Submitted:

05 February 2025

Posted:

05 February 2025

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

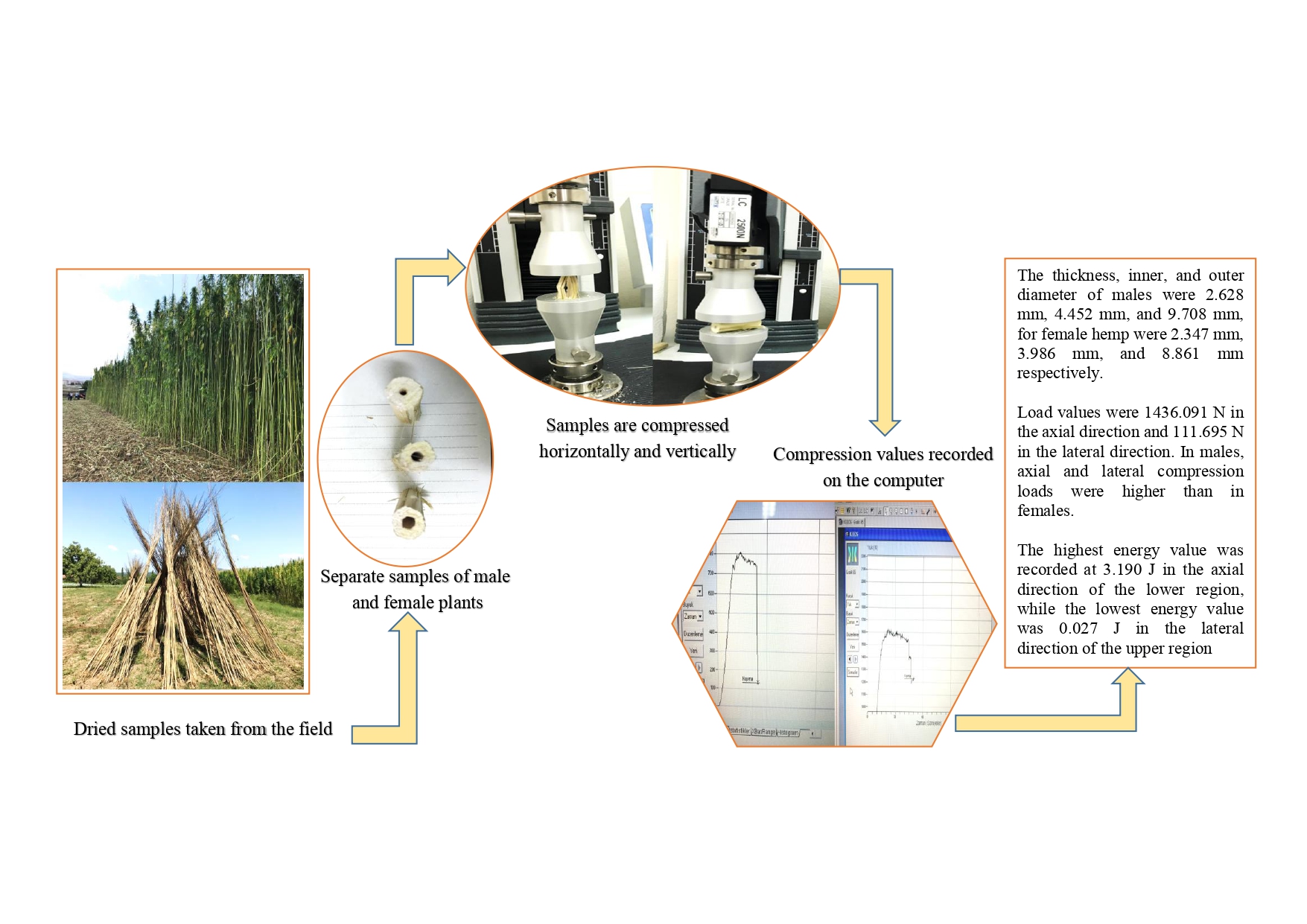

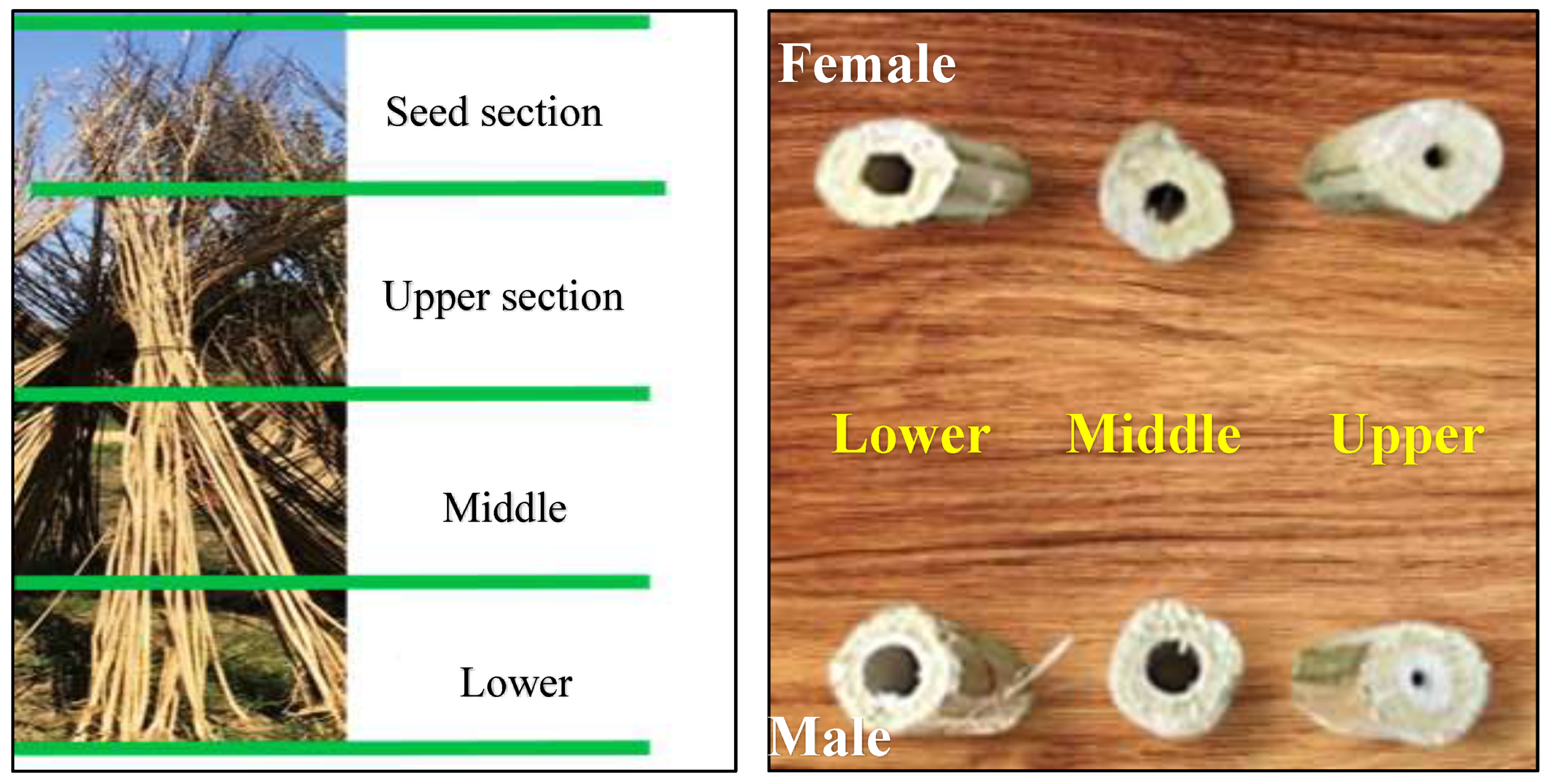

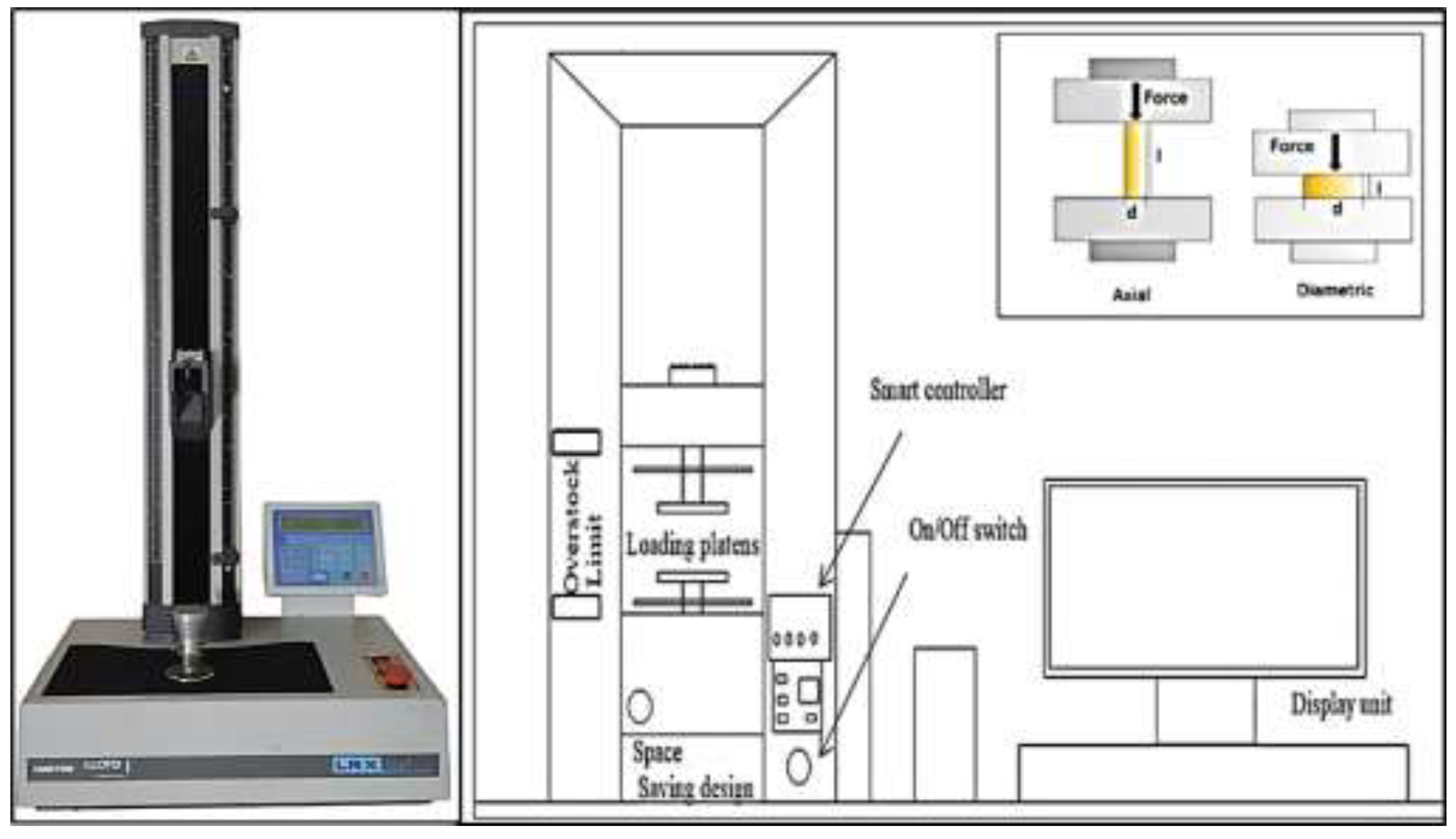

2.1. Preparation of Samples and Test Device

