1. Introduction

Smoke formation during closed and big area open fires sufficiently effects the ability of people to evacuate quickly and slows down fire fighting. Smoke is a product of incomplete combustion and it usually forms simultaneously with carbon monoxide. The smoke’s poisoning properties is caused not only by presence of small hard particles, but also by carbon monoxide which is absorbed on their surfaces. This eliminates the possibility of the presence of people and firefighters without special breathing equipment and requires preliminary or, implemented simultaneously with extinguishing the fire, removal of smoke from the premises or fire zone.

The smoke control methods currently used are ineffective. Thus, the use of smoke removal methods proposed in works [

1,

2] and based on the formation of air flows leads to an additional influx of fresh air, which can accelerate the spread of fire.

In the developments of Li-Wei, P.A.N. [

3], Ray, S.K. [

4] and Morlon, R. [

5] the use of highly dispersed water fog to reduce the concentration of smoke is proposed. This helps to temporarily improve visibility in the room for a short period of time (several minutes) [

6], but, subsequently, visibility again decreases to lower values due to the absorption and scattering of light on small water droplets.

The urgent need for smoke precipitation and the lack of effective solutions to this problem necessitate the search for new methods of smoke control. They should significantly improve visibility in a smoke-filled room by settling smoke to ensure the work of firefighters and the safe evacuation of people.

It is obvious that the efficiency of smoke precipitation can be increased by applying additional physical effect on smoke particles. One of the most effective methods of effecting solid particles in gaseous environments is acoustic agglomeration.

The agglomeration process for the deposition of smoke particles by the action of acoustic vibrations was discovered more than 30 years ago during the study of sirens - acoustic alarms - that were triggered by a fire. It was found that deposits of soot or resinous residues from smoke were formed on the surface and around the openings of the acoustic alarm, which formed in the form of patterns of a certain shape - Chladni figures, characterizing the presence of oscillatory processes [

7].

As shown in the works of J. Liu et al. [

8], acoustic agglomeration is a technology for influencing solid particles in gases, in which acoustic vibrations accelerate the relative motion of particles along the direction of wave propagation, as a result of which these particles combine with each other into agglomerates. The sizes of the agglomerates significantly exceed the original particles. At the same time, many researchers (Z. Wang, et al. [

9] and G. Zhang, et al. [

10]) confirmed that the agglomerates formed under acoustic influence are deposited under the action of gravity forces, and the particle count concentration decreases. The processes occurring during acoustic agglomeration have been widely studied in recent years, both experimentally and theoretically. A large number of results have been obtained for the analysis and selection of optimal modes and conditions of influence.

The effectiveness of acoustic agglomeration has been demonstrated for the deposition of coal fly ash [

11,

12], diesel exhaust particles [

13], TiO

2 particles [

14], soot particles [

14] and liquid droplets [

16]. The acoustic frequencies in the experiments were varied over an extremely wide sound range from 46 Hz [

17] to 18 kHz [

18]. The proposed agglomeration mechanisms are explained by orthokinetic interactions, acoustic wake effects, etc. Acoustic agglomeration has shown great potential in improving the efficiency of dust emission collection, extracting valuable particles or droplets from flue gases and preventing fogging at airports [

19,

20,

21,

22,

23]. As studies have shown, the impact of acoustic vibrations on soot aerosol with a mass concentration of 1.0 g/m

3 [

24,

25] leads to the formation of soot aggregates in the form of levitating disks with a diameter of 1–2 cm during a long (more than 10 min) acoustic impact time.

The presented results allow us to state that the acoustic agglomeration technology can improve visibility in smoke in a fire situation by reducing the smoke concentration at an early stage of a fire, and thus, help evacuation before the escape routes are blocked by open combustion. In addition, compared with other smoke removal methods, this technology has a number of advantages related to the simplicity of operation and high speed of reducing the concentration of smoke. However, there are a number of obstacles to its practical use:

– firstly, almost all positive results were achieved by combining particles with sizes greater than 3–5 μm;

– secondly, the main studies were carried out at an audio frequency, at a sound pressure level of 140 dB and more. However, high-intensity (>140 dB) acoustic radiation in the audible sound range is unacceptable for practical use in open spaces (or without the use of personal protective equipment) due to the mortal danger of such impact for humans and animals.

At the same time, it is known today that the most effective way to agglomerate small particles (less than 2.5 µm in size) is to use ultrasonic vibrations with a frequency of more than 22 kHz, which is safe for humans and animals. It has been established that ultrasonic vibrations quickly combine small particles into agglomerates and increase their size to 10 µm [

26,

27,

28]. However, for smoke particles, the largest number of which lies in the submicron range of 0.001–1 µm, even high-frequency ultrasonic vibrations are not effective enough. At the same time, the time it takes to reduce the concentration of particles by at least an order of magnitude can be tens of minutes, which is unacceptable in the case of fighting smoke during fires.

To improve the efficiency of acoustic agglomeration, various approaches have been proposed based on changing the characteristics of the acoustic wave or initiating secondary acoustic effects in the insonified medium, leading to additional convergence and enlargement of particles. Thus, in the works [

27] the creation of nonlinearly distorted waves to increase the effective cross-sectional area of the collision is considered. It is shown that with a nonlinearity coefficient of up to 0.8, the probability (area of effective particle collision) increases by 5–20 times [

27]. Also known are approaches based on initiating acoustic flows of various scales in the insonified medium (from the size of the insonified medium to the sizes corresponding to the pressure drop zones in the oscillatory process). It was found that such an approach allows increasing the efficiency of submicron particle agglomeration by 25%.

However, the practical implementation of these approaches is possible only in the case of creating resonance in the air gap, and this is achieved only in small layers, the thickness of which does not exceed several lengths of ultrasonic waves in the air. Real world rooms in which it is necessary to implement smoke precipitation differ significantly in size, so it is necessary to consider alternative approaches to increasing the efficiency of agglomeration, which are less demanding on the sound pressure level in the volume being sounded. Thus, to form nonlinearly distorted shock waves, it is necessary to create a sound pressure level of at least 180 dB, and to form intense acoustic vortices - at least 170 dB [

27]. This is technically not feasible in rooms, tunnels and open spaces.

As it was shown earlier, ultrasonic action allows for very rapid agglomeration of small particles and an increase in their size to 5–10 µm [

26,

27,

28]. However, further ultrasonic vibrations practically cease to act on the formed agglomerates of such a size that could be combined due to sound action, as shown earlier.

Therefore, in this paper, in order to create a highly efficient method for smoke agglomeration, it is proposed to study the effect of complex acoustic fields formed by several (at least two) emitters operating at the same or similar frequencies on smoke particles.

In this case, the intensification of smoke particle agglomeration will occur due to several factors. Since it is known that smoke particle agglomerates have an aspherical shape, in complex ultrasonic fields they will perform not only translational motion (due to the influence of a non-zero momentum during the collision of particles into an agglomerate), but also rotational motion (due to a non-zero angular momentum) [

29]. It is clear that the rotational motion of an aspherical agglomerate can increase the collision cross-sectional area. In this case, the greatest rotation can be achieved by changing the vector of the oscillatory velocity of the acoustic field both in magnitude and in direction. A change in the vector of oscillatory velocity is possible in the case of interaction of ultrasonic vibrations of two close frequencies with the formation of beats that arise and propagate over the interaction area of ultrasonic vibrations.

Therefore, it is of great interest to study the influence of dual-frequency ultrasonic action (about 20 kHz), which is capable of forming beats at a difference low frequency, effective for the sedimentation of agglomerates, when interacting with oscillations close in frequency. In this case, it is proposed to form beats at a frequency lower than human hearing, but higher than infrasonic, resonant frequencies of human internal organs. This will make such action safe for humans [

30].

