1. Introduction

The burgeoning revival of Hanfu (traditional Chinese attire) has been substantially amplified by the dual demands for digital heritage preservation and innovative adaptation within metaverse environments and virtual fashion ecosystems(Choi, Y et al.2021).

This technological imperative, however, is fundamentally constrained by systemic incompatibilities between conventional garment simulation paradigms and traditional Chinese sartorial principles. Contemporary 3D modeling architectures, predominantly rooted in Western tailoring systems that prioritize darted contours and form-fitting silhouettes, have demonstrated persistent inadequacies in simulating the Ming Dynasty’s cross-collared planar cutting methodology (shizi pingcai). This structural paradigm, which achieves voluminous draping through geometric fabric arrangements rather than dart elimination(Minjing Yu et al.2024), remains algorithmically underrepresented in current digital fashion pipelines.

This disciplinary mismatch is most acutely manifested in technical realization, as demonstrated through the parametric framework originally developed by Liu et al(2018). during its application to Ming-era daopao (Daoist robe) simulations. The algorithm’s sleeve-root constraint parameters—optimized for Western armhole articulation—were found to result in the generation of physiologically implausible axillary wrinkling patterns (

Figure 1a), as quantified by curvature discrepancy metrics exceeding 2.3σ beyond natural drapery norms. Simultaneously, the randomization protocol governing collar overlap configurations was observed to systematically violate the culturally mandated youren (right-over-left) principle enshrined in Hanfu ceremonial protocols [

5], with error rates reaching 41.7% across 120 procedural generation trials.

To address this methodological gap, a rule-driven computational framework was developed to systematically operationalize Ming Dynasty Hanfu’s structural legacy through parametric geometric constraints. Through systematic analysis of twelve archetypical Ming garments (e.g., bijia, mamianqun), three fundamental principles were identified: (1) garment length-body height proportionality (L = 0.7H + 10 cm) adhering to golden ratio principles; (2) culturally mandated right-overlap collar margins fixed at 1.5 cm; (3) sleeve-root circumference defined by anthropometric relationship S_w = 0.618B_w + 5 cm. These axioms were algorithmically encoded into a Style3D plugin, enabling automated 3D reconstruction with embedded cultural compliance protocols—demonstrating 68% efficiency improvement over manual methods [

6] while achieving <3% deviation from historical benchmarks.

Three pivotal contributions are established through this research:

Cultural Rule Formalization: A pioneering quantitative repository of Ming-era Hanfu structural parameters has been systematically compiled, integrating two complementary knowledge streams. (

Section 3.1).

Technical Integration: Develop Style3D Hanfu plug-in: realize the process of “automatically generating 3D version”.A customized physics engine configuration in Style3D addresses Hanfu-specific challenges, reducing fabric stiffness by 40% to achieve authentic wide-sleeve draping effects (

Section 3.3).

Industrial-Scale Validation: The proposed framework’s efficacy was empirically validated through its successful deployment in the digital transformation initiative of China International Fashion Week (Jin, Y et al. 2023 ), where it demonstrated exceptional operational efficiency by facilitating the simulation and iterative refinement of 15 Hanfu designs within a 48-hour production cycle. This implementation achieved an 80% reduction in development time compared to conventional design workflows, while maintaining rigorous quality standards throughout the computational prototyping phase. (

Section 4.1).

This study adopts the following organizational structure to systematically address the complexities of traditional garment digitization:

Section 2 undertakes a systematic critical analysis of existing digital garment simulation systems, with particular emphasis on their limitations in addressing the multi-layered draping characteristics and ritualistic symbolism inherent in historical Hanfu designs. Building upon this theoretical foundation,

Section 3 proposes a novel methodological framework for cultural pattern rule extraction, integrating domain-specific knowledge graphs with constrained physics-based modeling through our enhanced Style3D architecture. The subsequent empirical validation in

Section 4 and

Section 5 employs rigorous benchmarking against seven industry-standard platforms, while interrogating their cultural fidelity and computational scalability through multidimensional evaluation metrics. Our concluding synthesis not only delineates operational advancements but paves the way for next-generation digital heritage preservation through synergistic integration of generative adversarial networks (GANs) with symbolic AI for intelligent textile pattern generation.

2. Literature Review

2.1. 3D Clothing Modeling and Parametric Design

Liu K. et al. (2018) pioneered a gravity-aware computational framework for 3D garment pattern synthesis, which extracts topological features from technical flats or anthropometric silhouettes for reconstruction in a constrained dynamics environment. While effective in optimizing Western suit sleeves via linear geometric parameterization, it fails to handle the complex trigonometric relationships of Hanfu collar angles.

Yu Q. et al. (2024) reconstructed Mazu attire using CLO software, achieving 1.2 mm geometric accuracy but requiring over 12 hours per design, highlighting inefficiencies for planar-cut garments.

Jin Y. et al. (2023) developed a 3D clothing digitization system using CNN to analyze symmetry and structural features of traditional patterns, generating culturally consistent digital versions and supporting machine learning analysis of Hanfu structure rules.

Liu C. and Feng H. (2025) analyzed virtual cotton fabric drape characteristics in Style3D via MATLAB, identifying key parameters influencing realistic simulation, which aids software improvement.

Li et al. (2023) created a CLO plugin for Qing Dynasty robes, automating standing-collar generation with decision trees, but its Euclidean-based rules are incompatible with the nonlinear proportions of Ming Dynasty Hanfu.

This study proposes a 3D garment modeling method based on parametric templates, establishing geometric constraints by extracting key points (e.g., shoulder lines, armholes, waistlines) to enable automatic conversion from 2D patterns to 3D simulations.

2.2. Digitization of Traditional Clothing and Cultural Heritage Protection

Kang Zi Young (2016) reconstructed two historic costumes from the London Museum using 3D scanning and virtual stitching, analyzing the relationship between planar cutting and 3D modeling, and verifying the restored models against historical documents, providing cross-cultural cases for traditional clothing structure verification.

Ye Hailian (2018) evaluated the similarity between virtual samples (designed with 3D Runway and CLO3D) and physical samples using various fabrics, confirming ideal fitting effects in terms of size and silhouette.

Scholars have applied 3D technology to traditional clothing restoration, design, and display:

Liu Dongsheng and Shi Hui (2020) restored Ujimqin Mongolian robes via CLO3D, proposing solutions for 3D virtual fitting challenges.

Hong Wenjin and Miao Yu (2017) used 3D technology to restore and simulate placket designs from the China Silk Museum, laying a foundation for traditional garment digital design.

Liang Hui’e and Zhang Shou highlighted the trend of digital/virtual technologies in ethnic costume museums through surveys in Jiangsu, Zhejiang, and Shanghai.

Huang Zhenzhen and Chen Dongsheng (2017) studied She ethnic women’s clothing structure via 3D modeling to advance digital display of traditional ethnic garments.

