1. Introduction

As a kind of clean and renewable energy, the development and utilization of geothermal energy has attracted wide attention in the context of the current global energy structure transformation and environmental protection [

1,

2,

3]. As a key technology to obtain geothermal energy, the efficiency and cost of geothermal drilling are directly related to the economy of geothermal projects [

4,

5,

6,

7].

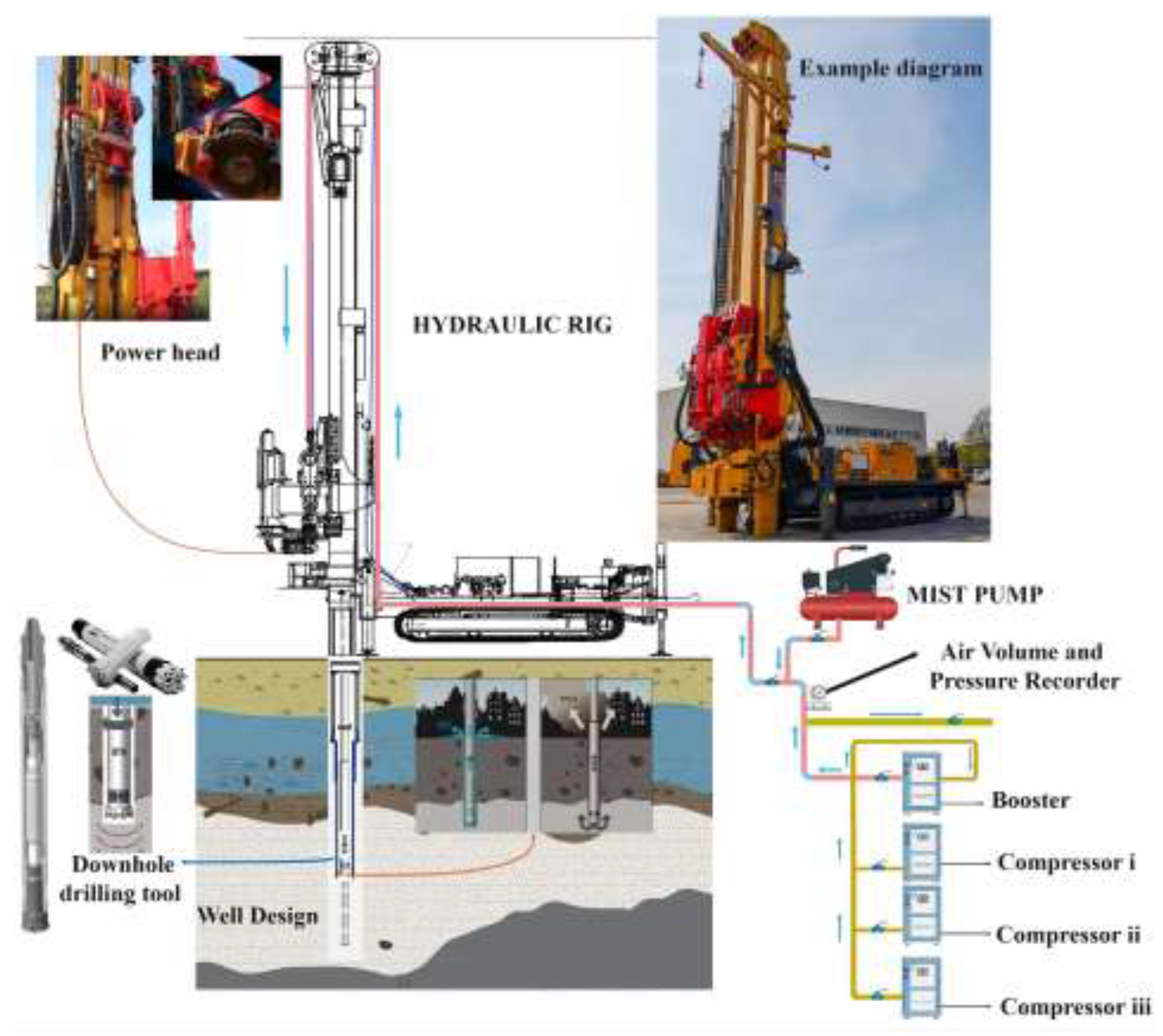

Air DTH hammer drilling (vibratory percussion drilling) has proven to be an efficient geothermal drilling technique (see

Figure 1 for its flow chart).

Most of the commonly used DTH hammer drill are center exhaust type single piston drilling hammer (valve drilling hammer and valveless drilling hammer), and the early engineering applications are mostly valve DTH hammer. At present, the most used is valveless drill hammer, which was invented by Bassinger in the early 1950s, the main feature is to cancel the upper and lower cavity of the valve plate, and directly use the hammer piston itself structure for gas distribution. The internal gas distribution structure of this kind of drill hammer is more complex, the processing requirements are slightly higher, but the effect of removing rock powder is better, so it can reduce the wear of the drill bit and improve the drilling efficiency. It is widely used in the construction process, and the drill hammer used in this paper is exactly this kind.

