1. Introduction

Kre’ alang weaving, as one of Sumbawa’s high cultural heritages, is the pride of the Indonesian nation and reflects the nation’s identity. Therefore, weaving in terms of production techniques, design, and products must be maintained and preserved [

1]. Currently, several villages in Sumbawa Regency still preserve the weaving tradition, but some have not preserved it. The sub-districts are now considered centers of woven fabric crafts in Sumbawa Regency, namely Moyo Hilir and North Moyo Districts [

2]. One of the factors driving the increasing trend of Kre’ Alang production in villages is the appeal from the Sumbawa Regency Government to preserve the existence of Kre’ Alang woven fabric. Real support from the Sumbawa Regency Government is that State Civil Apparatus is required to use woven fabric or Kre’ alang with a combination of batik every Thursday [

3]. The high demand for Kre’ alang as a material in making modern clothing by the community and the increasing number of cultural activities have had an impact on the emergence of fake Kre’ alang industries in areas outside Sumbawa Regency. Fake Kre’ alang does not meet the quality standards and aesthetics of Sumbawa’s Kre’ Alang. Concerns from weavers and cultural figures emerged when the quality of the kre’ aAang was considered not as good as the original Kre’ alang and abandoned the basic concept that should be inherent in this songket cloth [

2].

Based on these problems, the Sumbawa regional government is making efforts to revive the spirit of weaving artisans through several programs specifically for artisans. Sumbawa Regency has several centers of small and medium industries in clothing. One of them is located in Semeri Hamlet, Poto Village, Moyo Hilir District. Semeri Hamlet, Poto Village, has been designated as a Nesek Weaving Center by the Indonesian Ministry of Industry since 2016 [

4]. In addition, one of the simple efforts that needs to be done by the community in an effort to preserve cultural heritage, for example Kre’ Alang woven cloth by using the woven cloth products in several activities in daily life. The results of observations show that Kre’ Alang weaving is not very popular; consumers are more interested in using woven cloth from natural fiber yarn from other areas. Kre’ Alang sales use a make-to-order system, meaning that weavers only weave kre alang if consumers request or order it. Kre’ Alang business actors say that the yarn used to make kre’ alang weaving is selected yarn, which is the best quality, and the price is more expensive on the market. So that is the reason for the high selling price of Kre’ Alang. Another factor that influences product competition and marketing performance is the innovation factor of Kre’ Alang woven products [

5], [

6].

Based on the description, it is necessary to utilize local plants that are easy to cultivate. They can be used as an innovation in raw materials to replace Kre’ alang weaving yarn. So far, the raw material for Kre’ Alang weaving yarn comes from cotton fiber [

2]. Apart from cotton fiber, several natural fibers are alternative yarns for making woven fabrics, including snake plant fiber [

7], kenaf plant fiber [

8], pineapple leaf fiber [

9], silk fiber [

10], banana fiber [

11] and other fibers. Sisal fiber is one of the plants that has the potential to be a raw material for yarn. Sisal grows abundantly in the Sumbawa area as a plant that grows in tropical and barren soil. Sisal has the potential to be an alternative raw material for Kre’ alang weaving yarn. So far, sisal fiber from Sumbawa district has not been processed optimally. Sisal fiber has the characteristics of being strong, elastic, able to absorb color, resistant to salt water, and biodegradable [

12]. The weaving process can improve the quality and stability of natural fibers. However, natural fibers need to be tested first. Based on this background, researchers are interested in utilizing sisal fiber as Kre’ Alang woven fabric yarn. The quality of the fiber was tested in the laboratory to determine the characteristics and mechanical properties of the yarn, then compared with commercial yarns that weavers have used. After that, an evaluation of the quality of Kre’ Alang woven products from sisal fiber yarn was carried out based on consumer satisfaction perceptions using the integration of the Importance Performance Analysis (IPA) method and the KANO model.

2. Materials and Methods

2.1. Alkalization and coloring of sisal

The sample used grade A sisal fiber obtained from Labangka District, Sumbawa. Other materials used were 5% NaOH, distilled water, distilled water and wantex. The equipment used was a beaker, 1L measuring flask, pan, stove, filter, gloves, and universal pH indicator. The alkalization procedure was carried out by preparing 50 g of NaOH and adding enough distilled water until dissolved and then diluted to the limit line. Sisal was soaked in 5% NaOH solution for 2 hours. The sisal was drained and then washed until the pH was neutral. After that, the sisal was dried and labeled S1 (alkalized sisal). The S1 coloring procedure was carried out using Wantex. A total of 1 tsp of salt was dissolved in 2L of hot water. Then, 3 g of Wantex was added. The S1 sample was weighed as much as 25 g and then mixed evenly with the Wantex solution. The mixture of sisal and wantex was boiled using low heat for 30 minutes. S1 was labeled S1P.

