Submitted:

18 November 2024

Posted:

19 November 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

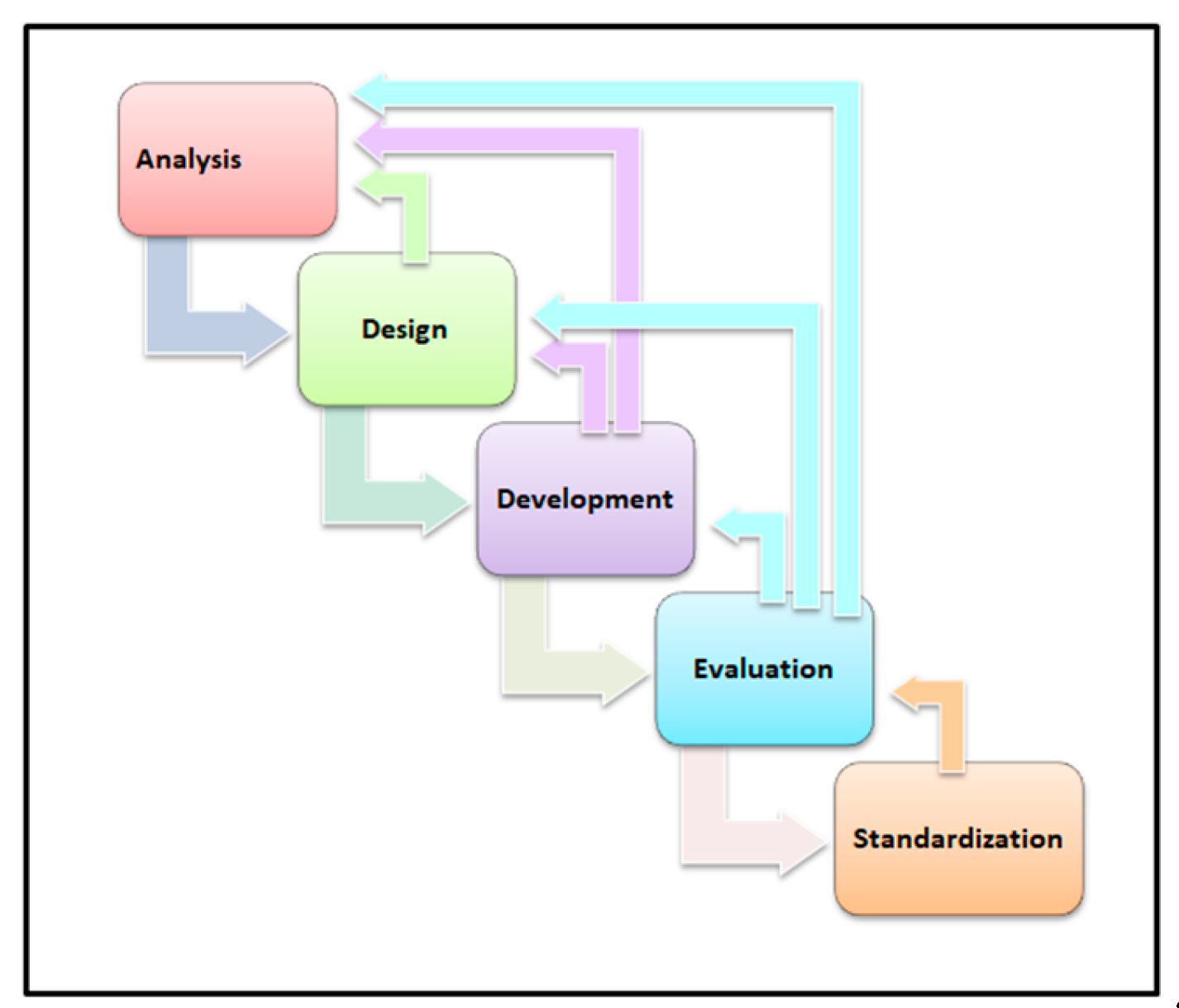

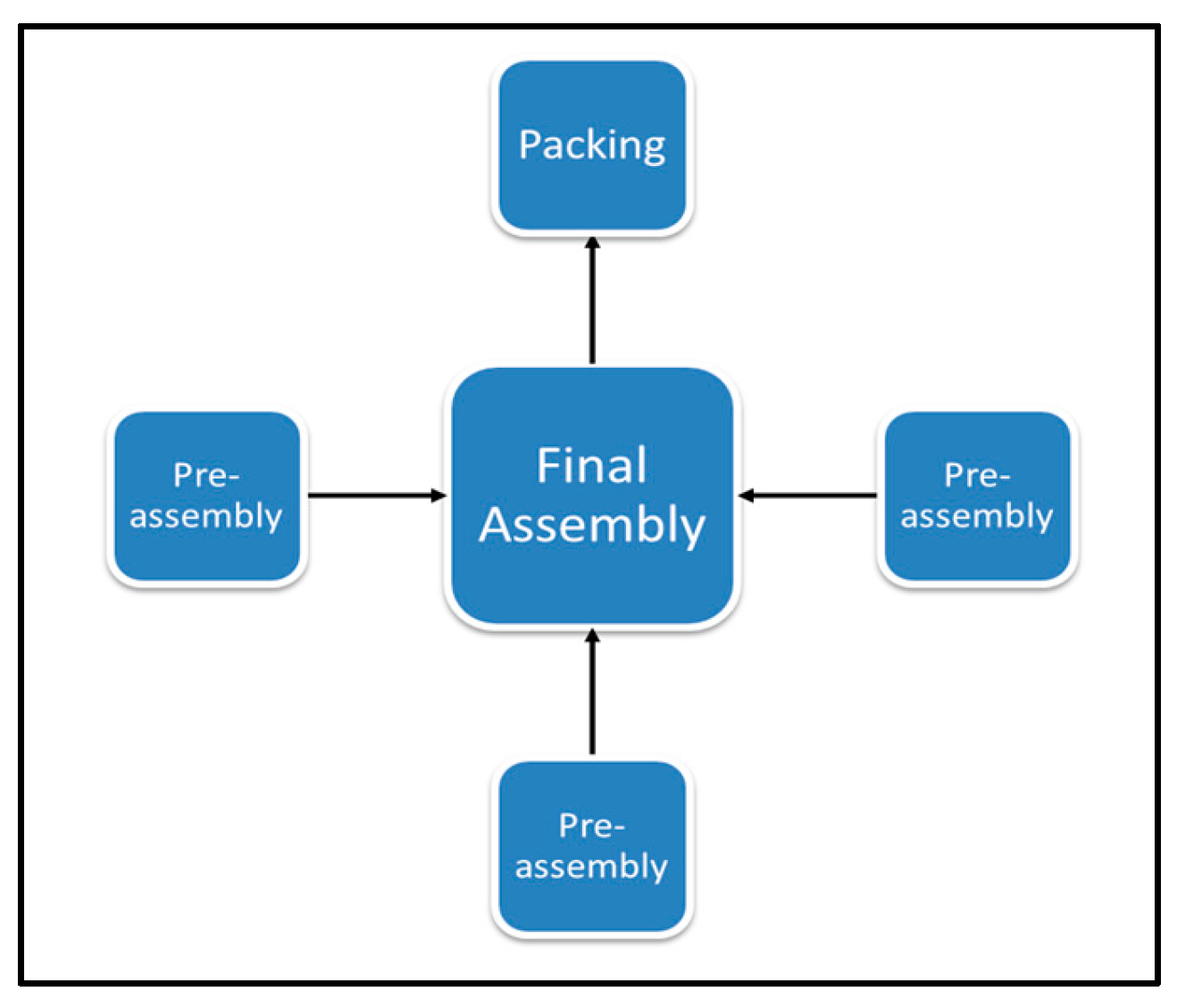

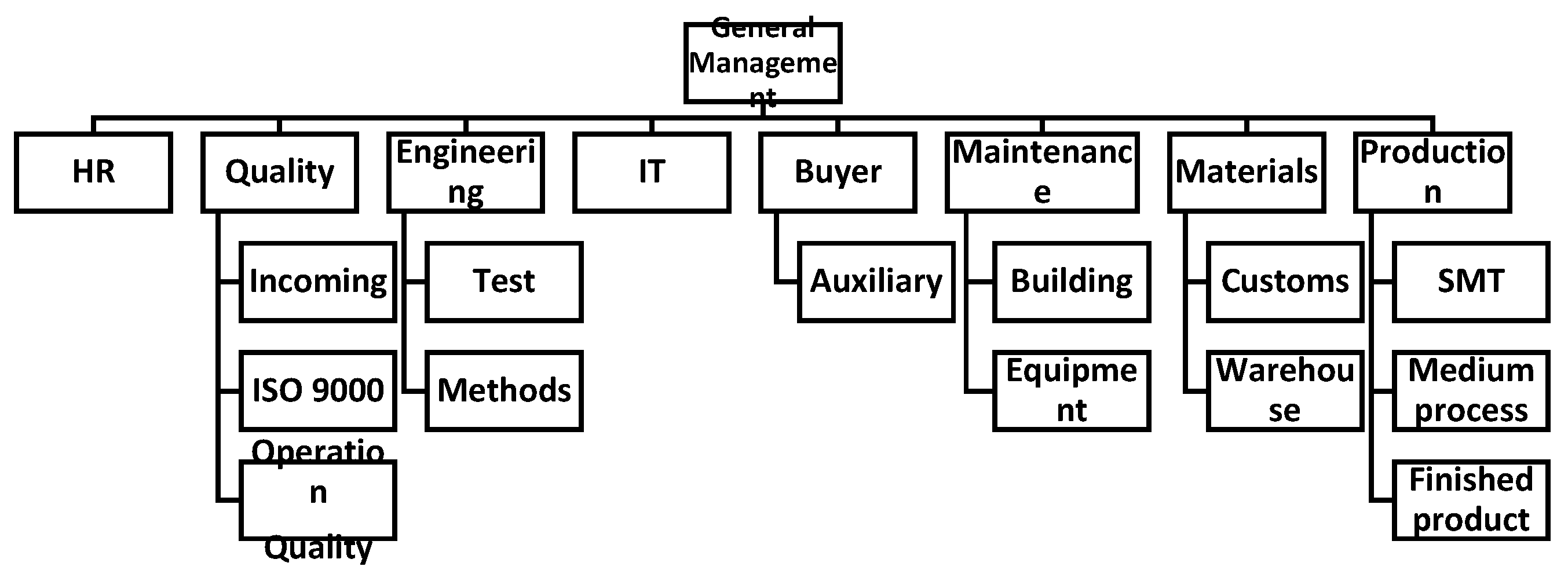

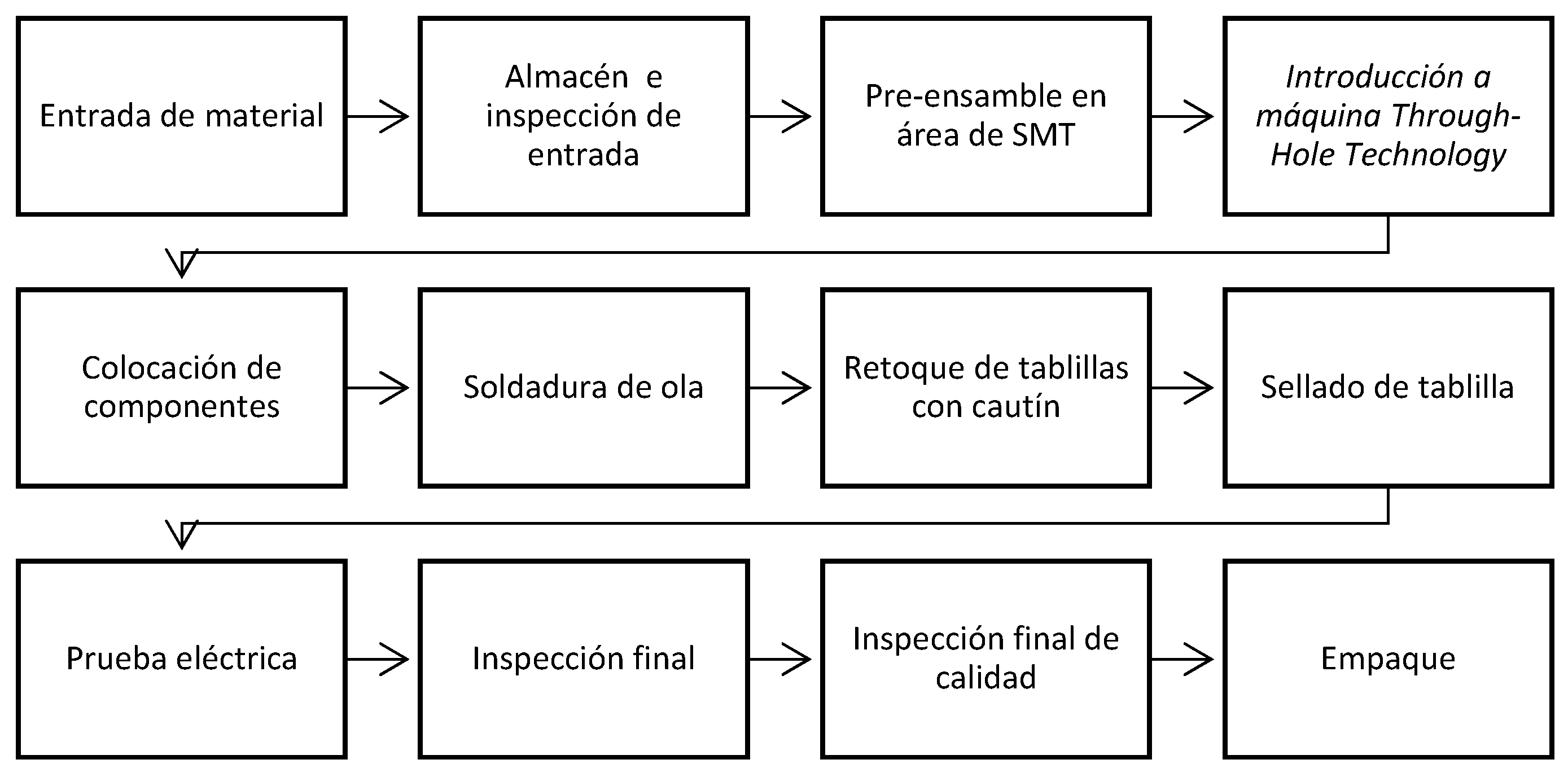

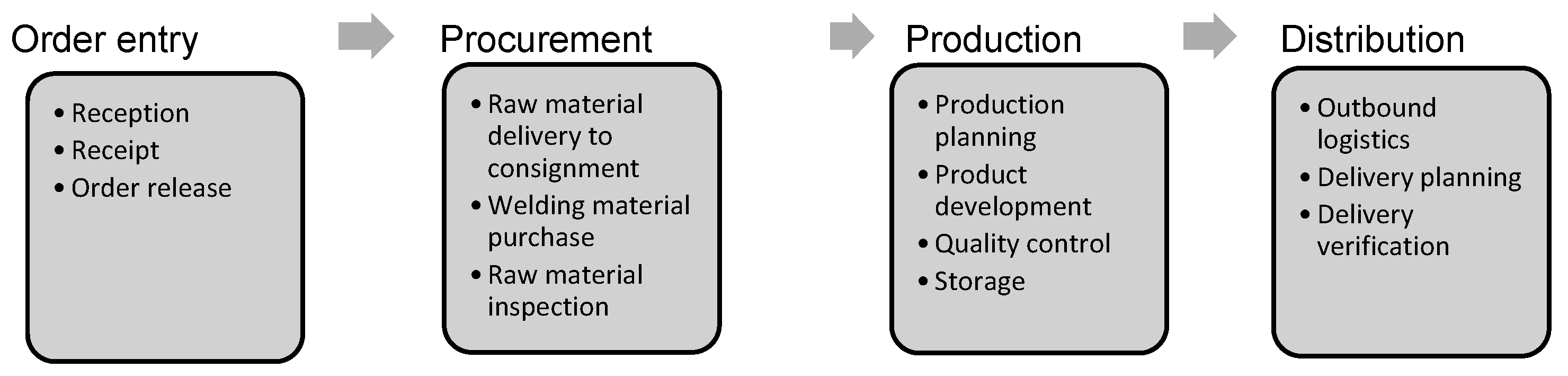

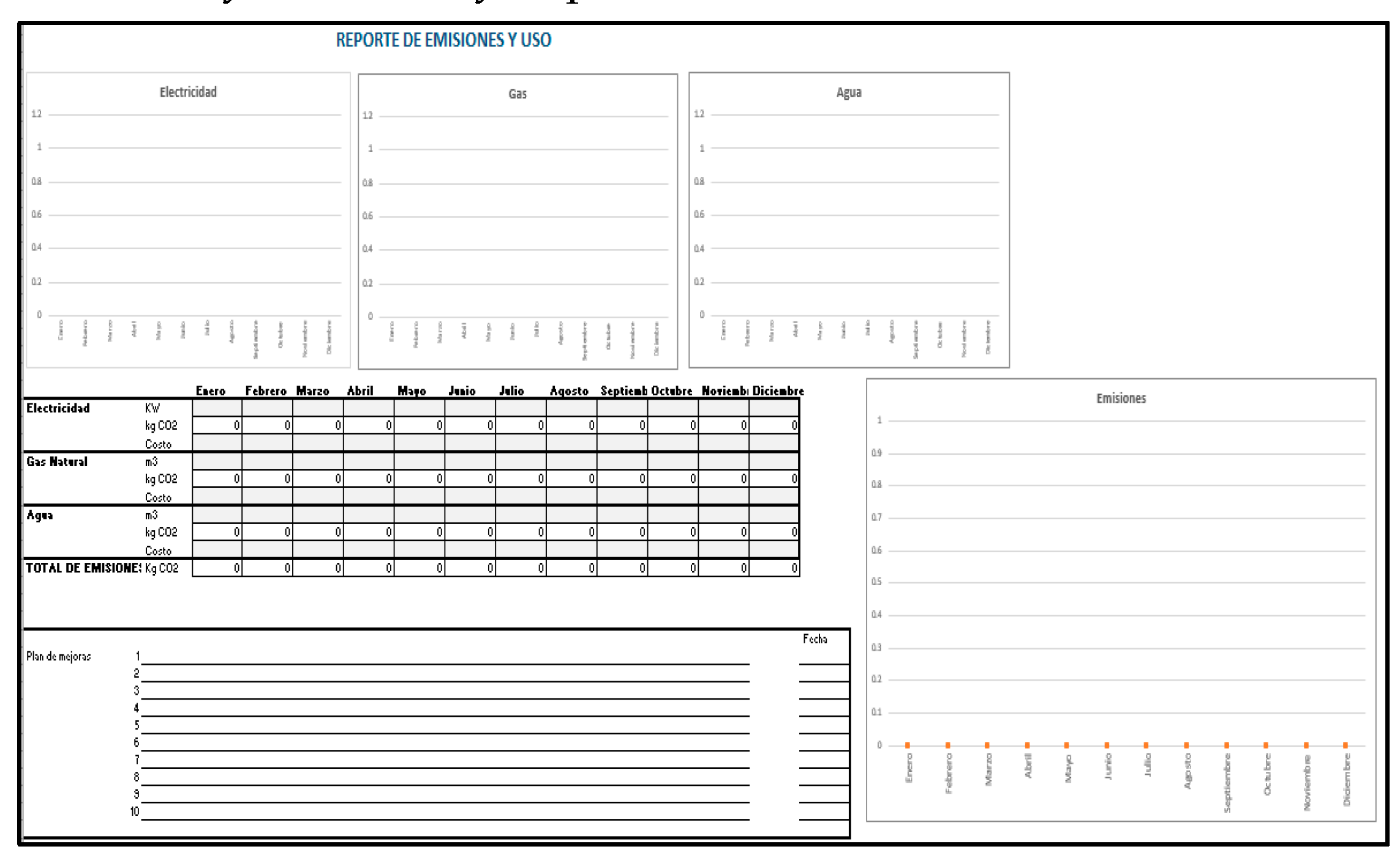

- Analysis: Before developing a sustainability management system, it is essential to carry out an analysis based on the measurement instrument proposed by Zapien (2018). Without a precise analysis, successful adoption is not possible. For this reason, it is also important to collect information about the company; processes it uses, both productive and administrative, installed equipment, products it generates, raw materials, waste generated in order to understand all operations and their interrelations, consumption of resources such as water and energy (Salieiev, 2024; Zhang, Ma & Yan, 2020). At the end of the analysis, a document will be obtained with practices that are carried out and those that are not, opportunities for improvement, and it will also have a process diagram of the inputs; raw material, water, electricity and gas, among others) and the output (scrap, emissions and water waste among others (Antonopoulos, Faraca & Tonini, 2021; Enyoghasi & Badurdeen, 2021). Likewise, an analysis of its value chain and a design analysis will be generated in order to observe where an eco-design can be implemented, finally, a portfolio or analysis of the implemented technologies will be carried out (Antonacci, Del Pero, Baldanzini & Delogu, 2022; Negri, Cagno, Colicchia & Sarkis, 2021).