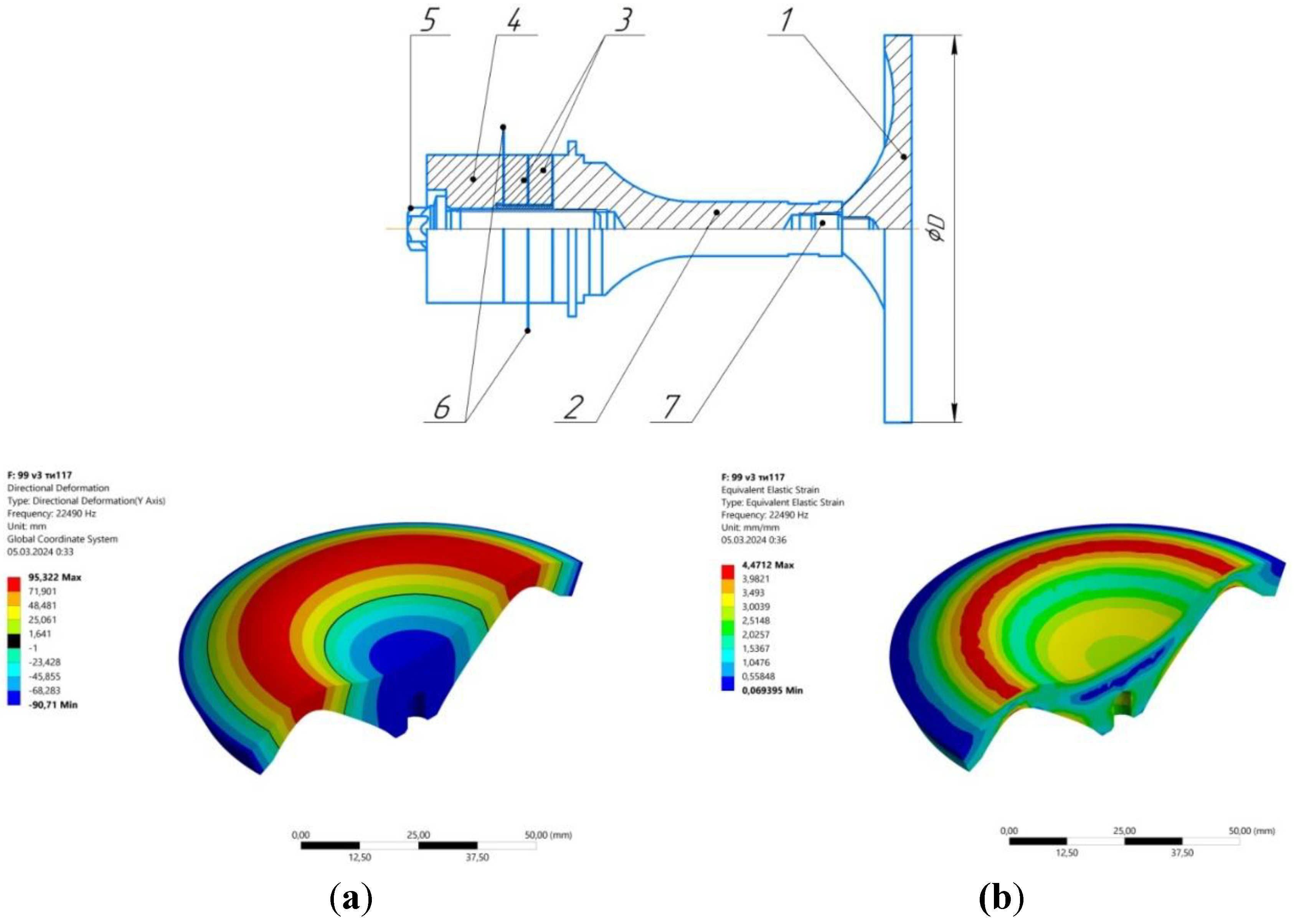

The creation of conditions for the formation of complex ultrasonic fields, when two ultrasonic waves and a difference low-frequency wave are directed at an angle to each other and have a phase shift, should ensure the most effective deposition of smoke. To create such an effect in practice, highly effective ultrasonic emitters have been proposed and developed, the design, adjustment features and application of which are discussed below.

3. Results and Discussion

3.1. Characteristics of the Acoustic Field Formed by Disk Radiators

Based on the results of the measurements, the directivity pattern and the dependence of the sound pressure level on the distance from the radiator (attenuation per unit length) were constructed for all three combinations of ultrasonic action: action by one radiator at one frequency; action by a double radiator consisting of two disks operating at one frequency; action by two disks at different frequencies.

