1. Introduction

Onion is one of the most important commercially grown bulbous vegetable crops upon which every kitchen, restaurant and family dependent on it throughout the year and it is one of the oldest cultivated and extensively used vegetables after tomato [

1]. The crop has a great contribution both for economic and health issues [

2] but the production is not sufficient enough to meet the huge demand every day. Sudden supply gap even for a day created huge economic impression in the market.

Onions are one of the few versatile vegetable crops that can be stored for an extended period of time for future use and can withstand rough handling and long-distance transport [

3]. Different governments and agencies have taken initiative for expansion of onion areas through various schemes in traditional ways and techniques by providing inputs even though which is not enough to mitigate the day-to-day demand. Some of the costly aeroponic, nutrient film technique, floating and aggregate techniques for production of onion bulb under glasshouse conditions [

4] are not feasible in some context.

Onions are preferred for its rich characteristic flavor and aroma due to presence of sugars and organic acids which contributed to the organoleptic test. The Pungency level and total soluble solids are important quality attributes of any onion bulbs though the lower pungency is more popular than the higher pungency for handling. Sweetness of onion mainly depends upon the higher levels of soluble solids. The quality parameters of onion influence the export and processing quality [

5].

Presently, growing of clean and healthy vegetables especially leafy vegetables in Nutrient Film Technique and in Floating system through hydroponically using artificial light and Styrofoam, Polysterene foam as rafts is very common under vertical farming system in urban and periurban areas and in some plant factories which is sometimes technology and skill dependent to manage the system irrespective of the huge installation and maintenance charges. Production of other vegetable crops under nutrient film technique, hydroponic, aeroponic or soilless system sometimes not feasible to the general growers though advantageous in the case of climate smart agriculture. With the expansion of urban horticulture, everyone now acquainted with the roof garden, varanda garden, vertical garden under soilless media or artificial media even though which are costly and sometimes unavailable to the growers. Very limited information is available in respect to growing of red bulb of onion under low cost hydroponic system for its growth, yield and quality even standardized package of practices for production of onion in hydroponics system.

Keeping in the view of the research gap of bulb production under field condition as well as cost effective production of onion under hydroponic, aeroponic, Nutrient Film Technique and other soilless cultivation system and to increase the production of onion without compromising the quality as a whole, an experiment has been framed with the aim to study the influence of different growing conditions and its implications especially hydroponic growing conditions for vegetative growth, initiation root and bulbs and production of onion bulbs for yield as well as quality of onion bulbs by using minimum inputs like Polythene and thermocol or polysterene foam and tap water.