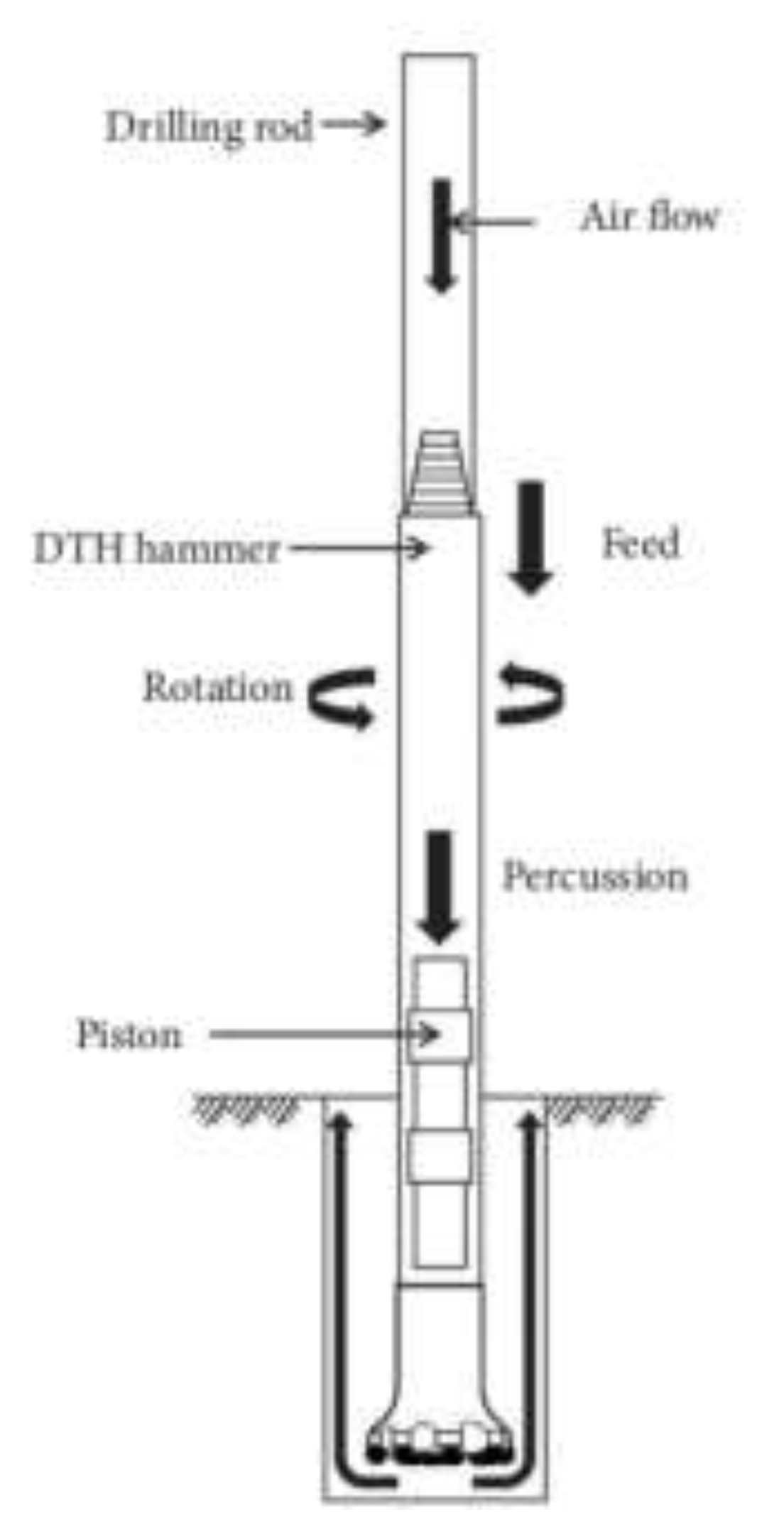

Working principle of DTH drilling hammer drill: when drilling, the air compressor to the power system of the drilling hammer continuously delivers high pressure air, high pressure air into the cylinder, the upper and lower cylinders of the piston and the cylinder position (see

Figure 2 for its flow chart), so as to achieve high pressure gas impact of the impactor piston for high-frequency reciprocating movement, impact work on the drill. At the same time, the low-speed rotation of the drill provides torque for the drill bit. Under the combined action of impact work and rotary torque, the drill bit makes continuous pulsating impact on the rock at the bottom of the hole until the generated volume is broken. At this time, the high pressure air will work through the annular gap between the drill pipe and the hole wall, carried by the high pressure air and discharged out of the hole, to avoid repeated rock fragmentation, with high drilling efficiency. In addition, the high pressure air flow after work on the one hand can play the role of slag removal, on the other hand can cool the drill, so that the heat generated during the contact with the rock is blown away. The rock breaking process of DTH hammer drill is completed under the combined action of weight on bit, impact force and rotary force. In the process of drilling, the impactor is subjected to reciprocating action of piston, which exerts axial force on the bit and produces axial speed. At the same time, the head of the impactor is connected with the external torsional structure to apply torque and generate rotary force. From the perspective of rock crushing, the axial speed is used to break rock, and the rotary force is to change the position of rock breaking, so that the drill can impact and grind the new rock face again, play the role of auxiliary rock breaking, and finally achieve the purpose of jointly breaking rock.

