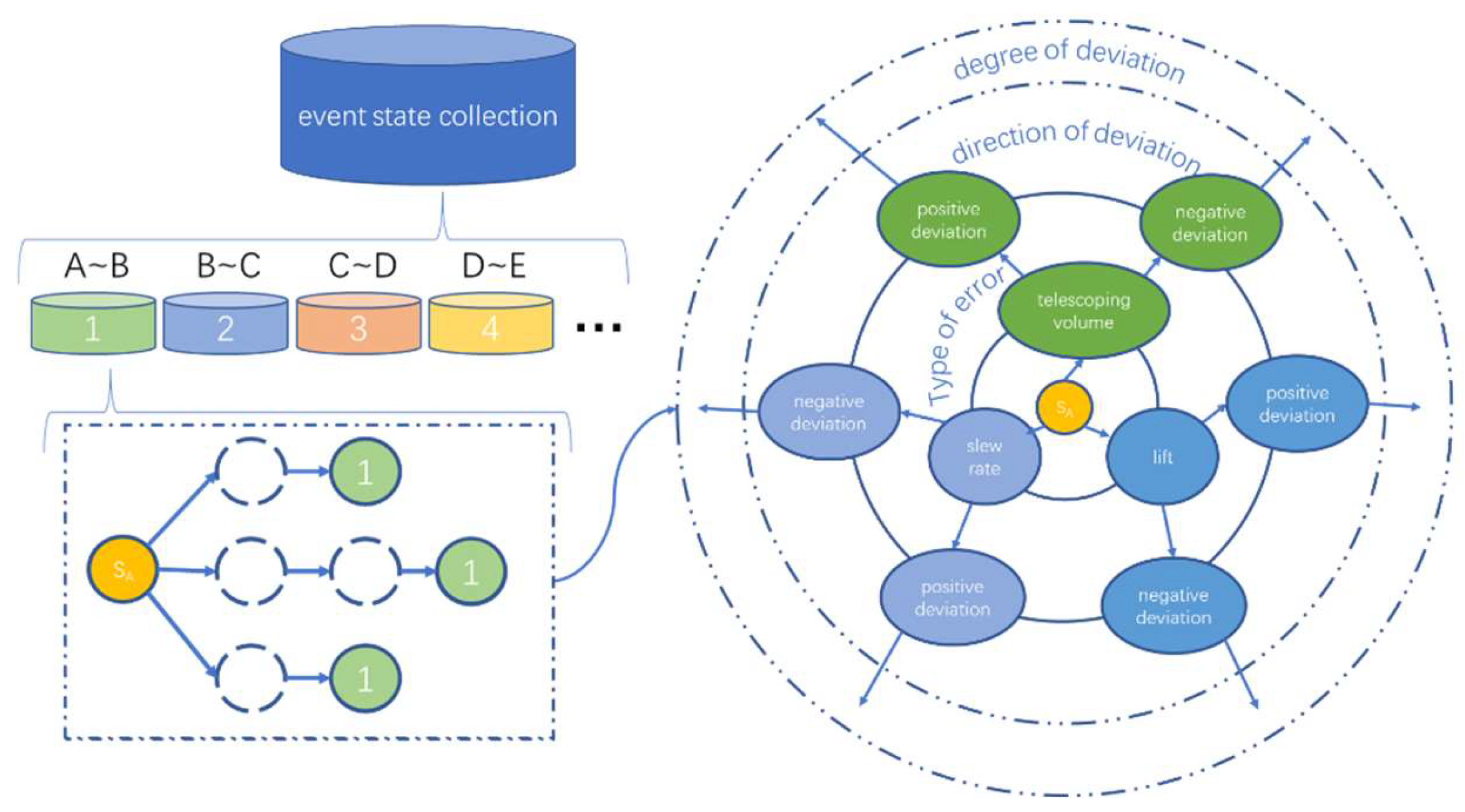

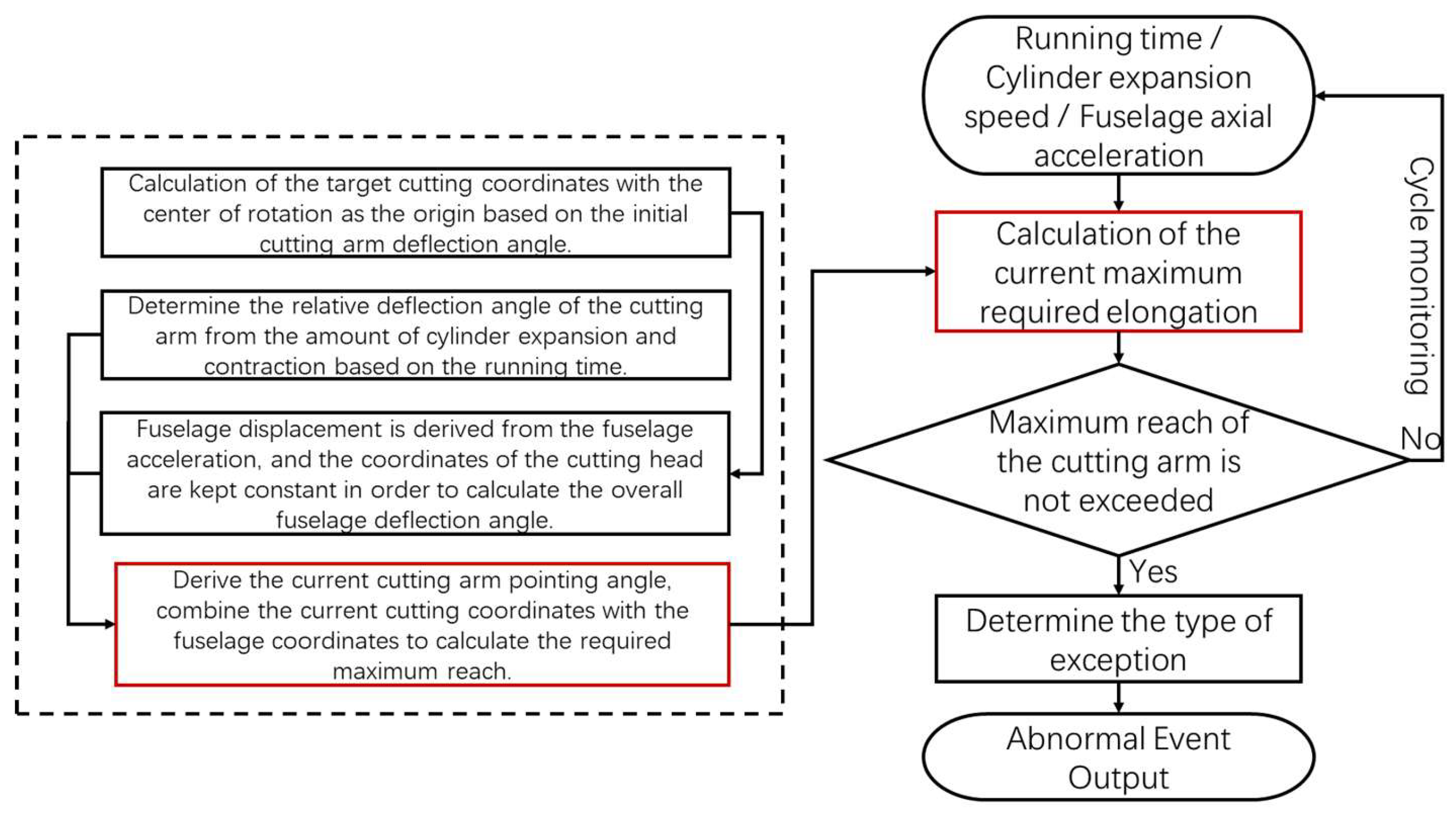

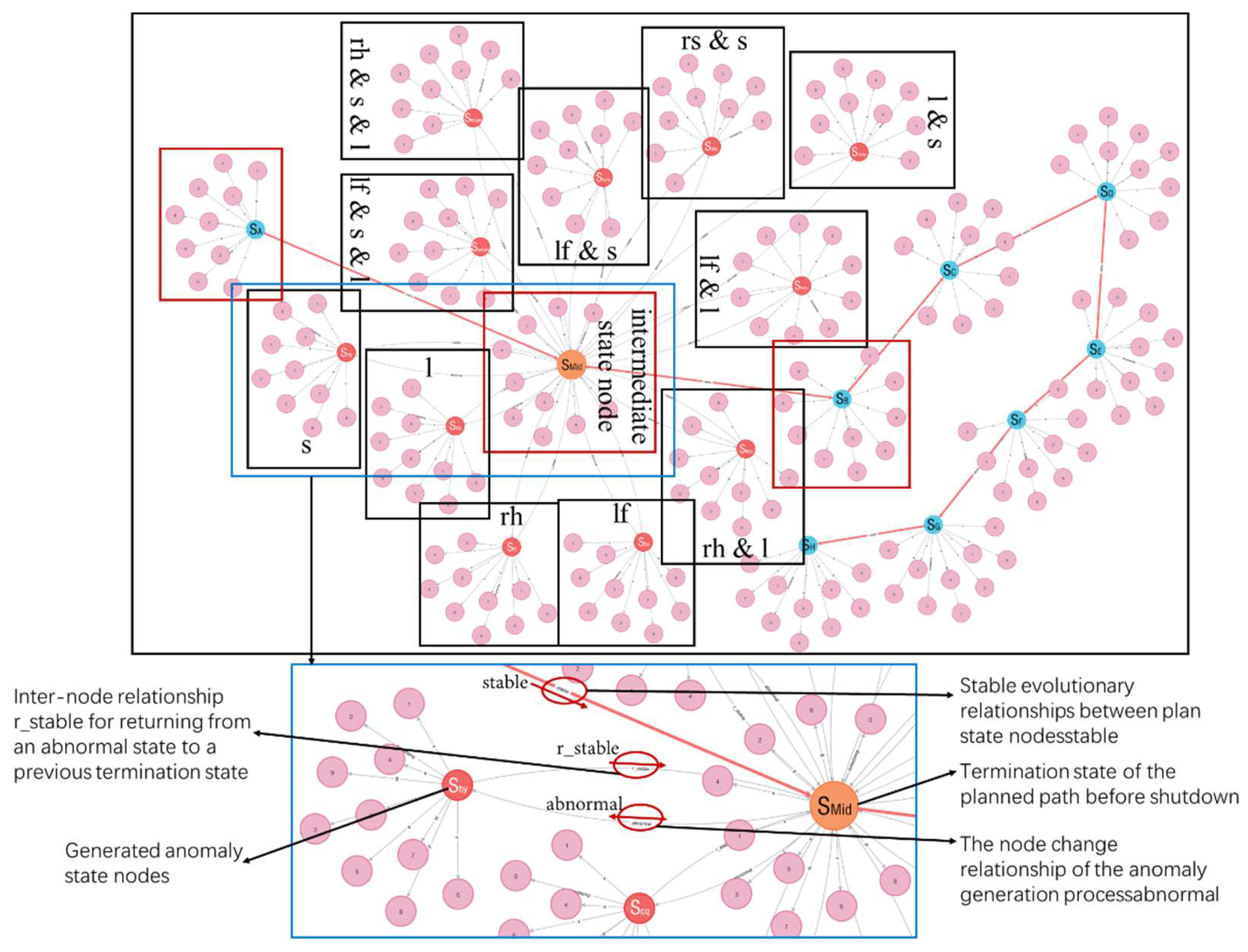

Determining the class of perturbation events is crucial to change the virtual real alignment strategy. The state evolution network contains various event trees, as shown in

Figure 11. Based on the event tree structure after the current state change, according to the categorized hierarchical storage model, starting from the type of stage at which the event occurs, one by one, downward comparison with the event trees already existing in the network is filtered. If the same event tree exists in the formed state evolution network, the strategy to correct the current perturbation is determined based on the historical processing scheme of the corresponding event. If the search and comparison results show that it does not exist, a new strategy needs to be formulated based on the current specific situation, and the new event tree is bound to the current processing strategy and stored into the existing state evolution network.

