Submitted:

18 November 2024

Posted:

19 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Volumetric Flow Rate Measurement Methods

2.2. Transient Flow Rate Models

2.3. Analytical Soft Sensor Model for Flow Rate Calculation

- .

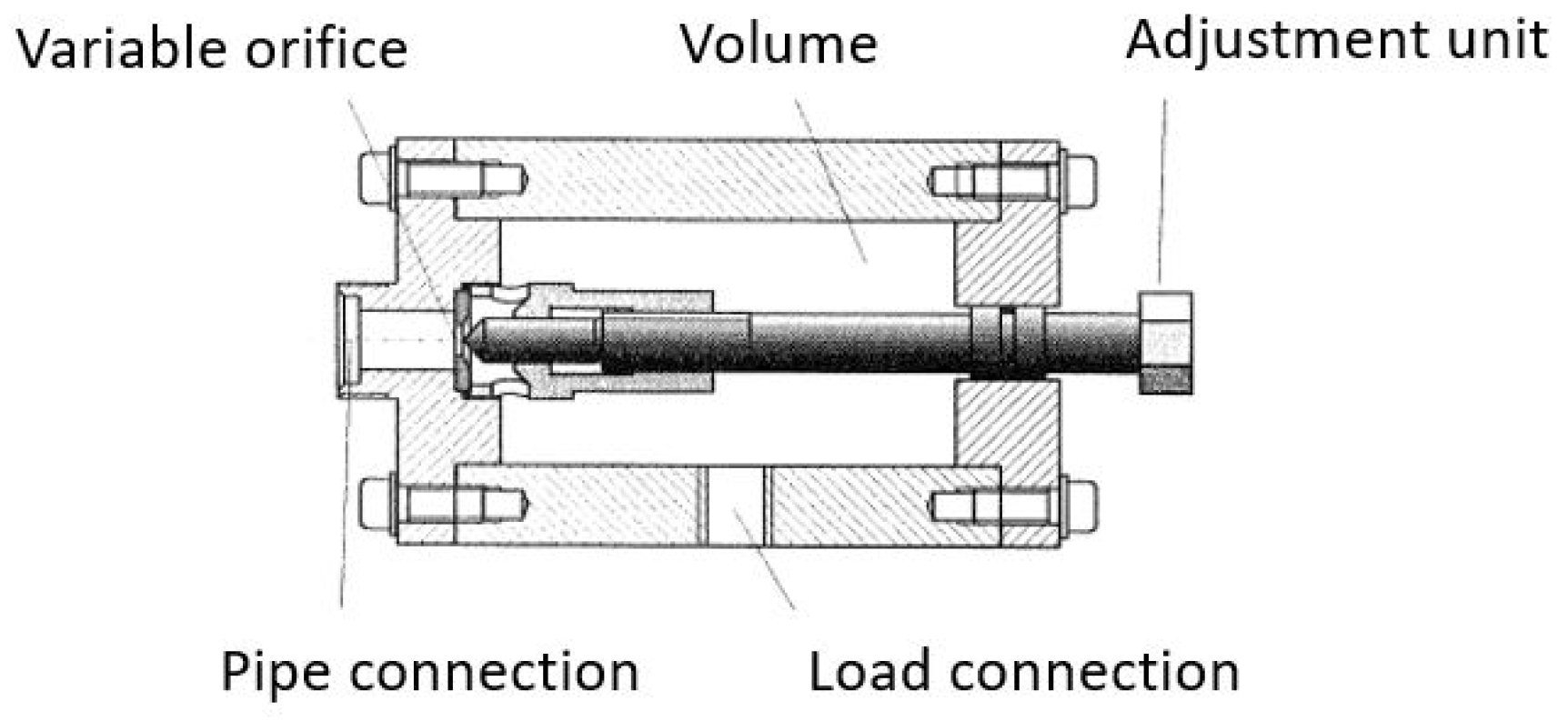

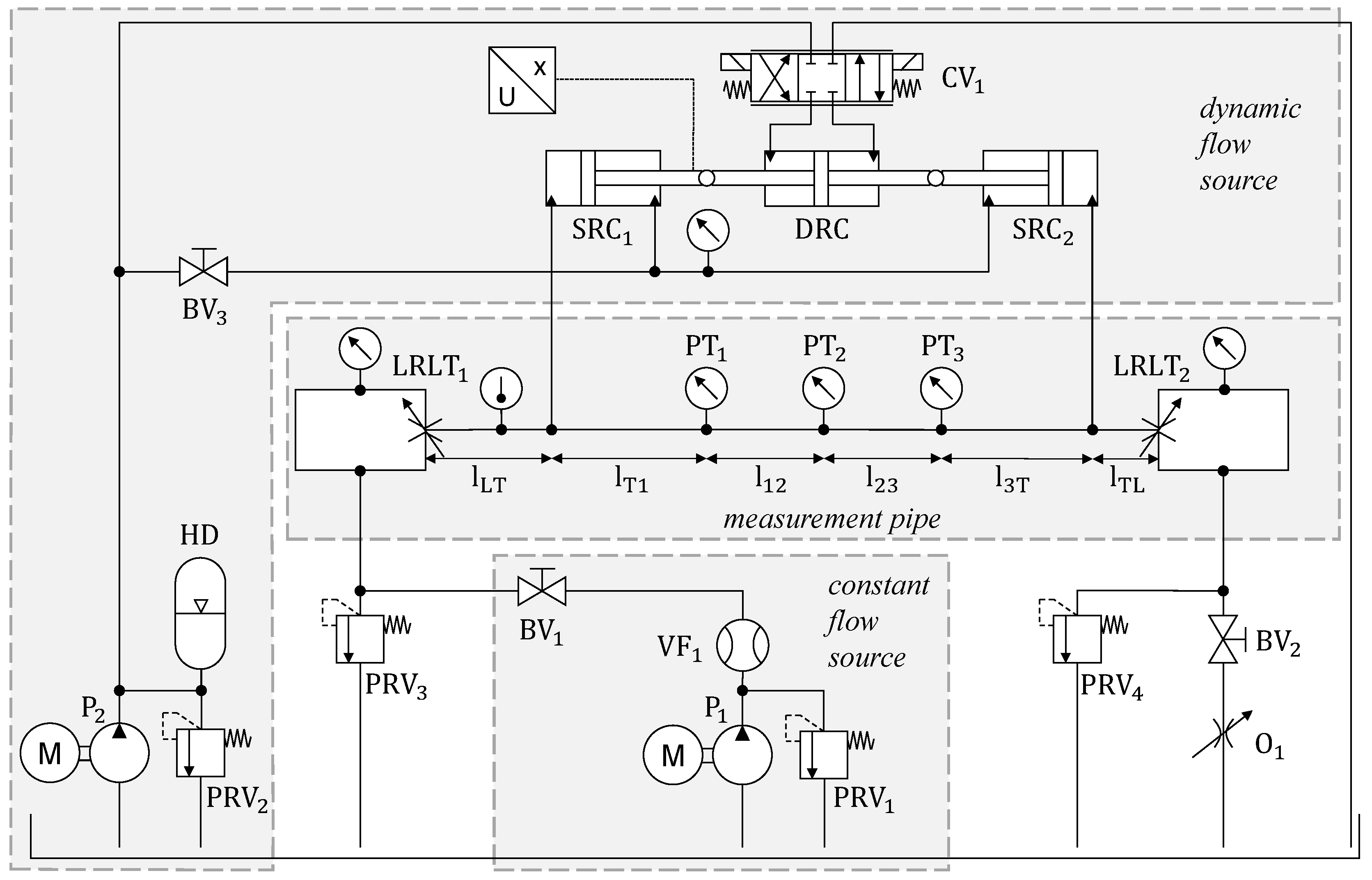

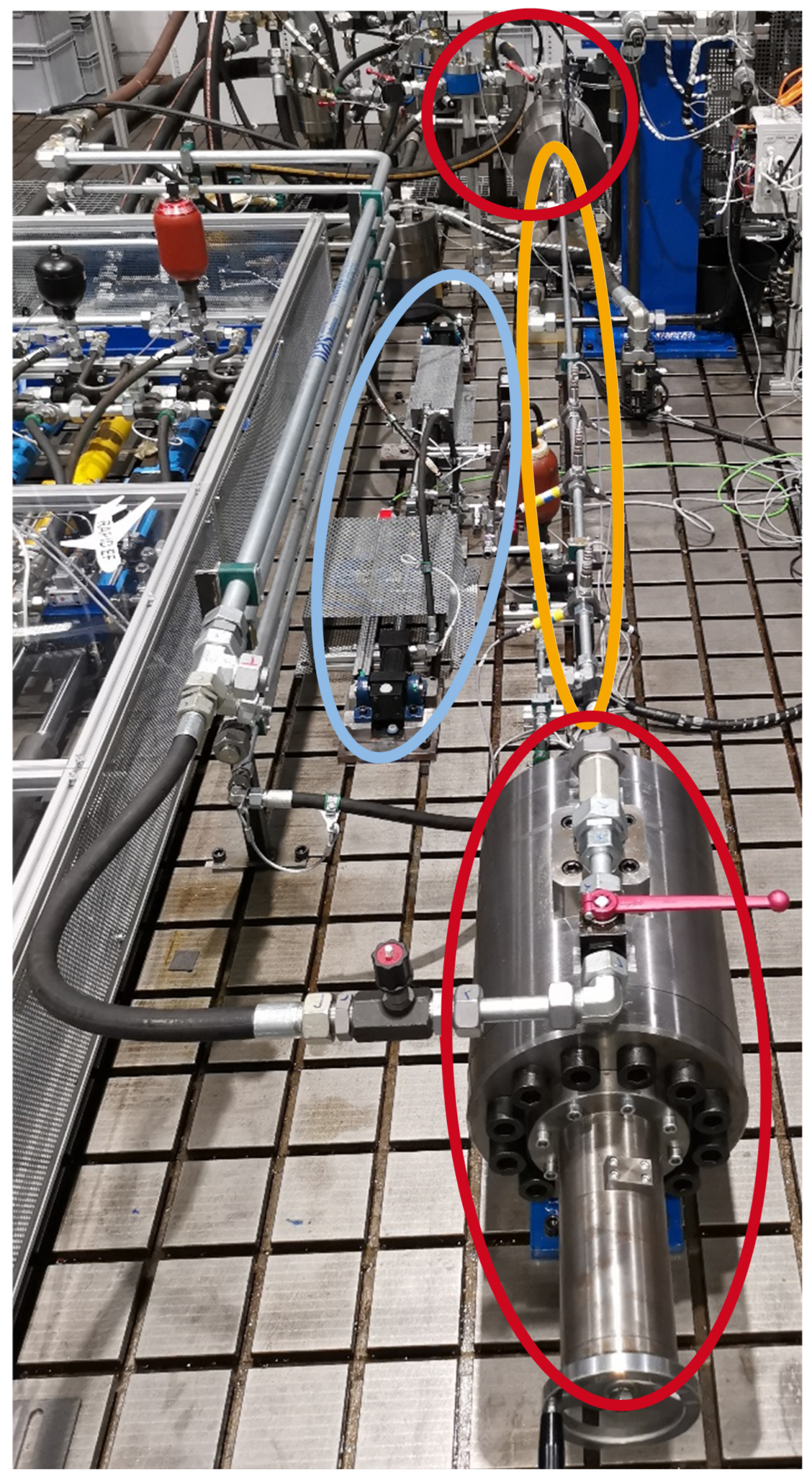

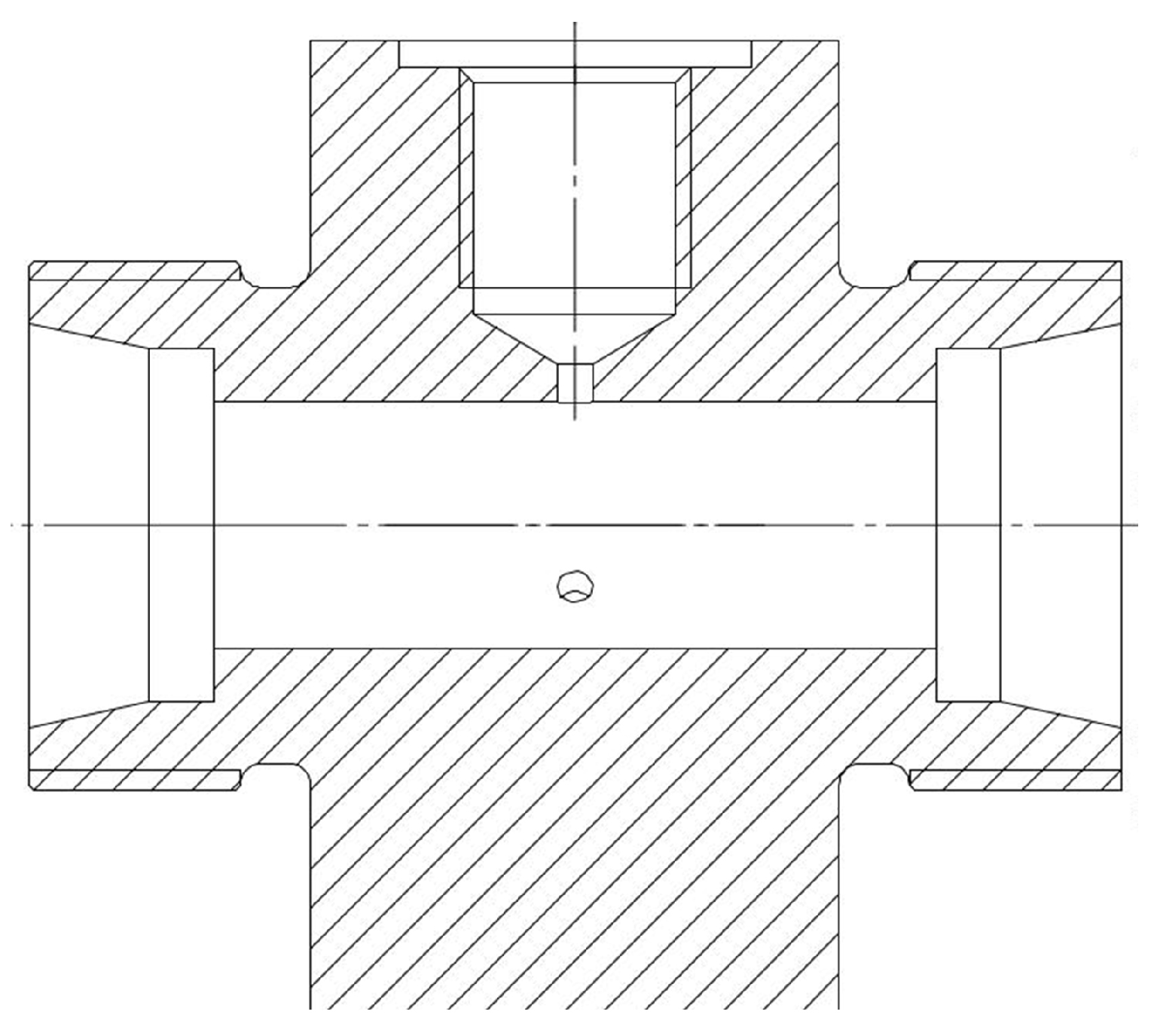

2.4. Test Rig

2.5. Test Cases

| Test Case | System Pressure [bar] |

Mean Volumetric Flow Rate [l/min] |

Degree of Non-uniformity [-] |

Frequency f [Hz] |

|---|---|---|---|---|

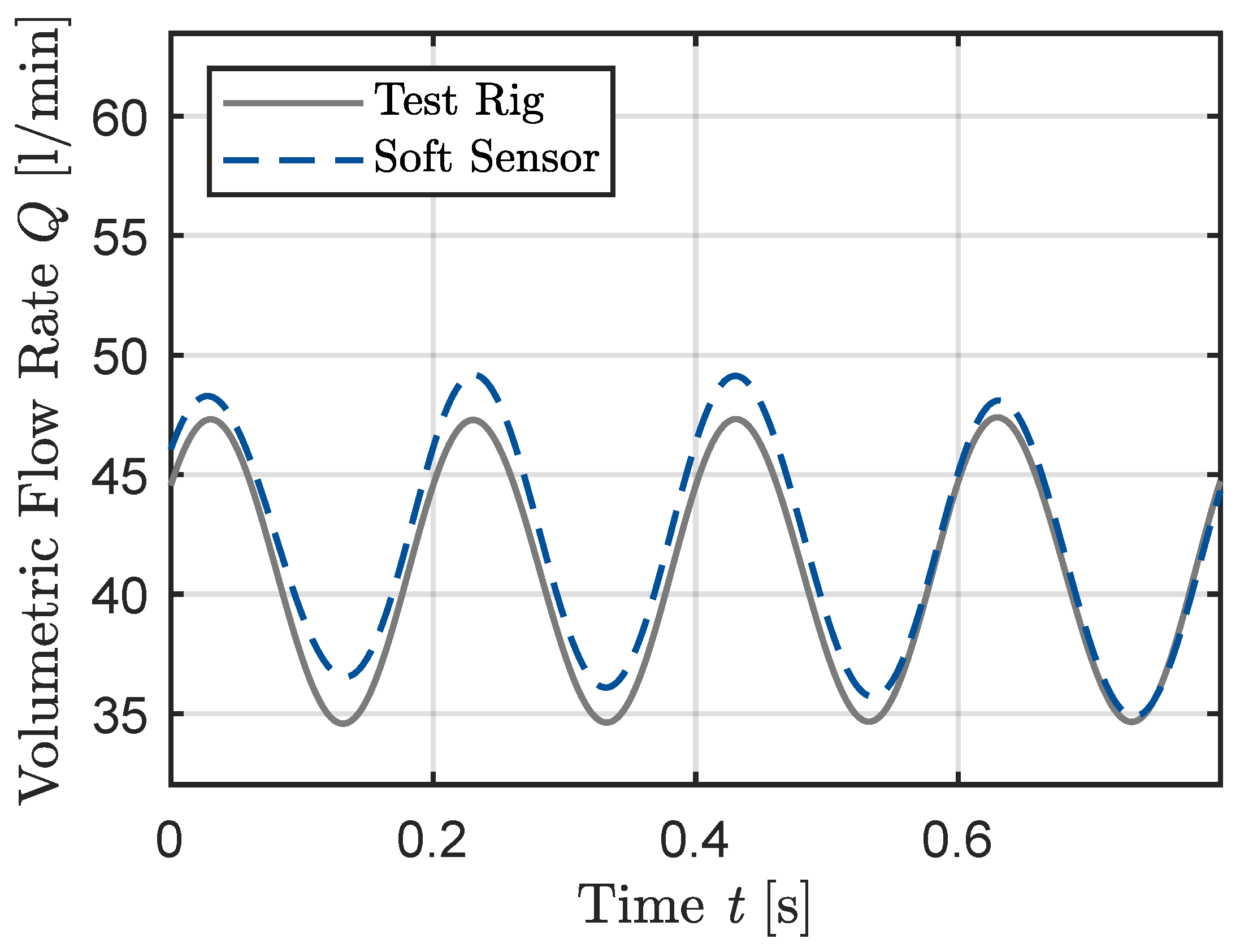

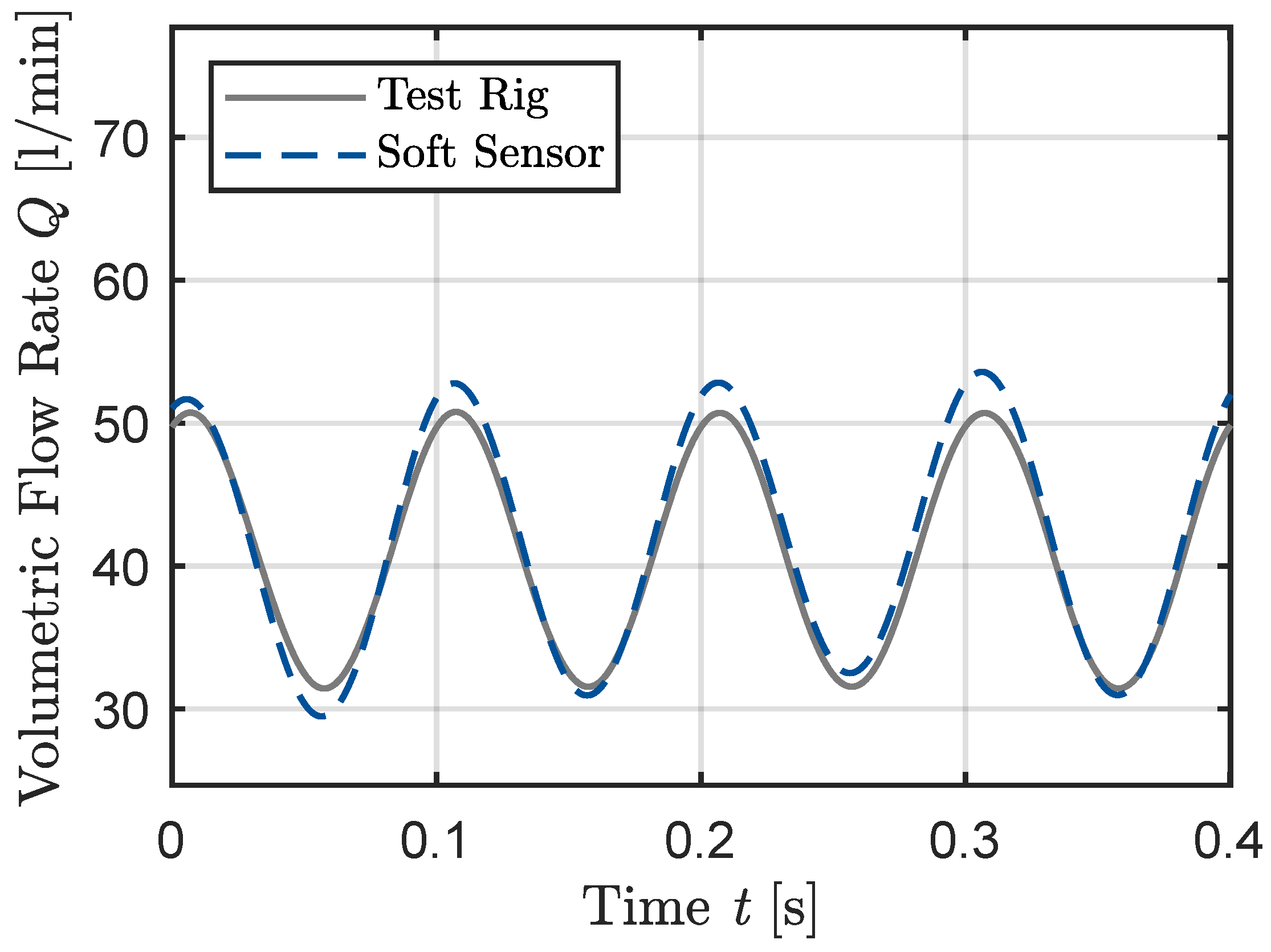

