2.1. Computer-Aided Design (CAD) Software

Garment pattern-making is also known as garment construction design, pattern cutting, etc. Traditionally garment pattern involves pattern makers drawing garment construction lines on a brown paper according a garment production drawing. After this, they cut the paper along these construction lines to acquire paper pieces that are used for cloth cutting. The work of patternmaking links fashion design and clothing making. It is considered as the highest technical work in the process of clothing design and production. Currently, pattern-making still relies heavily on pattern-makers’ experience. There are two methods to make a garment pattern: the traditional hands-on approach and the computer-aided process, both require sophisticated skills and It takes about a decade for a novice to master pattern-making.

Therefore, it is necessary for the clothing industry to develop a method that makes garment patterns efficiently without profes sional pattern-making knowledge input from the user.

In order to solve garment fitting issues and reduce the complexity of the problem to an acceptable level, various three dimensional (3D) to two dimensional (2D) flattening technologies have been proposed and developed to obtain garment patterns. Liu et al.proposed a mixed human body modeling method to model 3D body model for 3D pattern-making [

1]. Hinds et al. proposed a 3D mathematical model based on the gaussian curvature to unfold 3D surface into 2D plane for garment pattern development in their research [

2]. While, Kang and Kim constructed a fitting 3D garment for a special mannequin then unfolded the 3D garment model to acquire its 2D patterns [

3]. Cho et al. developed a 3D-to-2D pattern-making system based on a traditional draping system. They fitted fabric lattice to the contour surface and then cut panels according to curved lines. Garment patterns were then created by translating the three-dimensionally contoured panels into two dimensions [

4]. Jeong et al. used triangular meshes to construct a 3D garment surface and pieced these triangular meshes together in a 2D plane to obtain tight-fitting clothing pattern [

5,

6]. Au et al. divided the surface of a 3D virtual dummy into many areas according to the human body’s characteristic line and transformed the 3D surface of the prototype garment to a 2D cutting pattern [

7,

8]. Daanen and Hong used 3D a body scanner to construct a 3D body model constituted by many triangular meshes. They sewed these triangles between the waist and hip line together to form a “patchwork”-skirt. Finally, they designed other lower clothing based on the sewed skirt [

9]. Choi and Nam studied the pattern-unfolding issues of different upper lateral body types [

10]. Jin et al. modeled a 3D garment with constrained contour curves and style curves. They then flattened the 3D garment’s surface based on these curves [

11]. Bruniaux et al. constructed a garment 3D construction curves around a 3D mannequin and generated 3D surfaces based on these curves. Next, they obtained garment patterns by flattening the obtained 3D surfaces [

1][

15]. Zhang et al. proposed a method to model the 3D upper garment with ease allowance for pattern-making [

16]. Yan et al. [

17] drew 3D garment construction curves on a 3D model of a disable female, and then using these construction curves to simulate a 3D garment. Finally,the garment patterns were obtained by flattening the 3D garment. Brouet et al. proposed a fully automatic method to develop fit garments’ patterns for characters with different body shapes [

18].Meng et al. proposed series of new techniques from cross parameterization, geometrical and physical integrated deformation to develop garment pattern [

19]. Mok et al. proposed a customized fashion design system for non-professional users to create their preferred fashion designs in a user-friendly way [

20].

However, there are four shortcomings existing in the aforemen tioned researches: the proposed methods are either too complex to be realistically implemented in production processes, limited to simple styles and can hardly be applied to complicated styles, restricted to tight garments and involve little ease allowance, or did not consider all factors affecting the appearance of a garment such as gravity in a virtual environment.

Several studies have investigated the use of specific CAD software programs in garment sewing pattern-making. For example, a study by Lee et al. (2017) compared the performance of three different CAD software programs in creating patterns for women’s wear. The researchers found that all three programs were effective in reducing the time required to create patterns, but one program was superior in terms of accuracy and ease of use.

Another study by Kim et al. (2018) examined the use of 3D modeling software in generating patterns for men’s wear. The researchers found that 3D modeling software could provide more accurate and detailed patterns, as well as facilitate the visualization of the finished garment. However, they also noted that the learning curve for this type of software can be steep, and that additional training may be required to use it effectively.

In addition to CAD software, some studies have investigated the use of other technologies in garment sewing pattern-making. For example, a study by Al-Tamimi et al. (2019) explored the use of artificial intelligence (AI) algorithms in personalized pattern-making based on individual body measurements and historical fashion trends analysis. The authors identified several potential applications of AI in this field, including personalized pattern-making based on individual body measurements and historical fashion trends analysis.

Overall, the literature review suggests that the automation of garment sewing pattern-making using CAD software has significant benefits for the fashion industry. However, further research is needed to fully explore the capabilities and limitations of these technologies and to develop best practices for their implementation. Additionally, more studies are needed to investigate the impact of CAD software on other aspects of garment production, such as sample making and fitting.

