1. Introduction

Road paving has been one of the most important sectors in all countries of the world in recent years. However with the increase in the price of oil globally, the road paving has become expensive for some countries, so it has become necessary to introduce a new technology for road paving industry and asphalt manufacturing and to enhance the recycling the old asphalt in old roads, and with the addition of rubber as a sustainable material, A Previous researches showed that the use of rubber enhances the properties of asphalt mixture like durability, resistance to heat cracking and rutting and it has been obtained that the use of recycled asphalt pavement and crumb rubber provide considerable structural and financial enhancements to the construction [

1,

2,

3,

4], Another research concluded that adding crumb rubber to asphalt mixture increases its stability but reduces its flow. This indicates that using rubber can help asphalt mixtures resist permanent deformation [

5,

6]. However, another study stated that adding recycled asphalt to warm mix asphalt increased the resistance to rutting and moisture damage compared to warm mix asphalt mixtures without recycled asphalt [

7,

8]. Despite the previous research that studied the impact of adding recycled asphalt to rubberized asphalt mixture, the optimal percentage has not been clarified intensively. As a result, the current research has investigated the effect of different mixing percentages between recycled asphalt and hot mix asphalt. Moreover, the impact on the cost and properties has been also illustrated to reach the optimal percentage for adding the hot mix asphalt with rubber to the recycled asphalt to reach the highest stress and to know the enhanced properties to save the cost of paving roads to suit the economic situation of countries. Using the recycled mixture with the manufactured asphalt mixture will have environmental and economic effects and advantages [

9]. From previous research, it became clear that the best percentage for adding rubber to the asphalt mixture is 20% from the percentage of bitumen in the mixture [

10,

11], this percentage has been used in the mixtures design in this research that aims to add the rubberized asphalt mixture to the scraped asphalt to recycle it and get the optimal percentage of this combination.

Crumb rubber: Sustainable material, mixing this material with 20% (of) the bitumen wight will reduce the bitumen percentage in asphalt. Consequently, reduces the cost of asphalt paving, the cost of crumb rubber is about 30% of the cost of bitumen, as a result, adding crumb rubber obtained from end life tires to bitumen is a sustainable solution [

12,

13,

14] which results in a durable and flexible material with high resistance to wear, and weather conditions, Improving asphalt stability on one hand, and reducing the deformation and maintenance cost on the other hand are the main objectives of using recycled asphalt and adding crumb rubber to asphalt mixture [

15].

Crumb rubber can be mixed with asphalt in two different processes firstly, dry process in which crumb rubber is added to aggregate before mixing with asphalt. Secondly, wet process on which crumb rubber is mixed with asphalt at high temperature [

16].

RAP (Recycled asphalt pavement) consists of reclaimed asphalt of old roads and pavements which can be added and mixed into new asphalt mixtures. The use of RAP not only reduces the need for virgin materials but also reduces the carbon footprint of road construction (FHWA, 2016). However, the performance of RAP mixed with asphalt mixtures depends on the quality of reclaimed materials [

17].

2. Methodology

This research depends on mixing the scraped asphalt with new asphalt mixture. Mixing using the different percentages shown in the following table at different bitumen percentages 4.5%, 5%, 5.5%, 6%.

R: Recycled Asphalt

N: New hot mix Asphalt

First, starting with testing the scraped asphalt by the bitumen extraction test to percentage of bitumen in RAP.

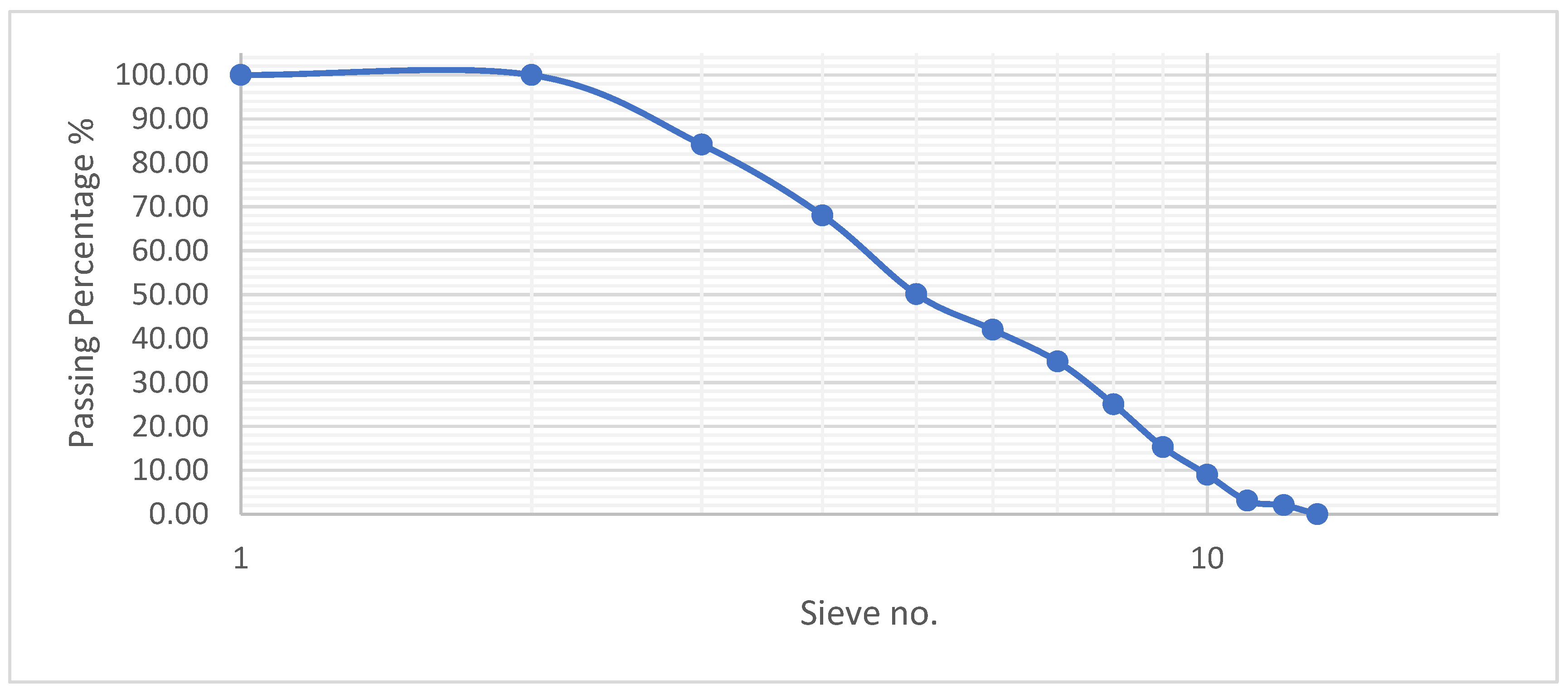

Then using the sieve analysis test to determine the gradation to measure it compliance with mixture design and the results have been shown in the following figure.