DTH hammer percussion drilling has high rock breaking efficiency and strong advantages in hard rock drilling, which can reduce the cost of geothermal drilling [

9,

10,

11,

12,

13,

14]. The DTH hammer drill bit mainly relies on the impact action to break rock, the drill teeth have strong impact resistance, but the shear resistance is relatively weak. When the hole diameter is large, the bit rotation speed is high, the impact frequency is low, the button diameter of edge tooth is small, and the rock strength is high, the space (in

Figure 2) between the adjacent rock dents (broken pit) left by the two adjacent of the hammer impact will be large and result in the residual rock ridge. This residual rock ridge produces tangential reaction force on the bit teeth, which caused the edge teeth fracture and break. The broken edge teeth aggravate the vibration of the downhole drilling tool and the wear of other teeth and the bit body further. Consequently the lifespan of the bit is shortened, while, the rate of penetration and drilling efficiency are decreased and the drilling cost is increased [

15,

16].

Therefore, how to improve the drilling efficiency and prolong the service life of the drill bit through the drill bit design is the key problem to be solved urgently in the field of geothermal drilling technology.

Convex PDC insert teeth with good thermal stability [

17,

18] were adopted. Xie Han and Liu Weiji et al. studied the influence of tooth profile design on the rock crushing effect of PDC bit teeth [

19,

20]. Based on spherical tooth interference assembly and air pressure, Chen Xin, Jing Yihao and Ren Haitao et al. analyzed the static mechanism of cone bit insert tooth loss [

21,

22,

23]. The application team, Wu Haidong, carried out the experiment of PDC bit crushing granite at 300℃ [

24]. Zhu Xiaohua et al. established a PDC bit tooth crushing dry hot rock model through numerical simulation [

25]. Research and application by petrochina Great Wall Drilling Engineering Co., Ltd. and Sandia National Laboratories in the United States have demonstrated the success of PDC geothermal drilling [

26,

27].