2.2. 3D Virtual Fitting Technology

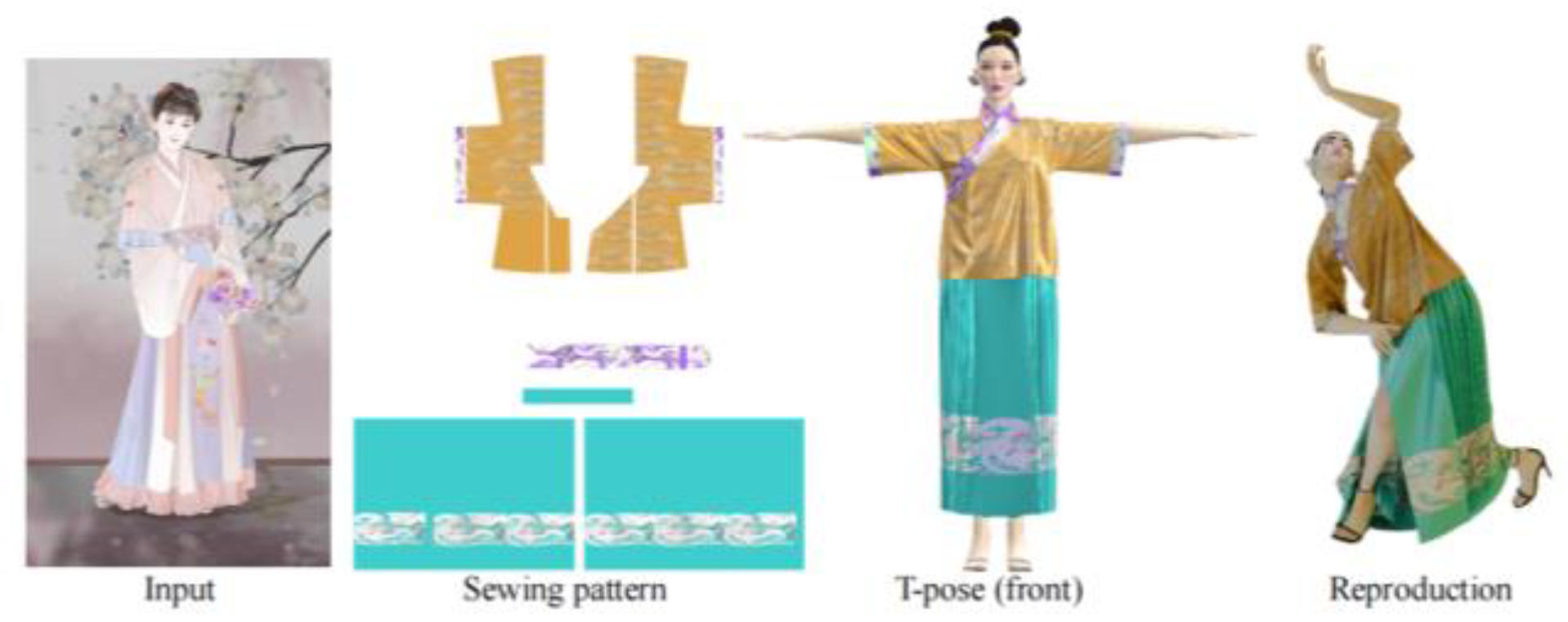

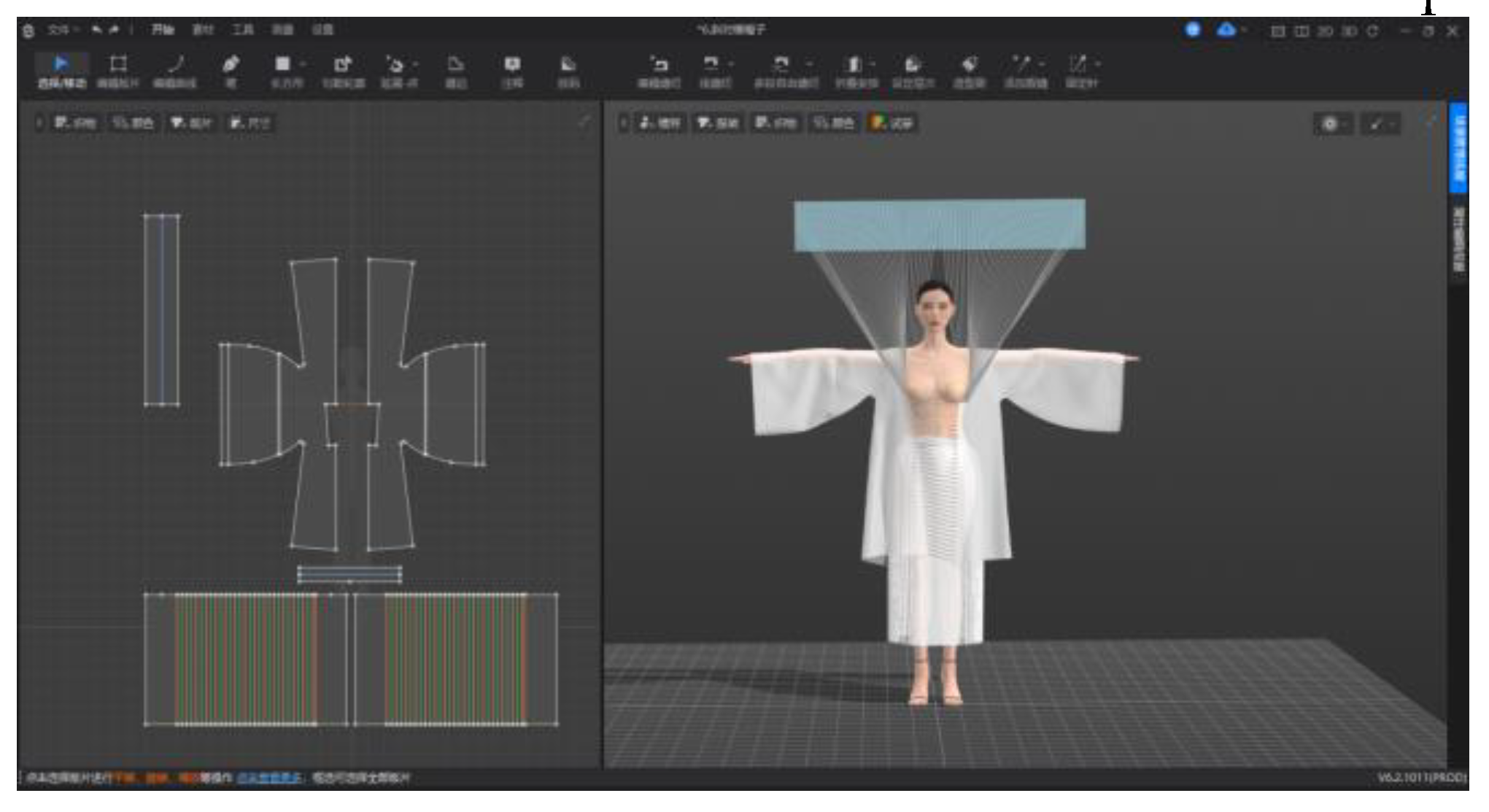

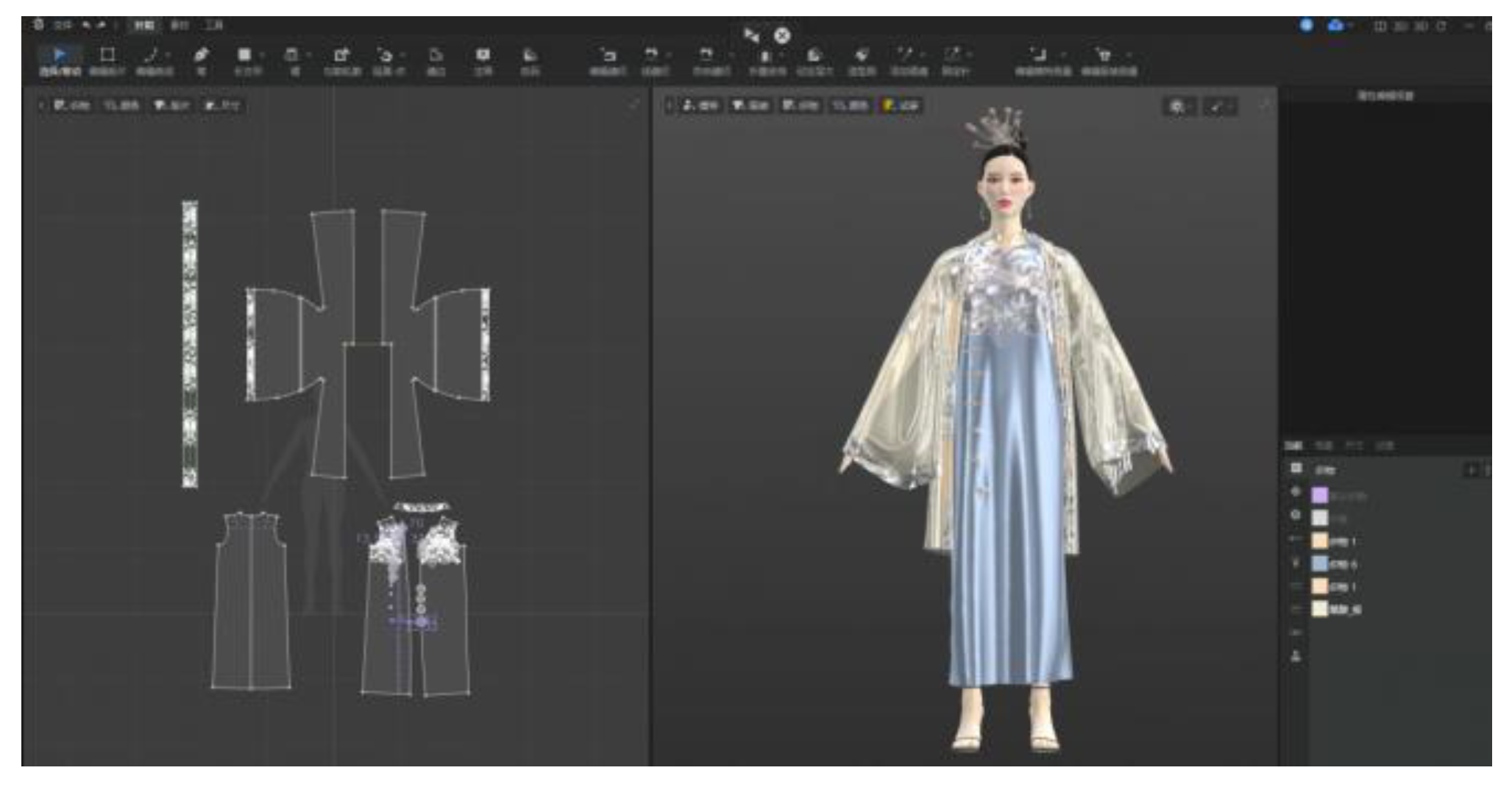

The 3D virtual fitting system relies on computer image processing technology and graphics theory, and through 3D human modeling technology, virtual stitching technology, and fabric simulation technology, it realizes the construction of the user’s virtual human model and the stitching and display of virtual clothing. [

21] Regarding the effect of virtual fitting, Ye Hailian [

22] used different fabrics to evaluate the similarity between virtual samples designed with 3D Runway and CLO3D and samples made with real fabrics, and verified the ideal fitting effect from the perspective of clothing size and silhouette. At present, the more mature 3D fitting software on the market include Style 3D from Hangzhou Lingdi Technology, CLO 3D from CLO Company in South Korea, and Modis from Lectra Company in France.