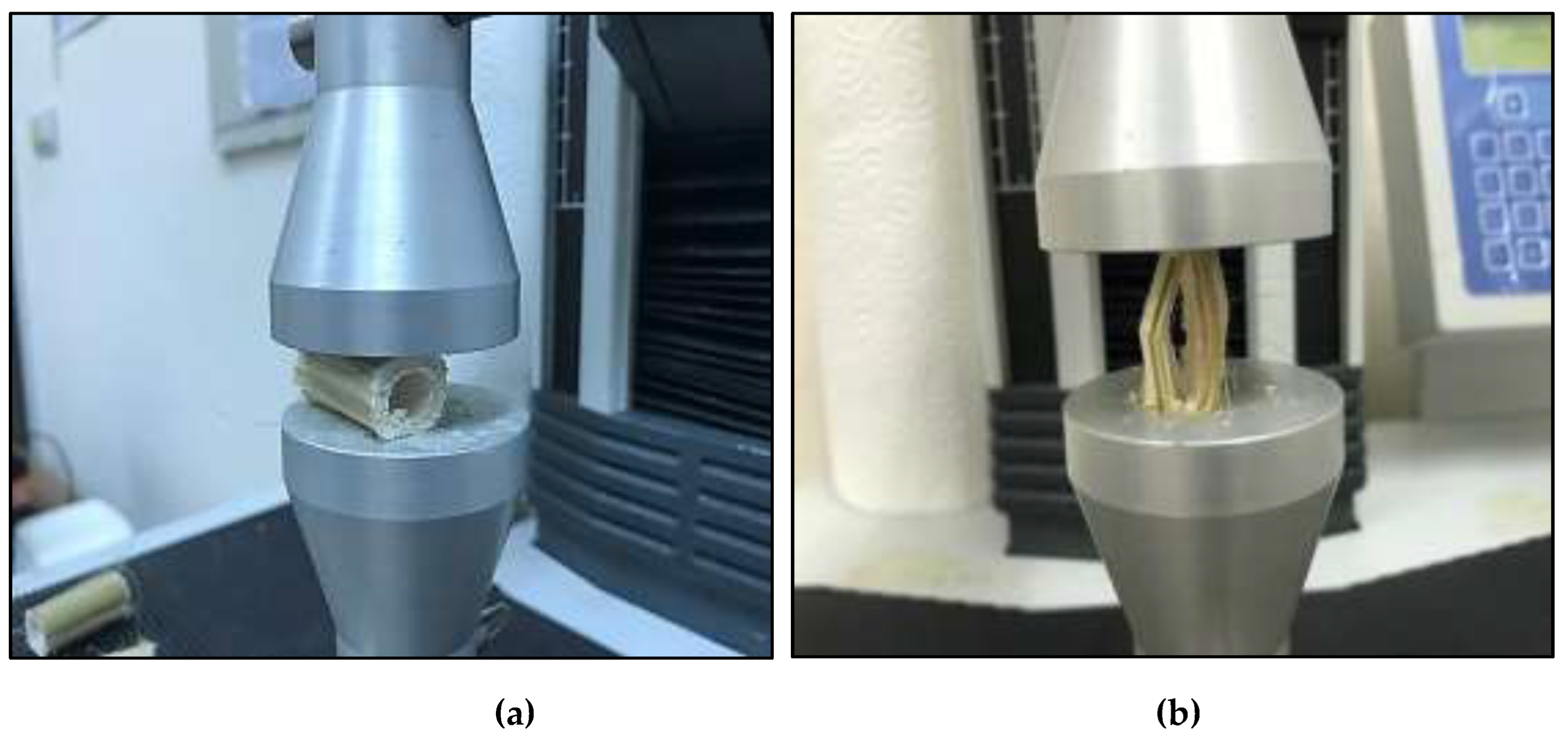

2.2. Compression Experiment Design

2.3. Measurements of Properties

2.3.1. Physical Measurement Values

2.3.2. Pressure Values

3. Results

3.1. Physical Properties of Hemp Stalks

3.2. Load Values of Hemp Stalk

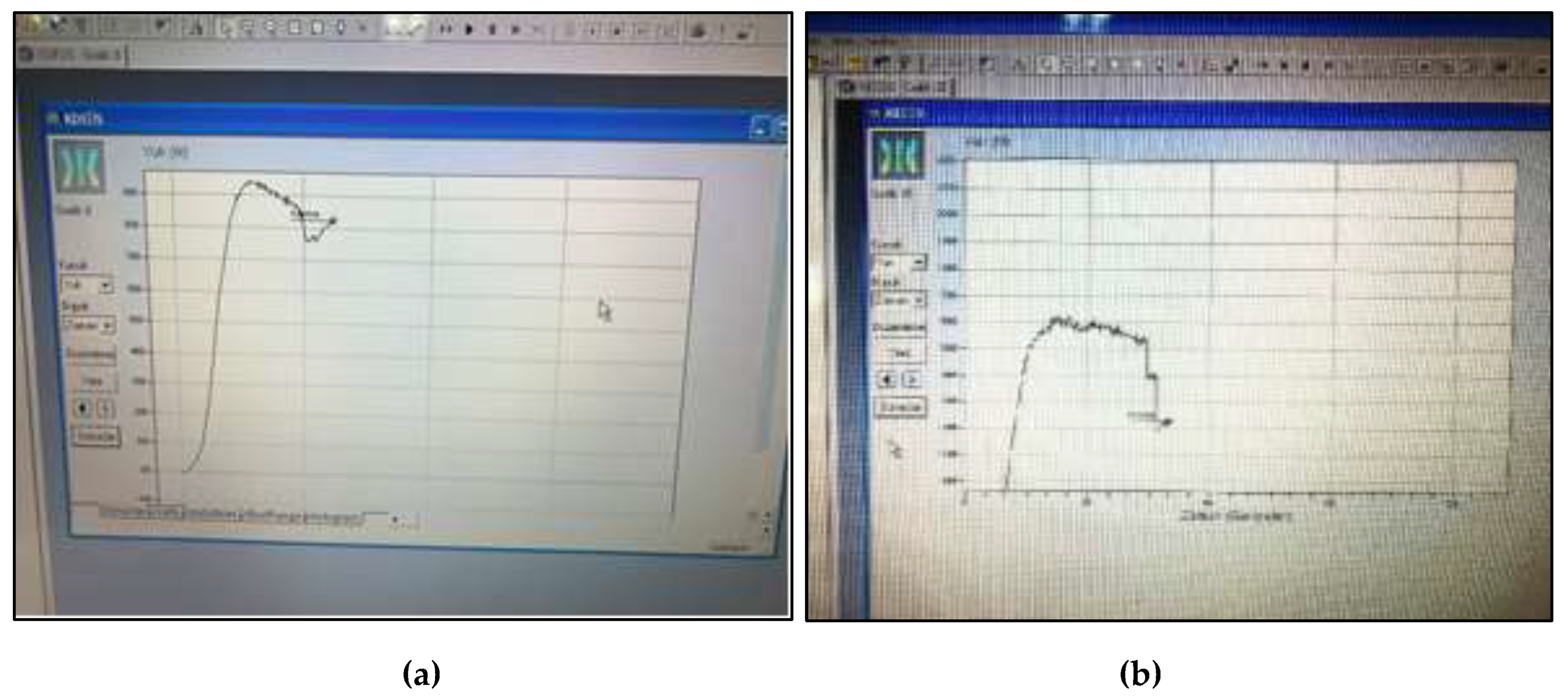

3.3. Deformation and Elongation Characteristics of Hemp Stalk

3.4. Energy Properties of Hemp Stalk

4. Discussion

5. Conclusions

Data Availability Statement

Conflicts of Interest

References

- Trono, D. Elicitation as a tool to improve the accumulation of secondary metabolites in Cannabis sativa. Phytochemistry Reviews. 2024, 17, 1-37. [CrossRef]

- Kaya, S.; Oner, E. Kenevir liflerinin eldesi, karakteristik özellikleri ve tekstil endüstrisindeki uygulamaları. Mehmet Akif Ersoy Üniversitesi Fen Bilimleri Enstitüsü Dergisi. 2020, 11, 108-23.