2.2. Integration of IPA Methods and KANO Model

Evaluation of consumer satisfaction level of Kre’ Alang weaving from sisal fiber yarn can use the IPA method, KANO method, and IPA-KANO integration. The steps of the IPA method are to determine the average value of the level of importance and performance of each attribute of Kre’ alang weaving from sisal fiber yarn, determine the limiting value of Importance Performance, and map all average values of attributes into a Cartesian diagram formed from Importance Performance values so that the low or high category of each attribute can be determined [

13]. The steps of the KANO method are to arrange each attribute of Kre’ alang weaving from sisal fiber into two forms (functional and dysfunctional), based on the respondent’s answers, match the KANO category (Must be (M), One dimensional (O), Attractive (A), Indifferent (I) and Questionable (Q)), referring to Blauth’s formula, the KANO category of each attribute of Kre’ alang weaving from sisal fiber yarn can be determined by considering the number of M, O and A with the number of R and Q [

14]. Meanwhile, IPA-KANO integration provides decisions on product attributes that must be improved and maintained effectively and firmly to avoid wrong choices. The principle of implementing IPA-KANO integration is by combining the results of the IPA quadrant with the results of the KANO category on each product attribute so that a grouping of categories is obtained, namely Survival, Fatal, Chronic Disease, Fitness, Major Weapon, Defenselles Strategy Point, Defenselles Zone, Supportive Weapon, Precious treasure, Dusty Diamond, Rought Srone and Beginning Jewellery [

15]. Six indicators need to be considered to assess the quality of woven fabrics: Performance, Features, Reliability, Conformance to specifications, Durability and Aesthetics [

16]. These indicators can be derived into question attributes (

Table 1) to be assessed by consumers of Kre’ alang weaving as respondents in the study. Respondents in this study were visitors to the Kre’ Alang weaving exhibition from sisal fiber yarn that the research team had organized, and the number of respondents who were willing to assess the quality of Kre’ Alang weaving from sisal fiber yarn (

Figure 2) was 110 people.

3. Results

3.1. Analysis of color, physical properties, strength, and fineness of sisal

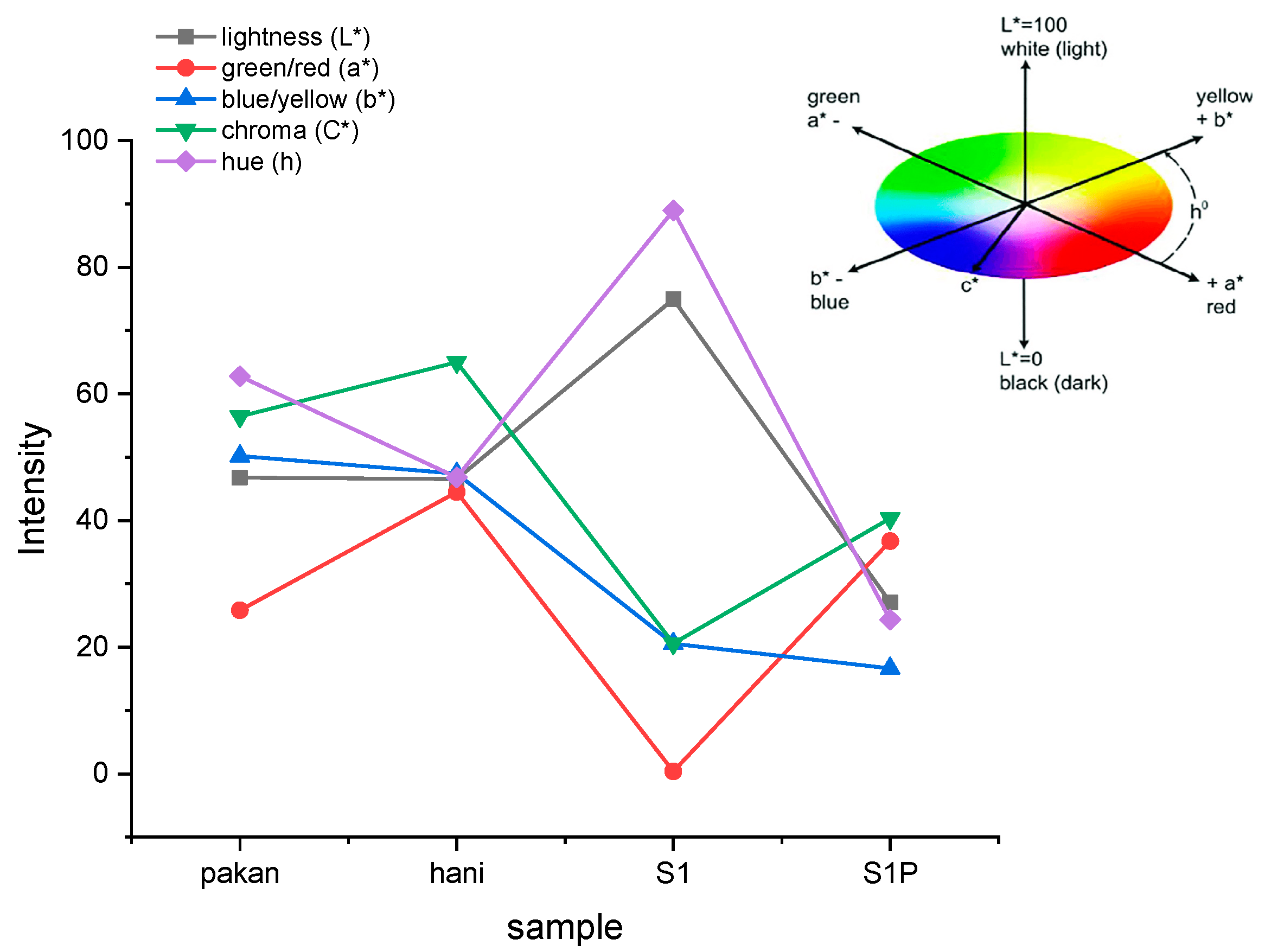

Figure 1.