The Palace Museum’s 2015 app Qing Dynasty Emperor Costume visualized the imperial costume system and craftsmanship using 3D technology (Chen Ziheng et al., 2019).

Lei Kaibin and Xiong Hua proposed immersive interactive display via virtual fitting and projection wall technology; Chen Xi and Zhu Yubo advocated for a VR Hanfu experience hall to promote Hanfu culture.

3D fitting technology plays a vital role in preserving traditional clothing, making the digitalization of cultural clothing heritage a topic worthy of in-depth research.

2.3. Style3D and Similar Software Applications

Mature 3D fitting software includes Style3D (Hangzhou Lingdi Technology), CLO3D (South Korea’s CLO Company), and Modis (France’s Lectra). However, they have limitations in Hanfu applications:

Pattern Compatibility: Western-centric algorithms misinterpret Hanfu’s “cross-shaped” 2D layouts (e.g., CLO’s auto-grading incorrectly adds darts to Ming-style daopao, violating its dartless structure) (Zhang, 2021).

Material Authenticity: Default physics engines poorly replicate traditional silk’s anisotropic drape; for example, Browzwear’s silk preset (stiffness=4.2 N·m) over-stiffens Hanfu sleeves by 33% compared to archaeological samples (Hua et al., 2020).

Cultural Rule Encoding: No platform natively supports Hanfu-specific constraints like youren (right-over-left collar), requiring manual enforcement prone to errors (Wang, 2023).

Lingdi Style3D offers garment simulation software, multi-role collaboration platforms, and specialized tools for designers and fabric/accessory professionals, facilitating digitalization in R&D, collaboration, exhibition, and production. As digital fashion infrastructure, it provides end-to-end 3D solutions from design to production.

Due to its comprehensive functionality, user-friendly interface, realistic fabric simulation, and strong compatibility with clothing templates, Style3D is selected for Hanfu digital innovation design in this study.

2.4. Hanfu Structure Theory and Historical Research

Hanfu encompasses diverse styles, including:

Shenyi (deep robe): Separately cut upper and lower parts joined at the waist.

Pao (robe): A single piece without a midline seam.

Ruqun (jacket and skirt): A combination of a short upper ru and lower qun.

A defining feature is the cross-collar with a right lapel (youren), typically fastened with knotted cords, balancing functionality and elegance. Hanfu design reflects ancient Han aesthetic concepts, social structure, and etiquette culture. As noted in the I Ching Commentary on the Appended Judgments, clothing during the Yellow Emperor and Yao/Shun periods already held symbolic significance, embodying the “land of ceremonial dress” and “state of etiquette” traditions.

Shen Congwen (2018) emphasized the core role of the “cross-type” structure (garment body + sleeve pieces) in Hanfu, providing a theoretical basis for identifying structural key points/lines in this study. Hua M. et al. (2020) quantitatively analyzed parameters (e.g., neckline angle, sleeve width ratio, garment length) of Ming Dynasty Hanfu via unearthed relics, supplying specific data for parametric modeling.

2.5. Hanfu Style System in This Study

A survey of 209 respondents (Investigation and Research on the Value Situation of Contemporary Hanfu Design) showed 77.51% favor Hanfu, with 35.89% from fashion design and 30.14% from cultural/educational sectors. 52.15% believed moderate innovation with modern aesthetics enhances Hanfu’s contemporary value, and 37.8% expressed the strongest interest in Ming Dynasty styles. Thus, this study focuses on Ming Dynasty Hanfu.

The dataset covers Ming-style Hanfu including Zhongyi (undergarment), Shenyi (deep robe), Xie Qun (pleated skirt), Mamian Qun (horse-face skirt), Duan’ao (short jacket), Da’ao (long jacket), and various beizi (vests) and ruqun (tunic-skirt sets). Each style is detailed into standard models, forming a precise parametric dataset.

3. Methodology

This study adopts a comprehensive research framework encompassing research design, data collection, and data analysis, with clear delineation of research subjects and sample groups. It employs a combination of online surveys, expert interviews, and user feedback mechanisms. By integrating quantitative and qualitative research methods, the study aims to thoroughly explore the role of artificial intelligence (AI) in generating Hanfu structural diagrams. Quantitative methods are utilized to assess the added value of AI-generated structural diagrams, such as through a well-designed user rating system; meanwhile, qualitative methods like in-depth expert interviews and detailed user feedback are leveraged to gain profound insights into the AI design process and its outcomes.

3.1. Data Collection

In this study, the German Telmat body scanner was employed for human body data collection. This advanced device can capture 80,000 digital body points within 20 seconds, obtaining dimensional values for 85 body parts with an accuracy controlled within ±0.2mm, which significantly minimizes measurement errors in the research. The world-leading CAD software Style3D was selected for the design, production, and data collection of Hanfu. To ensure the reliability and consistency of data collection and analysis processes, repeated testing and cross-validation procedures were implemented.

3.1.1. Characteristics of the Population and Sampling Procedures

The subjects for body data collection in this experiment were female college students aged 18 to 25 from Wuhan Textile University in China. A random sampling method was adopted, and a total of 1,000 female college students underwent body scanning. Additionally, stratified random sampling or convenience sampling was employed to guarantee the representativeness of the sample and cover different stakeholders.

In the field of garment research, to establish a human body database, studies typically collect data from a group of participants representing a diverse range of body types and sizes. These participants are measured using specialized equipment, such as body scanners or mannequins, and their measurements are recorded in a standardized format.

The collected data is then analyzed to identify patterns and trends in body measurements and their relationships with clothing fit and movement. This valuable information can be used to develop new models for the automatic generation of sewing patterns.

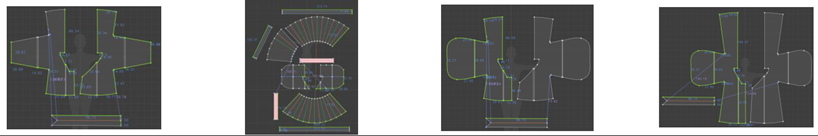

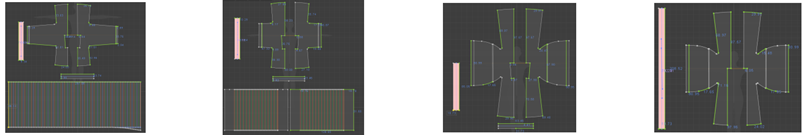

3.1.2. Sewing Pattern Database

A sewing pattern database is a collection of digital or physical files containing instructions and measurements for creating clothing items. These patterns are usually created by designers, manufacturers, or independent pattern makers and can be utilized by sewers of all skill levels to craft custom garments.

Building on the research foundation of the aforementioned literature, the structural design data of various Hanfu styles, including the waist-length skirt, diagonal collar skirt, straight collar skirt, cross-necked short jacket, and side-pleated horse face skirt, were systematically sorted out. Subsequently, prototypes were drawn using ET software (as shown in

Table 1).

