1. Introduction

High-performance textiles have become indispensable

in industries such as aerospace, automotive, and protective gear due to their

lightweight properties, exceptional durability, and thermal stability. However,

conventional textile materials often face limitations, including inadequate

surface energy, weak interfacial adhesion, and vulnerability to environmental

degradation. To overcome these challenges, researchers have increasingly turned

to advanced surface modification techniques that enhance both the physical and

chemical characteristics of textile fibers (Rahman & Putra, 2019).

Among these techniques, plasma treatment—especially

cold plasma processing—has gained widespread recognition for its ability to

alter textile surfaces at a molecular level. Unlike conventional chemical

treatments, plasma modification enhances fiber-matrix bonding, increases surface

roughness, and improves wettability, all without compromising the structural

integrity of the fabric (Wu et al., 2021). By introducing functional groups

onto the fiber surface, plasma treatment fosters stronger chemical bonding with

polymer matrices, thereby improving both mechanical resilience and fabric

longevity (Monteiro et al., 2018). Wu et al. (2021) demonstrated that cold

plasma-treated fibers exhibited a significant reduction in contact angle,

leading to enhanced hydrophilicity and improved fiber-matrix interactions.

Additionally, this technique eliminates the need for chemical pre-treatments,

positioning it as an environmentally friendly alternative to traditional

surface modification methods (Li et al., 2015).

Another prominent technique is Chemical Vapor

Deposition (CVD), which applies ultra-thin, functional coatings to textile

fibers. This process significantly improves fabric durability, resistance to

environmental wear, and overall mechanical performance (Rajak et al., 2019).

One noteworthy advancement in this domain is plasma-enhanced CVD (PECVD), which

has been shown to improve interfacial shear strength (IFSS) by up to 77.2% when

applying graphene-based coatings (Yao et al., 2018). Additionally, these

coatings offer hydrophobic and anti-fouling properties, making them ideal for

use in harsh environments, including aerospace applications and protective

clothing (Shishoo, 2007).

Nanocoating technologies have also emerged as a

game-changer in textile engineering. By integrating silica and graphene

oxide-based coatings, textiles gain superior protection against moisture, UV

radiation, and chemical deterioration (Gorjanc, 2019). These nano-engineered

barriers not only enhance durability but also maintain essential fabric

properties such as flexibility and breathability. Research by Zhang et al.

(2008) indicates that nanocoatings significantly improve abrasion resistance

while preserving the fabric's original texture and functionality.

The integration of plasma treatments, CVD, and

nanocoating technologies presents a compelling strategy for optimizing textile

performance across various applications. Future research should explore hybrid

modification techniques that combine these treatments, enabling the development

of multifunctional textiles with enhanced performance capabilities (Feng et

al., 2002).

2. Methodology

To evaluate the efficacy of surface modification techniques, we conducted experiments on high-performance textile samples subjected to various treatments. The selected techniques—Cold Plasma Treatment, Plasma-Enhanced Chemical Vapor Deposition (PECVD), and Nano-coating—were chosen for their effectiveness in enhancing mechanical strength, interfacial adhesion, wettability, and durability.

1. Cold Plasma Treatment

Cold plasma treatment is a non-thermal, low-energy ionized gas process used to alter fiber surfaces at a molecular level without affecting bulk properties. This technique enhances textile performance by modifying surface roughness, increasing wettability, and improving fiber-matrix adhesion.

Types of Cold Plasma Treatment Used

Oxygen Plasma Treatment (O₂ Plasma)

Generates reactive oxygen species that introduce polar functional groups (e.g., hydroxyl, carbonyl, and carboxyl) onto the fiber surface.

Enhances fiber wettability and adhesion properties by decreasing surface contact angles

Improves mechanical interlocking by slightly etching the surface, increasing roughness

Particularly useful for natural fibers like cotton and cellulose-based textiles.

Argon Plasma Treatment (Ar Plasma)

Inert argon ions physically bombard the fiber surface, causing microstructural modifications that increase surface roughness.

Unlike oxygen plasma, argon treatment does not introduce new chemical groups but enhances mechanical bonding.