Differences in intensity and hue of sisal fiber color.

Figure 1.

Differences in intensity and hue of sisal fiber color.

Table 1.

Sisal Fiber Color Test Results.

Table 1.

Sisal Fiber Color Test Results.

| Sample |

lightness (L*) |

green/red (a*) |

blue/yellow (b*) |

chroma (C*) |

hue (h) |

| Pakan |

46.753 |

25.796 |

50.153 |

56.416 |

62.781 |

| Hani |

46.556 |

44.516 |

47.388 |

65.020 |

46.790 |

| S1 |

74.952 |

0.358 |

20.544 |

20.560 |

88.960 |

| S1P |

27.082 |

36.728 |

16.656 |

40.332 |

24.376 |

Table 2.

Results Of Physical Properties Tests Of Sisal Fiber, Weft Yarn, And Hani Yarn.

Table 2.

Results Of Physical Properties Tests Of Sisal Fiber, Weft Yarn, And Hani Yarn.

| No. |

Test Type |

Test Method* |

Test Results* |

Test Method** |

Test Results** |

| S1 |

S1P |

Hani |

Weft |

| 1 |

Fineness of fiber |

SNI 08-1111-1989 |

|

|

SNI ISO 2060: 2010 |

|

|

| average, Tex (Denier) |

12,51 (112,55) |

16,14 (145,30) |

38,94 (15,20) |

19,30 (30,74) |

| CV, % |

13,48 |

16,61 |

4,83 |

7,01 |

| 2 |

Kekuatan serat per bundle |

SNI ISO 105-C06:2010 |

|

|

SNI 7650:2010 |

|

|

| Fiber strength per bundle |

|

|

|

|

| Tenacity |

|

|

|

|

| Average, gf/Tex |

31,85 |

23,21 |

32,96 |

13,24 |

| CV,% |

15,37 |

23,75 |

501,04 |

407,12 |

| Stretch |

|

|

|

|

| Average, % |

3,20 |

3,90 |

963 |

7,53 |

| CV,% |

13,98 |

24,66 |

|

|

| 3 |

Colorfastness to: |

SNI ISO 105-C06:2010 |

|

|

SNI ISO 105-C06:2010 |

|

|

| a. Washing 400C |

|

|

|

|

| - Discoloration |

|

4-5 |

4-5 |

3-4 |

| - Tarnishing on acetate |

|

4 |

4 |

3-4 |

| - Stains on cotton |

|

2 |

2 |

3-4 |

| - Staining on polyamide |

|

3-4 |

3 |

3-4 |

| - Stains on polyester |

|

3-4 |

4 |

4 |

| - Tarnishing of acrylic |

|

3-4 |

3-4 |

4 |

| - Staining on wool |

|

3-4 |

4 |

3-4 |

| |

|

|

|

|

|

|

| b. Sweat |

SNI ISO 105-E04:2015 |

|

|

SNI ISO 105-E04:2015 |

|

|

| 1. Acidic properties |

|

|

|

|

| - Discoloration |

|

4 |

4 |

4-5 |

| - Tarnishing on acetate |

|

4 |

4-5 |

4 |

| - Stains on cotton |

|

3-4 |

2-3 |

4-5 |

| - Penodaan pada poliamida |

|

4 |

3-4 |

4 |

| - Staining on polyamide |

|

4 |

4-5 |

4-5 |

| - Tarnishing of acrylic |

|

4 |

4-5 |

4-5 |

| - Staining on wool |

|

4 |

4 |

4 |

| |

|

|

|

|

|

|

| 2. Properties of Bases |

SNI ISO 105-X12:2016 |

|

|

SNI ISO 105-X12:2016 |

|

|

| - Discoloration |

|

4-5 |

4-5 |

4-5 |

| - Tarnishing on acetate |

|

4 |

4-5 |

4 |

| |

- Stains on cotton |

|

3-4 |

3-4 |

4 |

| |

- Staining on polyamide |

|

4 |

4 |

4 |

| |

- Stains on polyester |

|

4 |

4-5 |

4 |

| |

- Tarnishing of acrylic |

|

4 |

4-5 |

4-5 |

| |

- Staining on wool |

|

4 |

4-5 |

4-5 |

| |

c. Rubbing: |

|

|

|

|

| |

- Dry |

|

4 |

4 |

3 |

| |

- Wet |

|

2-3 |

3 |

2-3 |

Table 3.

Test Results Of Strength And Fineness Of Sisal Fiber, Weft Yarn, And Hani Yarn

Table 3.

Test Results Of Strength And Fineness Of Sisal Fiber, Weft Yarn, And Hani Yarn

| Parameter |

S1 |

S1P |

Hani |

Weft |

| Weight (g) |

0.056±0.008 |

0.073±0.012 |

0.008±0.000 |

0.015±0.001 |

| Tex |

12.506±1.686 |

16.144±2.681 |

15.201±0.740 |

30.741±2.073 |

| Denier |

112.552±15.175 |

145.300±24.133 |

38.943±1.880 |

19.301±1.353 |

| Strength (KP) |

4.980±1.167 |

5.280±1.261 |

17.820±1.881 |

42.200±4.203 |

| Stretch (%) |

3.200±0.447 |

3.900±0.962 |

7.128±0.753 |

16.880±1.681 |

| Heavy |

2.334±0.460 |

3.446±0.736 |

501.040±48.253 |

407.120±30.650 |

| Tenacity (g/tex) |

31.851 |

23.214 |

32.961 |

13.244 |

3.2. Kre’ Alang Weaving

Figure 2.