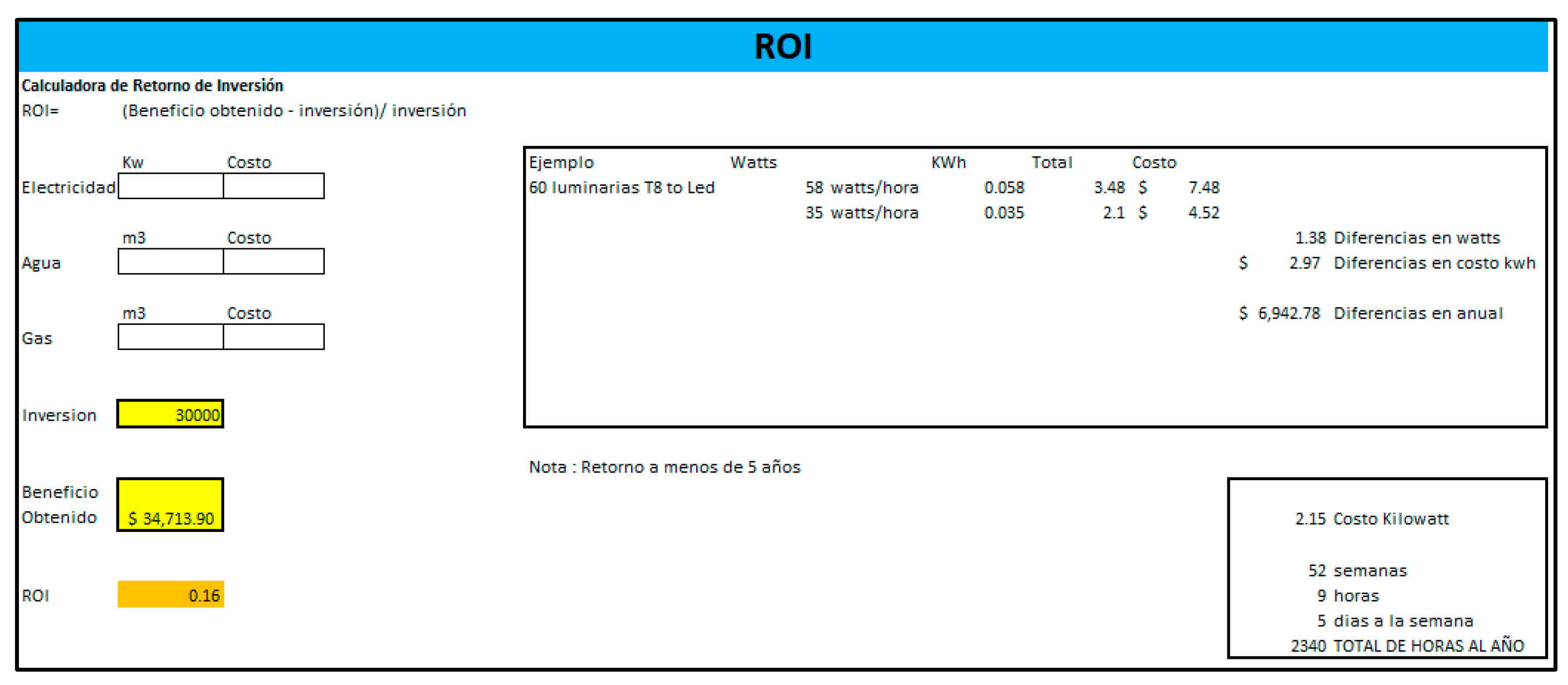

- Design: Taking into account the requirements of the environment, which have been extracted from the initial analysis, the design of the actions to be carried out is carried out, generating options and evaluating their technical and economic viability, this can be helped by techniques such as cause and effect diagram, dispersion diagram, FMEA, SWOT (strength, opportunities, weaknesses and threats), Pareto diagram, Decision tree, ROI (return on investment) study as mentioned by Murphy et al., 2022, Obiuto et al., 2024, Patidar et al., 2024 and Vardopoulos et al., 2021; by establishing the feasible and most convenient actions due to the impact that could be generated, we proceed to identify the person in charge of the area or department that affects the implementation of the activities in order to have an instructional design with the activities and leaders or managers who will carry out said activity. As a previous step to developing the adaptation of sustainability, training is necessary for all company employees (Bilderback, 2024), highlighting the importance of adopting sustainability and the balance it achieves between society, the environment and the economy through the minimization of negative impacts on the environment, safe products and processes for employees, communities and consumers, of course considering economic profitability, if necessary, returning to the previous step of analysis to add information.

- Development: The development phase continues, in which the plan is executed. At this stage, the leader or area assignee plays an active role in carrying out the training and corresponding activities. Likewise, the human resource assigned to environmental care must have a Gantt chart to plan and schedule tasks in order to follow up on the practices or actions to be implemented (Alves & Putnik, 2022), in order to create procedures, generating a sustainable practices management system; this must be prepared for the evaluation phase.

- Evaluation: The evaluation seeks to determine what the flaws are at the analysis, design and development level. From these, we will return to the relevant phases to continue with the process again. When the person responsible for the methodology in the company approves this stage, we will continue with the standardization stage.

- Standardization: The standardization of processes is essential for the success of any business (Nilashi et al., 2023). Rodríguez (2017) mentions that the activity in small and medium-sized companies is undervalued and that the important thing is to carry it out in a manner appropriate to their needs. Firstly, it is important that all senior employees and those in the company's supervisory area participate in the documentation of the standard method to be followed. Owen (2020) states that it is important to understand the attributes of sustainability adaptation initiatives and to identify gaps in research and practice; it is also necessary that they receive and provide their employees with adequate and continuous training (Aboramadan & Karatepe, 2021); as well as the determination of performance indicators that quantify compliance or level of performance (Neri et al., 2021 & Zapien & Valenzuela, 2024); This quantification can be based on the following indices: GWP, MIPS, LCA, Ecological Footprint or performance rates. And finally, the action guidelines, which means stating the guidelines that those involved must take into account when carrying out the activities to achieve the objective.

