Submitted:

04 December 2024

Posted:

05 December 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

3. Objectives

3.1. Research Questions

3.2. Purpose

3.3. Novelty

3.4. Hypothesis

4. Methods

4.1. Sample Description

4.1.1. Photovoltaic Cells Samples Description

| Isopropanol | Ethanol | Ethylene Glycol |

|---|---|---|

| No 20 nm SiO2 | No 20 nm SiO2 | No 20 nm SiO2 |

| 1.0 ml | 1.0 ml | 1.0 ml |

| 1.5 ml | 1.5 ml | 1.5 ml |

| 2.0 ml | 2.0 ml | 2.0 ml |

4.1.2. Glass Samples Description

| Isopropanol | Ethanol | Ethylene Glycol |

|---|---|---|

| No 20 nm SiO2 | No 20 nm SiO2 | No 20 nm SiO2 |

| 0.5 ml | 0.5 ml | 0.5 ml |

| 1.0 ml | 1.0 ml | 1.0 ml |

| 1.5 ml | 1.5 ml | 1.5 ml |

| 2.0 ml | 2.0 ml | 2.0 ml |

| Isopropanol | Ethanol | Ethylene Glycol |

|---|---|---|

| No 20 nm SiO2 | No 20 nm SiO2 | No 20 nm SiO2 |