- Rosso, E.; Armone, R.; Costale, A.; Meineri, G.; Chiofalo, B. Hemp seed (Cannabis sativa L.) varieties: lipids profile and antioxidant capacity for monogastric nutrition. Animals. 2024, 14, 2699. [CrossRef]

- Srisuk, S.; Intarat, T.; Damkham, N.; Pisitsak, P. Comparison of infrared-, ultrasonic-, and microwave-assisted mordanting methods for the natural dyeing properties of hemp fabrics. Fibers and Polymers. 2024, 25, 4349-60. [CrossRef]

- Chaowana, P.; Hnoocham, W.; Chaiprapat, S.; Yimlamai, P.; Chitbanyong, K.; Wanitpinyo, K.; Chaisan, T.; Paopun, Y.; Pisutpiched, S.; Khantayanuwong, S.; Puangsin, B. Utilization of hemp stalk as a potential resource for bioenergy. Materials Science for Energy Technologies. 2024, 7, 19-28. [CrossRef]

- Yimlamai, P.; Chitbanyong, K.; Wanitpinyo, K.; Puangsin, B.; Nanta, K.; Khantayanuwong, S.; Pisutpiched, S.; Chaisan, T.; Fei, B.; Hiziroglu, S. Properties of mixture of hemp bast and softwood pulp for filter paper manufacture. Heliyon. 2024, 10, 3. [CrossRef]

- Ahsan SM, Injamum-Ul-Hoque M, Shaffique S, Ayoobi A, Rahman MA, Rahman MM, Choi HW. Illuminating Cannabis sativa L.: The Power of Light in Enhancing C. sativa Growth and Secondary Metabolite Production. Plants. 2024, 13, 2774.

- Chen, Y.; Sadek, M.A.; Guzman, L.; Lague, C.; Landry, H. Simulation of tensile tests of hemp fibre using discrete element method. Agricultural Engineering International: CIGR Journal. 2014, 16, 126-35.

- Kurtuldu, E.; İşmal, ÖE. SÜRDÜRÜLEBİLİR TEKSTİL ÜRETİM VE TASARIMINDA YENİDEN DEĞER KAZANAN LİF: KENEVİR. Art-E. 2019, 1, 12-24.

- Kaur, G.; Kander, R. The sustainability of industrial hemp: a literature review of its economic, environmental, and social sustainability. Sustainability. 2023, 15, 6457. [CrossRef]

- Yano, H.; Fu, W. Hemp: A sustainable plant with high industrial value in food processing. Foods. 2023, 12, 651. [CrossRef]

- Tănase Apetroaei, V.; Pricop, E.M.; Istrati, D.I.; Vizireanu, C. Hemp Seeds (Cannabis sativa L.) as a Valuable Source of Natural Ingredients for Functional Foods—A Review. Molecules. 2024, 29, 2097.

- Kumar, I.M.; Mazhar, M.S.; Nawaz, S. Potential of Establishing Industrial Hemp Value Chains in Northern Australia. Electronic Journal of Structural Engineering. 2024, 29, 17-22. [CrossRef]

- Hua, K.Q.; Yi, S.Z.; Sheng, Q.C., Fu, W.Y.; Xuan, Z.; Xia, S.X.; Yan, C.X.; Dan, Y.D.; Dong, J.W.; Mei, Y.H.; Li, T.L. The Study Progress on Breeding of Flax and Industrial Hemp in China. Journal of Natural Fibers. 2024, 21, 2389159. [CrossRef]

- Shah, N.; Mwando, E.; Skewes, M. A.; Stanley, S.; Hartley, N. Industrial Hemp Variety Trials: Results from the Northern Territory. Agronomy Australia Conference, 21-24 October 2024, Albany, Australia. https://agronomyconference.com.

- Tsaliki, E.; Kalivas, A. Hemp Crop Opportunities. Ann Agric Crop Sci. 2024, 9, 1154. [CrossRef]

- Di Candilo, M.; Rannalli, P.; Diozzi, M. Investigation of cultivation methods for the mechanization of hemp seed harvest. Advances in horticultural science. 2003, 1, 3-8.

- Jicheng, H.; Cheng, S.; Xianwang, L.; Kunpeng, T.; Qiaomin, C.; Bin, Z. Design and Tests of Hemp Harvester. International Agricultural Engineering Journal. 2017, 26, 117-127.

- Shen, C.; Liang, S.M.; Liang, J.H.; Liu, H.L.; Huang, J.C.; Tian, K.P.; Zhang, B.; Yin, G.D. Status of hemp field production mechanization and research thoughts for China’s hemp production areas. International Agricultural Engineering Journal. 2020, 29, 194-204.