| Sine (Figure 6, Figure 7 and Figure 8) | 100 | 40 | , , | 5 |

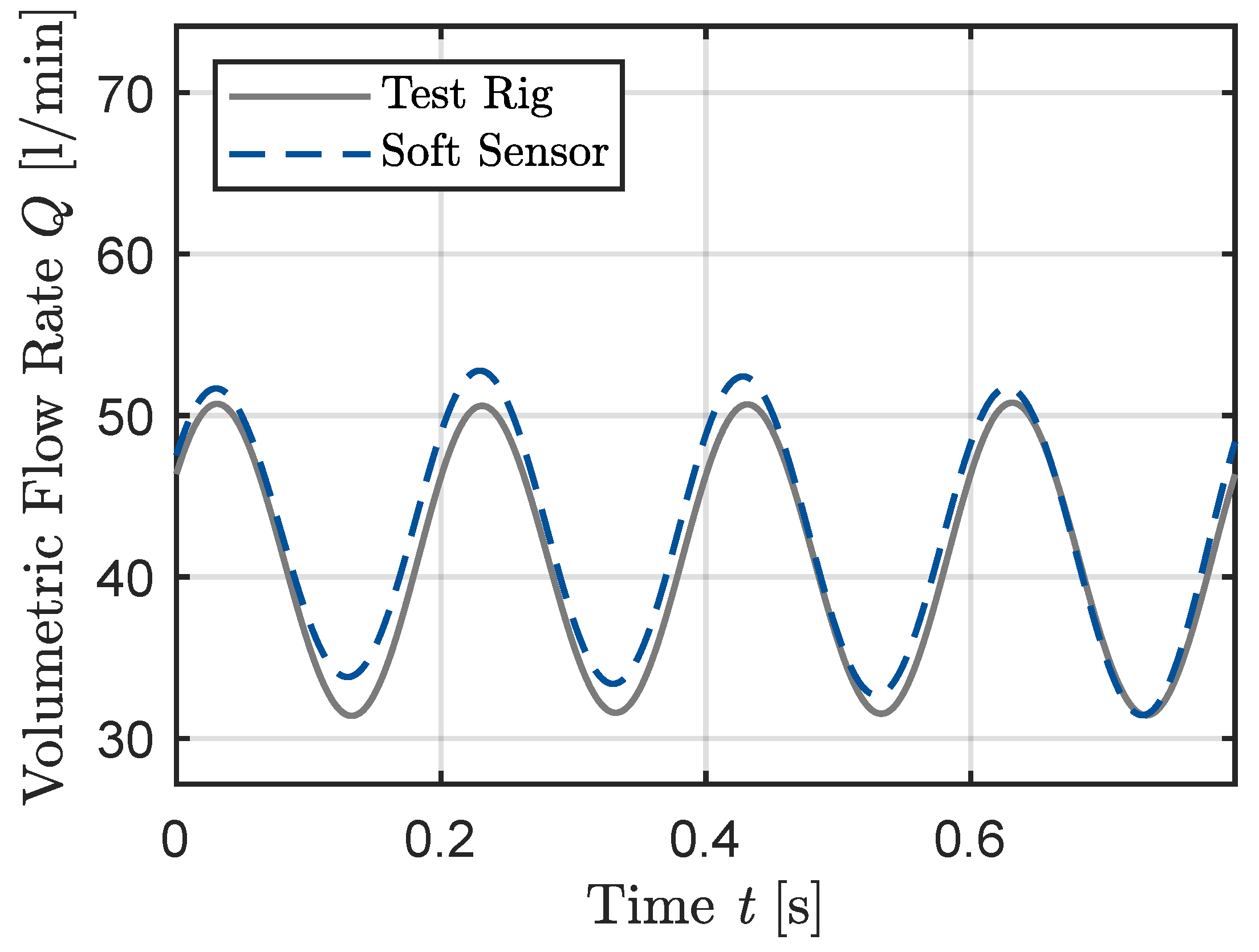

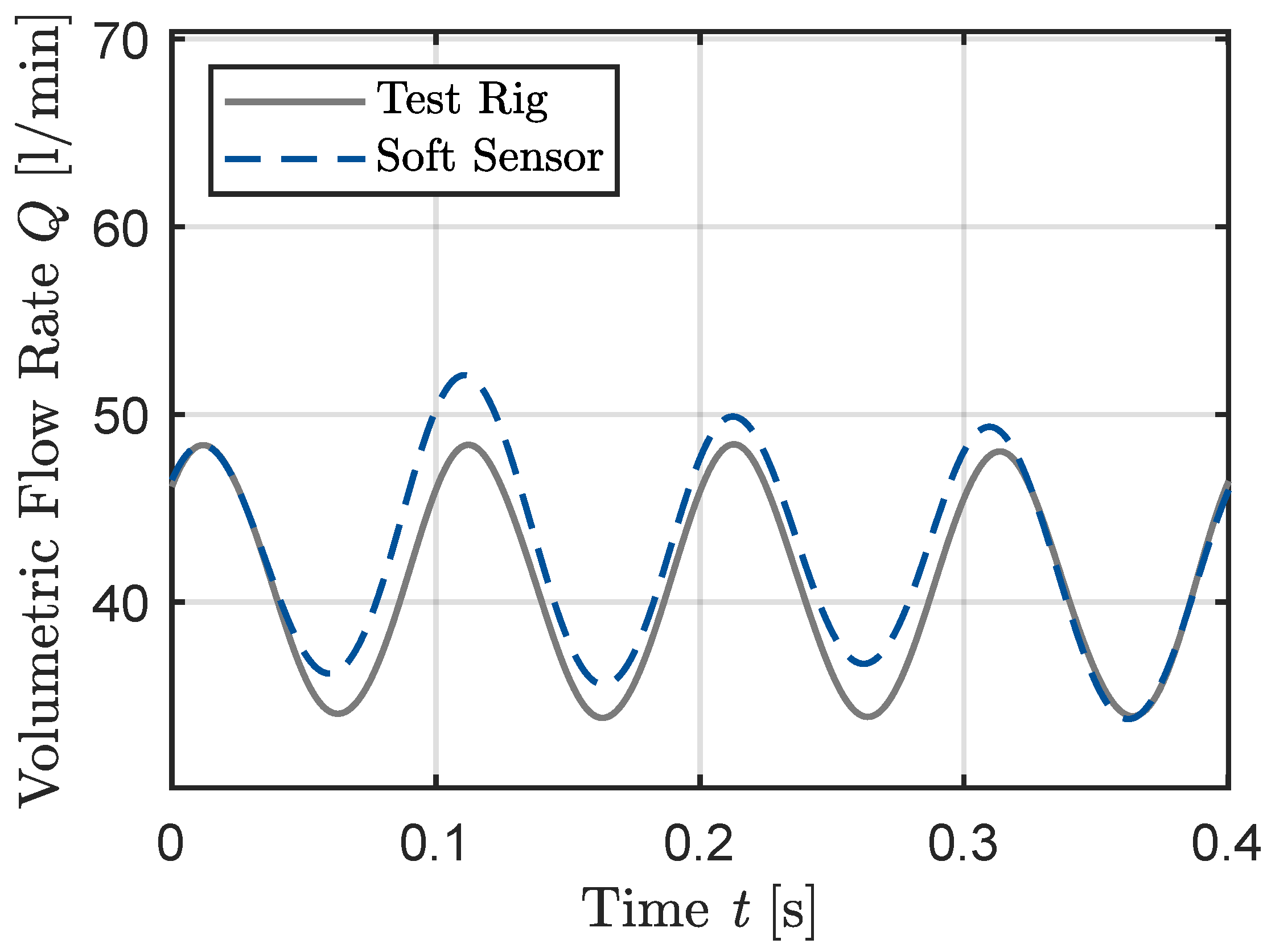

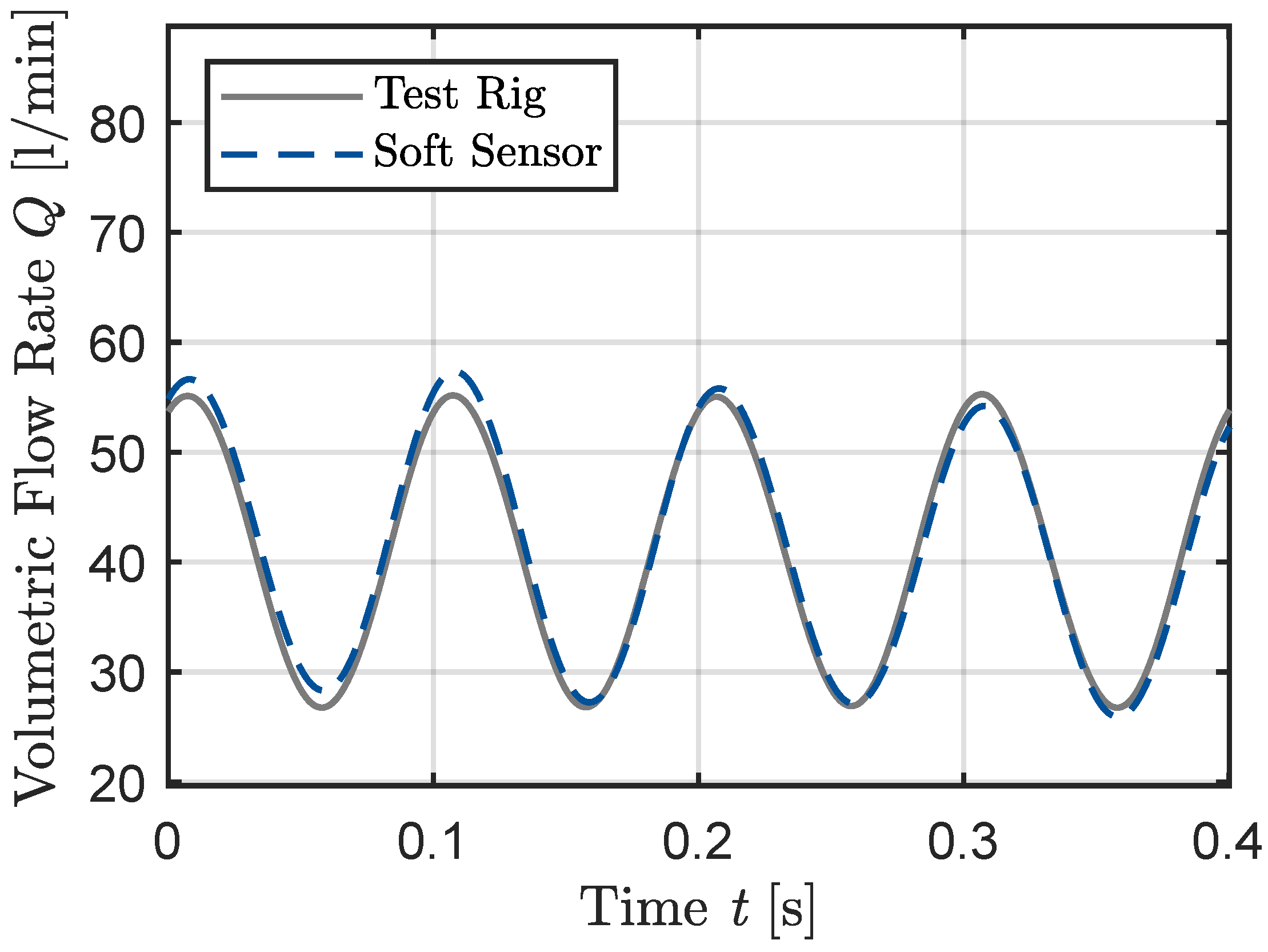

| Sine (Figure 9, Figure 10 and Figure 11) | 100 | 40 | , , | 10 |

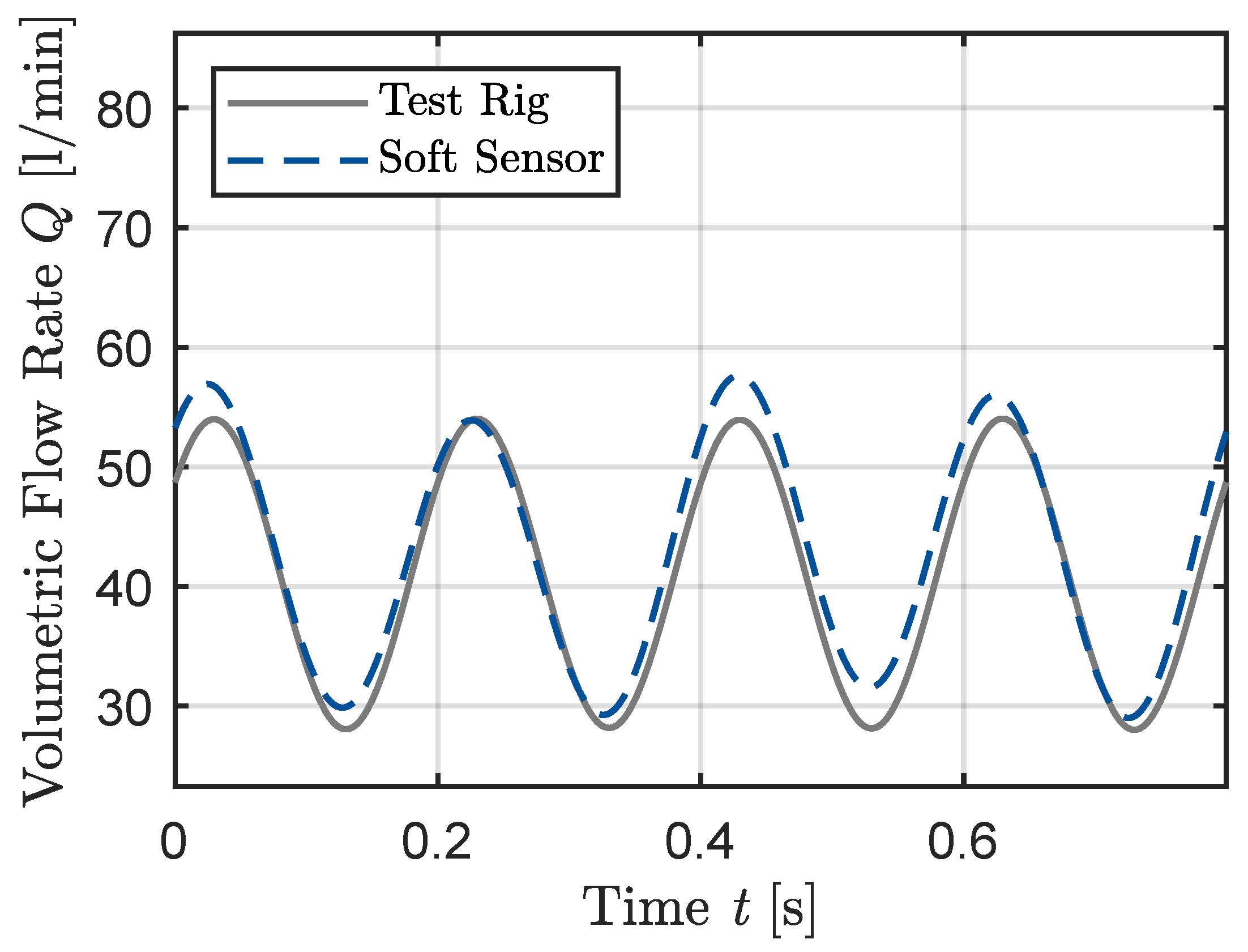

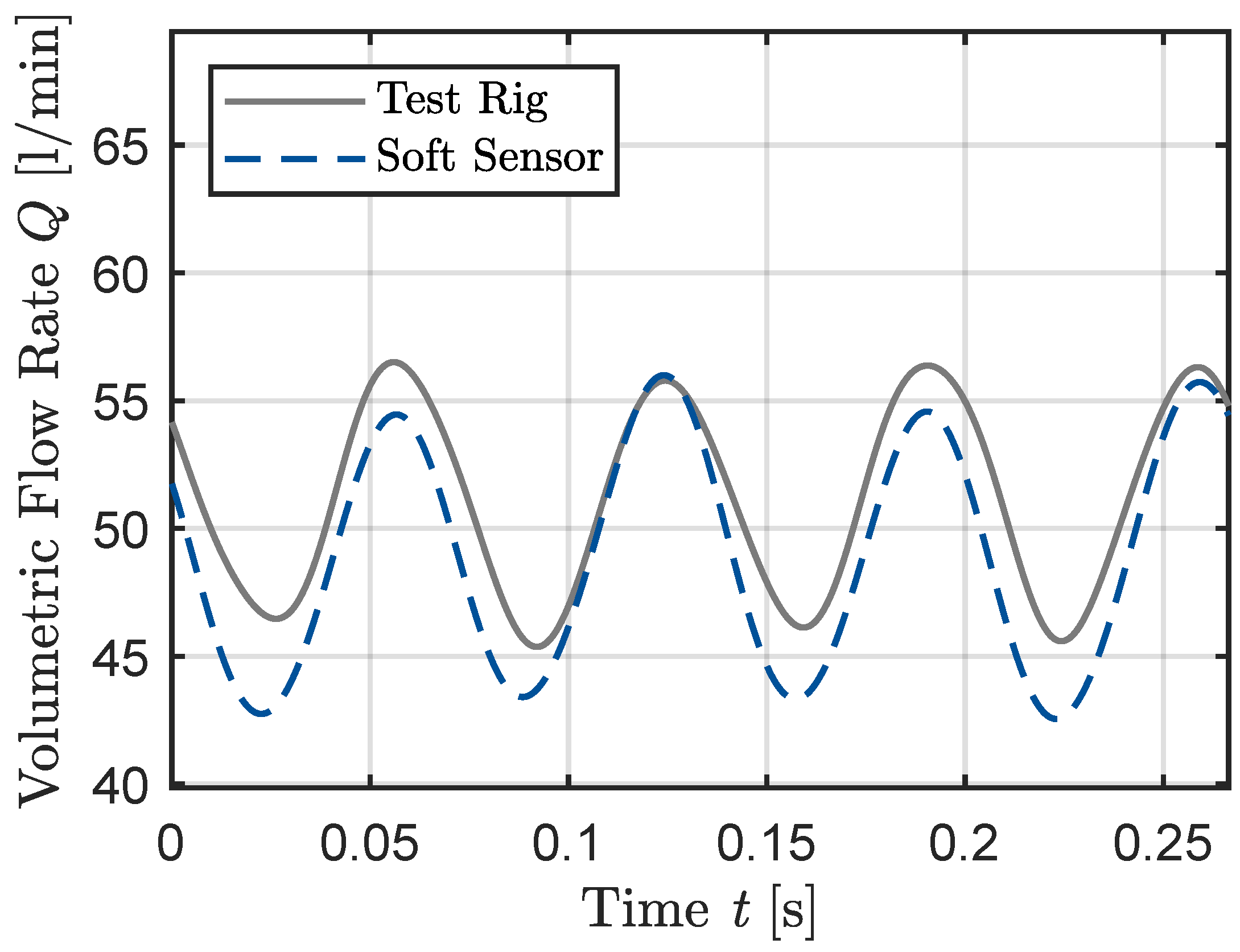

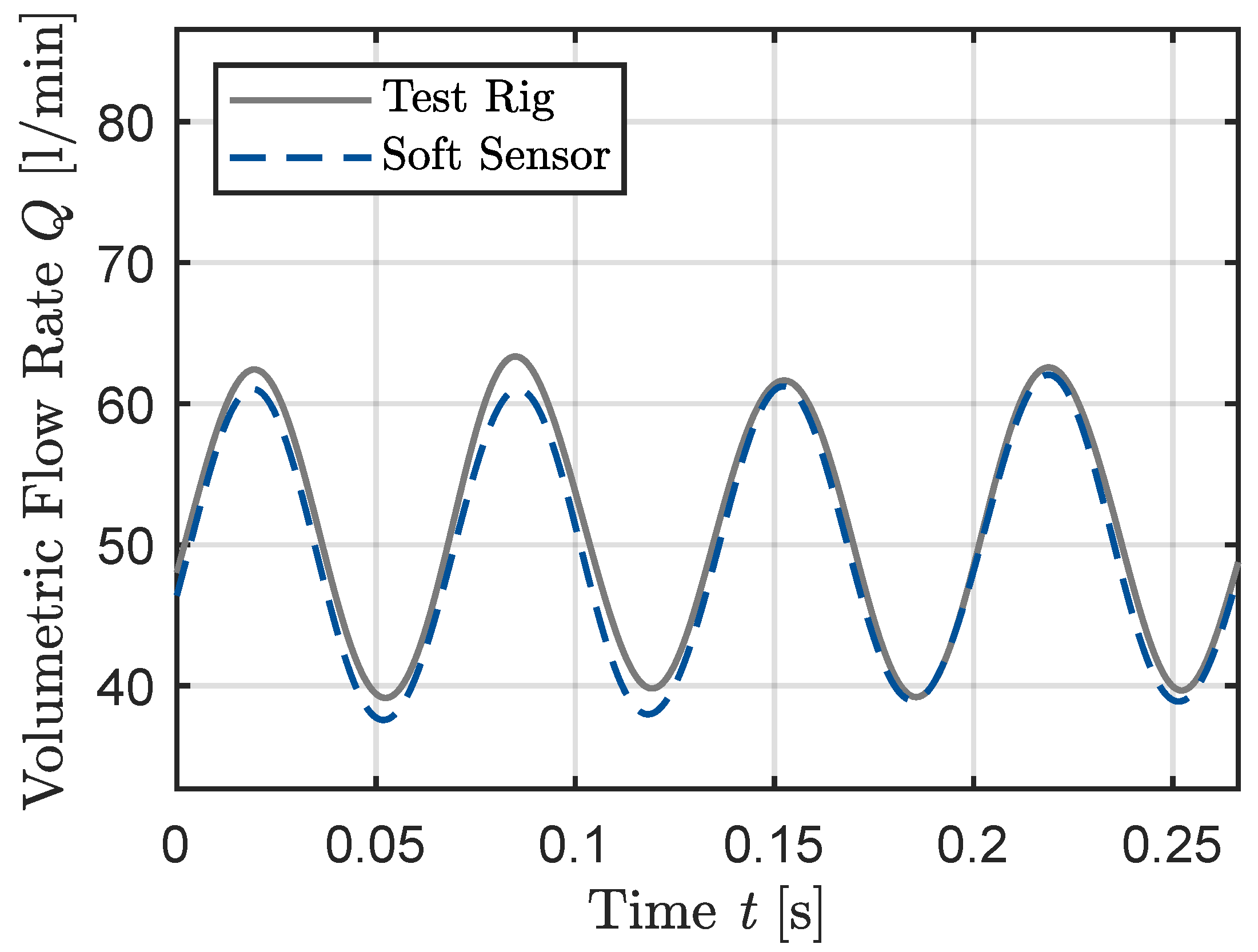

| Sine (Figure 12, Figure 13 and Figure 14) | 100 | 50 | , , | 15 |

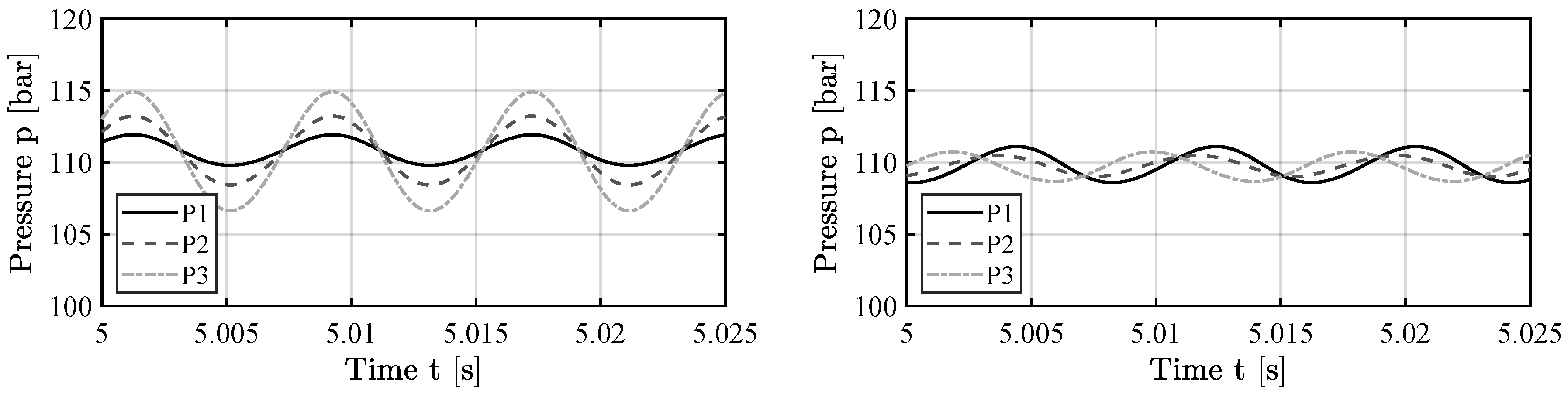

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BV | Ball Valve |

| CV | Control Valve |

| DRC | Double-rod Cylinder |

| HD | Hydraulic Damper |

| HP | Hagen-Poiseuille |

| HWA | Hot-wire Anemometry |

