Submitted:

02 December 2024

Posted:

03 December 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Literature Review

- cost-effectiveness (economy),

- time (price) and

- quality.

-

Name of diagnostic procedure

- ○

- Type of vehicle tested,

- ○

- cost,

- ○

- emission limit.

-

Success rate by vehicle type

- ○

- cost,

- ○

- emissions,

- ○

- success rate in %.

- The final indicator is emissions/cost, which determines the emissions and cost of the diagnostics used. This can be used as a basis for weighting.

1.2. Need for a New Concept: ECO-ECO-Diagnostics

- Ecology: diagnostic tests to maintain a balance between the transport ecosystem, the environment and living beings.

- Economy: diagnostic tests for economical vehicle operation.

2. Modern Vehicle Diagnostics

2.1. Systematization of Vehicle Diagnostics

-

Two main directions of vehicle diagnostics

- Off-board

- On-board

-

Vehicle diagnostics levels

- Deep diagnostics

- Selective diagnostics

-

Accessing diagnostic information

- Global interface

- Subsysteme interface

2.1.1. Main Directions of Vehicle Diagnostics

- OFF-BOARD DIAGNOSTICS:

- ON-BOARD DIAGNOSTICS:

2.1.2. Diagnostic Levels

- selective procedure and method,

- in-depth diagnostic procedure and method.

- Selective method

- Deep diagnostic method

-

ECO-Diagnostics

- ▪

- Emission Diagnostics

- ▪

- Energy consumption diagnostics (e.g., fuel consumption measurement, electrical consumption measurement)

-

Traffic safety diagnostics

- ▪

- Chassis diagnostics

- ▪

- Brake diagnostics

- ▪

- Shock absorber diagnostics

- ▪

- Lighting diagnostics

- ▪

- ADAS diagnostics

-

Other operational diagnostics

- ▪

- General engine diagnostics

- ▪

- Gearbox diagnostics

2.2. Access Diagnostic Information

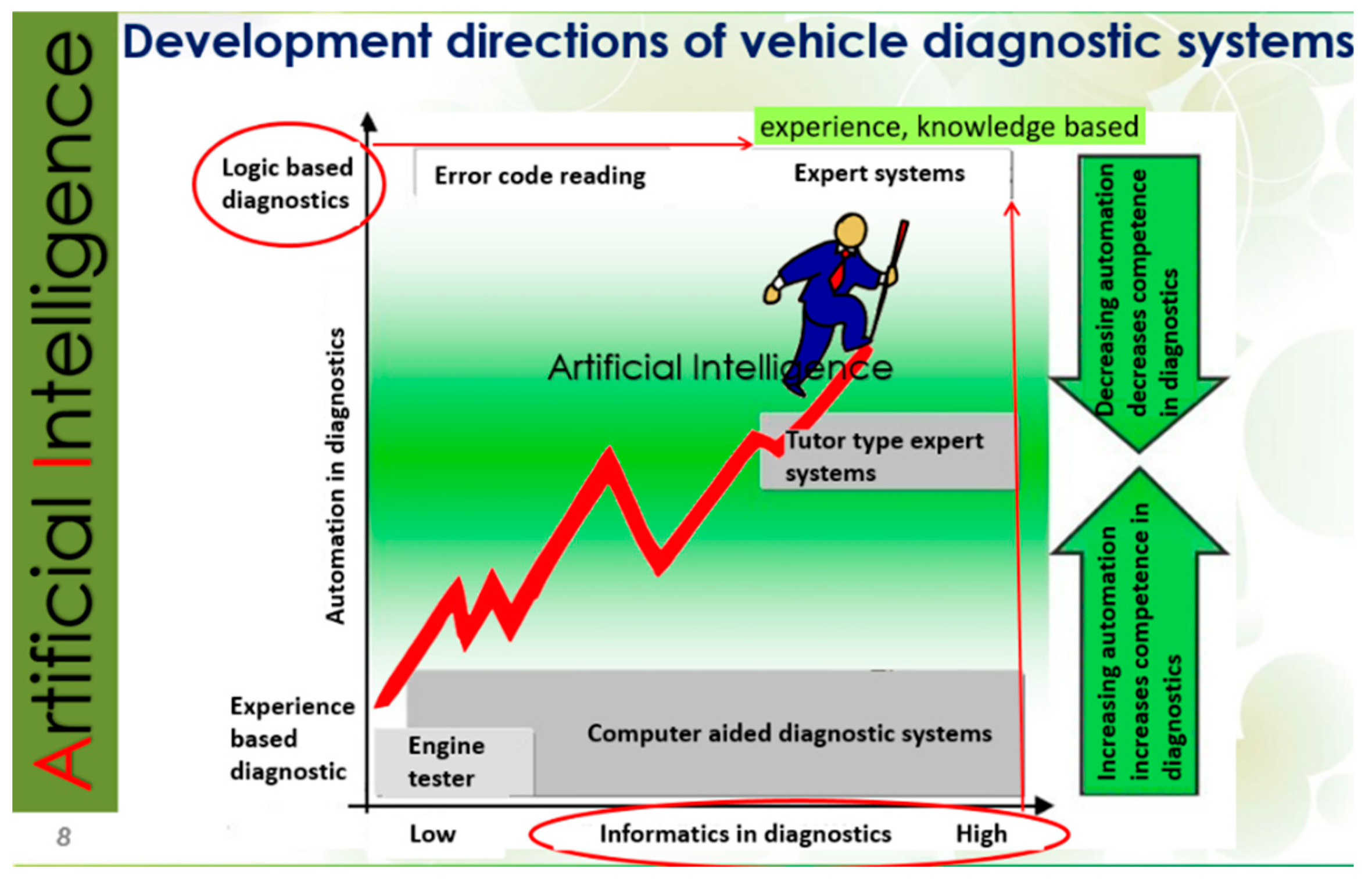

2.3. Complexity of Diagnostics and Artificial Intelligence

| Workshop size | Small workshops / brand-independent car repair shops | Large workshops / brand services | |

|---|---|---|---|

| Vehicle category | |||

| Premium category upper category | 20% of the tasks are diagnostics, 14% are complex cases | 26% of the tasks are diagnostics, 18% are complex cases | |

| Medium category small (compact) category | 12,5% of the tasks are diagnostics, 6% are complex cases | 16% of the tasks are diagnostics, 8% are complex cases | |

3. Methodology: ECO-DIAGNOSTICS as a New Concept

- Ecology: diagnostic tests to maintain a balance between the transport ecosystem, the environment and living beings.