2. Materials and methods

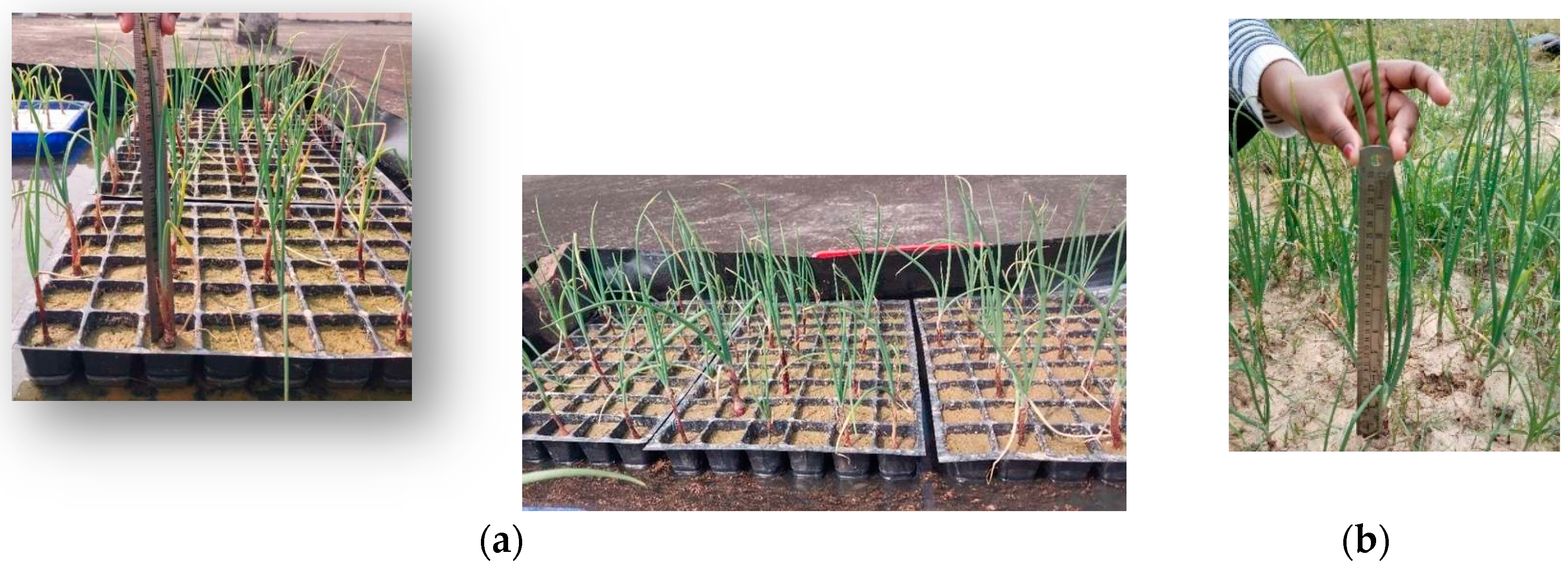

The experiment on production of onion bulb under low cost hydroponic system by using polythene sheet and polysterene foam as floating bed without using any seedling holders was carried out at open roof condition of the faculty building of Horticulture, Bidhan Chandra Krishi Viswavidyalaya during winter season of 2023-2024 following Complete Randomized Design with three replications with the aim to study the production possibility of onion bulbs under low cost hydroponic system and to study the effect of polysterene foam bed on vegetative growth of plant, root and bulb development in open condition under direct sunlight. Black polythene sheet of 100 micron thickness was used to make a container of 1.5 m x 1.1 m x 0.15 m for holding the water and polysterene foam of 45cm x 100 cm x 4 cm was used as a floating bed. A local red ellipsoid variety of West Bengal namely

Sukhsagar [

6] is employed for this experiment. The 40 days old onion seedlings of

Sukhsagar variety were transplanted in polysterene foam bed of hydroponic system along with field of Mondouri Horticultural Research Station of Bidhan Chandra Krishi Viswavidyalaya during the second week of January of 2024 to compare the growth and yield of the bulb in both the condition. The seedlings of onion were transplanted with a spacing of 5cm x 8cm in the punch hole of polysterene foam in the evening hours thereafter the these beds were floated in 10 cm height confined water of polythene container. The commercial grade fertilizer (19:19:19) @2g per litre of was applied at 11 DAT and 32 DAT, 45DAT. Sulphur(60%) @ 2g per litre of water was applied twice at 15DAT and 35 DAT. Micronutrient @ 25g was applied at 11 DAT as supplements of micronutrients.

The observations on vegetative growth of plants, root development, initiation of bulb, bulb development, changes in bulb geometry, and other bulb characters including quality of bulbs were studied from ten randomly selected plants of each replication and the data were analyzed statistically as per Bhattacharya and Dhakre [

7].

3. Results and Discussion

The production of red onion bulb of Sukhsagar variety under low cost floating system was experimented to study the vegetative growth of plants, root development, initiation of bulb, speed of bulb formation, bulb geometry, bulb yield and quality of bulbs under the low cost hydroponic system, which recorded satisfactory results in the very first attempt in India during the winter season in open roof system of direct sunlight condition. The mean performance of growth, yield and quality parameters along the changes in bulb geometry presented in the Table and discuss hereunder.

3.1. Vegetative growth of plants

The data related to various growth, yield and quality parameters of onion under the influenced of different substrate of water, sand and soil presented in the

Table 1 and

Table 2, illustrated in

Figure 1,

Figure 2,

Figure 3 and

Figure 4.

3.1.1. Plant height (cm)

At 30 days after transplanting (DAT), the significant maximum plant height of 41.33 cm was recorded in the polysterene foam bed of hydroponic system followed by open field condition (40.57cm) and minimum plant height of 25.33 cm recorded in the sand bed system. However, plant height in the field was statistically at par with the thermocol bed of hydroponic system but slightly higher than field indicated the influence of the water based growing condition for better growth of plant than the other growing conditions of sand and soil.

The growth rate of onion plant was much slower in sand might be due to texture and structural properties of the growing conditions. Additionally, the residual effects of soils help to grow plant better in soil bed than sand while the readily available nutrients dissolved in water and which can increase the uptake efficiency of plants through roots could be easier to plant than any other substrate resulted better plant growth in terms of height. The higher plant height of 25.2cm in hydroponic condition than 22.3cm for traditionally soil grown of spring onions at 21 days of planting and revealed that onion plants grew more efficiently in hydroponic conditions than soil based traditional conditions[

8]. Significantly taller plants of sweet onion at 31 DAT both in aggregate and floating system than NFT and aeroponics system was reported some coworkers [

4].

