Submitted:

12 February 2025

Posted:

12 February 2025

You are already at the latest version

Abstract

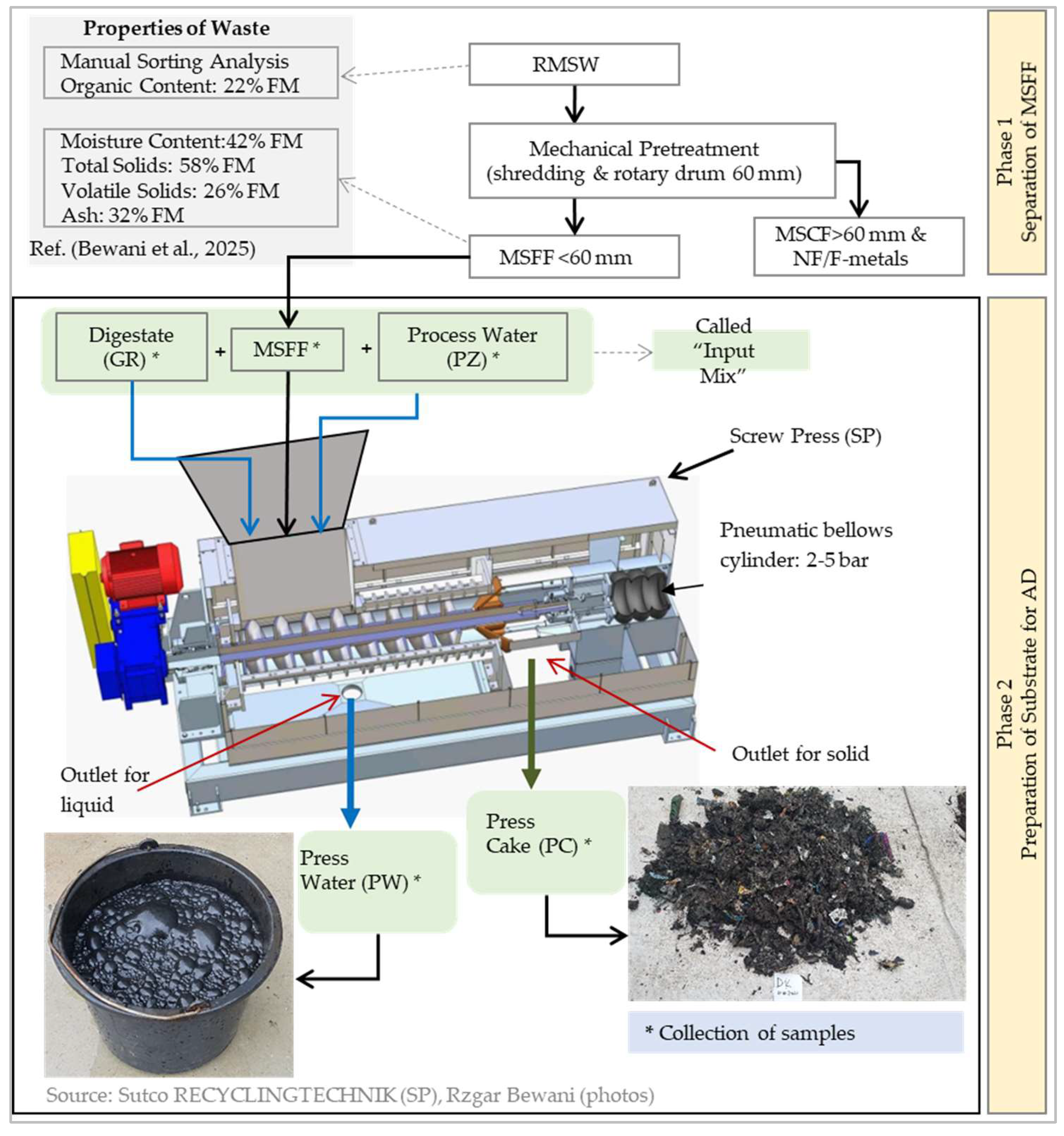

A three-year optimization study was conducted at a mechanical biological treatment (MBT) plant using a screw press to extract organic fractions from mechanically separated fine fractions (MSFF). The study aimed to optimize key operating parameters for the employed screw press (SP) such as pressure, liquid-to-MSFF, feeding quantity per hour, and press basket mesh size to enhance volatile solids and biogas recovery in the generated press water (PW) for anaerobic digestion (AD). Experiments were performed at the full-scale MBT facility to evaluate the efficiency of screw press extraction with other pretreatment methods like press extrusion, wet pulping, and hydrothermal treatment. The results indicated that hydrolysis of the organic fractions in MSFF was the most important factor for improving organic extraction from the MSFF to press water for fermentation. The optimal hydrolysis efficiency was achieved with a digestate and process water-to-MSFF of approximately 1,000 l/ton, with a feeding rate between 8.8 and 14 tons per hour. Increasing pressure from 2.5 to 4.0 bar had minimal impact on press water properties or biogas production, regardless of the press basket size. The highest volatile solids (29%) and biogas (50%) recovery occurred at 4.0 bar pressure with a 1,000 L/ton liquid-to-MSFF. Further improvements could be achieved with longer mixing times before pressing. These findings demonstrate the technical feasibility of the pressing system for preparing an appropriate substrate for the fermentation process and underscore the potential for optimizing the system. However, further research is required to assess the cost-benefit balance.

