1. Introduction

White LEDs based lighting has been proven with much uniques characteristics compare to compact lamp such as low power consumption, rapid response after be turned on, high color rendering index, long lifespan, low heat genneration, environnment friendly due to not containing murcury, and cost efficiency [

1,

2]. Among method for genneration white light, an simple and efficient way is the combination of a blue light excitation source (e.g. Blue LED die) and a conversion wavelength fluorescent material [

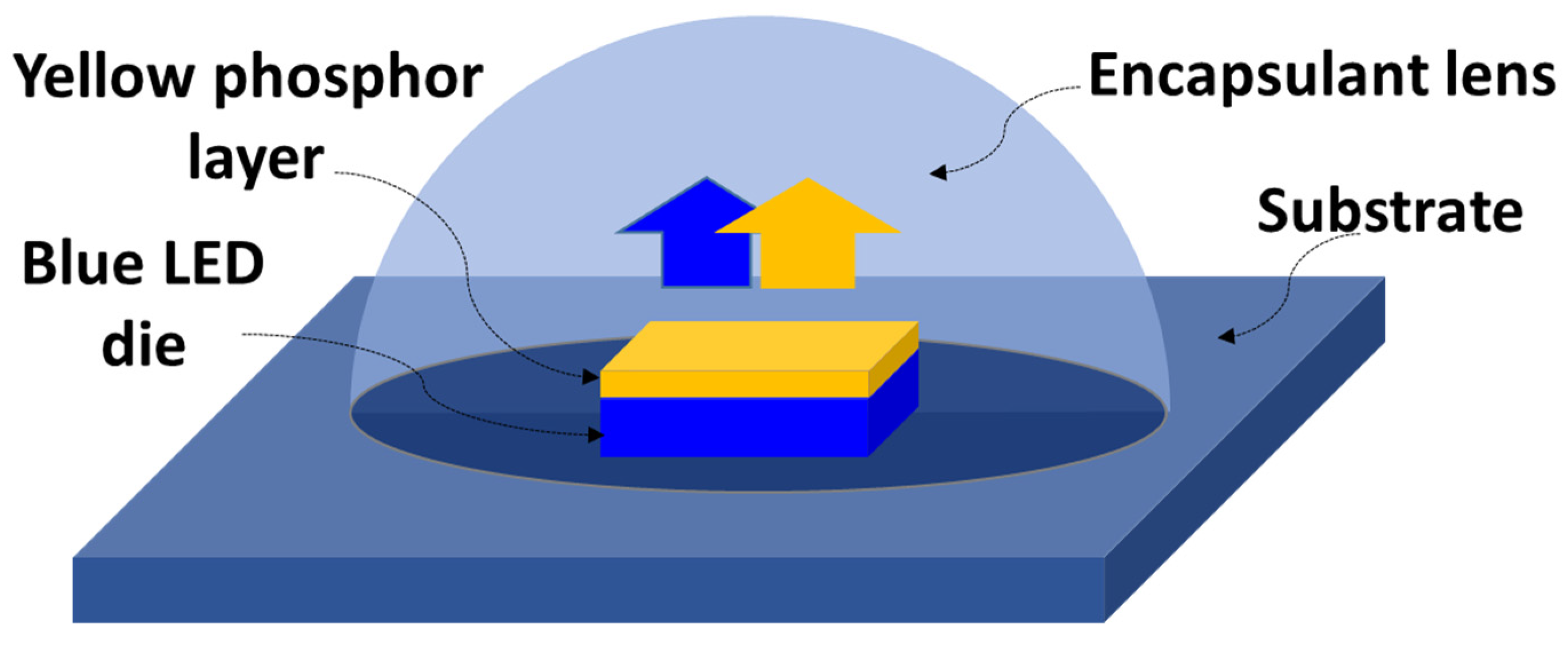

3]. The white LEDs can be fabricated by ultilizing one of these different package configurations such as dome, remote, and conformal structures. Among the different type of packaging configuration, the conformal structures is prefered due to compact size, high efficiency and extraction efficiency. In the conformal structures, a thin layer is fabricated on the blue LED die’s top surface which is sold on a sub-mount substrate, then this structure is packaged with a high refractive index and optical transparent property such as epoxy or sillicone gel.