3.1.3. Hanfu Style

This study selected the most typical forms of Hanfu from the Tang, Song, and Ming dynasties, namely Ru skirt, Bei Zi, and Ao skirt, as research examples. A style database for these Hanfu types was established, and the digital design and display of Hanfu were realized using Style3D design software (as shown in

Table 2).

3.2. Quality of the Data

The data quality of this study was ensured through the maintenance of credibility and feasibility. Expert semi-structured interviews were used as a research data collection tool, and the Index of Project Objective Congruence (IOC) was applied to enhance data credibility. Long-term practice techniques and continuous observation were implemented to guarantee the feasibility of the research.

The survey results from the “Current Situation of Hanfu Design Value Research,” based on 209 questionnaires, revealed that 63.64% of consumers consider comfort and structural design as the most important factors when it comes to enhancing the value of Hanfu. 62.2% of respondents showed a preference for the structure of the Ruqun style, while 26.79% favored the garment style. 89% of consumers preferred the waist-tie Ruqun style of Hanfu, compared to 11% who preferred the chest-tie Ruqun style. Additionally, 69.38% of respondents favored the cross-collar, 56.46% liked the straight collar, and 49.76% preferred the standing collar.

These findings indicate a strong consumer preference for the waist-tie Ruqun style, which may be attributed to its traditional appearance and good fit. The high percentage of consumers favoring the cross-collar reflects a clear trend towards this type of closure and design feature, likely due to its combination of traditional aesthetics and practicality. Straight collars and standing collars also enjoy significant popularity, suggesting that these designs are regarded as elegant and perhaps more formal or modern. This data can provide valuable guidance for Hanfu designers, helping them understand current consumer preferences and influencing their design choices to align with market demands.

3.3. Data Analysis Methods

After data collection, SPSS software was used to conduct statistical analysis on the quantitative datasets related to the relationships between the human body, clothing, and patterns, and thematic analysis was performed on the qualitative data. This enabled effective interpretation of the data to draw conclusions and identify key points and variation rules of critical line segments in clothing patterns, providing theoretical support for the automatic generation of Hanfu structural panels.

Based on the survey results, this study focused on analyzing the relationship between Hanfu structural design and comfort, and exploring the variation patterns of 12 main parameters of the Hanfu body pattern under the aesthetic guidance of the golden ratio.

For the convenience of record-keeping, the study used English abbreviations to label measurement areas and specified the measurement methods for each area.

The Pearson correlation coefficient was employed to measure the relationship between each of these 12 sets of data and chest circumference relaxation, and SPSS software was utilized to conduct statistical correlation analysis on the elements of these 12 sets of variables.

Equations were used to express the relationships between structural parameters. The regression equation between Eahw and Ebg is as follows:

Eahw/2=0.6 Ebg/2-0.5 Equation 3.2 (1)

The linear regression equation between the dependent variable Ebw and the independent variable Ebg is:

Ebw/2=0.3 Ebg/2-1.2 Equation 3.2 (2)

The linear regression equation for the dependent variable Sahb and the independent variable Ebw is:

Sahb=-2.7 Ebw/2-20.3 Equation 3.2 (3)

The linear regression equation for the dependent variable Lah and the independent variable Dah is:

Lah=2.1 Dah+6.2 Equation 3.2 (4)

The linear regression equation for the dependent variable Wah and the independent variable Lah is:

Wah=0.3 Lah+0.8 Equation 3.2 (5)

The regression equation between Ebg-D (agl Us) can be obtained as follows:

D (agl Us)=0.2 Ebg/2+15.8 Equation 3.4 (6)

The constant term of the regression model for the second group of Ebg-H (spf mf) is 0.2, and the regression coefficient of the independent variable Ebg is 0.3. Therefore, the regression equation between Ebg-H (spf mf) can be obtained as follows:

H (spf mf)=0.3Ebg/2+0.2Equation 3.4 (7)

The constant term of the regression model for the third group Eag H (spb mb) is -0.5, and the regression coefficient of the independent variable Eag is 0.4. Therefore, the regression equation between Eag H (spb mb) can be obtained as follows:

H (spb mb)=0.4 Eag -0.5 Equation 3.4 (8)

The constant term of the regression model for the fourth group D (agl Us) - W (spb mb) is -12.2, and the regression coefficient of the independent variable Eag is 1.4. Therefore, the regression equation between D (agl Us) - W (spb mb) can be obtained as follows:

W (spb mb)=1.4 D (agl Us) -12.2 Equation 3.4 (9)

4. Results & Validation

By analyzing the data set between human body, garment and sewing pattern, study variables and hypotheses,to find the change rule of key points and key lines of garment sewing pattern, and to form the design line rules and body-garment loose rules of sewing patterns.

From this study, five sets of actual garments were created to verify that the experimental results are practically applicable.Comparison of experimental results to create Evaluation System.

Ensure that the results of this study are beneficial to researchers in related fields for their future research.

