1. Introduction

The printed circuit boards (PCBs) found in all electronic devices, from smartphones and computers to household appliances and automotive systems are rich in precious metals such as gold, silver, copper and palladium, but also contain hazardous substances such as lead, mercury and brominated flame retardants. The disassembly of waste printed circuit boards (WPCBs) is critical for effective recycling and recovery of valuable materials, but traditional methods have significant limitations that hinder environmental sustainability and operational efficiency. One practical method is to disassemble boards manually, which is labor intensive and often results in incomplete recovery of electronic components, exposing workers to hazardous materials without adequate safety measures [

1,

2,

3,

4].

Chemical processes, although effective in breaking down certain materials, often rely on toxic solvents that pose significant handling and disposal challenges. Techniques such as hydrothermal and supercritical fluid treatments can be energy-intensive and costly, raising concerns about their feasibility for large-scale recycling operations [

1].The conventional techniques for disassembly are both labor-intensive and inefficient. Consequently, automated solutions based on cutting-edge technology, such as edge computing and the Internet of Things (IoT), are emerging as viable alternatives that enhance operational efficiency while also promoting sustainability. It is noteworthy that the integration of edge computing enables real-time data processing and decision-making throughout the disassembly process, thereby markedly enhancing resource recovery and minimizing the generation of hazardous waste [

5,

6]. This decentralized approach optimizes the utilization of network resources by facilitating the processing of data in close proximity to the source, thereby reducing latency and enhancing the management of voluminous information generated during disassembly operations. Furthermore, the integration of Internet of Things (IoT) technologies is being employed to enhance the efficiency of waste management practices. This involves the implementation of intelligent waste collection systems and enhanced monitoring capabilities that facilitate the implementation of responsible recycling practices and address the pressing urban waste management challenges [

7,

8].Despite the promise of these innovations, significant challenges remain. These challenges pertain to the deployment of automated systems, which may pose security concerns. Furthermore, robust regulatory frameworks are required to guide the recycling of e-waste [

9]. This paper explores how the integration of edge computing and IoT can revolutionize the disassembly of WPCBs. It highlights the benefits, challenges and future directions for research and development in this area.

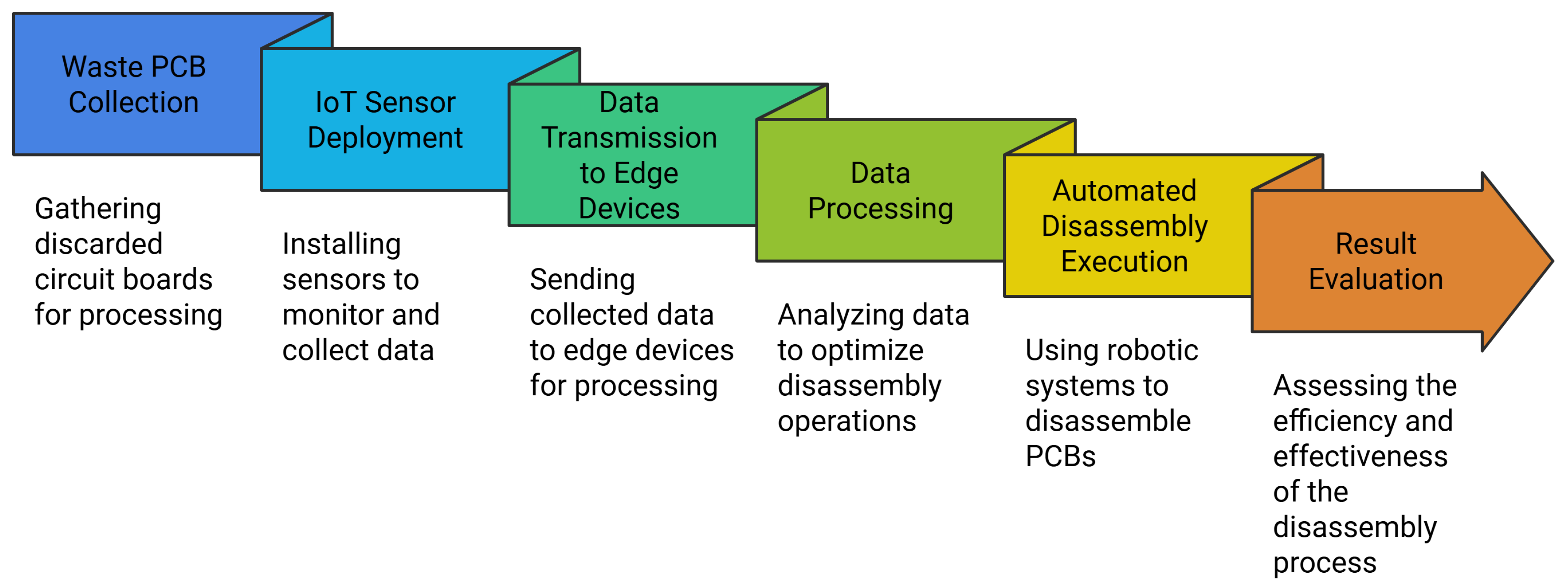

Figure 1 shows the automatic disassembly framework of proposed system started from WPCBs collection, IoT sensors integration, data transmission to edge devices for real time processing and evaluation of disassembly results

The main contribution of this paper is outlined as:

Exploration of the potential of edge computing-based IoT framework in waste management, with a particular focus on their ability to automate the disassembly process of WPCBs.

Presentation of a conceptual technological framework for integrating edge computing with the Internet of Things (IoT) to facilitate the automatic disassembly of WPCBs and the sorting of the various electronic components present on the surface of the board.

Detailed description of the experimental setup used to efficiently detect and localize electronic components on WPCBs using using state of art object detection models.

Discussion of the training and inference processes performed on edge devices, such as the NVIDIA Jetson Nano, and demonstrates the effectiveness of lightweight implementations in real-time environments.

Identification of the challenges faced in implementing edge computing-based IoT devices for recycling WPCBs and suggests potential future directions for research and development in this area.

The rest of the paper is structured as follows:

Section 2 provides a brief overview of the state of the art for both traditional and smart disassembly of WPCBs.

Section 3 presents a detailed account of the materials and methods employed, including a proposed technological framework based on IoT edge devices for selective disassembly and sorting of WPCBs.

Section 4 discusses the experimental results and presents a discussion of the challenges encountered.

Section 5 presents the conclusions and outlines future directions.

2. Related Work

This study explores the way into which IoT and edge computing could be efficient for intelligent disassembly electronic components from waste printed circuit boards to enable re-use and more efficient recovery of critical raw materials focuses on developing sustainable methods for recycling electronic waste (e-waste).

