Submitted:

02 December 2024

Posted:

03 December 2024

You are already at the latest version

Abstract

Nowadays, the application of protective multicomponent coatings based on hard metal nitrides is increasingly used to increase the resistance of structures and tools to wear, corrosion and oxidation. In the present work, the multicomponent system Ti-Al-Ta-Si-N is studied, which has high hardness and crack resistance combined with thermal stability and oxidation resistance. The process of formation of the nanocrystalline structure of the coating during its deposition on mate-rials plays a key role in the optimization of these properties. The nanocrystalline structure of the coating is formed due to Si impurity, which is poorly soluble in the Ti1−x−yAlxTayN system based on B1-TiN and segregates mainly along grain boundaries, forming grain boundary amorphous phases of SizN type. In order to find the optimal composition of multicomponent coatings with improved physical and mechanical properties, it is necessary to understand the peculiarities of interaction of Si impurity with the surface of B1-TiN phase in the presence of Al and Ta substitutional impurities. In the present work with the help of first-principles calculations of electronic and atomic structure of (001) and (111) surfaces of the Ti1−x−yAlxTayN system with adsorbed Si atom and interatomic bond study apparatus based on the calculation of a Crystal Orbital Hamilton Population and a Crystal Orbital Bond Index, the nature of the bonds between adsorbed Si and N, Ti, Al, Ta atoms of the Ti1−x−yAlxTayN surface system has been studied. It was found that the binding energy of Si with the Ti1−x−yAlxTayN surface system can be both higher and lower than the binding energy of its bonding with the surface of the binary TiN compound depending on the position of the Al and Ta substitu-tion atoms in the surface layers. The Si bonding with the atoms of the Ti1−x−yAlxTayN surface is ionic-covalent in nature. It is shown that the Si-Ta interaction has the highest degree of covalency and strength and the Si-Al interaction is predominantly ionic in most cases considered and is weaker than the Si-Ti and Si-N bonds. Impurity atoms of Al or Ta have very little effect on the Si-Ti and Si-N bonds due to the local nature of the bonds in the Ti1−x−yAlxTayN surface system with ad-sorbed silicon atom.

Keywords:

1. Introduction

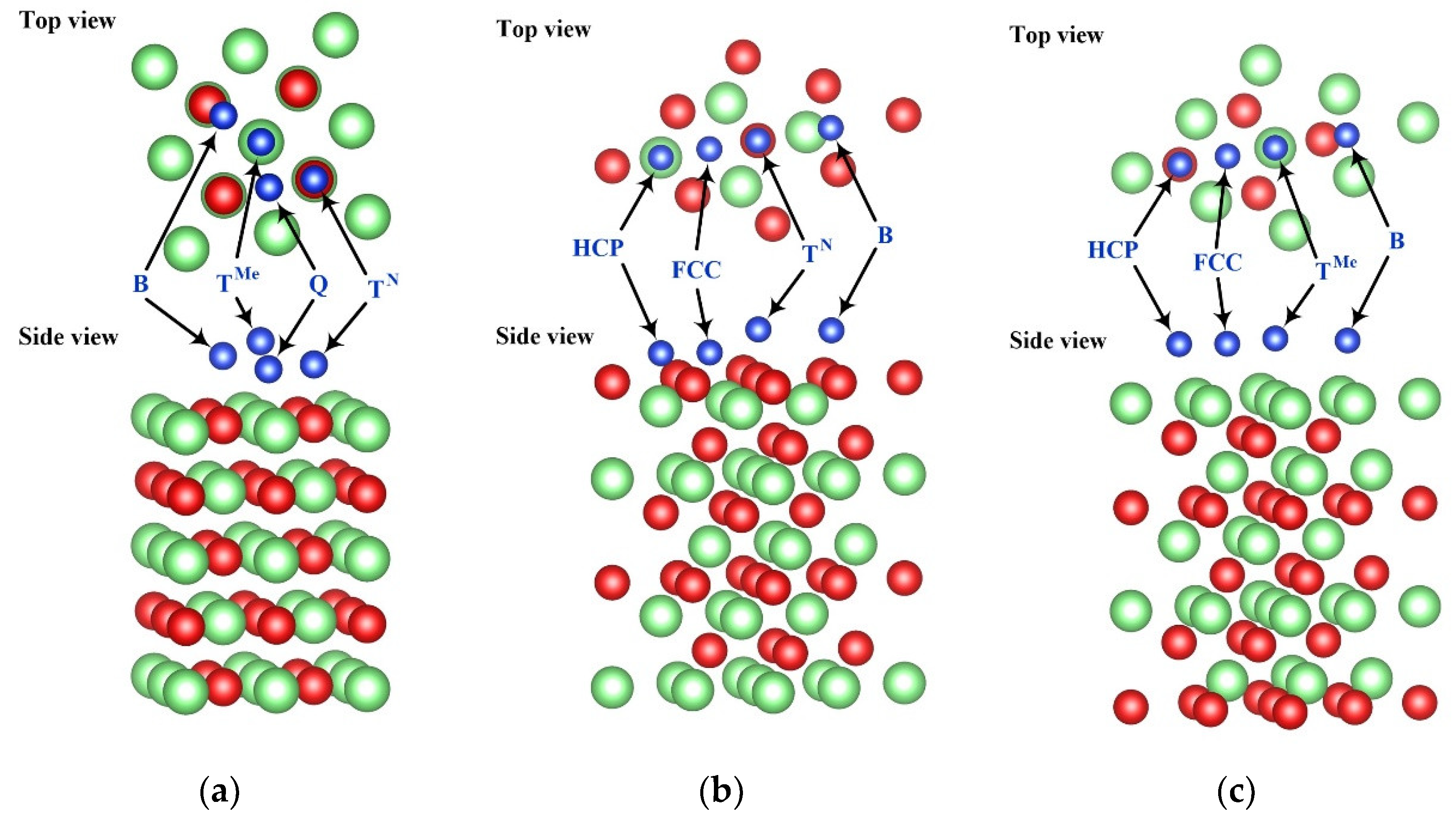

2. Calculation Methods and Details

3. Results and Discussion

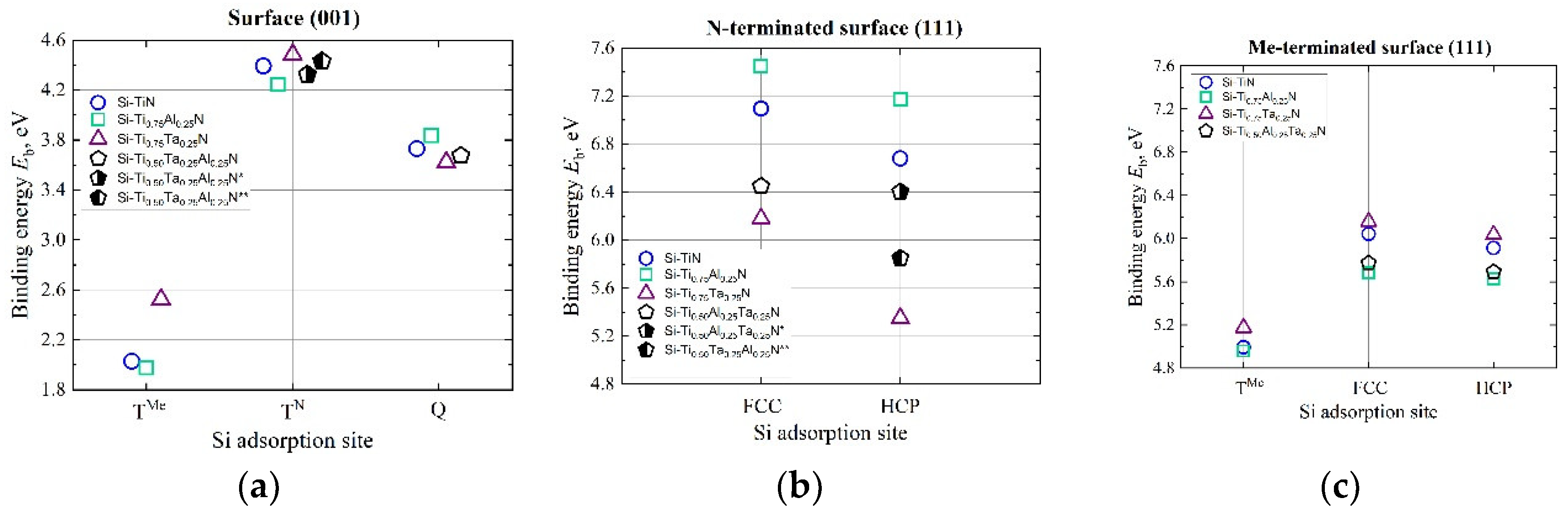

3.1. Binding Energy

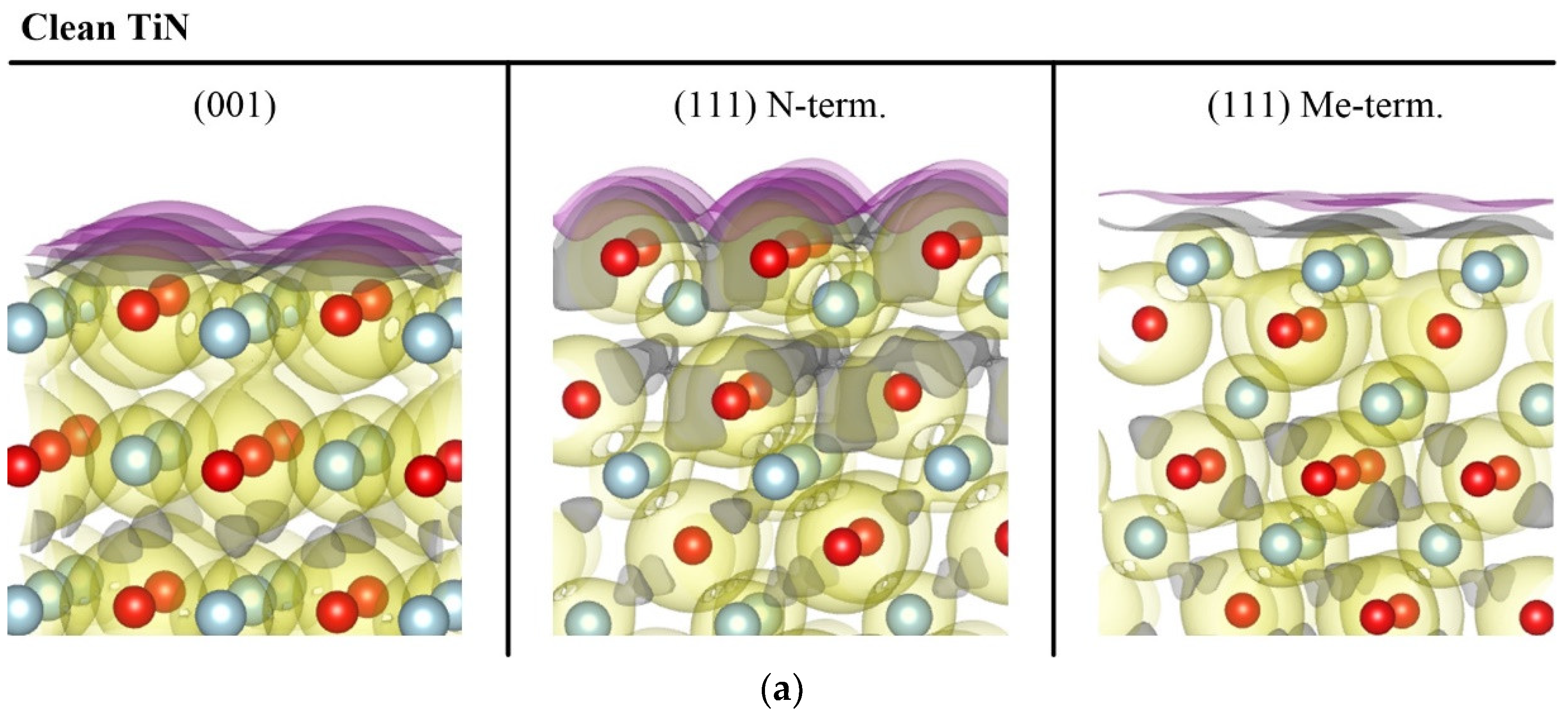

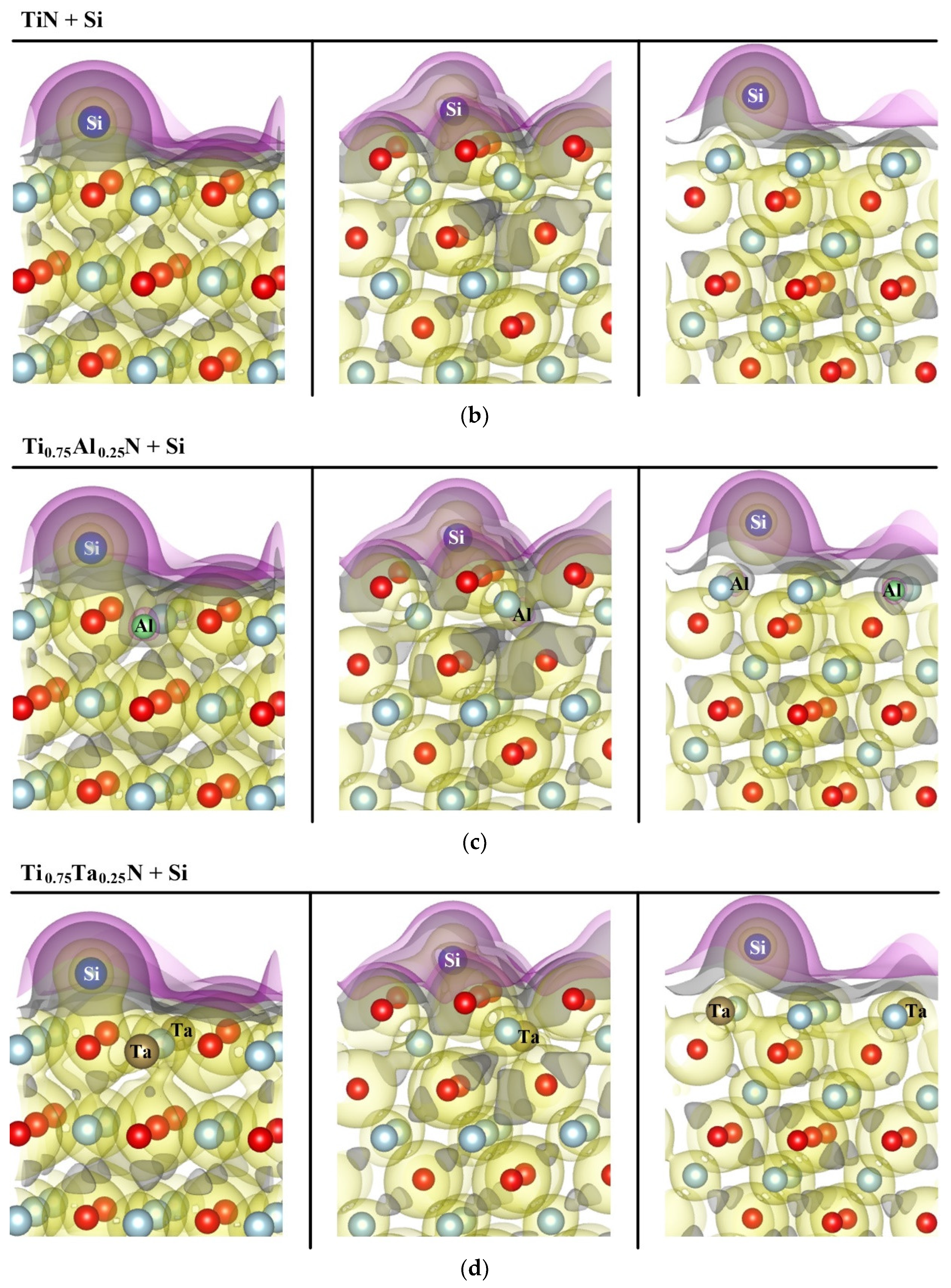

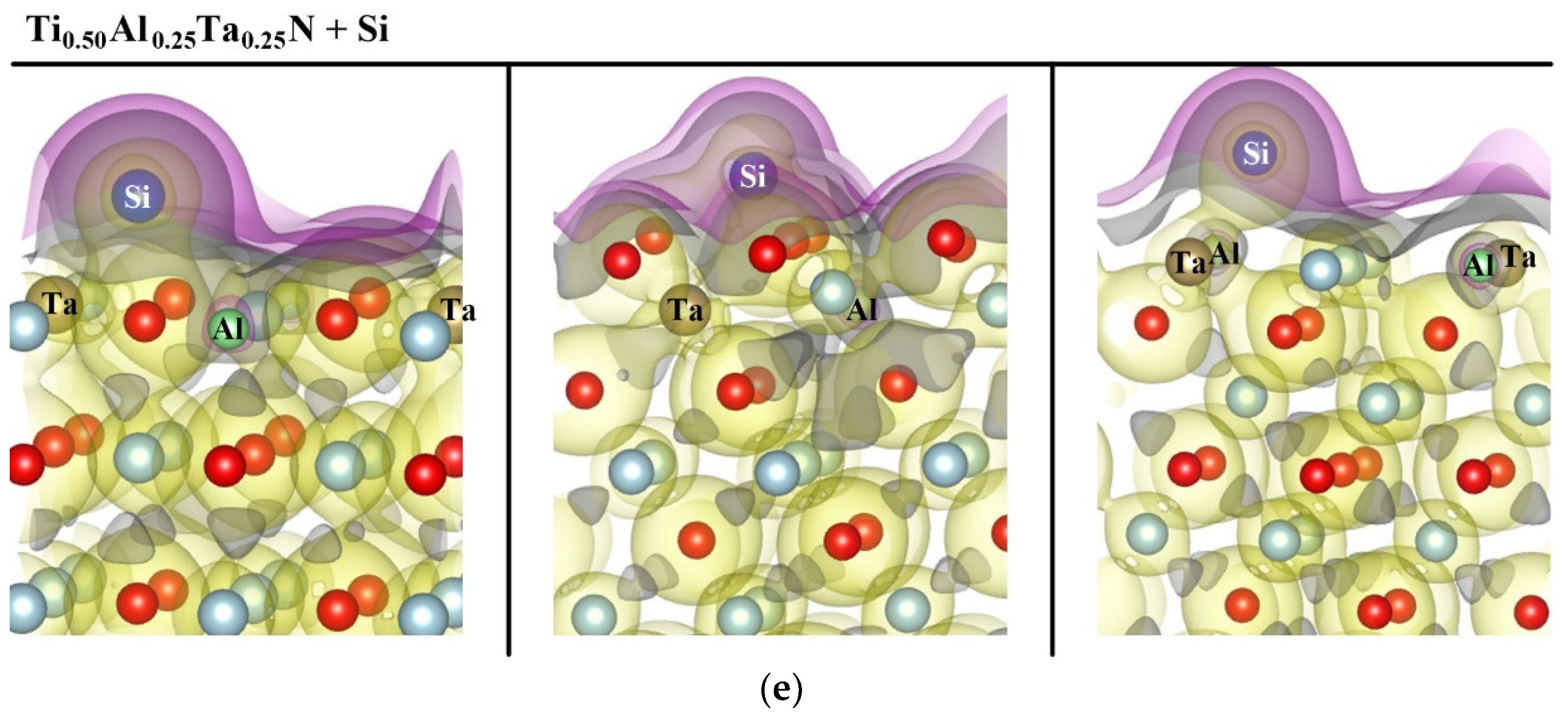

3.2. Valence Charge Density Distribution

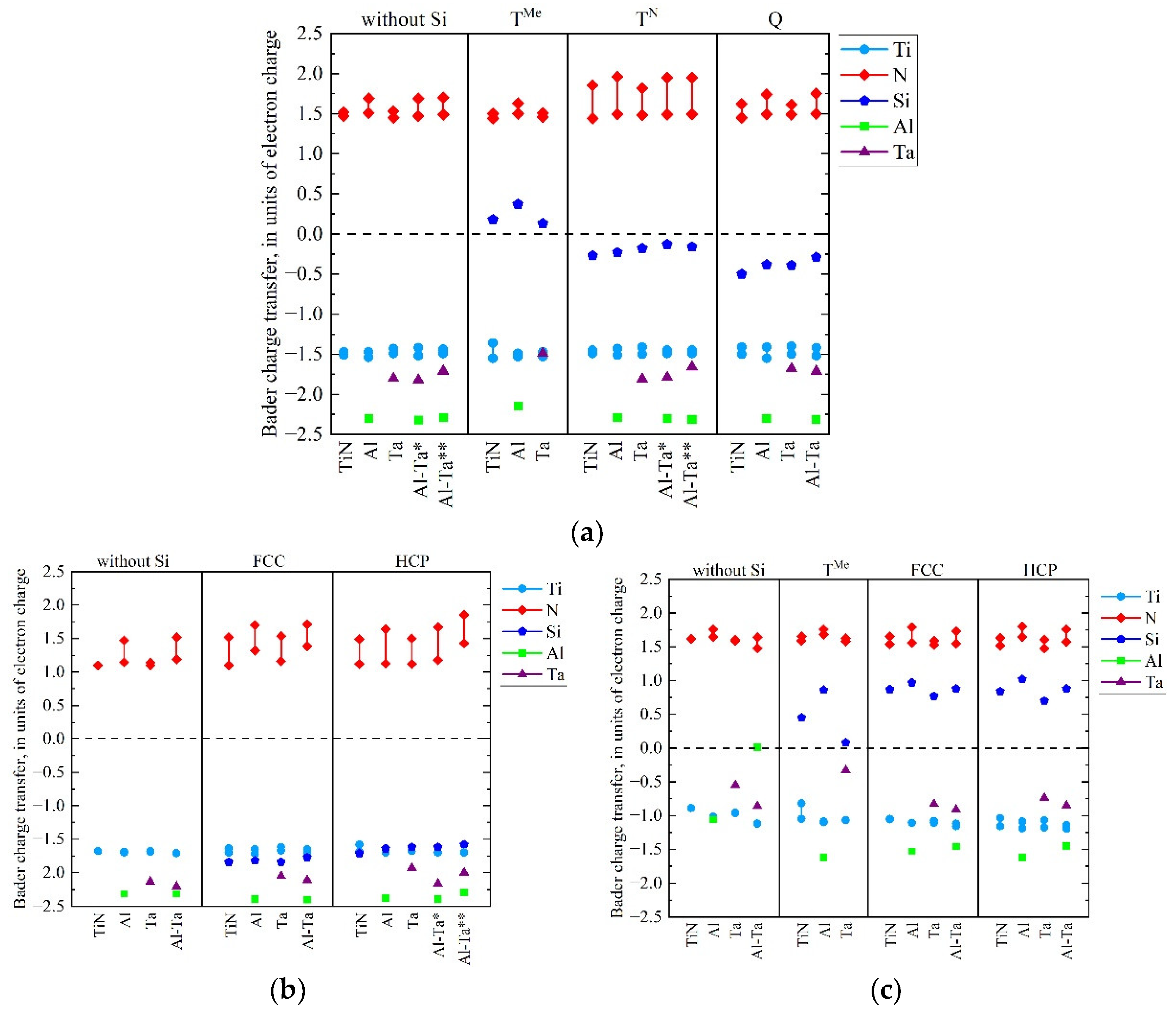

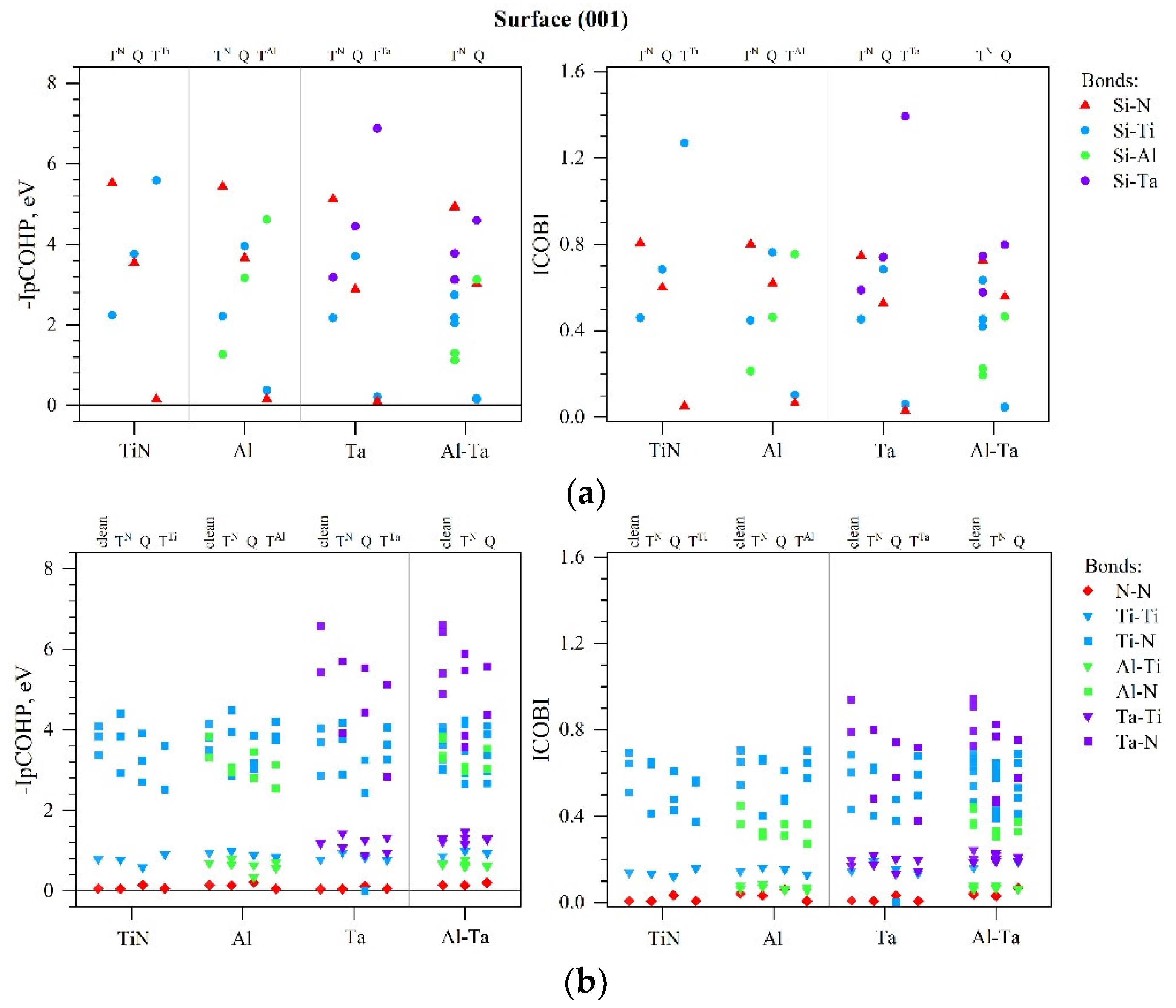

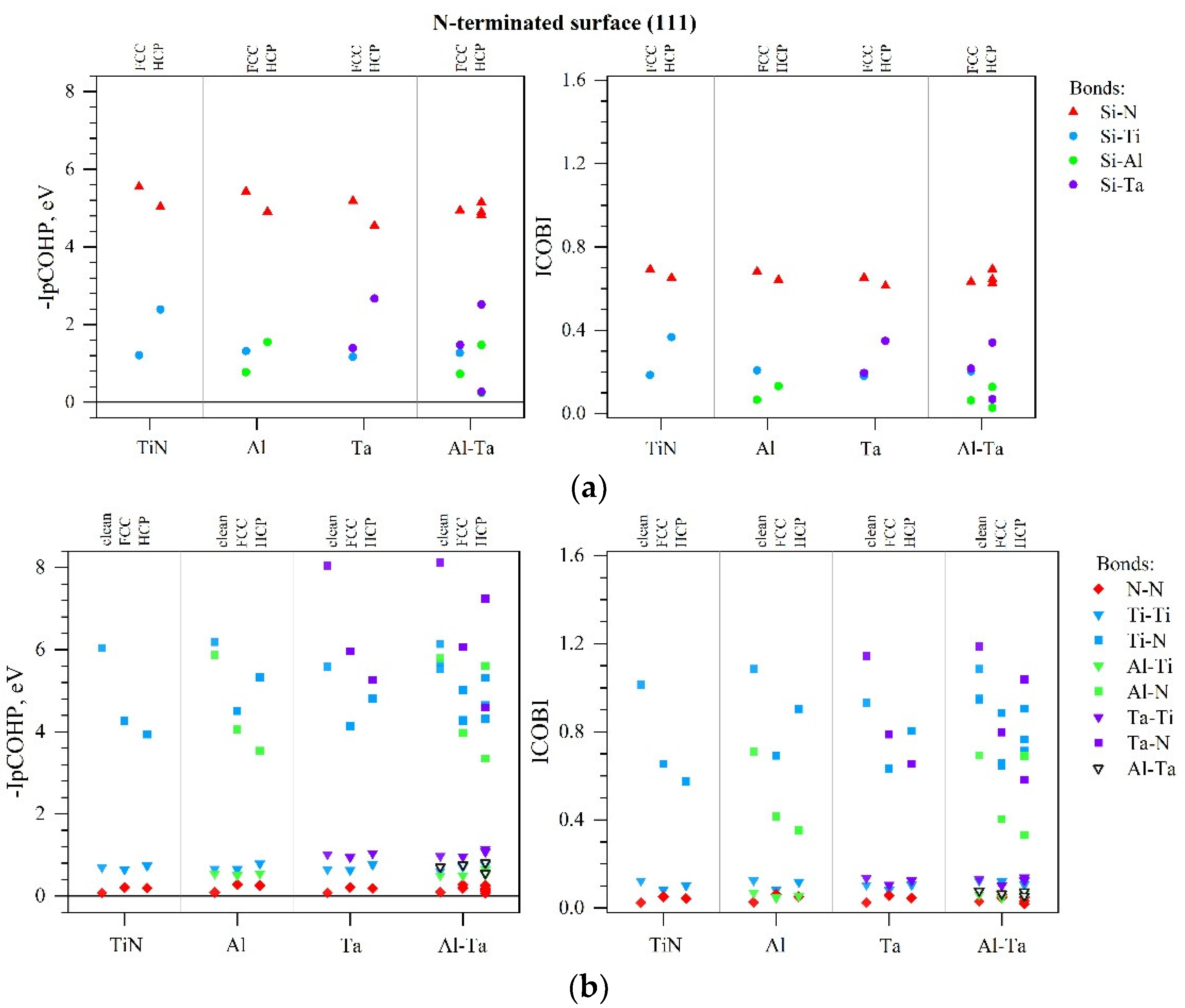