At 45 days after transplanting (DAT), the significant highest plant height of 43.79 cm of was recorded in open field followed by hydroponic grown onion (41.77cm) though both are statistically at par however lowest plant height of 29.50cm was recorded in sand grown onion. Though there was an increased growth rate recorded in all the substrate system, however soil bed system surplus the hydroponic system of floating bed in plant height of onion might be due to the steady support received from the soil for growth of the plants. The results revealed that the higher plant height of onion was recorded in open field system due to the better adoption of the plant in an acclimatized system, however favourable growing condition also makes better sense to the plant for growing in other growing conditions (

Figure 1 and

Figure 2). In earlier, length of the top upto 49.57 cm of Sukhsagar cultivar of onion in November planting time [

6] while plant height upto 60cm of Sukhsagar cultivar was also recorded earlier [

9].

3.1.2. Number of leaves per plant

Significantly highest number of leaves per plant at 30 days after transplanting (DAT) was recorded in the hydroponically grown plants (5.73) followed by 4.8 in open field condition whereas, the lowest number of leaves per plant was recorded in the sand grown onion. The number of leaves per plants exhibited significant differences among the different substrate indicated the better influenced of the hydroponic system over the other system. In earlier report revealed up to 12 numbers of leaves in hydroponic grown onion after 56 days monitoring of different sensors to provide better environment [

10] while better performance in leaf number in specified nutrient solutions in hydroponic grown green onion [

11] even polystyrene floating bed was better than the sand and gravel grown onion [

12]. In earlier, the number of leaves upto 8.16 of Sukhsagar cultivar of onion in November planting time [

6] however, number of leaves upto 5.3 of Sukhsagar cultivar of onion in open field condition was also recorded [

9].