Figure 1.

Results of sieve analysis test on scraped asphalt.

Figure 1.

Results of sieve analysis test on scraped asphalt.

Bitumen was added to the scraped asphalt by adding the remaining percentage of bitumen to the existing percentage in SA and divided into 20% of its rubber and 80% of its hot bitumen at a temperature of 180. After that, the components of the manufactured asphalt mixture were added, taking into consideration that the percentage of bitumen would also be 20% rubber and 80% hot bitumen at a temperature of 180 all components was mixed and then compacting the cylindrical sample 75 times on each side in Marshall mold with a dimension of 63.5 mm in height and 101.6 mm in diameter [

18,

19]. and the samples were made at the different percentages of mixing that were shown in

Table 1.

Table 1.

Percentages of mixing Recycled and New asphalt.

Table 1.

Percentages of mixing Recycled and New asphalt.

| R% |

90 |

80 |

70 |

60 |

50 |

40 |

30 |

20 |

10 |

| N% |

10 |

20 |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

Table 2.

Properties of the used bitumen in mixing.

Table 2.

Properties of the used bitumen in mixing.

| Test |

Results |

Specifications |

| Penetration 1/10 mm |

64 |

60 - 70 |

| Kinematic viscosity, Stokes 100°C |

420 |

+320 Centistoke |

| Softening point temperature °C |

48 |

45 - 50°C |

| Flash point temperature °C |

280 |

+250°C |

3. Experimental Tests

This test is a standard method used in the design of mixture and calculating not only the stability but also the flow values of asphalt mixtures. The mechanism of the test is to subject asphalt samples to compressive load through Marshall loading machine till the failure of the asphalt sample [

20]. The test gives the maximum load that the sample can withstand which defined as Marshall stability, which is an indicator of the strength of the mixture. Before starting the tests, all the samples were immersed in a water bath at 60 °C ± 1 °C for 35 mins ± 5 mins [

21]. The deformation happens to the sample during this test known as the flow of the mixture. These two parameters are vital to ensure that the pavement will perform suitably under high traffic loads. Marshall test is the most used test because of its simplicity, cost effectiveness, and reliability in giving the essential data for asphalt mixture design.

Figure 2.

Samples with different mix percentages.

Figure 2.

Samples with different mix percentages.

Figure 3.

Weighting the samples before testing.

Figure 3.

Weighting the samples before testing.

Figure 4.

Samples in the water bath before testing.

Figure 4.

Samples in the water bath before testing.

Figure 5.

Testing the samples with Marshal testing machine.

Figure 5.

Testing the samples with Marshal testing machine.