3.3. Silicon-Surface System Bond Type Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jagielski, J.; Khanna, A.; Kucinski, J.; Mishra, D.; Racolta, P.; Sioshansi, P.; Tobin, E.; Thereska, J.; Uglov, V.; Vilaithong, T.; et al. Effect of chromium nitride coating on the corrosion and wear resistance of stainless steel. Appl. Surf. Sci. 2000, 156, 47–64. [CrossRef]

- Sue, J.; Chang, T. Friction and wear behaviour of titanium nitride, zirconium nitride and chromium nitride coatings at elevated temperatures. Surf. Coat. Technol. 1995, 76, 61–69. [CrossRef]

- Schäfer, H.; Stock, H.-R. Improving the corrosion protection of aluminium alloys using reactive magnetron sputtering. Corros. Sci. 2005, 47, 953–964. [CrossRef]

- Li, Y.; Qu, L.; Wang, F. The electrochemical corrosion behaviour of TiN and (Ti,Al)N coatings in acid and salt solution. Corros. Sci. 2003, 45, 1367–1381. [CrossRef]

- Garcia, I.; De Damborenea, J. Corrosion properties of TiN prepared by laser gas alloying of Ti and Ti6Al4V. Corros. Sci. 1998, 40, 1411–1419. [CrossRef]

- Milošev, I.; Strehblow, H.-H.; Navinšek, B. Comparison of TiN, ZrN and CrN hard nitride coatings: electrochemical and thermal oxidation. Thin Solid Films, 1997, 303, 246–254. [CrossRef]

- Bernabai, U.; Cavallini, M.; Bombara, G.; Dearnaley, G.; Wilkins, M. The effects of heat treatment and implantation of aluminium on the oxidation resistance of Fe-Cr-Al-Y alloys. Corros. Sci. 1980, 20, 19–25. [CrossRef]