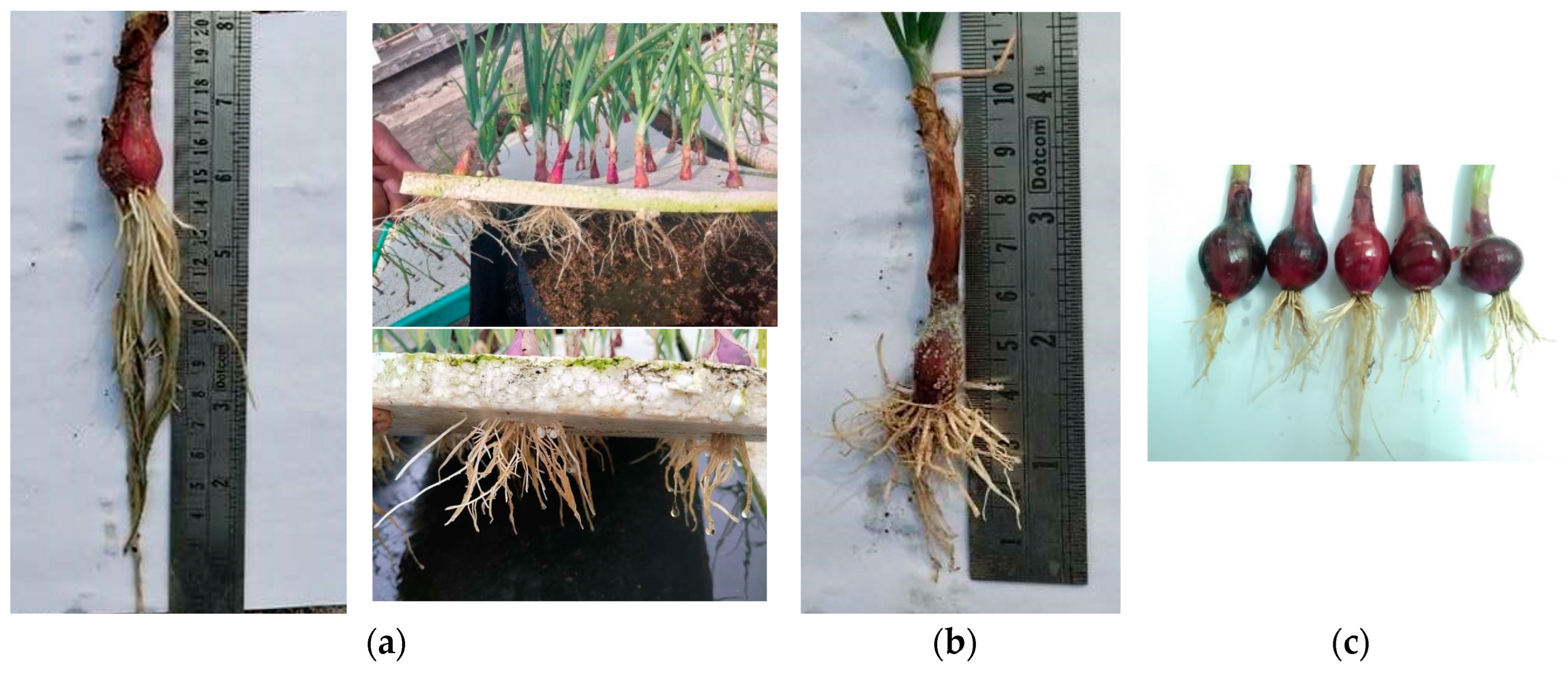

3.1.3. Root length (cm)

Root length of plant significantly influenced by the different substrate system at 35 days after transplanting (DAT) presented in the

Table 1 and depicted in

Figure 3. The significant maximum average root length of 18.7 cm was recorded in hydroponic grown plant followed by sand grown plant whereas minimum root length of 7 cm was recorded in field grown plant of onion. Root length in sand showed higher than the field grown plants. It indicated that the root proliferation depends on the substrate. The water grown plants exhibited three times higher root length than field even much higher than the sand indicated that the texture and structural properties might have inhibited the root growth by creating the physical barrier. The floating system exhibited white colour healthy root in early growth stages of onion plant while the brown colour root also found in aged plant seems less healthy however, the healthy root was observed in the field grown onion after harvesting.

However, significant highest root length of 20.13cm was recorded in floating bed of hydroponic system followed by sand bed (13.17cm) grown onion plants while field grown onion plants recorded 7. 81 cm of root length at 65 days after transplanting indicated the significant influenced of the substrates for the root length. Root length of hydroponic grown onion exhibited much lengthier roots than the other system might be due to the structural properties of the substrates which creates physical hindrance to root proliferation in the sand and field though onion is a shallow rooted crop and root growth restricted within the 15 cm of soil layers however, the results clearly indicated the significant influenced of substrate could restrict the root growth. On the other hand in hydroponic system plant able to grow roots easily to uptake the nutrients for its better growth and development.

As the growth of the plants have direct relation with root. The higher the roots of plant may have contributory effects for growth, yield and quality of the crops as root is one of the major receptive organs which can easily adsorb the nutrients from the growing media for better growth and development of the plants. The hairy root growth in tomato at two months after transplanting in low cost hydroponic system was recorded by earlier co-workers [

13]. In earlier, the variation in root length of onion plants in three supporting media of water (33.63 cm) sand (25.53 cm) and gravel (16.95 cm) and they [

12] suggested that the hard media makes many obstacles than the other media to pass the root easily. Sweet onion plants showed different root size and colour in different system and results revealed that Aeroponic (AER) and Floating (FL) plants developed the largest roots while Aggregates (AG) plants developed the smallest root system and also revealed the white root colour being the most functional and brown being the most aged and root system of AG appeared to be the healthiest followed by AER and NFT system while the least healthy root system was observed in FL growing plants. However, notable mass of new roots were observed in FL and NFT plants of sweet onion [

4].

3.1.4. Neck girth (mm)

Significantly maximum neck girth of 10.66mm was recorded in hydroponic grown plants at 35 DAT followed by field grown onion while minimum neck girth of 7.60mm recorded in sand grown onion which indicated the influenced of different substrate for the character. However, neck girth recorded at 45 DAT exhibited no significant influenced by the different substrate. Earlier report revealed the significant influenced of the media in respect to neck diameter, where, AG and FL recorded higher neck girth than NFT although FL did not differ from AG plants but exceeded NFT plants in terms of neck diameter at 59 DAT [

4] . However, the neck girth of 13.2 mm in Sukhsagar cultivar of onion was recorded in the field condition [

9].