| 0.5 ml | 0.5 ml | 0.5 ml |

| 1.0 ml | 1.0 ml | 1.0 ml |

| 1.5 ml | 1.5 ml | 1.5 ml |

| 2.0 ml | 2.0 ml | 2.0 ml |

4.2. Experimental Details

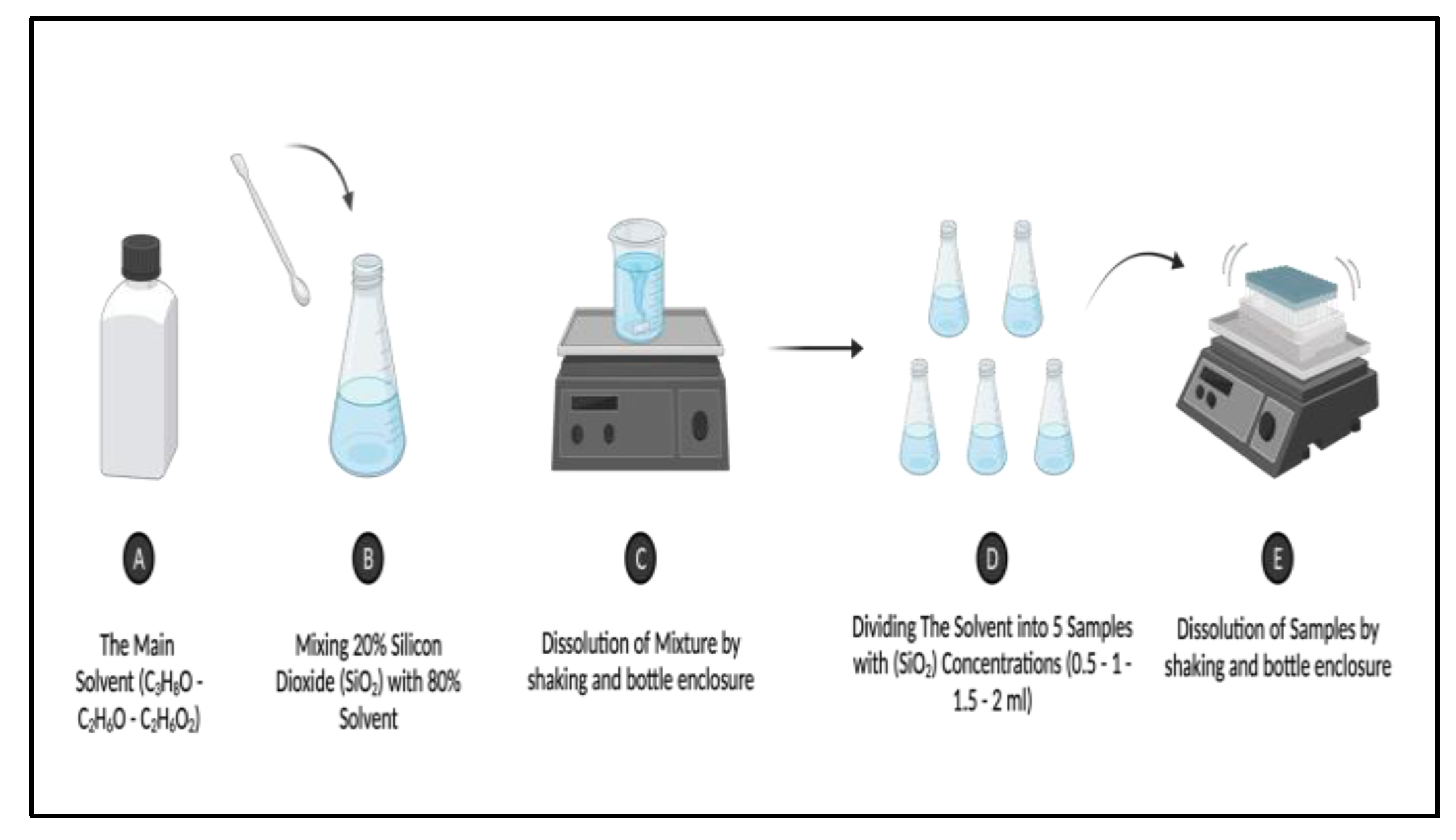

4.2.1. Solvent Preparation

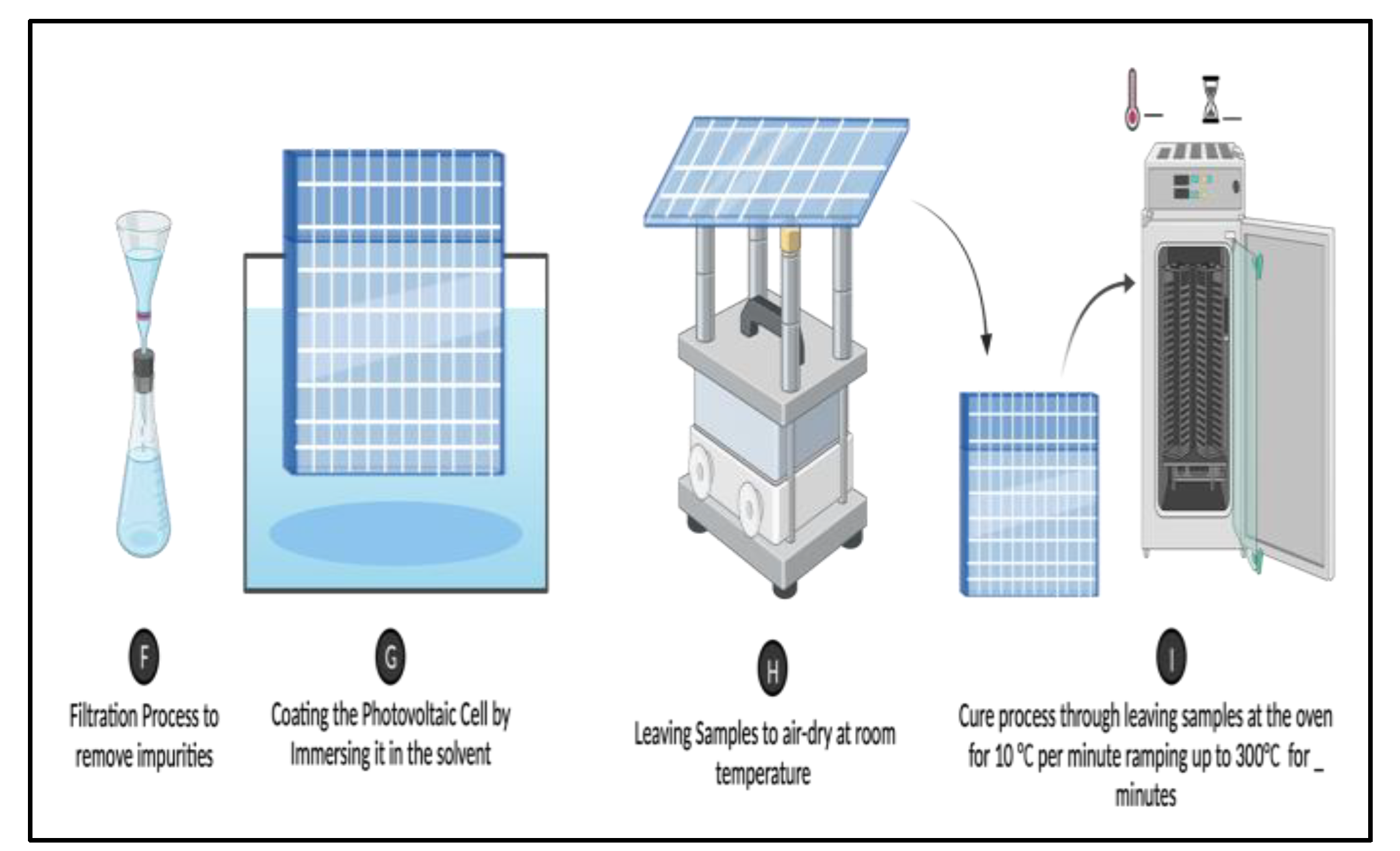

4.2.1.1. Photovoltaics and Large-Sized Glass Samples

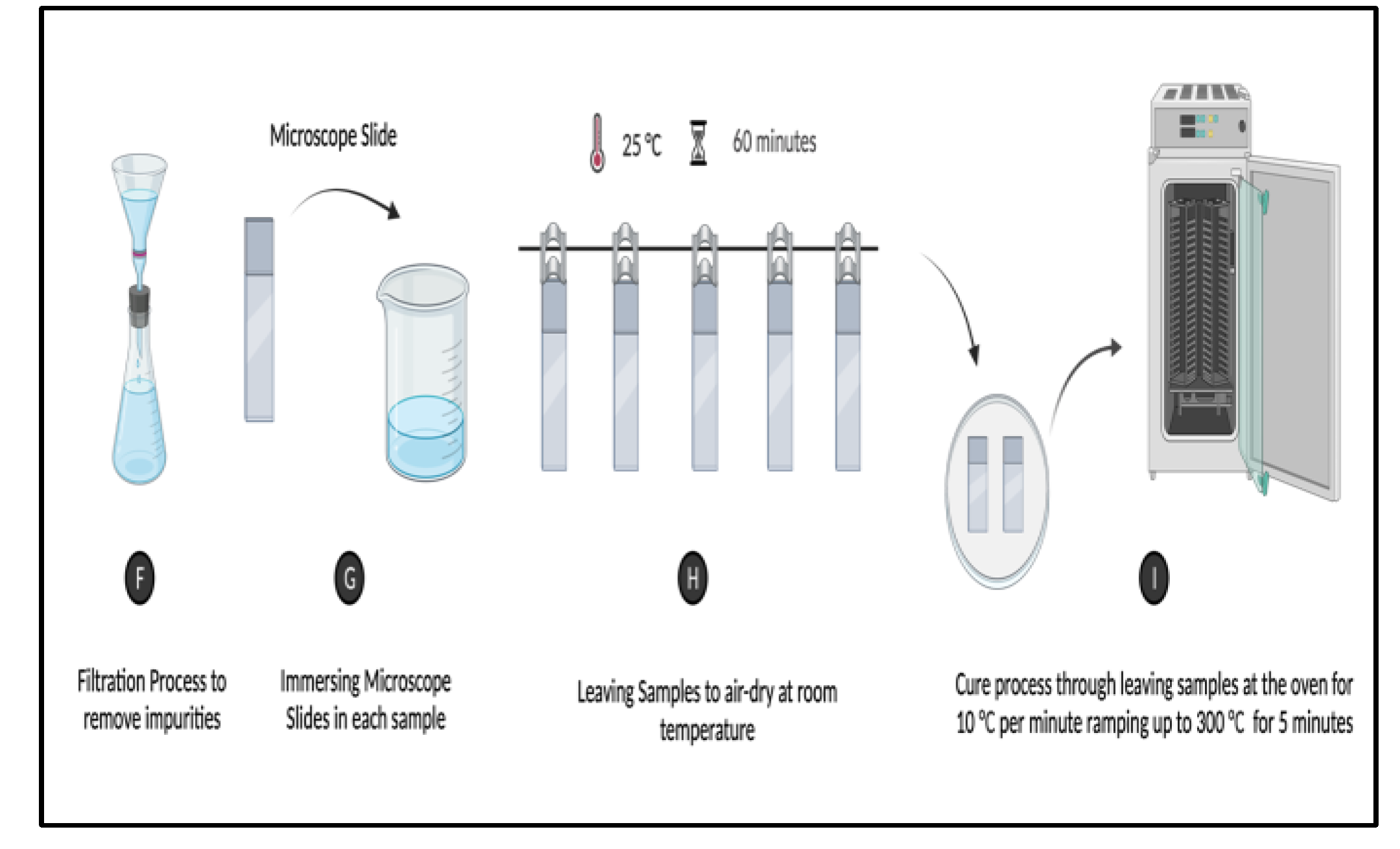

4.2.1.2. Small-Sized Glass Samples

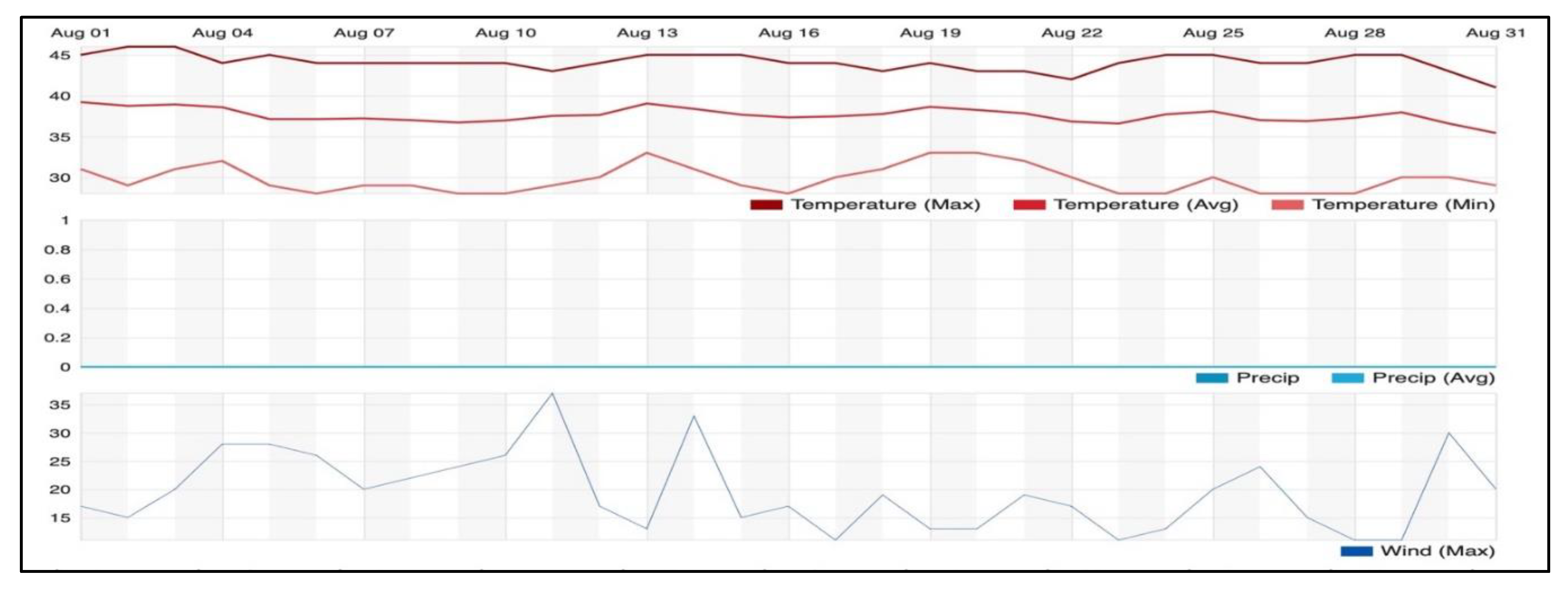

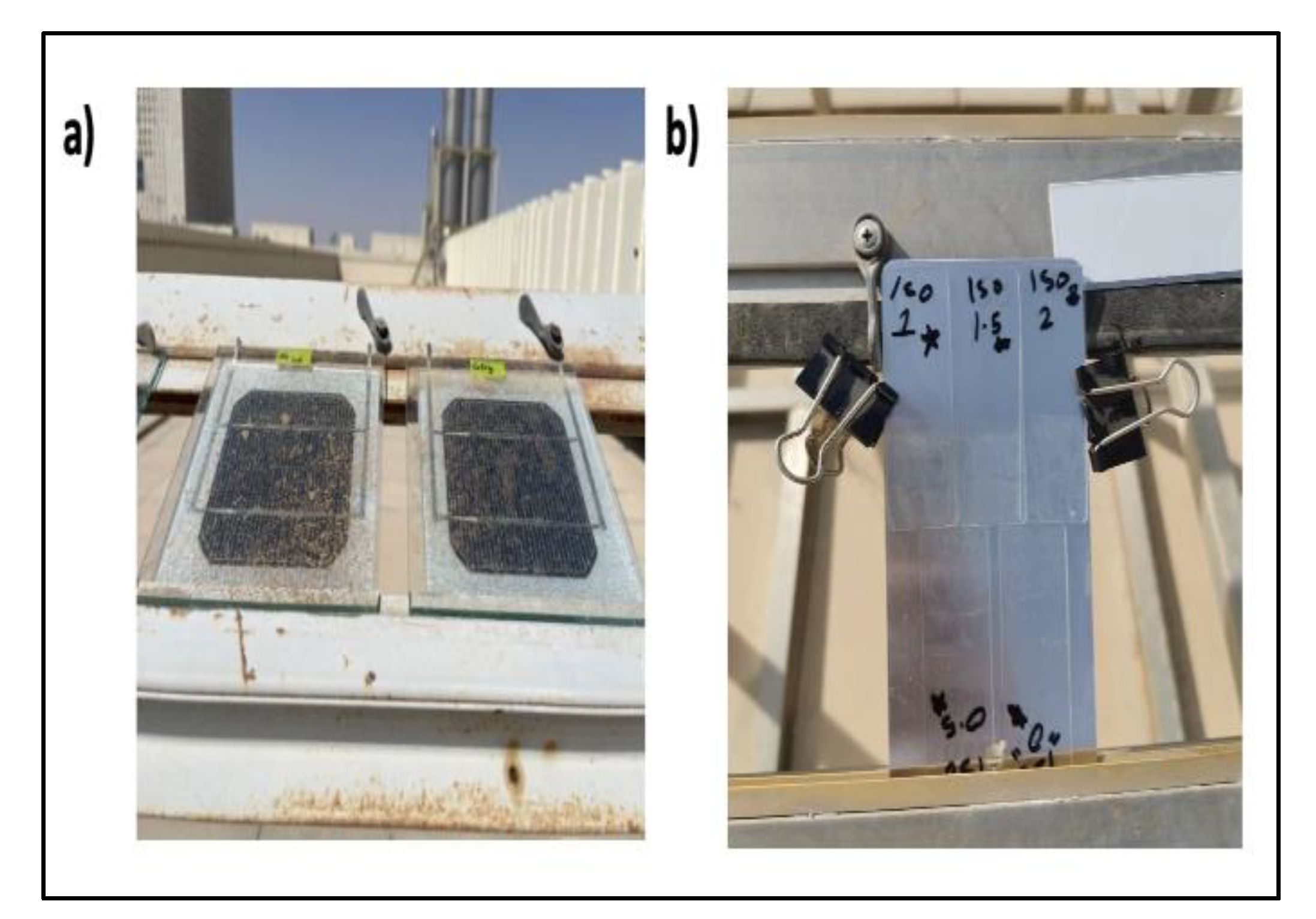

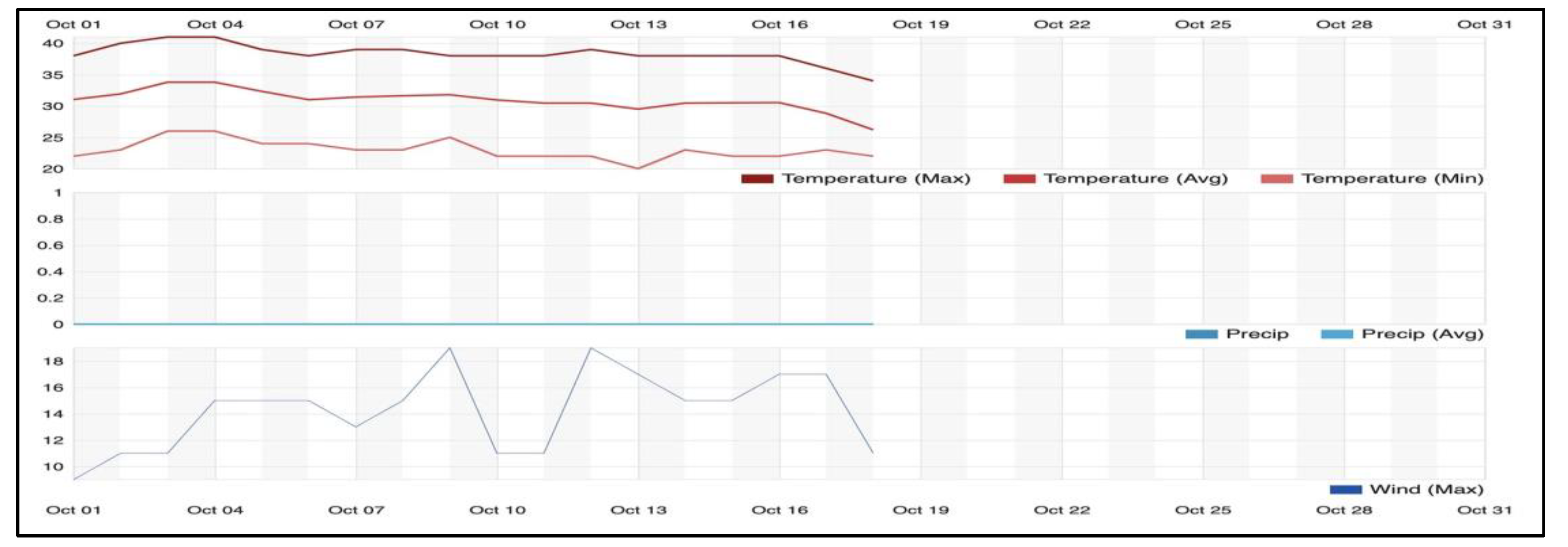

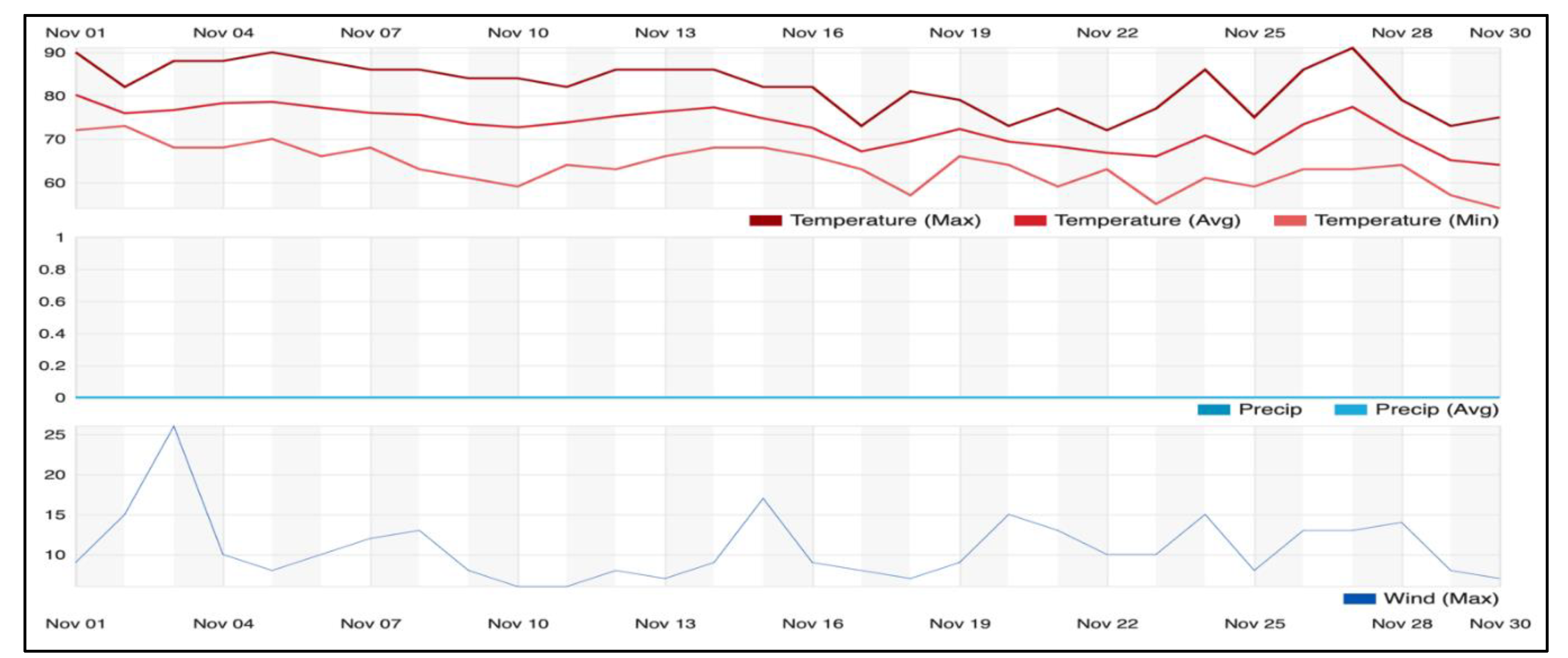

4.2.2. Benchmark Test Setup and Site Characteristics

4.2.2.1. Photovoltaic Cells and Large-Sized Glass Samples

4.2.2.2. Small-Sized Glass Samples

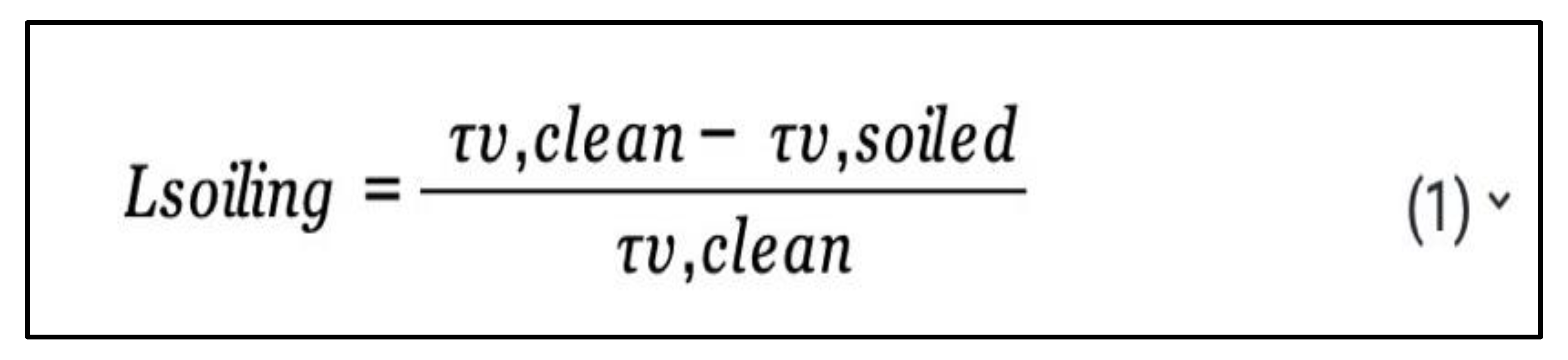

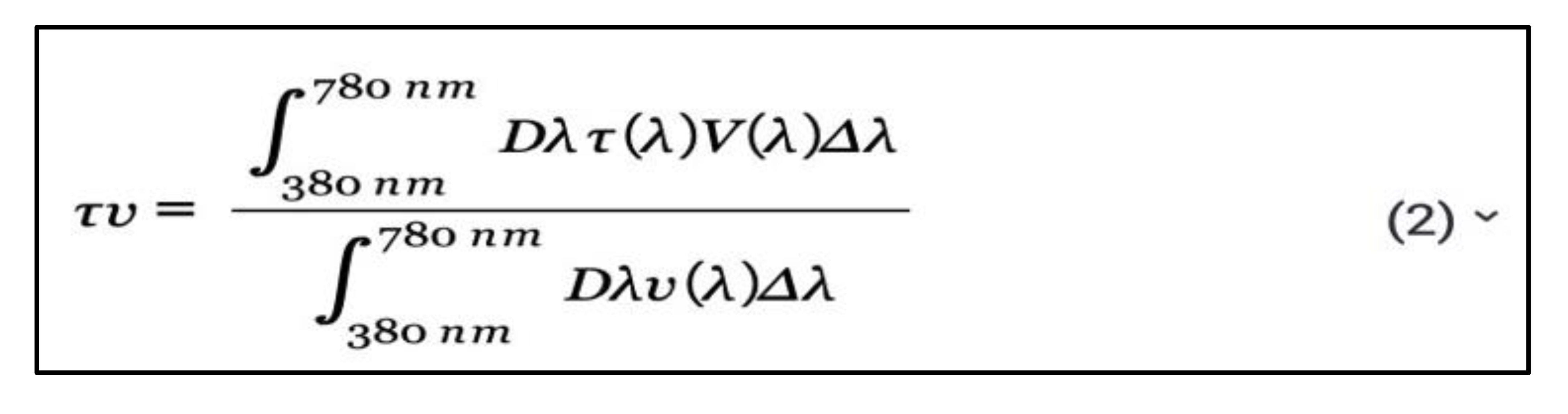

4.2.3. Transmittance Test Measurement

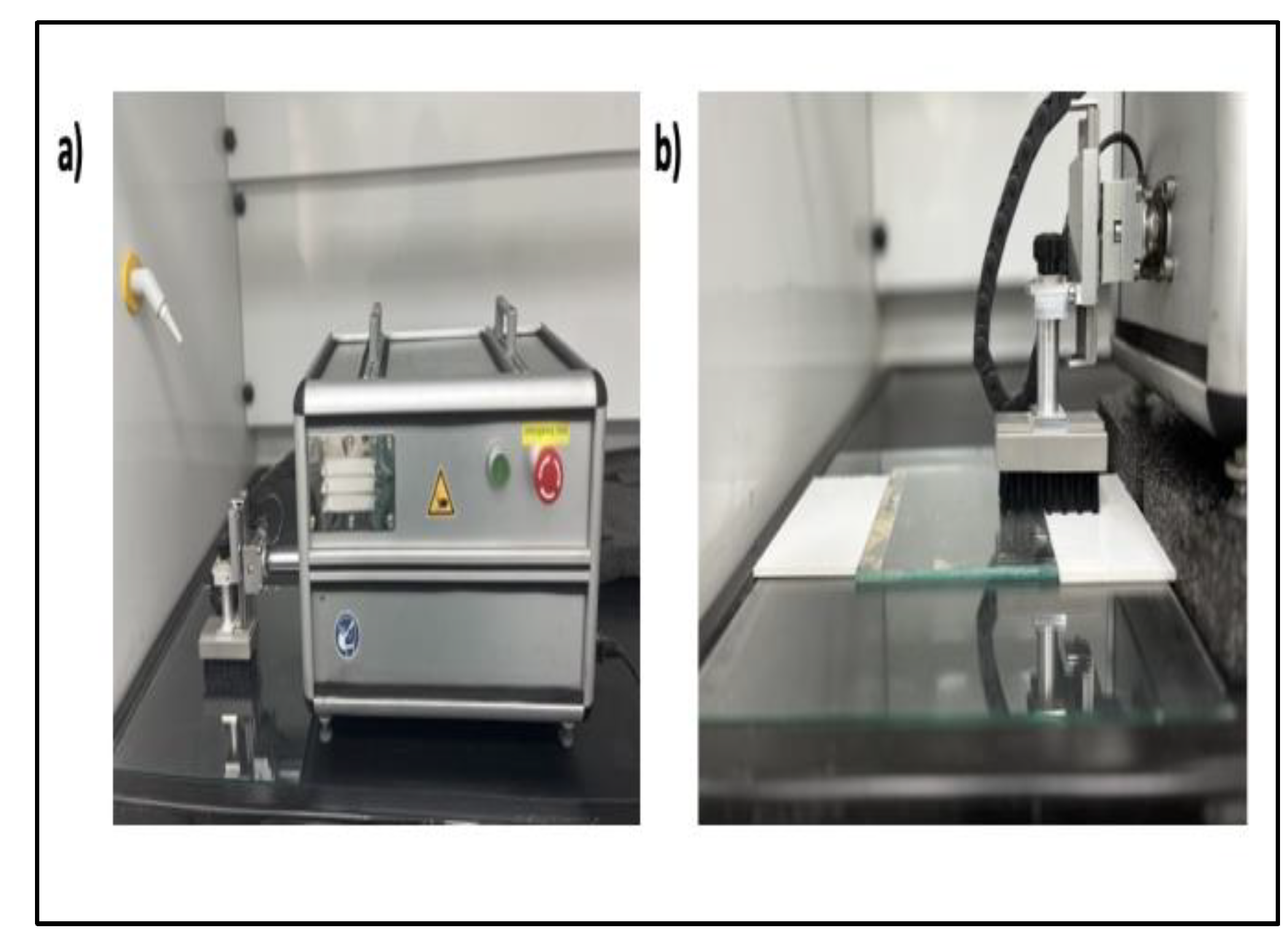