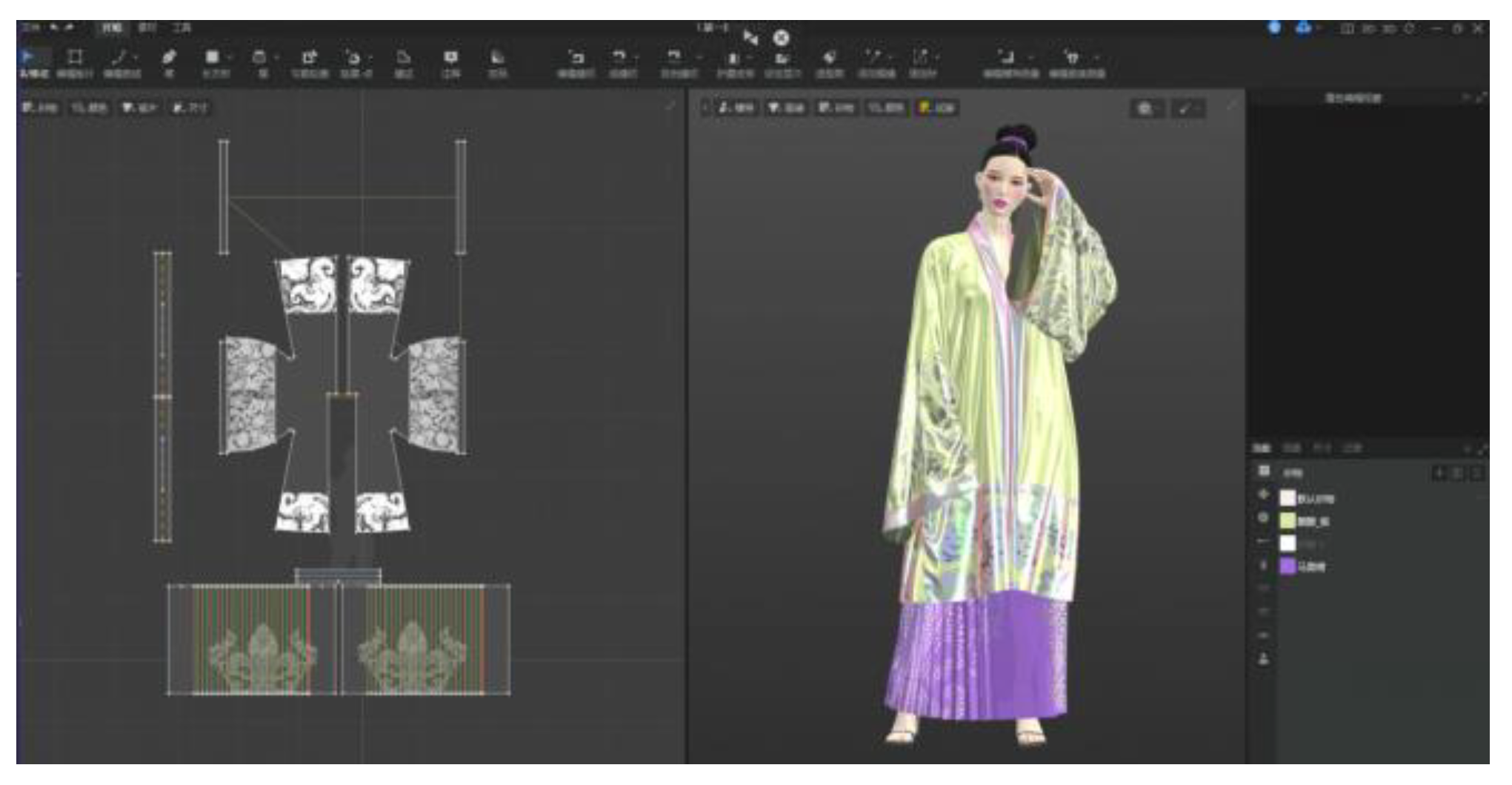

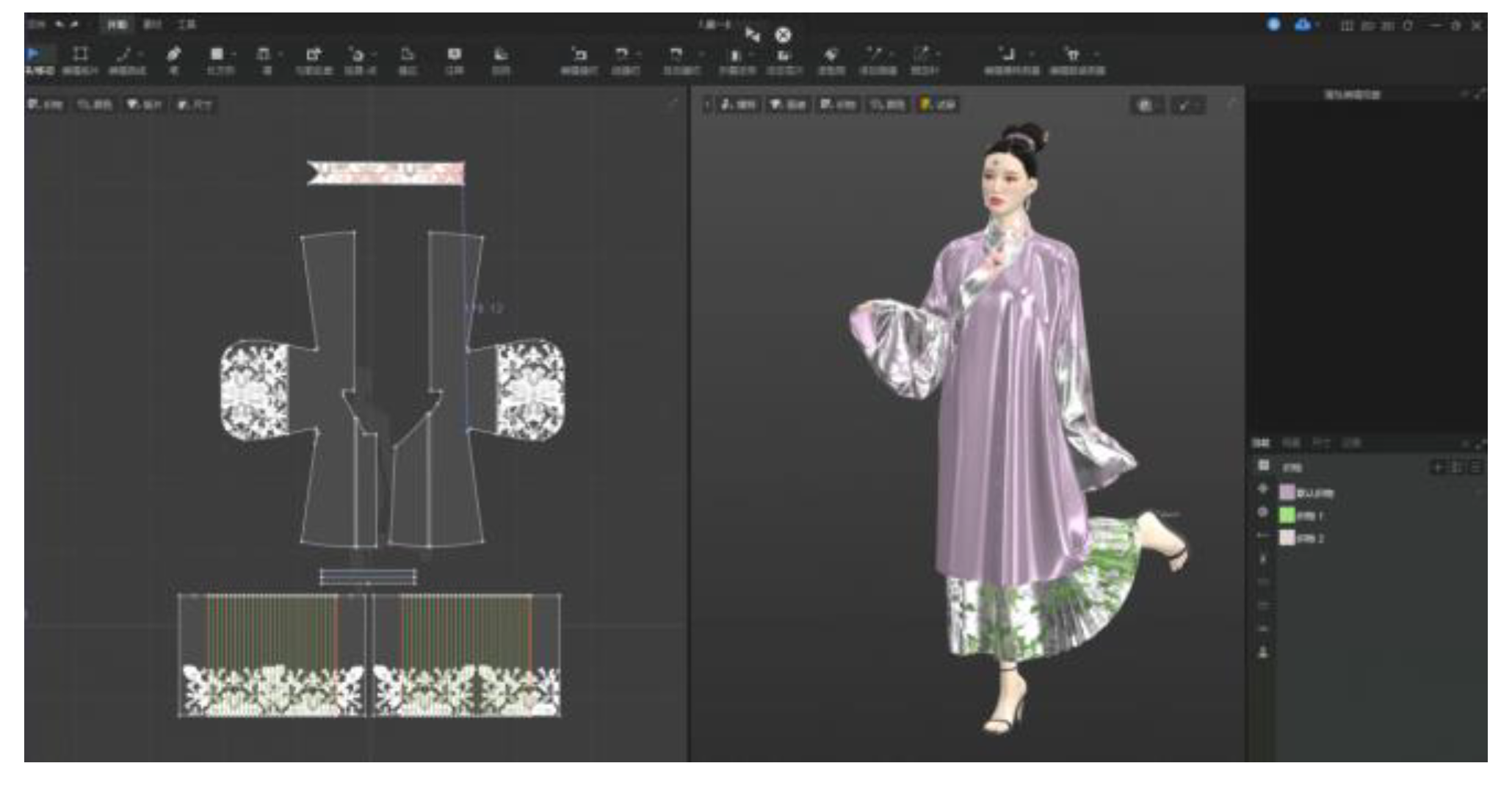

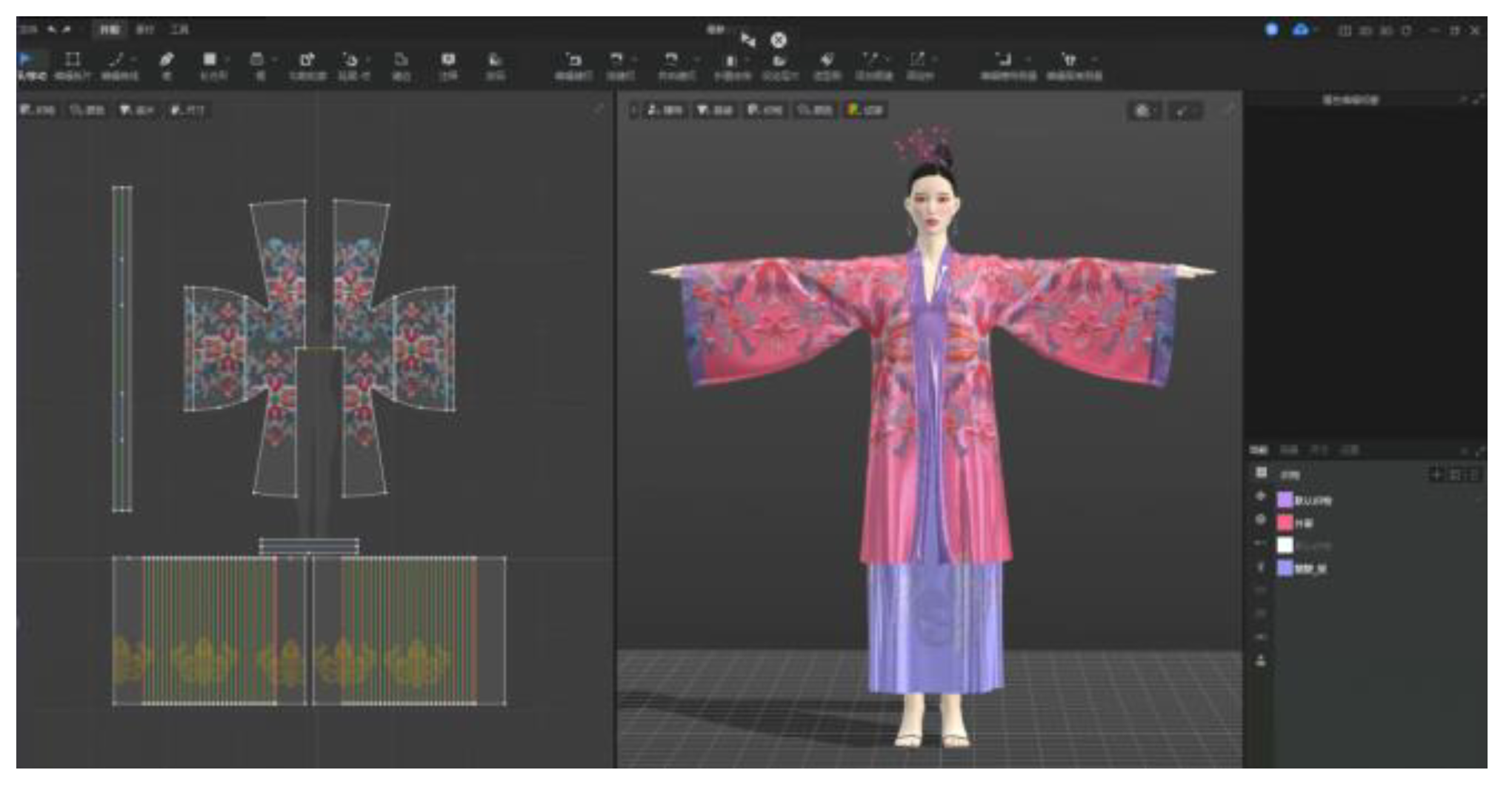

Although the application of 3D fitting technology in the clothing industry is still in its early stages, scholars have conducted a series of studies in the fields of traditional clothing restoration, design, and terminal display. Liu Dongsheng, Shi Hui, and others [

23] used CLO 3D software to restore the traditional Mongolian robe of the Ujimqin tribe and proposed systematic solutions to the problems encountered during the 3D virtual fitting process. Hong Wenjin, Miao Yu, and others [

24] used 3D technology to restore and virtually simulate the design of plackets in the collection of the China Silk Museum, laying a solid foundation for the digital design of traditional clothing. In terms of virtual display of traditional costumes, Liang Hui’e, Zhang Shou, and others conducted an investigation of ethnic costume museums in the Jiangsu, Zhejiang, and Shanghai regions, analyzed and studied digital display schemes, and believed that the use of digital and virtual technologies in ethnic costume museums is the trend. Huang Zhenzhen and Chen Dongsheng [

25] used 3D modeling technology to study the structure and craftsmanship of She ethnic women’s clothing collected in the She Ethnic Museum, in order to achieve the goal of digital display of She ethnic clothing and make new explorations into the digital display of traditional ethnic clothing. In 2015, the Palace Museum launched an app called Qing Dynasty Emperor Costume, which uses 3D technology to visually display the Qing Dynasty palace costume system and its craft characteristics. It is refreshing in promoting traditional Chinese costume culture. [

26] The display methods are becoming increasingly virtualized, de spatialized, and de materialized. Lei Kaibin and Xiong Hua proposed using virtual fitting technology and projection wall technology to achieve immersive and interactive clothing display. Chen Xi, Zhu Yubo, and others proposed the construction of a VR Hanfu experience hall, which is a new exploration and attempt at the dissemination of Chinese clothing culture. It can be seen that 3D fitting technology can play an important role in protecting and inheriting traditional clothing, and the digital construction of cultural clothing heritage is a topic worthy of in-depth research.

Lingdi Style3D is a company founded in 2015, which provides the underlying technical services of independent simulation engine and industrial software of industrial chain level, and is committed to building an integrated collaborative platform for 3D design. Lingdi Style3D founder and CEO Liu Qi has 20 years of experience in the garment industry, with his mastery of computer technology and in-depth understanding of the digital needs of the garment industry, he found the opportunity to start a business, and quickly cut into the digital sample clothing link. Lingdi Style3D’s main products are garment simulation design software and multi-role collaboration platform, which aims to solve the collaboration efficiency problems of designers, pattern makers and fabric and accessories procurement in the garment industry. In addition, Lingdi Style3D also provides special software for