Keywords:

1. Introduction

2. Results

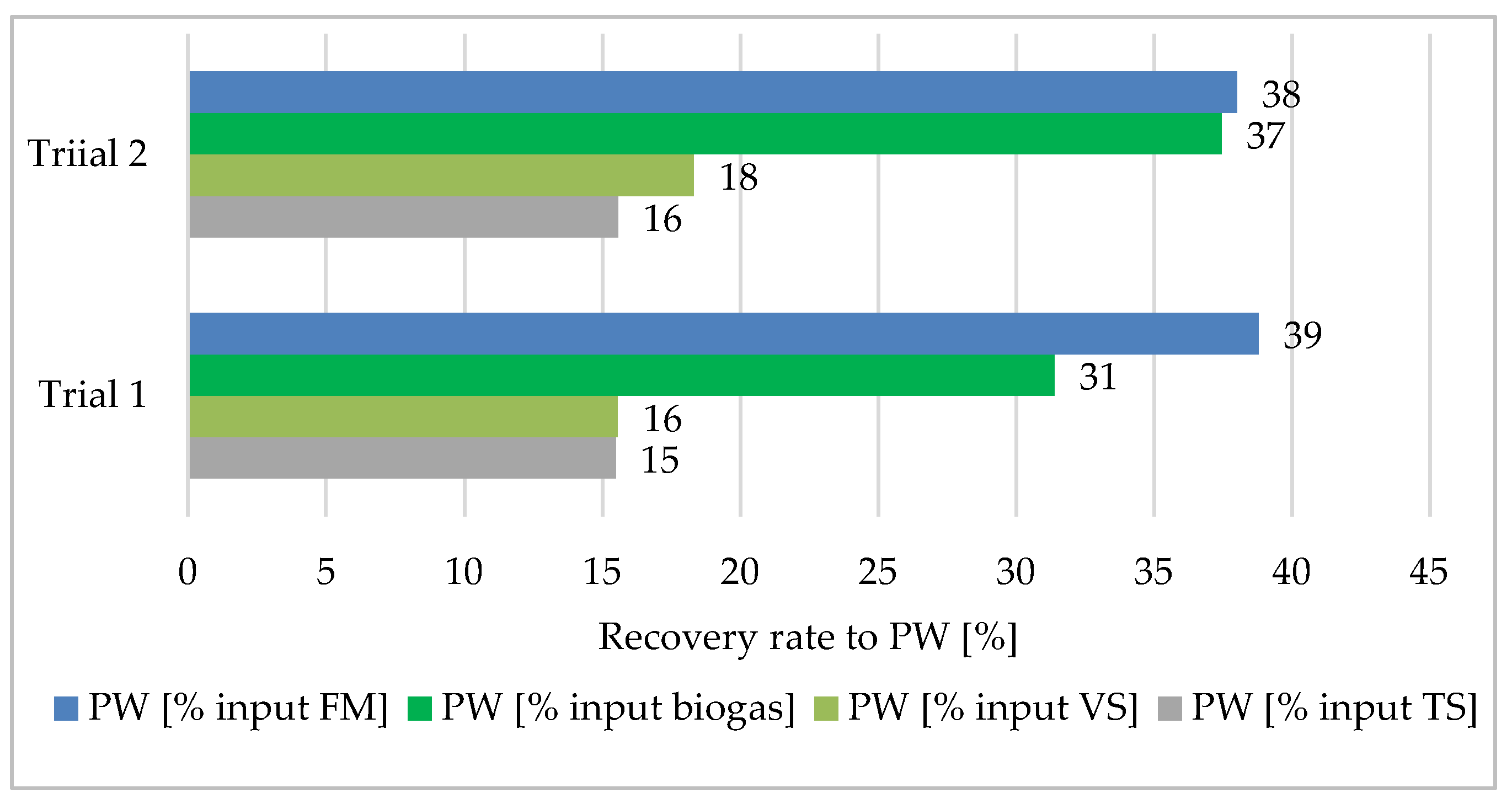

2.1. Impact of Screw Press Pressure on Press Water Properties and Recovery Rate from MSFF

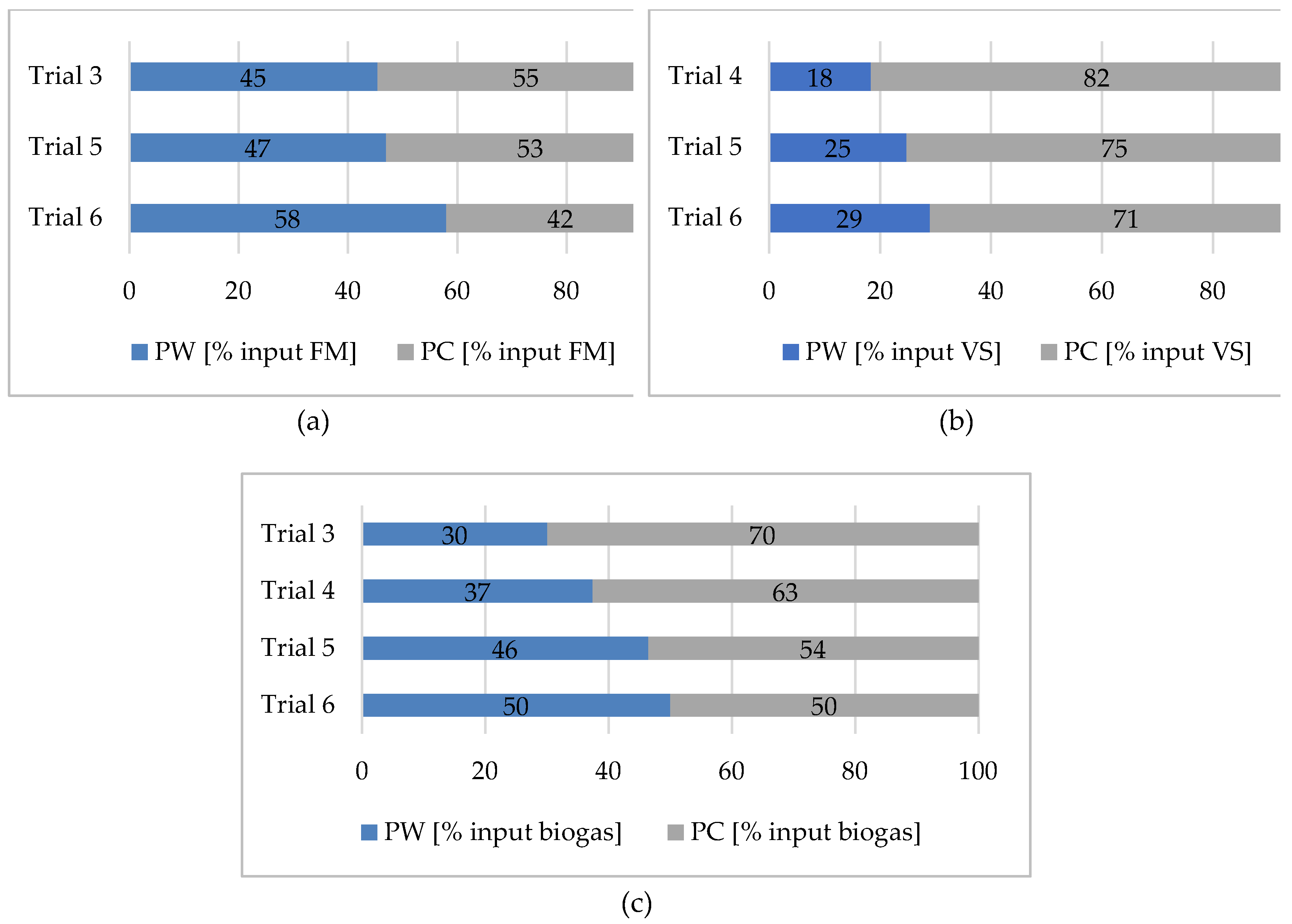

2.2. Impact of the Mixing of GR and PZ per ton MSFF on Press Water Properties and Recovery Rate from MSFF

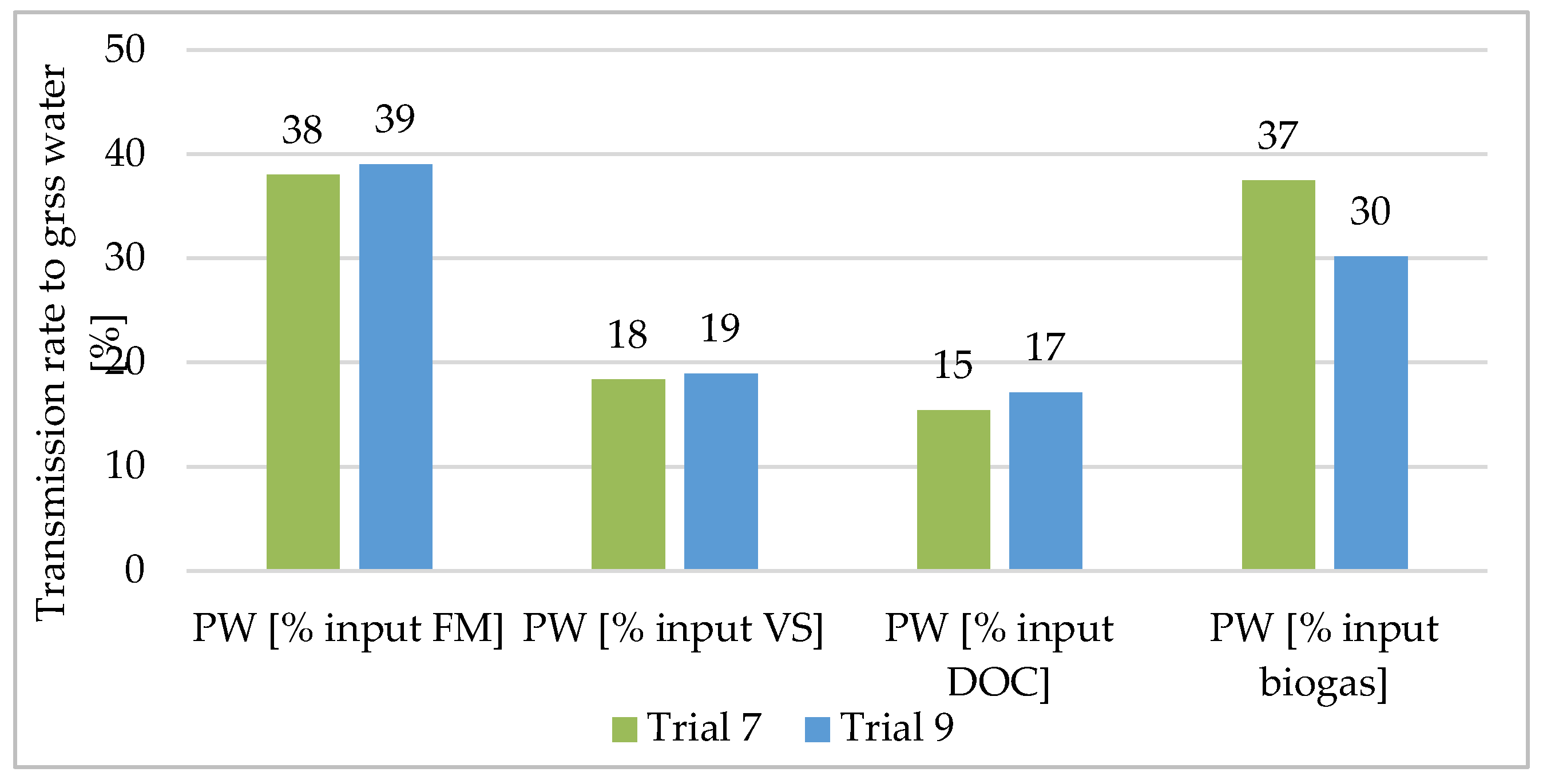

2.3. Impact of Feeding Rate of Input Mix on Press Water Properties and the Recovery Rate from MSFF