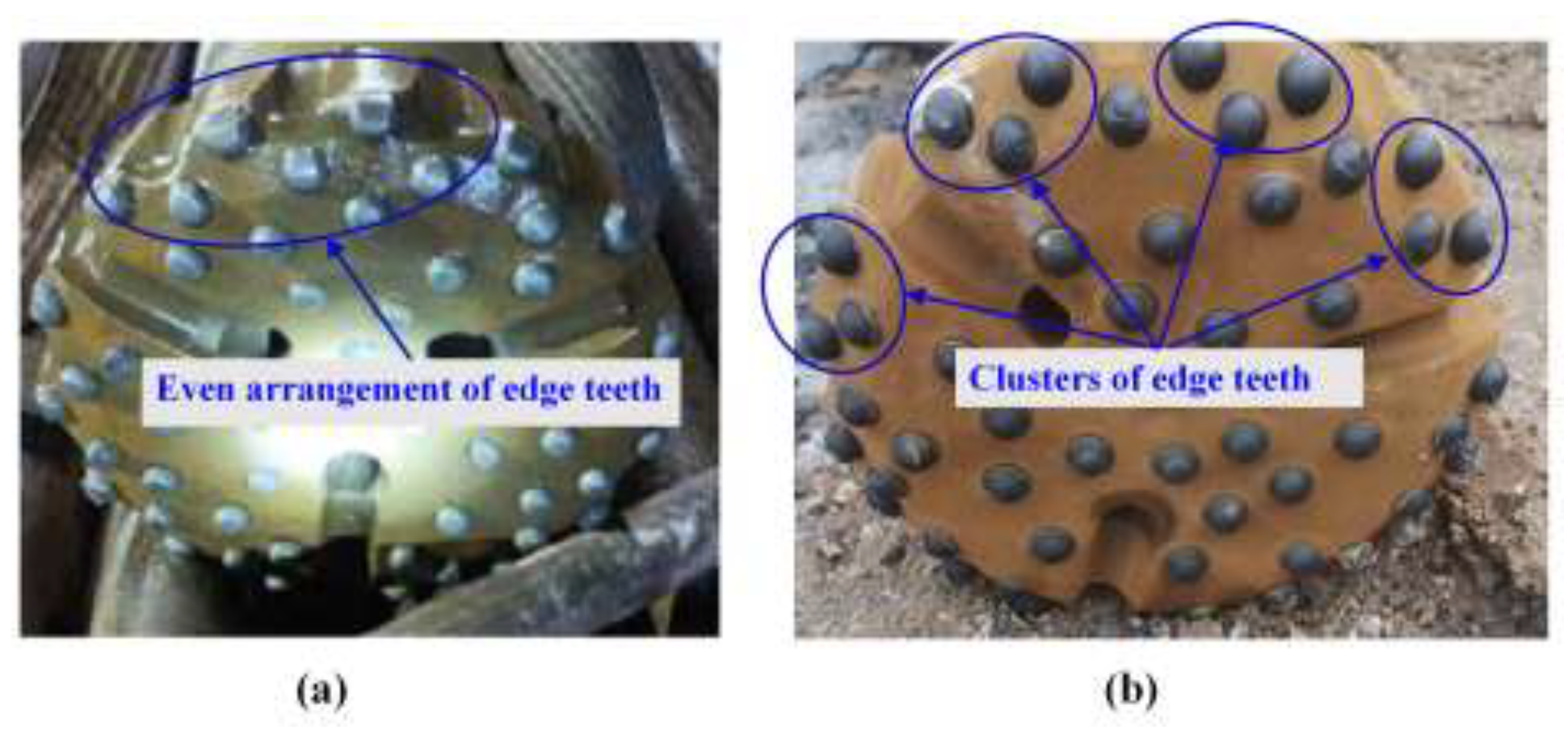

In this paper, the failure modes of bit teeth in the process of large-diameter and hard formation geothermal drilling are studied and analyzed. A new type of anti-shear DTH hammer drill bit is designed by deeply analyzing the mechanism of rock breaking and the working principle of drill bit. The cluster edge teeth of DTH hammer drill bit are mass-produced and widely field applied which achieved higher drilling efficiency, longer lifespan and lower drilling costs.

2. Failure Modes of DTH Hammer bit for Geothermal Drilling

Shanxi Heshun hot spring Well is located in the north of Malianqu village, Songyan Town, Heshun County, Jinzhong City, Shanxi Province, with a design well depth of 2500 m. The vertical distribution of strata is in order of Changcheng system Chuanlinggou Formation, Changcheng System Changzhougou Formation, Proterozoic Hutuo Group and Taiancient zone Shijilan Formation. The formation lithology of Changcheng System Chuanlinggou Formation is quartz-like sandstone, quartz sandstone, purplish red shale and sandy shale. The bottom is coarse giant quartz sandstone with gravel and quartzite. When drilling into the stratum containing quartz sandstone and quartzite, the edge teeth of the large-diameter drill hammer bit are seriously broken, resulting in less footage and short bit life. Four DTH hammer bits were used within 500 m well depth, i.e. 1# bit for 20-250 m, 2# for 250-296 m and 3# for 433-500 m. For observation and analysis, the failure modes of 1#, 2# and 3# bits are shown in

Figure 3, and the relevant technique parameters are described in

Table 1.

From the

Figure 3, the edge teeth of the bits were all broken with different inner ring teeth wear. Broken teeth have a greater impact on the normal work of air DTH hammer, too many broken teeth, air DTH hammer performance as mechanical drilling rate decrease, downhole vibration intensifies, aggravates the wear of other teeth of the drill bit and drill rigidbody wear.

There is relatively serious wear of inner ring teeth in 1# bit, while only sporadic fracture is seen in the inner ring teeth of 2# and 3# bits. Accordingly the 1# bit has a relatively long lifespan with footage of 230 m, and the 2# and 3# bits have 46 m and 67 m respectively. The reason for the long lifetime of 1# bit can be explained as parts of drilled formation is relative weak with medium strength, which can make inner ring teeth wear normally. The less cumulative footage of 2# and 3# bits are mainly caused by the high strength of drilled formation. The lifespan improvement of 3# to 2# is the resulted from the rotation speed from 60 to 30 rpm.

There are many reasons for side tooth breakage, such as formation breakage, worker improper operation, and high formation strength. Columns such as When drilling fracture development, broken belt, uneven texture layer, the drill bottom hole work is not stable, easy to cause the local column tooth instantaneous shear force is too large and the force is not balanced, resulting in tooth collapse. When drilling in cracks and uneven soft and hard rock, inappropriate weight on bit and speed will make the torque and shear force on carbide teeth increase intermittently, resulting in broken teeth and tooth collapse. Improper operation, drilling too hard will cause tooth collapse; Excessive pressure, uneven drilling, failure to timely reduce weight on bit and speed when meeting cracks, will also make the bit work unstable resulting in tooth collapse. In the process of drilling, we exclude the influence of the first two factors, and find that the formation lithology before the edge tooth fracture is mainly metamorphic quartz sandstone, and judge that the formation strength is high leading to the edge tooth fracture.