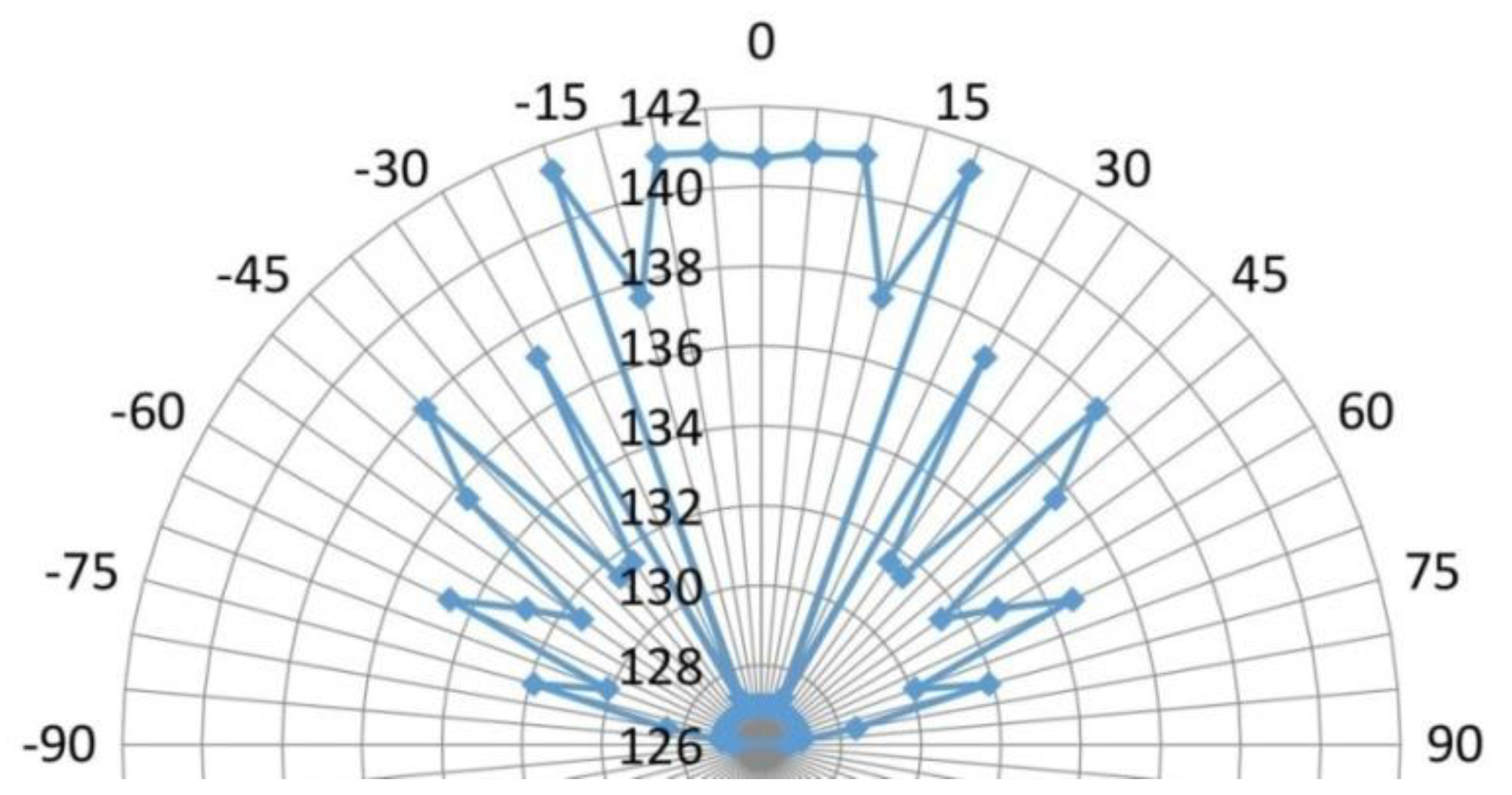

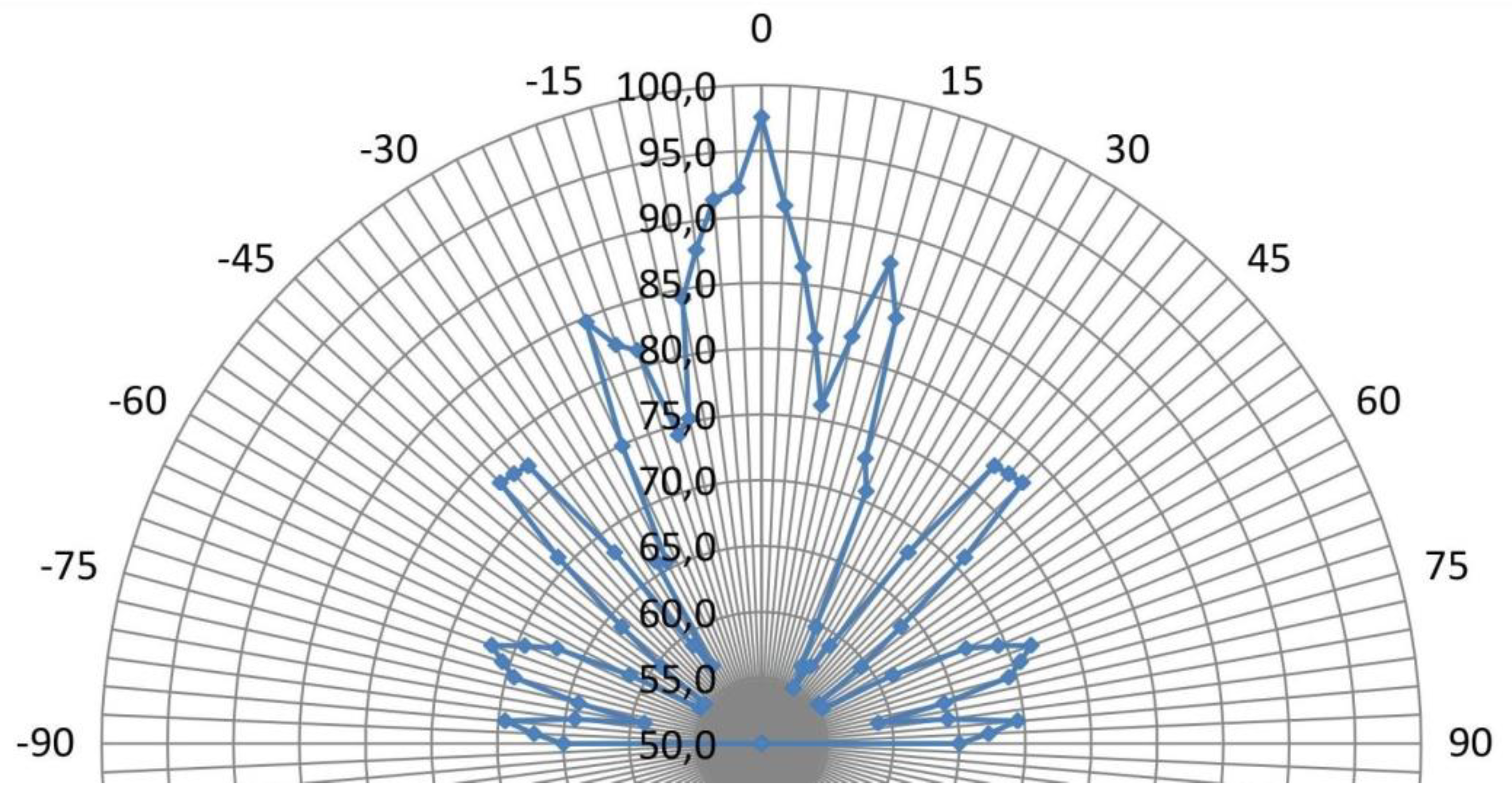

When acting by one radiator, it was found that the opening angle of the main lobe of the directivity pattern was 20°, the sound pressure level at a distance of one meter was 141 dB (

Figure 7).

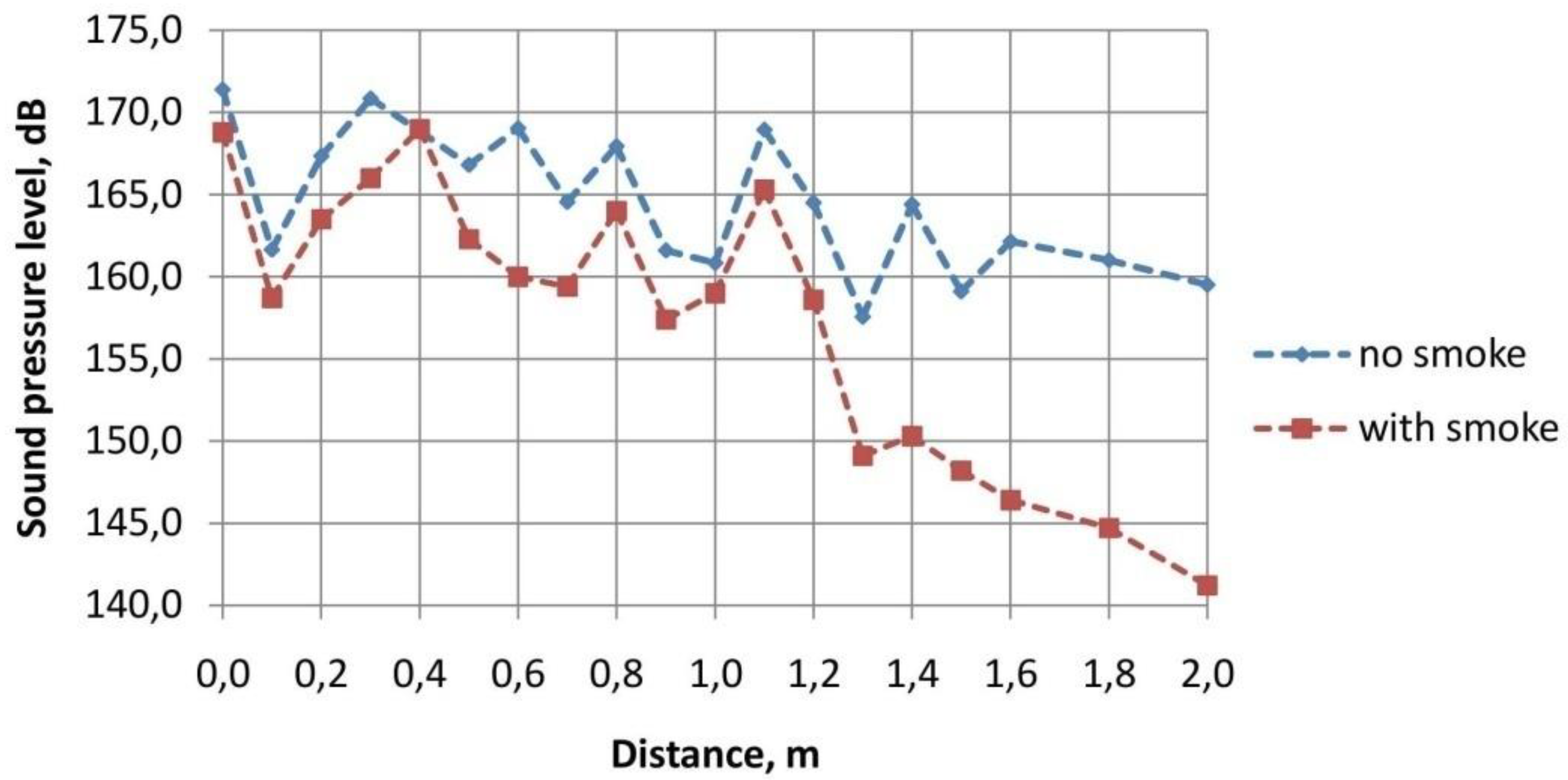

Next, the linear attenuation of ultrasonic vibrations generated by a single emitter was determined. Measurements were taken in a smoke chamber in clean air (without smoke) and when exposed to smoke. It was found that when propagating through smoke, ultrasonic vibrations attenuate much more strongly than when propagating through air. The results of comparative measurements are presented in

Figure 8.

The presented dependencies show that the sound pressure level generated by the disk emitter is higher in the smoke chamber than in the open space. This is due to the fact that the chamber walls prevent the lateral divergence of the energy of the emitted vibrations and direct it along the chamber. Due to this, at a distance of 1 m from the emitter, the SPL increases from 141 dB to 160 dB. However, the presence of smoke leads to a sharp decrease in the sound pressure level with distance from the emitter: from 160 dB in an empty chamber to 141 dB in a chamber filled with smoke (the data comparison is given at the exit from the chamber, the length of which was 2 meters). The difference of about 20 dB corresponds to a 100-fold decrease in the power of ultrasonic vibrations generated in the chamber!