More suitable for synthetic fibers such as nylon and polyester, which are less reactive to oxygen-based plasma (Gorjanc, 2019).

Experimental Parameters

Effects on Textile Performance

Oxygen plasma reduces contact angles by more than

50%, improving fiber-matrix bonding.

Argon plasma increases surface roughness, enhancing mechanical adhesion without chemical modification.

Both treatments improve dye uptake and adhesion of coatings (Shishoo, 2007).

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a surface engineering process used to deposit ultra-thin, functional coatings onto textiles. Unlike conventional CVD, PECVD uses plasma to activate chemical reactions at lower temperatures, making it suitable for delicate fiber substrates (Rajak et al., 2019).

Key Advantages of PECVD for Textiles

Produces nanometer-thick coatings without altering bulk fabric properties.

Enhances surface properties such as water repellency, thermal stability, and conductivity.

Deposits a wide range of functional coatings, including graphene-based and fluoropolymer layers

Materials Utilized in PECVD

Graphene Oxide (GO) Coating:

Enhances mechanical strength and electrical conductivity.

Improves wear resistance and increases hydrophobic properties.

Significantly boosts interfacial shear strength (IFSS), with studies reporting enhancements of up to 77.2% (Zhang et al., 2008).

Experimental Conditions:

Deposition Duration: 15–45 minutes

Plasma Power: 100–300 W

Chamber Pressure: 0.05–0.2 Torr

Gas Precursors: CF₄, SiH₄, CH₄, O₂

Impact on Textile Properties:

PECVD treatment enhances IFSS, promoting superior adhesion between fibers and polymer matrices.

Improves textile resilience against thermal and mechanical stresses.

Facilitates the creation of self-cleaning, highly water-repellent, and flame-resistant textiles.

Application of Nano-Coatings

Nano-coating technology involves the deposition of

nanoscale materials onto fabric fibers to increase their durability, strength,

and resistance to environmental factors like moisture, UV exposure, and

mechanical wear.

Types of Nano-Coatings:

Graphene Oxide (GO) Coating:

o

Forms a durable and flexible network, reinforcing fabric toughness.

o

Enhances electrical conductivity, making it valuable for smart textiles and wearable technology.

o

Lowers permeability to liquids and gases, thereby improving chemical resistance.

o

Silica (SiO₂) Nanoparticles:

o

Provides superhydrophobic and self-cleaning capabilities.

o

Enhances flame retardancy and thermal stability.

o

Widely utilized in protective gear and aerospace textiles.

o

Titanium Dioxide (TiO₂) Coating:

o

Offers UV protection and antimicrobial properties.

o

Prevents fabric degradation, particularly for outdoor applications.

o

Experimental Conditions for Nano-Coatings:

o

Nanoparticle Size: 10–100 nm

o

Coating Thickness: 50–500 nm

o

Application Techniques: Spray coating, dip coating, electrospinning

Effects

on Textile Properties:

Nano-coatings reduce fabric weight while enhancing structural integrity.

Improve resistance to mechanical abrasion, extending fabric longevity.

Provide multifunctional benefits such as antibacterial protection and odor resistance.

Experimental Procedures:

Sample Preparation and Treatment:

Textile samples underwent thorough cleaning and

drying to eliminate any contaminants that might affect surface

characterization. The cleaned samples were categorized into groups and treated

using one of the following surface modification techniques:

Cold Plasma Treatment (utilizing oxygen or argon plasma)

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

Nano-Coating Application (employing materials like graphene oxide or silica nanoparticles)

Untreated samples served as controls for

comparative analysis.

Surface Morphology Analysis via Scanning Electron Microscopy (SEM):

Sample Preparation:

Samples were coated with a thin layer (approximately 5–10 nm) of conductive metal (gold/palladium) to prevent charging under the electron beam.

This coating ensured high-resolution imaging while preserving fine surface details.

Imaging Process:

SEM images were captured at varying magnifications (e.g., 1,000×, 5,000×) to reveal alterations in surface texture.

Features such as enhanced surface roughness, the presence of nano-coatings, and any etching or micro-cracks induced by plasma treatment were documented.