3. Failure Mechanism and Common Improvement Solutions

3.1. The Drilling Parameter Matching of the DTH Hammer Drill Bit

As above mentioned, the DTH hammer drill bit mainly relies on the impact action to break the rock. The button of the percussive bit have strong impact resistance, but the shear resistance is relatively weak. Therefore, the drilling parameters of the DTH hammer drill bit, such as the hole diameter, the rotation speed, and percussive frequency and the bit teeth, are required to match well.

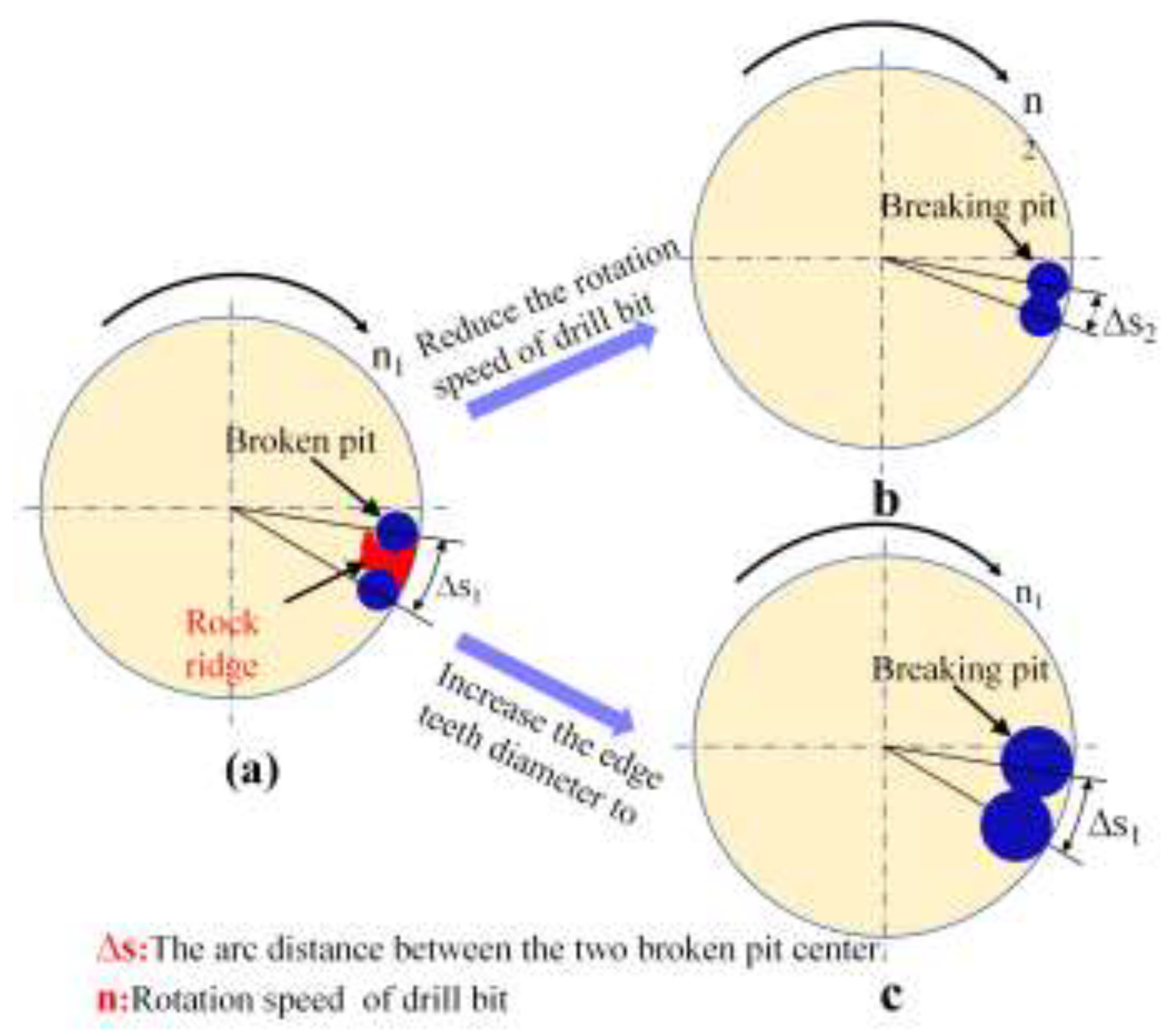

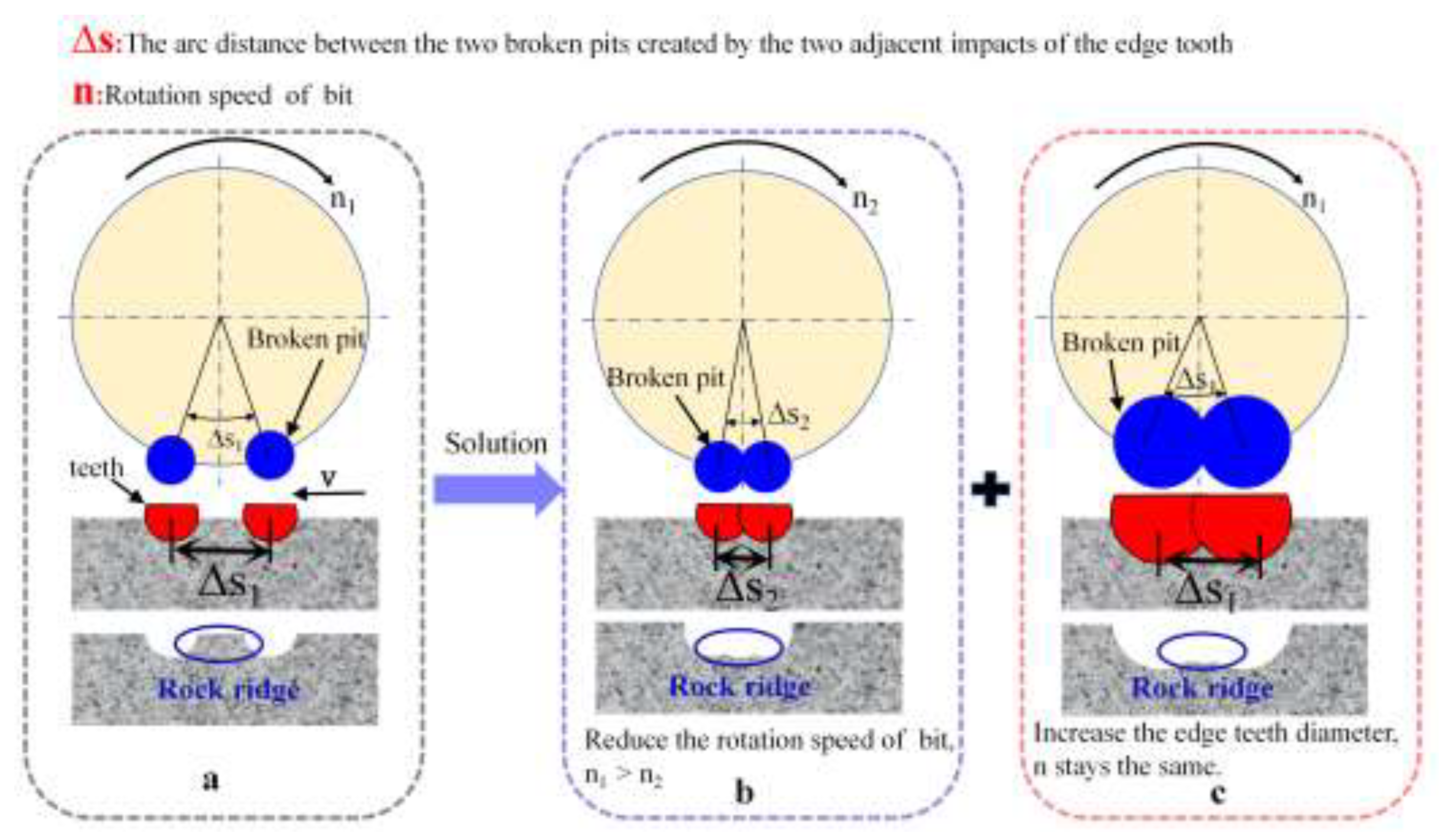

The drilling parameter matching for the DTH hammer bit has been studied deeply. In the early stage, based on the practice of down the hole hammer drilling, for the small diameter drilling with a diameter less than 150 mm, the American Water Well Association Camber proposed that the drilling tool rotation of 11 degrees per impact was the "optimal Angle", and the arc length of the edge tooth travel ∆S between the adjacent two impacts was 14.4 mm, as shown in

Figure 4. In order to meet the needs of ever-expanding drilling diameter, some scholars [

28] proposed the concept of "reasonable impact interval or moving arc length ∆S" based on the relationship of "optimal Angle". In addition to impact frequency, influences of ball tooth diameter and bit diameter on bit rotation speed are also considered. For example, impact bits with ball tooth diameter 14-15 mm are used. The drill bit is struck 32 times per revolution. If the impact frequency is 25 Hz, the drill bit rotation speed must not exceed 48 rpm. However, for drilling in large diameter hard rock formations, the rotation speed is lower and the diameter of PDC ball teeth is small. The actual rotation speed of the spindle (bit) is difficult to match with the frequency of the drill hammer and the diameter of the ball teeth, especially for the traditional rotary table drill drilling in large diameter hard rock holes.

3.2. The Failure Mechanism

The breakage of edge teeth occurs when the large-diameter drill bit is drilled into the high strength stratum. When the bit rotation speed is high, especially the rotary table drill rig is used, and the impact frequency is low, the arc distance ∆S

1 between two broken pit centers created by the two adjacent impact of edge teeth will be large, see

Figure 5 (a). The large arc distance will leave the rock unbroken, i.e. so-called the residual rock ridge. When the strength of the rock is high, the residual rock ridge cannot be broken away from the rock mass, and a strong tangential reaction force is generated on the rotating edge teeth of the bit, causing the edge teeth of the bit to be sheard failure.