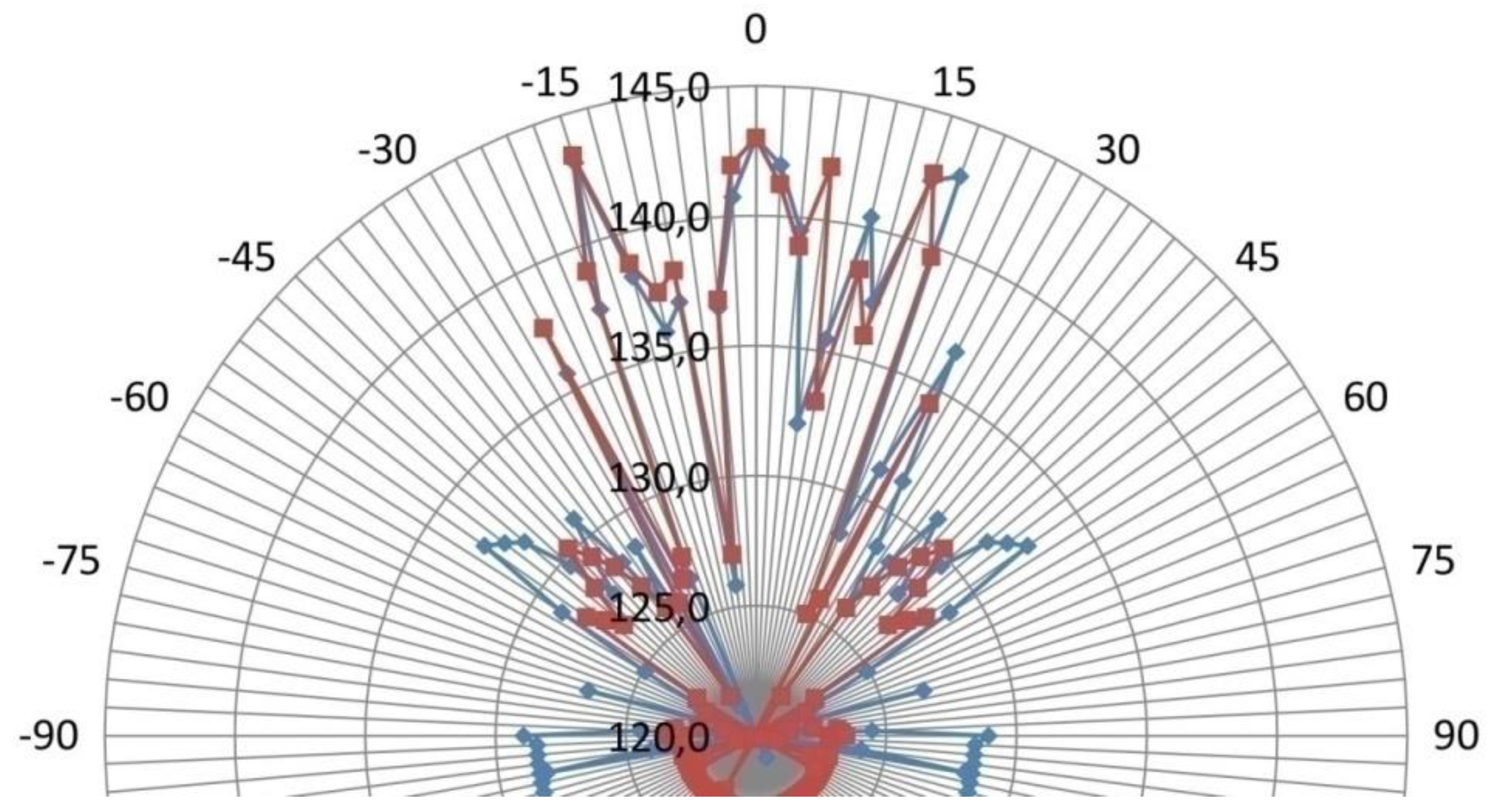

The obtained results confirm the necessity of influencing smoke with ultrasonic fields with a high level of sound pressure and a complex structure, increasing the probability of convergence and interaction of smoke particles. For this purpose, the characteristics of the acoustic field formed by two emitters operating at the same frequency and two emitters of different frequencies were studied. The measurement results (in the form of a directivity pattern in open space) are shown in

Figure 9.

It follows from the presented diagram that due to the use of two emitters, the maximum sound pressure level increased by 3 dB. At the same time, a narrow central lobe of the diagram with a width of ±5° was formed. Two symmetrical side lobes are distinguished in the diagram, extending from the acoustic axis of the emitter by 15°. The sound pressure level of these side lobes is equal to the central one and is ≈143 dB. When such an emitter acts in a limited space (smoke chamber), the presence of such lobes does not affect the radiation efficiency. As was shown earlier, the extended design of the chamber eliminates the divergence of ultrasonic vibrations. But when acting in open spaces, such lateral divergence must be excluded. This will be the direction of our further work.

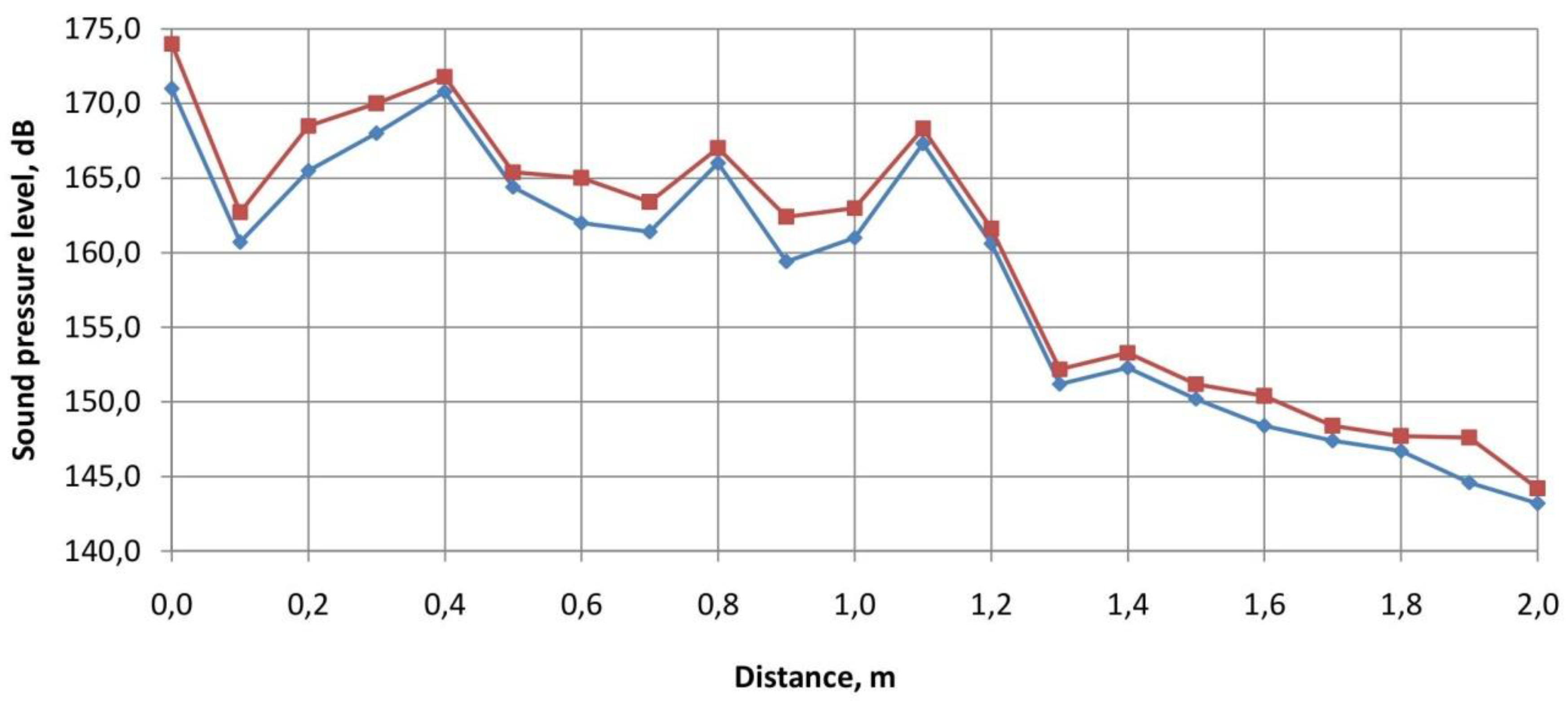

Figure 10 shows the results of the attenuation in relation to distance to source for different and equal-frequency operating disk emitters. The attenuation was also measured in a chamber filled with smoke.

From the presented dependencies it is evident that for two equal frequency emitters the sound pressure in the chamber filled with smoke is higher than for two multi-frequency emitters at 1.5-2 dB. The excess is observed both at a distance of 1 meter from the emitters and at a distance of 2 meters from the emitters, which should contribute to accelerated agglomeration of smoke.

In general, the results of sound pressure level measurements presented in

Figure 9 and

Figure 10 showed that both equal-frequency and multi-frequency ultrasonic action create practically identical complex acoustic fields on the deposited smoke. Thus, the various efficiency values of ultrasonic smoke agglomeration obtained in further experiments will be unambiguously determined only by the type of ultrasonic action (single-frequency or multi-frequency), and not by the sound pressure level.

However, when exposed to multi-frequency emitters, beats were formed at a difference frequency of 300 ± 5 Hz.

Figure 11 shows the directivity pattern for the generated oscillations of the difference frequency.

The angle of the main lobe of the directivity pattern was ±10 degrees, while the sound pressure on the main lobe of the directivity pattern reached 97.6 dB. The results of measuring the linear attenuation of a system of two ultrasonic emitters with reflectors and horns are shown in

Figure 12. The measurements were carried out with a smoke-filled chamber.