- Economy: diagnostic tests for economical vehicle operation.

| ECOLOGY | ECONOMY |

|---|---|

| Emission | Fuel consumption |

|

|

| Abrasion | Traffic safety |

|

|

| Noise-emission | Lifetime |

|

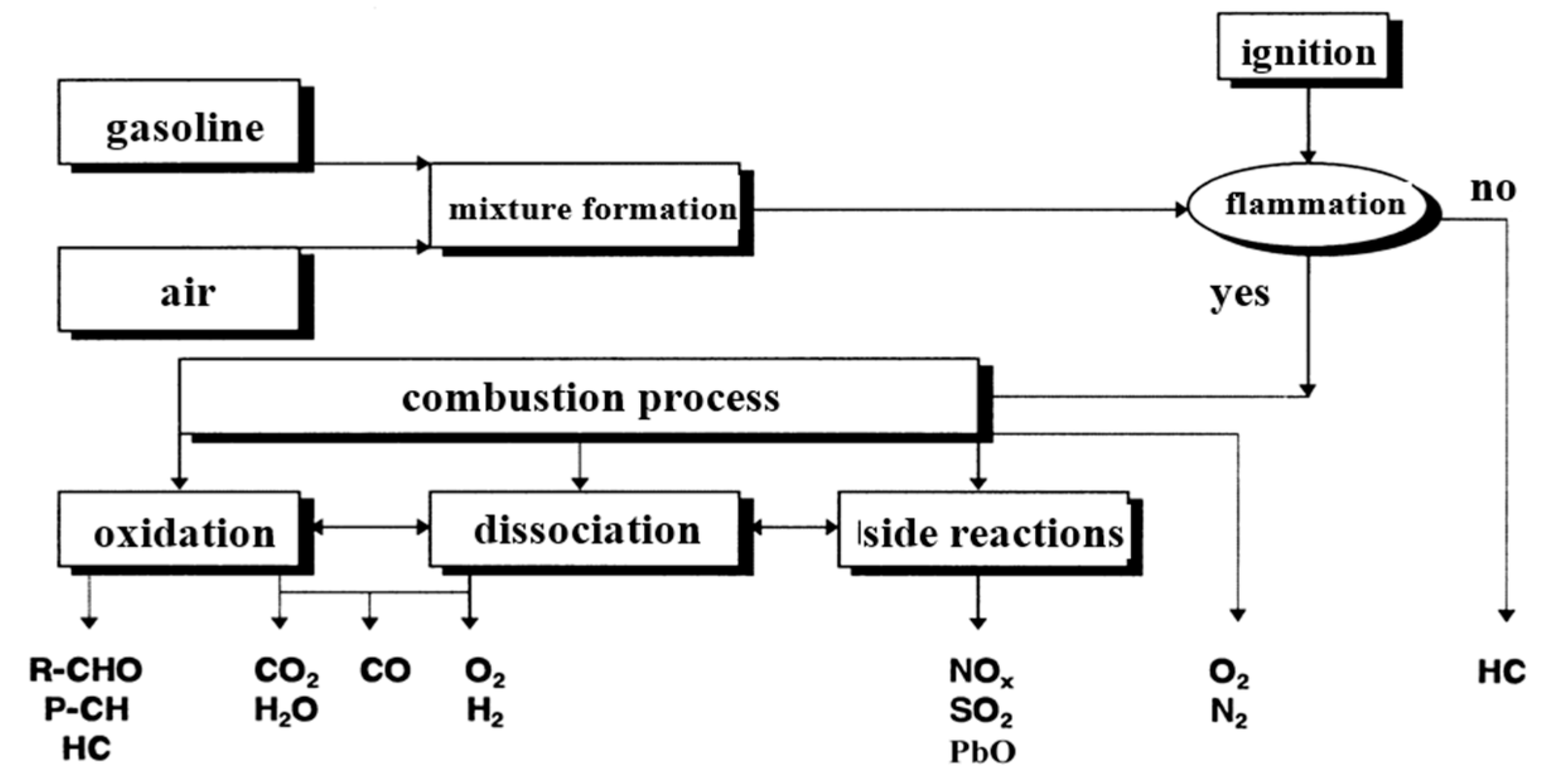

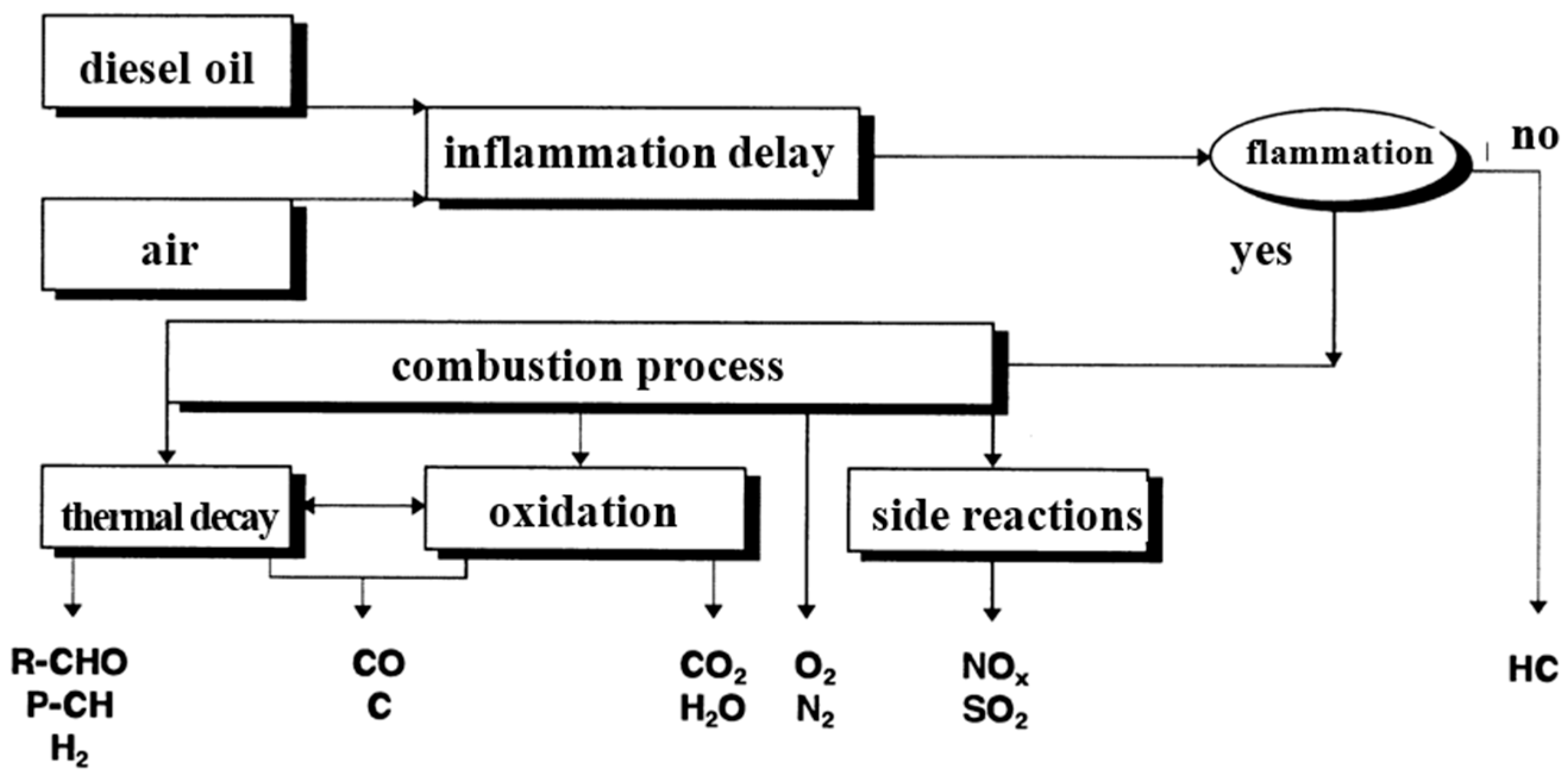

3.1. Ecology

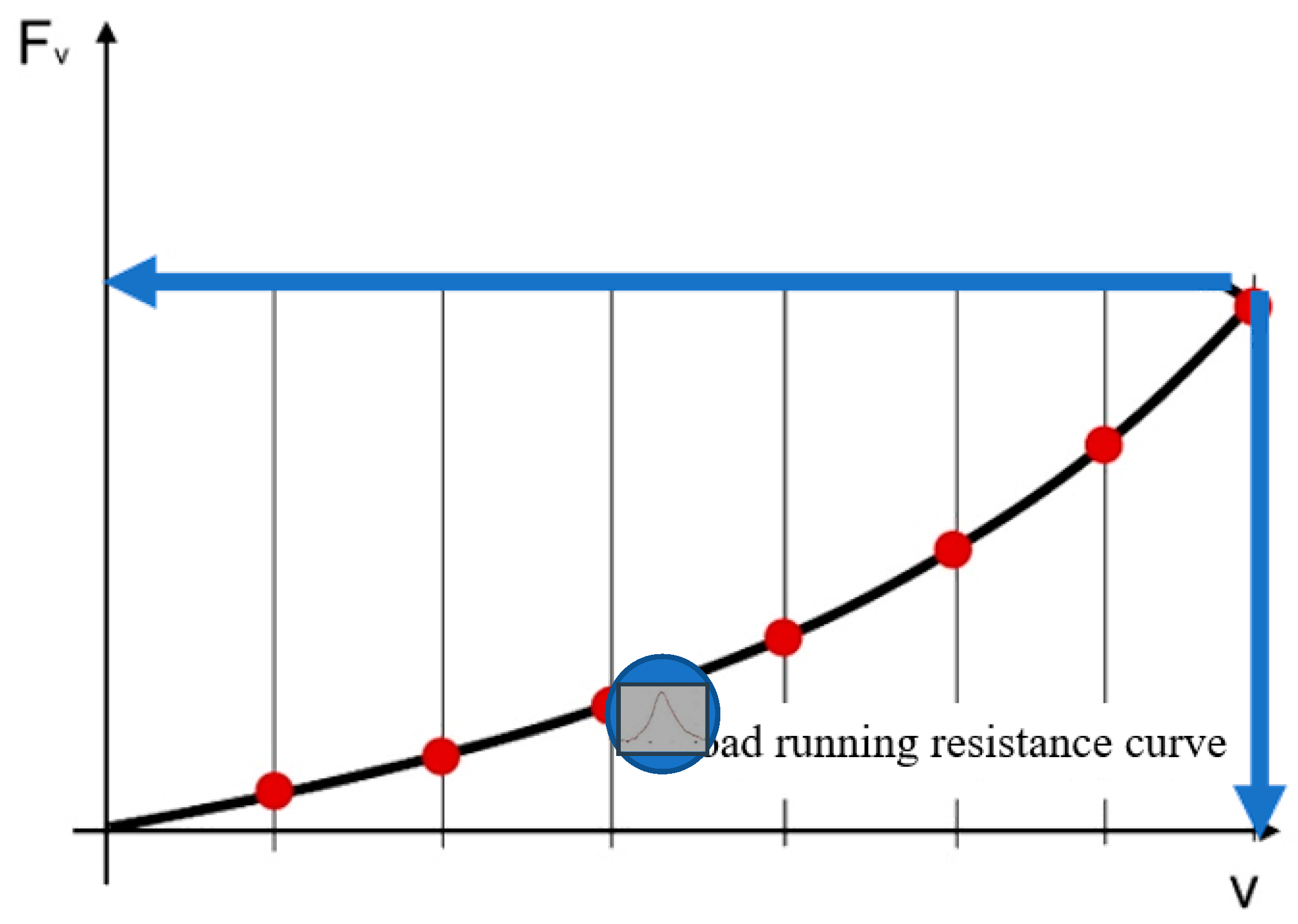

3.2. Example of Economy Diagnostics

- Each bus was measured twice:

- in diesel mode (sign NG in the chart headings)

- in diesel-LPG mode (sign G in the chart headings)

- The measurements were carried out after the stabilization of the operating point.

- Measured values:

- vehicle speed, v (km/h)

- traction, Fv (N)

- wheel power, (Pk)

- gear

- emission

- CO (%(v/v))

- CO2 (%(v/v))

- HC (ppm)

- O2 (%(v/v))

- NOx (ppm)

- smoking, k, (m-1)

- diesel oil consumption, (l/min)

- gas consumption (l/min)