Kre’ Alang woven products are a combination of weft yarn from sisal fiber yarn.

Figure 2.

Kre’ Alang woven products are a combination of weft yarn from sisal fiber yarn.

3.3. Integration of Science Methods and KANO Model

Table 4.

Level of Conformity of Each Quality Attribute of Kre’ Alang Weaving from Sisal Fiber Yarn.

Table 4.

Level of Conformity of Each Quality Attribute of Kre’ Alang Weaving from Sisal Fiber Yarn.

| Indikator |

Attribute |

Code |

Performance |

Importance |

level of confidence |

| Performance |

The quality of Kre’ Alang woven fabric from sisal fiber yarn. |

1 |

1,22 |

4,90 |

24,90% |

| Defects of Kre’ Alang woven fabric from sisal fiber yarn. |

2 |

1,80 |

4,45 |

40,45% |

| Strength of Kre’ Alang woven fabric from sisal fiber yarn. |

3 |

1,48 |

4,65 |

31,83% |

| Features |

Innovation in Kre’ Alang woven design from sisal fiber yarn. |

4 |

1,62 |

4,56 |

35,53% |

| Reliability |

The density of Kre’ Alang woven fabric from sisal fiber yarn. |

5 |

1,33 |

4,55 |

29,23% |

| The smoothness of Kre’ Alang woven fabric from sisal fiber yarn. |

6 |

1,77 |

4,39 |

40,32% |

| Conformance to specifications |

Kre’ Alang woven fabric from sisal fiber yarn can be marketed at a price that is according to quality. |

