1. Introduction

The elastic theory to obtain the warping coordinate and bimoment is presented.

To obtain the plastic bimoment the static or lower bound theorem is used. This theorem states if the equilibrium and plastic condition are verified, then factor ξ equals or is less than the plastic load combination. Where ξ is plastification factor that multiplies the combination of internal forces { ξNEd ξMy,Ed ξMz,Ed ξBEd ξVy,Ed ξVz,Ed ξTt,Ed ξTw,Ed }

In case of Torsion the following should be taken into account { ξBEd ξTt,Ed ξTw,Ed }, to obtain the plastic bimoment all the other internal forces are zero { ξBEd }

1.1. Elastic Theory

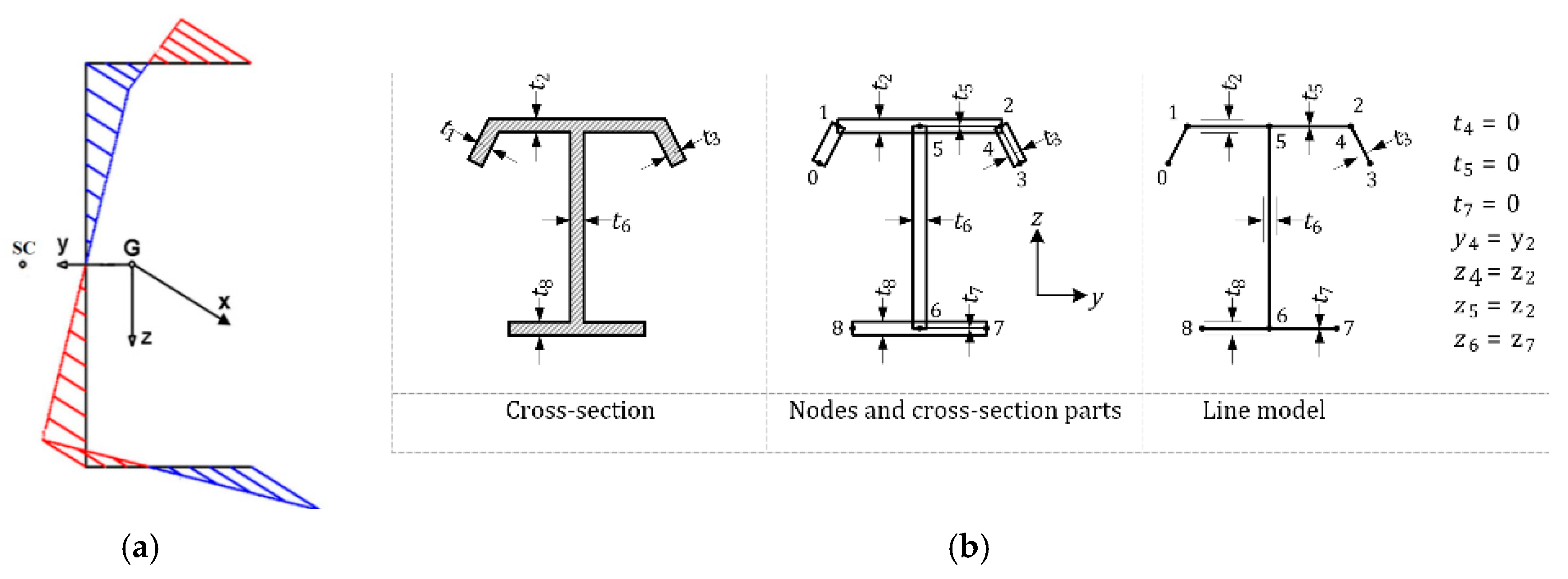

The classical approach to determining section properties is presented including sectorial coordinates using centroidal coordinates y

c and z

c see

Figure 1 (a) and (b).

(

can be chosen arbitrarily, typically taken as 0)

(

can be chosen arbitrarily, typically taken as 0)

It is convenient computationally to use any arbitrary starting coordinate system (

y,

z,

ω) and the parallel axis theorem to obtain the centroidal properties. For sectorial coordinates with respect to any pole,

The normalized sectorial coordinates about the shear center can then be determined using