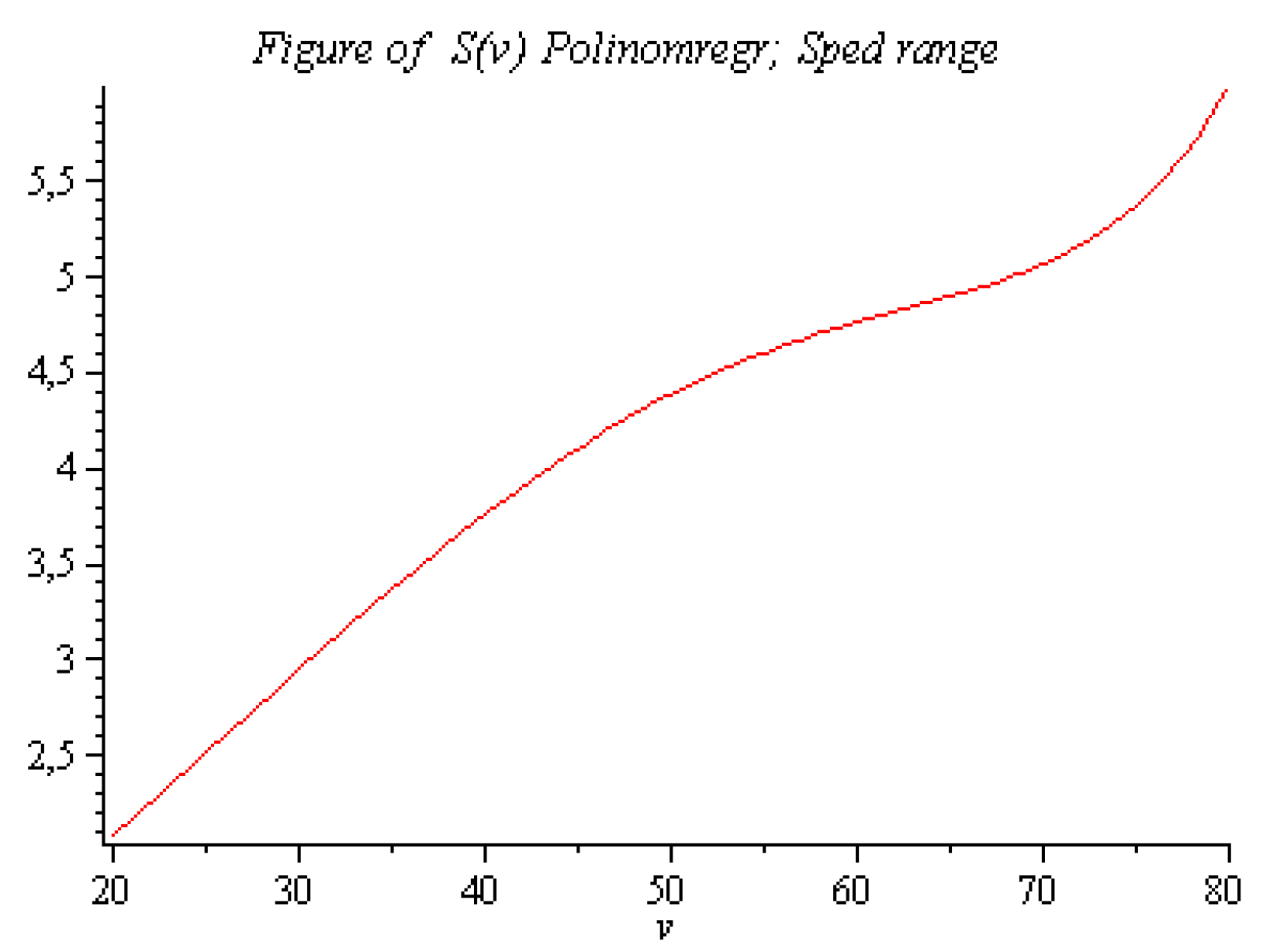

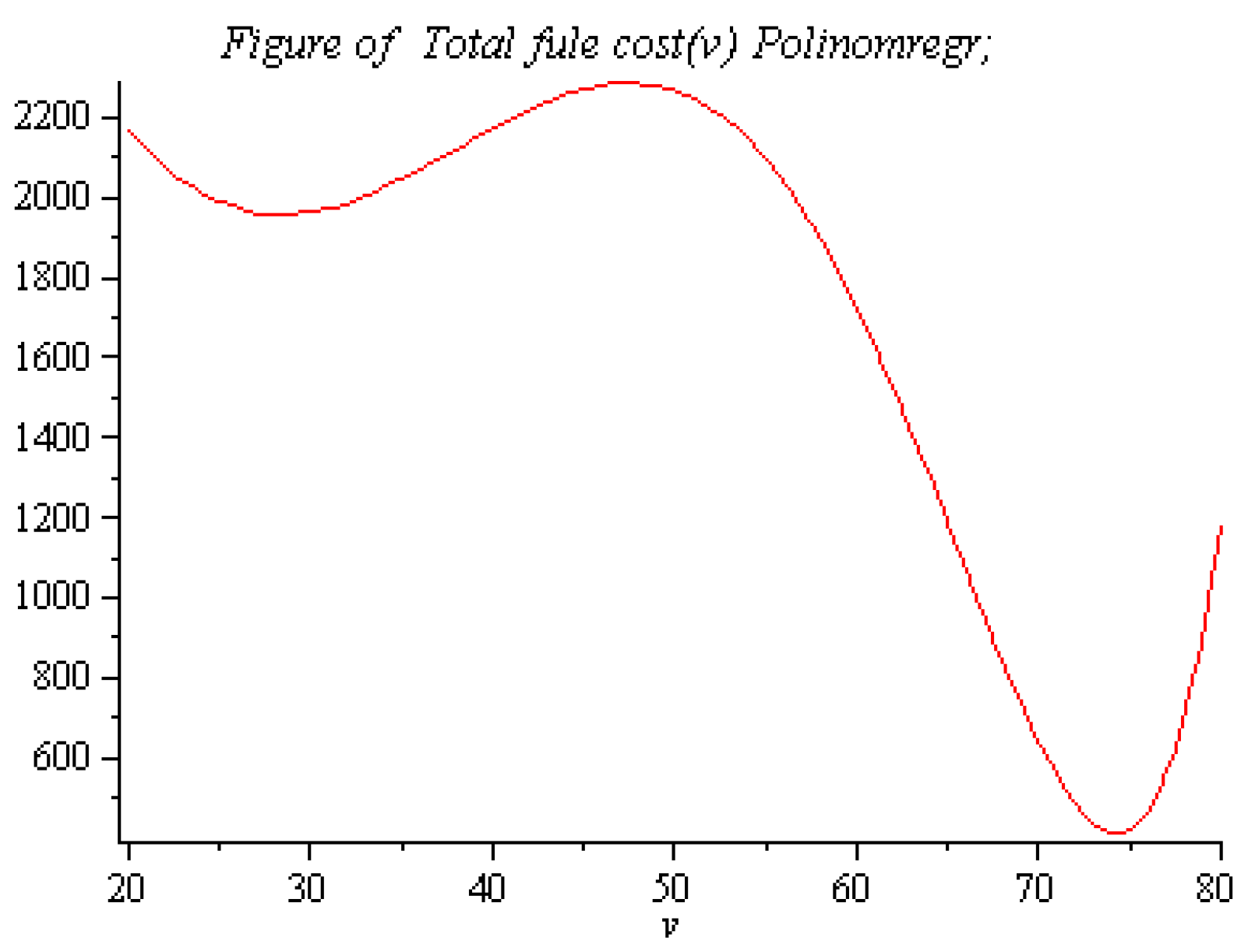

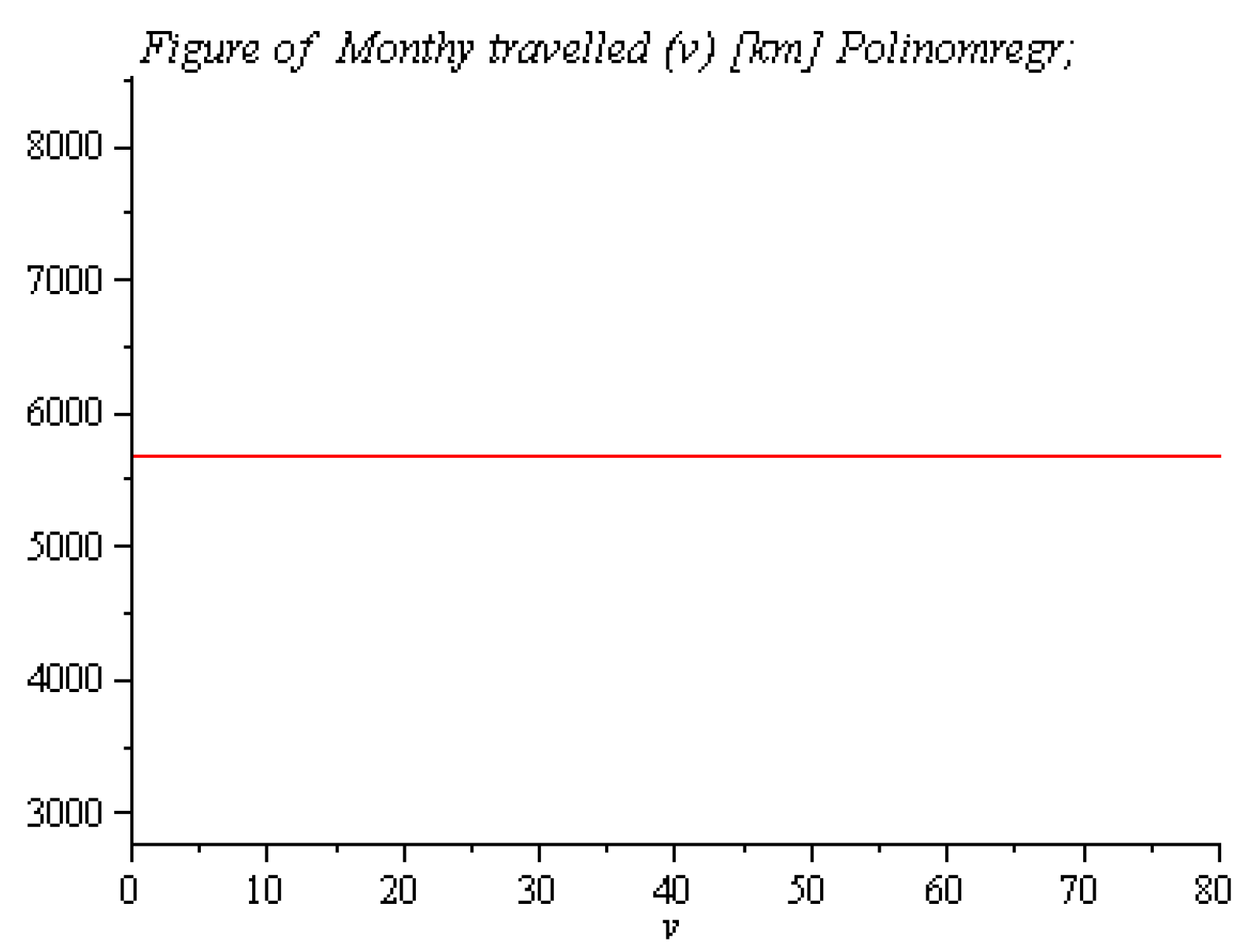

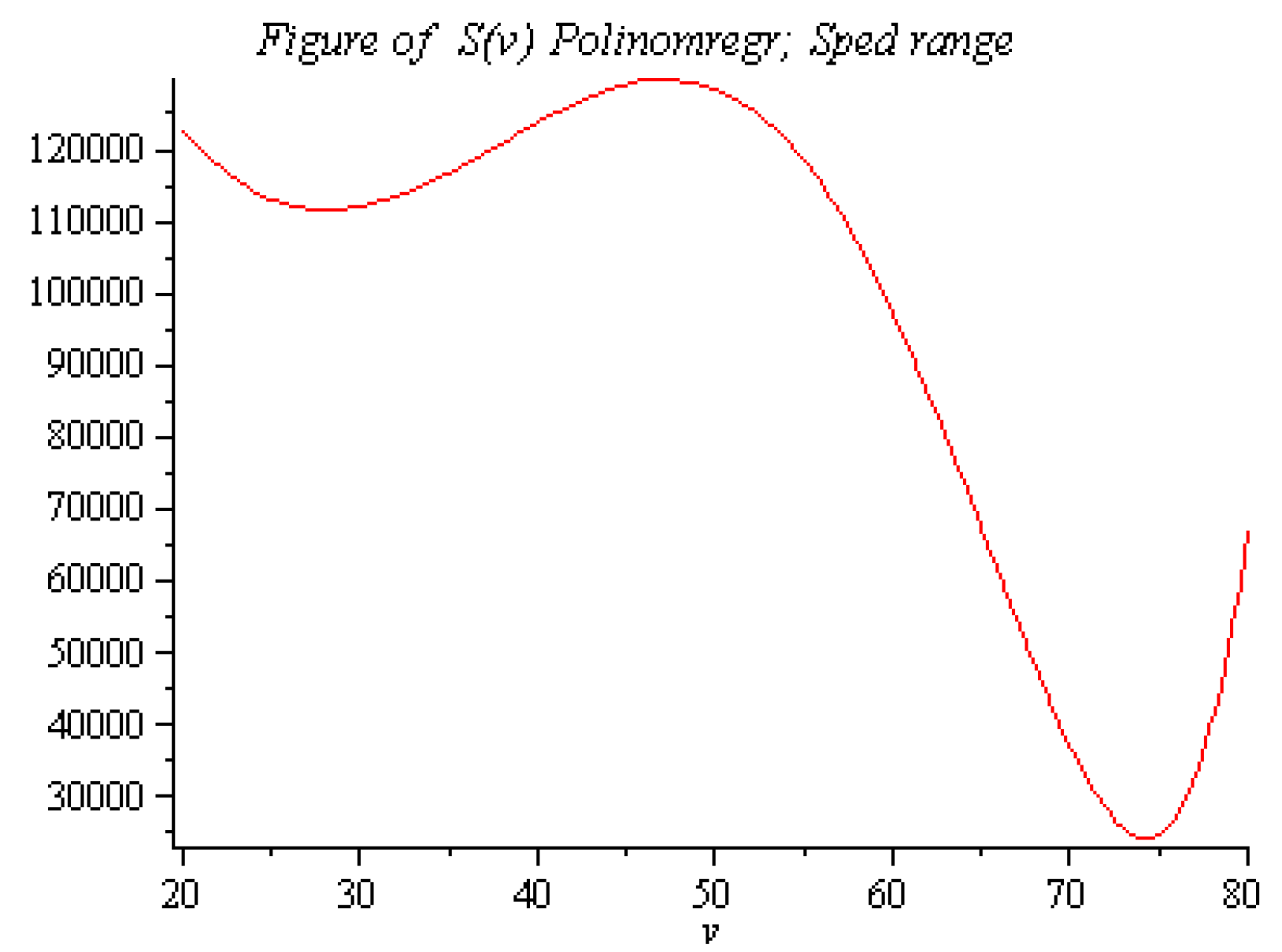

| Target speed of the vehicle[km/h] | Speed range | Total fuel cost[HUF/100 km] | Monthly travelled [km] |

Monthly cost change [Ft] |

|---|---|---|---|---|

| 20 | 2 | 1 400 | 5679 | 79 526 |