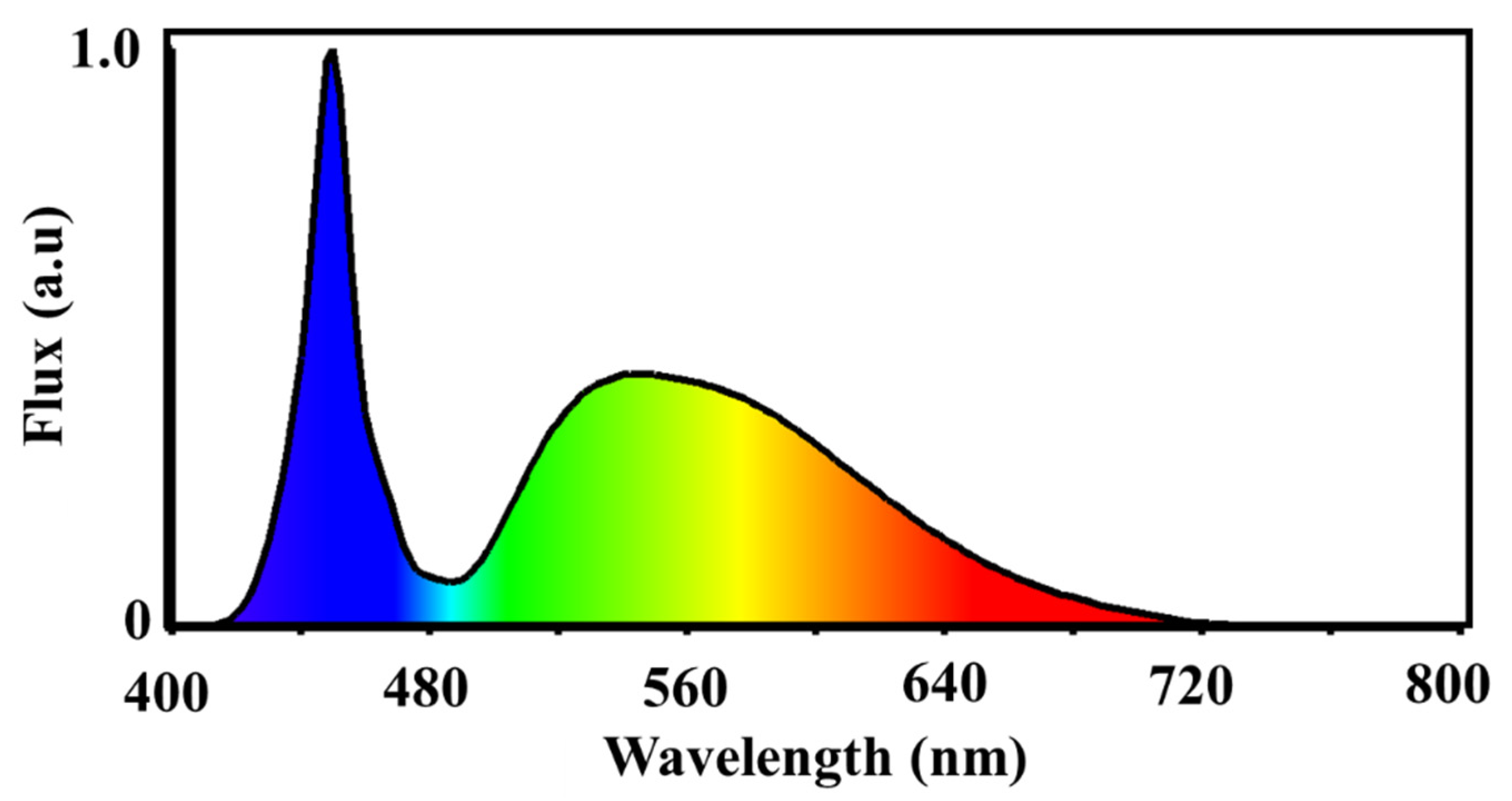

Figure 1 shows the illustration packaging structure of conformal type. The measurement of emission spectrum of pcW-LED packaged with conformal type is shown in

Figure 2, where it can see clear two emission band of blue and yellow band. The blue band is the portion of unabsorpbed blue light which emits form blue LED to excite the yellow phosphor. The broad yellow emission is the converted wavelength by yellow phosphor when absorbing the blue light. The mixture of output light has two emission band including transmitted blue light and converted yellow light. The power ratio of these two bands is well controlled to fabricate the white light with different optical performance.