2.4. Impact of Press Basket Size on Biogas Production

3. Materials and Methods

3.1. Characteristics of the Waste Used for Experiments

3.2. Experimental Setup

3.3. Investigated Operating Parameters

| Trial | Quality of MSFF | Pressure (bar) |

Added liquid (2) to MSFF (l/ton) |

Feeding rate of MSFF (ton/h) |

Press basket (mm) |

|

|---|---|---|---|---|---|---|

| EP (1) | Investigated (1)

|

4,5 | Constant | Constant | 5 | |

| EP1 | T1 | Constant | 2.5 | 790 | - | 5 |

| T2 | 4.0 | 750 | - | 5 | ||

| EP2 | T3 | Constant | 4 | 690 | - | 5 |

| T4 | 4 | 750 | - | 5 | ||

| T5 | 4 | 1000 | - | 5 | ||

| T6 | 4 | 1050 | - | 5 | ||

| EP3 | T7 | Constant | 4 | 750 | 8.8 | 5 |

| T8 | 4 | 740 | 9.0 | 5 | ||

| T9 | 4 | 750 | 10.20 | 5 | ||

| EP4 | T10 | Constant | - | - | - | 10 |

| T11 | 8 | |||||

| T12 | 5 |

- (1)

- EP: evaluated in a previous paper [4].

- (2)

- A mix of digestate (GR) recirculated from AD and process water (PZ), which is used water from cleaning purposes.