designers and fabric and accessories personnel. These tools and services have helped apparel enterprises to digitalize their R & D, collaboration, exhibition and production links. Lingdi Style3D, as the infrastructure of digital fashion, provides 3D digital solutions for the whole process from design to production for the garment industry. Recently, Style3D has also rapidly developed and launched a series of AIGC functions, including AI style analysis, AI pattern generation, AI version generation, AI material generation and rapid generation of new pictures on e-commerce. In terms of capital, Lingdi Style3D has also been recognized by many well-known investment institutions, and has completed nearly $100 million in Pre B + round financing. In addition, Lingdi Style3D also actively participates in industry exchange activities, such as co-sponsoring „Creating a Digital Future Together”-Lingdi Style3D 2021 China Garment Forum, to further promote the digitization process of the garment industry.

2.3. The Hanfu Style System in This Study

The style features of Hanfu are not only a legacy of traditional culture but also a display of ancient Chinese costume art. Whether in formal ceremonial occasions or daily life, Hanfu can exhibit its unique charm and cultural value.

Furthermore, the design of Hanfu not only reflects the aesthetic concepts of ancient Han people but also mirrors the social structure and etiquette culture of the time. For example, it is mentioned in the „Commentary on the Appended Judgments” of the I Ching that the clothing during the period of the Yellow Emperor and Emperors Yao and Shun already had symbolic significance, reflecting the cultural tradition of being a „country of ceremonial dress” and „state of etiquette.”

Hanfu has a variety of forms, including the robe system, deep robe system, robe and skirt system, and ruqun system. Among them, the deep robe system means that the upper and lower garments are cut separately and connected at the waist to form a whole; the robe system uses a single piece of cloth to cut both the upper and lower garments without a seam in the middle, creating a natural one-piece design; the ruqun system refers to the combination of an upper ru (short jacket) and a lower qun (skirt).

One of the typical characteristics of Hanfu is the cross-collar with a right lapel, where the front edges of the garment cross over each other, with the right side covering the left. Hanfu usually does not use buttons but instead employs knotted cords for fastening, which is convenient and adds to the flowing elegance of the clothing.

According to the survey results from „Investigation and Research on the Value Situation of Contemporary Hanfu Design,” based on 209 questionnaire responses, indicate that 77.51% of participants have a fondness for Hanfu. Among these, 35.89% are from the fashion design industry, and 30.14% hail from the cultural and educational sectors. Furthermore, 52.15% believe that a moderate level of innovation combined with modern aesthetics can enhance the contemporary value of Hanfu. In terms of various styles of Hanfu, a significant 37.8% of respondents expressed the most interest in the Ming Dynasty style. Consequently, this study will focus extensively on Ming Dynasty Hanfu.