Due to limitation of quantum efficiency, Stoke loss, optical loss, so that no matter what kind of packaged structure, the injection current for LED always has a strong relation to generated heat which causes the modification to optical property of output light. Understanding the relation of forwarded electrical current on thermal behavior of white LEDs is an easy way to control the thermal decay of output white light emission [

4,

5,

6,

7,

8,

9,

10,

11]. Related to the topics of thermal behavior of pcW-LEDs, many solution has been proposed and reported

. Different software has been used to model the thermal state of LED such as CFD software, COMSOL, and ANSYS [

12,

13,

14,

15,

16,

17]. The heat transfer model which utilized the software of ANSYS to predict the temperature characteristics in conformal packaging configuration [

15]. Tran et. al. developed a novel solution with combining of Matlab programing which can be applied to solve thermal problem at encapsulant material for electronic devices [

19].

In this paper, we study the thermal behavior of white LEDs by using the efficient steady-state thermal model. The influence of forward current to heat characteristics in the packaging domain is studied in both theoretical and empirical ways. The results have indicated the advantages of the thermal model not only in studying thermal behavior of conformal structure but also in the field of solid state lighting.

2. Thermal Modeling Description

The steady-state thermal model was established with using MATLAB software to program and apply the finite element method. Differrent heat condition in the LED structure is set and simulated to identify the temperature distribution [

16,

17,

18]. The similarity between simulation and experiment is validated with using thermal camera images to capture the temperature distribution of LED sample which was driven at the same heat condition as it is in the simulation. As a result, the temperature property in the white LED structure is visulized efficiently. In addition, the interpolation of the temperature within the white LED structure is contoured easily.