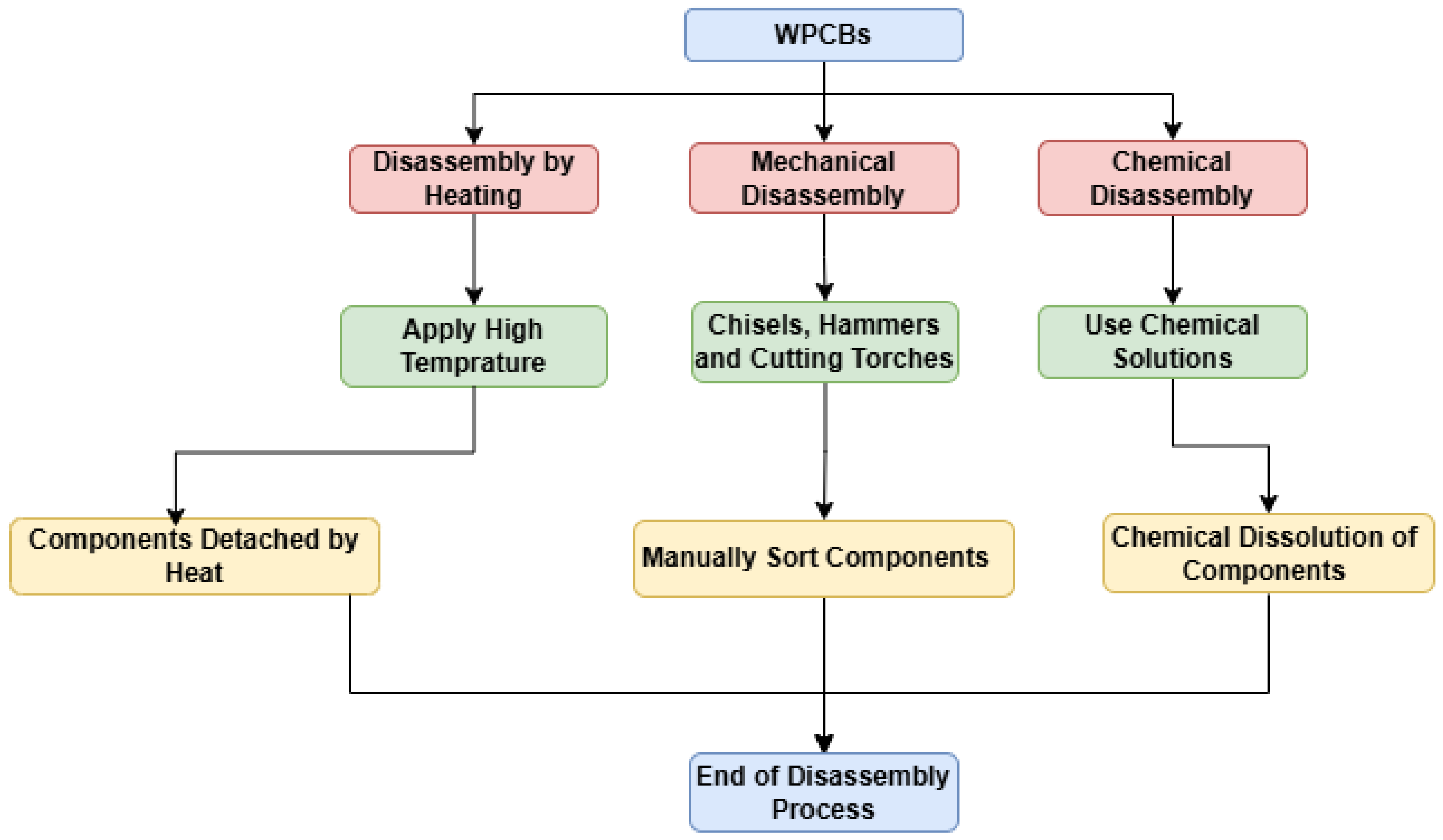

Figure 2 shows the traditional disassembly methods used for WPCBs disassembly.

2.1. Traditional Disassembly Methods

There are many precious metals present within WPCBs, including gold, silver, palladium, and platinum The quantity of each metal varies depending on the type of component, such as electronic pins, contain a minimum amount of gold and silver. Different conventional disassembly methods have been used to enable re-use and sustainable recycling of valuable materials from WPCBs, including: (1) Disassembly by Heating, (2) Mechanical Disassembly and (3) Chemical Disassembly.

2.1.1. Disassembly by Heating

WPCBs can be heated and mechanically processed with homemade or commercial tools. Electrical, gas, or wood fires produce heat. Temperature control and exhaust gas purification are inconsistently used, putting worker safety and the environment at risk. For instance, during the thermal treatment of waste printed circuit boards in a specialized apparatus. Certain industries employ tools equipped with engineering control systems that absorb, separate, and decompose toxic gas emissions [

10]. Hot fluid heating involves putting WPCBs in a heated liquid bath, utilizing substances like silicone or paraffinic oils, at temperatures ranging from 215 to 250°C [

11,

12,

13]. Electrochemical cells (ECs) are removed utilizing vibrators and ultrasonicators, thereby improving disassembly efficiency and optimizing thermal energy utilization. Liquid disposal and rinsing of WPCBs result in the generation of wastewater. Ionic liquids (ILs) are increasingly recognized for their stability and safety; however, issues related to cost, recyclability, and process stability persist [

14,

15]. Infrared radiation is another popular technique for melting solder for EC removal. Infrared radiators are strategically placed along the conveyor to liquefy the solder, enabling electronic components (ECs) to fall away by gravity or be removed by robotic grippers, while residual components are eliminated using a brush or shearing machine [

16]. Park and associates recently enhanced this process using a rotating rod and steel brush configuration, attaining a 94% disassembly rate at 250°C and 0.33 cm/s [

17].

Heated centrifugation facilitates the melting of solder from WPCBs via high-temperature spinning, enabling the efficient recovery of metals such as copper, lead, and tin. Preliminary experiments attained 240°C at 1400 rpm, while subsequent trials with temperatures reaching 1300°C resulted in over 90% recovery for various metals. This method demonstrates potential for elevated recovery rates; however, it necessitates meticulous temperature regulation to prevent decomposition and the release of toxic emissions [

18,

19]. Hot air, heated to 260°C, is frequently employed to melt solder for the disassembly of electronic components from waste printed circuit boards, typically utilizing portable heat guns [

20,

21,

22,

23]. Although it operates at a slower rate than infrared heating, it mitigates the risk of overheating in electric components. The advantages include low cost, high disassembly rate, and eco-friendliness; however, it is characterized by a lack of precise temperature control, particularly over extensive areas. Chen et al. developed a system that utilizes industrial exhaust heat in conjunction with hot steam, thereby improving temperature regulation and minimizing potential chemical risks [

16,

24].

Solder Bath Heating involves the brief exposure of WPCBs to molten solder at 230°C. However, excessive exposure poses a risk of overheating, complicating automation processes. This method, prevalent in China, typically entails the manual extraction of components through hammering. Workers encounter considerable health risks even with the presence of fume hoods, and the process generates hazardous waste due to the splashing of molten metals. Certain facilities employ aluminum foil to mitigate splash risk; however, this practice generates additional hazardous waste [

2].

2.1.2. Mechanical Disassembly

The manual disassembly of WPCBs, typically conducted in the informal sector, employs basic equipment such as chisels, hammers, and torches, frequently utilizing inexpensive labor. This process focuses on valuable components including aluminum heat sinks, batteries, coils, capacitors, RAM, and CPUs, which are subsequently resold or subjected to additional processing. Nonetheless, informal dismantling diminishes the residual value of remaining materials, adversely affecting the economic feasibility of licensed recycling operations [

25].

A Surface Cutting Knife is another mechanical method employed for the dismantling of surface electronic components. This mechanical method is frequently utilized in automated systems for recycling WPCBs. Surface cutting knives are highly efficient in dismantling the structure of PCBs while minimizing damage to the components, which is essential for optimizing recovery rates [

26,

27].

2.1.3. Chemical Disassembly

The chemical disassembly of WPCBs has evolved to enhance material recovery and reduce environmental impact. Chemical methods are frequently favored over thermal and mechanical techniques for several reasons: (i) diminished toxic emissions, (ii) decreased energy expenses, (iii) minimal thermal damage to reusable parts, and (iv) reduced residual solder that may contaminate subsequent hydro-metallurgical processes. Chemical methods have been devised to selectively dissolve exposed metals or solder in order to tackle these challenges. For instance, hydro-metallurgical processes employ acidic leaching, utilizing strong acids such as hydrochloric or nitric acid to facilitate efficient metal extraction under optimized conditions, thereby reducing dependence on toxic chemicals. Chloride leaching, utilizing copper(II) chloride and sodium chloride, promotes metal dissolution through cupric ions for subsequent electrochemical recovery [

28]. Bio-leaching, a sustainable method, employs microorganisms to extract metals such as gold and copper while minimizing the use of hazardous chemicals. Ultimately, electrode position selectively recovers metals after leaching, utilizing ionic liquids or molten salts to improve electrochemical stability and efficiency [

29].