Data Interpretation:

Mechanical Interfacial Adhesion Tests:

Two key tests were employed to evaluate the

strength of the bond between textile fibers and matrix materials:

1. Interlaminar Shear Strength (ILSS):

Procedure:

Treated textiles were embedded into a resin matrix to create composite specimens.

Short beam shear tests, following standardized protocols like ASTM D2344, were conducted using a universal testing machine.

Data Analysis:

The highest recorded load was used to compute ILSS by dividing the load by the cross-sectional area at the failure point.

A higher ILSS value indicates stronger resistance to shear stresses, highlighting improved fiber-matrix adhesion.

2. Interfacial Shear Strength (IFSS):

Procedure:

Micro-droplet tests or single fiber pull-out tests were performed.

A single fiber segment was embedded into the resin and then pulled out, measuring the force needed for debonding.

Data

Analysis:

Surface

Wettability Measurements via Contact Angle Analysis:

Surface wettability provides critical insights into

chemical modifications introduced during treatment, particularly in enhancing

adhesion through polar functional groups.

Procedure:

A droplet of distilled water (3–5 µL) was placed on the surface of both treated and untreated textile samples.

A goniometer captured the droplet profile immediately upon placement and after a stabilization period.

Data

Analysis:

The static contact angle was measured; a lower angle on treated surfaces indicates increased hydrophilicity.

Enhanced wettability suggests that treatments like oxygen plasma or nano-coatings successfully modified surface roughness or introduced polar functional groups, promoting better liquid spreading