- Klemm, H. Corrosion of silicon nitride materials in gas turbine environment. J. Eur. Ceram. Soc. 2002, 22, 2735–2740. [CrossRef]

- Fan, L.-S.; Tai, Y.-C.; Muller, R.S. IC-processed electrostatic micromotors. Sens. Actuators 1989, 20, 41–47. [CrossRef]

- Sproul, W.D.; Rothstein, R. High rate reactively sputtered TiN coatings on high speed steel drills. Thin Solid Films 1985, 126, 257–263, . [CrossRef]

- Raimondi, M.T.; Pietrabissa, R. The in-vivo wear performance of prosthetic femoral heads with titanium nitride coating. Biomaterials 2000, 21, 907–913. [CrossRef]

- Harris, S.; Doyle, E.; Vlasveld, A.; Audy, J.; Quick, D. A study of the wear mechanisms of Ti1−xAlxN and Ti1−x−yAlxCryN coated high-speed steel twist drills under dry machining conditions. Wear 2003, 254, 723–734. [CrossRef]

- Sutter, G.; Ranc, N. Flash temperature measurement during dry frictionp rocess at high sliding speed. Wear 2010, 268, 1237–1242. [CrossRef]

- Münz, W.-D. Titanium aluminum nitride films: A new alternative to TiN coatings. J. Vac. Sci. Technol. A Vacuum, Surfaces, Film. 1986, 4, 2717-2725. [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: a review. Mater. Sci. Eng. A 2003, 342 (1), 58–79, doi.org/10.1016/S0921-5093(02)00259-9.

- Liu, Z.-J.; Shum, P.; Shen, Y. Hardening mechanisms of nanocrystalline TiAlN solid solution films. Thin Solid Films 2004, 468 (1), 161–166. [CrossRef]

- Carvalho, S.; Ribeiro, E.; Rebouta, L.; Pacaud, J.; Goudeau, P.; Renault, P.; Riviere, J.; Tavares C. PVD grown (Ti,Si,Al)N nanocomposite coatings and (Ti,Al)N/(Ti,Si)N multilayers: structural and mechanical properties. Surf. Coat. Technol. 2003, 172 (2), 109–116. [CrossRef]

- Chen, L.; Paulitsch, J.; Du, Y.; Mayrhofer, P.H. Thermal stability and oxidation resistance of Ti-Al-N coatings. Surf. Coat. Technol. 2012, 206, 2954–2960. [CrossRef]

- Rachbauer, R.; Massl, S.; Stergar, E.; Holec, D.; Kiener, D.; Keckes, J.; Patscheider, J.; Stiefel, M.; Leitner, H.; Mayrhofer, P.H. Decomposition pathways in age hardening of Ti-Al-N films. J. Appl. Phys. 2011, 110 (2), 023515. [CrossRef]

- Christensen, N.; Gorczyca I. Calculated structural phase transitions of aluminum nitride under pressure. Phys. Rev. B. Condens. Matter. 1993, 47, 4307–4314. [CrossRef]

- Chen, L.; Holec, D.; Du, Y.; Mayrhofer, P.H. Influence of Zr on structure, mechanical and thermal properties of Ti-Al-N. Thin Solid Films 2011, 519 (16), 5503–5510. [CrossRef]

- Chim, Y.; Ding, X.; Zeng, X.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Films 2009, 517 (17), 4845–4849. [CrossRef]

- Moser, M.; Kiener, D.; Scheu, C.; Mayrhofer, P.H. Influence of yttrium on the thermal stability of Ti-Al-N thin films. Materials 2010, 3, 1573–1592. [CrossRef]

- Xu, Y.X.; Chen, L.; Pei, F.; Du, Y.; Liu, Y.; Yue, J.L. Influence of Hf on the structure, thermal stability and oxidation resistance of Ti-Al-N coatings. Thin Solid Films 2014, 565, 25–31. [CrossRef]

- Pfeiler, M.; Kutschej, K.; Penoy, M.; Michotte, C.; Mitterer, C.; Kathrein, M. The effect of increasing V content on structure, mechanical and tribological properties of arc evaporated Ti–Al–V–N coatings. Int. J. Refract. Met. Hard Mater. 2009, 27, 502–506. [CrossRef]

- Rachbauer, R.; Holec, D.; Mayrhofer, P.H. Increased thermal stability of Ti–Al–N thin films by Ta alloying. Surf. Coat. Technol. 2012, 211, 98–103. [CrossRef]

- Koller, C.M.; Hollerweger, R.; Sabitzer, C.; Rachbauer, R.; Kolozsvári, S.; Paulitsch, J.; Mayrhofer, P.H. Thermal stability and oxidation resistance of arc evaporated TiAlN, TaAlN, TiAlTaN, and TiAlN/TaAlN coatings. Surf. Coat. Technol. 2014, 259, 599–607. [CrossRef]

- Hollerweger, R.; Riedl, H.; Paulitsch, J.; Arndt, M.; Rachbauer, R.; Polcik, P.; Primig, S.; Maryfhoer, P.H. Origin of high temperature oxidation resistance of Ti–Al–Ta–N coatings. Surf. Coat. Technol. 2014, 257, 78–86. [CrossRef]

- Pfeiler, M.; Scheu, C.; Hutter, H.; Schnöller, J.; Michotte, C.; Mitterer, C.; Kathrein, M. On the effect of Ta on improved oxidation resistance of Ti–Al–Ta–N coatings. J. Vac. Sci. Technol. A 2009, 27, 554–560. [CrossRef]

- Yang, Y.; Xu, Y.X.; Chen, L.; Mayrhofer, P.H. Improved Ti-Al-N coatings through Ta alloying and multilayer architecture. Surf. Coat. Technol. 2017, 328, 428–435. [CrossRef]

- Grossmann, B.; Jamnig, A.; Schalk, N.; Czettl, C.; Pohler, M.; Mitterer, C. Tailoring agehardening of Ti1−xAlxN by Ta alloying. J. Vac. Sci. Technol. A 2017, 35, 060604–1–6. [CrossRef]

- Holec, D.; Rachbauer, R.; Chen, L.; Wang, L.; Luef, D.; Mayrhofer, P.H. Phase stability and alloy-related trends in Ti–Al–N, Zr–Al–N and Hf–Al–N systems from first principles. Surf. Coatings Technol. 2011, 206, 1698–1704. [CrossRef]

- Holec, D.; Zhou, L.; Rachbauer, R.; Mayrhofer, P.H. Alloying-related trends from first principles: An application to the Ti–Al–X–N system. J. Appl. Phys. 2013, 113, 113510. [CrossRef]