3. Case Study: Sustainable Management in an SME Industry

4. Discussion and Conclusions

References

- Aboelata, A. Assessment of green roof benefits on buildings’ energy-saving by cooling outdoor spaces in different urban densities in arid cities. Energy 2021, 219, 119514. [Google Scholar] [CrossRef]

- Aboramadan, M.; Karatepe, O.M. Green human resource management, perceived green organizational support and their effects on hotel employees’ behavioral outcomes. Int. J. Contemp. Hosp. Manag. 2021, 33, 3199–3222. [Google Scholar] [CrossRef]

- Álvarez Jaramillo, J.; Zartha Sossa, J.W.; Orozco Mendoza, G.L. Barriers to sustainability for small and medium enterprises in the framework of sustainable development—L iterature review. Bus. Strategy Environ. 2019, 28, 512–524. [Google Scholar] [CrossRef]

- Alves, C.; Putnik, G.D. (2022). Real-Time Management-Based Production Scheduling for Sustainability: An Introduction. In Smart and Sustainable Manufacturing Systems for Industry 4.0 (pp. 45-64). CRC Press.

- Antonacci, A.; Del Pero, F.; Baldanzini, N.; Delogu, M. Holistic eco-design tool within automotive field. IOP Conf. Ser. : Mater. Sci. Eng. 2022, 1214, 012045. [Google Scholar] [CrossRef]

- Antonopoulos, I.; Faraca, G.; Tonini, D. Recycling of post-consumer plastic packaging waste in the EU: Recovery rates, material flows, and barriers. Waste Manag. 2021, 126, 694–705. [Google Scholar] [CrossRef]

- Arvidsson, S. CEO talk of sustainability in CEO letters: towards the inclusion of a sustainability embeddedness and value-creation perspective. Sustain. Account. Manag. Policy J. 2023, 14, 26–61. [Google Scholar] [CrossRef]

- Bilderback, S. Integrating training for organizational sustainability: the application of Sustainable Development Goals globally. Eur. J. Train. Dev. 2024, 48, 730–748. [Google Scholar] [CrossRef]

- Broo, D.G. Transdisciplinarity and three mindsets for sustainability in the age of cyber-physical systems. J. Ind. Inf. Integr. 2022, 27, 100290. [Google Scholar] [CrossRef]

- Cardoni, A.; Zanin, F.; Corazza, G.; Paradisi, A. Knowledge management and performance measurement systems for SMEs’ economic sustainability. Sustainability 2020, 12, 2594. [Google Scholar] [CrossRef]

- Das, M.; Rangarajan, K.; Dutta, G. Corporate sustainability in SMEs: an Asian perspective. J. Asia Bus. Stud. 2020, 14, 109–138. [Google Scholar] [CrossRef]

- De Batista, M.; Letieri Farías, M.M.; Jankovic, V.V.; Mancini, C.M. (2022). Evaluación de sustentabilidad para sistemas ganaderos extensivos del sur de la provincia de Santa Fe.

- Ekins, P.; Zenghelis, D. The costs and benefits of environmental sustainability. Sustain. Sci. 2021, 16, 949–965. [Google Scholar] [CrossRef] [PubMed]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Fuentes, N.A.; Brugués Rodríguez, A.; González König, G.; Carrillo Viveros, J. (2020). El impacto económico en la industria maquiladora y en la región fronteriza del norte de México debido al alza de 100% del salario mínimo. Región y sociedad, 32-36. [CrossRef]

- Hermundsdottir, F.; Aspelund, A. Sustainability innovations and firm competitiveness: A review. J. Clean. Prod. 2021, 280, 124715. [Google Scholar] [CrossRef]

- IMCO (2024) INSTITUTO MEXICANO PARA LA COMPETITIVIDAD A.C. Desarrollando las PYMES que Requiere Méxicohttps://imco.org.mx/pymes_que_requiere_mexico_/ , recuperado el septiembre del 2024.