- Mariz, J.; Guise, C.; Silva, T.L.; Rodrigues, L.; Silva, C.J. Hemp: From Field to Fiber—A Review. Textiles. 2024, 4, 165-82.

- Zhou, Y.; Shen, C.; Li, X.W.; Zhang, B.; Huang, J.C.; Tian, K.P. Design and test of 4LMD-160 hemp harvester. Applied Mechanics and Materials. 2016, 15, 389-95. [CrossRef]

- Shen, C.; Bin, Z.; Xianwang, L.; Guodong, Y.; Qiamin, C.; Chunhua, X. Bench cutting tests and analysis for harvesting hemp stalk. Int J Agric & Biol Eng, 2017, 10, 56–67. [CrossRef]

- Assirelli, A.; Dal Re, L.; Esposito, S.; Cocchi, A.; Santangelo, E. The mechanical harvesting of hemp using in-field stand-retting: a simpler approach converted to the production of fibers for industrial use. Sustainability. 2020, 12, 8795. [CrossRef]

- Tilkat, E.; Hoşer, A.; Tilkat, E.A.; Süzerer, V.; Çiftçi, Y.Ö. Production of Industrial Hemp: Breeding Strategies, Limitations, Economic Expectations, and Potential Applications. Türk Bilimsel Derlemeler Dergisi. 2023, 16, 54-74.

- Sîrbu, F.D.; Dumitru, I.; Iuga, D.E.; Voicea, I.; Vlăduţ, N.V.; Oprescu, R.M. Considerations regarding the hemp harvesting. Acta Technica Corviniensis-Bulletin of Engineering. 2019, 12, 97-100.

- Tian, K.; Li, X.; Shen, C.; Zhang, B.; Huang, J.; Wang, J.; Zhou, Y. Design and test of cutting blade of cannabis harvester based on longicorn bionic principle. Transactions of the Chinese Society of Agricultural Engineering. 2017, 33, 56-61.

- Trociński, A.; Wieruszewski, M.; Bartkowiak, M.; Dziurka, D.; Mirski, R. The Influence of Hemp Fibers (Cannabis sativa L.) on the Mechanical Properties of Fiber–Gypsum Boards Reinforcing the Gypsum Matrix. Polymers. 2024, 16, 2644.

- Zhou, Y.; Li, X.; Shen, C.; Tian, K.; Zhang, B.; Huang, J. Experimental analysis on mechanical model of industrial hemp stalk. Transactions of the Chinese Society of Agricultural Engineering. 2016, 32, 22-9.

- Decker, A.; Drean, J.Y.; Sarazin, V.; Harzallah, O. Influence of Different Retting on Hemp Stem and Fiber Characteristics Under the East of France Climate Conditions. Journal of Natural Fibers. 2024, ,21, 2350621. [CrossRef]

- Leblicq, T.; Vanmaercke, S.; Ramon, H.; Saeys, W. Mechanical analysis of the bending behaviour of plant stems. Biosystems Engineering. 2015, 1, 87-99. [CrossRef]

- Khan, M. M,; Chen, Y.; Laguë, C.; Landry, H.; Peng, Q.; Zhong, W. Compressive properties of Hemp (Cannabis sativa L.) stalks. Biosystems Engineering. 2010, 106, 315-23. [CrossRef]

- Ahangarnezhad, N.; Najafi, G.; Jahanbakhshi, A. Determination of the physical and mechanical properties of a potato (the Agria variety) in order to mechanise the harvesting and post-harvesting operations. Research in Agricultural Engineering. 2019, 65.

- Galedar, M.N.; Tabatabaeefar, A.; Jafari, A.; Sharifi, A.; Rafiee, S. Bending and shearing characteristics of alfalfa stems. Agricultural Engineering International: CIGR Journal. 2008.

- Oke, B.O.; Kaul, R.N.; Mittal, J.P. Physical and mechanical properties of sorghum (Sorghum bicolor) stalk harvested at various intervals after grain maturity. Agricultural wastes. 1984, 11, 31-45. [CrossRef]

- Bhaholyotin, B.; Kradangna, P.; Ichito, K.; Goto, Y. Study on some physical properties of sugar cane for whole stalk harvester design. Agriculture and Natural Resources. 1988, ,22, 88-90.

- Assirelli, A,; Santangelo, E.; Stagno, F.; Roccuzzo, G.; Musio, S.; Amaducci, S. Hemp Sowing Seed Production: Assessment of New Approaches in North-Italy. Sustainability. 2022,14, 17020.

- Kumeroa, F.; Komahan, S.; Sofkova-Bobcheva, S.; Clavijo McCormick, A. Characterization of the volatile profiles of six industrial hemp (Cannabis sativa L.) cultivars. Agronomy. 2022, 12, 2651.