2.4.2. Real-Time Data-Driven

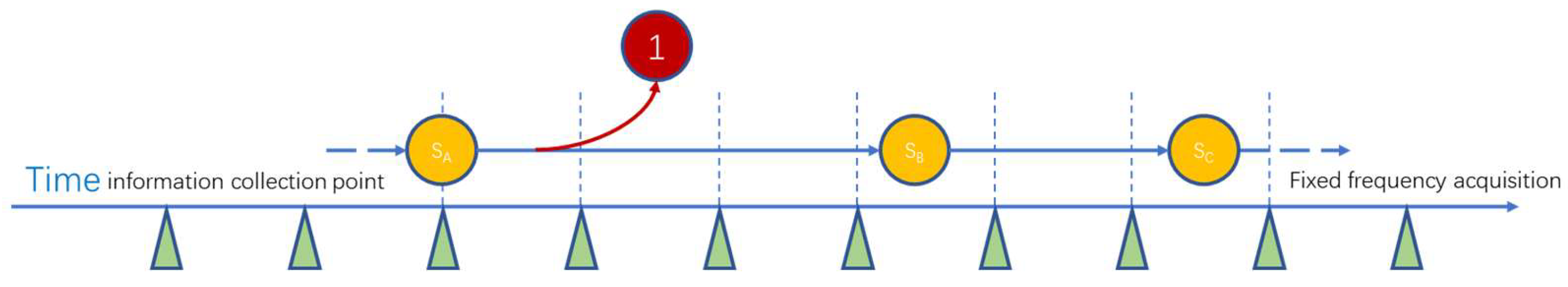

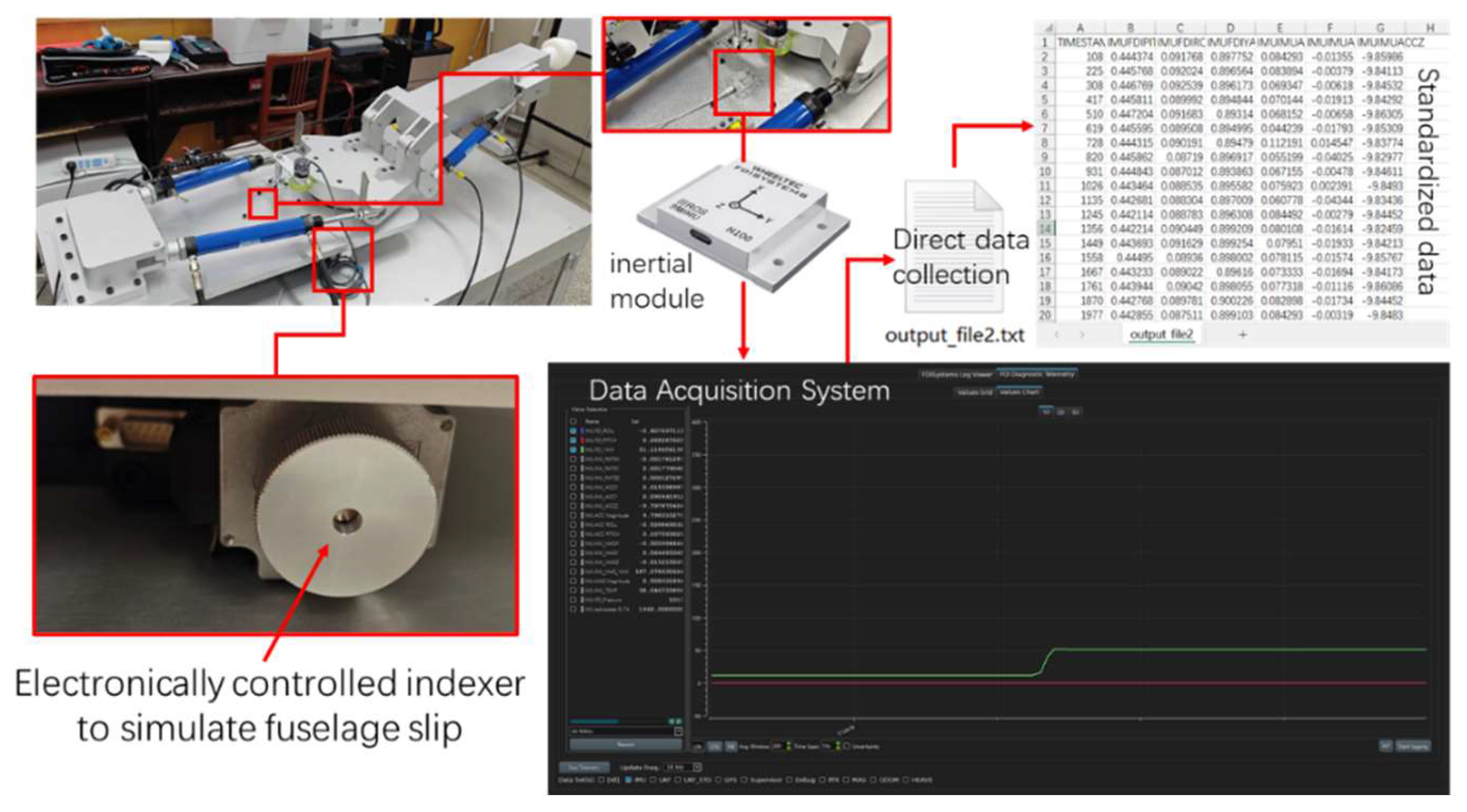

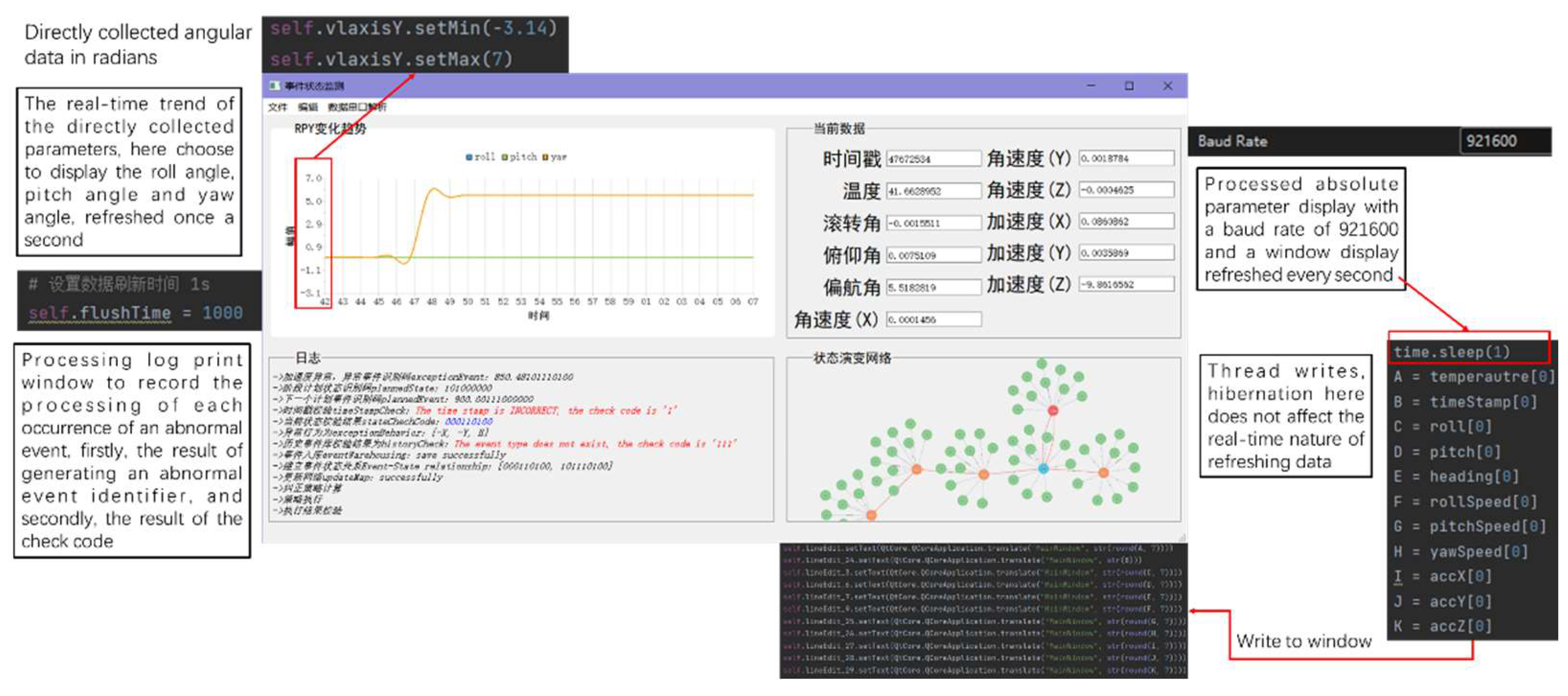

First, data are collected at a fixed frequency to monitor changes in equipment position parameters. The key parameters of the device, such as position, attitude, and velocity, can be accurately tracked mainly by periodically collecting them. A schematic diagram of real-time data acquisition is shown in

Figure 12. The data acquisition system operates at a preset fixed frequency, e.g., once per second or multiple times per second, depending on the operating characteristics of the equipment and the required monitoring accuracy. Each time data is collected it is instantly processed and analyzed to determine if the equipment is in normal operating condition. If an abnormal change in a monitored parameter is detected, the system immediately triggers a subsequent processing program. This process is automated, ensuring a rapid response to abnormal conditions.

Detection of abnormal changes is accomplished by setting normal ranges or thresholds for parameters. As soon as a parameter falls outside these preset ranges, the system recognizes the abnormality and initiates the appropriate processing. This involves not only automatically adjusting equipment settings or performing operations such as emergency shutdowns, but also issuing alarms to notify operators to prevent potential equipment damage or production accidents.

In addition, the mechanism is able to record the exact time the anomaly occurred and the stage of operation the equipment was in. This is critical for subsequent troubleshooting and system optimization, as it provides detailed timeline and contextual information to help engineers analyze why the anomaly occurred and take targeted measures for improvement.