2.1.4. Implications of Conventional Disassembly Methods

Thermal disassembly techniques, including infrared and hot fluid heating, achieve disassembly rates of up to 94% and facilitate swift component separation; nevertheless, they necessitate elevated temperatures (up to 1300°C), resulting in substantial energy expenses, safety hazards, and possible harm to reusable components. Mechanical disassembly, utilizing both manual techniques and automated tools such as surface cutting knives, achieves efficiency levels of 50–90% while promoting environmental sustainability. It presents low safety risks and moderate energy requirements; however, manual methods are labor-intensive and exhibit reduced effectiveness. Chemical disassembly, utilizing methods such as acidic leaching and bio-leaching, attains optimal recovery rates (80–95%) and functions at low to moderate temperatures (25–200°C), minimizing thermal degradation; nonetheless, it depends on toxic chemicals that present environmental and health hazards, and its scalability is constrained by waste management issues. Thermal methods are rapid but resource-intensive; mechanical techniques provide precision and sustainability; and chemical methods emphasize recovery quality, sacrificing environmental sustainability.

2.2. Automated Disassembly Methods

Existing literature review shows that the issue of recycling waste printed circuit boards has received considerable attention in recent years. Several researchers have explored the use of deep learning techniques to address the challenges associated with disassembling and sorting these components.

Many studies have been reported to automate the process of the WPCBs disassembly in an industrial environment [

5,

30,

31]. For instance, sharma et.al [

32] proposed computer vision-based system for real-time component identification from waste printed circuit boards. They utilized Yolov3 state of the art model for ECs identification using publicly available datasets. The study proposed the automatic sorting system to further recycling valuable material.

Another study [

33], authors utilized standard network architectures such as Faster Squeeze-Net and YOLOv3 to sort a variety of electronic components, including printed circuit boards, mixed electronic scrap, and batteries. The objective of this study was to demonstrate the feasibility of using deep learning-based object detection and classification models to automate the sorting process, which is a crucial step in the recycling of electronic waste.

A further study [

34] compared the performance of traditional computer vision approaches and deep learning-based methods for the detection and localization of e-waste components. The researchers found that deep learning-based methods, such as convolutional neural networks, outperformed traditional techniques in terms of accuracy and robustness. This highlights the potential of these advanced machine learning algorithms for automating the disassembly and recycling of electronic waste.

Pramerdorfer et al. [

35] addressed the problem of WPCB recognition. For this purpose, they prepared the PCB-DSLR dataset containing 748 WPCBs images. For classification, they trained a random forest [

36] using the dimensions and proportions of the PCBs. The correct classification rate obtained was 83%.

Li et al. [

37] developed a system for recognizing surface-mounted devices (SMD) on waste printed circuit boards such as resistors, capacitors, and integrated circuits. Their approach uses assembly print information and color distribution, and employs support vector machine (SVM) and k- nearest neighbor classifier (KNN) for recognition. In a subsequent work, Li et al. [

38] extended their previous work by incorporating 2D information. Despite using various local boundary features for segmentation, they noted that this approach could not be generalized due to variations among PCBs. Finally, in Li et al. [

39], a framework was proposed for reading the labels of integrated circuits using optical character recognition (OCR). Another study, weinert et al. [

40] proposed an automated system for classifying electronic waste utilizing deep learning techniques. Many researchers have applied computer vision methodologies specifically to PCB images. One application area is the automated optical inspection of PCBs, where techniques for identifying manufacturing-related defects are established.

Furthermore, researchers [

33,

41] have explored the use of domain randomization techniques to improve the performance of deep learning models in real-world scenarios, where factors such as lighting, noise, and deformations can affect the accuracy of component detection and classification. These studies emphasize the importance of developing robust and adaptable machine learning solutions to address the challenges posed by the diverse and complex nature of electronic waste streams.

Table 1 shows the detailed comparison of using automated methods incorporation with IoT and edge devices over traditional disassembly methods.

3. Materials and Methods

3.1. The role of Edge Computing and IoT in Waste Printed Circuit Boards Disassembly

Edge computing represents a distributed computing paradigm that processes data at the point of its generation, typically at the "edge" of the network. This architectural approach is of particular benefit to applications that rely on real-time decision-making, such as the automatic disassembly of WPCBs [

5]. The term "automatic disassembly" is used to describe the robotic procedure of dismantling electronic components from WPCBs, with the objective of enabling recycling [

42]. It is clear that traditional methods require manual work or ineffective mechanical procedures. This inevitably results in environmental contamination and health hazards from the emission of harmful compounds during disassembly [

2]. Edge devices processing real-time data markedly reduce overall system latency, facilitating faster and more precise decision-making in the disassembly of WPCBs. The Internet of Things (IoT) is the key to enhancing PCB disassembly. It enables communication and data sharing between the various devices involved in the process. IoT devices include sensors, actuators, cameras, and robotic arms, which are all interconnected to create a cohesive disassembly system. The integration of IoT technology in the disassembly of waste printed circuit boards (WPCBs) is revolutionizing the recycling process, boosting its efficiency, sustainability, and economic viability. The IoT is essential for real-time monitoring, data acquisition, and automation, which are crucial for enhancing the disassembly and recovery of valuable elements from electronic waste..

3.2. Proposed Conceptual Framework

Edge computing and IoT are the future of e-waste recycling. They offer a revolutionary method for disassembling WPCBs that addresses the drawbacks of traditional methods, including excessive energy consumption, labor intensity, and environmental hazards.

The proposed framework will overcome these limitations by utilizing advanced technologies. The framework is made up of connected elements. IoT sensors, edge computing devices (NVIDIA Jetson Nano), AI-driven decision-making systems, and robotic disassembly tools work together to make sustainable and efficient WPCBs disassembly a reality. The NVIDIA Jetson Nano is the ideal edge computing device for artificial intelligence and machine learning applications at the edge of the system. It incorporates a quad-core ARM Cortex-A57 CPU and a 128-core Maxwell GPU, enabling effective parallel processing for deep learning inference. The Jetson Nano is compatible with many frameworks, including TensorFlow, PyTorch, and ONNX, making it ideal for applications such as image recognition, object detection, and real-time analytics. This methodology integrates advanced computer vision models with edge computing functionalities to guarantee efficient, accurate, and sustainable electronic waste recycling.