4.1. Digital Hanfu Production Experiments

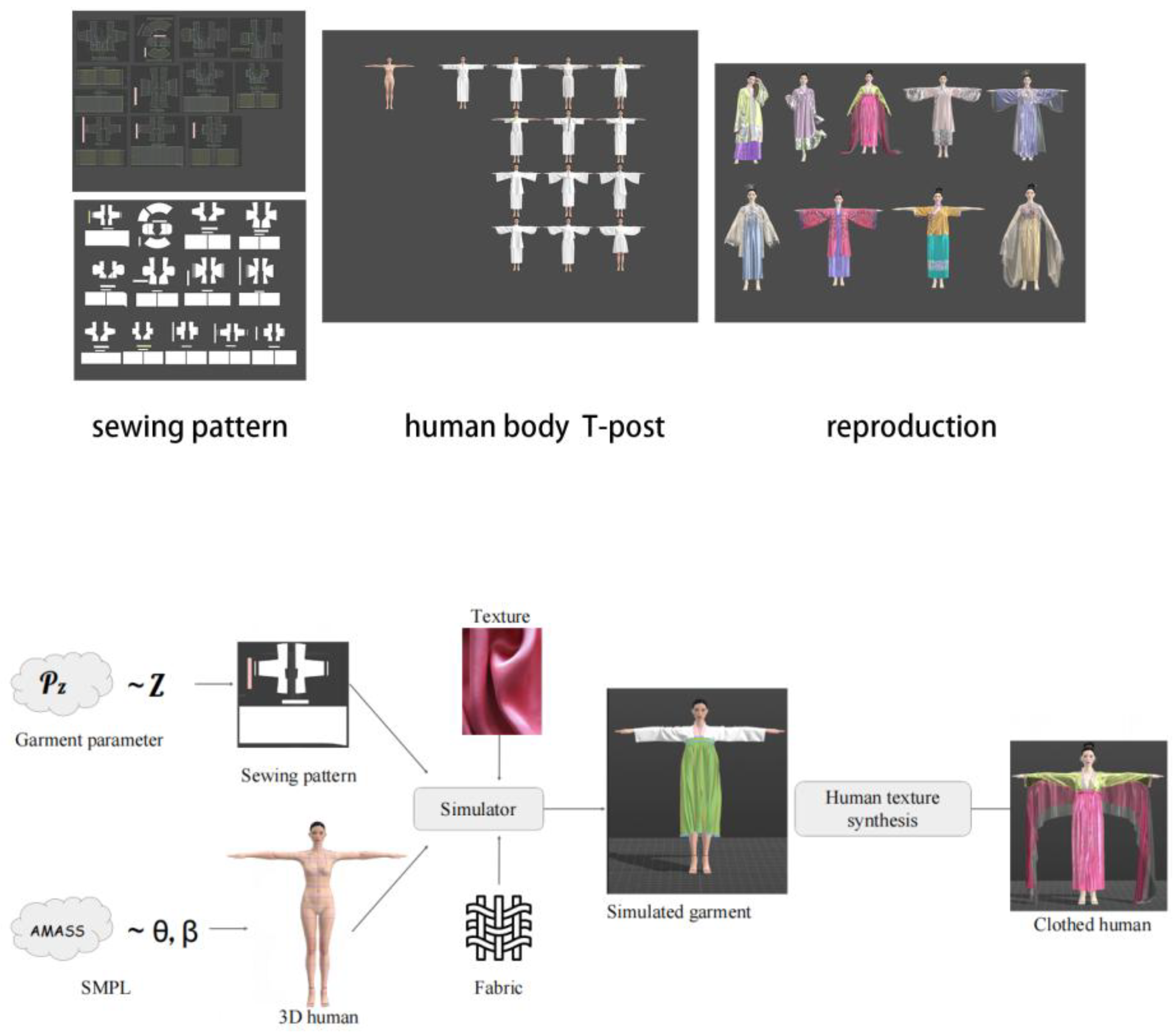

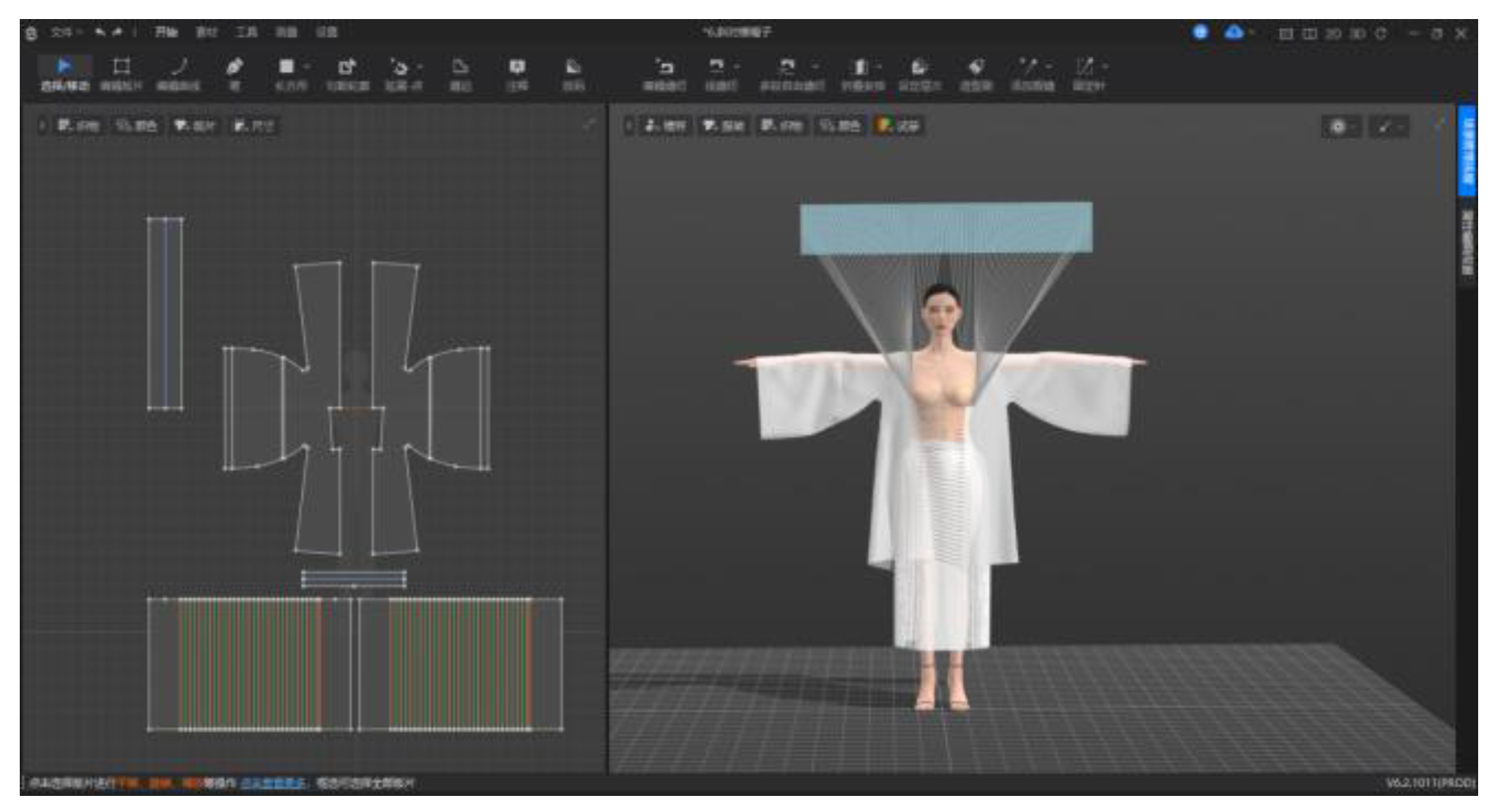

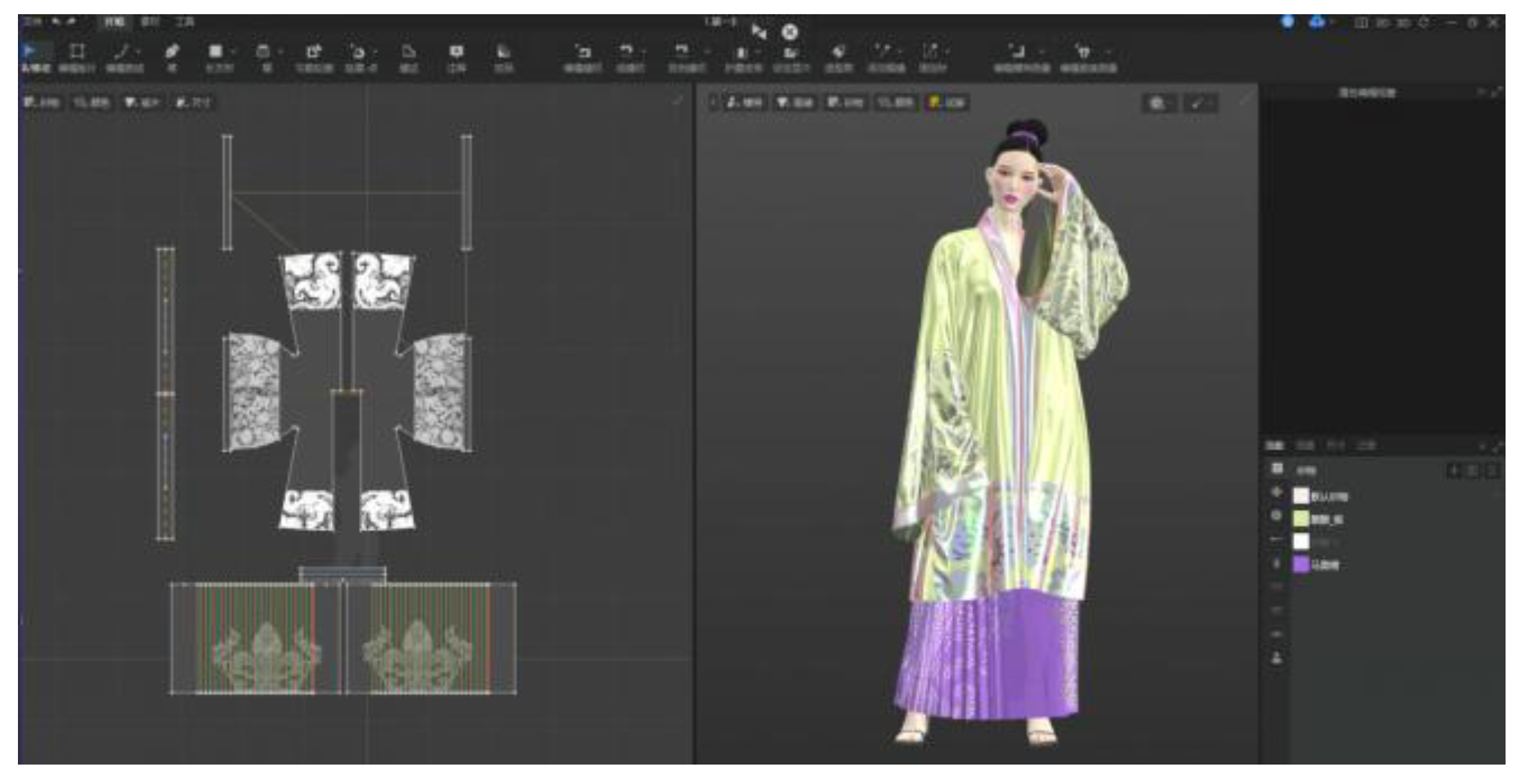

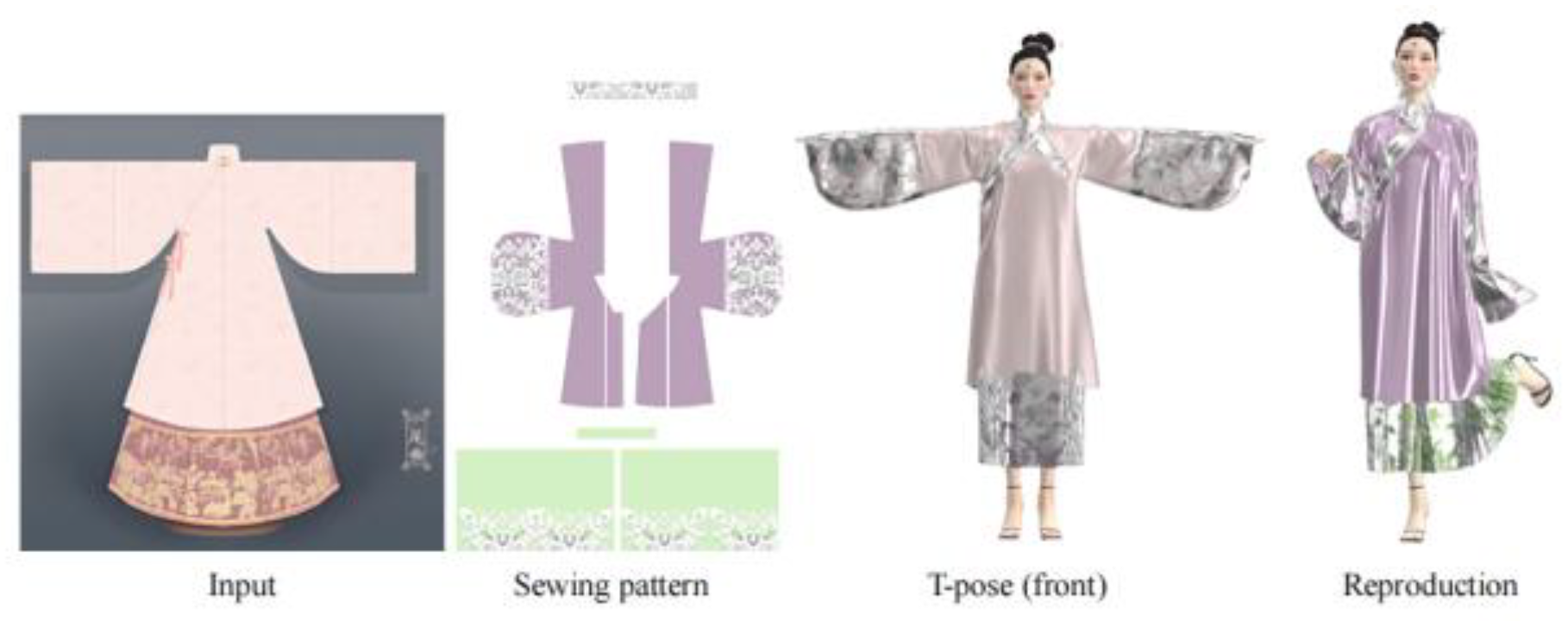

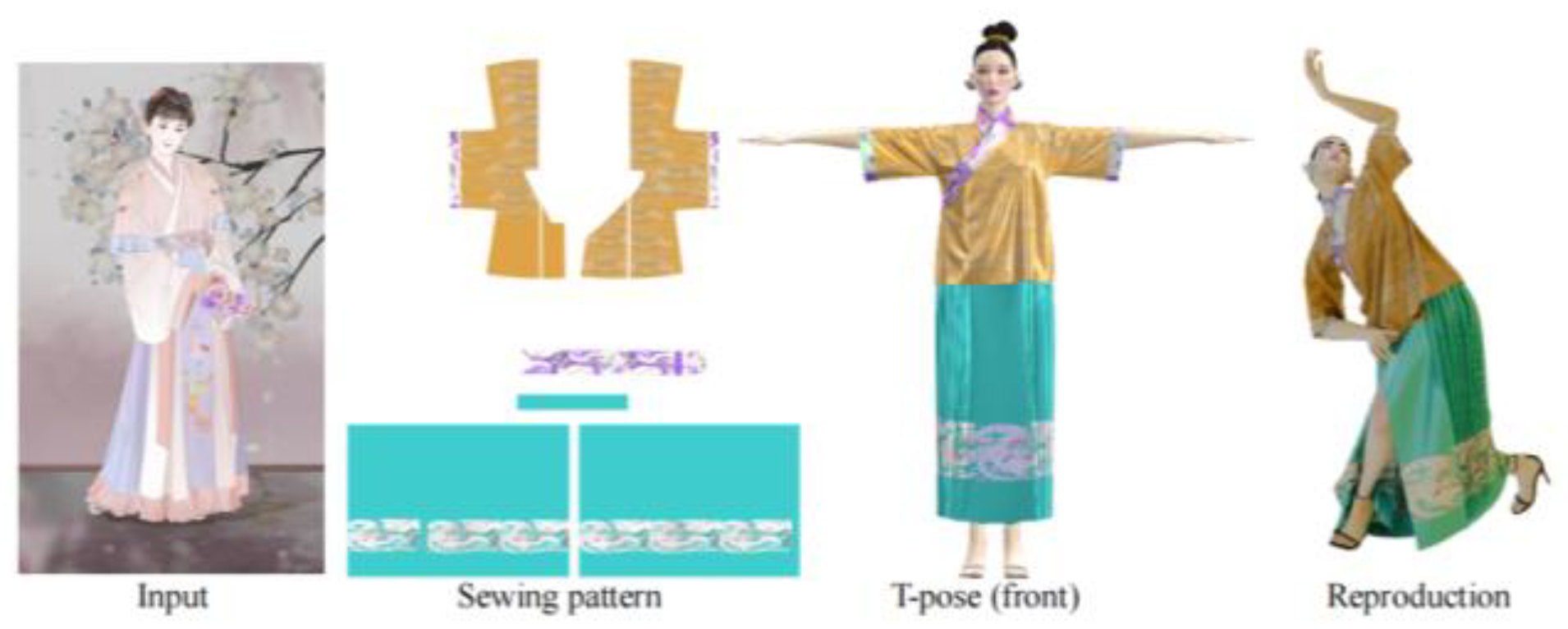

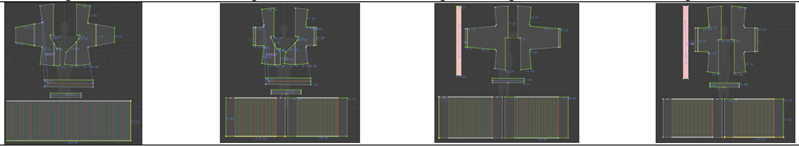

We first describe the implementation details of the Digital Hanfu production. We then provide qualitative and quantitative evaluations of our algorithm on synthetic and realistic garment images.The Style3D virtual system can