1.2. Plastic Theory

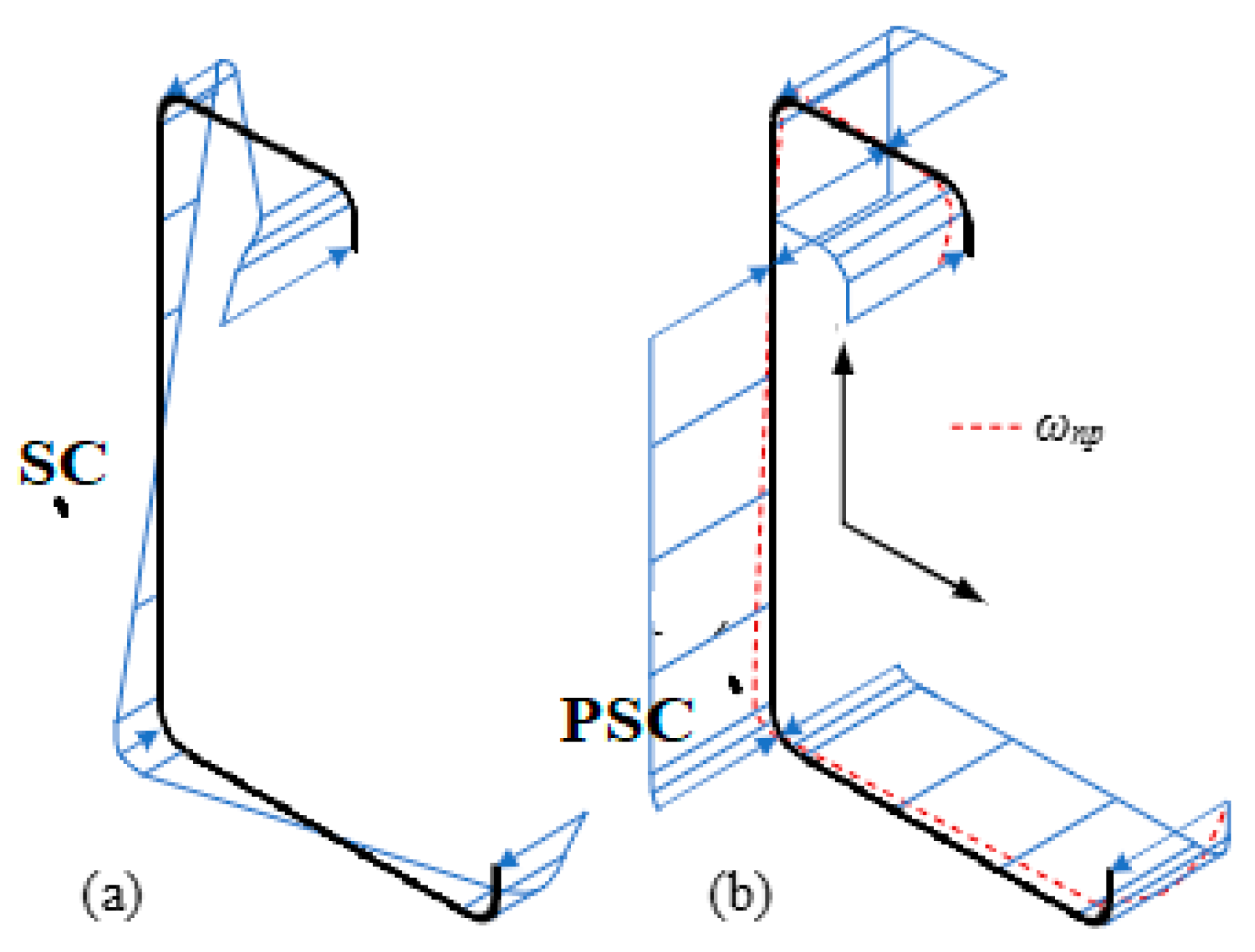

In method 1: The classical approach Glauz [

1] is used where the sign of

ωnp corresponds to the sign of

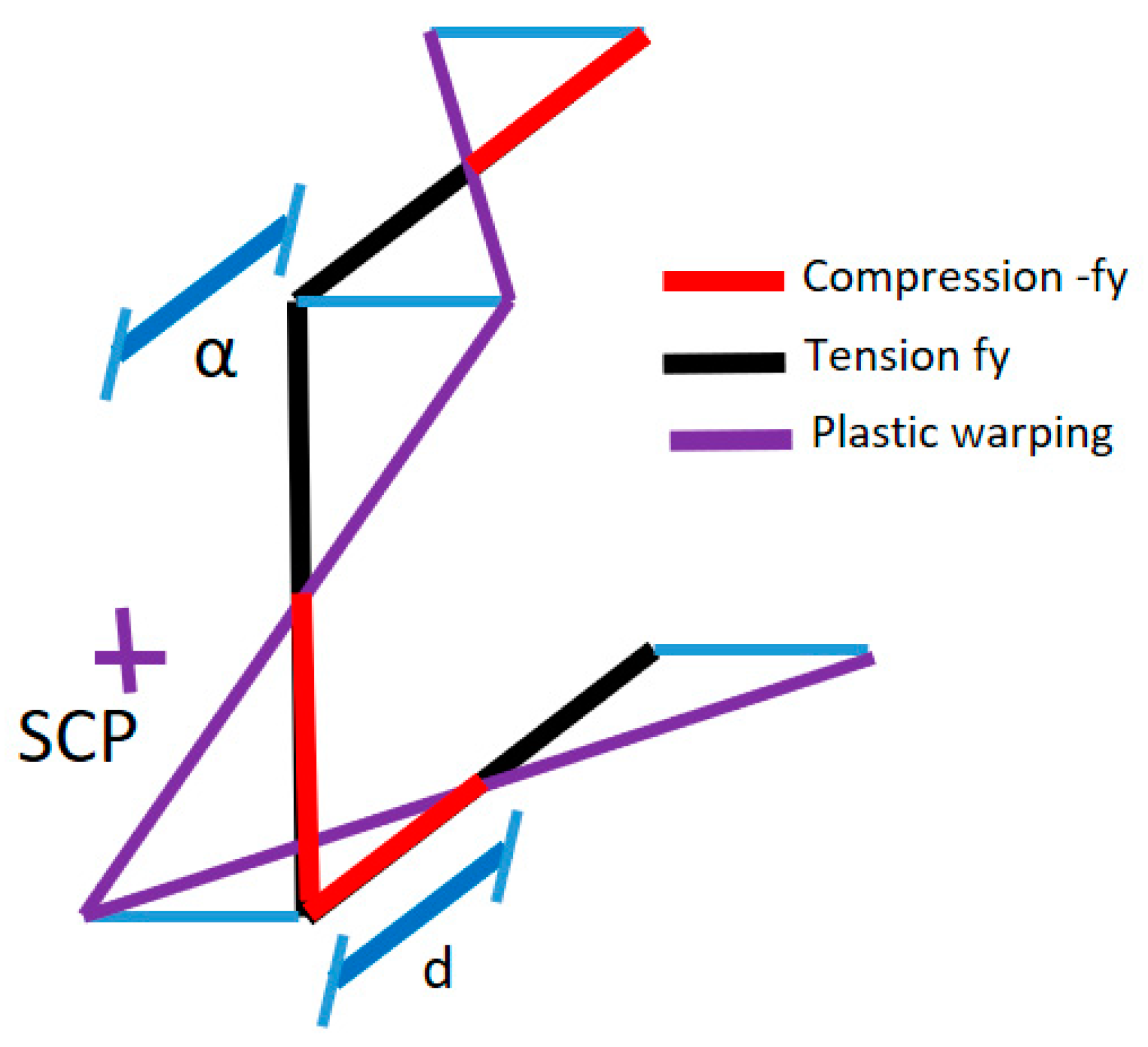

σ, see

Figure 2.

is determined such that there are equal areas of positive and negative stress (axial equilibrium). This is similar to locating the plastic neutral axis for flexure resulting in equal areas of positive and negative stress.

The plastic shear center is the location where the bimoment yield stresses associated with the sign of

ωnp result in flexural equilibrium.

If the bimoment yield stresses are determined by other means such that the net axial force and moments are zero, the plastic shear center location does not need to be determined.

Most terms drop out because is multiplied by , is multiplied by , and is multiplied by .

In the second method by Agüero [

2], the bimoment can be obtained using linear programming, maximizing the bimoment obtained by using as pole the elastic shear center that satisfies the constraints

N=

My=

Mz=0 and the stress at each point constrained to

fy

The plastic bimoment section modulus can be obtained as:

2. Numerical Examples

Figure 3.

Channel section illustration showing ypsc, zpsc, ωsp, and σwp.

Figure 3.

Channel section illustration showing ypsc, zpsc, ωsp, and σwp.

2.1. Channel Section

Middle line dimensions b=75mm h=187mm tf=13mm tw=10mm

The traditional approach using sectorial coordinates about the plastic shear center and precisely locating the stress reversals gives Zw=591.098 cm4, where ypsc=38.642mm and zpsc=0mm (distance between plastic shear center and centroid).

