Submitted:

05 December 2024

Posted:

06 December 2024

You are already at the latest version

Abstract

Keywords:

Introduction

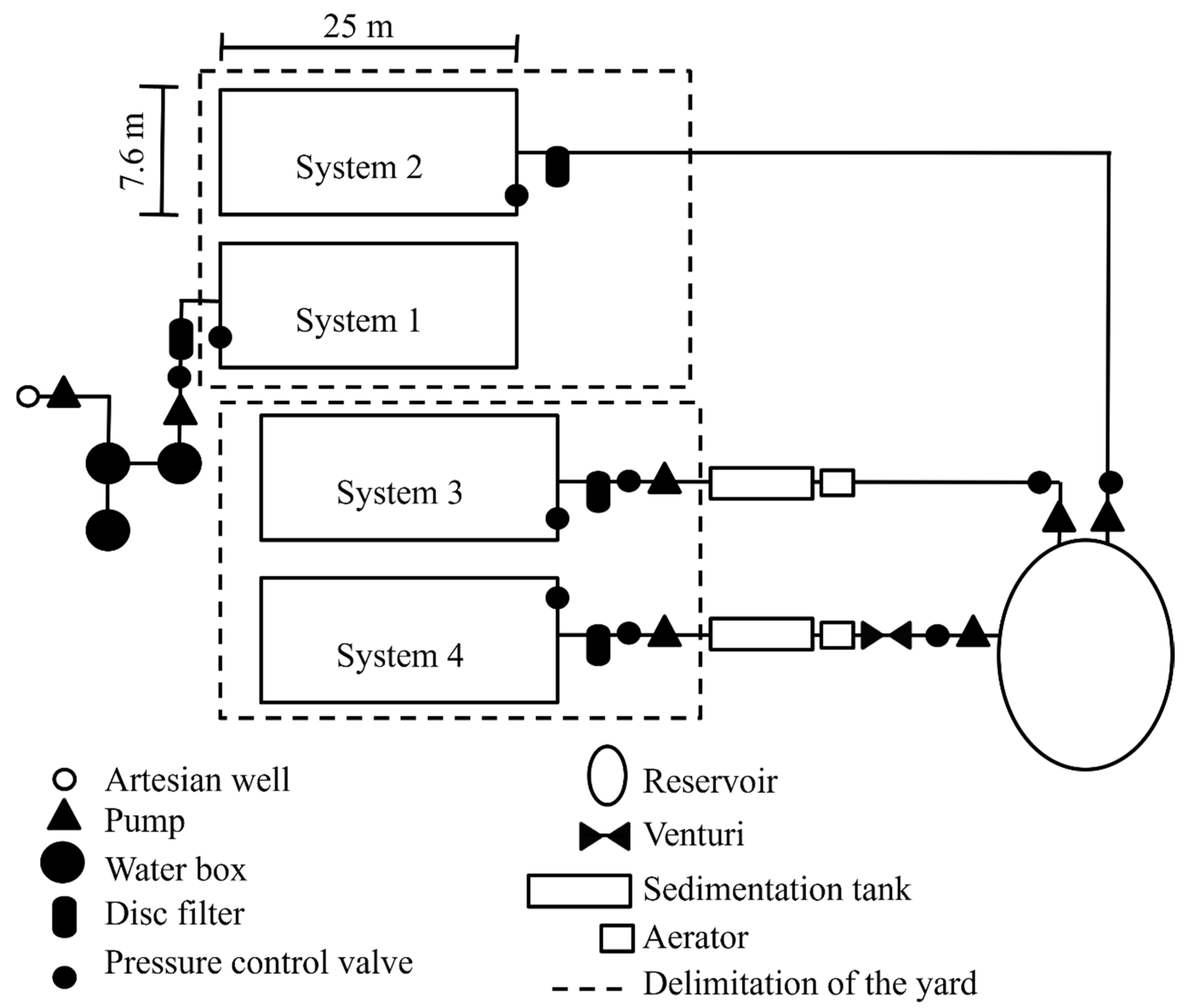

Materials and Methods

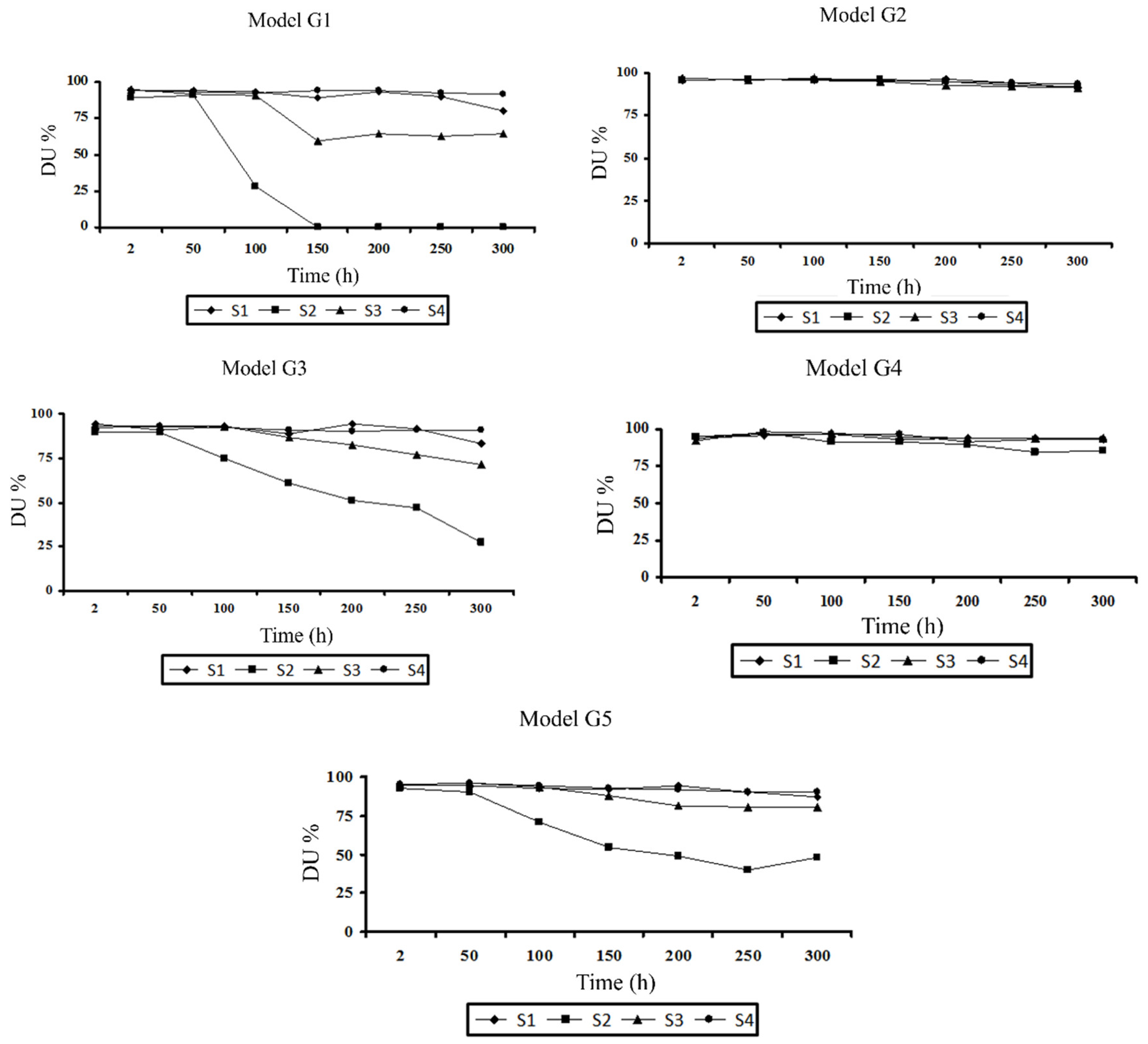

Results and Discussion

Water Analysis Results

Flow Rate Variation of the Dripper Models Throughout the Evaluations

Conclusion

References

- Azevedo Neto, J.M. Técnica de Abastecimento e Tratamento de Água, 3rd ed. CETESB/ASCETESB: São Paulo, Vol. 2, 1987; 320 p.