- Journeault, M.; Perron, A.; Vallières, L. The collaborative roles of stakeholders in supporting the adoption of sustainability in SMEs. J. Environ. Manag. 2021, 287, 112349. [Google Scholar] [CrossRef] [PubMed]

- Küchler, R.; Nicolai, B.M.; Herzig, C. A Novel Sustainability Management Tool for Small and Medium-Sized Food Manufacturers–Advantages and Improvement Opportunities. mrev management revue 2024, 35, 35–65. [Google Scholar] [CrossRef]

- Le, T.T.; Ikram, M. Do sustainability innovation and firm competitiveness help improve firm performance? Evidence from the SME sector in vietnam. Sustain. Prod. Consum. 2022, 29, 588–599. [Google Scholar] [CrossRef]

- Lewandowska, A.; Berniak-Woźny, J.; Ahmad, N. Competitiveness and innovation of small and medium enter-prises under Industry 4.0 and 5.0 challenges: A comprehensive bibliometric analysis. Equilibrium. Q. J. Econ. Econ. Policy 2023, 18, 1045–1074. [Google Scholar] [CrossRef]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A big data-driven framework for sustainable and smart additive manufacturing. Robot. Comput. -Integr. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Martins, A.; Branco, M.C.; Melo, P.N.; Machado, C. Sustainability in small and medium-sized enterprises: A systematic literature review and future research agenda. Sustainability 2022, 14, 6493. [Google Scholar] [CrossRef]

- Martins, A.; Branco, M.C.; Melo, P.N.; Machado, C. Sustainability in small and medium-sized enterprises: A systematic literature review and future research agenda. Sustainability 2022, 14, 6493. [Google Scholar] [CrossRef]

- Mendoza, O.G.; Galaviz, J.G. Análisis del desarrollo histórico de la industria maquiladora de exportación en México: caso de Ciudad Juárez, Chihuahua. Rev. Doxa Digit. 2018, 8, 135–152. [Google Scholar] [CrossRef]

- Murphy, D.J.; Raugei, M.; Carbajales-Dale, M.; Rubio Estrada, B. Energy return on investment of major energy carriers: Review and harmonization. Sustainability 2022, 14, 7098. [Google Scholar] [CrossRef]

- Negri, M.; Cagno, E.; Colicchia, C.; Sarkis, J. Integrating sustainability and resilience in the supply chain: A systematic literature review and a research agenda. Bus. Strategy Environ. 2021, 30, 2858–2886. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Lepri, M.; Trianni, A. A triple bottom line balanced set of key performance indicators to measure the sustainability performance of industrial supply chains. Sustain. Prod. Consum. 2021, 26, 648–691. [Google Scholar] [CrossRef]

- Nilashi, M.; Keng Boon, O.; Tan, G.; Lin, B.; Abumalloh, R. Critical data challenges in measuring the performance of sustainable development goals: Solutions and the role of big-data analytics. Harv. Data Sci. Rev. 2023, 5, 3–4. [Google Scholar] [CrossRef]

- Obiuto, N.C.; Ebirim, W.; Ninduwezuor-Ehiobu, N.; Ani, E.C.; Olu-lawal, K.A.; Ugwuanyi, E.D. Integrating sustainability into hvac project management: challenges and opportunities. Eng. Sci. Technol. J. 2024, 5, 873–887. [Google Scholar] [CrossRef]

- Owen, G. What makes climate change adaptation effective? A systematic review of the literature. Glob. Environ. Change 2020, 62, 102071. [Google Scholar] [CrossRef]

- Patidar, A.; Sharma, M.; Agrawal, R.; Sangwan, K.S.; Sarkar, P. Building supply chain resilience in developing economies: A weighted Ishikawa diagram approach. Oper. Manag. Res. 2024, 17, 363–386. [Google Scholar] [CrossRef]

- PROFEPA (2023) Certificados Emitidos por el Programa Nacional de Auditoria Ambiental publicado el 31 de diciembre del 2023.

- Rodríguez Naranjo, H. (2017). Propuesta de una metodología de producción más limpia en la división de pulpas y congelados de la Cooperativa Nacional de Productores de Sal en Limonal de Abangares.

- Salieiev, I. Organization of processes for complex mining and processing of mineral raw materials from coal mines in the context of the concept of sustainable development. Min. Miner. Depos. 2024, 18, 54–66. [Google Scholar] [CrossRef]

- Statista Research Department (2024). El producto interno bruto de México – Datos estadísticos. https://es.statista.com/temas/7764/pib-de-mexico/#topicOverview revisado el 10 sept 2024.

- Tseng, M.L.; Tran TP, T.; Ha, H.M.; Bui, T.D.; Lim, M.K. Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: A data driven analysis. J. Ind. Prod. Eng. 2021, 38, 581–598. [Google Scholar] [CrossRef]

- Vardopoulos, I.; Tsilika, E.; Sarantakou, E.; Zorpas, A.A.; Salvati, L.; Tsartas, P. An integrated SWOT-PESTLE-AHP model assessing sustainability in adaptive reuse projects. Appl. Sci. 2021, 11, 7134. [Google Scholar] [CrossRef]

- WCED, Special Working Session. World commission on environment and development. Our Common Future 1987, 17, 1–91. [Google Scholar] [CrossRef]

- Zapien Guerrero, C. (2018). Sustainable management in the manufactures sme of Juárez city. Instituto de Ingeniería y Tecnología. CIECONF - Proceedings in Scientific Conference, 222-225.

- Zapién, Cristina, and Valenzuela Facio Evelyn María (2024). Indicators of Sustainability in Manufacturing. No. 1 1866. EasyChair, 2024.