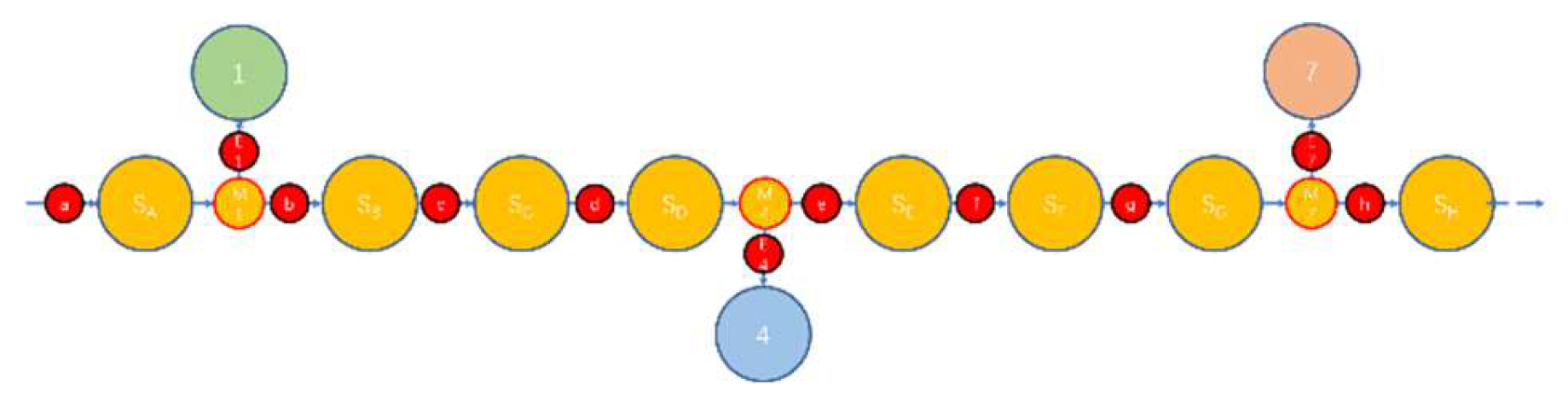

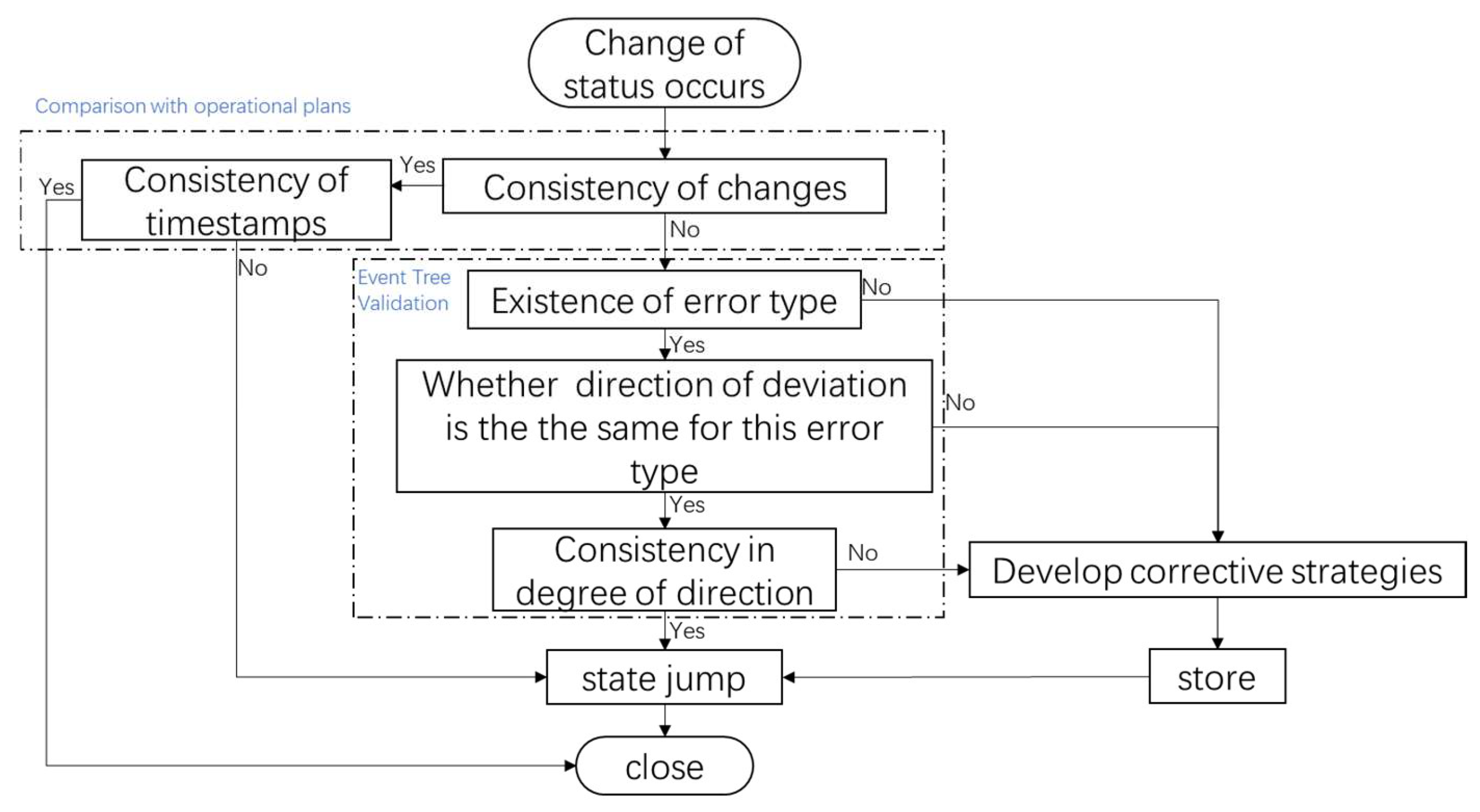

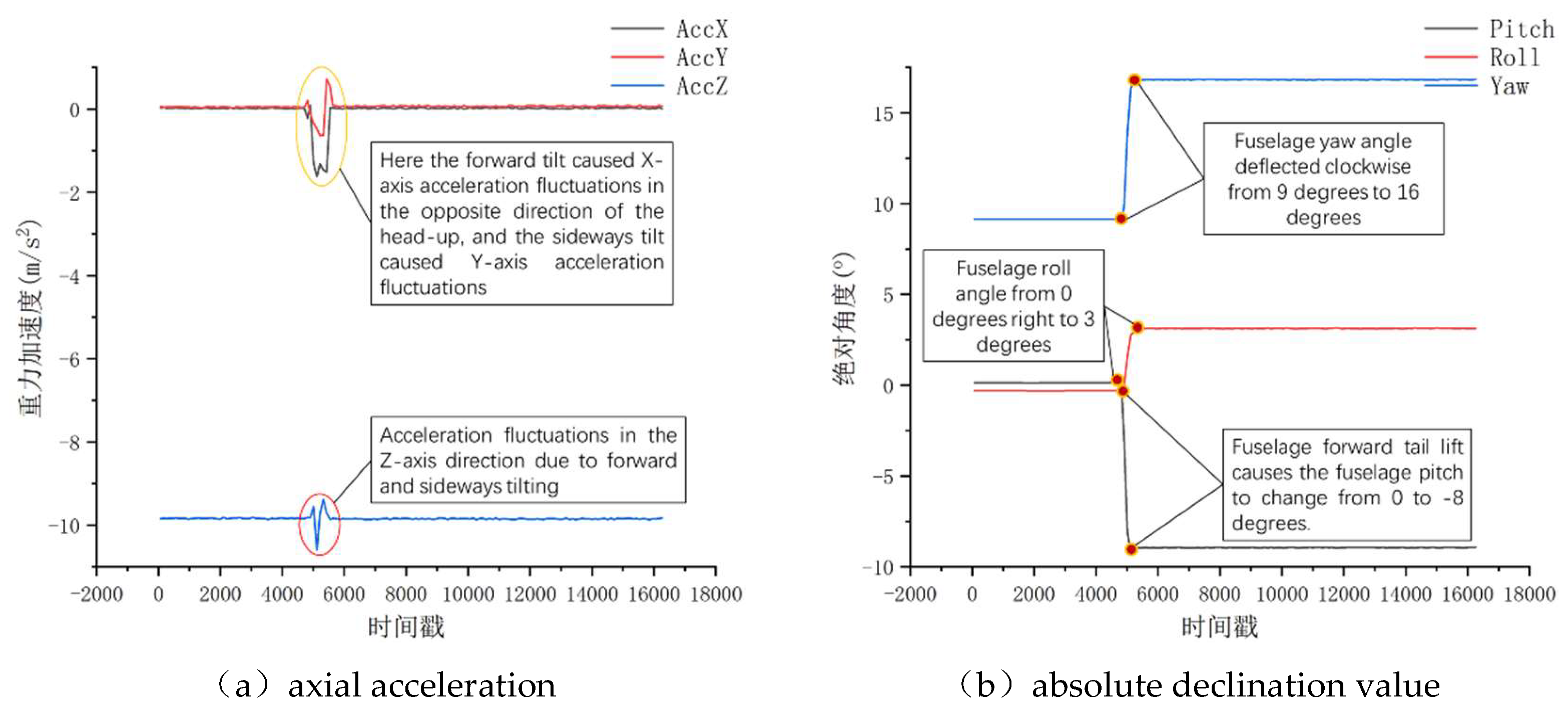

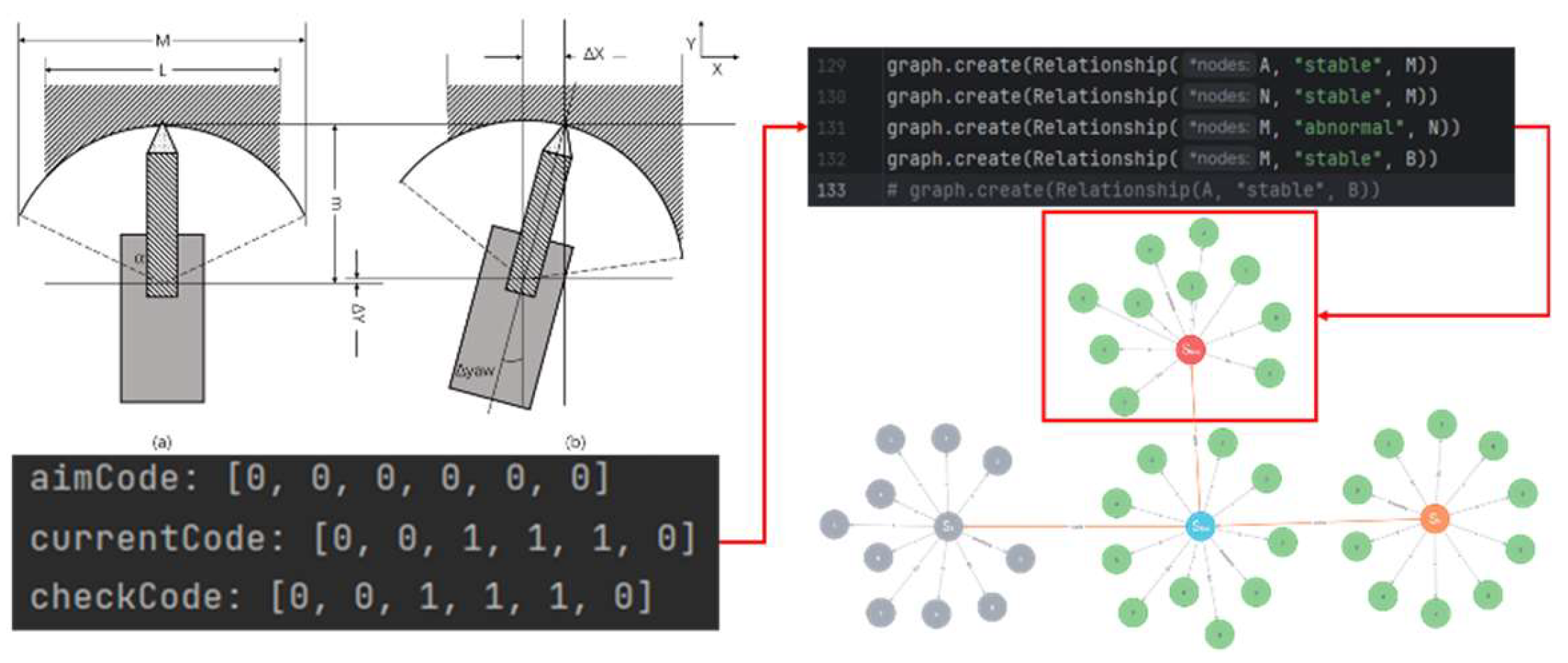

Real-time data drive will be used as a guarantee of the timeliness of the event triggering of the model in this paper, and the specific flow logic of the event triggering is shown in

Figure 13, which sequentially connects the modules in series according to the flow direction of the perturbation event information, and the fuselage slipping event is used as an example to illustrate the operation mechanism of the state evolution dynamics model.

When fuselage slip occurs, the coordinate positions (X, Y) as well as the orientation (H) of the fuselage undergoes different degrees of change. At time point Tn, by monitoring the acceleration changes of X, Y and H, the event state model is able to recognize the truncated state transition. By performing the different-or-other (XOR) operation on the actual state parameters and the planned state parameters, a result of 000110100 is obtained.Based on this result, the type of perturbation of the current event can be identified and compared with the historical event database to determine if the event type has been recorded. If the event matching result indicates that the type is known, the corresponding historical processing scheme is immediately activated. Conversely, if the matching result indicates that the current event type is unprecedented, a new state node 1 is created in the state evolution dynamics model and the state is associated with the event type, the event state vector En={1, Sn} is constructed, and the event is recorded according to the storage rules of the event database.

A fuselage slip event results in a shift in fuselage coordinates (X, Y) and fuselage orientation (H). By monitoring the acceleration changes of X, Y and H at a specific moment Tn, the event state model is able to recognize the changes in the truncated state. The result 000110100 is obtained by performing a different-or-or (XOR) operation on the actual state parameters and the planned state parameters.Based on this result, the perturbation type of the current event can be determined and matched with the historical event library to determine if the event type has been recorded. If the matching result indicates that the event type is known, the corresponding historical processing scheme is automatically executed. If it is a new event type, a new state node 1 is created in the state evolution dynamics model and the state is bound to the event type to form the event state vector En={1, Sn} and saved to the event library.

Emerging state nodes, triggered by unknown events, generate branches in the original state evolution network. Depending on the details of the state offsets and the criteria of the job plan, a path needs to be planned to guide the current abnormal state back to the normal state before the next scheduled job change node. Based on the results of the path planning, a control strategy for the state change can be developed and implemented.