| 30 | 3 | 3 693 | 5679 | 209 717 |

| 40 | 4 | 1 372 | 5679 | 77 900 |

| 50 | 4 | 1 447 | 5679 | 82 173 |

| 60 | 5 | 2 664 | 5679 | 151 306 |

| 70 | 5 | 319 | 5679 | 18 118 |

| 80 | 6 | 1 214 | 5679 | 68 942 |

- CO2-emission,

- NOx emission and

- diesel smoke,

f(r, a) = f1(x, y, z, a) i + f2(x, y, z, a) j + f3(x, y, z, a) k

- Speed range,

- Total fuel cost [HUF/100 km],

- Monthly travelled [km]

- Monthly cost change [HUF]

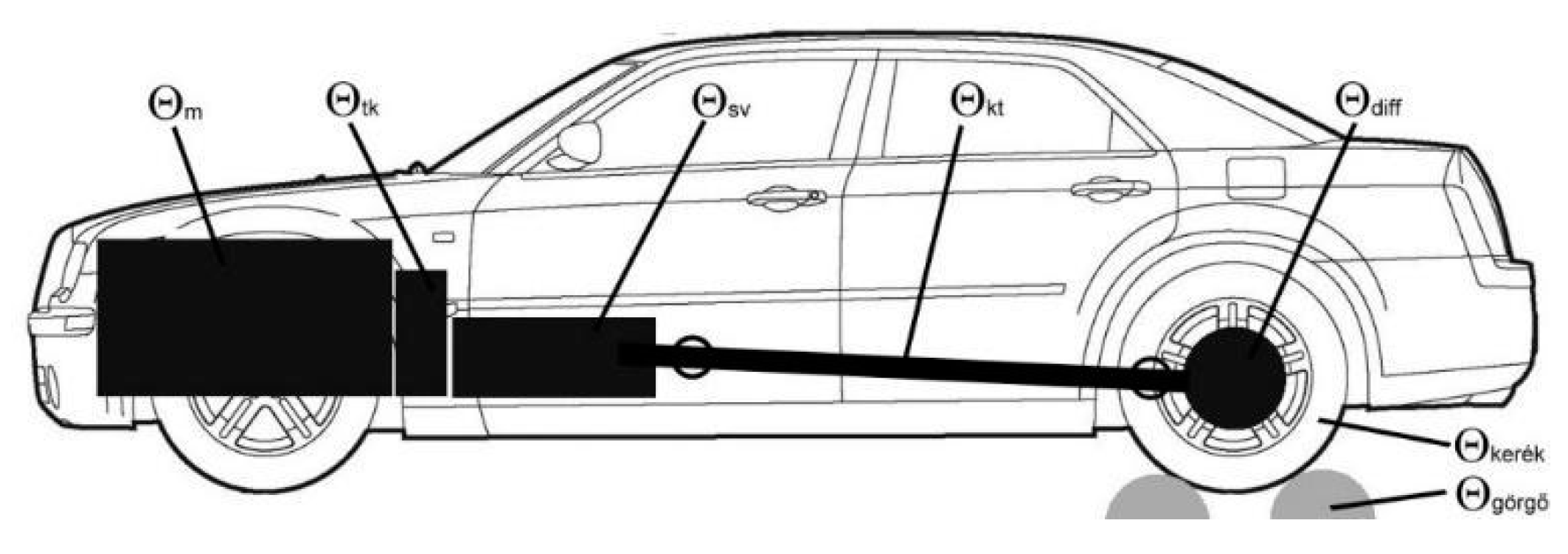

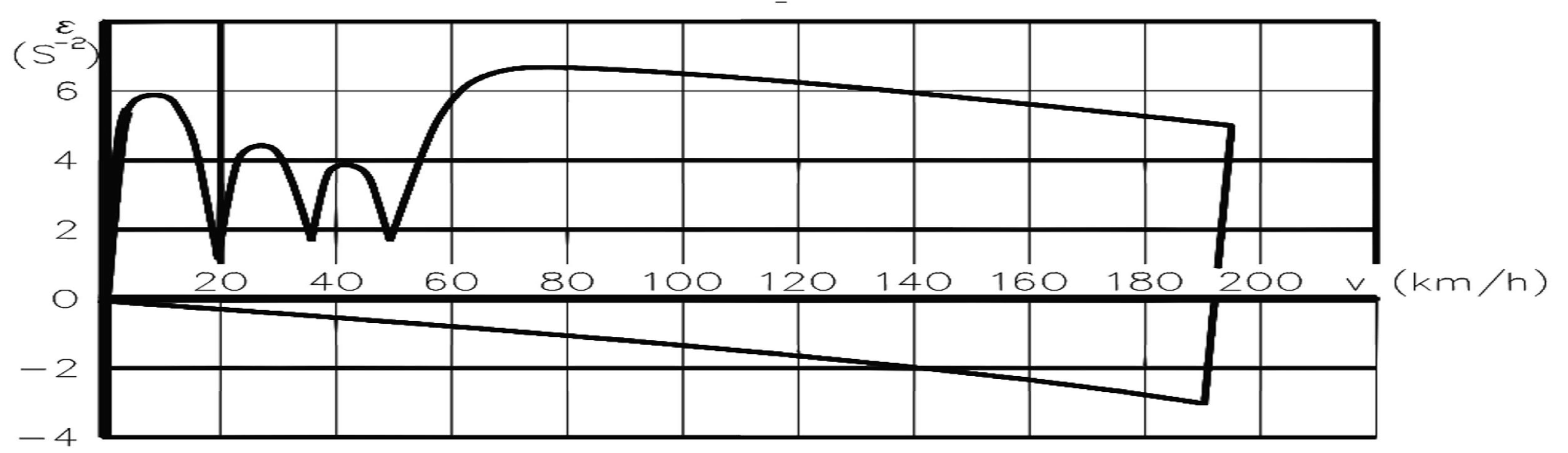

3.3. Economy

3.3.1. Example of Economy Diagnostics

- ACCELERATION PHASE: Accelerate the vehicle’s powertrain and power bench rollers at full load (full throttle) in free acceleration to rated engine speed in the gear to be tested.