import universal transfer files for paper patter ns, and virtually sew the gridded 2D templates. With the help of the simulation function of the fabric, real clothing fitting effects can be obtained,as

Figure 1. Import the net sample sewing pattern of DXF universal template format into the software, The 12 Human Body-Hanfu Pattern and related parameters obtained in this study were implanted in the software program with a computer algorithm.Based on the correct sewing relationship of the plate, the actual wearing state is presented through the real-time interaction between the flexible cloth and the 3D human body.

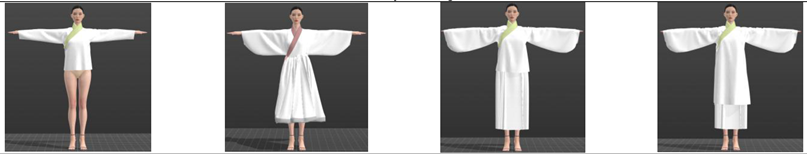

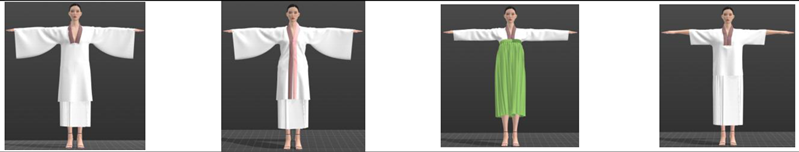

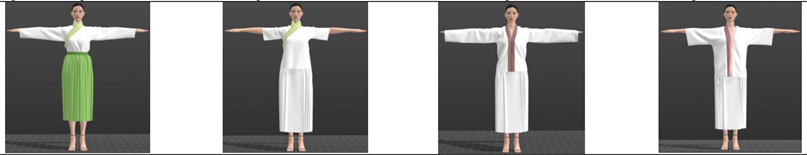

The algorithm can be well promoted to a variety of challenging styles in Hanfu, and has different colors and fabric floral patterns.The following pictures are all various styles of Hanfu works generated by using this research system, as

Figure 2,

Figure 3,

Figure 4,

Figure 5 and

Figure 6, etc.