- Rachbauer, R.; Holec, D.; Lattemann, M.; Hultman, L.; Mayrhofer, P.H. Electronic origin of structure and mechanical properties in Y and Nb alloyed Ti–Al–N thin films. Int. J. Mat. Res. (formerly Z. Metallkd.) 2011, 102, 735–742. [CrossRef]

- Rachbauer, R.; Blutmager, A.; Holec, D.; Mayrhofer, P.H. Effect of Hf on structure and age hardening of Ti–Al-N thin films. Surf. Coatings Technol. 2012, 10, 2667–2672. [CrossRef]

- Eremeev, S.V.; Shugurov, A.R. Chemical bonding analysis in Ti1‒x‒yAlxTayN solid solutions. Surf. Coat. Technol. 2020, 395, 125802. [CrossRef]

- Khetan, V.; Valle, N.; Duday, D.; Michotte, C.; Delplancke-Ogletree, M.-P.; Choquet, P. Influence of temperature on oxidation mechanisms of fiber-textured AlTiTaN coatings. ACS Appl. Mater. Interfaces 2014, 6, 4115–4125. [CrossRef]

- Kathrein, M.; Michotte, C.; Penoy, M.; Polcik, P.; Mitterer, C. Multifunctional multicomponent PVD coatings for cutting tools. Surf. Coat. Technol. 2005, 200, 1867–1871. [CrossRef]

- Pfeiler, M.; Fontalvo, G.A.; Wagner, J.; Kutschej, K.; Penoy, VM.; Michotte, C.; Mitterer, VC.; Kathrein, M. Arc evaporation of Ti–Al–Ta–N coatings: the effect of bias voltage and ta on high-temperature tribological properties. Tribol. Lett. 2008, 30, 91–97. [CrossRef]

- Tkadletz, M.; Mitterer, C.; Sartory, B.; Letofsky-Papst, I.; Czettl, C.; Michotte, C. The effect of droplets in arc evaporated TiAlTaN hard coatings on the wear behavior. Surf. Coat. Technol. 2014, 257, 95–101. [CrossRef]

- Grossmann, B.; Tkadletz, M.; Schalk, N.; Czettl, C.; Pohler, M.; Mitterer, C. High-temperature tribology and oxidation of Ti1‒x‒yAlxTayN hard coatings. Surf. Coat. Technol. 2018, 342, 190–197. [CrossRef]

- Xudong Sui, Guojian Li, Chenjie Jiang, Haidong Yu, Kai Wang, Qiang Wang, Effect of Ta content on microstructure, hardness and oxidation resistance of TiAlTaN coatings. Int. Journal of Refractory Metals and Hard Materials 2016, 58, 152–156. [CrossRef]

- Seidl, W.M.; Bartosik, M.; Kolozsvári, S.; Bolvardi, H.; Mayrhofer, P.H. Influence of Ta on the fracture toughness of arc evaporated Ti-Al-N. Vacuum 2018, 150, 24–28. [CrossRef]

- Seidl, W.M.; Bartosik, M.; Kolozsvári, S.; Bolvardi, H.; Mayrhofer, P.H. Improved mechanical properties, thermal stabilities, and oxidation resistance of arc evaporated Ti-Al-N coatings through alloying with Ta. Surf. Coat. Technol. 2018, 344, 244–249. [CrossRef]

- Mikula, M.; Truchlý, M.; Sangiovanni, D.G.; Plašienka, D.; Roch, T.; Gregor, M.; Ďurina, P.; Janík, M.; Kúš, P. Experimental and computational studies on toughness enhancement in Ti-Al-Ta-N quaternaries. J. Vac. Sci. Technol. A 2017, 35, 060602. [CrossRef]

- Shugurov, A.R.; Kuzminov, E.D.; Kasterov, A.M. et al. Tuning of mechanical properties of Ti1−xAlxN coatings through Ta alloying. Surf. Coat. Technol. 2020, 382, 125219. [CrossRef]

- Shizhi, L.; Yulong, S.; Hongrui, P. Ti-Si-N films prepared by plasma-enhanced chemical vapor deposition. Plasma Chem. Plasma Process. 1992, 12, 287-297. [CrossRef]

- Vepřek, S.; Reiprich, S. A concept for the design of novel superhard coatings. Thin Solid Films 1995, 268, 64-71. [CrossRef]

- Veprek, S.; Reiprich, S.; Shizhi, L. Superhard nanocrystalline composite materials: The TiN/Si3N4 system. Appl. Phys. Lett. 1995, 66, 2640-2642. [CrossRef]

- Vepřek, S.; Haussmann, M.; Reiprich, S.; Shizhi, L.; Dian, J. Novel thermodynamically stable and oxidation resistant superhard coating materials. Surf. Coat. Technol. 1996, 394, 86–87. [CrossRef]

- Vepřek, S.; Haussmann, M.; Reiprich, S. Superhard nanocrystalline W2N/amorphous Si3N4 composite materials. J. Vac. Sci. Technol. 1996, 46, A14. [CrossRef]

- Rogl P.F.; Schuster J.C. Phase Diagrams of Ternary Boron Nitride and Silicon Nitride Systems; ASM The Materials Society, Materials Park, Ohio, 1992; p. 566. https://api.semanticscholar.org/CorpusID:92868391.

- Veprek, S.; Zhang, F.; Veprek-Heijman, M. G. J. et al. Superhard nanocomposites: Origin of hardness enhancement, properties and applications. Surf. Coat. Technol. 2010, 204, 1898-1906. [CrossRef]

- Shugurov, A.R.; Kuzminov, E.D.; Garanin, Yu.A.; Panin, A.V.; Dmitriev, A.I. The effect of Si content on the microstructure and mechanical properties of Ti-Al-Ta-Si-N coatings. Vacuum, 2023, 216, 112422. [CrossRef]

- Sun, X.; Liu, Z.R.; Chen, L.; Chen L. Influence of Si and Ta mixed doping on the structure, mechanical and thermal properties of TiAlN coatings. Surf. Coat. Technol. 2023, 461, 129428. [CrossRef]

- Shugurov, A.R.; Kuzminov, E.D.; Derbin, A.Yu.; Panin, A.V.; Dmitriev, A.I. Effect of N2/Ar pressure ratio on the structure, mechanical and tribological properties of magnetron-sputtered Ti-Al-Ta-Si-N coatings. Surf. Coat. Technol. 2024, 492,131198. [CrossRef]

- Veprek, S. Recent search for new superhard materials: Go nano! J. Vac. Sci. Technol. A 2013, 31, 050822. [CrossRef]