7 |

1,53 |

4,65 |

32,90% |

| Durability |

Colorfastness of Kre’ Alang woven fabric from sisal fiber yarn. |

8 |

1,73 |

4,39 |

39,41% |

| Aesthetic |

The choice of Kre’ Alang woven motifs from sisal fiber yarn is diverse. |

9 |

1,56 |

4,55 |

34,29% |

| Combination of Kre’ Alang woven fabric colors from sisal fiber yarn. |

10 |

1,38 |

4,59 |

30,07% |

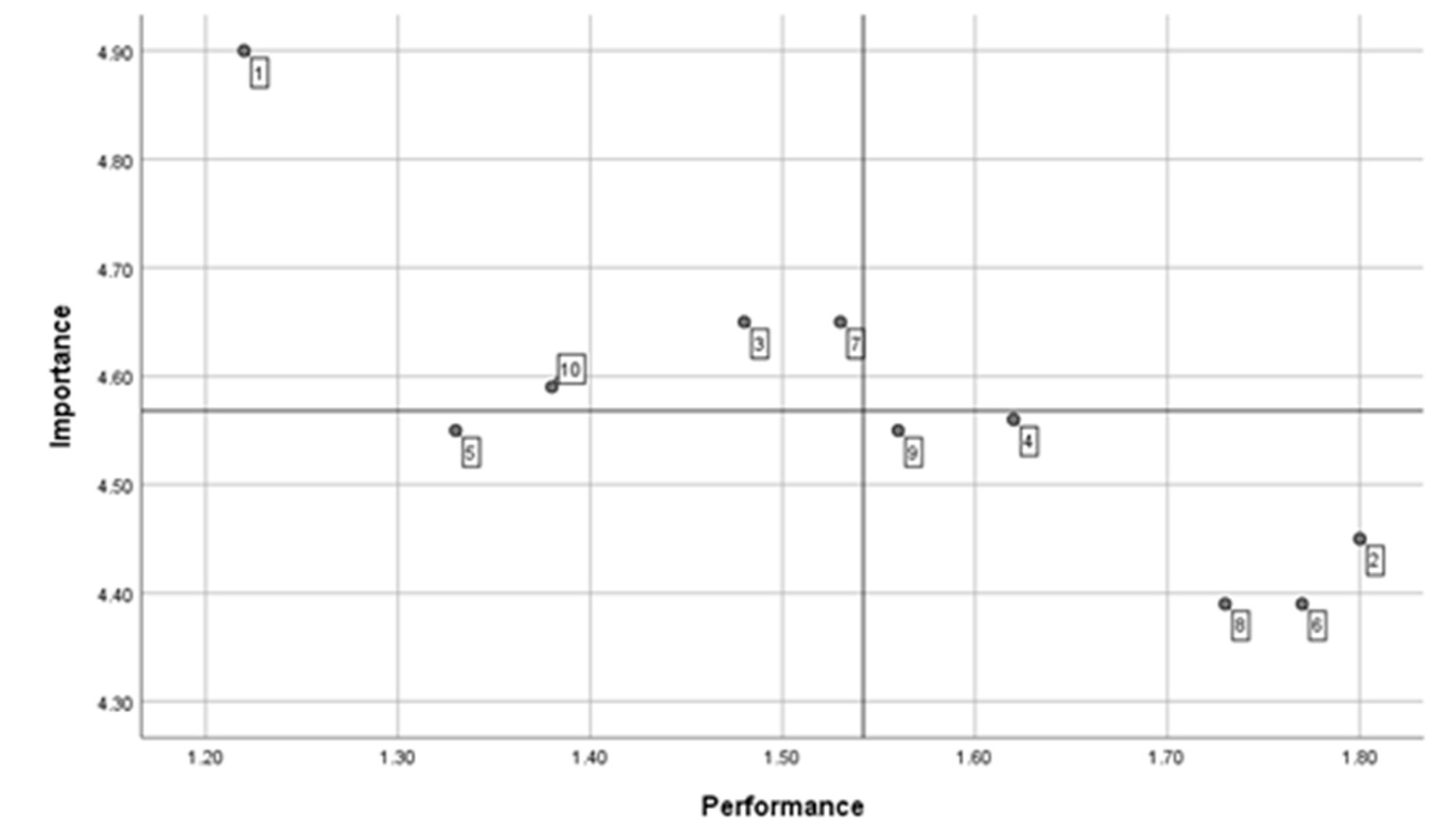

Figure 3.

Cartesian diagram

Figure 3.

Cartesian diagram

Table 5.

KANO Category Mapping

Table 5.

KANO Category Mapping

| Indikator |

Attribute |

Code |

O |

A |

M |

I |

R |

Q |

| Performance |

The quality of Kre’ Alang woven fabric from sisal fiber yarn. |

1 |

33 |

51 |

7 |

11 |

1 |

7 |

| Defects of Kre’ Alang woven fabric from sisal fiber yarn. |

2 |

28 |

19 |

27 |

26 |

6 |

5 |

| Strength of Kre’ Alang woven fabric from sisal fiber yarn. |

3 |

30 |

44 |

10 |

16 |

5 |

5 |

| Features |

Innovation in Kre’ Alang woven design from sisal fiber yarn. |

4 |

23 |

35 |

17 |

26 |

4 |

5 |

| Reliability |

The density of Kre’ Alang woven fabric from sisal fiber yarn. |

5 |

22 |

58 |

1 |

18 |

3 |

8 |

| The smoothness of Kre’ Alang woven fabric from sisal fiber yarn. |

6 |

16 |

40 |

13 |

27 |

10 |

4 |

| Conformance to specifications |

Kre’ Alang woven fabric from sisal fiber yarn can be marketed at a price that is according to quality. |

7 |

39 |

38 |

10 |

14 |

8 |

1 |

| Durability |

Colorfastness of Kre’ Alang woven fabric from sisal fiber yarn. |

8 |

28 |

36 |

8 |

22 |

9 |

7 |

| Aesthetic |

The choice of Kre’ Alang woven motifs from sisal fiber yarn is diverse. |

9 |

25 |

42 |

2 |

28 |

7 |

6 |

| Combination of Kre’ Alang woven fabric colors from sisal fiber yarn. |

10 |

46 |

40 |

8 |

8 |

3 |

5 |

Table 6.

Integrasi IPA-Kano.

Table 6.

Integrasi IPA-Kano.

| Code |

IPA Category |

KANO Category |

IPA-KANO |

Strategic Priorities |

| 1 |

II |

A |

Precious Treasure |

Keep it up 5 |

| 2 |

IV |

O |

Supportive Weapon |

Keep it up 4 |

| 3 |

II |

A |

Precious Treasure |

Keep it up 5 |

| 4 |

IV |

A |

Beginning Jewelry |

Keep it up 6 |

| 5 |

III |

A |

Rought Srone |

Upgrade 6 |

| 6 |

IV |

A |

Beginning Jewelry |

Keep it up 6 |

| 7 |

II |

O |

Major Weapon |

Keep it up 3 |

| 8 |

IV |

A |

Beginning Jewelry |

Keep it up 5 |

| 9 |

IV |

A |

Beginning Jewelry |

Keep it up 5 |

| 10 |

II |

O |

Major Weapon |

Keep it up 3 |

4. Discussion

4.1. Analysis of color, physical properties, strength, and fineness of sisal

The results of the color test of the S1 yarn sample and the S1P yarn sample are presented in

Table 1 and

Figure 1. The S1 yarn sample has the brightest color brightness, with an intensity of 74,952. The S1 yarn sample is yellowish white, while the S1P yarn sample is red, the weft yarn sample is dark yellow, and the hani sample is red. The S1 yarn sample is bright compared to the SIP and colored synthetic yarn. This indicates that the addition of dye makes the sisal fiber darker. Similar analysis results have also been carried out in previous studies, concluding that the addition of increasingly concentrated dyes causes the darker color of the fabric. There is a process of dye absorption into the fiber. The difference in color needs to be studied to determine the performance of the applied dye [

17]. The amount of lignin content influences the intensity of brightness. High lignin content causes dark colors such as dark brown, light brown, and brownish yellow [

18]. The brightness analysis of untreated sisal has an L value of 66.42, yellow. The higher L value indicates that the material is increasingly bright white [

19]. The L parameter shows dark to bright colors [

20].