| ILT | Inverse Laplace transformation |

| LRLT | Low-reflection line terminator |

| O | Adjustable Orifice |

| P | Hydraulic Pump |

| PIV | Particle Image Velocimetry |

| PT | Pressure Transducer |

| Re | Reynolds number |

| SRC | Single-rod Cylinder |

| SV | Switching Valve |

| VF | Volumetric Flow Rate Sensor |

Nomenclature

| Symbol | Definition | Unit |

| * | Denotation of a Variable in the Laplace Domain | [m2/s] |

| a | Speed of Sound | [m/s] |

| A | Cross-section of the Cylinder | [m2] |

| Geometric Parameter | [m2] | |

| Cross-section of the Pipe | [m2] | |

| Dissipation Number | [-] | |

| f | Frequency | [Hz] |

| Propagation Operator | [-] | |

| Modified Bessel function of the first kind of the i’th order | [-] | |

| K | Bulk Modulus | [Pa] |

| First part of the convolution integral | [-] | |

| Second part of the convolution integral | [-] | |

| Approximation of | [-] | |

| k | A Natural Number | [-] |

| l | Pipe section length | [m] |

| L | Length of the Pipe | [m] |

| m | Order of poles | [-] |

| Part of Assumed Weighting Function | [-] | |

| Part of Assumed Weighting Function | [-] | |

| N | Upper Limit of Residue Sum | [-] |

| Pressure Difference | [-] | |

| System Pressure | [bar] | |

| Pressure at Inlet | [bar] | |

| Pressure at Outlet | [bar] | |

| Q | Volumetric Flow Rate | [m3/s] |