4.2.4. Abrasion Test

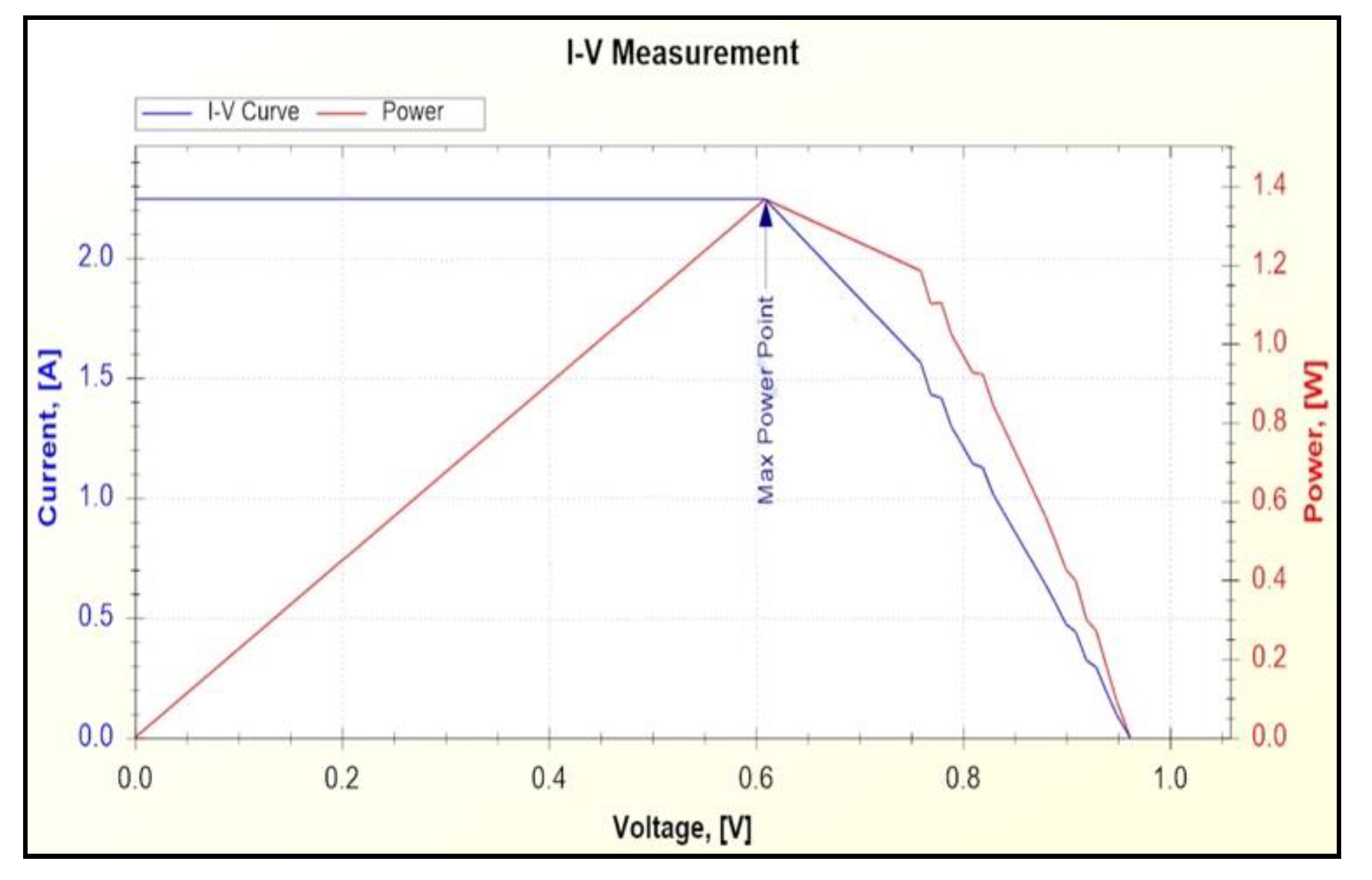

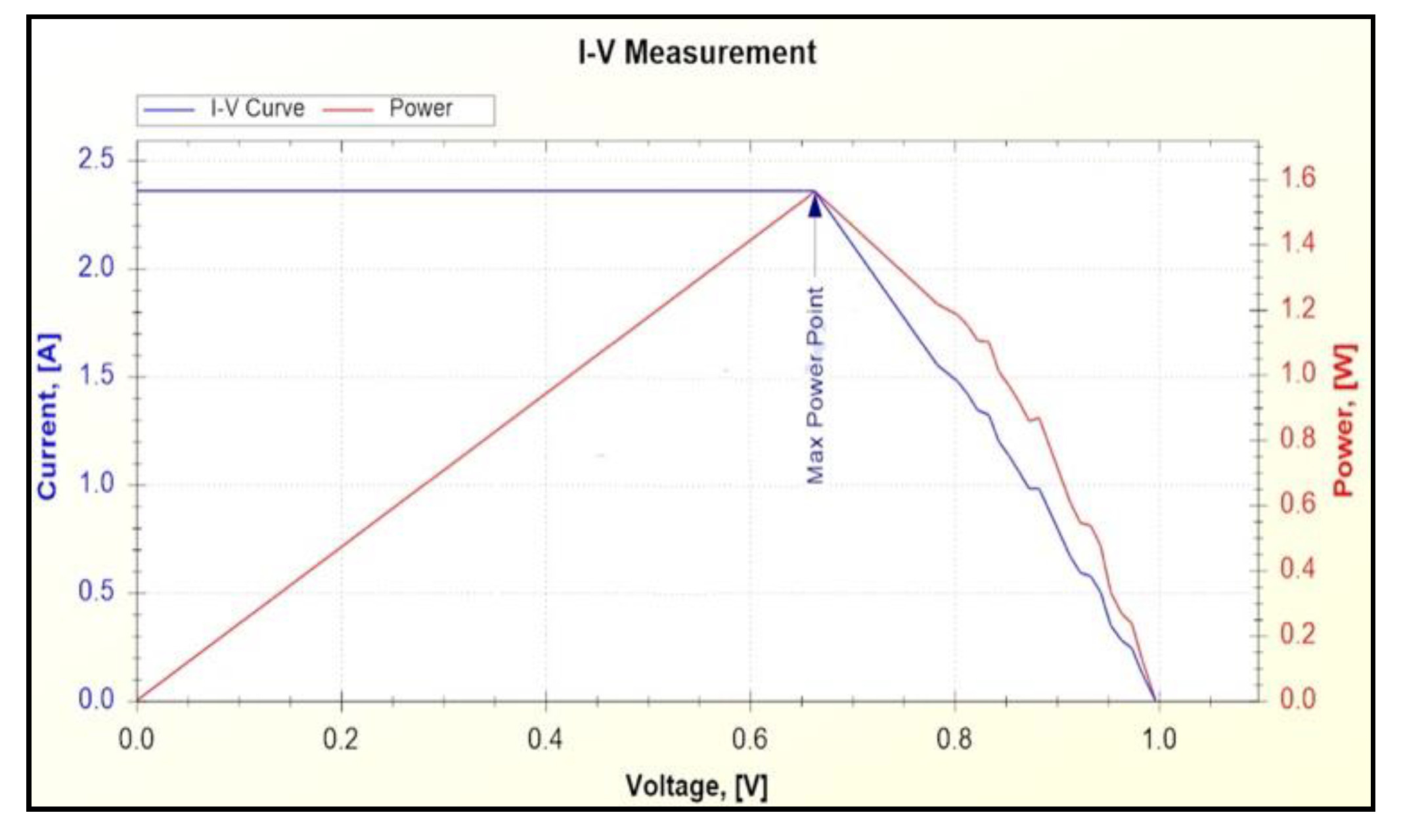

4.2.5. IV Measurement Test

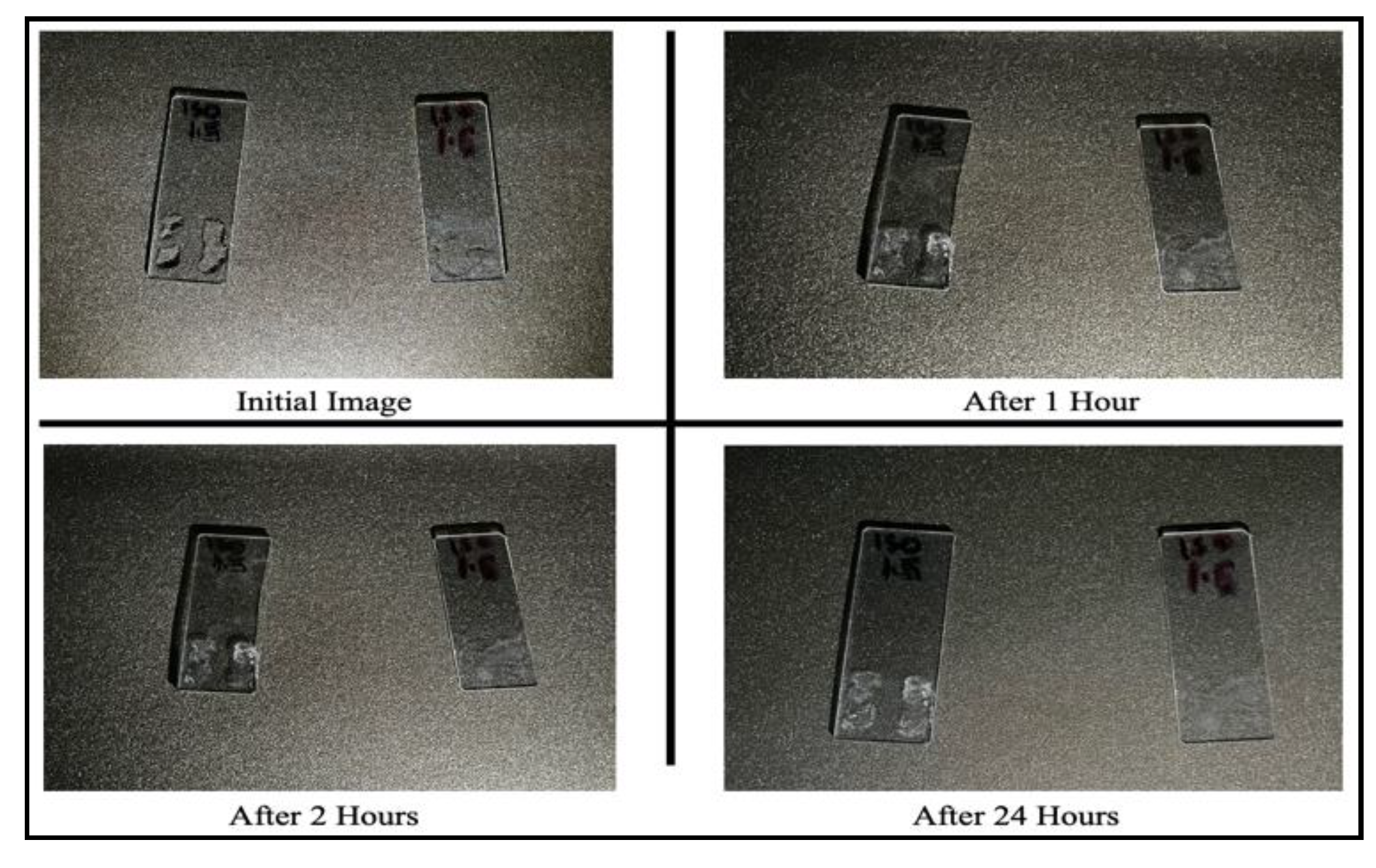

4.2.6. Chemical Stability Test

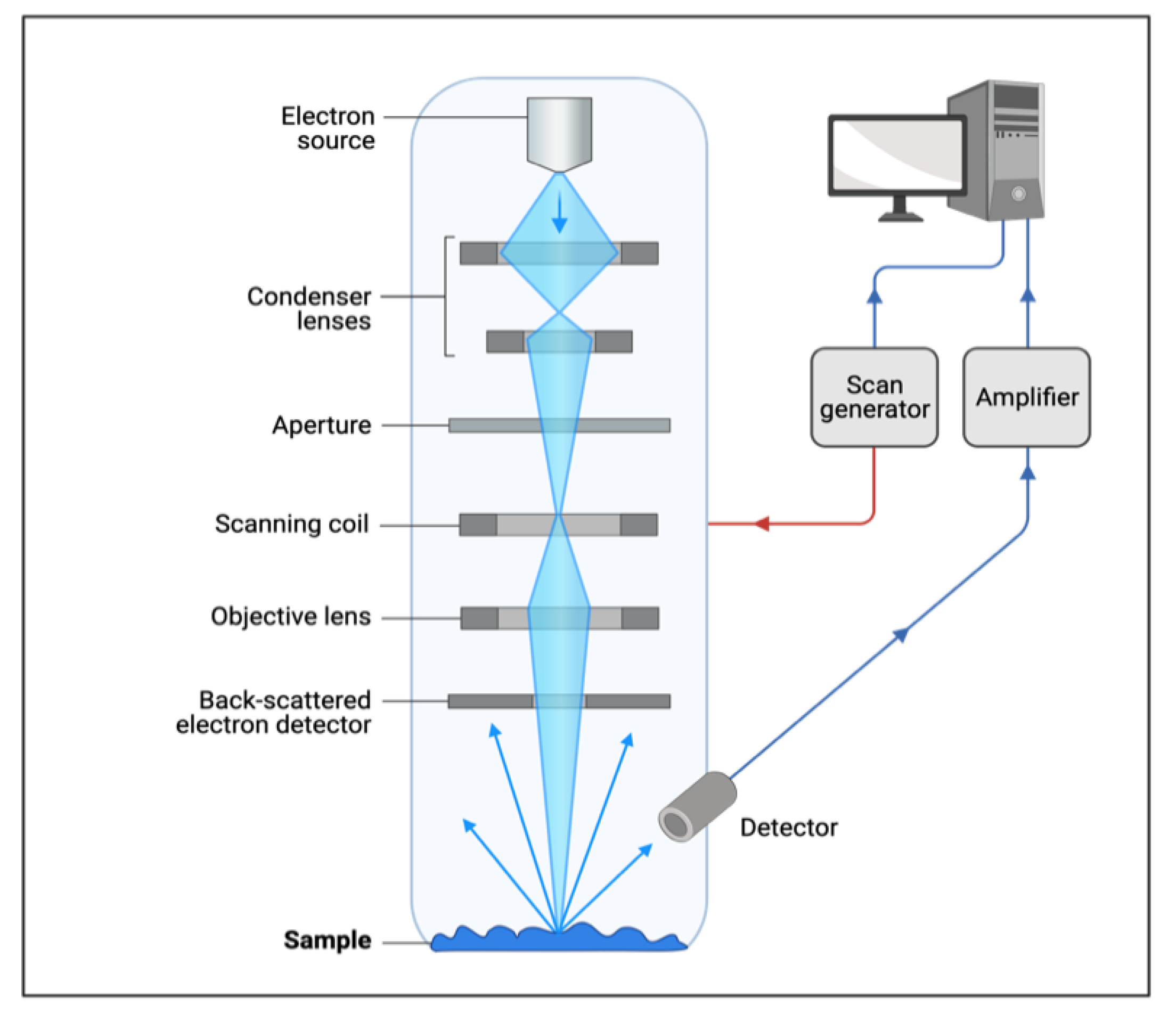

4.2.7. Scanning Electron Microscopy Test

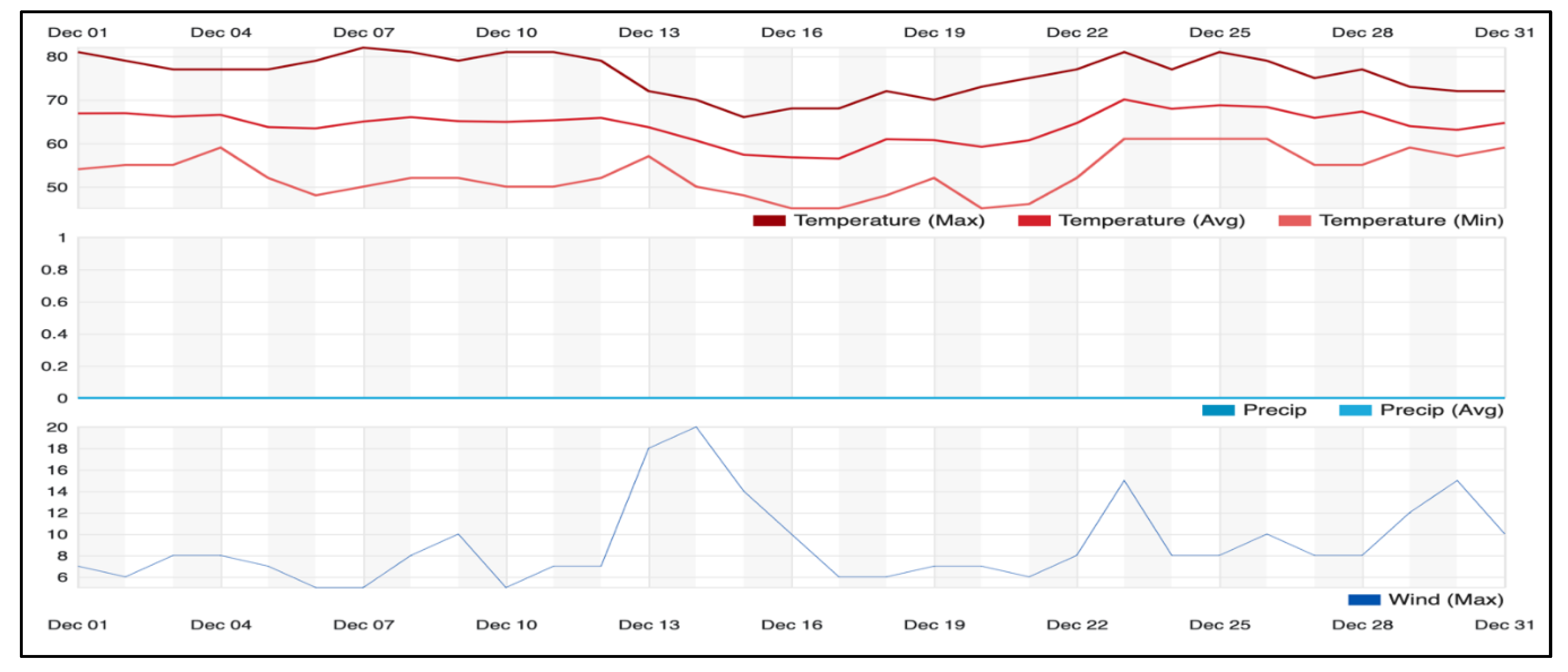

4.2.8. Environmental Parameters

5. Results

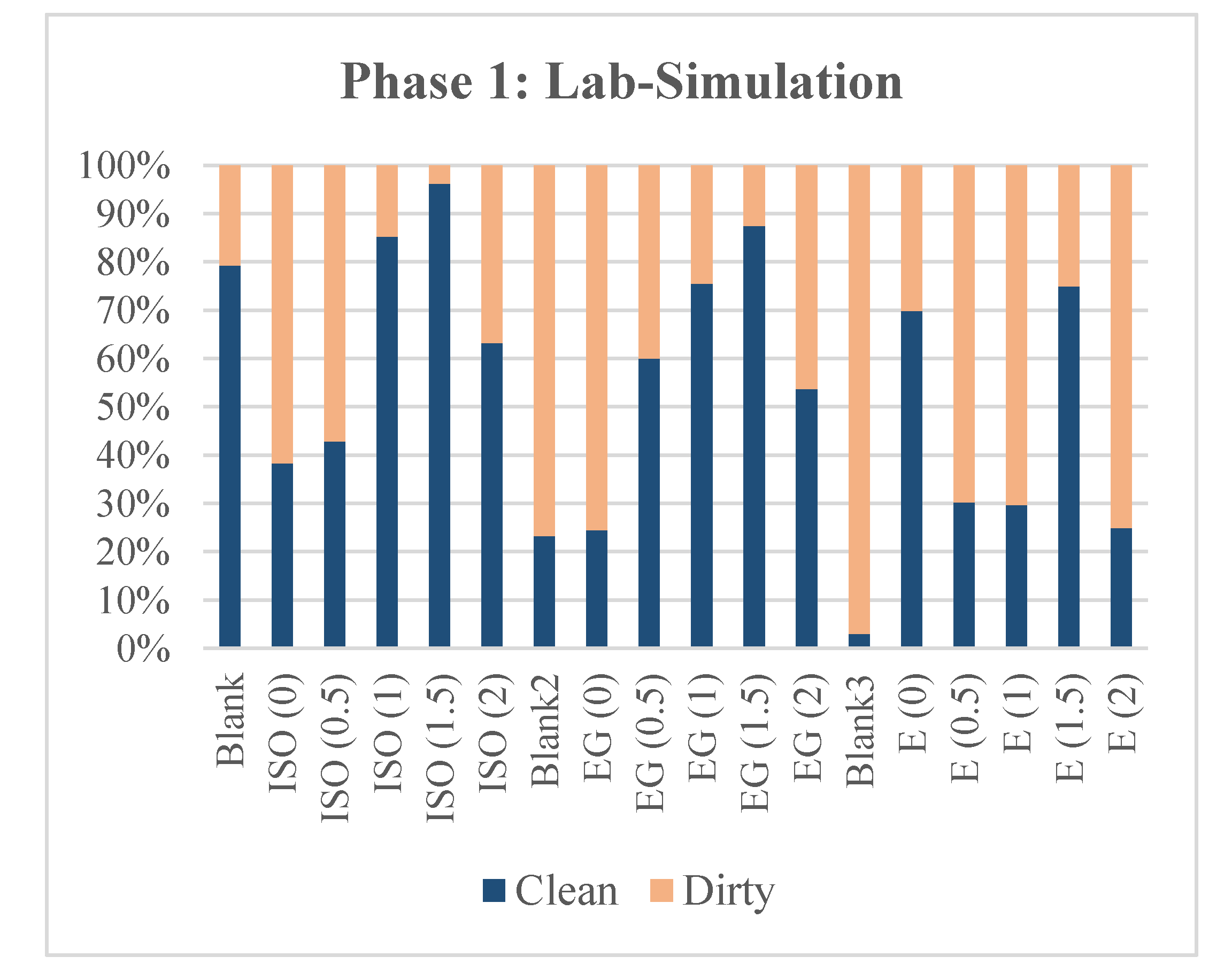

5.1. I-V Measurement Results

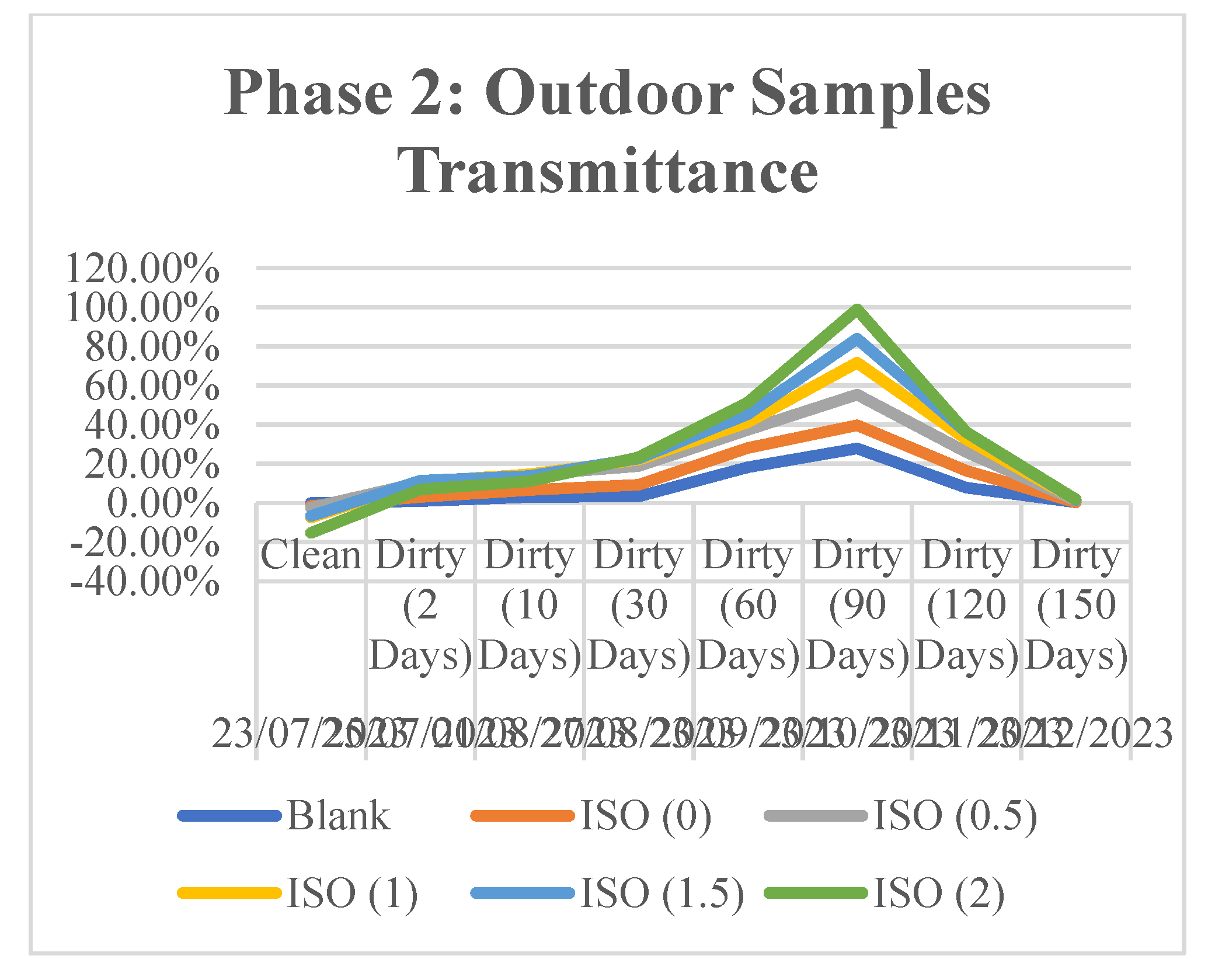

5.2. Transmittance Test Measurement Results

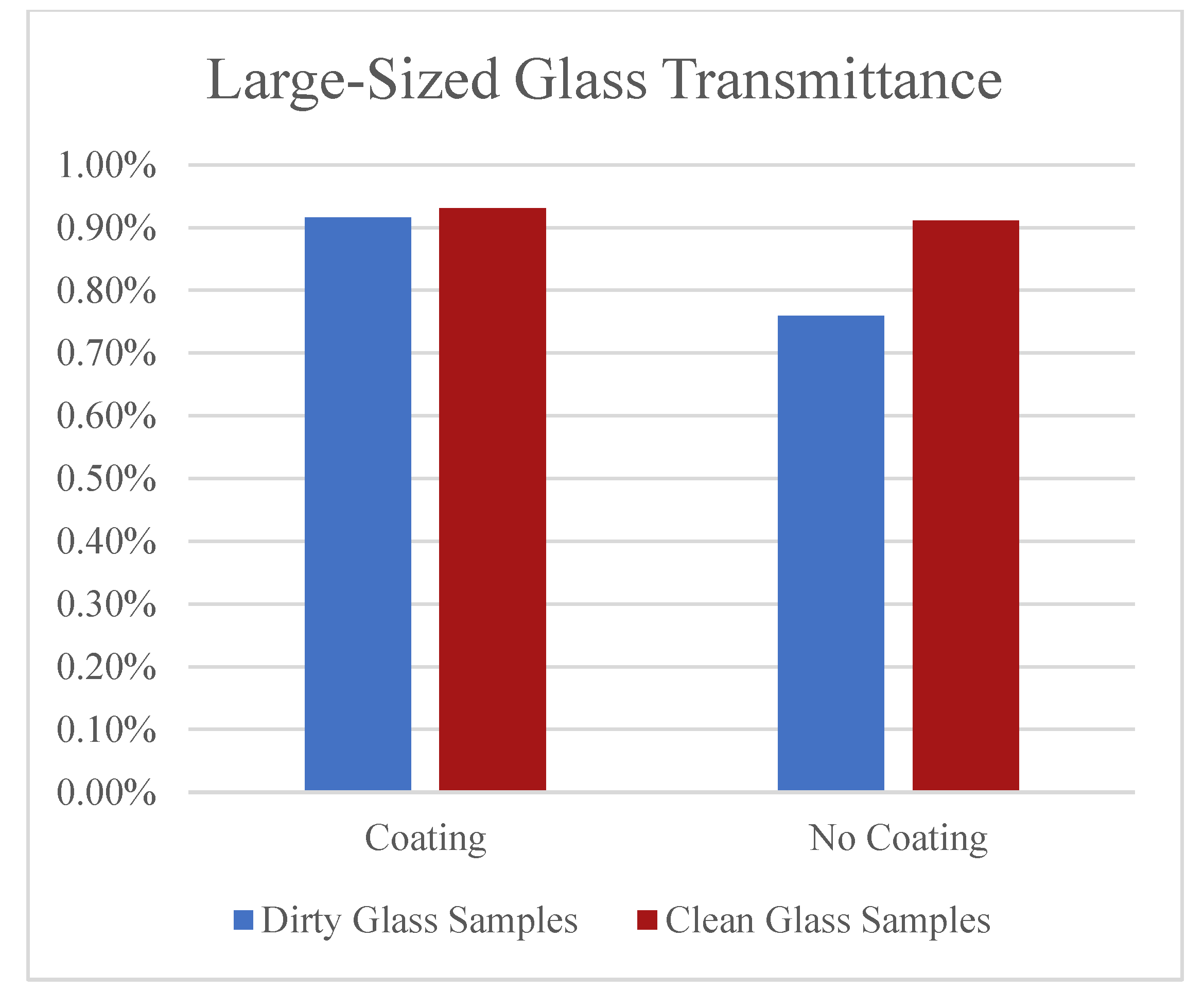

5.2.1. Large-Sized Glass

5.2.2. Small-Sized Glass

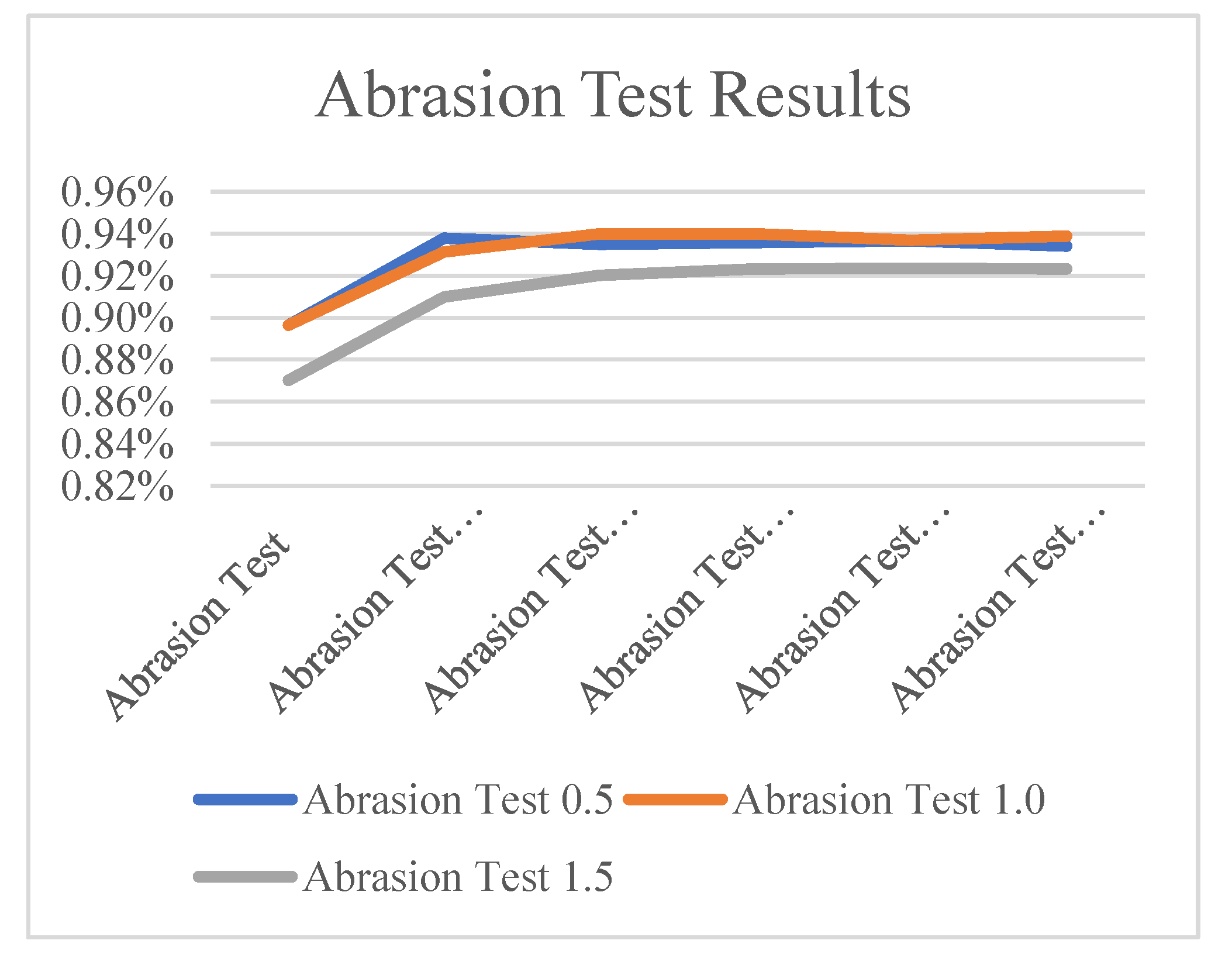

5.3. Abrasion Test Results

5.4. Stability Test Results

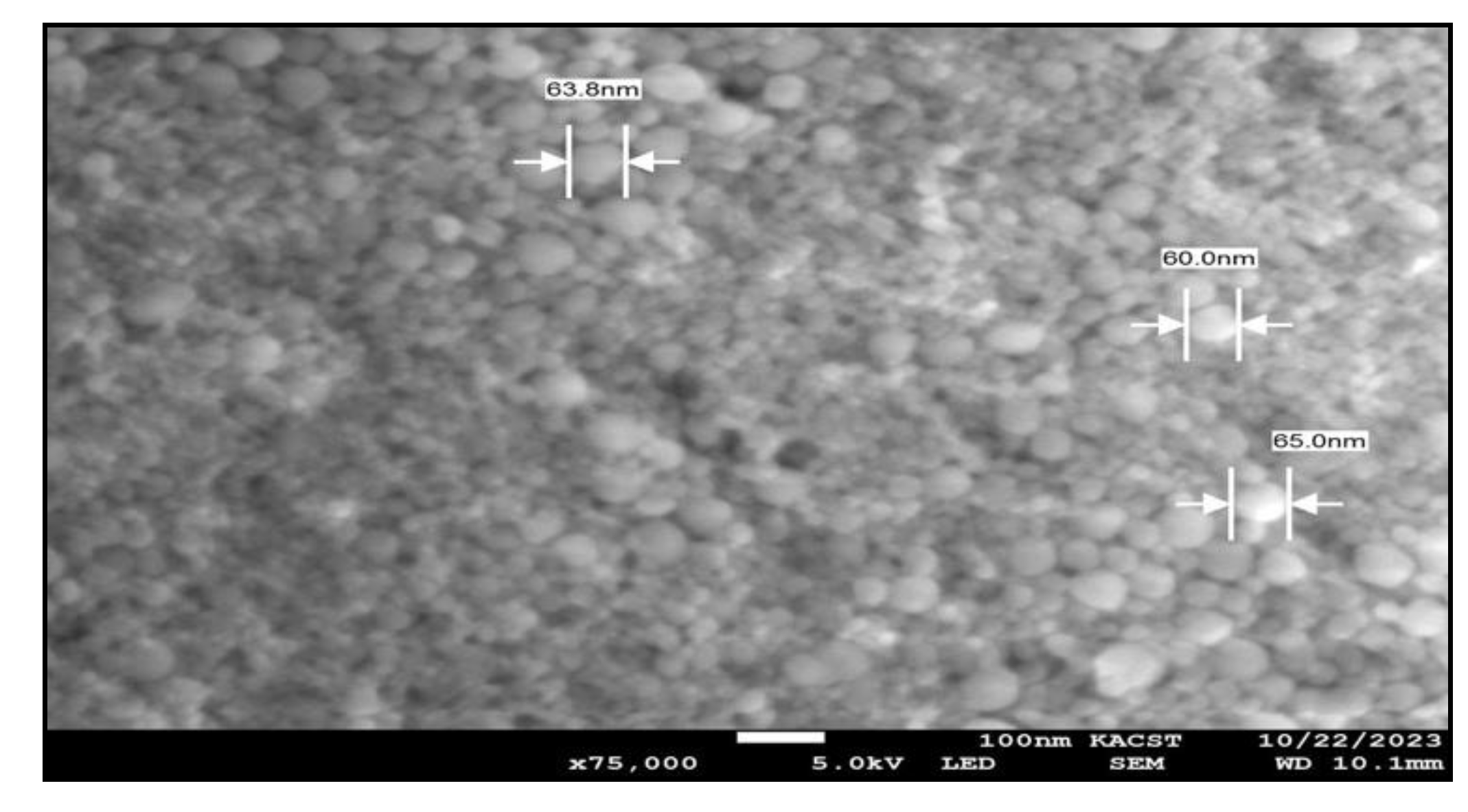

5.5. Scanning Electron Microscopy (SEM) Test Results

6. Conclusion and Discussion