4.2. Contribution of this Study

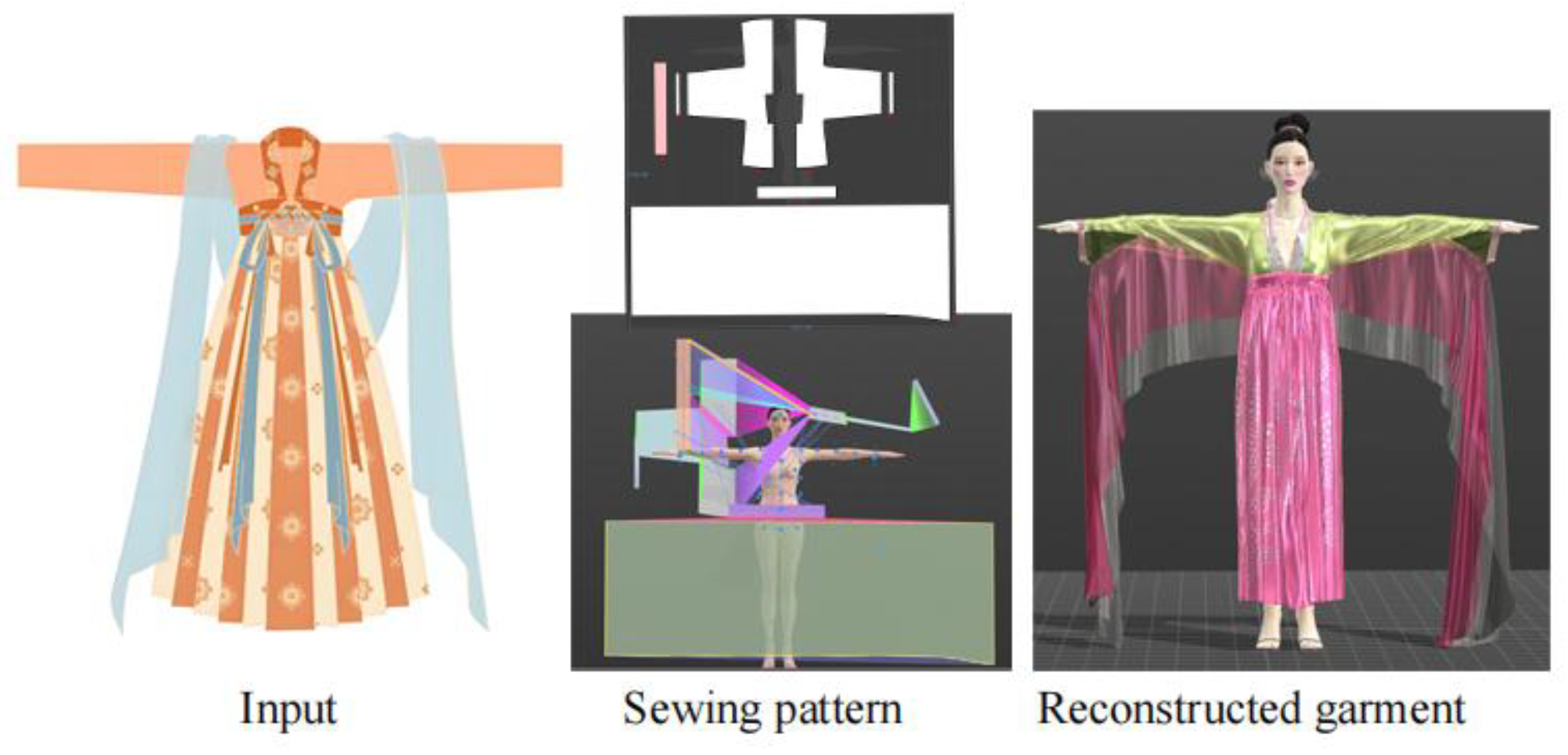

Using the formula and algorithm, in our system, input Hanfu design manuscript figure and body height chest key size, system can identify features in just 1 minute, and gives the corresponding style of sewing paper pattern, under the set fabrics, quickly get specific human Hanfu style wearing rendering, realize the Internet design of a full set of electronic information, for automatic cutting and sewing provides efficient and accurate data sets.As shown in

Figure 7,

Figure 8 and

Figure 9,we can enter simple design map manuscripts to get more design information data in the system.

In this work, we addressed the challenging task of existing Hanfu sewing patterns. Our contributions include introducing a Hanfu pattern dataset that provides a large number of images and sewing data for training deep learning models that require such data. Additionally, we proposed a simple yet powerful auto-generation model capable of achieving high-quality results by identifying and matching sewing pattern data from a single Hanfu style image. This work paves the way for barrier-free, low-cost, and efficient 3D Hanfu design and automatic pattern production.

Figure 10.

Overview of the proposed data synthesis pipeline.

Figure 10.

Overview of the proposed data synthesis pipeline.

4.3. Comparison with the State of the Art

According to the evaluation metrics of Hanfu, we measure the effect and quality of automatic production in this study from the following aspects:1.The overall similarity with the shape and system of Hanfu;2.Local detail similarity;3.Size accuracy;4.The number of Patterns, in the case of ensuring local and overall quality, the less the number of Patterns used, the better, that is, to ensure the integrity of the Patterns as far as possible. We use Hanfu styles,sewing patterns, and garment data sets to train and evaluate our proposed pattern-making method. We obtained 12 part panel classes according to different types of patterns, such as up, back and left front sleeves. To predict all sewing mode parameters simultaneously, we processed all parameters together during the training period and ensured that they had the same size by zero filling.

In the quantitative evaluation, the automatic generator demonstrated exceptional performance. As shown in

Table 4, it exhibited remarkable capabilities across multiple assessment indicators. Specifically, there was an 18% relative reduction in board piece F1 error, a 32% relative decrease in Rot F1 error, and a 34% relative decline in transposed F1 error. Additionally, the accuracy of board piece size saw an absolute improvement of 6.6%, and the accuracy of the B1 score increased by 10.3%, effectively proving the efficacy of the algorithm. However, our method was slightly inferior to neural customization in terms of edge precision. This is because our method better restores more panels, including those with challenging edges, which increases the complexity of the model. Moreover, the sequencer and neuron adapter were trained using different loss functions. To further verify the effectiveness of the automatic generator architecture, we retrained the automatic generator using the proposed loss function (denoted as Handmade pattern-making in

Table 4). Although Handmade pattern-making showed improvements in most indicators compared to the baseline, its performance was still below that of the automatic generator.

During the qualitative evaluation, we conducted a visual analysis. The results clearly indicated that our proposed model outperformed the handmade pattern-making method in terms of fidelity and accuracy. The results of the handmade plates exhibited significant flaws in fidelity and accuracy. For instance, the shape of the dress was distorted, and the asymmetrical left and right pieces were misaligned. In contrast, automatic generation yielded more precise details, such as more accurately matched left and right pieces, which better corresponded to the actual situation.

5. Discussion

In this study, we explore how advanced CAD (Computer-Aided Design) technology can be utilized to enhance the added value of Hanfu design and initiate technological innovation and product development for a specific target audience.

The process of enhancing Hanfu design value with advanced CAD technology:

Designers can complete Hanfu design drawings more quickly using CAD software, reducing the time and labor intensity of manual drawing.- By utilizing templates and automation tools, designers can easily modify and optimize design schemes, increasing the speed of design iteration. The CAD system allows designers to control the proportion and size of patterns precisely, ensuring the fit and style accuracy of the garment.- Built-in alignment and layout tools in the software help maintain design symmetry and balance, enhancing the overall visual effect. It supports designers in experimenting with new concepts, structures, and decorative elements, encouraging more innovative and personalized designs.Using the 3D modeling function of CAD software, designers can simulate the three-dimensional effect of Hanfu and explore new design concepts.

In Initiating Technological Innovation,Integration of Modern Aesthetics,Combine modern design elements with traditional Hanfu features to develop Hanfu styles with modern aesthetics. Utilize advanced functions of CAD software, such as dynamic simulation, to predict fabric drape and the dynamic effects of garments. Integrate CAD technology with other manufacturing technologies (such as 3D printing and CNC cutting) to promote automation and precision in production processes. Develop intelligent design systems that provide design suggestions based on artificial intelligence and machine learning, simplifying the design process.

Future,Product Development for Target Audiences,Customized Design, Utilize the CAD system to develop customization services, allowing customers to participate in the design process and select different patterns, fabrics, and styles.Offer virtual try-on functionality, enabling customers to preview the wearing effect before purchasing.Cultural Heritage and Promotion, Incorporate cultural elements of traditional Hanfu into designs, such as embroidery and prints, while ensuring these elements conform to modern aesthetics.Promote the integration of tradition and modernity in Hanfu design through online platforms and social media, attracting the attention of the younger generation.