Although the S1 yarn sample has the highest L, it has the lowest a* of 0.358. The positive a* intensity indicates the sample is red [

20], [

17]. S1 has the lowest red color intensity. The alkalization process has changed the color of sisal from white to yellowish white and can increase tensile strength [

21]. In addition, the alkali process can break hydrogen bonds in fibers and increase the cellulose amorphous structure [

22]. The analysis results of sisal fabric without nanosilver coating have been reported to have an a* of 1.89, with a gray/almost white color [

23]. Sisal without treatment has an a* of -0.60 [

7]. The negative value indicates that sisal tends to be green. The application of Wantex has reduced the b* intensity, as shown in

Table 1. Sequentially, the S1 and S1P yarn samples have b* of 20.544 and 16.656. A positive b* value is an indication that both samples are yellow. The correlation between yellow and bright colors indicates that the material tends to be shiny. Untreated sisal has a b* of 23.80 [

19]. The S1 yarn sample has a brighter color and is shinier than the S1P yarn sample. Chrome contains information about the bleaching process or the relationship between brightness and the number of colors in the material. Brighter and shinier materials reduce the number of colors [

24]. Based on the data in

Table 1, the S1 and S1P yarn samples each have a C* of 20,560 and 40,332—the S1 yarn sample.

Table 3 shows that the dyeing process causes the S1P yarn sample to be heavier, stronger, and more elastic than the S1 yarn sample; yarn from

Table 3 shows that the dyeing process causes the S1P yarn sample to be heavier, stronger, and more elastic than the S1 yarn sample, yarn from sisal fiber is heavier than synthetic yarn (weft yarn and hani yarn). Sisal fiber is known to contain around 10.66% water [

19]. The fiber matrix comprises polymers with a greater weight than monomers. Polydisperse polymers are composed of molecules of various sizes. At the same time, homopolymers are composed of the same molecules. Natural fibers are composed of pectin, protein, cellulose, and lignin. The composition of natural fibers is influenced by climate, maturity, extraction methods, and botanical conditions [

25]. The suitability of the fiber diameter size is seen from the Tex. The smaller the Tex, the lighter and smoother. Denier indicates the level of yarn thickness as a raw material for making fabric. An amount of 0.67 tex is equivalent to 6 deniers [

19]. Meanwhile, the tenacity value shows the unbreakable nature [

26]. The S1 yarn sample is smoother, thinner, and less breakable than the S1P yarn sample. Based on

Table 3, sisal fiber has a greater weight, denier, and tenacity than synthetic fiber.

4.2. Integration of Science Methods and KANO Model

The IPA method analysis was used to group the level of respondent suitability into a Cartesian diagram. Measurement of the level of respondent suitability was carried out on the quality of Kre’ Alang weaving (

Figure 2) from a combination of sisal fiber yarn as weft yarn and hani yarn. One of the motifs produced is a combination of Gili Liuk motifs and whale shark motifs [

27]. The quality attributes of Kre’ Alang weaving from sisal fiber yarn are shown in

Table 4. The average value of the importance level and performance level of Kre’ alang weaving quality from sisal fiber yarn obtained in

Table 4 are then described in a Cartesian diagram as in

Figure 3. Based on the functional and dysfunctional questionnaire data that were obtained, a KANO category classification analysis was carried out on the functional and dysfunctional data. Then, data was obtained on the results of mapping the number of consumers based on the KANO category for each attribute, which is presented in

Table 5.

The results of the IPA-KANO integration can provide information to develop strategies for weavers related to the attributes of Kre’ Alang woven products from sisal fiber yarn that need to be improved or maintained to improve the quality of weaving according to consumer satisfaction.

Table 6 presents the results of the analysis using the integration of the IPA method and the Kano method regarding the assessment by respondents/consumers of the quality of Kre’ Alang woven products from a combination of sisal fiber yarn.

Based on the evaluation using IPA-KANO integration on Kre’ Alang woven products from sisal fiber, the density of the woven fabric must be increased to increase consumer satisfaction. Meanwhile, the weavers must still maintain the quality, strength, innovation, smoothness, color fastness, price, selection of motifs, and color combinations that have been applied in making Kre’ Alang woven products from sisal fiber yarn.

Based on

Table 6, there are four attributes of Kre’ Alang weaving from sisal fiber yarn in the second quadrant, meaning that the quality, strength, selling price, and color combination of woven fabric from sisal fiber yarn are considered by consumers to be by expectations so that the level of satisfaction is relatively higher. Therefore, the attributes in this second quadrant need to be maintained because they are superior in the eyes of consumers. Consumers consider Kre’ alang weaving density from sisal fiber less critical because it is in the third quadrant. Therefore, weavers can reconsider this attribute because the influence on the benefits felt by consumers is very lacking. Meanwhile, consumers consider the characteristics of defects, innovation, smoothness, fastness, and selection of various motifs in Kre’ Alang woven fabric from sisal fiber yarn excessive because they are in the fourth quadrant. Therefore, weavers can reduce the level of treatment on these attributes so that weavers can save costs.

The evaluation results of Kre’ Alang weaving using the Kano method obtained two categories for its attributes, namely Attractive (A), meaning that the level of consumer satisfaction with Kre’ Alang woven fabric from sisal fiber yarn will increase very high with increasing quality of woven fabric, increasing strength of woven fabric, increasing innovation, increasing density of weaving, increasing smoothness of weaving, increasing durability of woven color and growing variety of motifs. However, a decrease in the performance of these attributes will not cause a reduction in the level of consumer satisfaction. One dimension (O), meaning that the level of consumer satisfaction with Kre’ Alang woven fabric from sisal fiber yarn has a level of consumer satisfaction that is directly proportional to the level of weaving defects, the level of suitability of the selling price with the quality of the weaving, and the level of attractive woven color combinations.