4. Experimental Results

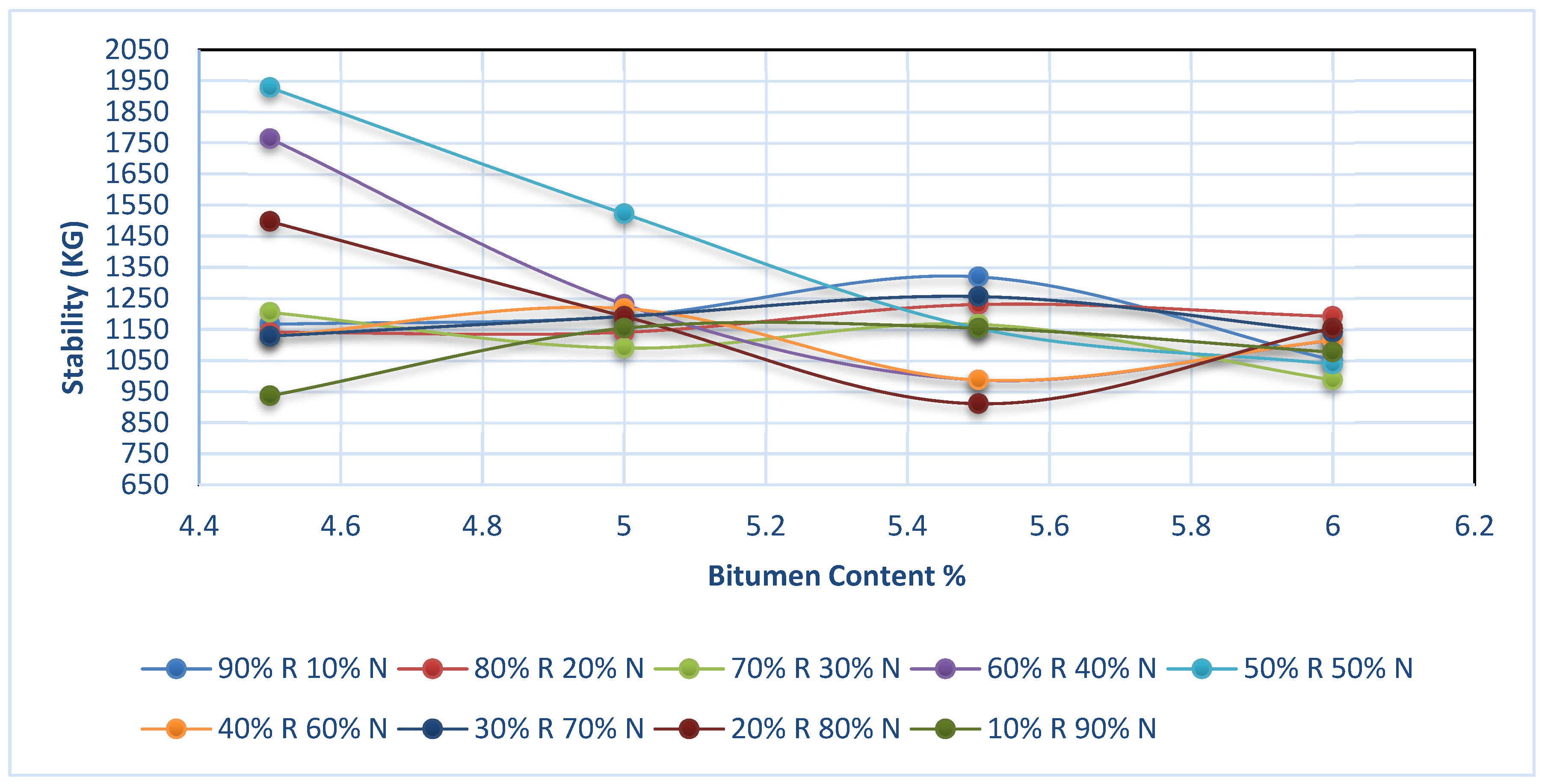

The previous Fig. represents the relationship between bitumen content percentage on the (x-axis) and Stability on the (y-axis) for the combination of new asphalt mixture (N) with different percentages of adding Recycled asphalt (R) with the addition of crumb rubber. Each line represents a different percentage of mixing RAP with rubberized asphalt mixture. Many remarkable results can be concluded from

Figure 6. First, it is obvious the increase of bitumen content leads to decrease in stability, the mixture with high percentage of RAP gives higher stability, but this graph showing it is clear that the balance between the percentage of RAP mixed with rubberized asphalt has a significant impact and gives high stability. The diagram shows that the mixing percentage between the rubberized mixture between RAP and new asphalt strongly influences the mixture stability as the bitumen content is adjusted. The mixture containing a higher percentage of RAP gives greater stability but also shows a decrease as bitumen content increases. Conversely, mixtures with a higher percentage of rubberized new asphalt in the mixture generally maintain more consistent, lower stability across different bitumen content. This shows the importance of carefully considering both mixing ratio for RAP with new asphalt mixture and bitumen content with the addition of crumb rubber to get the optimum stability, especially when balancing cost with performance.

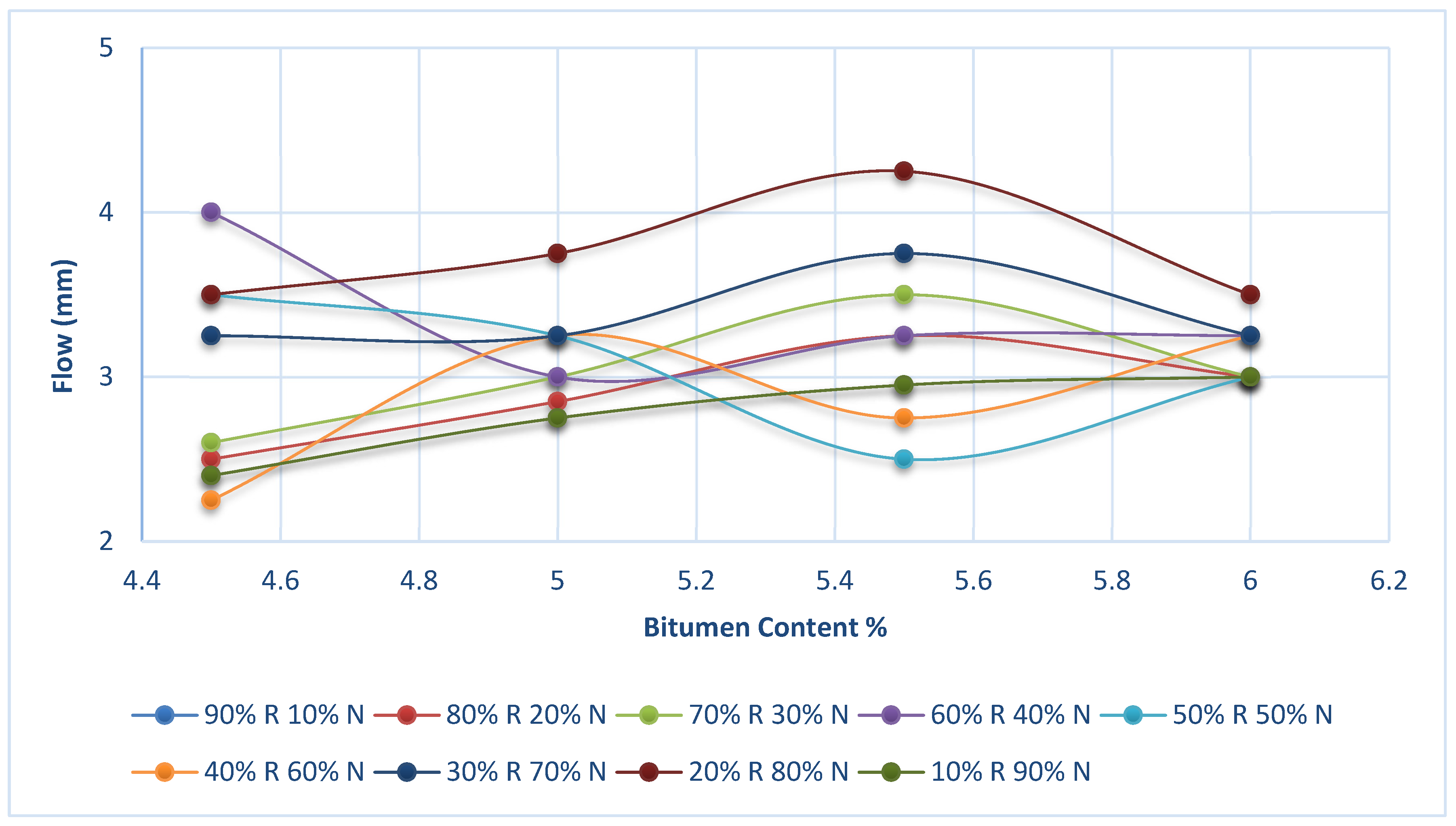

Figure 7 represents the relationship between bitumen content on the (x-axis) and the flow on the (y-axis) for the combination of new asphalt mixture (N) with different percentages of adding RAP (R) with the addition of crumb rubber. Each line represents a different percentage of mixing RAP with new asphalt mixture.