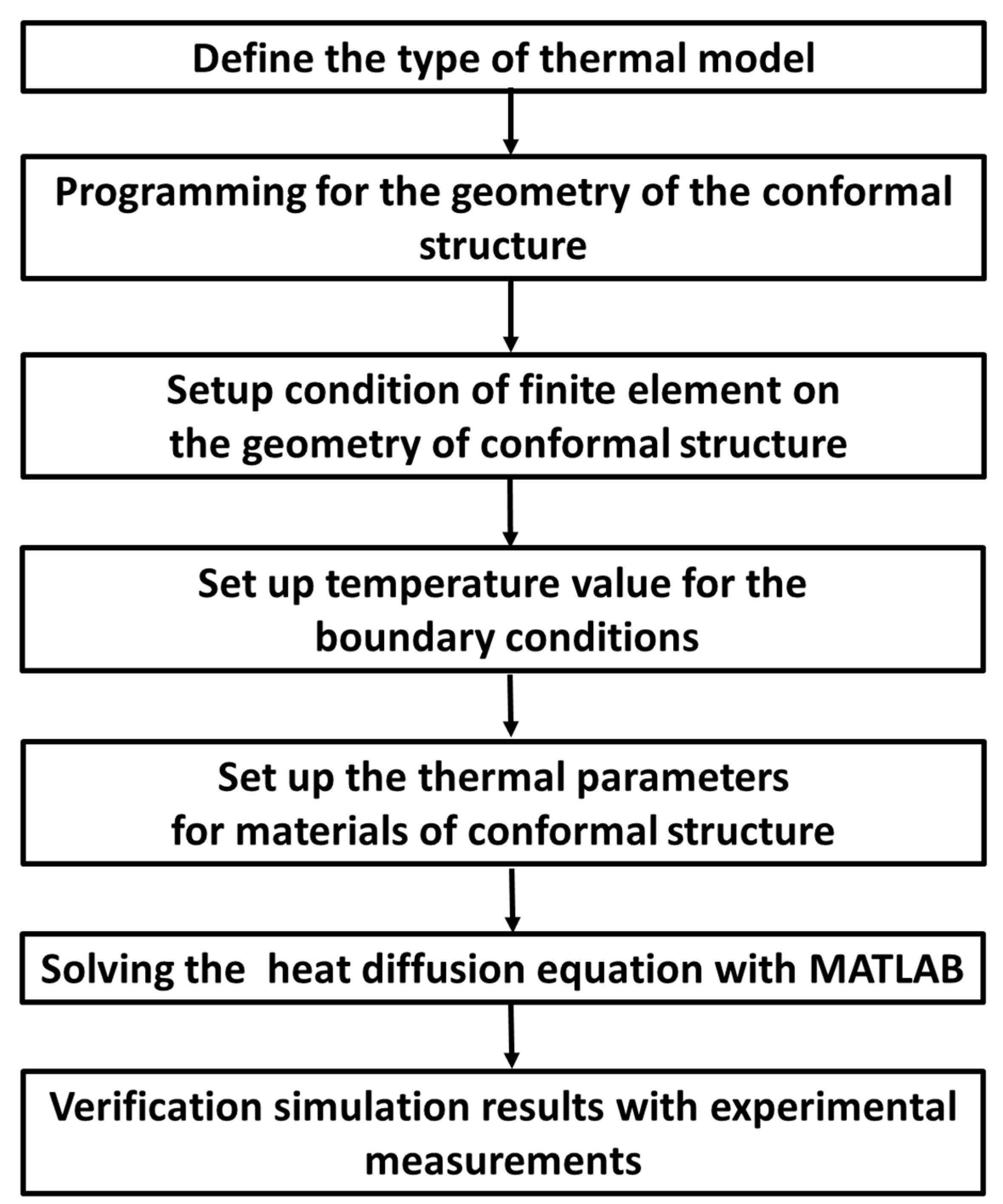

Figure 3 shows the flow chart in the thermal model for the conformal structure. In the first step, it is necessary to define the type of thermal model in the simulation. In this study, the thermal behavior of conformal structures is studied through the thermal model of steady state which is established using MATLAB software. In the second step, the geometry of the conformal structure is built by the programming correspondingly. In the next step, the geometry of the conformal structure is meshed with many tiny element. In this step, the parameter of element size is set so that the number of elements and the size of the conformal structure are suitable. In the fourth step, the temperature value for the boundary conditions is set and corresponds to the conditions of each injection current. In the fifth step, the thermal parameters for materials of conformal structure are set before running the simulation. In the sixth step, temperature distribution is visualized by solving the heat diffusion equation with MATLAB. In the step of number seven, the verification simulation results with experimental measurements to make sure the trustable of the established model. If the level of similarity is low, the parameters in the simulation are repeated until the simulation result has a high level to that of experiment results.