It follows from

Figure 12 that low-frequency oscillations are attenuated less in a smoky environment. With a lower initial value, the relative decrease in SPL at a distance of 1 m and 2 m from the emitters is 10 dB less than for ultrasonic frequencies. Thus, at a distance of 1 m from the radiating surface of the ultrasonic emitters, the sound pressure intensity was 84.1 dB, and at a distance of 2 meters – 77.8 dB.

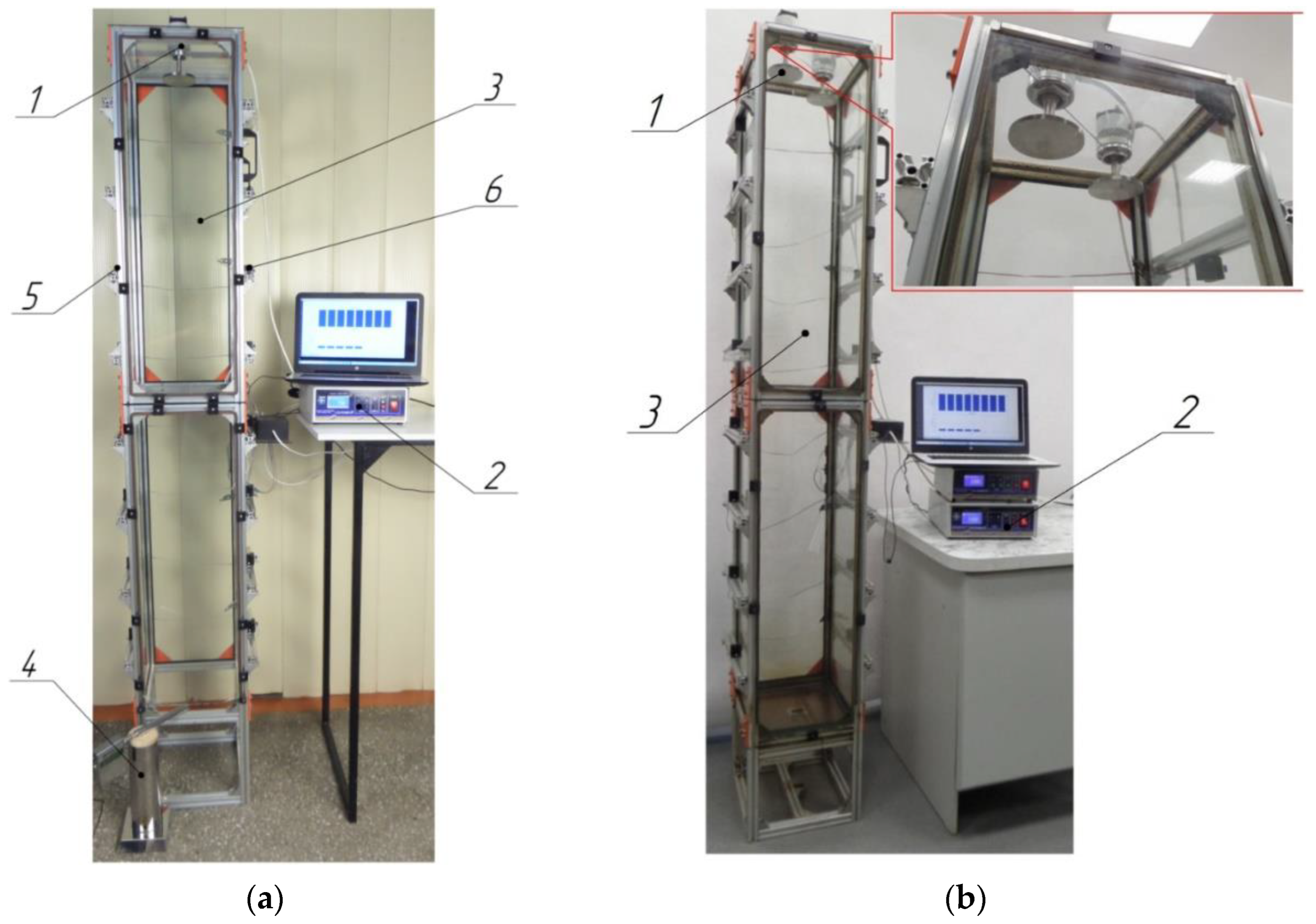

3.2. Qualitative Assessment of Smoke Precipitation Efficiency

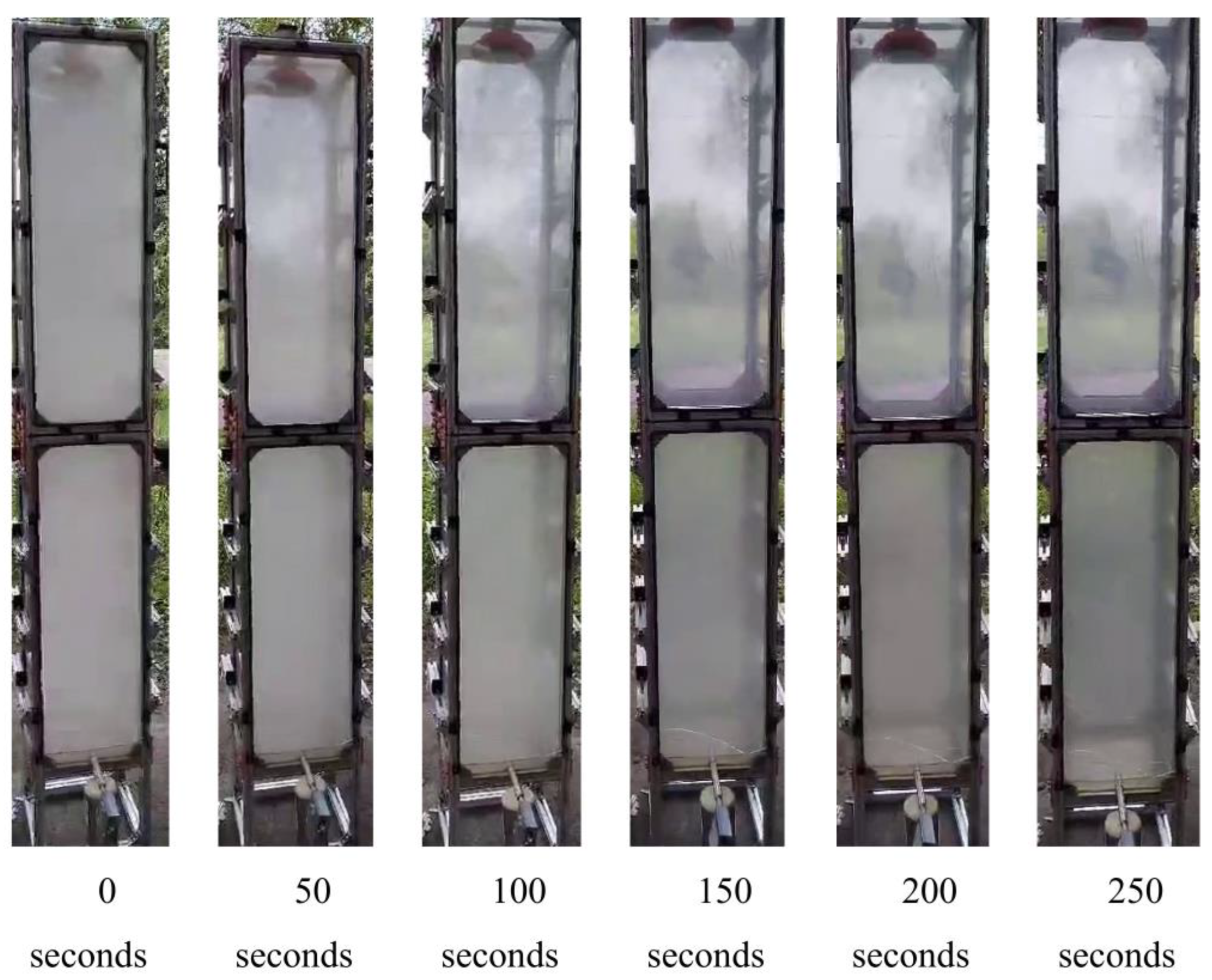

Preliminary experiments have shown that in less than 300 seconds of ultrasonic action, with the smoke generator operating in the chamber, complete deposition of smoke occurs – the chamber is completely cleared of smoke. Residual turbidity on the transparent walls of the chamber is caused by the deposition of smoke and resin particles on the walls under the action of ultrasonic vibrations. For comparison: when the smoke supply to the smoke chamber was turned off, the time of natural deposition of smoke (without ultrasonic action) in the chamber was about 30 minutes.