- ROLLING-OUT STAGE: Release the clutch, leaving the transmission in the given gear, allow the vehicle to decelerate to a stop

- vehicle speed (the circumferential speed of the wheel or roller):

- Practical considerations for measurement

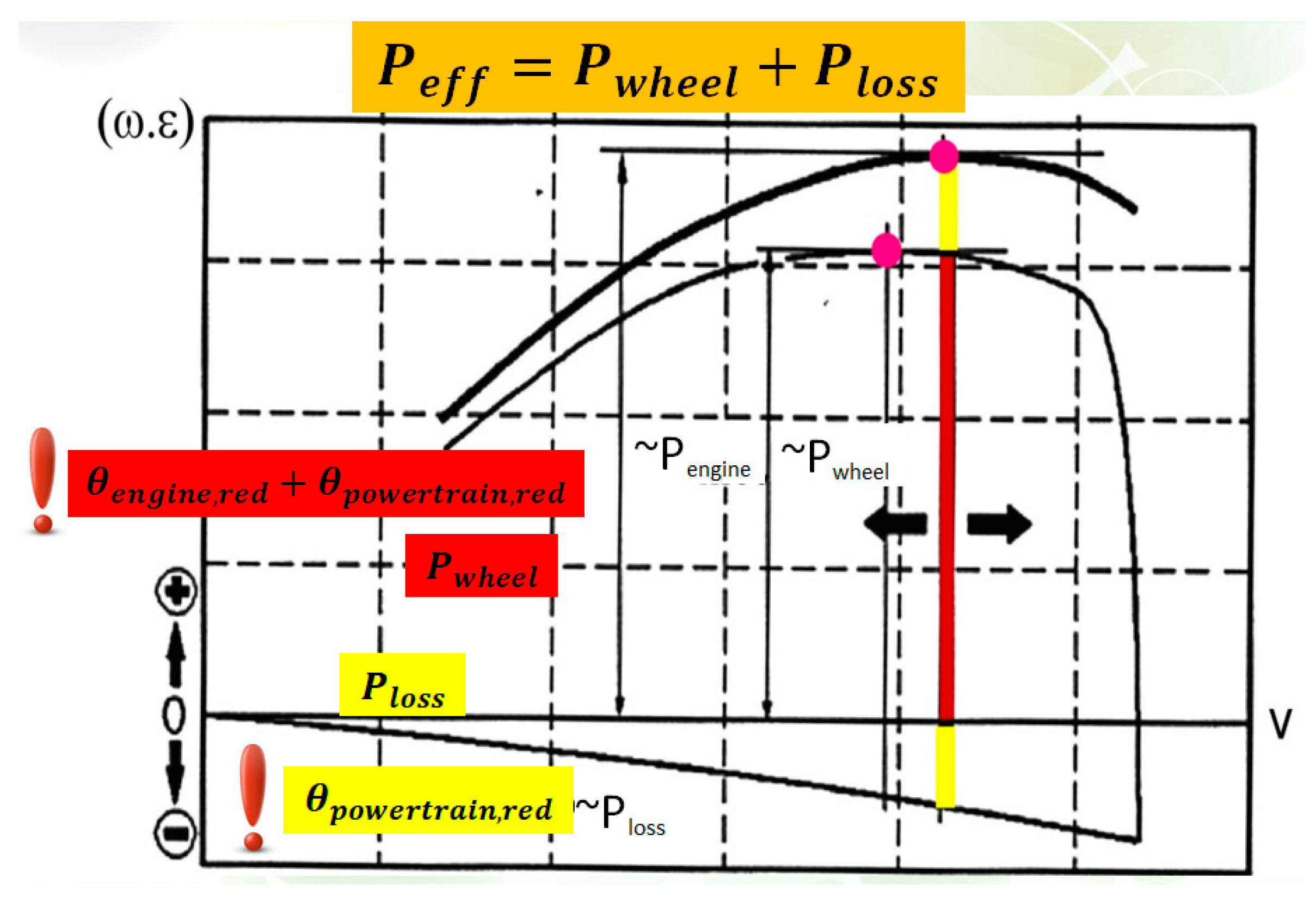

- Peff effective power of the engine

- Ploss loss of the powertrain

- Pwheel power delivered to the wheel

4. Discussion

5. Conclusions

Acknowledgments

References

- Yuanyuan GUO, Xunjie GOU, Zeshui XU, Marinko SKARE: Carbon Pricing Mechanism for the Energy Industry: A Bibliometric Study of Optimal Pricing Policies, Acta Montanistica Slovaca, Volume 27 (2022), 1. [CrossRef]

- Marcin RABE, Wojciech DROŻDŻ, Katarzyna WIDERA, Agnieszka ŁOPATKA, Piotr LEŻYŃSKI, Dalia STREIMIKIENE, Yuriy BILAN: Assessment of energy storage for energy strategies development on a regional scale, Acta Montanistica Slovaca, Volume 27 (2022), 1. [CrossRef]

- Marek Vochozka, Marek Vochozka, Jakub Horák,Jakub Horák, Tomáš Krulický, Tomáš Krulický, Pedro Pardal, Pedro Parda: Predicting future Brent oil price on global markets, January 2020, Acta Montanistica Slovaca 25(3):375-392. [CrossRef]

- Josef MaroušekJosef MaroušekOtakar StruneckýVojtěch BartošMarek VochozkaMarek Vochozka: Revisiting competitiveness of hydrogen and algae biodiesel, November 2022 Fuel 328(4):125317. [CrossRef]

- Iyaghigba, S.D.; Ali, F.; Jennions, I.K. A Review of Diagnostic Methods for Hydraulically Powered Flight Control Actuation Systems. Machines 2023, 11, 165. [CrossRef]

- Sharma, N.; Habibullah, P.S. A Review of IoT Technology for the Connected Autonomous Vehicles Ecosystem. Trends in Sciences 2022, 19. [CrossRef]