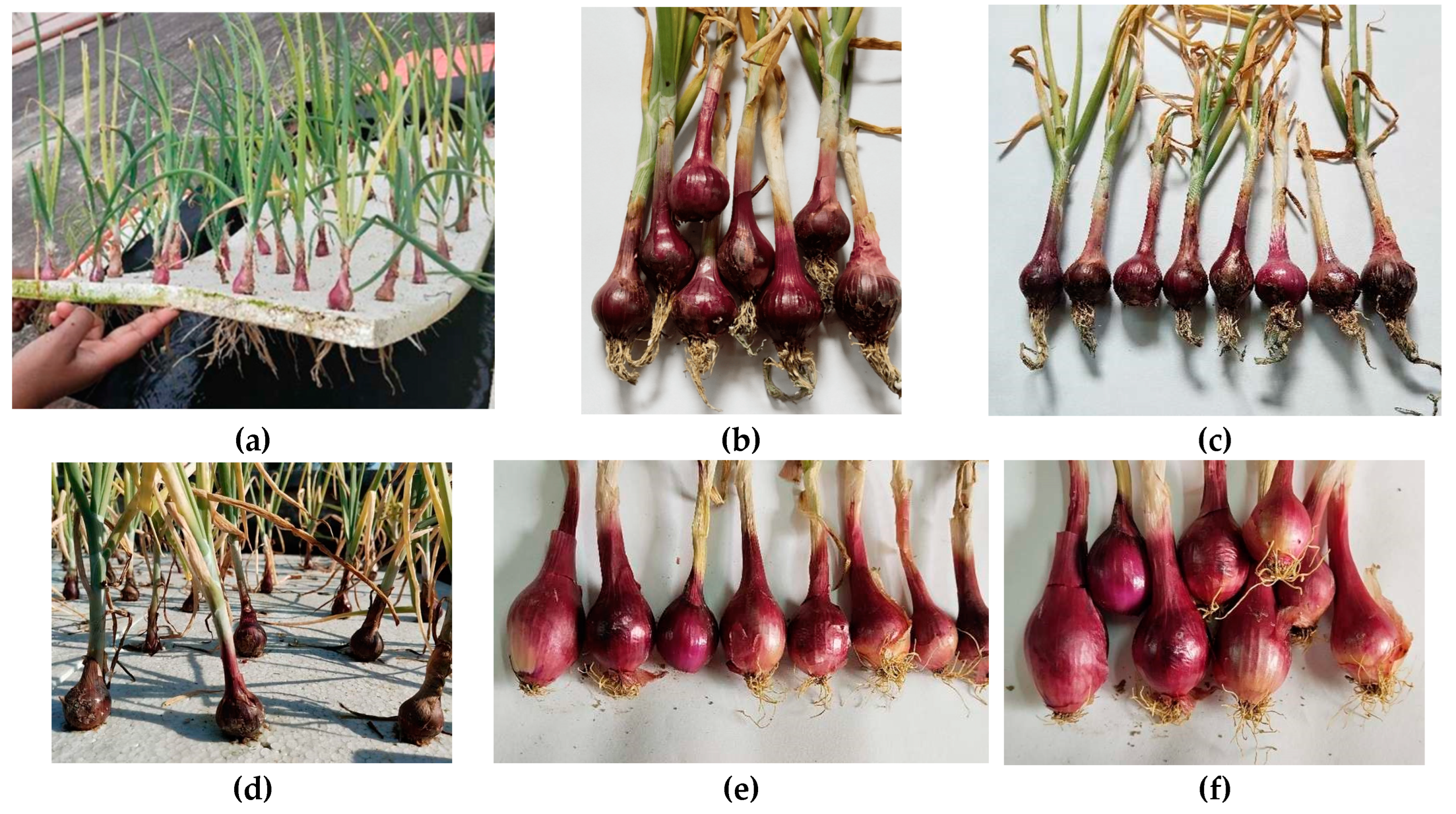

3.2. Bulb development parameters

The results related to initiation of bulb and bulb development presented in the

Table 2 and illustrated in

Figure 4 and its contributory effects to the total bulb yield. The shape and size of the bulbs is depended on the equatorial and polar diameter of bulb which influenced the bulb geometry if any changes occurred due to the effects of the different growing conditions.

3.2.1. Equatorial diameter (mm)

Significant highest equatorial diameter of bulb (24.99 mm) recorded at 35 days after transplanting (DAT) followed by field grown onion bulb (17.60 mm) whereas lowest equatorial diameter of bulb (16.42 mm) was recorded in sand bed system indicated the significant influenced of the substrates. The increased rate of bulb equatorial diameter quite higher in hydroponic system over the field and sand grown system might be due to higher growth rate of plant stimulate bulbing in the particular substrate. Early bulb development is important and positive sign in respect to early harvest of bulb which shorten the crop cycle and have commercial value and economically viable options for the growers. The temperature influences the onion life cycle; high temperatures cause early bulbing while low temperatures (even 15 to 20

0C) leading to bolting in tropical onion cultivars and suggested to control the precise temperature especially for studying of different growth phases of onion under controlled conditions and found that the inductive day length or long days of 16 h light and 8 h dark condition and optimum light quality (far-red) forms bulb [

14] whereas shorter day length (more than 14:30 h) is required for onion plants to enter into bulbing [

4].