- Cararo, D.C. et al. Analysis of clogging in drip emitters during wastewater irrigation. Applied Engineering in Agriculture 2006, 22(2), 251–257. [CrossRef]

- Coelho, R.D. et al. Caracterização hidráulica de gotejadores autocompensantes expostos à aplicação dinâmica de cloro livre (Parte II). Irriga 2008, 13(3), 411–425.

- Cordeiro, E. de A. Influência do tratamento de água ferruginosa no desempenho de sistema de irrigação por gotejamento. Viçosa. 2002. 92 f. Dissertation (Mestrado em Engenharia Agrícola), Universidade Federal de Viçosa.

- Costa, C.C. Estudo da susceptibilidade de tubos gotejadores ao entupimento por precipitados químicos de ferro. Lavras. 2000. 85 f. Dissertation (Mestrado em Engenharia Agrícola) Universidade Federal de Lavras.

- Denículi, W. et al. Uniformidade de distribuição de água, em condições de campo num sistema de irrigação por gotejamento. Revista Ceres 1980, 27(50), 155–162.

- Duran-Ros, M.; Puig-Bargués. J.; Arbat, G.; Barraga, J.; Cartagena, F.R. de. Effect of filter, emitter and location on clogging when using effluents. Agricultural Water Management 2009, 96, 67–79. [CrossRef]

- Ford, H.W. Iron ochre and related sludge deposits in subsurface drain lines. Cooperative Extension Service University of Florida, Gainesville, FL. Circular 671. 8 p. 1993.

- Hernandez, F.B.T.; Petinari, R.A. Qualidade de água para irrigação localizada. XXVII Congresso Brasileiro de Engenharia Agrícola, Lavras. Anais. p. 58–60, 1998.

- Hou, P.; Xiao, Y.; Muhammad, T.; Zhou, B.; Song, P.; Zhou, Y.; ... & Li, Y. Multi-factorial failure of pressure-compensating emitters in drip fertigation systems: An in-situ sampling investigation. Agricultural Water Management 2023, 275, 108036. [CrossRef]

- Keller, J.; Karmeli, D. Trickle irrigation design. Glendora: Rain Bird Sprinkler Manufacturing, 1975. 133p.

- Lequette, K.; Ait-Mouheb, N.; Adam, N.; Muffat-Jeandet, M.; Bru-Adan, V.; Wery, N. Effects of the chlorination and pressure flushing of drippers fed by reclaimed wastewater on biofouling. Science of the Total Environment 2021, 758, 143598. [CrossRef]

- Liu, H.; Huang, G. Laboratory experiment on drip emitter clogging with fresh water and treated sewage effluent. Agricultural Water Management 2009, 96, 745–756. [CrossRef]

- Martins, C.C. et al. Aplicação de cloro orgânico no tratamento de tubogotejador utilizado na irrigação com água ferruginosa. Acta Scientiarum Agronomy 2010, 32(1), 1–5.

- Mendes, J. da S.; Chaves, L.H.G.; Chaves, I. de B. Qualidade da água para consumo humano em comunidades rurais do município de Congo, PB. Revista Ciência Agronômica 2008, 39(02), 333–342.

- Merriam, J.L.; Keller, J. Farm Irrigation System Evaluation: A Guide For Management. Logan: Utah State University, 1978. 271p.

- Nakayama, F.S.; Boman, B.J.; Pitts, D.J. Maintenance. In: Lamm, F.R.; Ayars, J.E.; Nakayama, F.S. Microirrigation for Crop Production. Elsevier: Amsterdam, p. 289–430. 2007.