- Zhang, R.F.; Zhang, S.H.; Guo, Y.Q.; Fu, Z.H.; Legut, D.; Germann, T.C.; Veprek, S. First-principles design of strong solids: Approaches and applications. Phys. Rep. 2019, 826, 1–49. [CrossRef]

- Liu, X.; Lu, F.;Wu, S.; Ren, Y. Effects of different nitrogen-to-titanium atomic ratios on the evolution of Ti–Si–N islands on TiN(001) surfaces: First-principle studies. J. Alloys Compd. 2014, 586, 431–435. [CrossRef]

- Ren, Y.; Zhang, H.; Zhang, C.; Zeng, H.; Liu, X. First-principles study of the charge transfer and evolution of Si doping 2N2Ta islands adsorption on TaN(001) surfaces. Appl. Surf. Sci. 2017, 392, 350–355. [CrossRef]

- Koroteev, Y.; Svyatkin, L.; Ognev, S. Silicon adsorption on the (111) surface of TiN, AlN and TaN compounds. AIP Conf. Proc. 2023, 2899, 020080. [CrossRef]

- Svyatkin, L.; Ognev, S.; Syrtanov, M.; Koroteev, Y. Interaction of Si Atom with the (001) Surface of TiN, AlN and TaN Compounds. Coatings 2023, 13, 1453. [CrossRef]

- Chawla, V.; Jayaganthan, R.; Chandra, R. Structural characterizations of magnetron sputtered nanocrystalline TiN thin films. Materials Characterization 2008, 59, 1015-1020. [CrossRef]

- Gonze, X.; Amadon, B.; Antonius, G.; Arnardi, F.; Baguet, L.; Beuken, J.-M.; Bieder, J.; Bottin, F.; Bouchet, J.; Bousquet, E.; et al. The Abinit project: Impact, Environment and Recent Developments. Computer Physics Communications 2020, 248, 107042. [CrossRef]

- Romero, A.H.; Allan, D.C.; Amadon, B.; Antonius, G.; Applencourt, T.; Baguet, L.; Bieder, J.; Bottin, F.; Bouchet, J.; Bousquet, E.; et al. ABINIT: Overview and Focus on Selected Capabilities. The Journal of Chemical Physics 2020, 152, 124102. [CrossRef]

- Blöchl, P.E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953. [CrossRef]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758. [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [CrossRef]

- Louhibi-Fasla, S.; Achour, H.; Kefif, K.; Ghalem, Y. First-principles study of high-pressure phases of AlN. Phys. Proc. 2014, 55, 324–328. [CrossRef]

- Feldbauer, G.; Wolloch, M.; Bedolla, P.O. et al. Adhesion and material transfer between contacting Al and TiN surfaces from first principles. Phys. Rev. B 2015, 91, 165413. [CrossRef]

- Taehun, L.; Delley, B.; Stampfl, C.; Soon, A. Environment-dependent nanomorphology of TiN: The influence of surface vacancies. Nanoscale 2012, 4, 5183–5188. [CrossRef]

- Ren, Y.; Liu, X.; Tan, X.; Westkämper, E. Adsorption and pathways of single atomistic processes on TiN (111) surfaces: A first principle study. Com. Mat. Sci. 2013, 77, 102–107. [CrossRef]

- Xia, Q.; Xia, H.; Ruoff, A.L. Pressure-induced rocksalt phase of aluminum nitride: A metastable structure at ambient condition. J. Appl. Phys. 1993, 73, 8198–8200. [CrossRef]

- Zhang, R.; Ma, Q.-Y.; Liu, H. et al. Crystal Orientation-Dependent Oxidation of Epitaxial TiN Films with Tunable Plasmonics. ACS Photonics 2021, 8, 847–856. [CrossRef]

- Phani, A.R.; Krzanowski, J.E. Preferential growth of Ti and TiN films on Si(111) deposited by pulsed laser deposition. Appl. Surf. Sci. 2001, 174, 132–137. [CrossRef]

- Patel, N.; Wang, S.; Inspektor, A.; Salvador, P.A. Secondary hardness enhancement in large period TiN/TaN superlattices. Surf. Coat. Technol. 2014, 254, 21–27. [CrossRef]

- Shin, C.-S.; Gall, D.; Desjardins, P. et al. Growth and physical properties of epitaxial metastable cubic TaN(001). Appl. Phys. Lett. 1999, 75, 3808–3810. [CrossRef]

- Bader, R.F.W. Atoms in Molecules: A Quantum Theory; Clarendon Press: Oxford, UK, 1990; p. 458. [CrossRef]

- Dronskowski, R.; Bloechl, P.E. Crystal orbital Hamilton populations (COHP): Energy resolved visualization of chemical bonding in solids based on density-functional calculations. J. Phys. Chem. 1993, 97, 8617–8624. [CrossRef]

- Deringer, V.L.; Tchougréeff, A.L.; Dronskowski, R. Crystal orbital Hamilton population (COHP) analysis as projected from plane-wave basis sets. J. Phys. Chem. A 2011, 115, 5461–5466. [CrossRef]

- Maintz, S.; Deringer, V.L.; Tchougréeff, A.L.; Dronskowski, R. Analytic projection from plane-wave and PAW wavefunctions and application to chemical-bonding analysis in solids. J. Comput. Chem. 2013, 34, 2557–2567. [CrossRef]

- Maintz, S.; Deringer, V.L.; Tchougréeff, A.L.; Dronskowski, R. LOBSTER: A tool to extract chemical bonding from plane-wave based DFT. J. Comput. Chem. 2016, 37, 1030–1035. [CrossRef]

- Shugurov, A.R.; Kuzminov, E.D.; Garanin, Y.A.; Panin, A.V.; Dmitriev, A.I. Improvement of Mechanical Properties and Adhesion of Ti-Al-Si-N Coatings by Alloying with Ta. Lubricants 2022, 10, 178. [CrossRef]

- Christiansen, S.; Albrecht, M.; Strunk, H.P.; Veprek, S. Microstructure of novel superhard nanocrystalline-amorphous composites as analyzed by high resolution transmission electron microscopy. J. Vac. Sci. Technol. B. 1998, 16, 19–22. [CrossRef]

- Naik, A.A.; Christina Ertural, C.; Dhamrait, N.; Benner, P.; George, J. A Quantum-Chemical Bonding Database for Solid-State Materials. Sc. Data 2023, 10, 610. [CrossRef]

- Steinberg, S.; Dronskowski, R. The Crystal Orbital Hamilton Population (COHP) Method as a Tool to Visualize and Analyze Chemical Bonding in Intermetallic Compounds. Crystals 2018, 8, 225. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).