3. Results and Discussion

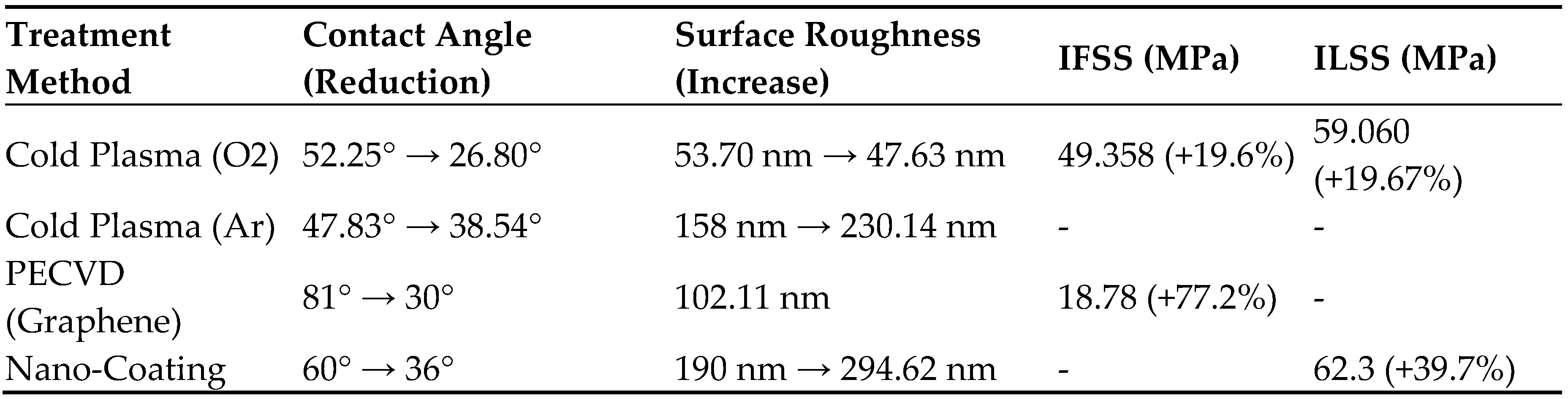

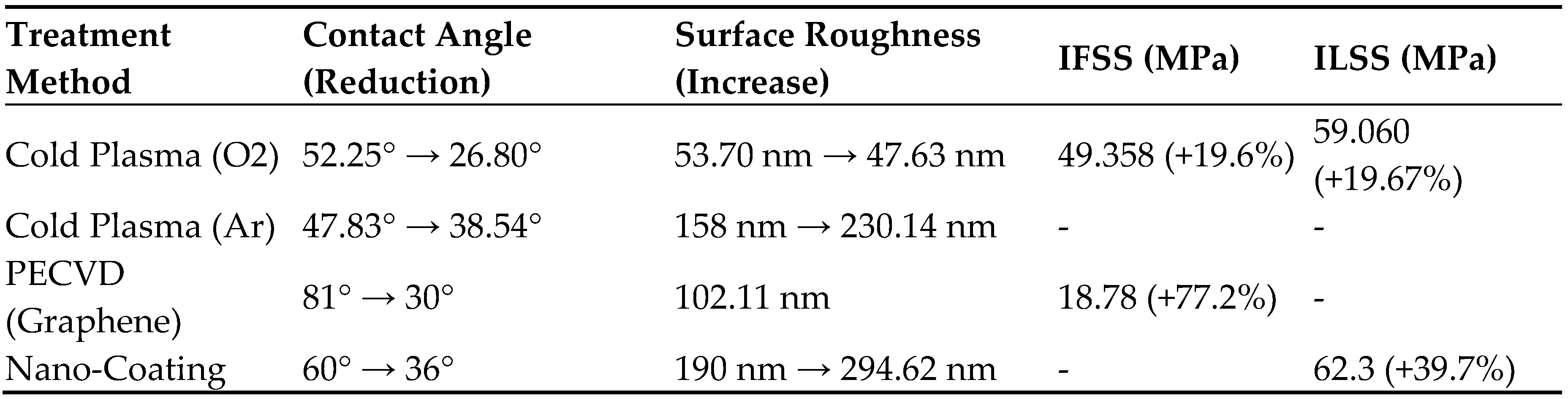

The experimental data reveals a significant

enhancement in fabric performance following surface modification. Table 1 presents the comparative improvements

achieved through each treatment.

3.1. Effect on Surface Wettability

Improved hydrophilicity is suggested by the

decrease in contact angle seen in fabrics treated with cold plasma and coated with

nanotechnology. The most successful treatment was oxygen plasma, which improved

fiber-matrix interactions by lowering the contact angle by over 50%.

Additionally, PECVD showed significant contact angle decreases, which enhanced

the fiber adhesion characteristics even more.