To obtain the part of the bottom flange under compression and top flange under tension {d} Fig. 3, the condition My=0 is used equation (31).

and taking into account that the shift of the plastic normal stresses from compression to tension takes place where the warping is zero the following equation (32) gives the distance of the plastic shear center to the web.

Method 2: With 10 fibers per element

Wpl,w=

Zw=594.874cm

4, and with 20 fibers per element

Zw= 591.517cm

4, so the results tend to converge to the precise solution with more fibers, also from equation in table 14 Agüero [

2]

Zw= 591.098cm

4

Ysc,el=47.559mm distance between elastic shear center and centroid.

Also W

plw=2878cm

4 was compared with the one obtained by Baláž [

4] for a UPE360.

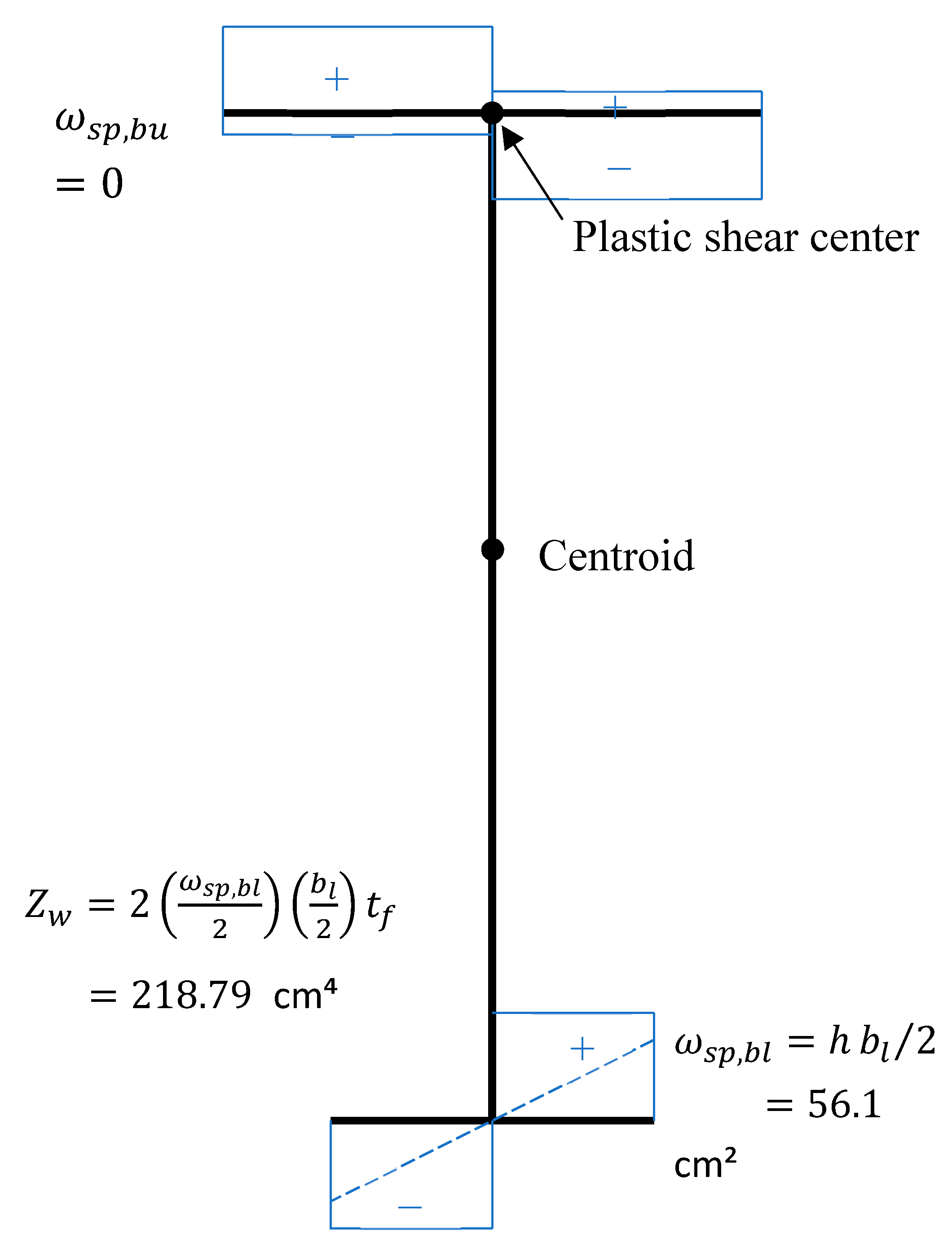

2.2. Mono-Symmetrical I Shape Section

Trahair [

5] pointed out that for this section the plastic bimoment did not depend on the pole position to compute the warping coordinate.