Mixtures with higher percentages of RAP mixed with rubberized asphalt mixture containing rubber (90%R 10%N and 80%R 20%N) show steady flow rates at different bitumen contents. This indicates they are quite stable.

Mixtures with balanced mix of RAP mixed with new asphalt mixture containing rubber (50%R 50%N and 40%R 60%N) show that the optimal bitumen content is about 5.2%. They perform best at this point, but generally they are stable across the board.

samples with low percentage of RAP (30%R 70%N, 20%R 80%N and 10%R 90%N) shows ascending manner of flow with the increase of bitumen content till the optimal point of bitumen content found which is around 5% to 5.5% then the flow shows descending manner with the increase of bitumen content than the optimal point. Consequently, it can be concluded that the mixtures with lower percentages of recycled asphalt mixed with rubberized asphalt are more sensitive to changes in bitumen content.

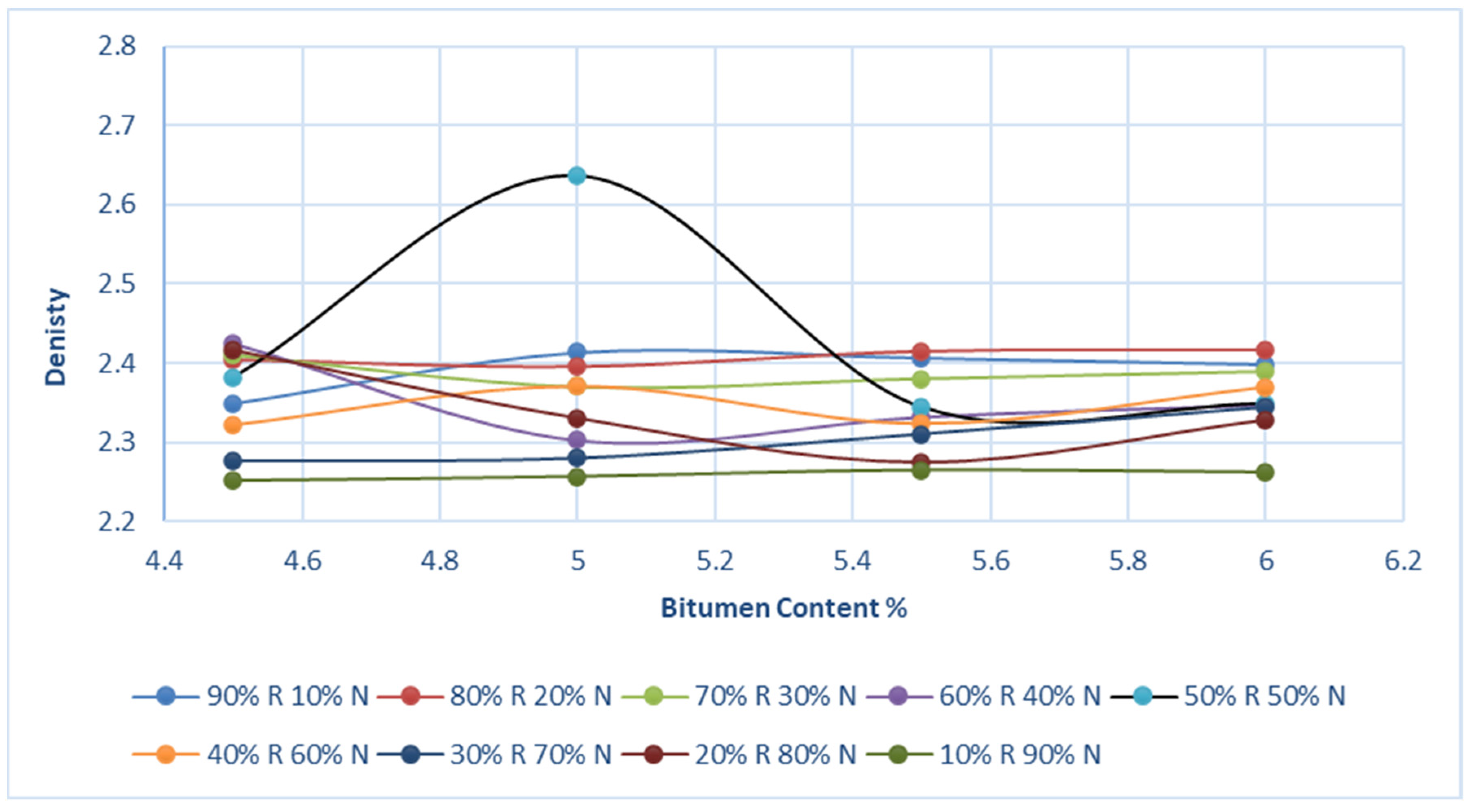

The previous Fig. represents the relationship between bitumen content on the (x-axis) and Marshal density on the (y-axis) for the combination of new asphalt mixture (N) with different percentages of adding Recycled asphalt (R) with the addition of crumb rubber. Each line represents a different percentage of mixed scraped asphalt with rubberized asphalt mixture. Marshall density graph shows that the balanced mix of recycled asphalt mixed with new asphalt mixture (50% R 50% N) gives the highest density at about 5% bitumen content. So, the blanched mix can give the best density which will be important and crucial to enhancing the road’s performance and durability.

Figure 8 illustrates that the density of most of the mixtures increases slightly for around 5% bitumen content then decreases. Thus, it can be concluded that it is the optimal bitumen content to maximize the density. The percentages of mixing that gives flat lines in the graph, especially the mixtures that have high percentages of new rubberized asphalt mixtures have a more stable density despite changing in bitumen content. Generally, it is obvious that the increase of new asphalt percentage improves the density and will be more stable. And the mixtures with higher percentages of recycled asphalt go up and down in density which means that the changing in bitumen content is more sensitive for those mixtures so, higher density can be achieved with high percentage of recycled asphalt in the mixture. However, it is needed to control the bitumen content.

5. Analytical Analysis

Figure 9.

Universal Machine Test.