3.2.1. Proposed Framework Components and Workflow

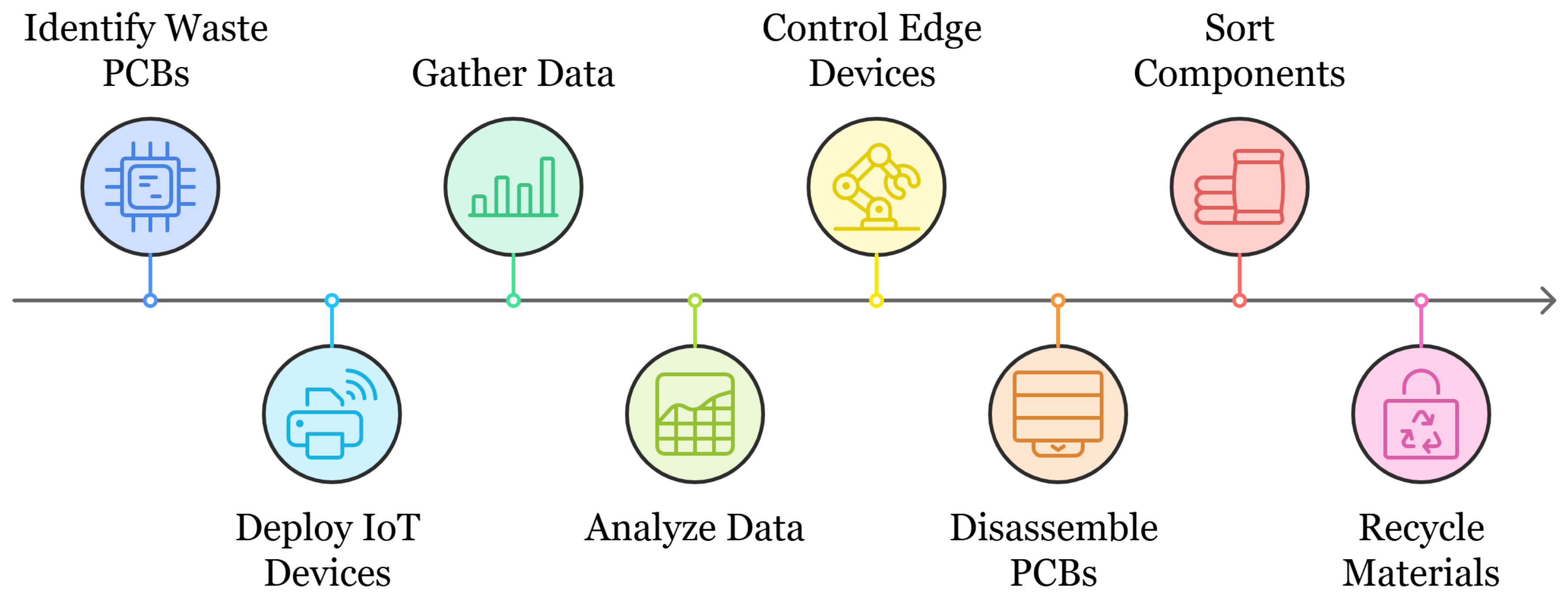

Figure 3 illustrates a detailed conceptual framework for the systematic disassembly and sorting of WPCBs. The framework incorporates cutting-edge technological innovations, including IoT devices, edge computing, and automation, to enhance the disassembly process. The framework comprises eight essential steps: identifying WPCBs’ electronic components, deploying IoT devices, collecting data, analyzing data, managing edge devices, disassembling WPCBs, sorting components, and recycling CRMs. Every phase is essential for establishing a sustainable and effective recycling system.

Identification of Waste Printed Circuit Boards: The process begins with the identification of WPCBs. In this phase, we identify and extract WPCBs from electronic waste streams. Sensors and cameras are used to visually recognize WPCBs based on their structural features. This step is crucial for starting the recycling process and ensuring that only relevant materials move on to the next stages.

Deployment of IoT Devices: IoT devices are used to monitor environmental conditions, assess progress, and collect real-time data from the system. These devices guarantee smooth coordination during the disassembly process by improving communication among the system’s components. IoT devices are essential for remote monitoring and control, which is crucial for scalability and automation.

Data Collection: The system gathers comprehensive data regarding the WPCBs at this juncture. The system gathers data via sensors, cameras, and other integrated input devices. This data encompasses visual attributes, material properties, and structural details of WPCBs, which are essential for precise component identification and disassembly.

Data Analysis: We process and analyze the collected data using sophisticated computational methods. We use algorithms in machine learning and edge computing [

31,

43] to identify components, classify materials[

5], and ascertain optimal disassembly techniques. This stage guarantees precise decision-making by leveraging real-time insights from the collected data.

Integration of Edge Devices: Edge devices, including robotic arms and automated tools, are governed by the analyzed data. This phase guarantees the physical handling and manipulation of WPCBs throughout the disassembly procedure. The system employs edge computing to reduce latency and improve operational efficiency, especially in high-velocity industrial settings.

Disassembling Waste Printed Circuit Boards: At this stage, we dismantle the identified WPCBs into their individual components. Automated instruments and robotic systems are used to meticulously extract components, including capacitors, integrated circuits, transistors, and resistors. We refine the disassembly process to reduce damage to reusable components and guarantee material recovery.

Sorting of Electronic Components: Upon disassembly, the components are categorized according to their material composition and functionality. Sorting is the only way to guarantee the segregation of reusable components from non-reusable ones. This classification system ensures a more efficient recycling process and significantly improves the recovery rate of valuable resources.

Recycling of Critical Raw Materials: The final phase is the recycling of the sorted electronic components. This involves the extraction of CRMs, including metals, plastics, and silicon, from non-reusable components. Recycled materials are processed and reintegrated into the manufacturing supply chain, enhancing sustainability and mitigating the environmental impact of electronic waste.

This framework ensures an efficient and sustainable method for the disassembly and recycling of electronic components. The question thus arises as to the means by which this is achieved. By integrating IoT devices, edge computing, and automation. This framework addresses the growing problem of e-waste in a direct and comprehensive manner. The framework promotes the recovery of resources, minimizes environmental impact, and enables the implementation of circular economy practices.

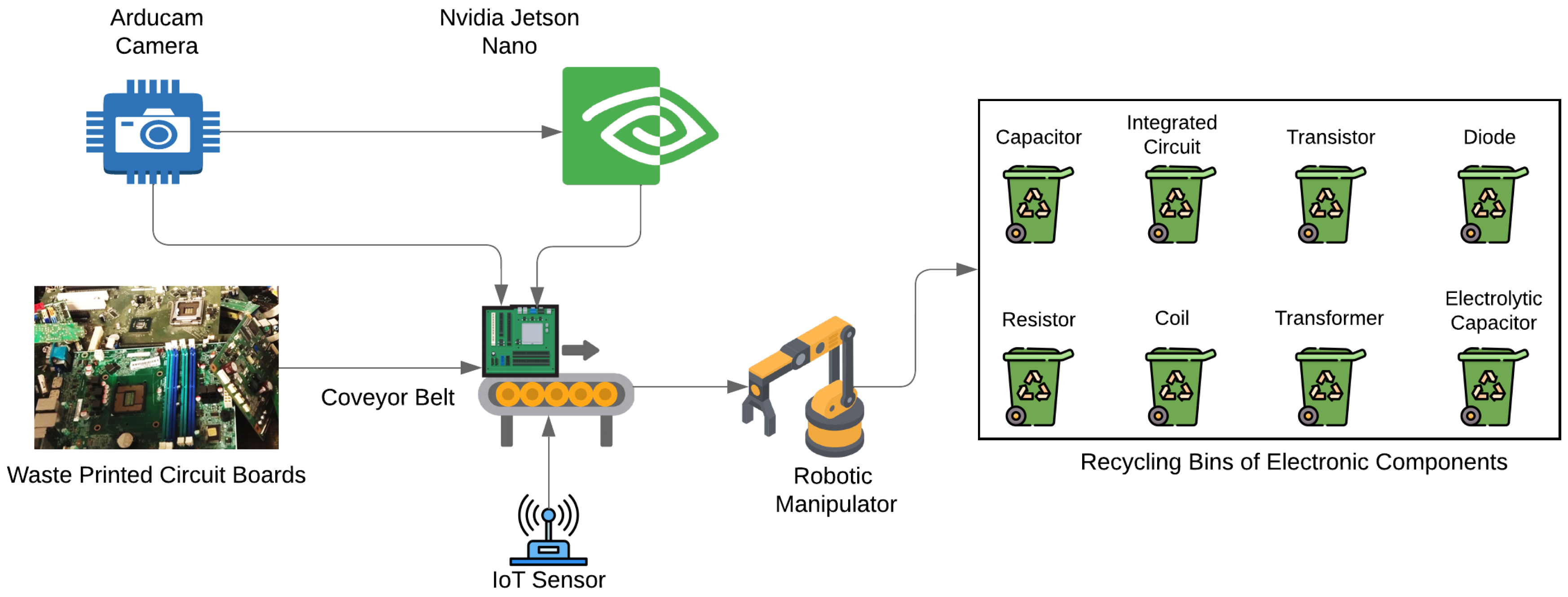

3.3. Industrial Realization of Automatic Disassembly of WPCBs

The Internet of Things (IoT) facilitates the disassembly of WPCBs by enabling communication and data sharing between the diverse range of devices involved in the process. These devices may include sensors, actuators, cameras, and robotic arms, which are interconnected to form a unified disassembly system.