- Pereira, D.J.S.; Lavanholi, R.; de Araújo, A.C.; de Camargo, A. P.; Ait-Mouheb, N.; Frizzone, J.A.; Molle, B. Evaluating sensitivity to clogging by solid particles in irrigation emitters: Assessment of a laboratory protocol. Journal of Irrigation and Drainage Engineering 2020, 146(11), 04020033. [CrossRef]

- Ramachandrula, V.R.; Kasa, R.R. Prevention and treatment of drip emitter clogging: a review of various innovative methods. Water Practice & Technology 2022, 17(10), 2059–2070. [CrossRef]

- Ravina, I.; Paz, E.; Sofer, Z.; Marcu, A.; Shisha, A.; Sagi, G. Control of emitter clogging in drip irrigation with reclaimed wastewater. Irrigation Science 1992, 13, 129-139. [CrossRef]

- Rebosura Jr., M.; Salehin, S.; Pikaar, I.; Keller, J.; Sharma, K.; Yuan, Z. The impact of primary sedimentation on the use of iron-rich drinking water sludge on the urban wastewater system. Journal of Hazardous Materials 2021, 402, 124051.

- Resende, R.S.; Coelho, D.R.; Piedade, S.M.S. Suscetibilidade de gotejadores ao entupimento de causa biológica. Revista Brasileira de Engenharia Agrícola e Ambiental 2000, 4(3), 368–375. [CrossRef]

- Ribeiro, P.A.A. de A.; Coelho, R.D.; Teixeira, M.B. Entupimento de tubos gotejadores convencionais com aplicação de cloreto de potássio (branco e vermelho) via duas qualidades de água. Engenharia Agrícola 2010, 30, 279–287.

- Shen, Y.; Puig-Bargués, J.; Li, M.; Xiao, Y.; Li, Q.; Li, Y. Physical, chemical and biological emitter clogging behaviors in drip irrigation systems using high-sediment loaded water. Agricultural Water Management 2022, 270, 107738. [CrossRef]

- Shi, K.; Lu, T.; Zheng, W.; Zhang, X.; Zhangzhong, L. A review of the category, mechanism, and controlling methods of chemical clogging in drip irrigation system. Agriculture 2022, 12(2), 202. [CrossRef]

- Singh, D.; Patel, N.; Singh, N.; Rosin, K. G.; Yadav, D.; Singh, S.; Gupta, A.K.; Kumawat, A.; Sharma, V.K.; Kumar, M. Emitter Clogging and Hydraulic Performance of Drip System under Different Water Qualities and Placement Techniques. Food Science and Engineering 2021, 112-125. [CrossRef]

- Solé-Torres, C.; Lamm, F.R.; Duran-Ros, M.; Arbat, G.; de Cartagena, F.R.; Puig-Bargués, J. Assessment of microirrigation field distribution uniformity procedures for pressure-compensating emitters under potential clogging conditions. Transa+ctions of the ASABE 2021, 64(3), 1063–1071. [CrossRef]

- Souza, J.A.A. de; Cordeiro, E. de A.; Costa, E.L. da. Aplicação de hipoclorito de sódio para recuperação de gotejadores entupidos em irrigação com água ferruginosa. Revista Brasileira de Engenharia Agrícola e Ambiental 2006, 10(1), 5–9.

- Teixeira, M.B.; Coelho, R.D.; Mélo, R.F. de. Avaliação de danos químicos em membranas de compensação de gotejadores, causados pela aplicação dinâmica de dose extrema de cloro livre (Parte I). Irriga 2008, 13, 392–410.

- Vieira, G.H.S. et al. Recuperação de gotejadores obstruídos devido à utilização de águas ferruginosas. Revista Brasileira de Engenharia Agrícola e Ambiental 2004, 8(1), 1–6.

- Wang, H.; Zhong, H.; Ling, G.; Hu, X.; Wang, W. Response of emitter clogging characteristics to fertilizer type and concentration based on fertigation. Irrigation Science 2023, 41(6), 769–782. [CrossRef]

- Wei, Q. et al. Rapid evaluations of anticlogging performance of drip emitters by laboratorial short-cycle tests. Journal of Irrigation and Drainage Engineering 2008, 134(3), 298–304.