- Zhang, J.; Ma, L.; Yan, Y. A dynamic comparison sustainability study of standard wastewater treatment system in the straw pulp papermaking process and printing & dyeing papermaking process based on the hybrid neural network and emergy framework. Water 2020, 12, 1781. [Google Scholar] [CrossRef]

| Mission | Direct the company's activities towards sustainability adaptation. |

|---|---|

| Vision | Have a novel and efficient methodology to adopt sustainability in the company. |

| Objective | Create an environmental commitment from the company's management and employees. |

| Risk analysis generated by machinery (machinery emissions); | Secretaría de Trabajo y previsión social |

| Training and authorization for handling hazardous waste; | |

| Risk analysis for hazardous substances; | |

| Risk analysis for cutting and welding activities; | |

| Hermeticity study in natural gas lines; | |

| Thermography study; | |

| Lighting study; | |

| Noise study; | |

| Static electricity study. | |

| Land use permit; | Municipio |

| Contingency plan. | |

| Environmental impact report; | Secretaria de desarrollo urbano y ecología |

| Emissions study (non-machinery facilities); | |

| Hazardous waste registry; | |

| Solid waste collectors (Selicsa); | |

| Hazardous waste collectors (eco-service); | |

| Industrial recycling collectors (Yonke Fénix). | |

| Registration as a waste generating company; | Secretaria del Medio Ambiente y Recursos Naturales |

| Hazardous waste warehouse; | |

| List of authorized personnel for handling hazardous waste; | |

| List and map of hazardous waste containers; | |

| Safety data sheet for chemical products used; | |

| Authorization of companies for final disposal of hazardous waste. |

| Equipment | Quantity |

| SMT (Surface Mount Technology) machinery for surface mounting of electronic devices | 4 |

| Wave soldering machines | 2 |

| Sealing booths, with extractor tube | 4 |

| Electric soldering irons | 45 |

| Weller soldering smoke extractors | 30 |

| Ceiling extractors | 2 |

| Extraction hood | 1 |

| Computer equipment | 26 |

| T8 lamps | 60 |

| Electric heating | 1 |

| Washing air | 1 |

| Refrigeration / Heating in administrative area | 1 |

| Half-turn valves, in bathroom area | 14 |

| Non-saving tanks | 19 |

| Microwaves | 9 |

| Refrigerators | 3 |

| Coffee makers | 3 |

| 1 Monitors electricity use through a report. | Not monitored as an environmental resource Cost/reading record. Power factor controlled. Motor peaks are controlled with capacitors. |

|---|---|

| 2 Monitors gas use through a report. | Does not monitor Records gas usage from November to March, winter months. It has a hanging heater and a package heater. |

| 3 Develops energy and gas efficiency practices. | Yes, it does practical work Assurance studies: • Hermeticity of natural gas lines; • Thermography; • Lighting studies; • Static electricity. Changing the lighting system from T12 to T8, changing ballasts from magnetic to electric. They have an electric freight elevator, which is no longer in use. |

| 4 Monitors drinking water use through a report. | They do not monitor They do record daily readings in a logbook for security personnel, and comments that regulate extraordinary cases. Monthly consumption is recorded. Cost is not recorded. Greater use in the hot season due to garden irrigation. |

| 5 Knows the destination of its residual loads (drainage/causes). | Yes, they know, it has a residual load permit, a residual water analysis and a technical opinion (Questionnaire for the application of residual loads). |

| 6 Develops water use practices. | Yes, it carries out practices Leak verification by maintenance. It does not have a fire sprinkler system. |

| 7 Makes use of treated water. | No, there is no facility or storage pool. The garden is watered with potable water |

| 8 Prepares a report on greenhouse gas CO2 emissions. | No, there is no consolidated format. EH&S reports annual emissions from heating and emissions of other waste generated by the production process in the general extraction hood. The energy and gas consumed are not transformed into CO2 emissions. |

| 9 Identifies the sources of waste generation. | No, there is a cafeteria service, so organic waste is not collected, and inorganic material is not separated for recycling (plastic, cardboard, aluminum, plastic lids) in the cafeteria or dining room. |

| 10 Maintains procedures for segregating organic and inorganic waste. | No, there is a cafeteria service, so organic waste is not collected, and inorganic material is not separated for recycling (plastic, cardboard, aluminum, plastic lids) in the cafeteria or dining room. |

| 11 Maintains programs for re-using internal waste generated. | No, there is no procedure for reusing material, although the reuse of solder slag generated by soldering irons is carried out without instruction or training on wave soldering machines. Production material is not reused, because it generates very little, but there is the opportunity to recover components from the boards, but they do not do it regularly unless they are short of material or it is expensive, so as not to exceed their goal. Sheets are reused, ensuring the use of both sides; there is no procedure, but there is a tray near the main printer for their disposal. |

| 12 Maintains a management plan for its solid waste. | Yes, if you have several management plans • Non-hazardous waste: • Recyclables • Domestic waste • Hazardous waste • Administrative waste |

| 13 Monitors the amounts and type of waste generated through a report. | Yes, if monitored in monthly meetings by the materials manager, the financial goal is 1%. A digital record is kept by the ISO 9001 department. |

| 14 Monitors what part of the waste (scrap) is recoverable. | Yes, if it is done: it is not accounted for or recorded internally, until the external company Ecoservicios reports the quantity. |

| 15 Knows if the process/service generates toxic waste. | Yes, if it has risk studies -Safety and hygiene diagnosis -Risk analysis for hazardous substances (cutting and welding). |

| 16 Identify the percentage of returnable packaging used by the total shipments. | Yes, if you do it in your packaging called Foam, antistatic separators, which are inside your boxes, these serve to protect the product from static, as well as from displacement. |

| 17 Coordinate with your client to take the product to collection sites when it reaches its useful life. | No, there is an integration of that step into your supply chain. |

| 18 Review a budget for investment in sustainable technologies or innovations. | No, it is not carried out. The return of non-hazardous waste (cardboard/plastics/pallets) is not specifically budgeted for environmental use. |

| 19 Conduct a return on investment control for each of the sustainable technologies and practices implemented. | Yes, a technical evaluation is carried out by maintenance, but it does not consider specific environmental aspects, but rather projects that are carried out in general. |

| 20 Collect and analyze the savings produced by the use of recycled materials, green energy, and recycled water, among other practices. | No, there is no record of this. Maintenance keeps a log of events that occur or installations that have been changed, to see changes or impacts on consumption. |

| 21 Control economic inputs for the recovery or transformation of scrap or waste. | No, the process is not carried out: The scrap metric is available, it is counted to reach the goal, but it will not be compared with what is recovered. |

| 22 Review technologies to ensure control of emissions or reduction of waste. E.g. Automatic shutdown of equipment after a prolonged period of non-use. |