3. Simulation Temperature at Different Injection Current

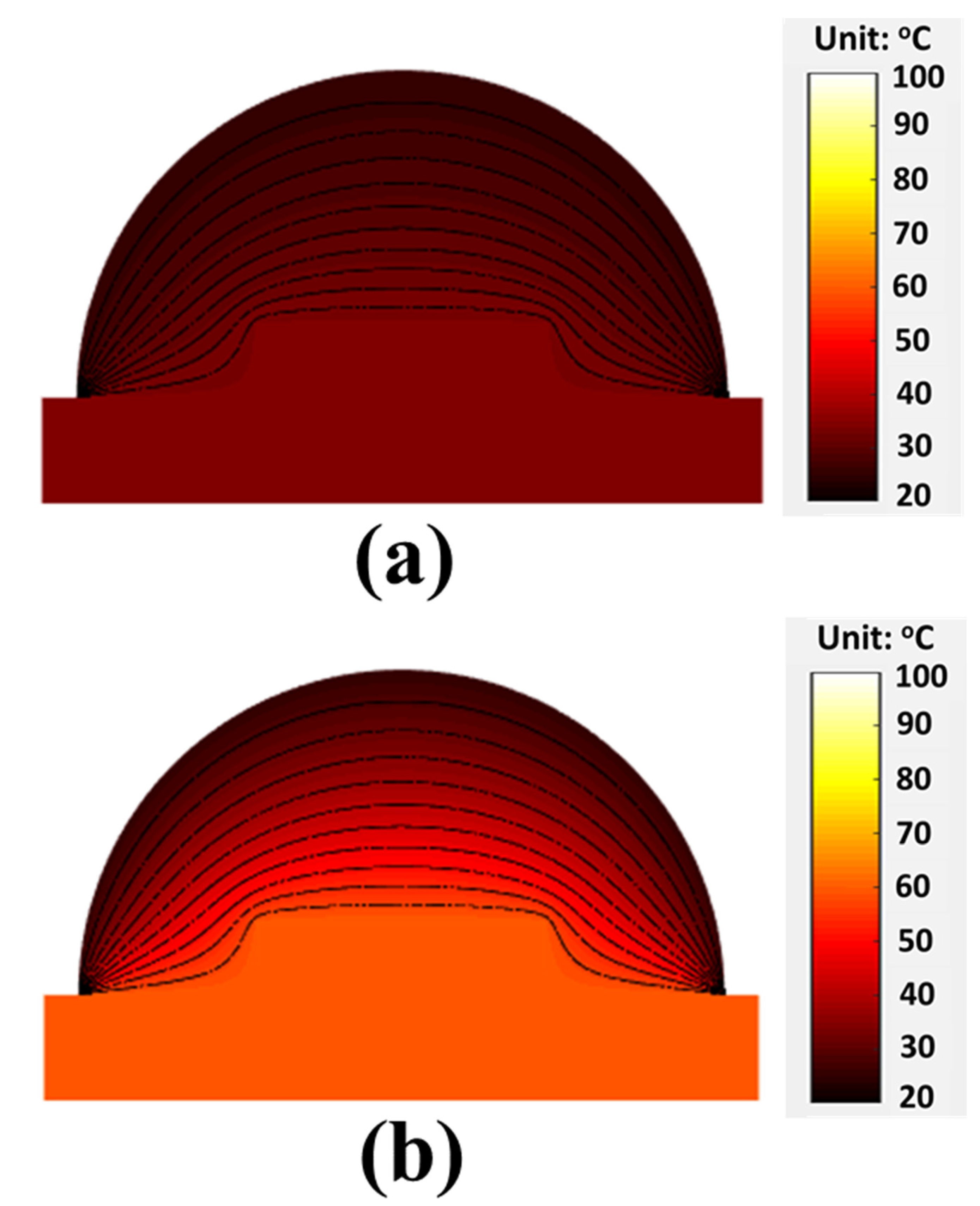

The mathermaltical model for heat transfer of white LEDs is sovled by using Matlab. The output results are collected and analyzed correspondently. In the running model, the influence of two big difference forwarded current is investigated including 50 mA and 250 mA. The value of temperature at juntion domain of LED chip at the forward current of 50 mA, and 250 mA, is 34

oC and 60

oC, respectively. The obtained simulation result is shown in

Figure 4. The influence of forward current is clearly seen. The value of temperature of white LEDs structure is proportional to value of forward electrical current. For the case using 250 mA, the hot spot occurs in the LED and its surrounding domain. The domain far from the LED die showed an lower value of temperature. This is related to the low thermal conductivity of encapsulanted material.

4. Verification of Thermal Model via Comparision with Experimental Measurement of Temperature Distribution at Simular Injection Current as in Simulation