3.3. Improvement Solution

For large diameter geothermal drilling with high strenth formation, the well matched of the rotation speed of the drill bit, the impact frequnecy and the diameter of edge tooth is required to eliminate the hard rock ridge, which will cause the teeth of the outer ring of the bit to wear and break quickly. Generally, the harder the rock or the larger the diameter of the bit, the more it is required to use a lower rotation speed to overcome the edge tooth fracture of the high-strength formation drilling. Through the design of the drill hammer bit, the matching problem of impact frequency, ball tooth diameter and bit speed can be solved [

29,

30].

3.3.1. Reduce the bit Rotation Speed or Increase The Impact Frequency

Reduce the bit speed (n

2<n

1), or increase the impact frequency, reduce the spacing between the rock teeth of the two adjacent impacts at the bottom of the hole, so that there is no residual rock, and eliminate the tangential reaction force on the bit teeth, see

Figure 5 (b). If the drill diameter is 311 mm, the ball tooth diameter is 14 mm, and the impact frequency is 25 Hz, about 21.5 rpm is required. However, in actual drilling, the speed can not be reduced to the expected (n

2), especially the reduction of the speed of the rotary table drill will be limited by the mechanical system transmission chain.

3.2.1. Increase the Edge Teeth Diameter

Choose a larger diameter DTH bit ball teeth when the drill tooth is designed, see

Figure 5 (c). At present, the commonly used spherical tooth diameter specification 14-18 mm, further increasing the diameter of the single tooth on reducing the drill speed is not obvious.