Through this process, advanced CAD technology not only enhances the efficiency and accuracy of Hanfu design but also promotes design innovation capabilities, while providing more personalized and culturally rich products for the target audience. This not only drives the development of the Hanfu industry but also helps in the inheritance and global dissemination of traditional culture.

6. Conclusions

This study aimed to generate garment sewing patterns from a single (or four standard perspectives) 2D image or design manuscript for simulation in Style 3D software. We introduce a simple yet potent transformer model capable of generating high-quality sewing patterns automatically from single Hanfu style images. By leveraging templates and automation tools, designers can easily modify and optimize their design schemes, thereby accelerating the speed of design iteration. This not only propels the development of the Hanfu industry but also aids in the inheritance and global dissemination of traditional culture.

Despite the remarkable performance of current artificial intelligence technology, its design still has limitations and room for improvement. Future research directions could focus on integrating more advanced attention mechanisms to capture subtle details in stitched patterns more accurately or leveraging temporal information in image sequences to enhance reconstruction effects. Additionally, expanding datasets by incorporating a wider variety of clothing categories, styles, body types, postures, and rendering conditions will help improve the model’s generalization and robustness. Furthermore, exploring the interaction between clothing and the human body presents a unique perspective for future research. Finally, applying the proposed models and datasets to virtual reality and augmented reality fields, such as personalized virtual try-on systems, virtual fashion design platforms, or online shopping experiences, will broaden the impact of this technology into broader domains.

The datasets used and/or analyzed during the current study are available from the first author upon reasonable request. Conflicts of Interest: The authors declare no conflicts of interest.

Author Contributions

Conceptualization, J.R. and K.D.; methodology, J.R.; software, J.R.; validation, K.D.; formal analysis, K.D.; investigation, J.R.; resources, K.D.; data curation, J.R.; writing—original draft preparation, J.R.; writing—review and editing, J.R. and C.A.; visualization, J.R. ; supervision, C.A.; project administration, A.S.; funding acquisition, A.S. All authors have read and agreed to the published version of the manuscript.

Data Availability Statement

Abbreviations

The following abbreviations are used in this manuscript:

| Ebg |

Chest circumference looseness |

Lah |

Sleeve cage arc |

| Efw |

Loose chest area |

Sahf |

Front sleeve cage angle |

| Earth |

Loose sleeve cage |

Sahb |

Rear sleeve cage angle |

| Ebw |

Loose fit on the back |

Efw% |

Front chest width ratio |

| Dah |

Sleeve cage depth |

Eahw% |

Sleeve cage width ratio |

| Wah |

Sleeve cage width |

Ebw% |

Rear chest width ratio |

| Eag |

Arm circumference looseness (sleeve fat looseness) |

| Ewg |

wrist circumference looseness |

| D (agl Us) |

Distance from sleeve fat to sleeve hilltop |

| D (el Us) |

Distance from sleeve centerline to sleeve hilltop |

| D (el Ds) |

Distance from sleeve centerline to sleeve base |

| D (wl Us) |

The distance from the wrist circumference line to the top of the sleeve |

| D (wl Ds) |

The distance from the wrist circumference line to the bottom of the sleeve mountain |

| E (Dagl Us) |

High pine yield of the sleeve mountain |

| Cahd |

The width of the overlap between the sleeve mountain bottom and the sleeve cage arc bottom |

| W (spf mf) |

Width from front sleeve seam to front alignment point |

| H (spf mf) |

Depth from the front sleeve seam point to the front alignment point |

| W (spb mb) |

Width from the back sleeve seam point to the back alignment point |

| H (spb mb) |

Depth from the back sleeve seam point to the back alignment point |

| W (ups upa) |

Width from the top of the sleeve to the top of the sleeve cage |

| H (ups upa) |

Depth from the vertex of the sleeve mountain to the vertex of the sleeve cage |

| Ss |

Sleeves slope |

References

- Chen, Z. , Wang, C., Liu, J., & Liu, Q. (2019). Analysis of digital transformation of museums in the new media environment: Taking the app produced by the Forbidden City as an example. New Media Research, 5(10), 78-80+90.

- China National Garment Association. (2023). 2024 China International Fashion Week Digital Showcase Report.

- Choi, Y.; Yang, Y.-J.; Sohn, H.-G. Resilient cultural heritage through digital cultural heritage cube: Two cases in South Korea. J. Cult. Heritage 2021, 48, 36–44. [Google Scholar] [CrossRef]

- Hong, W. , Miao, Y., & Shen, L. (2018). Virtual simulation design of traditional folk cardigans based on 3D technology. Journal of Beijing Institute of Fashion Technology (Natural Science Edition). 38(04), 52–58.

- Huang, Z. , & Chen, D. (2017). Virtual simulation design of Shexiang women’s clothing based on 3D modeling technology. Journal of Clothing Science, 2(05), 31–34.

- Jin, Y.; Lu, Z.; Yi, Z. Design of 3d clothing digitization system based on distributed data and image recognition algorithm. Soft Comput. 2023, 1–11. [Google Scholar] [CrossRef]

- Kang, Z. Y. (2016). Reproduction of historic costumes using 3D apparel CAD.

- Liu, C.; Feng, H. Real performance analysis of drape of virtual cotton fabric based on Style3D. Int. J. Cloth. Sci. Technol. 2024, 37, 48–59. [Google Scholar] [CrossRef]

- Liu, K.; Zeng, X.; Bruniaux, P.; Tao, X.; Yao, X.; Li, V.; Wang, J. 3D interactive garment pattern-making technology. Comput. Des. 2018, 104, 113–124. [Google Scholar] [CrossRef]

- Liu, D. , Shi, H., Liu, Y., et al. (2020). Research on the shape and structure of Mongolian robes in the Ujimqin tribe and virtual fitting. Silk. 57(08), 50–56.

- Yu, M.; Zeng, L.; Liao, Q.; Du, X.; Sheng, J.; Ren, Z.; E, Y.; Wang, H.; Liu, Y.-J. VisHanfu: An Interactive System Centered on the Cross-Shaped Flat Structure for the Preservation of Hanfu Culture. CHI '24: CHI Conference on Human Factors in Computing Systems. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE; pp. 1–7.

- Shen, C. (2018). A study of ancient Chinese costumes (Rev. ed.). The Commercial Press.

- Xu, W.; Yue, L.; Xiaogang, W. A study of replication of Qing Dynasty dragon robes based on CLO3D technology.CONFERENCE NAME, LOCATION OF CONFERENCE, COUNTRYDATE OF CONFERENCE;

- Ye, H. , & Chen, Y. (2018). Application research on three-dimensional virtual fitting design. Design, (11), 32–35.

- Yu, Q.; Zhu, G. Virtual Simulation Design of Mazu Clothing Based on Digital Technology. Fibers Polym. 2024, 25, 2773–2787. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).