- Flores Fernández, A.; Sánchez Morales, E.; Botsch, M.; Facchi, C.; García Higuera, A. Generation of Correction Data for Autonomous Driving by Means of Machine Learning and On-Board Diagnostics. Sensors 2023, 23. [CrossRef]

- Chen, C.C.; Tian, S.L.; Teng, C.C.; Yang, C.W.; Yen, M.H. Integration of Second-Generation On-Board Diagnostics Data via Deep Learning to Develop Eco-Driving Analysis System Applicable to Large and Small Cars. Sensors and Materials 2022, 34, 2467–2478. [CrossRef]

- Kamimoto, T. A Review of Soot Sensors Considered for On-Board Diagnostics Application. International Journal of Engine Research 2017, 18, 631–641. [CrossRef]

- Chen, S.H.; Wang, J.F.; Wei, Y.R.; Shang, J.; Kao, S.Y. The Implementation of Real-Time on-Line Vehicle Diagnostics and Early Fault Estimation System. In Proceedings of the Proceedings - 2011 5th International Conference on Genetic and Evolutionary Computing, ICGEC 2011; 2011; pp. 13–16.

- Mouzakitis, A.; Muniyappa, N.; Parker, R.; Puthiyapurayil, S. Advanced Automated Onboard Vehicle Diagnostics Testing;

- Guan, B.; Zhan, R.; Lin, H.; Huang, Z. Review of the State-of-the-Art of Exhaust Particulate Filter Technology in Internal Combustion Engines. J Environ Manage 2015, 154, 225–258. [CrossRef]

- Han’guk T’ongsin Hakhoe.; Hanʼguk Chŏnja Tʻongsin Yŏnʼguso. ICTC 2012 : 2012 International Conference on ICT Convergence : “Global Open Innovation Summit for Smart ICT Convergence,” October 15-17, 2012, Ramada Plaza Jeju Hotel, Jeju Island, Korea; IEEE, 2012; ISBN 9781467348287.

- Cai, D.; Fraedrich, K.; Guan, Y.; Guo, S.; Zhang, C.; Zhu, X. Urbanization and Climate Change: Insights from Eco-Hydrological Diagnostics. Science of the Total Environment 2019, 647, 29–36. [CrossRef]

- Tsybunov, E.; Shubenkova, K.; Buyvol, P.; Mukhametdinov, E. Interactive (Intelligent) Integrated System for the Road Vehicles’ Diagnostics. In Proceedings of the Lecture Notes of the Institute for Computer Sciences, Social-Informatics and Telecommunications Engineering, LNICST; Springer Verlag, 2018; Vol. 222, pp. 195–204.

- Peter Mock, John German: The future of vehicle emissions testing and compliance, How to align regulatory requirements, customer expectations, and environmental performance in the European Union, International Council on Clean Transportation, Berlin, 2015.

- Vehicle Emissions Testing Programme Moving Britain Ahead, Department for Transport, Crown, 2016, ISBN 978147431308.

- Le Liu, Lihui Wang, Liyun Qian, Peilin Geng, Wei Zhao, and Jingyuan Li: Experimental study on the emission influence of the fuel system faults for light-duty vehicle, E3S Web of Conferences 268, 01051 (2021), VESEP2020. [CrossRef]

- Giorgio Rizzoni, Simona Onori, Matteo Rubagotti: Diagnosis and Prognosis of Automotive Systems: motivations, history and some results, Proceedings of the 7th IFAC Symposium on Fault Detection, Supervision and Safety of Technical Processes, Barcelona, Spain, June 30 – July 3, 2009.

- Helmut Frank, Uwe Schmidts: Vehicle Diagnostics – The whole Story, Diagnostics_Congress_Elektronik Automotive, 2007- 03_Press Article Florian Schwarz: Entwicklung und Einsatz innovativer HMI-Software zur Diagnose elektronischer Steuergeräte in der Automobilindustrie, Dissertation, Passau, 2008.

- Marko Rešetar: INNOVATIVE APPROACH TO VEHICLE DIAGNOSTICS, UDC 629.054, Doktorski studij na FSB: Uvod u znanstveno istraživački rad 2015/2016 1.

- Salama A. Mostafa, Mohd Sharifuddin Ahmad, Mazin Abed Mohammed and Omar Ibrahim Obaid Implementing an Expert Diagnostic Assistance System for Car Failure and Malfunction, IJCSI International Journal of Computer Science Issues, Vol. 9, Issue 2, No 2, March 2012, ISSN (Online): 1694-0814.

- Dipl.-Ing. Tobias Carsten Müller: Neuronale Modelle zur Offboard-Diagnostik in komplexen Fahrzeugsystemen, genehmigte Dissertation, Coburg, 2011.

- Dr. Lakatos István, Ádám Titrik, Tamás Orbán: Data determination of an internal combustion engine for model set-up, HUNGARIAN JOURNAL OF INDUSTRIAL CHEMISTRY 39: pp. 35-40. (2011), Veszprém, Pannon Egyetem, 2011. 08.29-09.01.

- Dr. István Lakatos: Neue auf Zylinderdruckindizierung basierende motordiagnostische Prüfungsmethode, Acta Technica Jauriensis, Győr, 2013, pp 9, ISSN 1789-6932 (9 pages).

- Dr. István Lakatos: Development of a new method for comparing the cold start- and the idling operation of internal combustion engines, Periodica Polytechnika Transportation Engineering, Budapest, 2013, ISSN 1587-3811 (online version) ISSN 0303-7800 (paper version) (19 pages).

- Dr. István Lakatos: Elaboration of a new method for developing a diagnostic procedure for motor vehicles based on a model, Periodica Polytechnika Transportation Engineering, Budapest, 2013, ISSN 1587-3811 (online version) ISSN 0303-7800 (paper version), ISSN 1785-8860 (14 pages).

- Dr. István Lakatos: Diagnostic measurement for the effective performance of motor vehicles, Acta Polytechnica Hungarica, Budapest, 2013 (12 pages).

- Martyushev, N. v.; Malozyomov, B. v.; Khalikov, I.H.; Kukartsev, V.A.; Kukartsev, V.V.; Tynchenko, V.S.; Tynchenko, Y.A.; Qi, M. Review of Methods for Improving the Energy Efficiency of Electrified Ground Transport by Optimizing Battery Consumption. Energies (Basel) 2023, 16. [CrossRef]

| 1 | Own edition |

| 2 | [14] |

| 3 | Dr. Iván Nagyszokolyai, Dr. István Lakatos: Automotive diagnostics, University Course Material, ISBN 978-963-279-661-1, Typotex, Budapest. 2011 |

| 4 | Source: Embitel Technologies |

| 5 | Own research and editing |

| 6 | Own research and editing |

| 7 | Own research and editing |

| 8 | Own measurement and research (Southern Hungary Transport Company) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).