3.4. Sampling and Laboratory Analysis

4. Discussion

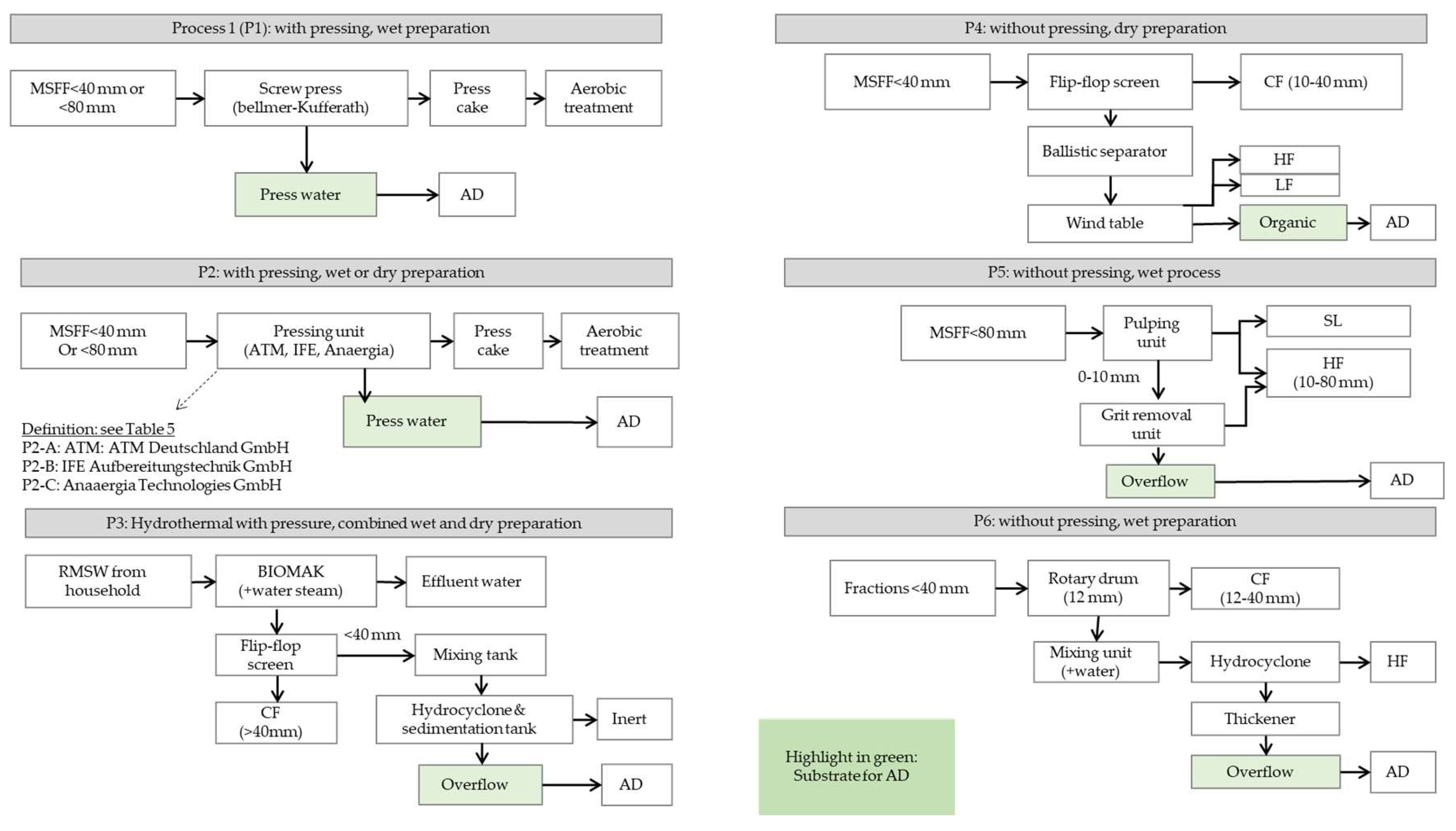

4.1. Maximum Biogas Recovery into Substrate for Anaerobic Digestion Based on Waste Mass

4.2. . Comparison of the Recovery Rate of Organic Matter and Biogas to Substrate for Anaerobic Digestion as reported in the Literature

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wirtschaftsbetriebe Duisburg,Abfallentsorgungsgebührensatzung Gültig ab 01.01.2025 (Lesefassung), 2025. Accessed: Jan. 24 2025. [Online]. Available: https://www.wb-duisburg.de/Downloads/index.php .

- L. de Baere and B. Mattheeuws, "Anaerobic digestion of msw in EUROPE," 2017.

- R. Campuzano and S. González-Martínez, "Characteristics of the organic fraction of municipal solid waste and methane production: A review," Waste management (New York, N.Y.), vol. 54, pp. 3–12, 2016. [CrossRef]

- R. Bewani, A. Nassour, T. Böning, and M. Nelles, "Expansion of mechanical biological residual treatment plant with fermentation stage for press water from organic fractions; involving a screw press to prepare the suitable press water for anaerobic digestion," 2025.

- M. Meirer, W. Müller, and A. Bockreis, "Pretreatment of MSW for co-digestion in waste water treatment plants," in Waste Management and The Environment VIII, Valencia, Spain, 2016, pp. 277–288.

- M. Meirer, W. Müller, and A. Bockreis, "Mechanische Abtrennung biogener Reststoffe aus Restabfall für die Co-Vergärung in Faultürmen kommunaler Kläranlagen," Österr Wasser- und Abfallw, vol. 69, 9-10, pp. 397–404, 2017. [CrossRef]

- D. Arina, "Comparison of municipal solid waste characteristics after separation by star and drum screen systems," 4th International Conference CIVIL ENGINEERING`13 Proceedings Part I ENVIRONMENT AND ENVIRONMENTAL EFFECTS, 2013.

- D. Arina, J. Kalnacs, R. Bendere, and A. Murasovs, "Mechanical pre-treatment for separation of bio-waste from municipal solid waste: case study of district in Latvia," in Engineering for Rural Development, 2019.

- R. Bayard, J. d. A. Morais, G. Ducom, F. Achour, M. Rouez, and R. Gourdon, "Assessment of the effectiveness of an industrial unit of mechanical-biological treatment of municipal solid waste," Journal of hazardous materials, vol. 175, 1-3, pp. 23–32, 2010. [CrossRef]

- T. L. Hansen, J. C. La Jansen, A. Davidsson, and T. H. Christensen, "Effects of pre-treatment technologies on quantity and quality of source-sorted municipal organic waste for biogas recovery," Waste management (New York, N.Y.), vol. 27, no. 3, pp. 398–405, 2007. [CrossRef]

- M. Meirer, Physikalische Aufbereitung von Restabfällen zur Co-Vergärung in Abwasserreinigungsanlagen. Leopold-Franzens-Universität Innsbruck, 2018. Accessed: Apr. 15 2024.