No, it does not perform a complete technology review. |

| 23 Review technologies to reduce the amount of waste they generate. | No, it is not performed Preventive and corrective maintenance is not performed. |

| 24 Review administrative processes that use paper, and could be replaced by an electronic database. | Yes, if they have a continuous improvement procedure, they do not have a sustainability rating. |

| 25 Conducts eco-innovation projects in its products | Yes, if they have a continuous improvement procedure, they do not have a sustainability rating. |

| 26 Conducts eco-innovation projects in its processes. | Yes, if they have a continuous improvement procedure, they do not have a sustainability rating. |

| 27 Conducts eco-innovation projects in its organization. | No, I do not identify eco-innovation projects |

| 28 Conducts training for company personnel on environmental care, recycling, toxic waste, environmental accidents, among others. | No, there is no specific training in environmental care, it is only handled on an annual basis: |

| 29 Communicates the company's environmental behavior to its employees. | No, there are no environmental guidelines to be communicated. |

| 30 Knows what percentage of its suppliers have a sustainable certification (clean industry/ISO 14000). | No, they don't know it, they are only required to have the certification according to their line of business in some cases if ISO 9001 is required. |

| 31 Knows what percentage of its total products are recycled or reused at the end of their life cycle. | No, it is not unknown whether the customer of the final product that makes up the sub-assembly performs this operation. |

| 32 Has identifications for being a green product (eco labels) if applicable. | No, it does not guarantee that the materials used are non-toxic, non-harmful or non-sustainable. |

| 33 Knows what percentage of its customers are interested in having a sustainable certification (clean industry/ISO 14000) | No, he does not know this information |

| 34 Conducts environmental actions in the environment of its company (reforestation, cleaning of parks or vacant lots, among others). | Yes, they do a noise study and reforestation of parks and gardens. |

| 35 Coordinate with your client to take the product to collection locations when it reaches its useful life. | No, because it is a contract manufacturing company. |

| Focus | Practice proposals |

|---|---|

| Energy efficiency | Analyze energy flows in industrial processes to improve designs and minimize total energy use (electricity, gas or other energy sources). • Design of switches, to divide areas such as; office bathrooms on the second floor. • Intensity flows in the dining area. • Connections with separate switches in the area where microwaves are installed in the dining room. • Benches to avoid peaks generated by installed equipment. • Optimize energy use. • Training and awareness of the use of computer equipment shutdown. • Training and awareness of the use of power switches. • Establish procedures for turning off machinery and equipment such as soldering irons or testing (double verification by security guards on their tours) • Proposal for a coffee maker area in office areas, to concentrate the installed household appliance equipment (refrigerators, coffee makers, heaters, microwaves). • Proposal for the installation of the Wattio smart thermostat, which can be programmed and controlled through a mobile application, an internet connection is required. Use of renewable energy. • Evaluation of the use of solar panels for the industrial warehouse space, return on investment and cost benefit. Evaluate energy costs. • Based on records, monitor which months have higher consumption and what are the potential causes (Ishikawa Diagram). Invest in cleaner energy technologies. • In case of changing luminaires, which have electric ballasts, see the adaptation and purchase of T5 tubes to eliminate the installed T8s. The benefit in consumption is from 58 watts to 35 watts. Record and treatment of information. • Record of energy consumption to convert it to CO2 emissions. • Raise awareness in the company based on energy consumption goals and abiotic materials such as water use. |

| Water use | Evaluate flow and supply. • Non-saving toilets installed, reduce the amount of flushing by placing a mass inside it, such as a water bottle, to reduce the amount of liters per flush. Evaluate costs. • In the consumption record, an increase is detected in summer due to watering the garden of the facilities. Invest in cleaner technologies focused on reduction. • Washing faucets; half-turn, non-saving, in one minute of open faucet approximately 10 liters can be wasted, the ecological faucets with automatic closing or adjustable pressure from 5 to 13 seconds guarantee a consumption of 1.9 liters per minute. Use of treated or recycled water. • There is no contact with the purple line that contains recycled water from the city, by the water board. • Contact with JMAS to see the proximity of this and evaluate the long-term benefit based on high consumption generated in summer. Avoid contamination of soil and residual water. • Ensure that all processes that use water as an input are documented to ensure the disposal of contaminated water. Record and process information. • Record and communicate this to employees to make them participate in the savings (cost and water consumption). |

| Input/consumption efficiency | Evaluate flow and supply. • Materials; there is control of the highest cost material by priority, and inventories under control. • These practices are excluded because it is a company that manufactures by contract and most of the material is on consignment: Reverse logistics/ Green supply chain/ Biodegradable materials/ Suppliers certified in sustainability standards. Reduce or eliminate the generation of pollutants at their sources of origin. • Ensure the change from lead to lead-free solder. 6R methodology (reduce, reuse, recover, redesign, remanufacture and recycle). • Provide training on this method, ensure its correct use where applicable and that there are people assigned to the rework process. • Establish a material reuse procedure. • Establish a material recycling procedure and place visual aids for containers, as well as their training. Returnable packaging. • Evaluate returnable packaging with local clients. • Biodegradable packaging, rubber strapping. Return of profits for discarded materials and sale to recycling companies or symbiotic companies. • Present the economic returns of recycling as a metric or supply to sustainable investments. Decrease in delivery cost • Continue with the practice of distributing and optimizing the use of transportation, in case of not having a procedure, standardize. |

| Technologies and innovation | Maintenance and safety of machinery and equipment in order to prevent contamination and regulate energy consumption. • Perform predictive maintenance on installed equipment. • Evaluate energy consumption. Computerized controls to reduce energy consumption. • Shutdown of computer equipment checked from the network, IT. Dematerialization or digitalization of documents. • Digitalization of documents, detailed analysis of processes by department, use email with digital files to send information. • Minimization of productive hour-by-hour sheet space reports (put two reports on a single sheet). • Use of whiteboards to communicate production and use fewer sheets. • Contact a sheet recycler to collect and shred sheets that already have confidential information. Better technologies to improve manufacturing processes without contamination. • Adaptation or installation of extraction hoods • Ensure the use of filters in soldering iron processes, since no extractor has a fan filter to contain volatile material. R&D in the organization, products and processes and organization. • Training on what Eco-innovations are (products, processes and organization). • Design for disassembly; in test boards generated or for recycling, or to reduce the use of inputs. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).