- Leme, F.M.; Schönenberger, J.; Staedler, Y.M.; Teixeira, S.P. Comparative floral development reveals novel aspects of structure and diversity of flowers in Cannabaceae. Botanical Journal of the Linnean Society. 2020, ,193, 64-83. [CrossRef]

- Shi, J.; Schilling, S.; Melzer, R. Morphological and genetic analysis of inflorescence and flower development in hemp (Cannabis sativa L.). bioRxiv. 2024, 2024-01.

- Spitzer-Rimon, B.; Duchin, S.; Bernstein, N.; Kamenetsky, R. Architecture and florogenesis in female Cannabis sativa plants. Frontiers in plant science. 2019, 2, 350. [CrossRef]

- Shi, J.; Toscani, M.; Dowling, C.A.; Schilling, S.; Melzer, R. Identification of genes associated with sex expression and sex determination in hemp (Cannabis sativa L.). Journal of Experimental Botany. 2025, 76,175-90. [CrossRef]

- Bafort, F.; Libault, A.; Maron, E.; Kohnen, S.; Ancion, N.; Jijakli, M.H. Operational Costs and Analysis of Agronomic Characteristics on Cannabidiol and Cannabigerol Hemp (Cannabis sativa L.) in Hydroponic Soilless Greenhouse and Field Cultivation. Horticulturae. 2024, 10, 1271.

- El Bakali, I.; Hassoun, M.; Boutahar, A.; El Bakali, S.; Sakar, E.H.; Kadiri, M.; Merzouki, A. A comparative evaluation of biomass and resin by-products attributes of six hemp (Cannabis sativa L.) cultivars grown in Rif Mountains (northern Morocco). Vegetos. 2024, 14, 1-3. [CrossRef]

- Spano, M.; Di Matteo, G.; Ingallina, C.; Sobolev, A.P.; Giusti, A.M.; Vinci, G.; Cammarone, S.; Tortora, C.; Lamelza, L.; Prencipe, S.A.; Gobbi, L. Industrial hemp (Cannabis sativa L.) inflorescences as novel food: The effect of different agronomical practices on chemical profile. Foods. 2022, 11, 3658. [CrossRef]

- Barbosa-Xavier, K.; Pedrosa-Silva, F.; Almeida-Silva, F.; Venancio, T.M. Cannabis Expression Atlas: a comprehensive resource for integrative analysis of Cannabis sativa L. gene expression. Physiologia Plantarum. 2024, 176, 70010.

- Campbell, L.G.; Peach, K.; Wizenberg, S.B. Dioecious hemp (Cannabis sativa L.) plants do not express significant sexually dimorphic morphology in the seedling stage. Scientific Reports. 2021, 11,16825.

- Zhou, Y.; Li, X.; Shen, C.; Tian, K.; Zhang, B.; Huang, J. Experimental analysis on mechanical model of industrial hemp stalk. Transactions of the Chinese Society of Agricultural Engineering. 2016, 32, 22-9.

- Li, X.; Du, G.; Wang, S.; Meng, Y. Influence of Gender on the Mechanical and Physical Properties of Hemp Shiv Fiber Cell Wall in Dioecious Hemp Plant. Bioresources. 2015, 1, 10. [CrossRef]

- Mazian, B.; Bergeret, A.; Benezet, J.C.; Malhautier, L. Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibres harvested at the beginning of flowering. Industrial crops and products. 2018, ,116,170-81. [CrossRef]

- ASTM Standards. D695-08 : Standard test method for compressive properties of rigid plastics. West Conshohocken, PA, USA : ASTM International. 2008.

- Aydın, İ.; Arslan, S.J. Mechanical properties of cotton shoots for topping. Industrial Crops and Products. 2018, ,112, 396-401. [CrossRef]

- Scutaru, M. L.; Cofaru, C.; Drăghicescu, H. T. Research on Study Hemp Fiber Subjected to Three Point Bend Tests. The 4th International Conference Advanced Composite Materials Engineering. COMAT. 2012.

- Hemmatian, R.; Najafi, G.; Hosseinzadeh, B.; Tavakoli, Hashjin, T.; Khoshtaghaza, M. H. Experimental and Theoretical Investigation of the Effects of Moisture Content and Internodes Position on Shearing Characteristics of Sugar Cane Stems. J. Agr. Sci. Tech. 2012, 14, 963-974.

- Huang, J.; Shen, C.; Ji, A.; Tian, K.; Zhang, B.; Li, X.; Chen, Q. Design and test of two-wheeled walking hemp harvester. International Journal of Agricultural and Biological Engineering. 2020, 13, 127-37.

- Esehaghbeygi, A.; Hoseinzadeh, B.; Khazaei, M.; Masoumi, A. Bending and shearing properties of wheat stem of alvand variety. World Applied Sciences Journal. 2009, 6, 1028-32.

- Tavakoli, H.; Mohtasebi, S. S.; Jafari, A. Effect of Moisture Content and Loading Rate on the Shearing Characteristics of Barley Straw by Internode Position. Agricultural Engineering International: the CIGR Ejournal. Manuscript 2009, 1176.