| Volumetric Flow Rate from the Cylinder | [m3/s] | |

| Mean Volumetric Flow Rate | [m3/s] | |

| Maximum Volumetric Flow Rate | [m3/s] | |

| Minimum Volumetric Flow Rate | [m3/s] | |

| Stationary Volumetric Flow Rate | [m3/s] | |

| Volumetric flow rate at Inlet: and Outlet: | [m3/s] | |

| R | Radius of the Pipe | [m] |

| Reynolds Number | [-] | |

| Hydraulic Resistance | [Pa/(m3/s)] | |

| s | Laplace Variable | [-] |

| Approximation of the Function | [-] | |

| t | Time | [s] |

| Normalized Time | [-] | |

| v | Velocity of the Cylinder | [m/s] |

| Weighting function at End of the Pipe | [-] | |

| Weighting function at port | [-] | |

| Negative of | [-] | |

| Compressible Weighting Function at port 1 | [-] | |

| Incompressible Weighting Function | [-] | |

| Womersley Number | [-] | |

| z | Number of Pistons of an Axial Piston Pump | [-] |

| Discharge Coefficient | [-] | |

| Degree of Non-uniformity | [-] | |

| Normalized Laplace Variable | [-] | |

| Poles of the Weighting Function | [Pas] | |

| Series impedance | [] | |

| Dynamic Viscosity | [Pas] | |

| Kinematic Viscosity | [m2/s] | |

| Pressure Variation Frequency | [1/s] | |

| Fluid Density | [kg/m3] | |

| Normalized Time | [s] |

References

- Sutera, S.P.; Skalak, R. The History of Poiseuille’s Law. Annual Review of Fluid Mechanics 1993, 25, 1–20. https://doi.org/10.1146/annurev.fl.25.010193.000245. [CrossRef]

- Richardson, E.G.; Tyler, E. The transverse velocity gradient near the mouths of pipes in which an alternating or continuous flow of air is established. Proceedings of the Physical Society 1929, 42, 1–15. https://doi.org/10.1088/0959-5309/42/1/302. [CrossRef]

- Manhartsgruber, B. Instantaneous Liquid Flow Rate Measurement Utilizing the Dynamics of Laminar Pipe Flow. Journal of Fluids Engineering 2008, 130. https://doi.org/10.1115/1.2969464. [CrossRef]

- Kashima, A.; Lee, P.; Ghidaoui, M. A selective literature review of methods for measuring the flow rate in pipe transient flows. BHR Group - 11th International Conferences on Pressure Surges 2012, pp. 733–742.