Regardless of whether the event is known or not, the quality of synchronization of the virtual intercept scene with the physical intercept scene needs to be ensured by the state leaping mechanism during the execution of the state correction policy. The virtual intercept and physical intercept will execute the control strategy simultaneously, and the physical intercept scene will continuously feedback state changes to the virtual control platform. The virtual cutoff model performs over-the-top state evolution based on the feedback information and control strategy to reduce the lag of virtual-real information transfer.

When the physical scene state evolves according to the control command to the moment corresponding to the superprior state, the virtual-reality consistency evaluation will be performed. The evaluation first checks the state similarity, if it does not meet the alignment criteria, the control strategy is adjusted according to the state deviation. If the similarity meets the criteria, the consistency of the control strategy is checked. If both the state and the control strategy are consistent at this moment, it indicates that the information transmission delay problem has been solved and the virtual-real synchronization has been achieved, and no further loop feedback and strategy adjustment is required. Virtual cutoff and physical cutoff will synchronize to adjust the cutoff state to within the planned range according to the latest control strategy, and the state evolution network records this change path to form a closed loop. After the disturbance event is processed, the new state evolution path will be used as a reference for future processing. As the process is triggered multiple times, the disturbance event types will be more comprehensive, the state evolution network will be more complete, and the efficiency and reliability of the state evolution dynamics model will be improved.

2.4.3. State Transition Mechanism (STM)

After the abnormal state is recognized, a state jumping mechanism is employed to ensure that the transition to the normal operating state is both rapid and smooth. To ensure the accuracy of the information feedback from the remote control platform, the state jump involves the synchronization of the physical digging site and the virtual control environment. This synchronized processing improves the accuracy and reliability of the jump process, enabling an efficient transition from abnormal to normal conditions. By keeping the data of the two environments synchronized in real time, the time delay of information transmission is minimized, which enhances the ability to instantly control the operation status.