However, the steady increased of equatorial diameter of bulb is recorded at 45 days after transplanting (DAT). Significantly maximum equatorial diameter of 31.65 mm recorded in the field followed by hydroponic system (30 mm) though both showed statically at par whereas, minimum diameter of bulb (24.01 mm) was recorded in sand grown onion indicated the significant influenced of the substrates might be due to the better vegetative growth of plants which translocate the photosynthates to bulbing. The adaptability of onion plants in the growing conditions or substrates especially in field and residual nutrient availability etc. might have positive influenced to bulbing of onion. Generally, Sukhsagar cultivar of onion takes 90-100 days to reach the maturity for harvesting of bulb which is quite lengthier period for the growers. The results indicated that the faster bulb development in the floating system of thermocol bed might be a viable option for the growers to get early bulbs to minimize the production gap. In earlier, equatorial diameter of bulb of 3.56 cm of Sukhsagar cultivar of onion during November planting time was recorded [

6] however, bulb equatorial diameter of 55.6 mm at 120 days after harvesting of Sukhsagar cultivar of onion in the field condition also revealed b earlier co-workers [

9].

3.2.2. Polar diameter (mm)

Significant highest polar diameter of bulb was recorded in the hydroponic system of polysterene foam bed (21.20 mm) followed by the open field (16.05 mm) while the lowest polar diameter (14.69 mm) was recorded in sand grown onion bulb at 35 days after transplanting (DAT) which indicated the positive influenced of the substrates. The water grown bulb exhibited much higher polar diameter than the other growing conditions of sand and soil.

However, in contrary the significant highest polar diameter of bulb (38.76 mm) was recorded in the soil grown plants followed by the plants grown in polysterene foam bed of hydroponic system (34.95 mm) whereas the lowest polar diameter of bulb was recorded in the sand bed system (25.15 mm) at 45 days after transplanting (DAT) indicated the significant influenced of thermocol or polysterene foam bed for changes in the polar diameter of bulb of onion. The polar diameter of bulb showed much higher in the field grown onion than the floating bed of hydroponic system and sand bed system. The sharp increase of polar diameter than the equatorial effected in the shape and size of the bulb which formed the globular shaped bulb while floating bed of polysterene foam bed exhibited somewhat round shaped bulb indicated the changes in bulb geometry towards sphericity. In contrast, no effects for shape index of bulb in floating system might be due to the used of Styrofoam board as a bedding material not even in other system [

4]. The growth rate of polar diameter of bulb might be restricted due to the stiffness of the thermocol while in field polar diameter of the bulb exhibited as usual as per characters laid for the Sukhsagar cultivar of onion. In earlier, the higher polar diameter of bulb of 5.32 cm than equatorial diameter (3.58cm) of Sukhsagar cultivar of onion during the November planting time [

15] however, in contrary, the lesser polar diameter of bulb (49.8mm) than equatorial diameter of bulb (55.6 mm) of Sukhsagar cultivar of onion in the field condition was also reported previous researchers[

9].

3.2.3. Individual bulb weight (g)

The individual bulb weight was recorded at 60 days after transplanting presented in

Table 2. The growth of onion plants in the hydroponic system adversely affected due to some unavoidable circumstances forced to harvest the bulb early stages of maturity. The significant highest individual weight of the bulb (21.86g) was recorded from the hydroponic system followed by field (20.72g) whereas, lowest individual bulb weight (20.59g) which indicated the positive influenced of different substrate for bulb yield.

The floating bed of hydroponic system performed better in terms of bulb weight might be due to the overall vegetative growth of the plants and faster rate of nutrient uptake efficiency than the other system. In earlier, polystyrene foam of hydroponic system exhibited slightly higher bulb weight of 7.74g and 3 bulblets per plants than the sand and gravel system by using the natural environment set up and the harvesting of the bulb was done at 120 days after planting [

16] while 7.87 kg/m

2 in floating system followed by AG (7.57 kg/m

2) and AER (6.22 kg/m

2), while the NFT (5.20 kg/m

2) showed lowest bulb yield of sweet onion and harvesting was done at 244 DAS/104 DAT [

4] . In earlier, the average bulb weight of Sukhsagar cultivar of onion is 58.74 g [

4] while bulb weight upto 62.00g when planted in November in the field condition found better results than the earlier planting time of September and October [

15] while, the bulb weight of 80.6g at 130 days after harvesting of Sukhsagar cultivar in the field condition was revealed [

9].

Here in the present investigation quite impressive bulb weight was recorded even at early harvesting of bulbs. The hydroponic system of floating bed will be very helpful for the onion growers to get higher yield subject to face any adversity during the growth stages of plants.