Figure 4 shows detailed industrial realization of an automated disassembly system of WPCBs and sorting of electronic components into their specified bins. The industrial implementation of automated disassembly of WPCBs aims to develop efficient, economical, and environmentally sustainable recycling methods. These systems enhance productivity and safety by reducing dependence on manual labor, thereby improving the recovery rates of valuable materials such as gold, copper, and palladium. Furthermore, the process reduces waste production and alleviates environmental risks linked to the improper disposal of WPCBs, fostering a cleaner and more sustainable method of electronic waste management.

The procedure begins with the transfer of WPCBs on a conveyor belt, which is monitored by an ArduCam camera linked to an NVIDIA Jetson Nano for real-time image capture and analysis. The images are then subjected to analysis in order to identify the various electronic components present, with the use of state-of-the-art object detection algorithms. An IoT sensor is integrated into the system to provide supplementary environmental or operational data, thereby facilitating accurate control and monitoring. Subsequently, a robotic manipulator is employed to select and categorize the identified electronic components (ECs) into specified recycling bins according to their type. These include capacitors, integrated circuits, transistors, diodes, resistors, coils, transformers, and electrolytic capacitors. This system enhances the efficiency and precision of recycling processes, thereby facilitating sustainable electronic waste management.

3.4. Experimental Setup

The experimental setup comprised the preparation of the dataset, training of the model, validation, and inference on the Leonardo Cineca HPC server, which employed NVIDIA A100 GPUs.

3.4.1. Dataset Preparation

The dataset was acquired using an Arducam 12.4 MP camera linked to an NVIDIA Jetson Nano under a variety of recycling conditions, including variable lighting, different orientations, distances from the camera, cast shadows, viewpoints, and various resolutions. The dataset comprises high-resolution images of WPCBs, with each image annotated with labelled components. These components include:

The images were collected in a variety of orientations and conditions to ensure the robustness of the training and evaluation processes.

Figure 5 shows the example of custom V-PCBs dataset prepared in an internal environment.

3.4.2. Hardware and Software System

In conducting experiments, the Leonardo Cineca HPC server [

44] was employed for the purposes of training, validating, and testing models. The specifics of the hardware configuration are provided below:

The software used for the experimental setups is given below:

3.4.3. Model Configurations

In the course of our experiments, we employed four distinct variants of the cutting-edge YOLO model: The models utilized in our experiments were YOLOv8 [

45], YOLOv9 [

46], YOLOv10 [

47], and YOLOv11 [

48]. The performance of each model architecture was subjected to rigorous analysis while maintaining consistency in hyperparameter settings. The specific details regarding the parameters are provided below:

Batch Size: 8

Epochs: One thousand epochs with early termination.

Learning rate: Learning rate set at 0.01 utilizing cosine annealing.

Augmentation: Mosaic augmentation, stochastic scaling, and horizontal flipping.

4. Experimental Results and Discussion

The efficacy of each model was evaluated using cutting-edge key performance indicators. The following metrics were employed: average precision (AP), recall, F1-score, training duration per epoch, and inference time per image.

4.1. Model Evaluation

We evaluated four different YOLO models: YOLOv8, YOLOv9, YOLOv10, and YOLOv11 in our experiments using custom V-PCBs dataset in order to facilitate the automatic disassembly and sorting process. The results of the assessment of each model are presented in the following section.

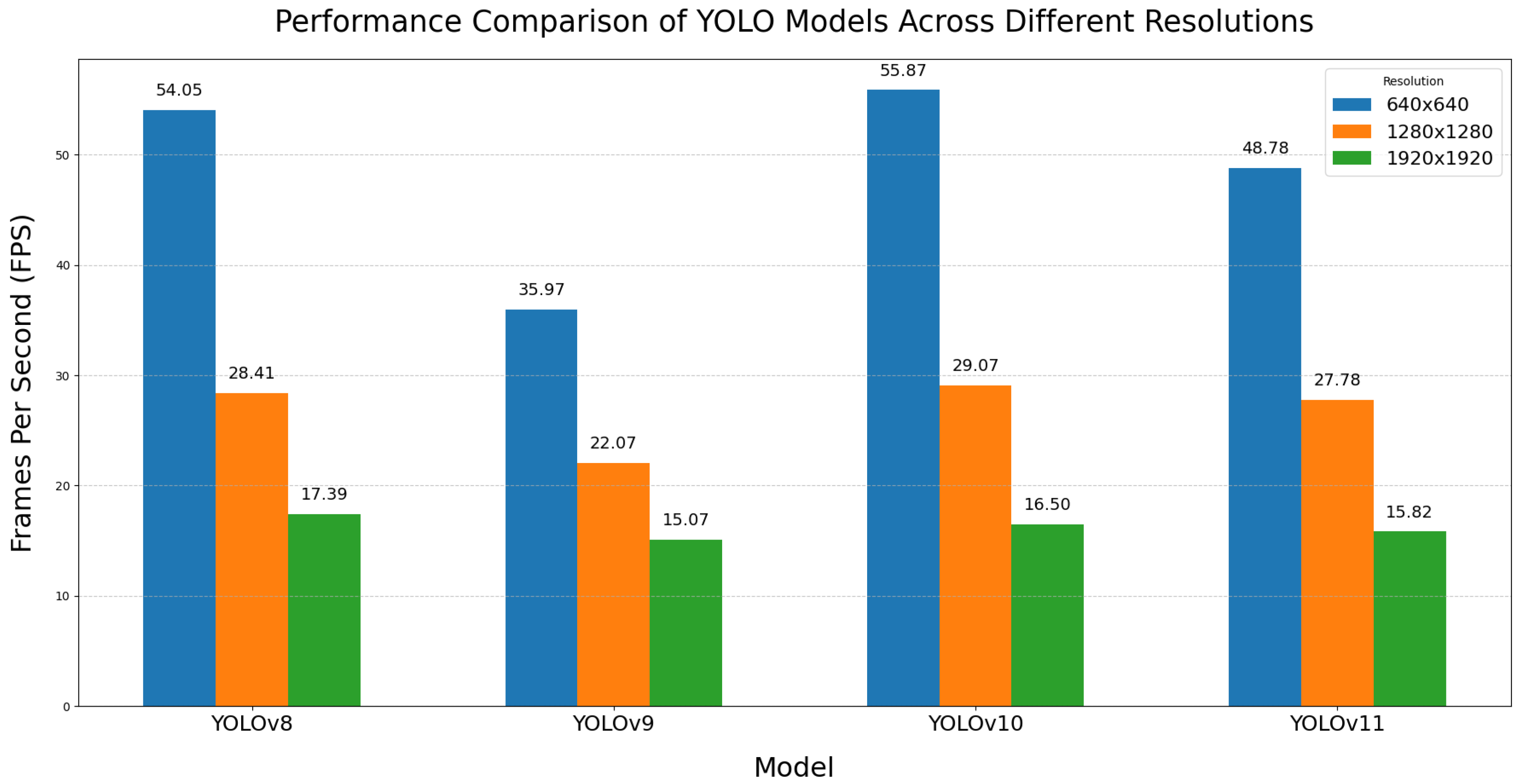

The YOLOv8 model demonstrated consistent accuracy and recall across all resolutions. The moderate computational requirements of the model made it a viable choice for general applications. Nevertheless, its training and inference times were slower than those of more recent models, limiting its suitability for real-time or high-throughput applications.