6.1. Discussion

6.1.1. Impact of Anti-soiling Coatings on I-V Evaluations

6.1.2. Light Transmittance and Soil Resistance

6.1.3. Influence of Concentration on Transmittance in Petite Glass Samples

6.1.4. Resistance to Wear and Longevity

6.2. Conclusion

6.2.1. Contributions and Value Add

6.2.2. Impact

6.2.3. Real-World Applications

References

- L. Micheli, M. G. Deceglie, M. Muller, "Predicting photovoltaic soiling losses using environmental parameters: An update," Progress in Photovoltaics: Research and Applications 27 (2019) 210–219.

- D. Goossens, "Wind tunnel protocol to study the effects of anti-soiling and anti-reflective coatings on deposition, removal, and accumulation of dust on photovoltaic surfaces and consequences for optical transmittance," Solar Energy 163 (2018) 131–139.

- C. Zhu, "Deep color, heat-reflective, superhydrophobic and anti-soiling coatings with waterborne silicone emulsion," Solar Energy Materials and Solar Cells 199 (2019) 129–135.

- K. Ilse, "Techno-economic assessment of soiling losses and mitigation strategies for solar power generation," Joule 3 (2019) 2303–2321.

- M. Gul, Y. Kotak, T. Muneer, "Review on recent trend of solar photovoltaic technology," Energy Exploration & Exploitation 34 (2016) 485–526.

- Z. Song, J. Liu, H. Yang, "Air pollution and soiling implications for solar photovoltaic power generation: A comprehensive review," Applied Energy 298 (2021) 117247–117247.

- N. Chundi, "Ambient condition curable, highly weather stable anti-soiling coating for photovoltaic application," Solar Energy Materials and Solar Cells 230 (2021) 111203–111203.