Figure 9.

Universal Machine Test.

Using the universal testing machine has been used to evaluate the mechanical properties of materials [

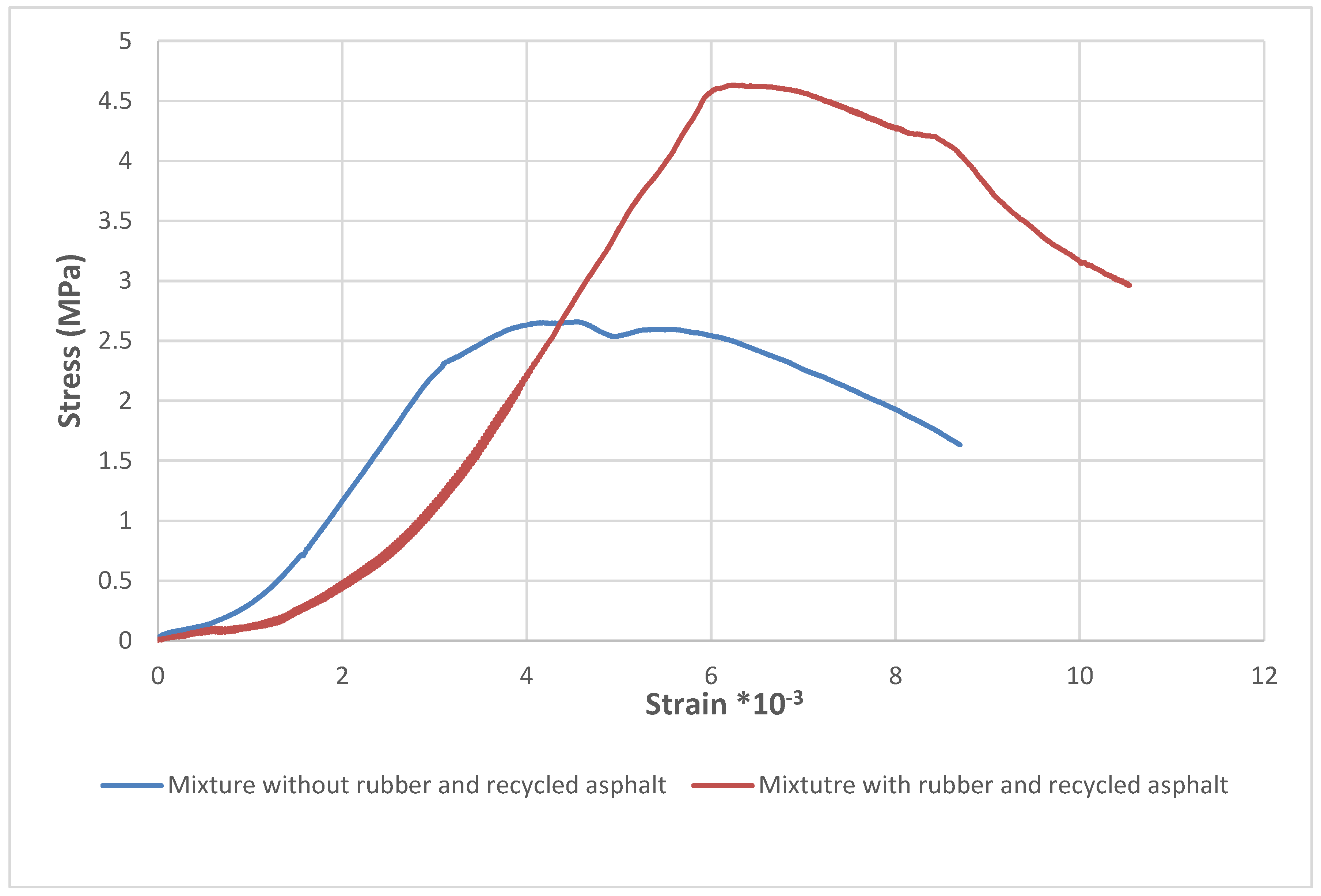

22]. So, getting stress strain has been obtained by testing two samples by compression test.

Figure 10.

Stress strain curve resulted from universal machine test for the samples.

Figure 10.

Stress strain curve resulted from universal machine test for the samples.

The first sample mixture with rubber and recycled asphalt was combination between 50% new asphalt and 50% recycled asphalt with 5% bitumen content divided into 20% rubber and 80% bitumen, The stress strain curve became as shown in the previous figure:

From the figure the modulus of elasticity of this sample of asphalt equals 731 MPa.

The second sample mixture without rubber and recycled asphalt was a new asphalt mixture with 5% bitumen percentage without any additions and from the stress strain curve became as shown in the previous figure:

the modulus of elasticity of this sample of asphalt equals 640 MPa.

All these results used to make a simulation with Abaqus software to get the actual deformation and actual stress distribution on the two samples of asphalt by making a model with a subgrade of 50cm and base layer of 30cm and asphalt layer of 10cm by entering the modulus of elasticity of each layer and enter the stress and strain values of asphalt layer which resulted from the universal test and applying a moving load of 8 tons.

5.1. Abaqus Software ©

Abaqus © is commonly used by researchers to simulate the performance of materials under different conditions such as stress levels and temperature fluctuations. The software Abaqus is adept at managing simulations across an array of sectors including biomedical and civil engineering fields. The precision of results generated by Abaqus aids in the design and testing of materials prior to deployment saving resources and time in the process. Abaqus provides a friendly user interface. Seamlessly integrates with various engineering tools making it a popular option for detailed simulations.