- Wiklund, D.; Peluso, M. Quantifying and Specifying the Dynamic Response of Flowmeters. Conference: ISA 2002, 422, 463–476.

- Mottram, R. Introduction: An overview of pulsating flow measurement. Flow Measurement and Instrumentation 1992, 3, 114–117.

- Ligeza, P. Static and dynamic parameters of hot-wire sensors in a wide range of filament diameters as a criterion for optimal sensor selection in measurement process. Measurement 2020, 151.

- Duensing, Y.; Richert, O.; Schmitz, K. Investigating the Condition Monitoring Potential of Oil Conductivity for Wear Identification in Electro Hydrostatic Actuators. Proceedings of the ASME/Bath 2021 Symposium on Fluid Power and Motion Control 2021.

- Brunone, B.; Berni, A. Wall Shear Stress in Transient Turbulent Pipe Flow by Local Velocity Measurement. Journal of Hydraulic Engineering 2010, 136.

- Grant, I. Particle image velocimetry: A review. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science 1997, pp. 55–76.

- Henry, M.; Zamora, M. The dynamic response of Coriolis mass flow meters: Theory and applications. Technical Papers of ISA 2004, 454.

- Brereton, G.J.; Schock, H.J.; Rahi, M.A.A. An indirect pressure-gradient technique for measuring instantaneous flow rates in unsteady duct flows. Experiments in Fluids 2006, 40, 238–244. https://doi.org/10.1007/s00348-005-0063-z. [CrossRef]

- Brereton, G.J.; Schock, H.J.; Bedford, J.C. An indirect technique for determining instantaneous flow rate from centerline velocity in unsteady duct flows. Flow Measurement and Instrumentation 2008, 19, 9–15. https://doi.org/10.1016/j.flowmeasinst.2007.08.001. [CrossRef]

- Sundstrom, L.R.J.; Saemi, S.; Raisee, M.; Cervantes, M.J. Improved frictional modeling for the pressure-time method. Flow Measurement and Instrumentation 2019, 69, 101604. https://doi.org/10.1016/j.flowmeasinst.2019.101604. [CrossRef]

- Foucault, E.; Szeger, P. Unsteady flowmeter. Flow Measurement and Instrumentation 2019, 69, 101607. https://doi.org/10.1016/j.flowmeasinst.2019.101607. [CrossRef]

- García García, F.J.; Fariñas Alvariño, P. On an analytic solution for general unsteady/transient turbulent pipe flow and starting turbulent flow. European Journal of Mechanics - B/Fluids 2019, 74, 200–210. https://doi.org/https://doi.org/10.1016/j.euromechflu.2018.11.014. [CrossRef]

- García García, F.J.; Fariñas Alvariño, P. On the analytic explanation of experiments where turbulence vanishes in pipe flow. Journal of Fluid Mechanics 2022, 951, A4. https://doi.org/10.1017/jfm.2022.651. [CrossRef]

- Urbanowicz, K.; Bergant, A.; Stosiak, M.; Deptuła, A.; Karpenko, M. Navier-Stokes Solutions for Accelerating Pipe Flow—A Review of Analytical Models. Energies 2023, 16, 1407. https://doi.org/10.3390/en16031407. [CrossRef]

- Urbanowicz, K.; Bergant, A.; Stosiak, M.; Karpenko, M.; Bogdevičius, M. Developments in analytical wall shear stress modelling for water hammer phenomena. Journal of Sound and Vibration 2023, 562, 117848. https://doi.org/10.1016/j.jsv.2023.117848. [CrossRef]

- Bayle, A.; Rein, F.; Plouraboué, F. Frequency varying rheology-based fluid–structure-interactions waves in liquid-filled visco-elastic pipes. Journal of Sound and Vibration 2023, 562. https://doi.org/10.1016/j.jsv.2023.117824. [CrossRef]

- Bayle, A.; Plouraboue, F. Laplace-Domain Fluid–Structure Interaction Solutions for Water Hammer Waves in a Pipe. Journal of Hydraulic Engineering 2024, 150. https://doi.org/10.1061/JHEND8.HYENG-13781. [CrossRef]

- Brumand-Poor, F.; Kotte, T.; Pasquini, E.; Schmitz, K. Signal Processing for High-Frequency Flow Rate Determination: An Analytical Soft Sensor Using Two Pressure Signals. Preprints 2024.

- Brumand-Poor, F.; Kotte, T.; Pasquini, E.; Kratschun, F.; Enking, J.; Schmitz, K. Unsteady flow rate in transient, incompressible pipe flow. Z Angew Math Mech. e 2024.

- Brumand-Poor, F.; Schüpfer, M.; Merkel, A.; Schmitz, K. Development of a Hydraulic Test Rig for a Virtual Flow Sensor. In Proceedings of the Proceedings of the Eighteenth Scandinavian International Conference on Fluid Power (SICFP’23), 2023.

- Stecki, J.S.; Davis, D.C. Fluid Transmission Lines—Distributed Parameter Models Part 1: A Review of the State of the Art. Proceedings of the Institution of Mechanical Engineers, Part A: Power and Process Engineering 1986, 200, 215–228.

- Almondo, A.; Sorli, M. Time Domain Fluid Transmission Line Modelling using a Passivity Preserving Rational Approximation of the Frequency Dependent Transfer Matrix. International Journal of Fluid Power 2006, 7, 41–50. https://doi.org/10.1080/14399776.2006.10781238.

- Weber H., Ulrich, H. Laplace-, Fourier- und z-Transformation; Vieweg+Teubner Verlag: Wiesbaden, 2012. https://doi.org/10.1007/978-3-8348-8291-2.

- Krantz, S.G. Handbook of Complex Variables; Birkhäuser: Boston, MA, 1999.

- Goodson, R.E. Distributed system simulation using infinite product expansions. SIMULATION 1970, 15, 255–263.

- Maple 2019, 2019.

- Dietmar Findeisen, S.H. Ölhydraulik - Handbuch der hydraulischen Antriebe und Steuerungen; Springer Vieweg Berlin, Heidelberg, 2015.

- Will, D.; Gebhardt, N.; Nollau, R.; Herschel, D. Hydraulik: Grundlagen, Komponenten, Schaltungen; Springer, 2008.

- D’Souza, A. Dynamic Response of Fluid Lines. Journal of Basic Engineering 1964, 86, 589–598.

- Gong, J.; Lambert, M.; Zecchin, A.; Simpson, A. Experimental verification of pipeline frequency response extraction and leak detection using the inverse repeat signal. Journal of Hydraulic 2016, 54, 210–219.

- Schmitz, K.; Murrenhoff, H. Hydraulik, vollständig neu bearbeitete auflage ed.; Vol. 002, Reihe Fluidtechnik. U, Shaker Verlag: Aachen, 2018.

- Butterworth, S. On the Theory of Filter Amplifiers. Experimental Wireless & the Wireless Engineer 1930, 7, 536–541.

| Frequency f [Hz] | Degree of Non-uniformity [-] | Mean Error | Standard Deviation |

|---|---|---|---|

| 5 (Figure 6, Figure 7 and Figure 8) | , , | , , | , , |

| 10 (Figure 9, Figure 10 and Figure 11) | , , | , , | , , |

| 15 (Figure 12, Figure 13 and Figure 14) | , , | , , | , , |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).