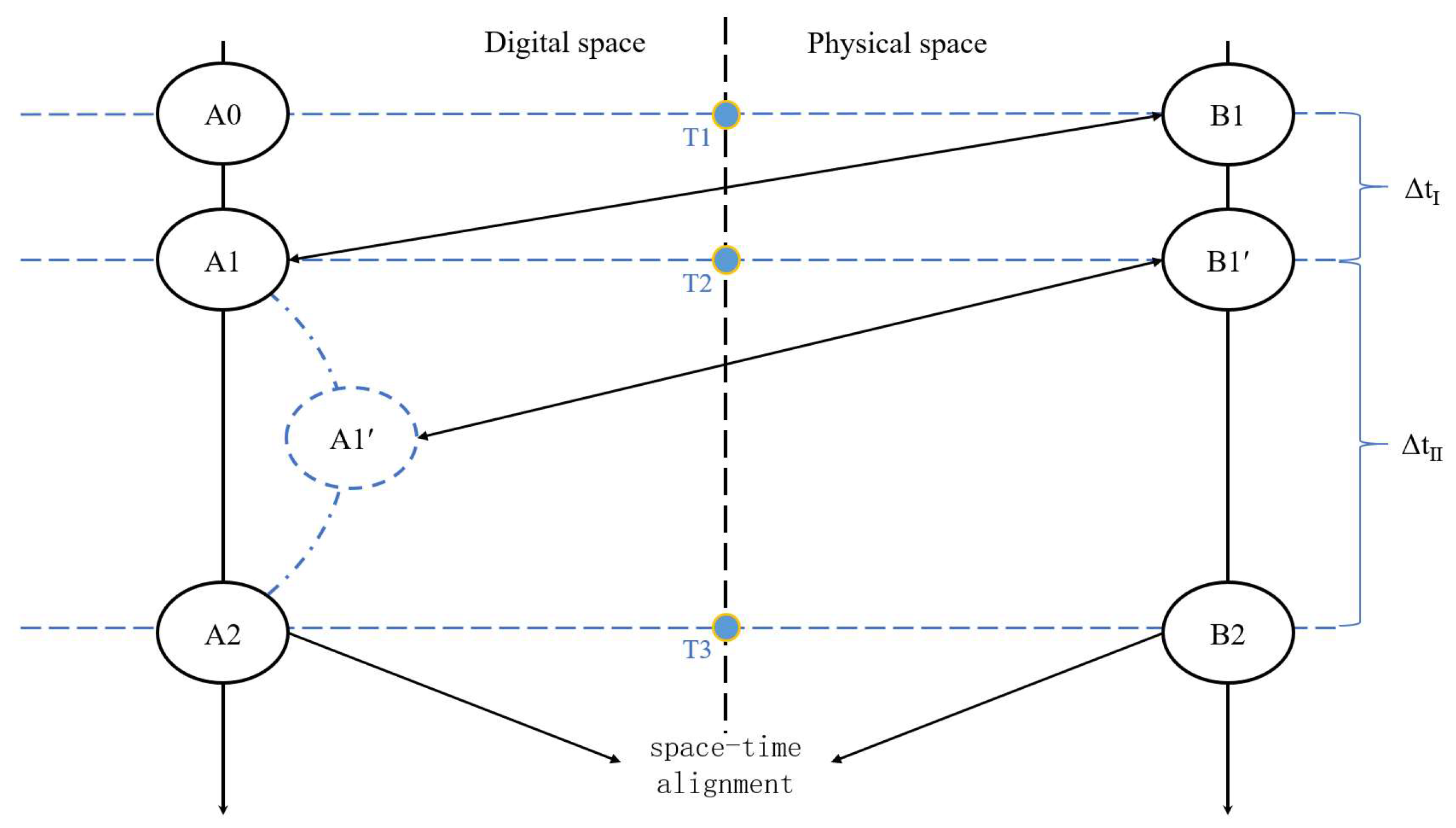

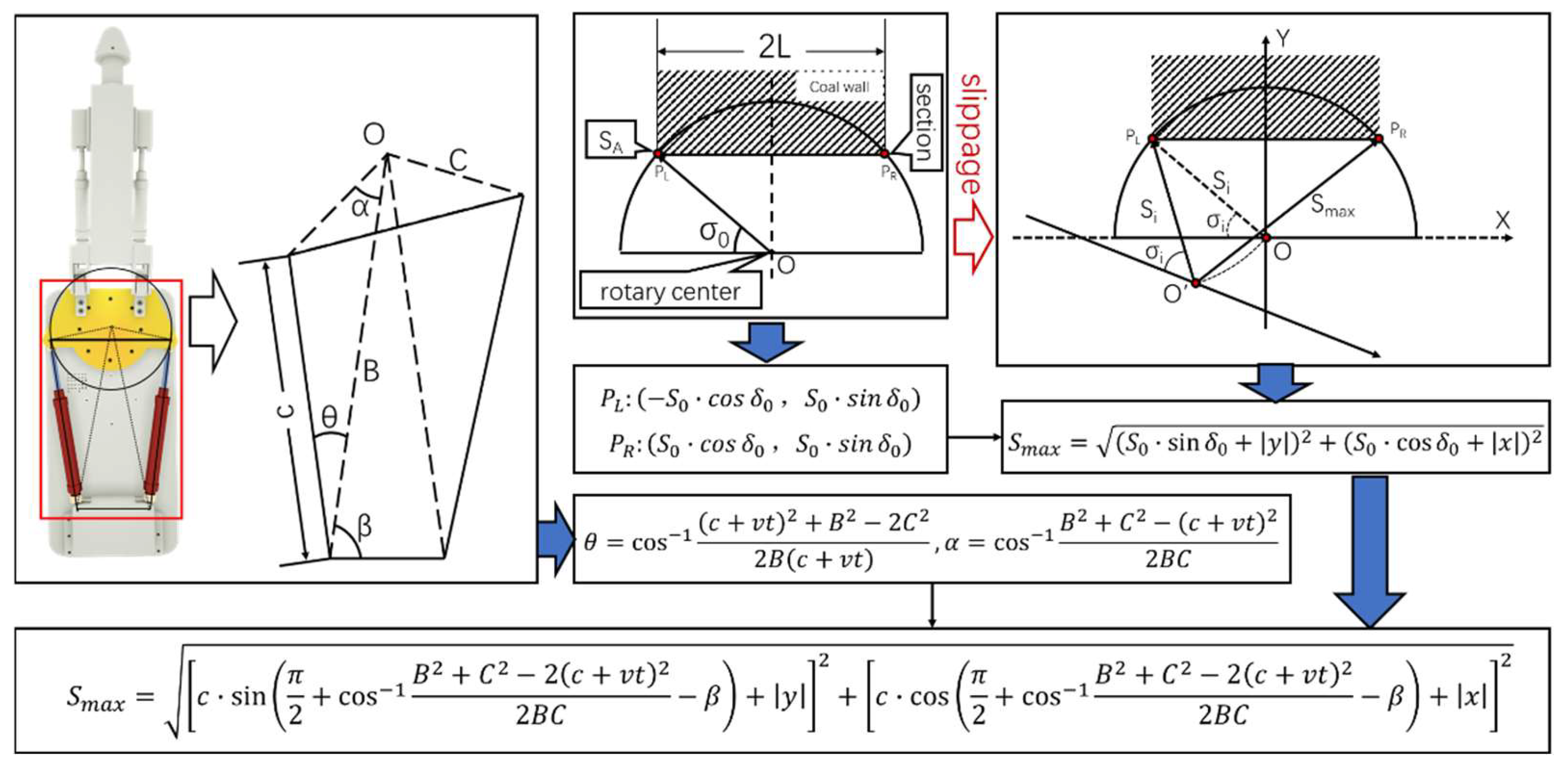

The leap process involves synchronization work in both spatial and temporal dimensions, including threshold synchronization and periodic synchronization. As shown in

Figure 14, at the T1 moment, the physical spatial model executes a control instruction that is scheduled to perform a state change at the same time as the digital twin. However, the moment when the digital spatial model executes this instruction is not synchronized with the physical model due to the inherent time delay. The digital model completes the state change to A1 at the moment of T2, corresponding to the state of the physical model at the moment of T1 B. At this point, the digital space side is already behind ΔtⅠ compared to the time when the instruction was executed in the physical space, and the state of the physical model has transitioned to an intermediate state B1′.

In order to optimize the digital twin hysteresis problem caused by the inherent time delay, the digital model will predict the future state evolution of the physical model when the state change is performed at the T2 moment. The predicted state of the physical model will be changed to B2 at the moment of T3, and the digital model will take the predicted B2 as the goal of the state change, and take the moment of T3 as the endpoint of the change to carry out the state leap of the digital twin model. At this time, the digital model will no longer follow the state evolution route of the physical model via the intermediate state B1′, and the state of the object on one side of the digital space will be changed directly from A1 to A2 via ΔtⅡ.

After completing the leap, the bilateral spatial model state will reach a real sense of spatio-temporal synchronization at the T3 moment. By predicting and adjusting the state change target and time of the digital model, the effect of the inherent time delay on the digital twin lag can be effectively reduced, and more accurate spatio-temporal synchronization can be achieved.