The results of the evaluation of Kre’ Alang weaving using the integration of the IPA-KANO method show there are five categories produced to increase consumer satisfaction with the quality of the weaving. The first category is Precious Treasure. This category is attractive to Kre’ alang Kre’ alang weaving consumers, which is a valuable component for weavers and must be maintained. These components are the quality and strength of Kre’ alang alang weaving from sisal fiber. The second category is Supportive Weapon, meaning that the category of Kre’ Alang woven fabric from sisal fiber yarn is not defective and can be used as a supporting weapon in terms of competing with woven products from other regions. The third category is Beginning Jewelry, meaning that attributes such as innovation in design, fineness of weaving, color fastness of weaving, and various motif variations in Kre’ Alang weaving from sisal fiber are considered the beginning of becoming a gem. The fourth category is rough stone, meaning that the density attribute of Kre’ alang weaving from sisal fiber yarn has a relatively low attraction and needs to be polished so that this category can be increased and have an effect on increasing consumer satisfaction. The fifth category is Major Weapon, meaning that the attributes found in Kre’ Alang sisal fiber weaving, such as price according to quality and attractive color combinations, can be the primary weapon for weavers to be able to eliminate the existence of competing weaving from other regions.

5. Conclusions

Alkalized sisal fiber has a bright and shiny color. The dyeing process causes the color of the sisal fiber to darken, which is the result of observations on the mechanical properties of the sisal fiber. Undyed sisal has smoother, thinner, and less easily broken properties compared to after being dyed. Overall, the mechanical properties of sisal yarn are still less strong than those of synthetic yarn used by weavers. Efforts are needed to increase fiber strength. Sisal fiber is greener and is available as a local natural potential of Sumbawa.

Based on the evaluation using the integration of the IPA-KANO method on Kre’ Alang woven products from sisal fiber, the density of the woven fabric must be increased to increase consumer satisfaction. Meanwhile, the weavers must maintain the quality, strength, innovation, smoothness, color fastness, price, selection of motifs, and color combinations that have been applied in making Kre’ alang woven products from sisal fiber yarn.

Author Contributions

Koko Hermanto, Sahri Yanti, and Fauzi Widyawati conceived the idea, developed the theory and methodology, carried out the experimental work, collected the data, and analyzed the data. Shinta Esabella collected the data. Koko Hermanto and Sahri Yanti wrote the original manuscript.

Funding

The authors would like to thank the support of the Ministry of Education, Culture, Research, and Technology, Indonesia and Sumbawa University of Technology, Indonesia.

Data Availability Statement

The data in this study is divided into two categories based on the data source: data obtained from laboratory test results and data obtained from distributing questionnaires to respondents (accessible:

http://surl.li/dafakb).

Acknowledgments

The research team would like to thank the Ministry of Education, Culture, Research and Technology, Directorate General of Higher Education, Research and Technology, through the Directorate of Research, Technology and Community Service, for the financial assistance through the Fundamental Research scheme that allowed this research activity to be carried out.

Conflicts of Interest

All authors declare no conflict of interest among them.

References

- Kurniasari, N.M.U.; Sudirtha, I.G.; Budyani, I.D.M. Akulturasi Budaya Bali Pada Tenunan Flores. Pendidikan Teknologi dan Kejuruan 2023, 20, 137–146.

- Zubair, M. Pengkajian Kain Sumbawa Kere Alang; Dak Nonfisik BOP Museum dan Taman Budaya: Mataram, 2019;

- Amar, S.; Suyasa, I.M.; Mahsun Strategi Pengembangan Produk Ekonomi Kreatif Kain Tenun Kere’ Alang Sebagai Daya Tarik Wisata Di Desa Poto Kecamatan Moyo Hilir. Journal Of Responsible Tourism 2022, 2, 431–442.

- Jufrie Trend Positif Indeks Masyarakat Digital (IMDI) Kabupaten Sumbawa Available online: https://diskominfotik.sumbawakab.go.id/index.php/berita/id/1752/trend-positif-indeks-masyarakat-digital--imdi--kabupaten-sumbawa.html (accessed on 8 November 2024).

- Sofya, N.D.; Ekastini; Hermanto, K. The Analysis of Factors Influencing Product Competitive Advantage in Improving Marketing Performance of Kre ’ Alang Weaving. In Proceedings of the The 2nd International Conference of Mathematics Education, Learning, and Application; Kurniati, D., Ed.; AIP: Jember, Indonesia, 2023; pp. 1–6.

- Sofya, N.D.; Ekastini; Hermanto, K. Analisis Indikator Penyusunan Variabel Laten Ynag Mempengaruhi Kinerja Pemasaran Tenun Kre’ Alang. Jurnal ilmiah Clobal Education 2023, 4, 2124–2131.

- Br Napitupulu, L.O.; Widyasanti, A.; Thoriq, A.; Yusuf, A. The Study of Process and Characteristics of Woven Fabric from Plant Fibers of Lidah Mertua (Sansevieria Trifasciata P.). Jurnal Ilmiah Rekayasa Pertanian dan Biosistem 2019, 7, 207–220. [CrossRef]

- Salsabila Masykur, F.; Puspitasari, C. Eksplorasi Serat Dan Kain Kenaf Dengan Teknik Tekstil Pada Produk Fesyen. In Proceedings of the e-Proceeding of Art & Design; Telkom University, 2019; Vol. 6, pp. 4102–4107.