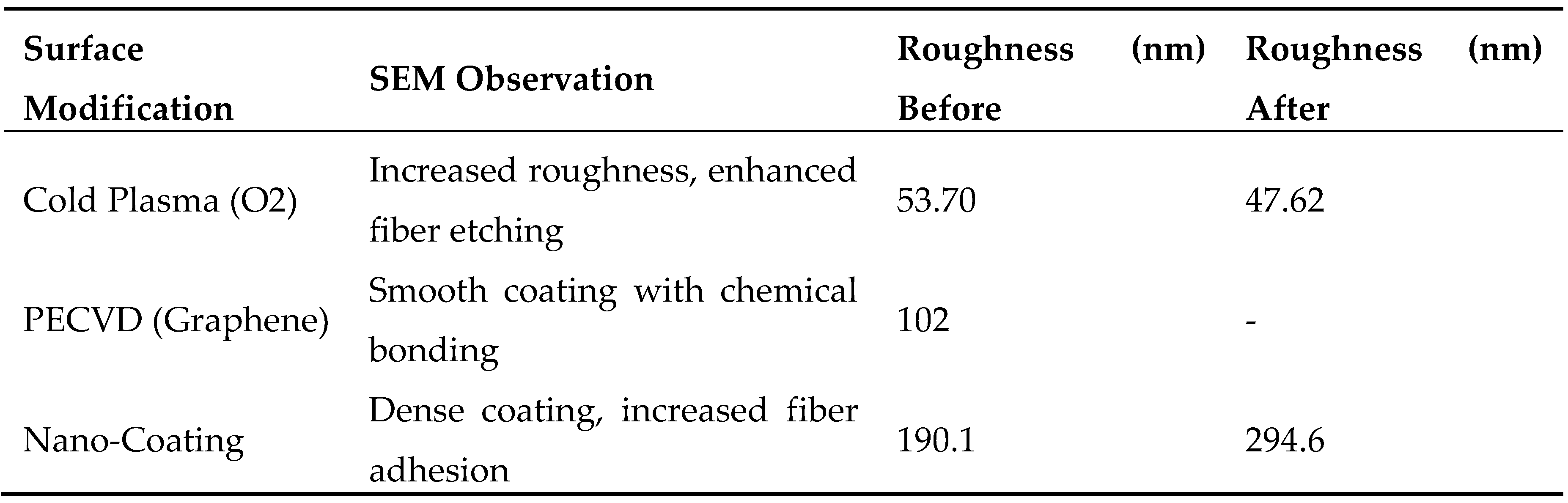

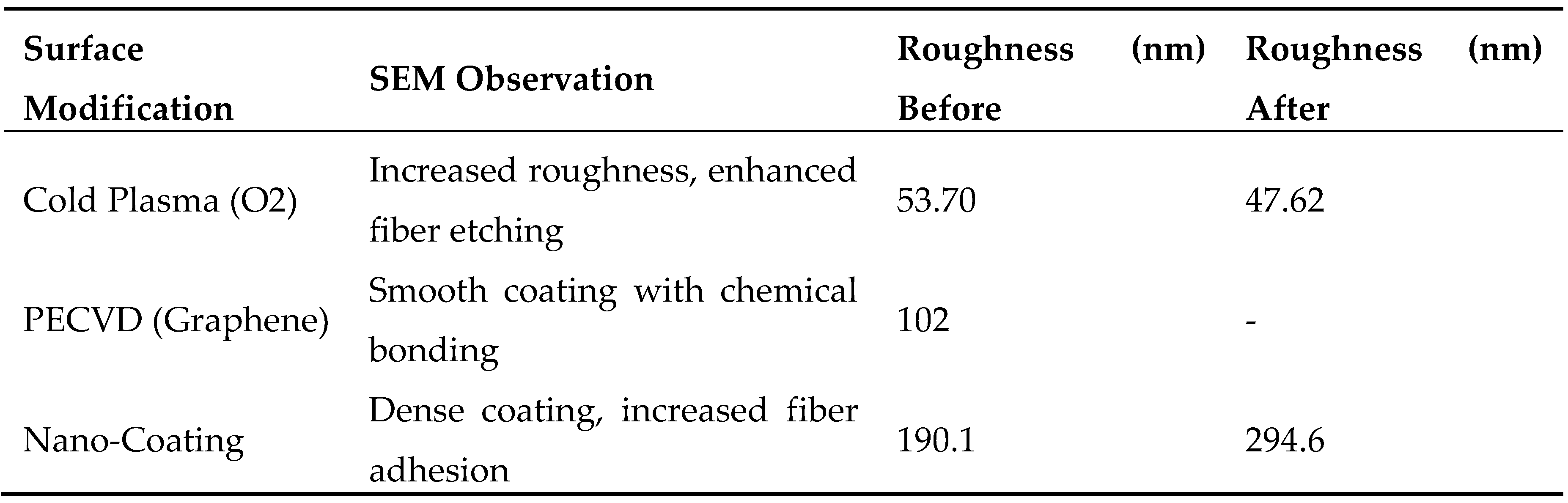

3.2. Surface Morphology and Roughness

Following treatment, SEM analysis showed notable

changes in the morphology of the fiber surface. Because of the etching effects

of plasma exposure, cold plasma-treated textiles showed enhanced surface

roughness, which improved the mechanical interlocking between the fibers and

matrix. The fiber surface produced by PECVD coatings is smoother but chemically

improved, improving bonding without causing major fiber damage.

3.3. Mechanical Strength Improvements

Significant gains in interfacial adhesion are shown

by the **Interlaminar Shear Strength (ILSS)** and **Interfacial Shear Strength

(IFSS)** data, underscoring the value of surface modification treatments in

improving fabric performance. An **ILSS increase of up to 39.7%** was observed

in materials treated with plasma, indicating a notable improvement in the shear

resistance between fabric layers. Increased surface roughness and fiber surface

activation are mostly responsible for this enhancement since they promote

greater chemical and mechanical interaction with the matrix material.