- Yazid, E.A.; Wafi, A.; Saraswati, A. Techniques for reducing iron (Fe) content in groundwater: An article review. Journal of Islamic Pharmacy 2021, 6(1), 40–45. [CrossRef]

- Zhang, J.; Xiao, Y.S.; Wu, Y.; Jia, F.; Li, S.; Zhou, B.; Li, Y. Effects of microorganisms on clogging process and clogging substances accumulation of drip irrigation emitters using the high-sediment water sources. Irrigation Science 2022, 40(6), 845–856. [CrossRef]

| Model | Type | Flow rate (L h-1) |

Internal diameter (mm) | Outer diameter (mm) | Pressure (kPa) |

Dripper spacing (m) |

| G1 | Tape | 0.74 | 15.8 | – | 68.67 – 98.1 | 0.20 |

| G2 | SC1 | 2.30 | 13.7 | 16.0 | 49.05 – 392.4 | 0.75 |

| G3 | SC | 3.40 | 13.7 | 16.0 | 58.86 – 392.4 | 1.00 |

| G4 | SC | 2.30 | 13.7 | 16.0 | 58.86 – 392.4 | 0.75 |

| G5 | SC | 2.10 | 14.8 | 16.0 | 49.05 – 343.3 | 0.75 |

| Iron content in irrigation water (mg L-1) | ||||||||||

| Time of operation (h) | Water source | System 2 | System 3 | System 4 | ||||||

| 1 | 2, 3 and 4 | F* | Dr | St | F | Dr | St | F | Dr | |

| 0 | < 0.10 | 2.80 | 2.60 | 2.20 | 2.20 | 2.20 | 2.20 | 2.30 | 2.20 | 1.90 |

| 50 | < 0.10 | 4.00 | 3.90 | 3.70 | 3.30 | 3.40 | 3.40 | 3.80 | 3.40 | 3.40 |

| 100 | < 0.10 | 2.60 | 2.50 | 2.50 | 2.30 | 2.10 | 2.10 | 1.80 | 1.80 | 1.70 |

| 150 | < 0.10 | 3.00 | 2.80 | 2.00 | 2.40 | 2.40 | 2.30 | 2.80 | 2.70 | 2.50 |

| 200 | < 0.10 | 3.20 | 2.70 | 1.80 | 2.60 | 2.60 | 2.40 | 3.00 | 3.00 | 3.00 |

| 250 | < 0.10 | 2.80 | 2.60 | 1.60 | 2.50 | 2.50 | 2.30 | 2.90 | 3.30 | 3.10 |

| Sources of variation | G.F. | Sum of squares | Mean square | F | Significance |