- Soeprijanto, S.; Ningrum, E.O.; Puspita, N.F.; Hamzah, A.; Rahmawati, D. Penerapan Mesin Opening Dalam Pembuatan Benang Dari Serat Daun Nanas Di Desa Satak Kabupaten Kediri. Sewagati 2023, 7, 593–601. [CrossRef]

- Salam, A.; Iswar, M.; Pali, B.; Anggai, A.; Rantemangnga, J. Modifikasi Alat Pemintal Benang Sutera Untuk Industri Rumah Tangga. Jurnal Sinergi Jurusan Teknik Mesin 2019, 17, 101. [CrossRef]

- Kuslambang, E.P.; Kusumarini, Y.; Suprobo, F.P. Eksperimen Potensi Kain Serat Pisang Sebagai Material Produk Pelengkap Interior. Jurnal Intra 2019, 7, 954–963.

- Katarina, L.; Widowati, T.; Kumala, A.D. Kelayakan Serat Sisal (Agave Angustifolia) Untuk Pembuatan Hair Extension Pada Penataan Lepas. Beauty and Beauty Health Education Journal 2023, 12, 86–96.

- Sever, I. Importance-Performance Analysis: A Valid Management Tool? Tourism Management 2015, 48, 43–53. [CrossRef]

- Bilgili, B.; Erci, A.; Ünal, S. Kano Model Application in New Product Development and Customer Satisfaction (Adaptation of Traditional Art of Tile Making to Jewelries). Procedia - Social and Behavioral Sciences 2011, 24, 829–846. [CrossRef]

- Tseng, C.C. An IPA-Kano Model for Classifying and Diagnosing Airport Service Attributes. Research in Transportation Business and Management 2020, 37, 100499. [CrossRef]

- Rauf, N.H.; Nur, T.; Malica, H.S. Perbaikan Kualitas Kain Sutera Dengan Menggunakan Metode Kano Dan Metode Quality Function Deployment (Qfd). Journal of Industrial Engineering Management 2018, 3, 26. [CrossRef]

- Ramadhan, F.H.; Dewi, E.N.; Anggo, A.D. Pengaruh Perbedaan Konsentrasi Ekstrak Pewarna Alami Rumput Laut (Sargassum Sp.) Terhadap Mutu Warna Kain Katun Batik. Jurnal Ilmu dan Teknologi Perikanan 2020, 2, 42–49. [CrossRef]

- Yu, W.; Yi, Y.; Wang, H.; Yang, Y.; Zeng, L.; Tan, Z. Light-Colored Cellulose Nanofibrils Produced from Raw Sisal Fibers without Costly Bleaching. Industrial Crops and Products 2021, 172, 114009. [CrossRef]

- Widyasanti, A.; Napitupulu, L.O.B.; Thoriq, A. Physical and Mechanical Properties of Natural Fiber from Sansevieria Trifasciata and Agave Sisalana. In Proceedings of the IOP Conference Series: Earth and Environmental Science; 2020; Vol. 462.

- Fadhlurrohman, I.; Setyawardani, T.; Sumarmono, J. Karakteristik Warna (Hue, Chroma, Whiteness Index), Rendemen, Dan Persentase Whey Keju Dengan Penambahan Teh Hitam Orthodox (Camellia Sinensis Var. Assamica). JITIPARI (Jurnal Ilmiah Teknologi dan Industri Pangan UNISRI) 2023, 8, 10–19. [CrossRef]

- Amsalu Fode, T.; Chande Jande, Y.A.; Kivevele, T.; Rahbar, N. A Review on Degradation Improvement of Sisal Fiber by Alkali and Pozzolana for Cement Composite Materials. Journal of Natural Fibers 2024, 21. [CrossRef]

- Ramaiah, G.; Tilahun, A.; Negawo, T.A.; Baraki, S.Y.; Legese, R.; Asfaw, D. Development of Green Composite Utilizing Sisal Strands and Sustainable 3-D Printed PLA Layers. Textile and Leather Review 2024, 7, 938–970. [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Kóczán, Z.; Bak, M.; Alpár, T. Colorful and Facile in Situ Nanosilver Coating on Sisal/Cotton Interwoven Fabrics Mediated from European Larch Heartwood. Scientific Reports 2021, 11, 1–13. [CrossRef]

- Quintana, E.; Valls, C.; Vidal, T.; Blanca Roncero, M. An Enzyme-Catalysed Bleaching Treatment to Meet Dissolving Pulp Characteristics for Cellulose Derivatives Applications. Bioresource Technology 2013, 148, 1–8. [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results in Engineering 2023, 19.

- Mahato, K.; Goswami, S.; Ambarkar, A. Morphology and Mechanical Properties of Sisal Fibre/Vinyl Ester Composites. Fibers and Polymers 2014, 15, 1310–1320. [CrossRef]

- Hermanto, K.; Widyawati, F.; Yanti, S.; Esabella, S. Disain Motif Hiu Paus Sebagai Tambahan Motif Tenun Kre Alang Benang Serat Sisal Menggunakan Teknik Gambar Pixel Art. Jurnal Ilmiah Global Education 2024, 5, 2467–2474. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).