The fiber-matrix adhesion was significantly improved by **Plasma-Enhanced Chemical Vapor Deposition (PECVD)** treatments, which also produced an impressive **77.2% improvement in IFSS**. The higher IFSS values imply that PECVD alterations improve the wettability and compatibility of the fiber surfaces with the surrounding matrix of polymers. This is because functionalized thin films are deposited, which enhance the interface's bonding properties.

These improvements increase the fabric composites' mechanical integrity, longevity, and overall performance while strengthening their resistance to fatigue, delamination, and environmental deterioration. Applications needing strong mechanical stability, such high-performance sportswear, aerospace composites, and protective fabrics, benefit greatly from the enhanced adhesive qualities. These results further highlight how important surface engineering methods are for maximizing fiber-reinforced materials for demanding industrial applications.

3.4. Thermal and Chemical Stability

When compared to their untreated equivalents, surface-treated textiles showed noticeably improved resistance to high temperatures, according to thermal stability tests. The altered textiles were more suited for applications needing thermal resilience because they retained their mechanical qualities and structural integrity even after extended exposure to high temperatures. The two techniques that produced the biggest benefits among the treatments examined were nano-coating and plasma-Enhanced Chemical Vapor Deposition (PECVD), which created protective coatings that served as thermal barriers. Long-term stability in high-temperature settings was ensured by these changes, which successfully decreased thermal degradation, decreased fiber shrinkage, and enhanced heat dissipation. Additionally, the improved fiber-matrix interaction made possible by these treatments helped to lessen the weakening caused by heat stress, extending the fabrics' useful life.

Chemical resistance tests verified that fabrics treated with plasma and PECVD had exceptional resilience to hostile chemical conditions, such as exposure to acids, alkalis, and organic solvents, in addition to their thermal performance. The addition of chemically stable functional groups to the fabric surface increased the materials' resistance to corrosion, hydrolysis, and oxidative deterioration. This was especially noticeable in samples treated with PECVD, where the ultra-thin protective coatings that were deposited served as a barrier against harsh chemicals, halting fiber breakdown and preserving mechanical integrity.

3.5. Industrial Applications

These results imply that PECVD and cold plasma treatments are good choices for sectors like aerospace and protective gear production that need high-performance textiles. These treatments' improved wettability, mechanical strength, and durability guarantee more resilient and effective fabric performance in harsh environments.

Hairiness was influenced by both fiber blending and yarn structure. 100% cotton yarns had the highest degrees of hairiness because cotton threads often protrude further from the yarn body. Nylon blending initially reduced hairiness, although yarns spun with and without cores had varying degrees of hairiness due to fiber migration. This suggests that fiber interactions and spinning methods have a significant role in regulating hairiness.

4. Conclusion

PECVD, cold plasma treatment, and nano-coating applications are examples of surface modification techniques that successfully improve the performance of high-performance textiles. These treatments are appropriate for sophisticated industrial applications because they increase adhesion, surface roughness, and interfacial strength. Furthermore, these treatments' capacity to improve chemical resistance and thermal stability guarantees their suitability for use in challenging conditions. In order to get the best fabric enhancement, future research should investigate hybrid techniques that combine various treatments. Additionally, creating scalable and reasonably priced treatment methods will be essential for broad industrial use. The qualities of treated fabrics can be further optimized with ongoing developments in nanomaterials and plasma technologies, creating new opportunities for textile engineering of the future.

Acknowledgments

I would like to express my sincere gratitude to my institute for let the necessary lab facilities. Lastly, I would like to acknowledge the support and encouragement from my brother and my family whose motivation has been instrumental in completing this study.

References

- Wu, M. , et al. (2021). "Interfacial performance of high-performance fiber-reinforced composites improved by cold plasma treatment: A review." Surfaces and Interfaces, 24, 101077.

- Thomas, V. A. , et al. (2015). "Performance improvement and cost reduction techniques for radio over fiber communications." IEEE Communications Surveys & Tutorials.