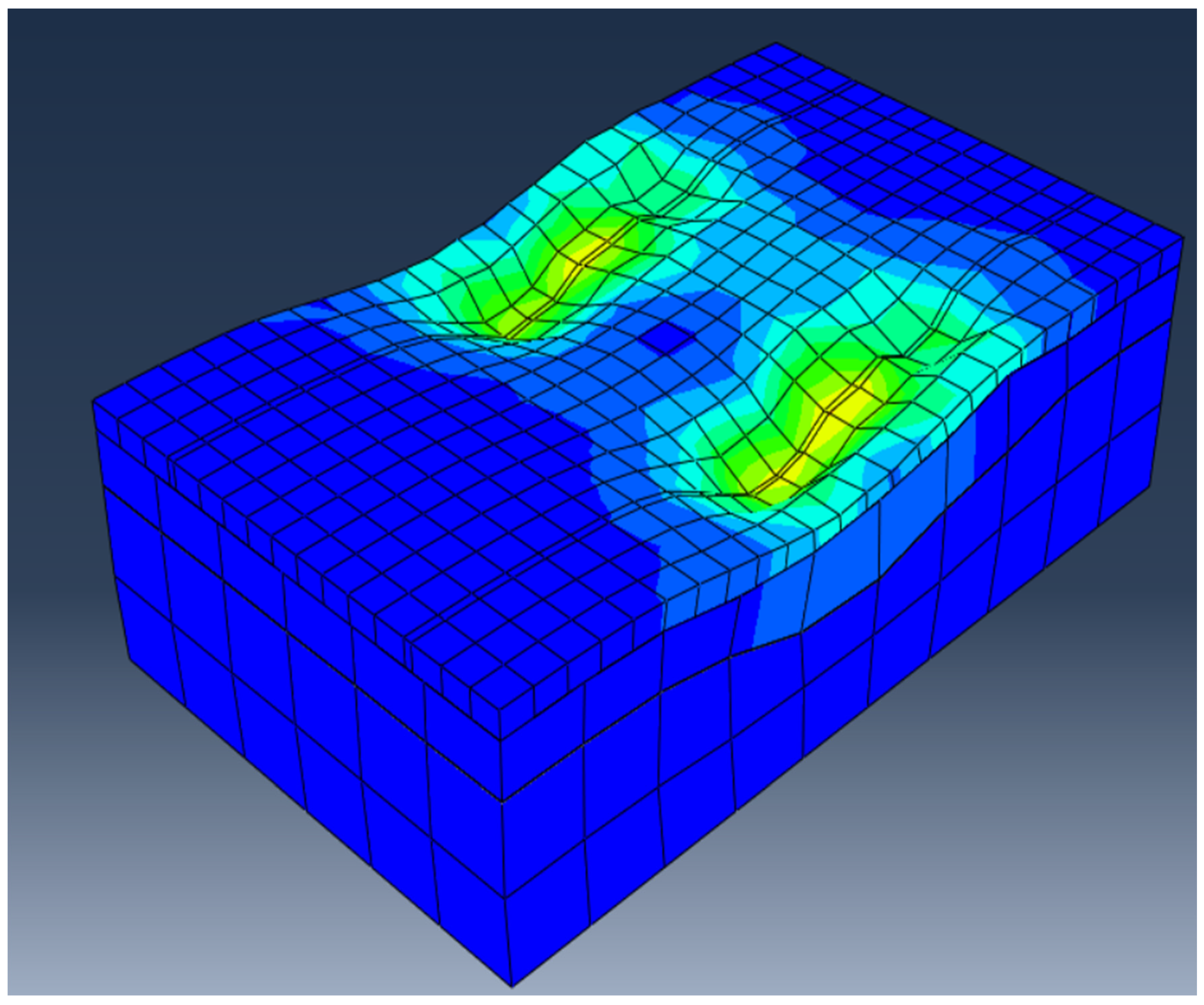

Figure 11.

Software output of simulation.

Figure 11.

Software output of simulation.

The results of simulation were shown in the graphs of the following figures:

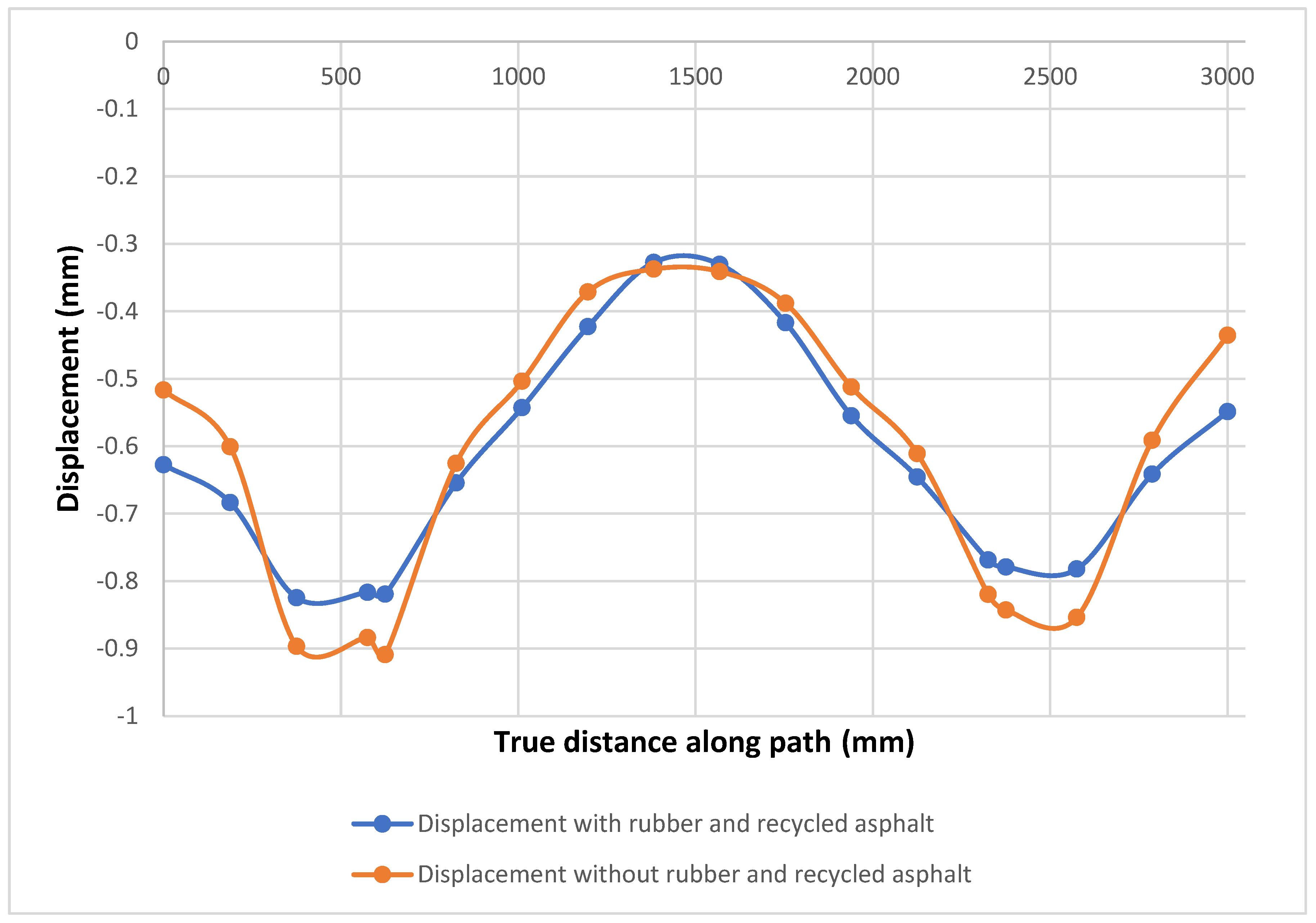

The previous Fig. compares the displacement that happened along path with applying an axial load of 8 tons for simulation for the two different asphalt samples. The first contains recycled asphalt with 50% and rubber with new asphalt with 50% percentage of the sample weight. However, the second sample contains only asphalt without any additions and both with bitumen content of 5%. From

Figure 12 the first sample with recycled asphalt and rubber showing less displacement along the path than the sample of asphalt only which indicates that the use of rubber and recycled asphalt will reduce the overall displacement along the sections of the path which may help in reducing the deformation and enhance the load bearing capacity of the road which indicates better performance of the pavement.

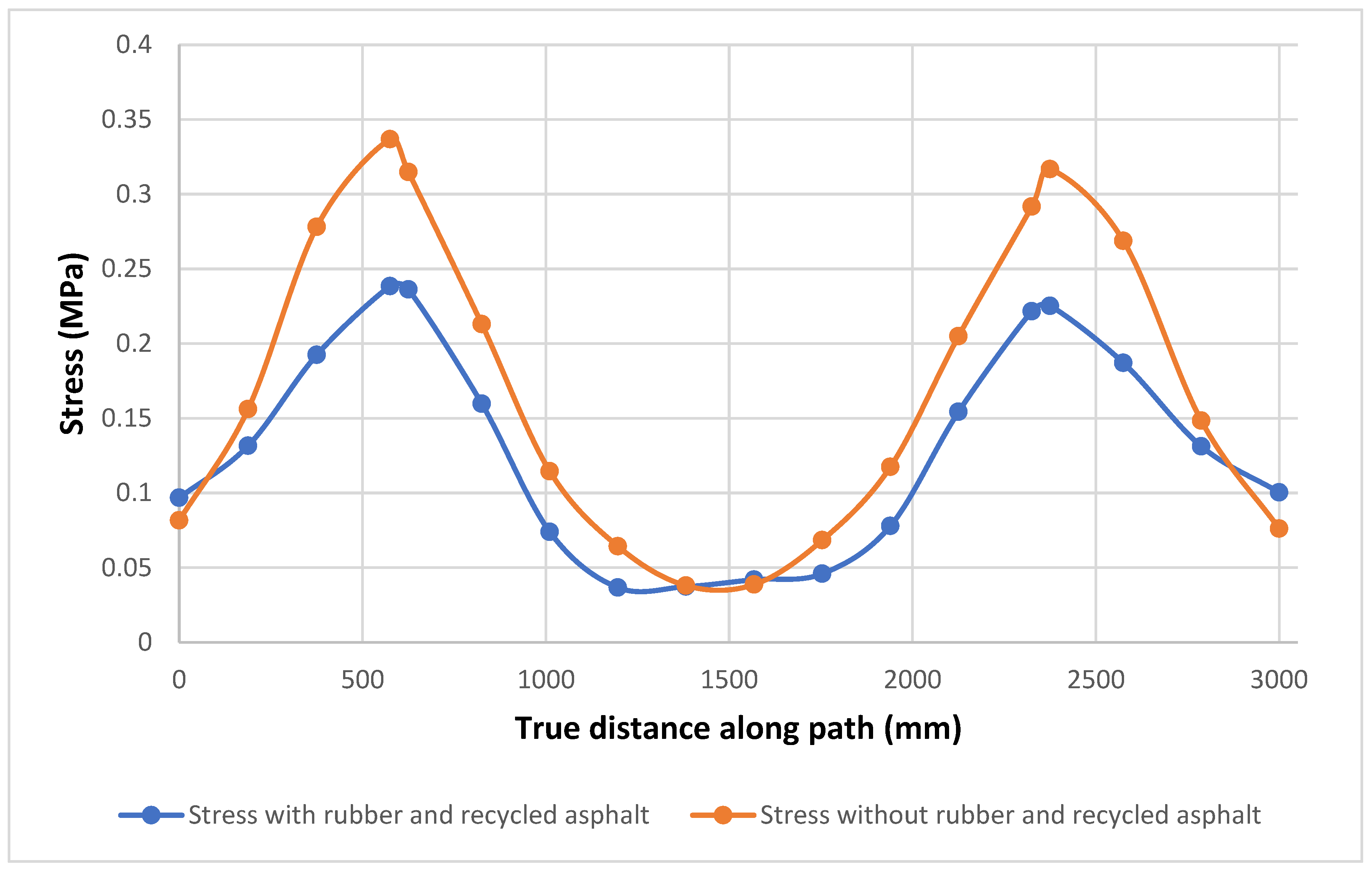

Figure 13 compares the stress distribution along path with applying load of 8 ton for simulation for the two different asphalt samples. As shown from the

Figure 13 the mixture without rubber and recycled asphalt shows higher stress values than the second mixture which contains rubber and recycled asphalt which resulting that the use of recycled asphalt and rubber in the mixture enhances the performance of pavement by reducing the stress level which increases the lifespan of road and decreases the probability of the pavement failure under the load repeating.