- Hoseinzadeh, B.; Shirneshan, A. Bending and shearing characteristics of canola stem. American-Eurasian journal of agricultural & environmental sciences. 2012, 12, 275-81.

- Chen, Y.; Gratton, J.L.; Liu, J. Power requirements of hemp cutting and conditioning. Biosystems Engineering. 2004 ,87, 417-24. [CrossRef]

- Squires, C.A.; Netting, K.H.; Chambers, A.R. Understanding the factors affecting the compressive testing of unidirectional carbon fibre composites. Composites Part B: Engineering. 2007, 38, 481-7.

- Chen, Y.; Chen, J.; Zhang, Y.; Zhou, D. Effect of harvest date on shearing force of maize stems. Livestock Science. 2007, 111, 33-44.

- İnce, A.H.; Uğurluay, S.; Güzel, E.; Özcan, M.T. Bending and shearing characteristics of sunflower stalk residue. Biosystems Engineering. 2005, 92, 175-81. [CrossRef]

- Li, X.; Wang, S.; Du, G.; Wu, Z.; Meng, Y. Variation in physical and mechanical properties of hemp stalk fibers along height of stem. Industrial Crops and Products. 2013, 42, 344-8. [CrossRef]

- Lo, T.Y.; Cui, H.Z.; Leung, H.C. The effect of fiber density on strength capacity of bamboo. Materials letters. 2004, 58, 2595-8. [CrossRef]

- Galedar, M.N.; Jafari, A.; Mohtasebi, S.S.; Tabatabaeefar, A.; Sharifi, A.; O'dogherty, M.J.; Rafiee, S.; Richard, G. Effects of moisture content and level in the crop on the engineering properties of alfalfa stems. Biosystems engineering. 2008, 101, 199-208. [CrossRef]

- O'dogherty, M.J.; Huber, J.A.; Dyson, J.; Marshall, C.J. A study of the physical and mechanical properties of wheat straw. Journal of agricultural engineering research. 1995, 62,133-42. [CrossRef]

- Halyk, R. M. Tensile and Shear Strength Characteristics of Alfalfa Stems. Unpublished Master of Science thesis, University of Nebraska, Lincoln.1962.

- Boydaş, M.G.; Comakli, M.; Sayinci, B.; Kara, M. Effects of moisture content, internode region, and oblique angle on the mechanicalproperties of sainfoin stem. Turkish Journal of Agriculture and Forestry. 2019, 43, 254-63.

| Sources of Variation |

Parameters | ||

|---|---|---|---|

| Thickness (mm) |

Inner Diameter (mm) |

Outer Diameter (mm) |

|

| Sex | |||

| Male | 2.628 a | 4.452 a | 9.708 a |

| Female | 2.347 b | 3.986 b | 8.681 b |

|

Direction Axial Lateral |

2.562 a 2.413 b |

||

|

Section Lower Middle Upper |

3.149 a 2.335 b 1.978 c |

4.915 a 4.843 a 2.901 b |

11.142 a 9.585 b 6.857 c |

|

LSD Sex Direction Section |

0.0334* 0.0334* 0.0409* |

0.0648* n.s 0.0794* |

0.0829* n.s 0.1016* |

| CV | 0.1779 | 0.2035 | 0.1195 |

| Sources of Variation |

Parameters | ||

|---|---|---|---|

| Load (N) |

Distance (mm) |

Energy (J) |

|

| sex | |||

| Male | 877.396 a | 1.888 a | 1.403 a |

| Female | 670.390 b | 1.781 b | 1.068 b |

|

Direction Axial Lateral |

1436.091 a 111.695 b |

2.949 a 0.719 b |

2.423 a 0.048 b |

|

Section Lower Middle Upper |

1025.566 a 765.345 b 530.768 c |

2.024 a 1.853 a 1.627 b |

1.634 a 1.261 b 0.812 c |

|

Sex × Direction Male-Axial Female-Axial Male-Lateral Female-Lateral |

1627.584 a 1244.598 b 127.208 c 96.182 c |

3.091 a 2.808 b 0.685 c 0.754 c |

2.762 a 2.085 b 0.044 c 0.052 c |

|

Direction × Section Axial-Lower Axial-Middle Axial-Upper Lateral-Lower Lateral-Middle Lateral-Upper |

1911.262 a 1434.081 b 962.932 c 139.870 d 98.605 d 96.611 d |

3.190 a 2.482 b 1.597 c 0.078 c 0.039 c 0.027 c |

|

|

LSD Sex Direction Section Sex-Direction Direction-Section |

21.9215* 21.9215* 26.8482* 31.0016* 37.9691* |

0.0270* 0.0270* 0.0331* 0.0382* n.s |

0.0444* 0.0444* 0.0543* 0.0627* 0.0769* |

| CV | 0.3754 | 0.1951 | 0.4759 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).