- A. Cesaro, V. Cieri, and V. Belgiorno, "Press-extrusion pretreatment of the organic fraction of municipal solid waste for enhanced methane production," J Mater Cycles Waste Manag, vol. 23, no. 1, pp. 130–138, 2020. [CrossRef]

- BTA International GmbH, BTA – biotechnical recycling. [Online]. Available: https://bta-international.de/ (accessed: Nov. 11 2024).

- J. Effenberger, L. Jahn, and V. Kuehn, "Co-digestion of press liquids of source-sorted municipal organic waste in anaerobic sludge treatment of municipal wastewater treatment plants," Water science and technology : a journal of the International Association on Water Pollution Research, vol. 73, no. 12, pp. 3080–3086, 2016. [CrossRef]

- A. Blank and E. Hoffmann, "Upgrading of a co-digestion plant by implementation of a hydrolysis stage," WASTE MANAGEMENT & RESEARCH, vol. 29, no. 11, pp. 1145–1152, 2011. [CrossRef]

- M. S. Romero-Güiza, M. Peces, S. Astals, J. Benavent, J. Valls, and J. Mata-Alvarez, "Implementation of a prototypal optical sorter as core of the new pre-treatment configuration of a mechanical–biological treatment plant treating OFMSW through anaerobic digestion," Applied Energy, vol. 135, pp. 63–70, 2014. [CrossRef]

- A. Jank, W. Müller, S. Waldhuber, F. Gerke, C. Ebner, and A. Bockreis, "Hydrocyclones for the separation of impurities in pretreated biowaste," Waste management (New York, N.Y.), vol. 64, pp. 12–19, 2017. [CrossRef]

- K. Osei and R. Andoh, "Optimal Grit Removal and Control in Collection Systems and at Treatment Plants," in World Environmental and Water Resources Congress 2008, Honolulu, Hawaii, United States, 2008, pp. 1–7.

- Lopes, Alice do Carmo Precci, "Mechanical pretreatment of residual waste for codigestion in wastewater treatment plants," 2021.

- K. Schu, Ed., Sand im Getriebe der Vergärung? International congress, CH-Solothurn, Schweiz, 2008.

- H. GE, P. D. Jensen, and B. Damien J., "Pre-treatment mechanisms during thermophilic–mesophilic temperature phased anaerobic digestion of primary sludge," Water Research, vol. 44, no. 1, pp. 123–130, 2010. [CrossRef]

- H. Carrère et al., "Pretreatment methods to improve sludge anaerobic degradability: a review," Journal of hazardous materials, vol. 183, 1-3, pp. 1–15, 2010. [CrossRef]

- J. Ayala, B. MacKenzie, and J. McWilliams, "Thermal hydrolysis integration in anaerobic digestion process-biomethane (ECONWARD, BIOMAK)", Personal communication, Aug. 2024.

- J. Mata-Alvarez, J. Dosta, M. Romero-Güiza, X. Fonoll, M. Peces, and S. Astals, "A critical review on anaerobic co-digestion achievements between 2010 and 2013," Renewable and Sustainable Energy Reviews, vol. 36, pp. 412–427, 2014. [CrossRef]

- S. Luste, H. Heinonen-Tanski, and S. Luostarinen, "Co-digestion of dairy cattle slurry and industrial meat-processing by-products--effect of ultrasound and hygienization pre-treatments," Bioresource technology, vol. 104, pp. 195–201, 2012. [CrossRef]

- F. Fantozzi and C. Buratti, "Anaerobic digestion of mechanically treated OFMSW: experimental data on biogas/methane production and residues characterization," Bioresource technology, vol. 102, no. 19, pp. 8885–8892, 2011. [CrossRef]

- S. E. Nayono, Foodwaste as a co-substrate in a fed-batch anaerobic biowaste digester for constant biogas supply, 2009.

- Nowak and C. Ebner, "Verwertung organischer Reststoffe in Faulbehältern kommunaler Kläranlagen," Österr Wasser- und Abfallw, vol. 68, 3-4, pp. 108–117, 2016. [CrossRef]

- D. Novarino and M. C. Zanetti, "Anaerobic digestion of extruded OFMSW," Bioresource technology, vol. 104, pp. 44–50, 2012. [CrossRef]

- Abfallzweckverband Südniedersachsen, MBA - Verfahrensbeschreibung: Phase I: Mechanische Aufbereitung (MA) der Abfälle Phase II: Biologische Behandlung (BA) in der Trockenvergärung. [Online]. Available: https://www.as-nds.de/mba/verfahren/index.html (accessed: Oct. 5 2024).

- Sutco Recyclingtechnik GmbH, "Forschungs- und Entwicklungs-Vorhaben Energieeffiziente Bioabfallverwertung = EnBV: Abschlussbericht Anschlussvorhaben," 2015. Accessed: Apr. 15 2024.