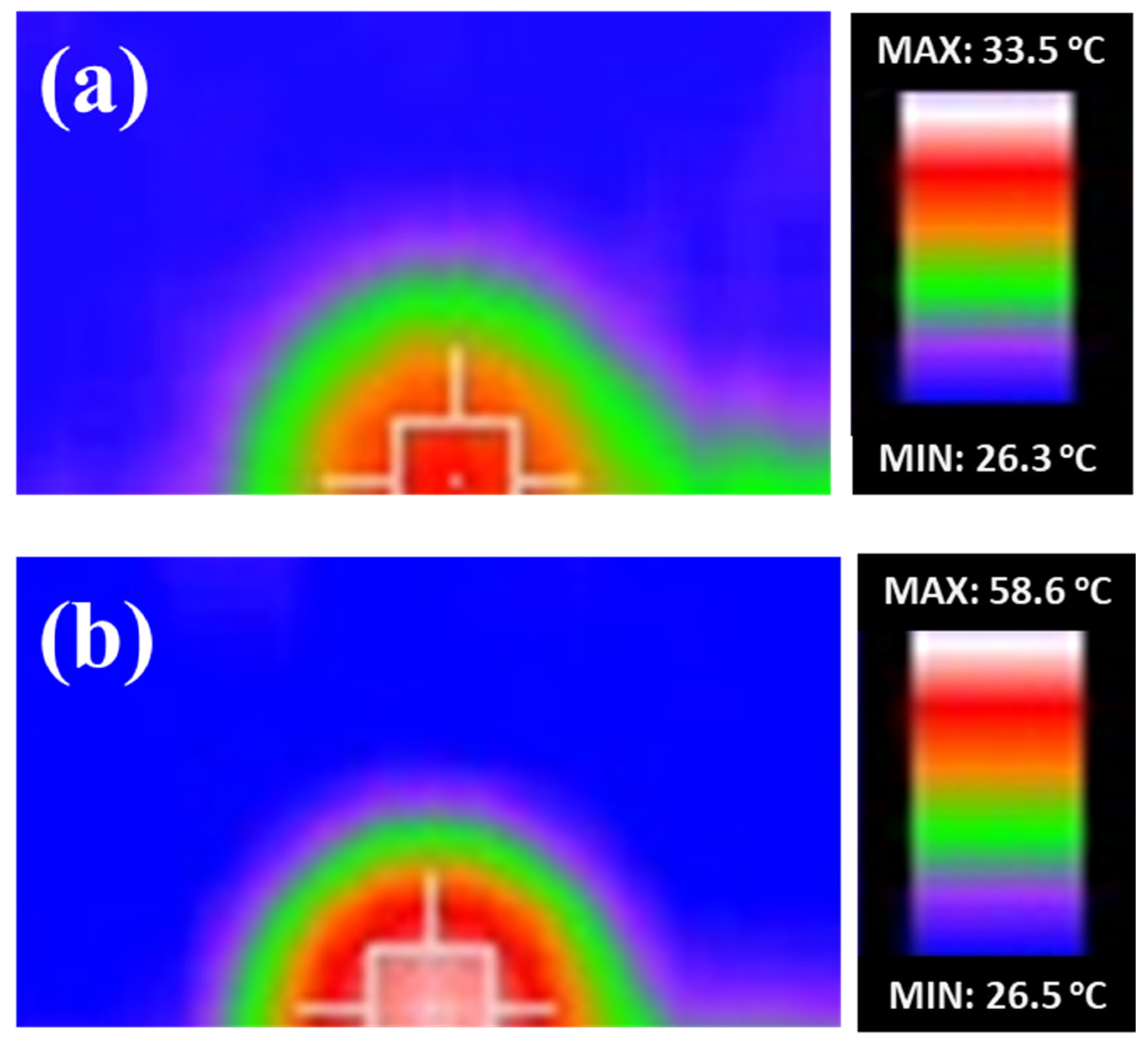

In validation of the proposed model, the comparision between simualtion and experimental result is conducted. In experiment, the camera is used to capture the thermal image which coresponding to the same value of forward currentd as used in the simulation. The experimental results are shown in

Figure 5.

Figure 5(a) shows the temperature values of sample at the forward currents of 50 mA.

The value at the hotest region as using the farward current of 50 mA is 33.5 oC. It is easy to see the non-uniformity in color in the experimental result. This indicates the significant deviation of temperature values in the white LEDs encapsulant volume. The color difference shows a variation of temperature at different location of the white LEDs packaging volume. In comparison generally, the experimental results showed a high similarity to that of simulation results.

Figure 5(b) show the case of the white LEDs is bias forward at a higher injection currents of 250 mA. The value of the hostest domain at the forwared electrical current of 250 mA is 58.6

oC. The thermal behavior show clear influence of driving electrical current on the temperature distribution in LED structure via color difference. The hottest location is at the LED die and phosphor region. The temperature of encasulant region is lower. This indicated that the heat is accumulated at the the LED die and phosphor region higher than the rest region. The origin of this phenomena is caused by the low thermal conductivity of encapsulant material (e.g. 0.2 W/m.K).

In generally, the high similarity between experimental results for the case of 50 mA and 250 mA to simulation results has showed that the success of the thermal model. This model is can apply to study the influence of driving electrical current on the thermal behavior in the packaged structure of white LED, or effect of encapsulant material to the heat accumualted inside the package structure.

5. Conclusisons

In summary, we proposed and demonstrated a thermal model to study the behavior of white LEDs which are packaged using a conformal structure.

The thermal behavior of different injection currents on the temperature distribution in the packaged space is simulated and then verified with empirical measurement. The experimental results showed a high similarity to that of the simulation results.

The obtained result indicated that a location near to the LED chip shows the hottest behavior. The temperature is gradually decrease as the region close to the outer boundary of the encapsulanted lens. It is suggested that the injection current should be selected as suitable to avoid overheating at the LED die region which can reduce the efficiency of the overall pcW-LEDs sample.

The results have indicated the advantages of the thermal model not only in studying the thermal behavior of conformal structure but also in the field of solid-state lighting

References

- Schubert E.-F., Kim J.- K, (2005). Solid-state light sources getting smart. Science, 308, 1274-1278.

- Narendran N., Gu Y., (2005). Life of LED-Based White Light Sources. J. Display Technol., 1, 167-171.

- Schubert, E. (2006). Light-Emitting Diodes (2nd ed.). Cambridge: Cambridge University Press.