Middle line dimensions bu=100mm bl=60mm h=187mm tf=13mm tw=10mm

The distance {d} from the plastic shear center to the lower part of the upper flange can be obtained applying the condition Mz=0, this results in equation (33).

The plastic shear center lies within the thickness of the larger flange:

zpsc=78.851mm. The tension and compression stresses are apportioned across the thickness of the larger flange to attain equilibrium but have negligible contribution to the plastic bimoment. Due to symmetry, the normalized plastic sectorial coordinates and plastic bimoment section modulus can easily be determined as shown in

Figure 4.

Method 2: With 10 fibers per element Wpl,w=Zw=218.79cm

4 also from equation in table 13 Agüero [

2] the same value is obtained.

Zsc,el=47.974mm distance between elastic shear center and centroid.

2.3. Section Non-Symmetrical

Channel section different width top and bottom flange.

middle line dimensions bu=75mm bl=50mm h=187mm tf=13mm tw=10mm

The traditional approach using sectorial coordinates about the plastic shear center and precisely locating the stress reversals gives Zw=303.889 cm4, where ypsc=15.118mm and zpsc=84.795mm, distance between plastic shear center and centroid.

Method 2: With 10 fibers per element Wpl,w=Zw=303.875cm4

Ysc,el=35.102mm Zsc,el=31.259mm distance between elastic shear center and centroid.

3. Conclusions

The present paper present 2 methods to obtain the plastic bimoment of thin walled sections. In the first method plastic shear center needs to be obtained, while in the second method linear programming is used to maximize the plastic bimoment using as pole to obtain the unit warping the elastic shear center. Numerical examples for monosymmetric I shaped section, channel section and non symmetric section show perfect agreement.

About the interaction with other non zero internal forces { ξN

Ed ξM

y,Ed ξM

z,Ed ξB

Ed ξV

y,Ed ξV

z,Ed ξT

t,Ed ξT

w,Ed } the bimoment is different computed using the plastic shear center to obtain the unit warping as suggested by Osterrieder [

6,

8] and Trahair [

5] than computed using the elastic shear as suggested by Kindmann [

7,

9] leading to different interaction plastic diagrams.

Funding

This research project is supported by the Slovak Grant Agency VEGA no. 1/0155/23.

Nomenclature

according to the Eurocode 3

References

- Glauz, R. . Plastic bimoment determination for cold-formed steel open sections. CFSRC Reports. 2023.

- Agüero A, Baláž I, Höglund T, Koleková Y. Plastic Design of Metal Thin-Walled Cross-Sections of Any Shape Under Any Combination of Internal Forces. Buildings. 2024; 14(12):3890. [CrossRef]

- Agüero, A. , “Thin wall section elastic plastic” Software, Online available from https://labmatlab-was.upv.es/webapps/home/thinwallsectionelasticplastic.html, 2024.

- Baláž, I.; Koleková, Y. Resistances of I- and U-Sections. Combined Bending and Torsion Internal Forces. In Proceedings of the Eurosteel 2017, Copenhagen, Denmark, 13–15 September 2017; Paper No. 13_12_ 772 on USB. pp. 1–10. [CrossRef]

- Trahair N., S. Plastic torsion analysis of monosymmetric and point-symmetric beams. ASCE J. Struct. Eng. 1999; 125(2). [CrossRef]

- Osterrieder, P. , Werner F., Kretschmar J. Plastic flexural-torsional buckling design of beams with open thin walled cross sections. Proceedings of SDSS97, Nagoya, Japan, 1997.

- Kindmann R., Frickel J. Grenztragfähigkeit von häufig verwendeten stabquerschnitten für beliebige Schnittgröβen. Stahlbau 1999;68:817-28.

- P. Osterrieder, J. Kretzschmar. First-hinge analysis for lateral buckling design of open thin-walled steel members. J Constr Steel Res, 62 (2006), pp. 35-43. [CrossRef]

- QST I-plastisch. RUBSteEl eEducation Tool, Ruhr-Universität Bochum; Lehrstuhl für Stahl-, Leicht- und Verbundbau. Version 10; 2014. https://www.stahlbau.ruhr-uni-bochum.de/sb/service/rubsteeltools.html.en.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).