The results of visual observation of ultrasonic agglomeration of smoke are shown in the photo (

Figure 13).

Thus, it has been qualitatively confirmed that there is an increase in the transparency of the air environment due to the agglomeration of smoke particles under the action of ultrasonic vibrations, and initial data have been obtained for conducting comparative tests. This confirms not only the fundamental possibility of using ultrasonic action as a means of combating smoke, but the need to study it to identify more effective modes and conditions of this action.

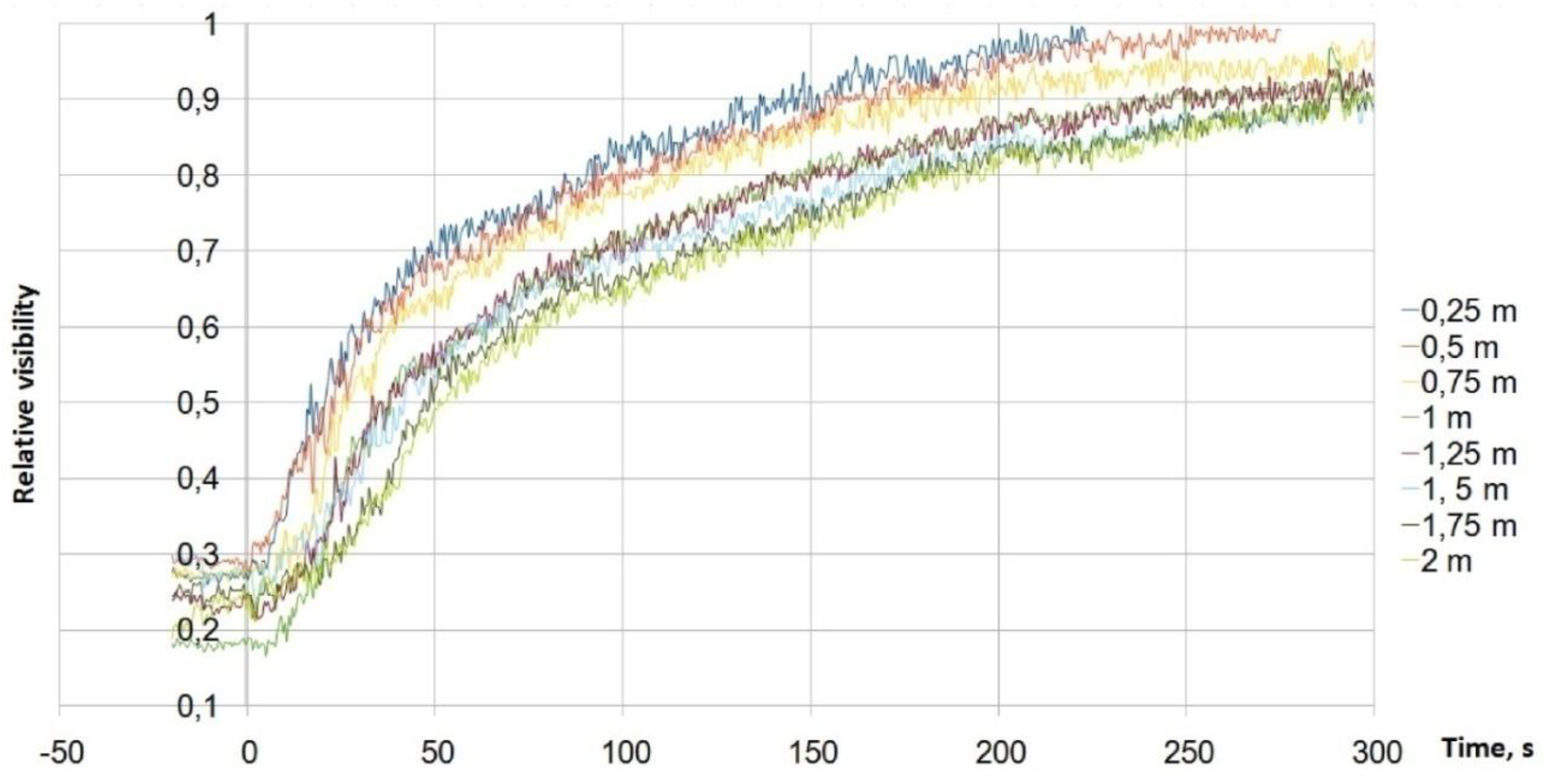

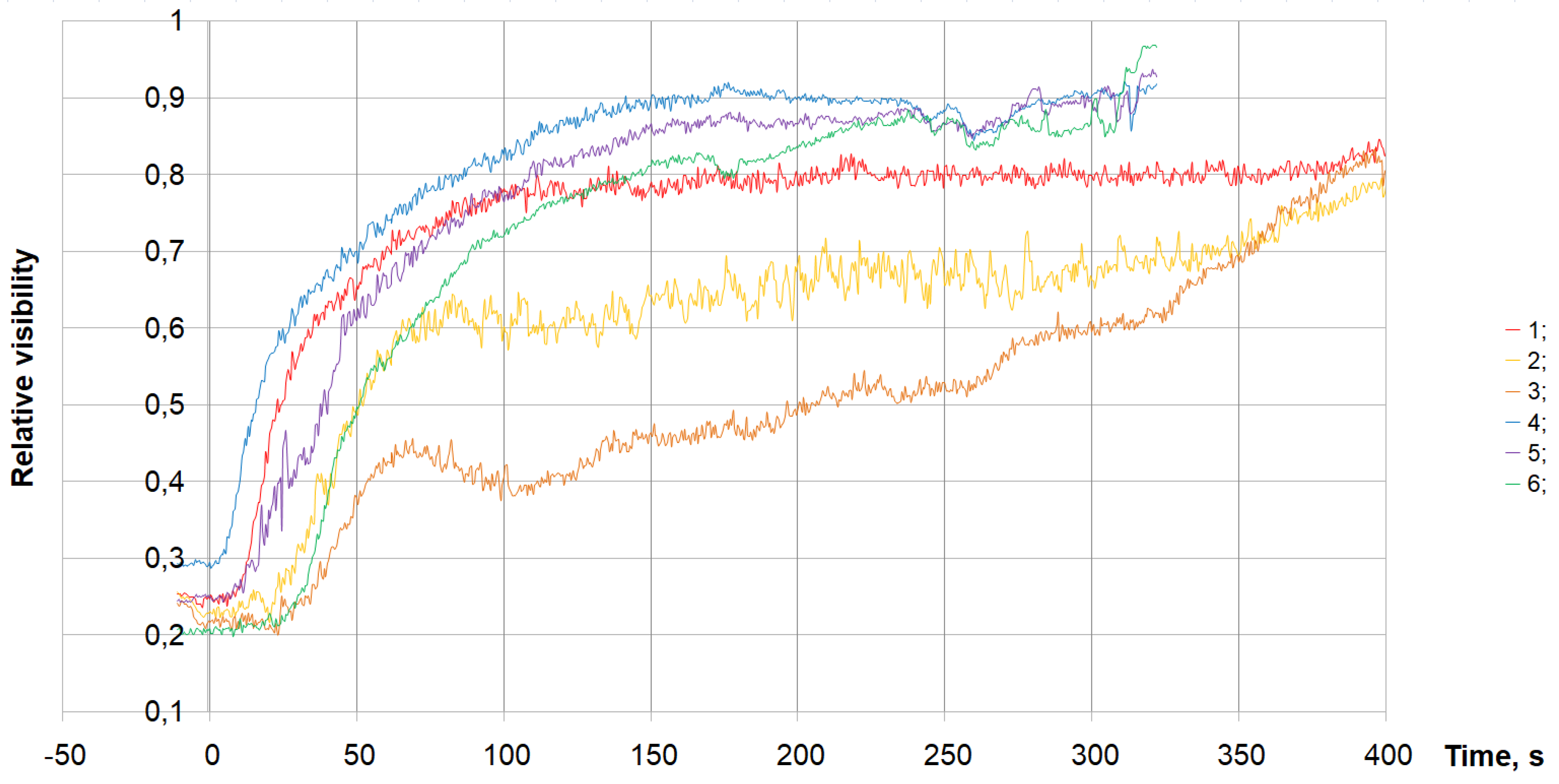

3.3. Results of Smoke Deposition by One Emitter

Using optical sensors installed in the smoke chamber, the relative change (relative to smoke-free air in the room) in visibility at different distances from the emitter was measured. The results are shown in

Figure 14. Data from every second sensor is shown. In

Figure 14, the parameter of the curves is the distance in meters from the emitter to the optical pair measuring relative visibility.