- EVA mbh and Universität Rostock, "FuE-Vorhaben „Presswasservergärung Restabfall = PV-R“: An die Deutsche Bundesstiftung Umwelt (DBU)," Deutsche Bundesstiftung Umwelt (DBU), 2017. Accessed: Apr. 25 2023.

- Lopes, Alice do Carmo Precci and A. Bockreis, "Mechanical pretreatment of municipal solid waste for co-digestion in wastewater treatment plants," 2021.

- D. Bolzonella, P. Pavan, S. Mace, and F. Cecchi, "Dry anaerobic digestion of differently sorted organic municipal solid waste: a full-scale experience," Water science and technology : a journal of the International Association on Water Pollution Research, vol. 53, no. 8, pp. 23–32, 2006b. [CrossRef]

- Anaergia Technologies GmbH, Separator FSP - Anaergia Technologies - Komponenten für eine nachhaltige Zukunft (EN). [Online]. Available: https://www.anaergia-technologies.com/en/products/separation/separator/ (accessed: Oct. 19 2024).

- M. Meirer, W. Müller, and A. Bockreis, "Innovative Abfallaufbereitung: Erzeugung hochwertiger Substrate für Biogas- & Kläranlagen: Poster. Österreichische Abfallwirtschaftstagung 2017," 2017.

- M. Nelles, T. Böning, R. Bewani, and A. Nassour, FuE-Vorhaben „Presswasservergärung Restabfall“: Endbericht (Entwurf vom 15.2.2022), 2022. Accessed: Apr. 25 2023.

- A. Bernstad, L. Malmquist, C. Truedsson, and J. La Cour Jansen, "Need for improvements in physical pretreatment of source-separated household food waste," Waste management (New York, N.Y.), vol. 33, no. 3, pp. 746–754, 2013. [CrossRef]

- R. Bewani, T. Böning, A. Nassour, and M. Nelles, "Increasing the Efficiency of Mechanical-Biological Residual Waste Treatment through the Fermentation of the Liquid after Pressing the Organic Fractions," in 13. WISSENSCHAFTSKONGRESS Kreislauf- und Ressourcenwirtschaft: In Zusammenarbeit mit der Fakultät für Bau- und Umweltingenieurwesen der Technischen Universität Wien, Technischen Universität Wien, 2024, pp. 145–150. Accessed: Apr. 15 2024.

- J. Wagner, T. Kuegler, J. Baumann, M. Günther, and E. Finke, "Bericht zur Fortschreibung der Sortierrichtlinie 1998: Bericht zur Fortschreibung der Richtlinie zur einheitlichen Abfallanalytik in Sachsen," Freistaat Sachsen, 2014. Accessed: Apr. 15 2024. [Online]. Available: https://publikationen.sachsen.de/bdb/.

- Fermentation of organic materials Characterisation of the substrate, sampling, collection of material data, fermentation tests: VDI4630, 4630, VEREIN DEUTSCHER INGENIEURE, Nov. 2016.

- E. Favoino, M. Giavini, and S. A. Di Parco Monz, "Bio-waste generation in the EU - current capture and future potential," 2020. Accessed: 07.2023. [Online]. Available: https://biconsortium.eu/downloads/bio-waste.

- European Compost Network, Bio-Waste Management plays a Keyrole in Bioeconomy - European Compost Network. [Online]. Available: https://www.compostnetwork.info/policy/circular-economy/bio-waste-management/ (accessed: Feb. 25 2024).

- H.-J. Dr. Dornbusch et al., "Vergleichende Analyse von Siedlungsrestabfällen aus repräsentativen Regionen in Deutschland zur Bestimmung des Anteils an Problemstoffen und verwertbaren Materialien: Abschlussbericht," INFA GmbH, Ahlen; ARGUS GmbH, Berlin; Witzenhausen-Institut GmbH, Witzenhausen; Ingenieur-Büro Manfred Kanthak, Berlin, 2020. Accessed: Mar. 16 2021. [Online]. Available: http://www.umweltbundesamt.de/publikationen.

- Umweltbundesamt, Residual waste in Germany has nearly halved in 35 years. [Online]. Available: https://www.umweltbundesamt.de/en/press/pressinformation/residual-waste-in-germany-has-nearly-halved-in-35 (accessed: Feb. 25 2024).

| Trial | TS [% FM] | VS [% FM] | DOC [mg/l] | BY [l(N)/kg VS] | |

|---|---|---|---|---|---|

| PE1 | T1 | 14.87 | 8.43 | 8360 | 605 |

| T2 | 15.38 | 10.58 | 7320 | 563 | |

| PE2 | T3 | 18.02 | 10.50 | 4200 | 357 |

| T4 | 15.38 | 10.58 | 7320 | 562 | |

| T5 | 18.73 | 10.31 | 10920 | 554 | |

| T6 | 14.75 | 7.18 | 9270 | 613 | |

| PE3 | T7 | 15.38 | 10.58 | 7320 | 562 |

| T8 | 18.12 | 5.83 | 10240 | 729 | |

| T9 | 20.87 | 10.58 | 7970 | 389 | |

| Literature review | |||||

| RMSW (1) | Pressing | 9-24 | 6-16 | - | 450-760 |

| Biowaste (2) | Pressing | 10-28 | 7-25 | - | 50-458 |

| RMSW (3) | Pressing | 35 | 21 | - | 660 |

| RMSW (4) | Dry Screening | 55-65 | 29-49 | - | 290-320 |

| Biowaste (5) | Wet Pulping | 12-17 | 10-12 | - | 770-810 |

- (1)

- Wet process with pressing: Pressing MSFF separated from RMSW [4].