3.2.4. Number of scales

Average highest number of scales per bulb was recorded in the floating system (7.73) while the other two system recorded same number of scales per bulb (7.53) and no variations was recorded between the substrates of sand and soil grown bulb even not much varied with the hydroponic system indicated least influenced by the growing conditions. Although, bulb diameter is mainly dependent on the thickness of the scales which might be differed in the substrates due to variations were recorded in the bulb diameter though the number of scales is same which can be compensated by the thickness of the scales. Thickness of the scales might be due to the accumulation of higher photosynthates in the bulb. In earlier, the number of scales up to 8.1 for Sukhsagar cultivar of onion was recorded in field condition [

9].

3.3. Bulb quality parameters

The two important quality parameters were estimated and presented in the

Table 3 while pungency of onion was estimated by the organoleptic test. Total Soluble Solid was estimated by hand refractometer and total sugar was estimated as method described by Ranganna, 1977 [

17].

3.3.1. Total Soluble Solid (TSS) (0Brix)

Significant maximum TSS of 11.61

0Brix was recorded in the bulbs harvested from the field at 60 days after transplanting, followed by sand grown bulbs (8.31

0Brix) whereas, minimum TSS of 8.23

0Brix was recorded in bulbs harvested from the hydroponic system and both showed statistically at par each other. However, water and sand grown bulbs did not vary much while much higher amount of TSS was exhibited by the bulbs harvested from the field indicated the influenced of the growing conditions. Previously, TSS up to 7.05

0Brix in NFT grown bulbs[

18] however TSS of Agrifound Dark Red variety of onion ranges from 10.5 to 11

0Brix in sand bed system with the various organic treatments [

19] while TSS up to 13.4

0Brix for the Sukhsagar cultivar of onion under field grown bulbs recorded by earlier researchers [

9].

3.3.2. Total Sugar (%)

Significant highest total sugar percentage was recorded 6.45% followed by 5.25% while lowest total sugar (5.11 %) was estimated from the bulbs harvested in hydroponic grown bulbs. Total sugar value was slightly higher in the bulbs harvested from field indicated the influenced of the soil-based growing conditions however total sugar did not vary much in the bulbs harvested from sand and water based growing conditions. In earlier, total sugar percentage of Agrifound Dark Red variety of onion ranges from 5.98 to 7.19 in sand bed system with the organic treatments [

18].

3.3.3. Pungency of bulbs

The pungency levels of bulbs were evaluated through organoleptic test and presented in the

Table 3. The bulbs harvested from hydroponic growing conditions showed strong pungency followed by sand and soil grown bulbs. It was also observed that the higher level of pungency is inversely correlated with the total soluble solids and total sugar content of bulbs.

The quality parameters of bulbs are important for fresh, processing and storing. The higher level of sugar and soluble carbohydrates contributed sweetness of bulbs which influence the export and processing quality [

5]. The Pungency level and total soluble solids are important quality attributes of any onion bulbs though the lower pungency is more popular than the higher pungency for handling. Sweetness of onion mainly depends upon the higher levels of sugar and soluble solids. The quality parameters of onion influence the

4. Conclusion

The floating bed of hydroponic based growing conditions performed better in terms of highest plant height, highest root length, higher neck girth, maximum equatorial diameter, highest bulb weight and maximum number of scales per bulb. Hence, overall vegetative growth of the plants, root development, early bulb initiation and faster rate of bulb development and better establishment of plants, higher level of pungency and lesser sweetness in terms of quality attributes in floating bed of hydroponic system over the sand and soil based growing conditions. The floating bed of hydroponic system is also a low cost viable technique for the growers as it can easily be accommodated in roof garden, verandah garden, and balcony garden etc even this floating system may be suitable for vertical farm growers to get early higher yield of the bulb to fetch better market price. It is very easy to handling and low maintenance cost even lower production cost as well as early harvesting could be possible which the prime importance factors for the onion growers. Hence, it might be helpful for future growers to increase the onion production as a whole to meet the demand after several trials in different locations subjected to fulfill the conditions emerged from the experiment.

Funding

There has been no financial support for the work.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors without undue reservation.

Acknowledgement

Authors are highly thankful to the Bidhan Chandra Krishi Viswavidyalaya for providing the facilities for the research programme.

Conflict of Interest

The authors announce that they have no conflict of interest.