Before the experiment, the chamber was filled with smoke to its full height. The moment the ultrasonic action began corresponds to the zero mark on the time axis. It is evident that at the initial moment of time (during the first 50 s) there is a significant increase in visibility in the smoke chamber, up to 0.8 of the visibility in the absence of smoke at a distance of 0.25 m from the emitter. At the same time, at a distance of two meters from the emitter, the relative visibility is no more than 0.6 (the supply of smoke to the smoke chamber did not stop). Visually, this corresponds to the second photograph in

Figure 13, where a significant gradient of smoke density is observed as the distance from the emitter located at the upper end of the chamber increases.

Figure 14.

Measurement of relative visibility from the time of ultrasonic exposure for different distances (in m) from the emitter.

Figure 14.

Measurement of relative visibility from the time of ultrasonic exposure for different distances (in m) from the emitter.

This may be due to both the continuous flow of smoke into the chamber through the lower end and the increased attenuation of ultrasonic vibrations in a dispersed medium containing smoke particles. With further ultrasonic exposure, the relative visibility increases and levels out along the height of the chamber, asymptotically approaching 1 near the emitter and reaching 0.9 at a distance of 2 meters from the emitter (the flow of smoke into the chamber did not stop). The obtained dependencies allow us to state that ultrasonic exposure not only causes agglomeration of smoke particles, but also suppresses the flow of new smoke particles from the source into the sounded volume.

Thus, it was established that the action of ultrasonic vibrations ensures agglomeration and sedimentation of smoke. This leads to an increase in visibility, almost to the state of a smoke-free chamber. However, the required exposure time turns out to be unacceptably long for the practical application of ultrasonic agglomeration in real conditions (for example, for the rapid evacuation of people).

To increase the efficiency of agglomeration of smoke particles, complex ultrasonic fields and nonlinear effects initiated in them (rotation of agglomerates, and low-frequency acoustic beats that can enhance the effect of ultrasonic vibrations) were further used.

3.4. Smoke Precipitation in Complex Acoustic Fields

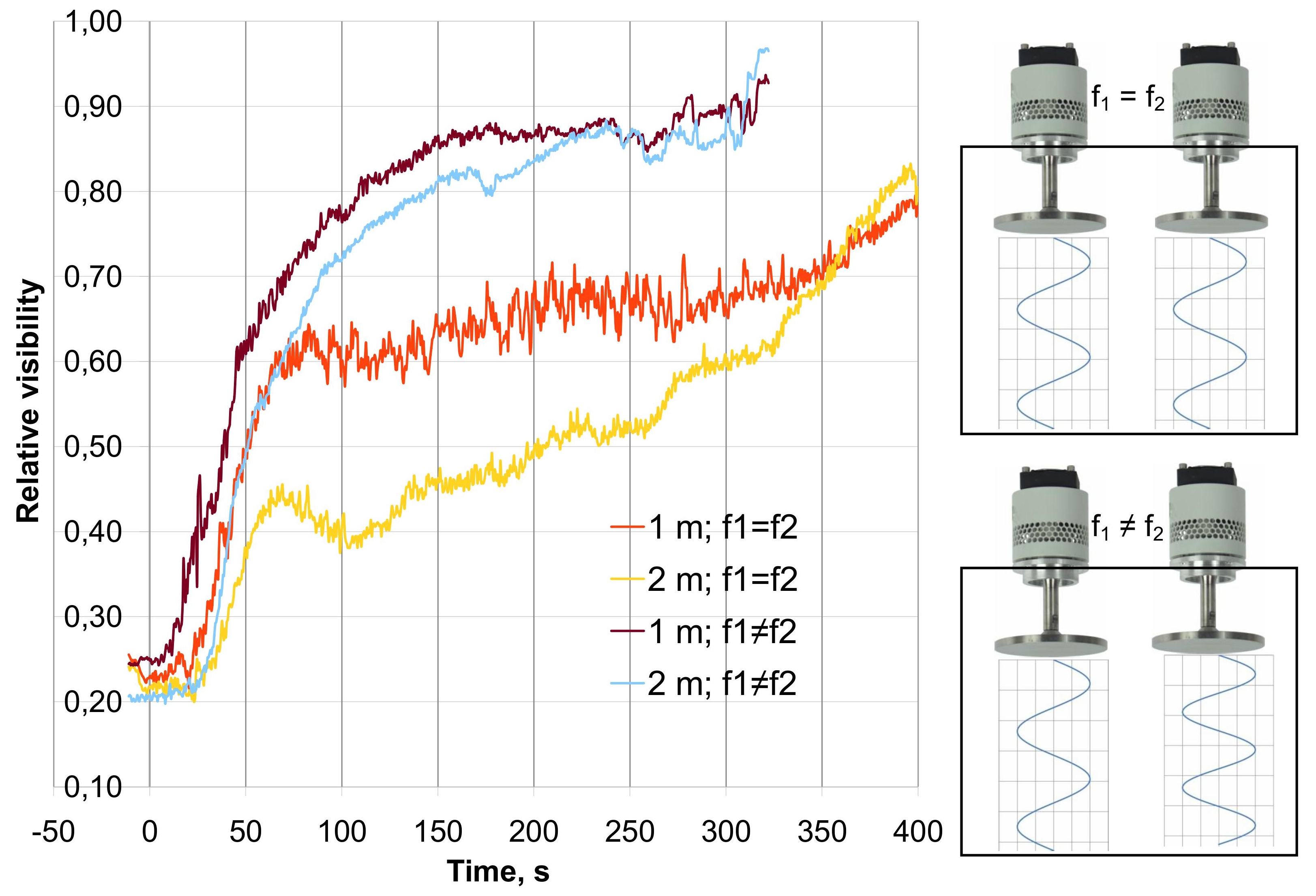

Such acoustic fields can be created using two emitters. The emitters must operate synchronously at one frequency or at two close frequencies to initiate rotational motion of agglomerates (for additional increase in the collision cross-section of smoke particles) additional formation of acoustic beats (for subsequent agglomeration and final sedimentation of large particles and primary agglomerates of sizes from 1 μm). The smoke flow rate was 5 l/min. Otherwise, the conditions of the experiment were similar to the previous one. The dependencies of the change in relative visibility for each type of ultrasonic action (at one frequency and different frequencies) are shown in

Figure 15.

In this figure, the graphs of warm shades (curves 1, 2, 3) show the dependencies of relative illumination for two disks operating at the same frequency, and cold shades (curves 4, 5, 6) – for disks operating at different frequencies. In each experiment, signals from 3 sensors located at distances of 0.25 m, 1 m and 2 m from the emitters were compared.

As can be seen from the graphs (

Figure 15), for disks operating at one frequency, a significant gradient of relative visibility is observed depending on the distance from the emitters. Thus, at the initial moment of time (during the first 50 s), a significant increase in visibility is observed in the immediate vicinity of the emitters, up to 0.65 (curve 1). However, visibility deteriorates significantly as the distance from the ultrasonic emitters increases. At a distance of 1 m, the relative visibility does not exceed 0.5, and at 2 m 0.25 (in comparison with single-frequency exposure by two emitters 0.65 and 0.5, and with exposure by one emitter at a distance of 2 m no more than 0.6). Moreover, the resulting gradient of relative visibility remains almost constant throughout the experiment. This indicates that the use of 2 disk emitters, which provided an increase in SPL by 3 dB (the acoustic power increased by 2 times) does not allow compensating for a similar increase in the flow rate of smoke entering the chamber. The speed of ultrasonic agglomeration of smoke particles is not enough to compensate for the influx of new particles. This is why the minimum relative visibility (maximum smoke) is observed in the area where smoke enters the chamber. In the previous experiment with one emitter, such a visibility gradient was not observed.

Starting from 250 s, the visibility gradient along the height of the smoke chamber begins to decrease. Thus, the relative visibility at a distance of 2 m from the emitter begins to increase sharply. This is due to the burning of sawdust (in 250 seconds, a 20 gram weight of sawdust burns completely) in the smoke generator and a decrease in the density of smoke entering the chamber. The smoke particles remaining in the chamber are gradually displaced in the direction of the emitters and agglomerate under the action of ultrasonic vibrations. This explains the fact that in the middle of the chamber (at a distance of 1 m), the longest time is required to achieve the maximum value of relative visibility.

Thus, the impact of two emitters at one frequency and increased by 3 dB SPL for a smoke supply capacity increased by 2 times does not allow suppressing the smoke supply from the source to the sounded (protected volume). In turn, for two-frequency impact, significantly different dependencies were obtained. The increase in relative visibility occurs almost simultaneously throughout the entire volume of the smoke chamber. That is, the graphs of relative visibility for different distances from the emitter change almost identically.