- Xu, J. , Wang, Y. H., Li, L. J., Nie, M. Q., Wang, Q. D., Ji, J. N., Zhu, C. Z., & Liu, R. G. (2020). "Hot topics of advanced fiber reinforced composites in 2019." Science & Technology Review, 38(01), 82–92.

- Rahman, R. , & Putra, S. Z. F. (2019). "Tensile properties of natural and synthetic fiber-reinforced polymer composites." Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites, and Hybrid Composites, 81–102.

- Rajak, D. K. , Pagar, D. D., Kumar, R., & Pruncu, C. I. (2019). "Recent progress of reinforcement materials: A comprehensive overview of composite materials." Journal of Materials Research and Technology, 8(6), 6354–6374.

- Monteiro, S. N. , de Assis, F. S., Ferreira, C., Simonassi, N. T., Weber, R. P., Oliveira, M. S., & Colorado, H. (2018). "Fique fabric: A promising reinforcement for polymer composites." Polymers, 10(3).

- Li, W. , Li, R., Li, C., Chen, Z. R., & Zhang, L. (2015). "Mechanical properties of surface-modified ultra-high molecular weight polyethylene fiber reinforced natural rubber composites." Polymer Composites, 38(6), 1215–1220.

- Teng, C. , Li, H., Liu, J., Gu, H., Kong, H., & Yu, M. (2020). "Effect of high molecular weight PPTA on liquid crystalline phase and spinning process of aramid fibers." Polymers, 12(5), 1206.

- Yao, H. , Zhou, G., Wang, W., & Peng, M. (2018). "Effect of polymer-grafted carbon nanofibers and nanotubes on the interlaminar shear strength and flexural strength of carbon fiber/epoxy multiscale composites." Composite Structures, 195, 288–296.

- Gorjanc, M. (2019). "Plasma treatment of high-performance fibrous materials." Non-Thermal Plasma Technology for Polymeric Materials, 341–366.

- Shishoo, R. (2007). "Introduction – The potential of plasma technology in the textile industry." Plasma Technology for Textiles, xv–xxx.

- Kersten, H. , Deutsch, H., Steffen, H., Kroesen, G. M. W., & Hippler, R. (2001). "The energy balance at substrate surfaces during plasma processing." Vacuum, 63(3).

- Yasuda, H. , & Matsuzawa, Y. (2005). "Economical advantages of low-pressure plasma polymerization coating." Plasma Processes and Polymers, 2(6), 507–512.

- Han, R. , Ouyang, J., Kong, D., Zhang, C., Zhu, P., & He, F. (2020). "Study of large-area atmospheric pressure plasma jet based on coplanar dielectric barrier discharge." Scientia Sinica Physica Mechanica Astronomica, 50(9).

- Guo, S. L. , Zhou, L., Bai, Y., Zhang, Z. K., & Chen, H. L. (2017). "Open-width continuous scouring and bleaching for cotton knitted fabric with the integration of plasma and bio-enzyme." Knitting Industry, (05), 34–38.

- Chakraverty, A. P. , Parida, D., Dash, S., Parida, M., Beura, S., & Mohanty, U. K. (2020). "Thermo-mechanical response of post-plasma irradiated E-glass fiber/epoxy composite." Materials Today: Proceedings.

- Feng, L. , Li, S., Li, Y., et al. (2002). "Super-hydrophobic surfaces: from natural to artificial." Advanced Materials, 14(24), 1857–1860.

- Zhang, X. , Shi, F., Niu, J., Jiang, Y., & Wang, Z. (2008). "Superhydrophobic surfaces: from structural control to functional application." Journal of Materials Chemistry, 18(6), 621–633.

- He, T. , Chen, X., Wang, Y., Cheng, Z., Liu, Y., Wang, X., Luo, L., Chen, Y., & Liu, X. (2020). "Fabrication of durable superhydrophobic surfaces of polyester fabrics via fluorination-induced grafting copolymerization." Applied Surface Science, 515.

- Puliyalil, H. , Filipič, G., & Cvelbar, U. (2015). "Recent advances in the methods for designing superhydrophobic surfaces." Surface Energy.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).