Based on the state leap principle, threshold synchronization refers to the critical state B1′ that is reached at the moment of T2 if a side slip occurs in the body during the physical digging operation during the operation cycle. Once the sideslip exceeds the preset threshold, only adjusting the boring arm can no longer meet the operational requirements, and then a new disturbance event is considered to have occurred. The mapping relationship between the current event and the state is stored in the library and embedded into the state evolution network model. The physical operation must adjust the body parameters to return to the normal operation state. The state evolution path of the digital twin may deviate from the real digging site because the operation state experiencing the sudden perturbation is not in the original plan. In order to ensure the synchronization between reality and reality after a disturbance event, the corrective control commands of the physical tunneling operation need to be combined with the auxiliary guidance of the digital twin. Based on the current physical operation state, the digital twin predicts the future operation state of the physical object based on the corrective control instructions to carry out the super-prevolutionary state evolution, and adjusts the corrective control instructions appropriately according to the degree of compliance of the evolution results, and carries out the super-prevolutionary state evolution again. Through multiple cyclic leaps, the physical digging operation is finally brought back on track, realizing the temporal and spatial alignment of the bilateral space operation at the moment of T3.

Periodic synchronization, on the other hand, is to conduct a virtual-real consistency evaluation at the beginning of each intercept (an operation cycle) every time an operation instruction is issued, in order to enhance the reliability of virtual-real synchronization. By performing synchronization evaluation at the beginning of each operation cycle, possible deviations can be detected and corrected in time to ensure the consistency between reality and reality. This method helps to improve the accuracy and stability of the entire boring operation and reduce the risk of operational deviations due to disturbing events.