- Z.-S. Huang, "Experimental investigation of the anti-soiling performances of different wettability of transparent coatings: Superhydrophilic, hydrophilic, hydrophobic and superhydrophobic coatings," Solar Energy Materials and Solar Cells 225 (2021) 111053–111053. [CrossRef]

- M. A. M. D. Jesus, Lopes, "Anti-soiling coatings for solar cell cover glass: Climate and surface properties influence," Solar energy materials and solar 185 (2018) 517–523.

- H. Kawamoto, "Electrostatic cleaning equipment for dust removal from soiled solar panels," Journal of Electrostatics 98 (2019) 11–16. [CrossRef]

- De, Shoubhik, et al. "Surface engineering of solar glass covers for soiling related issues by applying electrodynamic screens (EDS)." Surfaces and Interfaces 25 (2021): 101222.

- Elamim, "Performance analysis of innovative cleaning and soiling mitigation solutions in the semi-arid climate of Benguerir Morocco," Heliyon 9 (5) (2023).

- D. Adak, R. Bhattacharyya, H. C. Barshilia, "A state-of-the-art review on the multifunctional self-cleaning nanostructured coatings for PV panels, CSP mirrors and related solar devices," Renewable and Sustainable Energy Reviews 159 (2022) 112145–112145.

- Nayshevsky, Illya, et al. "Fluoropolymer coatings for solar cover glass: Anti-soiling mechanisms in the presence of dew." Solar Energy Materials and Solar Cells 206 (2020): 110281.

- Hossain, Mohammad Istiaque, et al. "Anti-soiling coatings for enhancement of PV panel performance in desert environment: a critical review and market overview." Materials 15.20 (2022): 7139.

- Lisco, Fabiana, et al. "Degradation of hydrophobic, anti-soiling coatings for solar module cover glass." Energies 13.15 (2020): 3811.

- Zhao, Wenjun, and Hao Lu. "Self-cleaning performance of super-hydrophilic coatings for dust deposition reduction on solar photovoltaic cells." Coatings 11.9 (2021): 1059.

- IEA. "Annual solar PV capacity additions by application segment, 2015-2022." IEA, Paris. [URL]. Licensed under CC BY 4.0.

- S. Yamamoto, R. Kuwahara, K. Tanaka, "Effects of chemistry of silicon surfaces on the curing process and adhesive strength for epoxy resin," ACS Applied Polymer Materials 4 (2022) 6038–6046.

- Sayyad, Javed, and Paresh Nasikkar. "Design and development of low-cost, portable, on-field IV curve tracer based on capacitor loading for high power-rated solar photovoltaic modules." IEEE Access, vol. 9, 2021, pp. 70715-70731.

- "Riyadh, Riyadh, Saudi Arabia Weather History." Weather Underground, www.wunderground.com/history/monthly/sa/riyadh/OERK. Accessed 19 Oct. 2023.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).