The enhanced inference speed and average precision (AP) of YOLOv9, particularly at reduced resolutions such as 640x640, represent an improvement over YOLOv8. Therefore, YOLOv9 represents a compelling option for scenarios where resources are limited. Nevertheless, it demonstrated diminished resilience in high-resolution tasks, exhibiting inferior overall detection performance for complex or densely packed WPCB images in comparison to YOLOv10 and YOLOv11.

The YOLOv10 model has been demonstrated to represent the optimal choice for achieving a balance between inference speed and detection accuracy. It demonstrated particularly strong performance at 1280x1280 resolution, offering a notable trade-off between computational efficiency and precision-recall metrics. Nevertheless, the training duration was slightly longer than that of YOLOv11, indicating the possibility of enhanced architectural efficiency.

The YOLOv11 model was identified as the most robust and accurate, achieving the highest average precision (90.4%), recall (87.6/%), and F1-score (88.9%) at the maximum resolution of 1920x1920. The model exhibited an effective training process, rendering it suitable for large-scale tasks. Nevertheless, its inference speed at reduced resolutions was slightly inferior to that of YOLOv9 and YOLOv10, which may limit its utility in situations where real-time processing is essential.

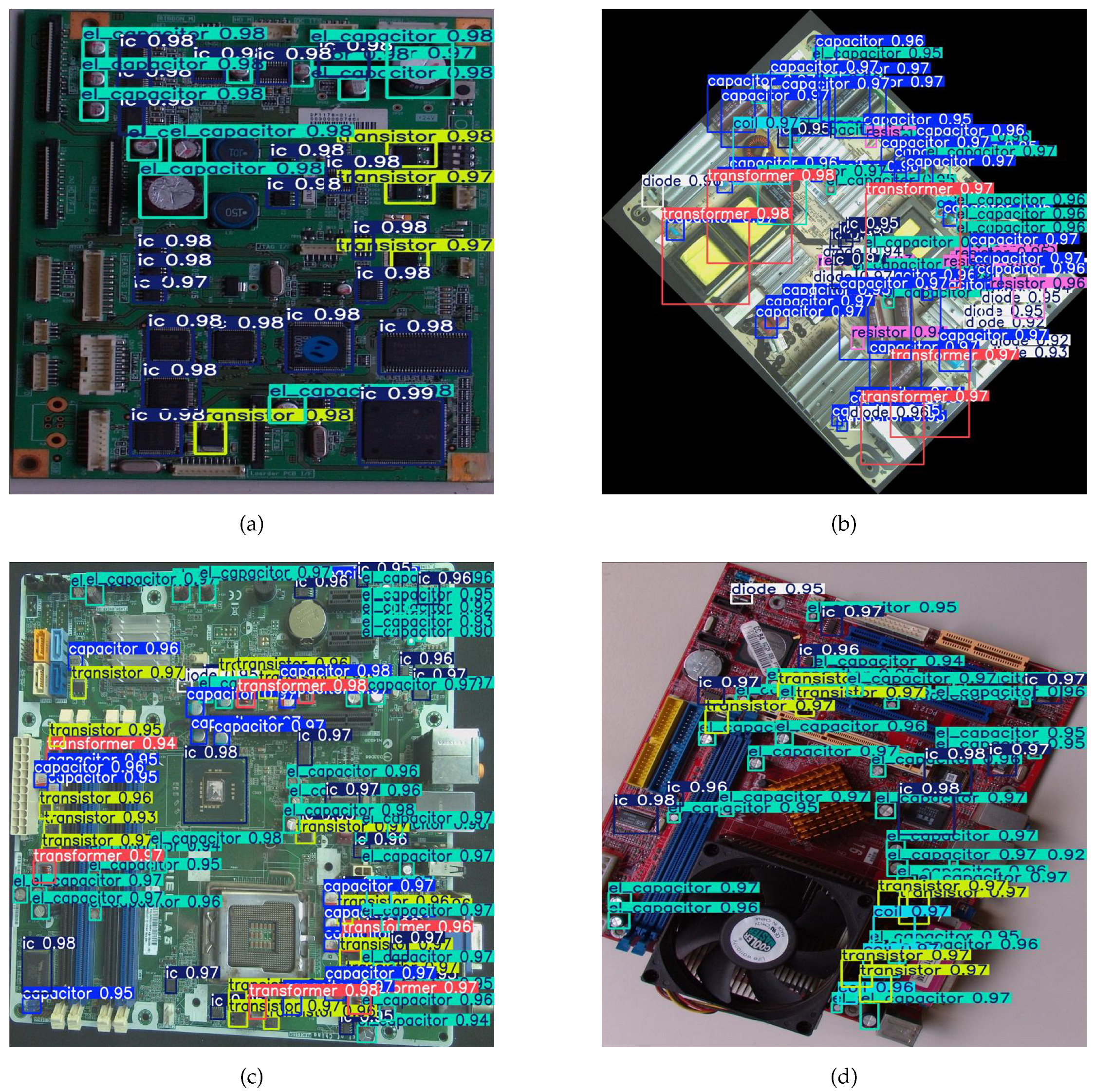

Figure 6 shows the detail comparison of each YOLO model with V-PCBs dataset.

4.2. Discussion

Figure 7 shows the details results achieved using V-PCBs dataset. The analysis demonstrated that an increase in image resolution consistently resulted in enhanced detection performance across all models. The use of high-resolution images (1920x1920) facilitated the extraction of enhanced features, which proved beneficial for the detection of small or intricate printed circuit board (PCB) components. YOLOv11 demonstrated the most pronounced performance enhancements at 1920x1920, attaining the highest Average Precision (AP) and F1-score among the evaluated models. This highlights the effectiveness of the method in managing complex tasks that require precise object localization and classification.

The ability to perform inference is a fundamental aspect of real-time applications. YOLOv10, operating at a resolution of 640x640, has been identified as the fastest model, exhibiting an inference time of 9.9 ms per image with a frame rate of 55.87. The expeditious processing of YOLOv10 renders it an optimal choice for scenarios that require prompt decision-making. Although YOLOv11 exhibited slightly slower inference times at lower resolutions, it demonstrated superior accuracy, thereby establishing itself as a promising candidate for high-precision tasks. YOLOv11 exhibited the most rapid training durations across all resolutions, which is indicative of its optimized architecture and effective resource allocation. This efficiency is particularly advantageous in scenarios that necessitate frequent model retraining or the use of extensive datasets.

Each model demonstrates a unique trade-off between speed and precision. YOLOv11 is optimal for applications requiring the utmost precision, such as the detection of defects or the assurance of quality in printed circuit boards (PCBs). In contrast, YOLOv10 at a resolution of 1280x1280 offers a harmonious equilibrium, combining enhanced detection precision with relatively rapid inference speeds. Although YOLOv9 is less robust at higher resolutions, it is a viable option for lightweight applications where speed is a priority. The choice of a model is contingent upon the availability of resources and the specific requirements of the task at hand. The experimental analysis revealed that YOLOv11 exhibited the highest versatility and accuracy, while YOLOv10 demonstrated the optimal balance between speed and accuracy.

The experiment results were highly effective in the server environment, showcasing their ability for precise object detection and classification. Deploying these models on edge devices, such as the Jetson Nano, is crucial for real-time and scalable automated disassembly solutions. The YOLOv5 model, tested on the Jetson Nano using the V-PCB dataset, achieved satisfactory results, maintaining strong detection accuracy and inference speed despite the device’s computational limitations. This evaluation highlights the feasibility of deploying AI models in resource-limited environments, offering a practical solution for automated WPCB disassembly workflows. Additionally, the adaptability of YOLOv5 to the Jetson Nano suggests that advanced models like YOLOv8, YOLOv9, YOLOv10 and YOLOv11 could be optimized for next-generation edge devices like the Jetson Orin or Jetson Orin Nano Super. These advanced Jetson devices provide greater computational power and memory, enhancing the performance of state-of-the-art models in real-time applications. This scalability ensures the seamless integration of cutting-edge AI models into industrial recycling systems, advancing efficient on-site WPCB disassembly and CRM recovery.