This allows us to state that due to the acoustic effects (rotation of agglomerates, acoustic beats) arising from the interaction of different-frequency ultrasonic vibrations, it is possible to achieve not only a uniform increase in visibility in the smoke chamber, but also suppression of smoke entering the chamber from the source. At the same time, the value of the generated sound pressure and, accordingly, the energy costs for the smoke agglomeration process did not increase.

To determine the reduction in time for establishing the maximum value of relative visibility, the experimental results were summarized in

Table 2.

The results show that a high level of sound pressure is created near the emitter, sufficient for effective agglomeration, both with equal-frequency and with different-frequency ultrasonic exposure.

Thus, multi-frequency exposure allows accelerating the agglomeration process (if we consider a distance of 0.25 m) by approximately 1.9 times: from 175 seconds with equal frequency to 90 seconds with multi-frequency. If we consider a distance of 1 meter, then approximately 3.3 times: from 250 seconds with equal frequency to 75 seconds with different frequencies. If we consider a distance of 2 meters, then approximately 5 times: from 300 seconds with equal frequency to 60 seconds with different frequencies.

Thus, it can be concluded that the multi-frequency impact (at a sound pressure level of no more than 140 dB) increased the probability of collision of smoke particles and their agglomerates due to the interaction of ultrasonic vibrations of two frequencies with the formation of beats, which contributed to imparting rotational motion to the agglomerates in acoustic fields with different vibrational velocity vectors.

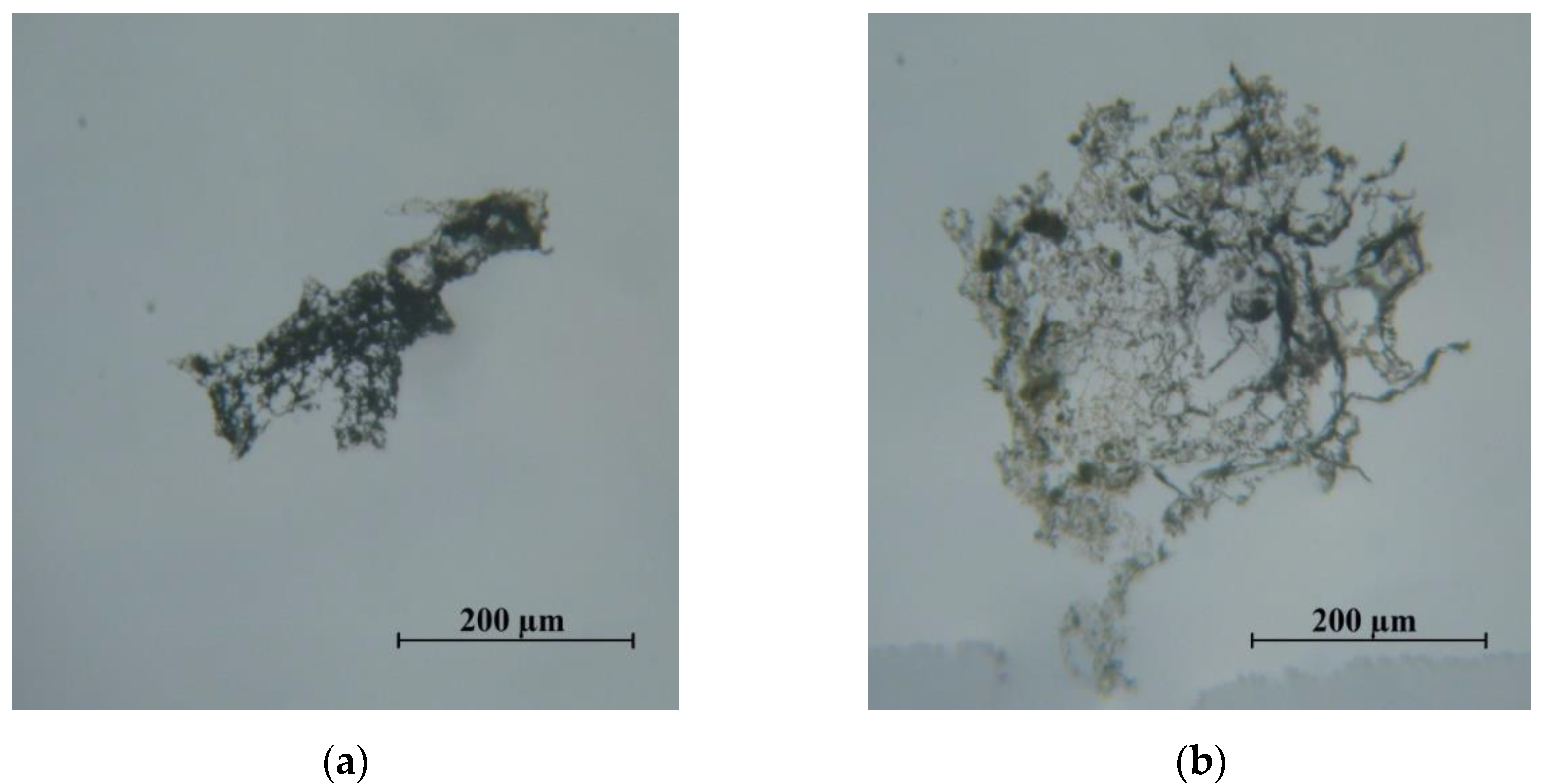

3.5. Visual Analysis of Smoke Particle Agglomerates

To assess the influence of rotational motion and acoustic beats on the shape and size of agglomerates, samples were collected by catching the formed agglomerates at a distance of 2 m from the emitters. The agglomerates were caught on a microscope slide covered with a layer of immersion liquid.

Figure 16 shows an example of photographs of smoke particle agglomerates obtained using the Lomo Mikmed-6 microscope.

Direct image analysis shows that multi-frequency (

Figure 16(b)) exposure produces larger agglomerates of smoke particles. The agglomerates have a more porous structure, and their shape resembles a regular disk. This porous structure may be due to the fact thatthe final shape of the agglomerate was obtained by merging smaller agglomerates (which are formed by combining the original smoke particles with ultrasonic frequency oscillations) under the action of beats. In turn, the disk-shaped shape is due to the rotation of the agglomerate around one of the axes. Since the agglomeration time under different frequency exposure is 1.6 times less than under equal frequency exposure, the agglomerate was exposed to ultrasonic vibrations for a shorter time and did not have time to compact due to the “sticking” of a large number of initial smoke particles.

In turn, the agglomerate (

Figure 16(a)), obtained with equal-frequency action, has an elongated shape due to the absence of rotation and the location of the agglomerate along the antinodes of the ultrasonic field. It is also known that in the case of a polydisperse distribution of the size of suspended particles, the most likely is the attachment of small particles to larger ones (compared to the probability of combining particles of similar sizes). This is why the agglomerate (

Figure 16(a)) has a denser structure formed by multiple "sticking" of small smoke particles to the agglomerate nucleus (initially a larger smoke particle). A detailed determination of the morphology of agglomerates depending on the type of ultrasonic action will be the direction of further research.

In general, the obtained results allowed us to establish that the effect of multi-frequency oscillations allows us to reduce the time required for complete removal (agglomeration of particles) of smoke by 2.5 times, compared to the action of one emitter, and by at least 1.6 times compared to the use of two emitters operating at the same frequency. This allows us to recommend this method of action when developing practical methods and designs of emitters for combating smoke during fires.

4. Conclusions

Based on the analysis, it was established that the efficiency of smoke precipitation is increased by using additional physical action on smoke particles with ultrasonic vibrations, which ensure the agglomeration of small particles into agglomerates.

To increase the efficiency of ultrasonic smoke precipitation, it is proposed to act on smoke particles with acoustic fields of complex structure, formed by several (at least two) emitters operating at different frequencies.

To form such fields, highly efficient bending oscillating ultrasonic emitters have been proposed and developed, simultaneously generating ultrasonic (22 kHz) oscillations in the range with a sound pressure level of at least 140 dB (at a distance of 1 meter) at two slightly different frequencies (no more than 300 Hz).

The practical implementation of smoke deposition in the experimental setup provided a relative visibility of 0.8 at a distance of 1 m, and 0.9 at 2 m (in comparison with single-frequency exposure by two emitters 0.65 and 0.5, and with exposure by one emitter at a distance of 2 m no more than 0.6).

In this case, complete smoke deposition occurred twice as fast as with ultrasonic action by two equal-frequency emitters.

Two-frequency action for smoke deposition does not require an increase in energy costs and is achieved by combining small particles into agglomerates under the action of high-frequency ultrasonic vibrations and further combining the formed agglomerates when creating conditions for their additional rotational movement of agglomerates by low-frequency vibrations arising from the interaction of ultrasonic vibrations of different frequencies.

The obtained results indicate the effectiveness of two-frequency action for accelerating the process of smoke deposition and can be recommended for practical application.