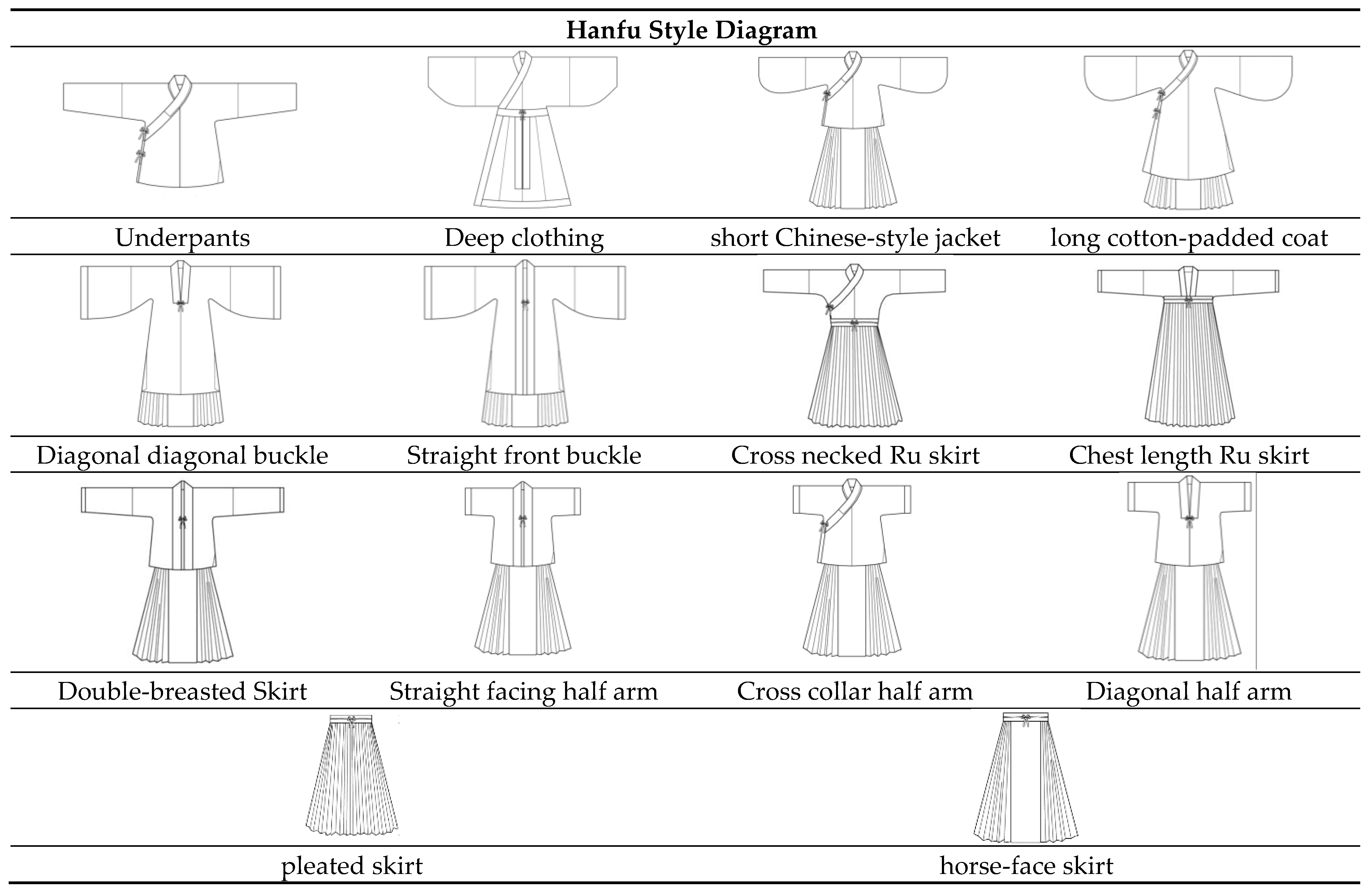

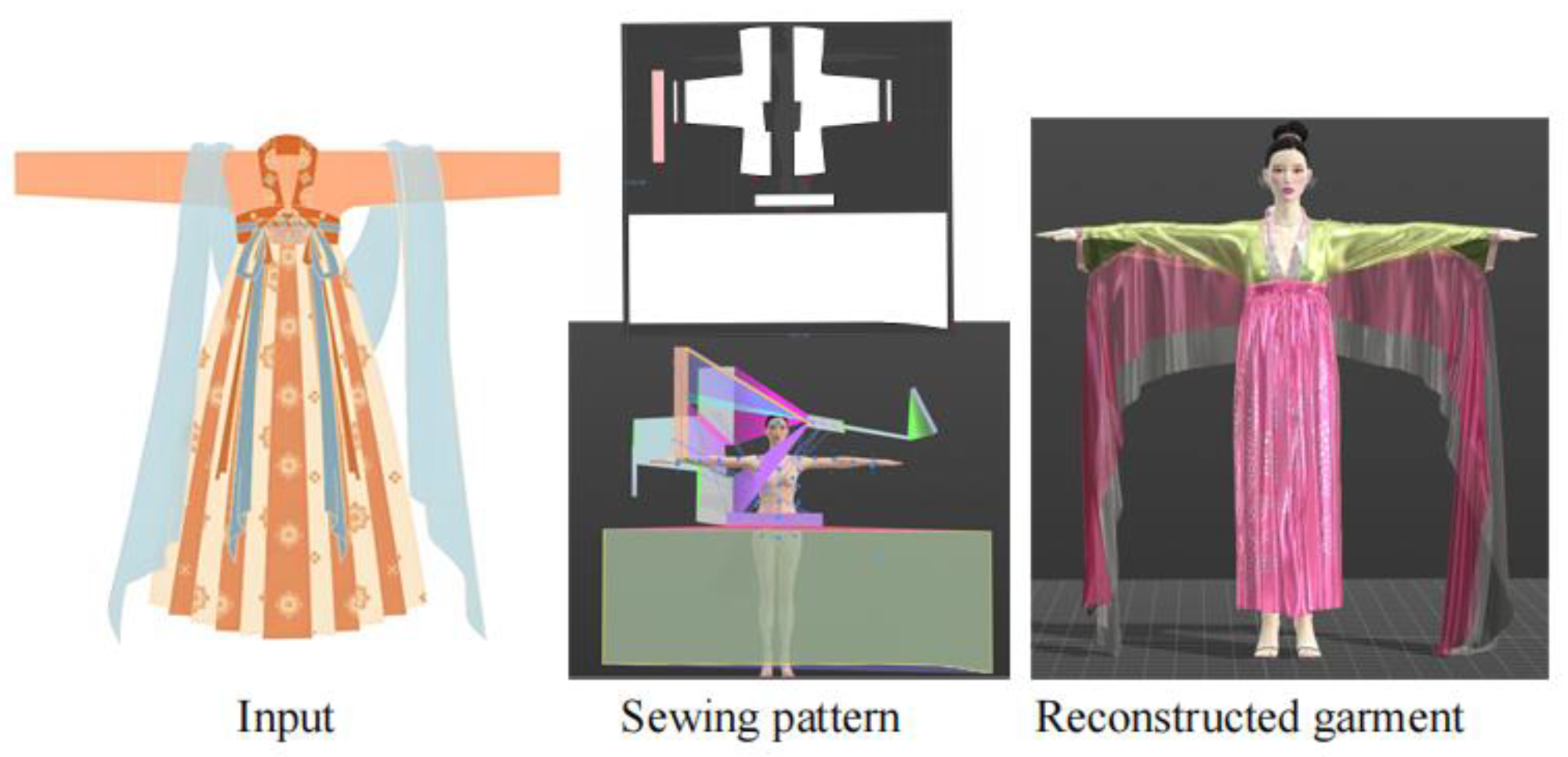

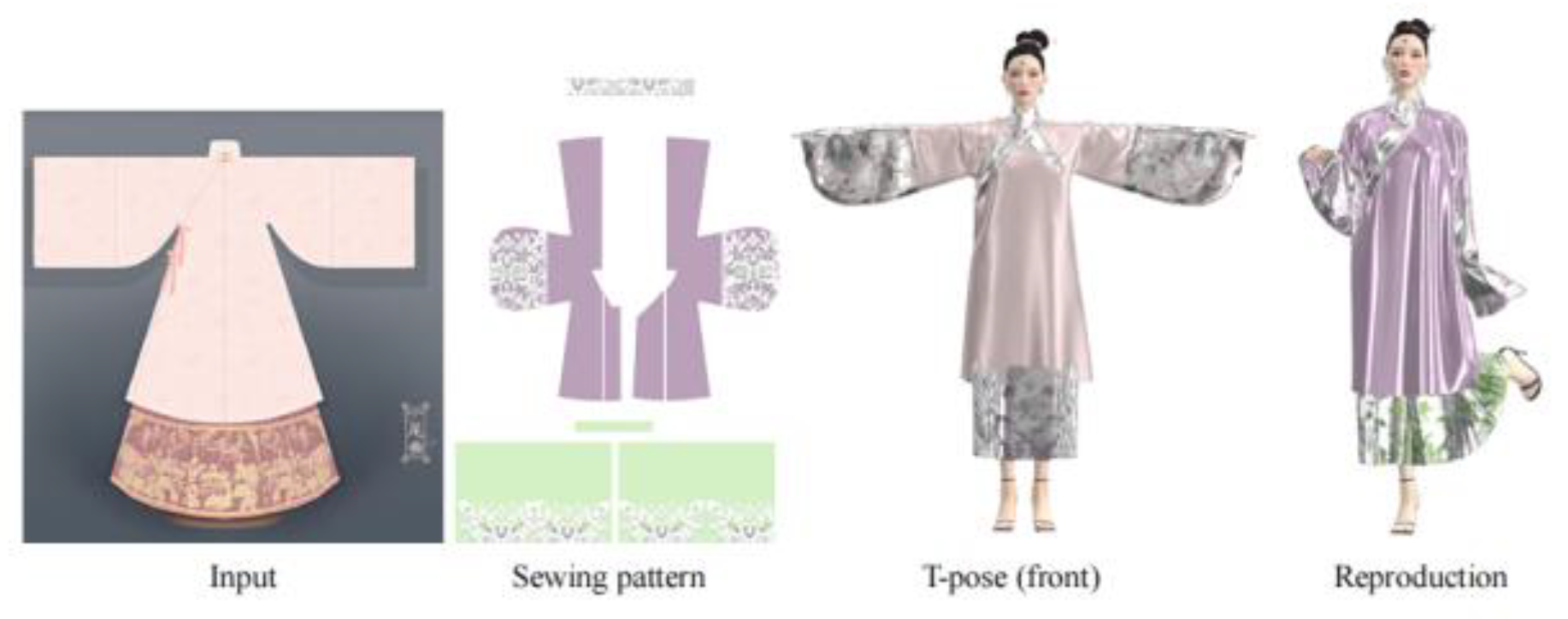

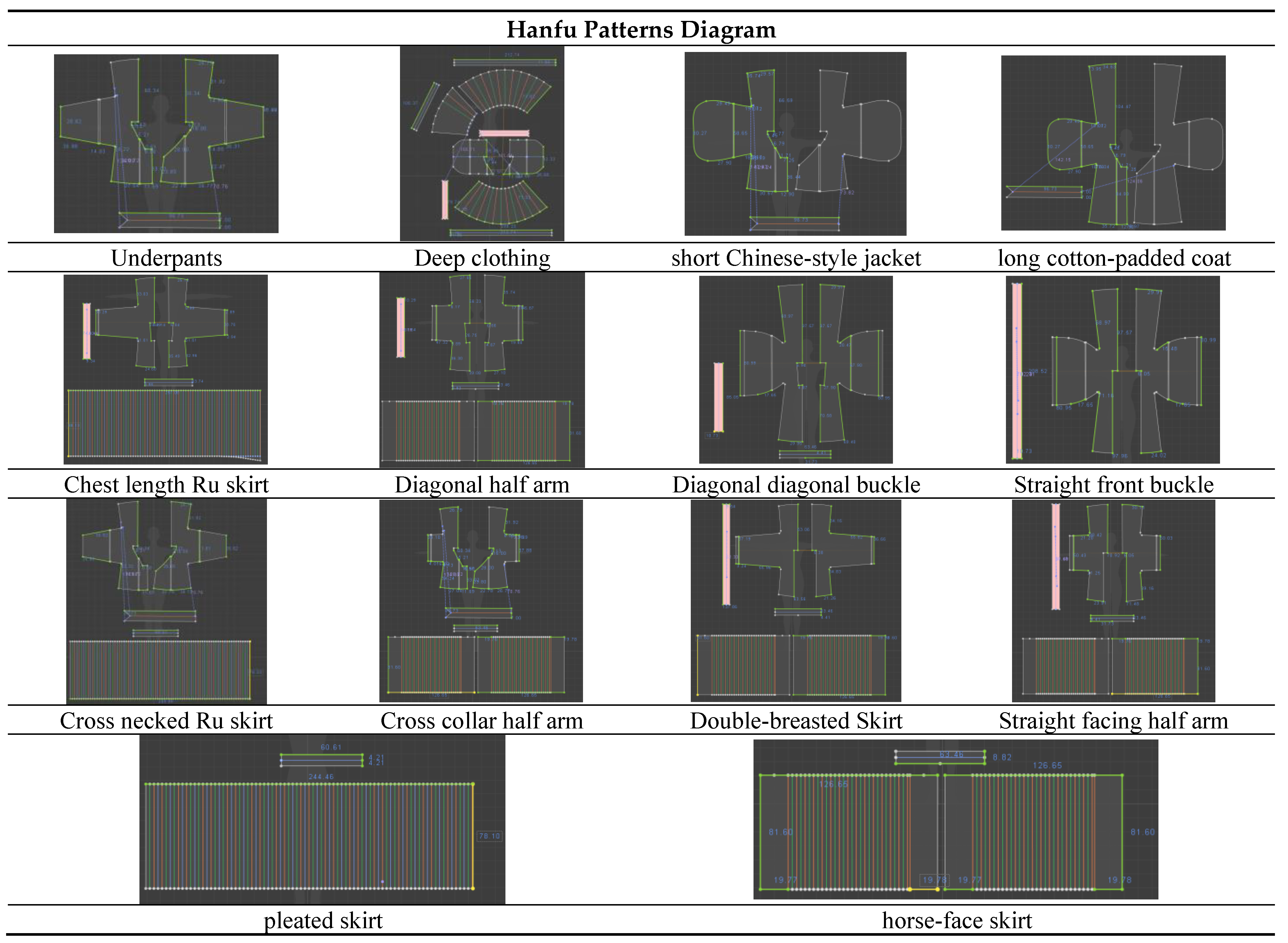

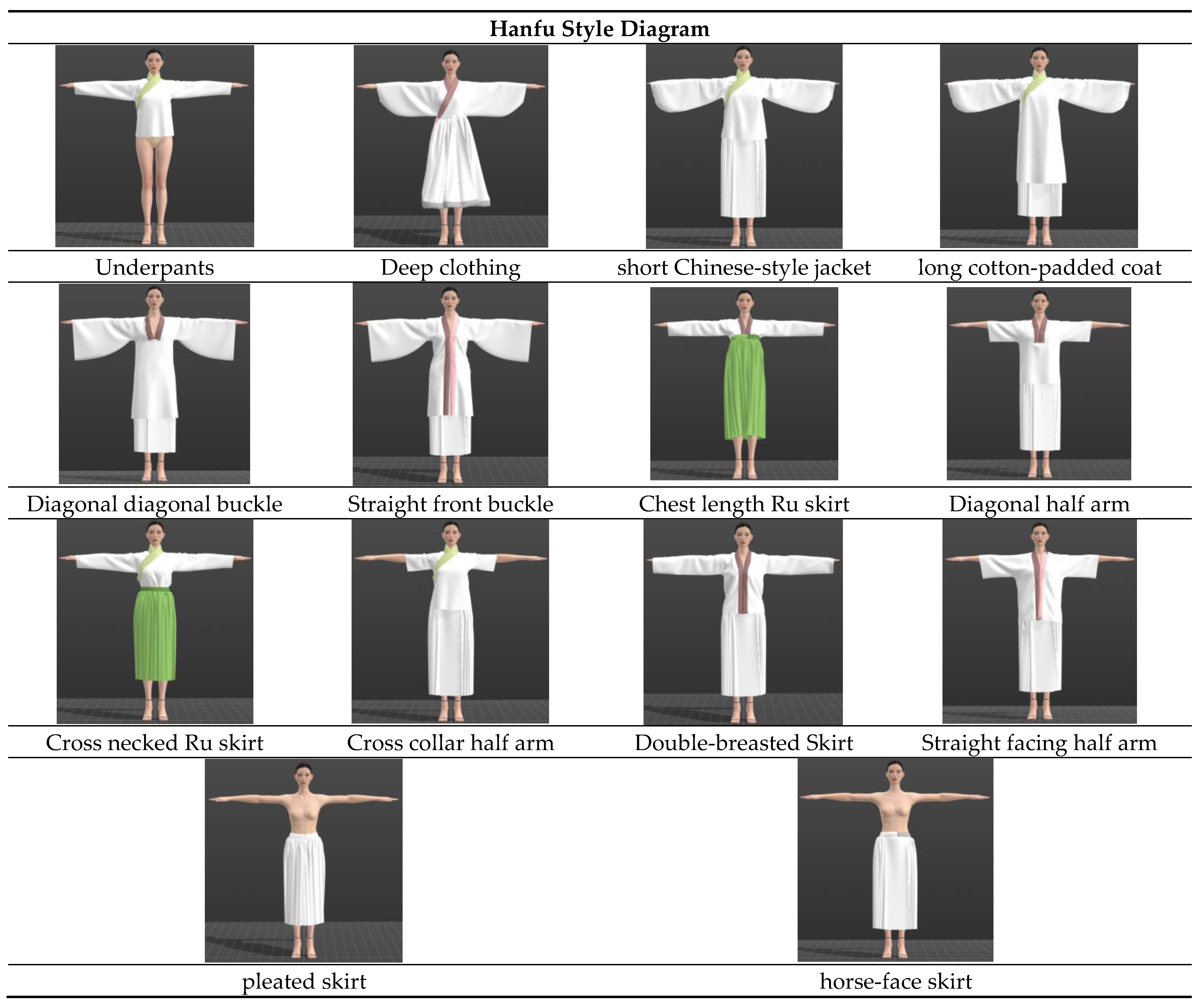

This dataset is structured around the Ming-style Hanfu framework, organizing patterns and drafts for Hanfu styles including the Zhongyi (undergarment), Shenyi (deep robe), Xie Qun (pleated skirt), Mamian Qun (horse-face skirt), Duan’ao (short jacket), Da’ao (long jacket), Xie Duijin Beizi (diagonal front-fastening vest), Zhi Duijin Beizi (straight front-fastening vest), Jiaoling Ruqun (cross-collar tunic and skirt), Jiaoling Banbi (cross-collar half-sleeve), Duijin Ruqun (front-fastening tunic and skirt), Zhi Duijin Banbi (straight front-fastening half-sleeve), Qixiong Ruqun (chest-level tunic and skirt), and Xie Duijin Banbi (diagonal front-fastening half-sleeve). Each style is further detailed into standard models, resulting in a precise and comprehensive set of parametric data.

Table 1.

Hanfu Style Diagram .

Table 1.

Hanfu Style Diagram .

Due to the advantages of Style 3D’s comprehensive functionality, simple and easy to operate interface, good fabric simulation effect, and strong compatibility with clothing template files, this research will use Style 3D for digital innovative design of Hanfu.