5. Challenges and Future Directions

The effective disassembly of WPCBs is contingent upon the precise identification and localization of the electronic components present within the WPCBs. The rapidity and superior quality of disassembly achieved by robotics has led to an increased use of this technology to address such tasks. The identification of electronic components from WPCBs with simple designs that can be easily disassembled has been previously examined. As electronic components become more complex and smaller in size, WPCBs exhibit greater design diversity and an expanding range of circuit board materials. In the context of electronic component detection, a two-dimensional top-view image of a WPCB resembles a binary image comprising a background and clustered objects of varying shapes and sizes, including components, solder joints, and color markings on the PCBs. The pervasive occurrence of part-to-part and intra-part resemblance, as evidenced by the presence of prints, electrodes, and assorted patterns on components, renders conventional object detection and counting methodologies inadequate for addressing this challenge.

The most prevalent methodology for addressing the challenge of electronic component detection from WPCBs entails object classification, followed by object localization and estimation through the delineation of the objects’ regions. The efficacy of the electronic component detection process is contingent upon achieving an optimal equilibrium between accuracy and mean average precision. The proposed detection methods are insufficient for resolving this problem. The role of edge computing and the Internet of Things (IoT) in the automatic disassembly of WPCBs is highly transformative, offering substantial improvements in efficiency, safety, and environmental sustainability. These technologies facilitate real-time data processing, decentralized decision-making, and enhanced communication between disassembly devices, thereby enhancing the efficiency and efficacy of e-waste management. While there are challenges and limitations to the widespread adoption of these technologies, the potential benefits are substantial.

As research and development continue, the integration of edge computing, the Internet of Things (IoT), and other advanced technologies, including artificial intelligence (AI) and machine learning, will likely become increasingly important in the effort to manage e-waste and recover valuable materials. By adopting these innovations, the e-waste recycling industry can transition towards more sustainable practices that not only safeguard the environment but also facilitate the circular economy.

6. Conclusions

This paper presents a technologically advanced conceptual framework for the automated disassembly of WPCBs using edge computing and the Internet of Things (IoT) devices. The framework highlights the role of edge devices and IoT in improving the efficiency of disassembly and sorting processes, thereby facilitating the effective recycling of high-density electronic components within WPCBs. To efficiently detect and localize electronic components from WPCBs using robotic disassembly and sorting, we conducted several experiments using advanced object detection models from the YOLO family. We used Leonardo’s high-performance CINECA supercomputer for training and inference, and evaluated different YOLO variants to obtain the best results. Among the models evaluated, YOLOv11 showed superior performance, outperforming other variants such as YOLOv8, YOLOv9, and YOLOv10 in terms of accuracy and efficiency. This highlights the robustness and suitability of YOLOv11 to address the challenges of component identification in an automated disassembly and sorting system. We also examine the barriers to the deployment of these technologies, including scalability, real-time processing, and integration, and explore future prospects for improving automated WPCB recycling solutions. This strategy aims to improve the sustainable management of electronic waste by optimizing resource recovery and reducing the environmental impact.

Author Contributions

All authors contributed equally to conceptualization, methodology, discussion of results and revision of the paper. M.M. also implemented the software, curated the data, performed the experiments and wrote the first draft of the paper.

Funding

The Ph.D. position of the first author is funded by MUR (DM n. 360 of 04-21-2022)

Data Availability Statement

Sample data is available upon request from the authors.

Acknowledgments

We acknowledge ISCRA for awarding this project access to the LEONARDO supercomputer, owned by the EuroHPC Joint Undertaking, hosted by CINECA (Italy).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhao, W.; Xu, J.; Fei, W.; Liu, Z.; He, W.; Li, G. The reuse of electronic components from waste printed circuit boards: a critical review. Environmental Science: Advances 2023, 2, 196–214. [Google Scholar] [CrossRef]

- Wang, J.; Guo, J.; Xu, Z. An environmentally friendly technology of disassembling electronic components from waste printed circuit boards. Waste management 2016, 53, 218–224. [Google Scholar] [CrossRef]

- Krishnamurthy, R.; Cecil, J. A next-generation IoT-based collaborative framework for electronics assembly. The International Journal of Advanced Manufacturing Technology 2018, 96, 39–52. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, B.; Gao, Y.; Xu, Z. An automatic sorting system for electronic components detached from waste printed circuit boards. Waste Management 2022, 137, 1–8. [Google Scholar] [CrossRef]

- Mohsin, M.; Zeng, X.; Rovetta, S.; Masulli, F. Measuring the Recyclability of Electronic Components to Assist Automatic Disassembly and Sorting Waste Printed Circuit Boards. arXiv 2024, arXiv:2406.16593. [Google Scholar]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Cabri, A. Virtual Mines–Component-level recycling of printed circuit boards using deep learning. arXiv 2024, arXiv:2406.17162. [Google Scholar]

- Luo, S.; Wan, F.; Lei, G.; Xu, L.; Ye, Z.; Liu, W.; Zhou, W.; Xu, C. EC-YOLO: Improved YOLOv7 Model for PCB Electronic Component Detection. Sensors 2024, 24, 4363. [Google Scholar] [CrossRef]

- Dai, W.; Nishi, H.; Vyatkin, V.; Huang, V.; Shi, Y.; Guan, X. Industrial edge computing: Enabling embedded intelligence. IEEE Industrial Electronics Magazine 2019, 13, 48–56. [Google Scholar] [CrossRef]

- Vishnu, S.; Ramson, S.J.; Senith, S.; Anagnostopoulos, T.; Abu-Mahfouz, A.M.; Fan, X.; Srinivasan, S.; Kirubaraj, A.A. IoT-Enabled solid waste management in smart cities. Smart Cities 2021, 4, 1004–1017. [Google Scholar] [CrossRef]

- Hao, J. Dismantling, How to Remove Electronic Chips and Other Elements on Waste Circuit Boards? Available online: https://www.youtube.com/watch?v=17vNj4pwl6A (accessed on 13 November 2024).

- Zeng, X.; Li, J.; Xie, H.; Liu, L. A novel dismantling process of waste printed circuit boards using water-soluble ionic liquid. Chemosphere 2013, 93, 1288–1294. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, B.; Ghosh, M.; Parhi, P.; Mukherjee, P.; Mishra, B. Waste printed circuit boards recycling: an extensive assessment of current status. Journal of cleaner production 2015, 94, 5–19. [Google Scholar] [CrossRef]

- Huang, H.; Pan, J.; Liu, Z.; Song, S.; Liu, G. Study on disassembling approaches of electronic components mounted on PCBs. In Proceedings of the Advances in Life Cycle Engineering for Sustainable Manufacturing Businesses: Proceedings of the 14th CIRP Conference on Life Cycle Engineering, Waseda University, Tokyo, Japan, June 11th–13th, 2007.; pp. 263–266.