References

- Sidhu, J.S.; Ali, M.; Al-Rashdan, A.; Ahmed, N. Onion (Allium cepa L.) is potentially a good source of important antioxidants. J. Food Sci. Technol. 2019, 56(4),1811-1819. [CrossRef]

- Yeshiwas, Y.; Alemayehu, M.; Adgo, E. The rise and fall of onion production; its multiple constraints on pre-harvest and post-harvest management issues along the supply chain in northwest Ethiopia, Heliyon 2023, 9(5), e15905. [CrossRef]

- Tripathi, P.C.; Lawande, K.E. Onion storage in tropical region : A review. Curr. Hort. 2019, 7(2), 15–27. [Google Scholar] [CrossRef]

- Mouroutoglou, C.; Kotsiras, A.; Ntatsi, G.; Savvas, D. Impact of the Hydroponic Cropping System on

Growth, Yield, and Nutrition of a Greek Sweet Onion (Allium Cepa L.) Landrace. Horticulturae 2021, 7: 432. [CrossRef]

- Dhumal, K.; Datir, S.; Pandey, R. Assessment of bulb pungency level in different Indian cultivars of onion

(Allium cepa L.). Food Chem 2007, 100(4), 1328-1330. [CrossRef]

- Karak, C. ; Hazr,a P. Influence of environment on growth and bulbing of onion (Allium cepa L.) under

Gangetic alluvial plain of West Bengal. Ind. J. Agril. Sci. 2014, 84(4), 492-497 . [CrossRef]

- Bhattacharya, D.; Dhakre, D.S. CRD analysis with equal number of replications by using D x D Statfield.

Microsoft Excel office 2024. https://psbvb.ac.in.

- Bhandari, K. Evaluating the Efficiency of Hydroponic Farming. Inter. Res. J. Modern Engg. Technol. Sci. 2023, 5(4), 2415–2421. [Google Scholar] [CrossRef]

- Mandal, J.; Ajgalley, R.; Saha, D.; Mohanta, S. Growth, yield and quality of onion cultivars under laterite belt of Eastern India. Veg. Sci. 2019, 46 (1&2), 129-131. [CrossRef]

- Rahmat, R.F.; Adnan, S.; Anugrahwaty, R.; Alami, E.P.S.; Siregar, B. Red onion growth monitoring system in hydroponics environment. J. Phys: Conf. Series 2019, 1235, 012117. [CrossRef]

- Santos, J.E.; Luz, J.M.Q.; Oliveira, R.C.; Almeida, R.F.; Silva, J.R.; Lana, R.M.Q. Cultivation of green onion (Allium fistulosum L.) with support channels and nutrient solution in hydroponic. Com Sci. 2021 12, 3775. [CrossRef]

- Khatun, I.; Haider, I.; Das, S.K.; Hossen, R. Performance test of three supporting media during outdoor hydroponic farming of onion. Plants Ecosystem 2021, 1, 3–8. [Google Scholar] [CrossRef]

- Sabrina Naz, S.; Haq, A.H.M.R.; Rahman, M.M.; Khatun, M. An Initiative for Developing Low Cost Hydroponic System. Haya: Saudi J. Life Sci. 2021, 6(1), 9-13. [CrossRef]

- Khosa, J.; Lee, R.; Joshi, S.; Shaw, M.; McCallum, J.; Macknight, R. A Guide for the Cultivation of Onion under Controlled Environment Conditions. HortScience 2018, 53(12), 1746–1749. [Google Scholar] [CrossRef]

- Halder, A.; Karak, C.; Naik, A.; Samanta, M.K.; Hazra, P. (2009) Identification of suitable early rabi onion varieties under West Bengal conditions. J. Crop Weed 2009, 5(1), 131-134.

https://www.cwss.in/Journal/Complete_jurnal/Vol5_1__25.pdf.

- Khatun, I.; Karim, S.; Das, S.K.; Hossen, R. Onion cultivation approach by custom-made outdoor hydroponics: A very first attempt in Bangladesh. J. Aridland Agri. 2021, 7, 48–51. [Google Scholar] [CrossRef]

- Rangana, S. Handbook of analysis and quality control for fruits and vegetable products(2nd ed.). Tata McGraw-Hill Publishing Company Limited. 1977.

- Singh, A.; Bahadur, V.; Topno, S.E.; Prasad, V.M.; Kerketta, A. Effect of Different Levels of NPK and Micronutrients for Plant Growth, Bulb and Quality of Onion (Allium cepa) in NFT System of Hydroponics. Int. J. Environ. Clim. Change 2023, 13(9), 2261–2272. [Google Scholar] [CrossRef]

- Nag, D.; Dutta, A.K. Yield and quality of Sand Mulched Onion with the Application of Different Liquid Organic Manures. Environ. Ecol. 2017, 35 (2B), 1050—1054. (https://environmentandecology.com/ CABI).

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).