- (2)

- Wet process with pressing: Pressing biowaste [4].

- (3)

- Wet process with pressing (250 bars): Pressing MSFF separated from RMSW [11, 35].

- (4)

- Dry process without pressing: Screening MSFF without pressure [11].

- (5)

- Wet process without pressing: Biowaste in pulping and hydrocyclone [11].

| Press basket size | 10 [mm] | 8 [mm] | 5 [mm] |

| Biogas volume [m3/week] | 5,513 | 6,213 | 5,987 |

| Biogas volume [m3/day](1) | 840 | 900 | 890 |

| Recovery of Biogas | Trial 9 | Trial 3 | Trial 8 | Trial 1 | Trial 2/4/7 | Trial 6 | Trial 5 |

|---|---|---|---|---|---|---|---|

| [m3/ton RMSW] | 18 | 18 | 21 | 22 | 25 | 33 | 34 |

| [m3/ton MSFF] | 29 | 29 | 33 | 36 | 40 | 53 | 55 |

| [m3/ton VS in RMSW] | 82 | 84 | 95 | 103 | 115 | 152 | 157 |

| Materials | Fresh Mass | Total Solid (TS) | Volatile Solid (VS) | Biogas | ||||

|---|---|---|---|---|---|---|---|---|

| Recovery rate [% input FM] | Concentration [% FM] | Recovery rate [% input TS] | Concentration [% FM] | Recovery rate [% input VS] | Biogas potential [m3/Mg VS] | Recovery rate [% input biogas] | ||

| (1) P1: This study (Trial 5-6)P: 4.0 bars GR+PZ/MSFF: 1,050 l/ton Mixing time before pressing: No Mesh size: 5 mm |

MSFF<60mm | 55 | 28 | 389 | ||||

| GR | 12 | 4.8 | 192 | |||||

| PZ | 1.0 | 0.4 | 778 | |||||

| Input Mix | 100 | 32 | 100 | 16 | 100 | 364 | 100 | |

| PW for AD | 47-58 | 15 | 23-29 | 7.2 | 25-29 | 613 | 46-50 | |

| PC | 42 | 50 | 71 | 25 | 71 | 249 | 50 | |

| (2) P2-A: Piston pressP: 50 bars Water (10 °C)/MSFF: 330 l/ton Mixing time before pressing: 2 h Mesh size: 8 mm |

MSFF<80mm | 72 | 46,10 | 470 | ||||

| Tap water | - | |||||||

| Input Mix | 100 | 48 | 100 | 30,72 | 100 | 100 | ||

| PW for AD | 49 | 35 | 35 | 21,70 | 34 | 320 | 23 | |

| PC | 51 | 61 | 65 | 39,65 | 66 | - | ||

| (3) P2-B: Piston pressP: 40 bars Water (70 °C)/MSFF: 1,560 l/ton Mixing time before pressing: 1,5 h Mesh size: 12 mm |

MSFF<40mm | 74 | 47 | 360 | ||||

| Tap water | - | |||||||

| Input Mix | 100 | 29 | 100 | 18,27 | 100 | 100 | ||

| PW1 for AD | 67 | 9 | 22 | 69 | 24 | 450 | 30 | |

| PW2 for AD | 5 | 19 | 3 | 64 | 3 | - | 4 | |

| PC | 28 | 77 | 75 | 62 | 72 | - | 66 | |

| (4) P2-C: Piston pressP: 250 bars Water /MSFF: 160 l/ton Mesh size: 8 mm |

MSFF<80mm | 50 | 25 | 570 | ||||

| Tap water | ||||||||

| Input Mix | 100 | 42 | 100 | 21 | 100 | 100 | ||

| PW for AD | 57 | 35 | 47 | 21 | 54 | 660 | 63 | |

| PC | 43 | 53 | 53 | 23 | 46 | 470 | 37 | |

| (5) P4: Dry ProcessScreening: 5 mm, 10 mm No pressure No water addition |

MSFF<40mm | 63-67 | 38-49 | 470 | ||||

| Substr. for AD | 31-39 | 55-65 | 27-38 | 29-49 | 24-38 | 290-320 | 17-23 | |

| Rest | 69-61 | 73-62 | 76-62 | 83-77 | ||||

| (6) P3: Thermal ProcessP: 4.0 bars Water steam (150 °C)/MSFF: 1,250 l/ton Mesh size: 40 mm |

MSFF<90 mm | 46 | 59 | |||||

| Water steam | ||||||||

| Input Mix | 20 | 26 | ||||||

| Substr. for AD | 80 | 14 | 53 | 13 | 38 | |||

| Rest | 20 | 47 | 62 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).