6. Conclusion

In this research it has been successfully proven the advantages of mixing the crumb rubber and recycled asphalt with the new asphalt mixtures. This combination of these materials totally enhanced the mechanical properties of the asphalt mixtures, helped in increasing stability and lower stress levels under loads and reduced the deformation. After a series of laboratory tests such as universal machine test and Marshall stability test and after testing more than 70 samples of asphalt with different percentages of mixing, it has been shown that the balanced mix of 50% recycled asphalt and 50% New asphalt mixture with 5% bitumen content including crumb rubber with 20% of the weight of bitumen offered the optimal performance. Simulation using Abaqus software also confirmed these results, showing that the modified mixture achieved high displacement and stress resistance. Both results extracted from simulation using Abaqus software and field experiments approved that using crumb rubber and recycled asphalt can lead to constructing more sustainable and cost-effective roads. All these results and findings will make a very well foundation for future research in enhancing asphalt mixtures for different environmental and economic conditions.

Acknowledgments

The authors would like to introduce their deep thanks to the Arab Academy for Science, Technology and Maritime transport, Egypt (AAST) for supporting this research and for using all the laboratories.

Availability of data: results and materials

All materials are available and data available on request due to privacy restrictions.

References

- Hashim, S., Al-Mosawe, H., & Mohammed, H. (2023). The influence of using recycled asphalt pavement and crumbed rubber on asphalt pavement: a review. Al-Nahrain Journal for Engineering Sciences, 26(2), 74–82. [CrossRef]

- Xiao, F., & Amirkhanian, S. N. (2010). Laboratory investigation of utilizing high percentage of RAP in rubberized asphalt mixture. Materials and structures, 43(1), 223-233. [CrossRef]

- Alfayez, S. A., Suleiman, A. R., & Nehdi, M. L. (2020). Recycling tire rubber in asphalt pavements: State of the art. Sustainability, 12(21), 9076. [CrossRef]

- Aghapour, M., & Babagoli, R. (2020). Effect of reclaimed asphalt pavement on performance of rubberised asphalt mixtures. Proceedings of the Institution of Civil Engineers-Construction Materials, 173(6), 284-297. [CrossRef]

- Khadim, H. M., & Al-Mosawe, H. M. (2024). Crumb rubber modification for enhanced rutting resistance in asphalt mixtures. Open Engineering, 14(1). [CrossRef]

- [6] Arabani M, Tahami SA, Taghipoor M. Laboratory investigation of hot mix asphalt containing waste materials. Road Mater Pavement Des. 2017;18(3):713–29. [CrossRef]

- Yousefi, A. A., Haghshenas, H. F., Underwood, B. S., Harvey, J., & Blankenship, P. (2023). Performance of warm asphalt mixtures containing reclaimed asphalt pavement, an anti-stripping agent, and recycling agents: A study using a balanced mix design approach. Construction and Building Materials, 363, 129633. [CrossRef]

- Alavi, Z., Hung, S., Jones, D., & Harvey, J. (2016, May 1). Preliminary Investigation into the Use of Reclaimed Asphalt Pavement in Gap-Graded Asphalt Rubber Mixes, and Use of Reclaimed Asphalt Rubber Pavement in Conventional Asphalt Concrete Mixes.

- Zhang, X., Chen, H., Barbieri, D. M., Lou, B., & Hoff, I. (2022). The classification and reutilisation of recycled asphalt pavement binder: Norwegian case study. Case Studies in Construction Materials, 17, e01491. [CrossRef]

- Musa, S. S., Al-Mukaram, N., & Dakhil, I. H. (2024). Asphalt binder modified with recycled tyre rubber. Open Engineering, 14(1). [CrossRef]

- Lv Q, Huang W, Zheng M, Hu Y, Yan C, Wang J. Understanding the particle effects and interaction effects of crumb rubber modified asphalt regarding bonding properties. Constr Build Mater. 2022; 348:128716. [CrossRef]

- Duan, K., Wang, C., Liu, J., Song, L., Chen, Q., & Chen, Y. (2022). Research progress and performance evaluation of crumb-rubber-modified asphalts and their mixtures. Construction and Building Materials, 361, 129687. [CrossRef]

- Fakhri, M., & Azami, A. (2017). Evaluation of warm mix asphalt mixtures containing reclaimed asphalt pavement and crumb rubber. Journal of Cleaner Production, 165, 1125-1132. [CrossRef]

- Segre, N.; Joekes, I. Use of tire rubber particles as addition to cement paste. Cem. Concr. Res. 2000, 30, 1421–1425. [CrossRef]

- Amirkhanian, Serji N. “Utilization of crumb rubber in asphaltic concrete mixtures–South Carolina’s Experience.” See ref 3 (2001): 163-174, USA.

- T. Butz, J. Muller, G. Riebesehl, Innovative methof for producing crumbed rubber modified asphalt, 5th Eurasphalt & Eurobitume Congress, Istanbul, 2012.

- Asphalt Pavement Recycling with Reclaimed Asphalt Pavement (RAP) - Recycling - Sustainability - Pavements - Federal Highway Administration. (n.d.).

- Aksoy A, Iskender E, Kahraman HT. Application of the intuitivek-NN Estimator for prediction of the Marshall Test (ASTMD1559) results for asphalt mixtures. Constr Build Mater. 2012; 34:561-9. [CrossRef]

- Caroles, L., Tumpu, M., Rangan, P. R., & Mansyur, N. (2021). Marshall properties of LASBUTAG asphalt mixes with pertalite as a modifier. IOP Conference Series Earth and Environmental Science, 871(1), 012064. [CrossRef]

- Prasetia, Djakfar, L., Wisnumurti, N., & Sabarudin, A. (2022). Marshall tests for asphalt concrete wearing course ASB Lawele containing capsule calsium alginate as Self-Healing Additive. IOP Conference Series Earth and Environmental Science, 1117(1), 012005. [CrossRef]

- Tan, E. H., Zahran, E. M., & Tan, S. J. (2022). The optimal use of crumb rubber in hot-mix asphalt by dry process: A laboratory investigation using Marshall mix design. Transportation Engineering, 10, 100145. [CrossRef]

- Huňady, R., Sivák, P., Delyová, I., Bocko, J., Vavro, J., & Hroncová, D. (2024). Upgrade of the universal testing machine for the possibilities of fatigue tests in a limited mode. Applied Sciences, 14(10), 39. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).