- Ching-Cherng Sun, Quang-Khoi Nguyen, Tsung-Xian Lee, Shih-Kang Lin, Chi-Shou Wu, Tsung-Hsun Yang, Yeh-Wei Yu, (2022). Active thermal-fuse for stopping blue light leakage of white light-emitting diodes driven by constant current. Sci Rep., 12, 12433. [CrossRef]

- Quang-Khoi Nguyen , Benoit Glorieux, Gilles Sebe , Tsung-Hsun Yang, Yeh-Wei Yu , Ching-Cherng Sun, (2023). Passive anti-leakage of blue light for phosphor-converted white LEDs with crystal nanocellulose materials. Sci Rep. 13, 13039. [CrossRef]

- Singh P., Tan C.-M, (2016). Degradation Physics of High-Power LEDs in Outdoor Environment and the Role of Phosphor in the degradation process. Sci. Rep., 6, 24052. .

- Davis J.- L., Mills K.-C., Bobashev G., Rountree K.-J., Lamvik M., Yaga R., Johnson C., (2018). Understanding chromaticity shifts in LED devices through analytical models. Microelectron. Reliab., 84, 149-156. [CrossRef]

- Yazdan Mehr M., Bahrami A., Van Driel W.-D., Fan X.-J., Davis J.- L., Zhang G.-Q, (2020). Degradation of optical materials in solid-state lighting systems. Int. Mater. Rev., 65, 102-128. [CrossRef]

- Su Y.-F., Yang S.-Y., Hung T.-Y., Lee C.- C., Chiang K.-N, (2012). Light degradation test and design of thermal performance for high-power light-emitting diodes. Microelectron. Reliab., 52, 794-803.

- Quang-Khoi Nguyen, (2024). An Optimized method of thermoelectric cooler-based thermal management for improving the luminous efficacy of light-emitting diodes. Photonics Lett. Pol.., vol. 16, no. 1, pp. 10–12. [CrossRef]

- Quang-Khoi Nguyen, Thi-Phuong-Loan Nguyen, Van-Tuan Huynh, Nguyet-Thuan Phan, and Huynh-Tuan-Anh Nguyen (2023). An efficient decay model for studying the luminous flux behavior of phosphor-converted white light-emitting diodes. Photonics Lett. Pol., vol. 15, no. 4, pp. 72–74. [CrossRef]

- Krzysztof Baran, Marcin Leśko, Henryk Wachta, and Antoni Różowicz, (2019). Thermal Modeling and Simulation of High Power LED Module, AIP Conference Proceedings., 2078, 020048.

- Han-Kuei Fu, Chien-Ping Wang, Hsin-Chien Chiang, Tzung-Te Chen, Chiu-Ling Chen, Pei-Ting Chou, (2013). Evaluation of temperature distribution of LED module. Microelectron. Reliab., 53, 554–559. [CrossRef]

- Chen Maoxing, Xu Chen, Xu Kun, and Zheng Lei, (2013). Thermal simulation and analysis of flat surface flip-chip high power light-emitting diodes. J. Semicond., 34.

- Cher Ming Tan, Preetpal Singh, Wenyu Zhao, and Hao-Chung Kuo, (2018). Physical Limitations of Phosphor layer thickness and concentration for White LEDs. Sci. Rep., 8, 2452. [CrossRef]

- Frank P. Incropera and David P. Dewitt (2002). Fundamentals of Heat and Mass Transfer, Fifth Edition. New York: J. Wiley.

- Quang-Khoi Nguyen, and Thi-Hanh-Thu Vu, (2023). An Efficient Method for Simulating the Temperature Distribution in Regions Containing YAG:Ce3+ Luminescence Composites of White LED. J. Compos. Sci, 7, 301. [CrossRef]

- Trong-Nam Tran, Van-Tuan Huynh, Thi-Hanh-Thu Vu, Nguyet-Thuan Phan, Huynh-Tuan-Anh Nguyen, Quang-Khoi Nguyen, (2024). Study of steady state thermal model for white light LEDs thermal management application at encapsulant level. Photonics Lett. Pol., vol. 16, no. 1, pp. 13–15. [CrossRef]

- Chi-Cuong Tran, and Quang-Khoi Nguyen. (2022). An Efficient Method to Determine the Thermal Behavior of Composite Material with Loading High Thermal Conductivity Fillers. Journal of Composites Science 6 (7), 214. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).