- Cao, Y.; Mu, T. Comprehensive investigation on the thermal stability of 66 ionic liquids by thermogravimetric analysis. Industrial & engineering chemistry research 2014, 53, 8651–8664. [Google Scholar]

- Zhu, P.; Chen, Y.; Wang, L.Y.; Zhou, M. A new technology for recycling solder from waste printed circuit boards using ionic liquid. Waste management & research 2012, 30, 1222–1226. [Google Scholar]

- Duan, H.; Hou, K.; Li, J.; Zhu, X. Examining the technology acceptance for dismantling of waste printed circuit boards in light of recycling and environmental concerns. Journal of environmental management 2011, 92, 392–399. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.; Han, Y.; Park, J. Apparatus for electronic component disassembly from printed circuit board assembly in e-wastes. International Journal of Mineral Processing 2015, 144, 11–15. [Google Scholar] [CrossRef]

- Zhou, Y.; Qiu, K. A new technology for recycling materials from waste printed circuit boards. Journal of Hazardous Materials 2010, 175, 823–828. [Google Scholar] [CrossRef] [PubMed]

- Meng, L.; Zhong, Y.; Guo, L.; Wang, Z.; Chen, K.; Guo, Z. High-temperature centrifugal separation of Cu from waste printed circuit boards. Journal of Cleaner Production 2018, 199, 831–839. [Google Scholar] [CrossRef]

- Wang, J. Research on the key technology of automatically disassembling electronic components from WPCBs by industrial waste heat. Ph.D. Thesis, Southwest University of Science and Technology, Mianyang, China, 2013. [Google Scholar]

- Wang, J.; Xu, Z. Disposing and recycling waste printed circuit boards: disconnecting, resource recovery, and pollution control. Environmental science & technology 2015, 49, 721–733. [Google Scholar]

- Chen, M.; Wang, J.; Chen, H.; Ogunseitan, O.A.; Zhang, M.; Zang, H.; Hu, J. Electronic waste disassembly with industrial waste heat. Environmental science & technology 2013, 47, 12409–12416. [Google Scholar]

- Pan, X.; Li, Z.; Zhi, H.; Wang, L. Method and apparatus of separation for electronic components and solders from printed circuit boards. Chinese Patent No. 2007102015321 2007. [Google Scholar]

- Duan, H.; Li, J.; Liu, Y.; Yamazaki, N.; Jiang, W. Characterization and inventory of PCDD/Fs and PBDD/Fs emissions from the incineration of waste printed circuit board. Environmental science & technology 2011, 45, 6322–6328. [Google Scholar]

- Yang, C.; Tan, Q.; Liu, L.; Dong, Q.; Li, J. Recycling tin from electronic waste: a problem that needs more attention. ACS Sustainable Chemistry & Engineering 2017, 5, 9586–9598. [Google Scholar]

- Maurice, A.A.; Dinh, K.N.; Charpentier, N.M.; Brambilla, A.; Gabriel, J.C.P. Dismantling of printed circuit boards enabling electronic components sorting and their subsequent treatment open improved elemental sustainability opportunities. Sustainability 2021, 13, 10357. [Google Scholar] [CrossRef]

- Vermeșan, H.; Tiuc, A.E.; Purcar, M. Advanced recovery techniques for waste materials from IT and telecommunication equipment printed circuit boards. Sustainability 2019, 12, 74. [Google Scholar] [CrossRef]

- Carneiro, M.F.C.; Leão, V.A. The role of sodium chloride on surface properties of chalcopyrite leached with ferric sulphate. Hydrometallurgy 2007, 87, 73–82. [Google Scholar] [CrossRef]

- Altinkaya, P.; Liipo, J.; Kolehmainen, E.; Haapalainen, M.; Leikola, M.; Lundström, M. Leaching of trace amounts of metals from flotation tailings in cupric chloride solutions. Mining, Metallurgy & Exploration 2019, 36, 335–342. [Google Scholar]

- Cabri, A.; Masulli, F.; Rovetta, S.; Mohsin, M. Recovering Critical Raw Materials from WEEE using Artificial Intelligence. In Proceedings of the The 21st International Conference on Modelling and Applied Simulation; 2022. [Google Scholar]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Cabri, A. Real-Time Detection of Electronic Components in Waste Printed Circuit Boards: A Transformer-Based Approach. arXiv 2024, arXiv:2409.16496. [Google Scholar]

- Sharma, H.; Kumar, H. A computer vision-based system for real-time component identification from waste printed circuit boards. Journal of Environmental Management 2024, 351, 119779. [Google Scholar] [CrossRef]

- Fnu, A.; Zodage, T.; Thillaivasan, U.; Lai, X.; Chakwate, R.; Santillan, J.; Oti, E.; Zhao, M.; Boirum, R.; Choset, H.; et al. RGB-X classification for electronics sorting. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). IEEE; 2022; pp. 5973–5980. [Google Scholar]

- Bassiouny, A.M.; Farhan, A.S.; Maged, S.A.; Awaad, M.I. Comparison of different computer vision approaches for e-waste components detection to automate e-waste disassembly. In Proceedings of the 2021 International Mobile, Intelligent, and Ubiquitous Computing Conference (MIUCC). IEEE; 2021; pp. 17–23. [Google Scholar]

- Pramerdorfer, C.; Kampel, M. A dataset for computer-vision-based PCB analysis. In Proceedings of the 2015 14th IAPR international conference on machine vision applications (MVA). IEEE; 2015; pp. 378–381. [Google Scholar]

- Breiman, L. Random forests. Machine learning 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Li, W.; Esders, B.; Breier, M. SMD segmentation for automated PCB recycling. In Proceedings of the 2013 11th IEEE International Conference on Industrial Informatics (INDIN). IEEE; 2013; pp. 65–70. [Google Scholar]

- Li, W.; Jiang, C.; Breier, M.; Merhof, D. Localizing components on printed circuit boards using 2d information. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT). IEEE; 2016; pp. 769–774. [Google Scholar]

- Li, W.; Neullens, S.; Breier, M.; Bosling, M.; Pretz, T.; Merhof, D. Text recognition for information retrieval in images of printed circuit boards. In Proceedings of the IECON 2014-40th Annual Conference of the IEEE Industrial Electronics Society. IEEE; 2014; pp. 3487–3493. [Google Scholar]

- Weinert, K.; Pandey, V.; Naranjo Corona, S.; Danielewski, A. Autonomous waste characterization in environmentally conscious decision making. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. American Society of Mechanical Engineers, Vol. 58165; 2017; p. 004. [Google Scholar]

- Tremblay, J.; Prakash, A.; Acuna, D.; Brophy, M.; Jampani, V.; Anil, C.; To, T.; Cameracci, E.; Boochoon, S.; Birchfield, S. Training deep networks with synthetic data: Bridging the reality gap by domain randomization. In Proceedings of the Proceedings of the IEEE conference on computer vision and pattern recognition workshops, 2018; pp. 969–977.

- Naito, K.; Shirai, A.; Kaneko, S.i.; Capi, G. Recycling of printed circuit boards by robot manipulator: A Deep Learning Approach. In Proceedings of the 2021 IEEE International Symposium on Robotic and Sensors Environments (ROSE). IEEE; 2021; pp. 1–5. [Google Scholar]

- Mohsin, M.; Rovetta, S.; Masulli, F.; Greco, D.; Cabri, A. Deep learning-powered computer vision system for selective disassembly of waste printed circuit boards. In Proceedings of the 2024 IEEE 8th Forum on Research and Technologies for Society and Industry Innovation (RTSI). IEEE; 2024; pp. 115–119. [Google Scholar]

- Turisini, M.; Amati, G.; Cestari, M. Leonardo: A pan-European pre-exascale supercomputer for HPC and AI applications. arXiv 2023, arXiv:2307.16885. [Google Scholar] [CrossRef]

- Jocher, G.; Chaurasia, A.; Qiu, J. Ultralytics YOLOv8 2023.

- Wang, C.Y.; Liao, H.Y.M. YOLOv9: Learning What You Want to Learn Using Programmable Gradient Information. arXiv 2024, arXiv:2402.13616. [Google Scholar]

- Wang, A.; Chen, H.; Liu, L.; et al. YOLOv10: Real-Time End-to-End Object Detection. arXiv 2024, arXiv:2405.14458. [Google Scholar]

- Jocher, G.; Qiu, J. Ultralytics YOLO11, 2024.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).