| System | 3 | 4.6671 | 1.5557 | 65.72 | ** |

| Residue (a) | 12 | 0.2840 | 0.0236 | ||

| Model | 4 | 803.5583 | 200.8896 | 17.777.84 | ** |

| Valve | 1 | 0.03184 | 0.03118 | 2.81 | ** |

| Model × valve | 4 | 0.2071 | 0.0517 | 4.57 | ** |

| Model × assessment | 12 | 5.4318 | 0.4526 | 39.96 | ** |

| System. × valve | 3 | 0.0089 | 0.0029 | 0.26 | |

| Model × syst. × val. | 12 | 0.1231 | 0.0102 | 0.91 | |

| Residue (b) | 108 | 1.2234 | 0.0113 | ||

| Assessment | 6 | 5.0612 | 0.8435 | 125.09 | ** |

| Ass. × syst. | 18 | 1.2732 | 0.0707 | 10.49 | ** |

| Ass. × model | 24 | 2.5159 | 0.1048 | 15.54 | ** |

| Ass. × val. | 6 | 0.1985 | 0.0330 | 4.90 | ** |

| Ass. × model × val. | 24 | 0.4098 | 0.01707 | 2.53 | ** |

| Ass. × model × syst. | 72 | 4.3111 | 0.0598 | 8.87 | ** |

| Ass. × syst. × val. | 18 | 0.4748 | 0.02637 | 3.91 | ** |

| Ass. × val. × syst. × mod | 72 | 0.4784 | 0.0066 | 0.98 | |

| Residue (c) | 720 | 4.8551 | 0.0067 | ||

| Total | 1119 |

| Mod. | System | Time (h) | ||||||

| 2 | 50 | 100 | 150 | 200 | 250 | 300 | ||

| G1 | S1 | 0.82 a | 0.73 a | 0.71 a | 0.62 a | 0.71 a | 0.68 a | 0.58 a |

| S2 | 0.87 a | 0.77 a | 0.46 b | 0.36 b | 0.37 b | 0.36 b | 0.37 b | |

| S3 | 0.85 a | 0.77 a | 0.71 a | 0.63 a | 0.66 a | 0.68 a | 0.46 ab | |

| S4 | 0.80 a | 0.75 a | 0.77 a | 0.75 a | 0.79 a | 0.71 a | 0.60 a | |

| G2 | S1 | 2.26 a | 2.24 a | 2.25 a | 2.23 a | 2.24 ab | 2.21 ab | 2.09 c |

| S2 | 2.23 a | 2.29 a | 2.28 a | 2.32 a | 2.35 a | 2.35 a | 2.49 a | |

| S3 | 2.34 a | 2.22 a | 2.29 a | 2.33 a | 2.25 ab | 2.27 ab | 2.29 b | |

| S4 | 2.32 a | 2.23 a | 2.22 a | 2.21 a | 2.16 b | 2.14 b | 2.06 c | |

| G3 | S1 | 3.39 a | 3.50 a | 3.38 a | 3.25 ab | 3.39 a | 3.31 a | 3.19 ab |

| S2 | 3.31 a | 3.40 a | 3.16 b | 3.15 b | 3.08 b | 2.94 b | 2.80 c | |

| S3 | 3.41 a | 3.48 a | 3.42 a | 3.34 a | 3.20 ab | 3.25 a | 3.32 a | |

| S4 | 3.46 a | 3.54 a | 3.34 a | 3.33 a | 3.32 a | 3.32 a | 3.12 b | |

| G4 | S1 | 2.42 a | 2.33 c | 2.51 a | 2.15 c | 2.50 ab | 2.37 b | 2.31 b |

| S2 | 2.25 b | 2.17 c | 2.26 b | 2.27 bc | 2.35 bc | 2.19 c | 2.21 b | |

| S3 | 2.48 a | 2.67 b | 2.41 ab | 2.40 b | 2.27 c | 2.42 ab | 2.56 a | |

| S4 | 2.51 a | 2.92 a | 2.52 a | 2.60 a | 2.58 a | 2.54 a | 2.58 a | |

| G5 | S1 | 2.17 a | 2.12 ab | 2.01 a | 1.96 a | 1.97 a | 1.97 a | 1.61 b |

| S2 | 2.05 a | 1.99 b | 1.75 b | 1.53 b | 1.80 b | 1.62 b | 1.54 b | |

| S3 | 2.20 a | 2.13 ab | 2.01 a | 1.97 a | 1.88 ab | 2.00 a | 1.89 a | |

| S4 | 2.20 a | 2.17 a | 2.12 a | 2.08 a | 2.03 a | 1.90 a | 1.77 a | |

| Sources of variation | G.F. | Sum of squares | Mean square | F | Significance |

| System | 3 | 26461.34 | 8820.44 | 906.14 | ** |

| Residue (a) | 4 | 71.12 | 17.78 | ||

| Model | 4 | 17821.44 | 4455.36 | 457.71 | ** |

| Assessment | 6 | 10713.06 | 1785.51 | 183.43 | ** |

| Assessment × model | 24 | 7087.25 | 295.30 | 30.34 | ** |

| Assessment × system | 18 | 11621.65 | 645.64 | 66.33 | ** |

| Model ×system | 12 | 21432.39 | 1786.03 | 183.48 | ** |

| Assess. × model × syst. | 72 | 9660.39 | 134.17 | 13.78 | ** |

| Residue (b) | 136 | 1323.83 | 9.73 | ||

| Total | 279 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).