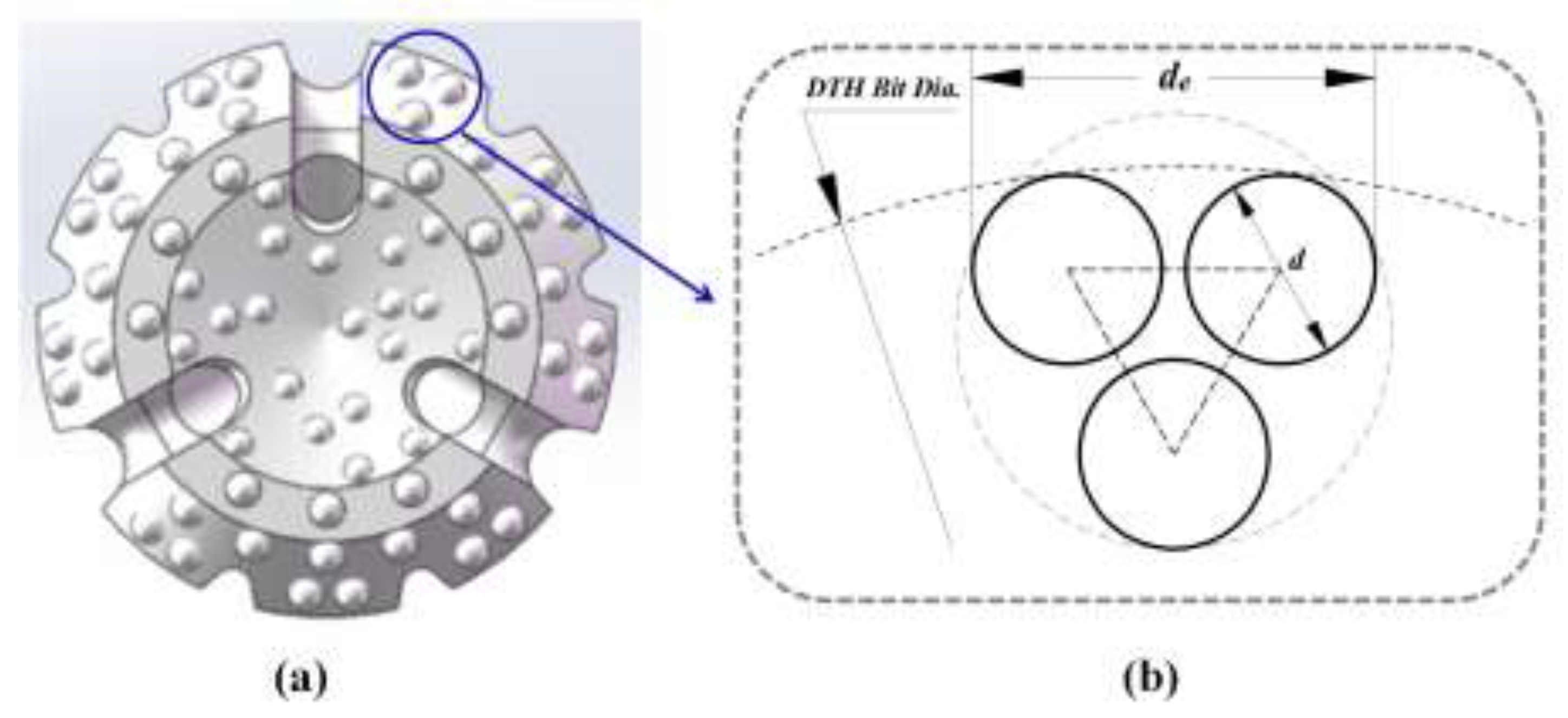

4. Cluster Design of the Edge Teeth of The Drill Bit and The Rotation Speed Matching

The process of DTH drilling is a transient dynamic crushing of brittle materials, and the cracks extend along the grain or joint of the rock. The edge teeth cluster arrangement is adopted, and the three ball teeth are as close as possible to meet the installation requirements. The rock between the ball teeth in the cluster is broken through crack propagation [

31,

32,

33]. Equivalent diameter:

Where, de is tooth equivalent diameter, mm; d is the diameter of a single tooth, mm.

The equivalent diameter of the spherical tooth is at least 2 times larger than that of a single spherical tooth. According to the "optimal Angle" relation of drilling, the edge teeth of the drill hammer are arranged in the cluster as shown in

Figure 6b, making it equivalent to a large-diameter bit edge teeth. It meets the requirement of rock tooth spacing (∆S

2<∆S

1) for two impacts at the bottom of the hole near the drill teeth, reduces the residual rock ridge, eliminates the tangential reaction force on the drill teeth, and can deduce the relationship between the impact frequency, bit diameter, ball tooth diameter and bit speed.

Where, n is drill rotation speed, rps; is rock fracture coefficient, here is 0.8; f, is impact frequency, Hz; D is Drill bit diameter, mm.

The reasonable rotation speed is proportional to the equivalent diameter of the cluster teeth and the impact frequency, and inversely proportional to the bit diameter. It is beneficial to prevent the fracture of the side teeth by matching the reasonable bit gear with the rotation speed.

When the impact frequency is 25-28 Hz, the equivalent diameter of the three spherical teeth with a spherical tooth diameter of 16 mm is 32 mm, and the drill bit diameter D is 311 mm, then, the upper rotation speed of the drill bit can be estimated as 44 rpm according to equation (2). Most of the drill disc rigs or top drive rigs can drill 311 mm diameter hole. Lifting the limit of excessive rotation speed in the low gear of the rig.

By expanding the equivalent diameter of the edge teeth (see

Figure 6a), the edge teeth cluster allows drilling at a higher rotation speed, ensuring that two adjacent fracture holes are connected at normal rotation speed, and the ridge between them is clipped, improving the life of the bit in drilling high-strength formations. According to the idea of cluster tooth arrangement, the drill bit (diameter is 311 mm) with a drilling hammer was innovatively designed, as shown in

Figure 6. Meanwhile, the drill tooth density was appropriately increased for hard strata. The area of chute should be increased to meet the requirements of chute removal [

34].

5. Field Application

High strength strata were also encountered during the drilling process of Dalian hot spring well. The formation is Qiaotou Group of Nanhua system, and the lithology is mainly metamorphic quartz sandstone, mixed with siltstone and slate. The edge teeth of the drill bit are easy to break, resulting in frequent tripping and bit changing, which not only has great labor intensity, but also seriously affects the drilling efficiency and increases the drilling cost. The well was 325 mm in diameter. One drill bit was used for 90-179 m interval drilling, with 89 m footage under about 30 rpm bit rotation speed. Subsequently, another bit for 179-220 m interval, with about 27 rpm rotation speed and 41 m footage.

The failure mechanism of the drill bit in this well is similar to that in Heshun hot spring well in Shanxi Province, that is, the drill diameter is large, the formation strength is high, and the diameter of the drill bit teeth is poorly matched with the drill speed and the impact frequency of the drill hammer. It was decided to use the newly designed anti-shear DTH hammer drill bit with cluster edge teeth for field test drilling. On October 30, 2022, after drilling 90 m, the edge teeth of the bit did not break, and the inner ring teeth did not wear significantly. On November 3, 2022, after another 100 m down the hole drilling, 2-3 inner ring teeth were slightly worn, and the damage of side teeth was not obvious, as shown in

Figure 7; On November 7, 2022, after 30 m redrilling, about 11 ball teeth were worn and the side teeth were not broken, but they could still be used. When the cumulative footage reaches 365 m, the side teeth wore seriously with 1-2 broken. There is a 5 mm diameter reduction. During the process of dealing with the accidents in the hole, about 81 m of cement plug was drilled.

The innovative design of the cluster edge-toothed bit drilled 365 m in the same hole, while also drilling 81m of cement plug. Compared to the two previous bits of with 89 m and 41m footage, the bit life was increased by 4.1 and 8.9 times, respectively. At present, this new drill bit has been mass produced and promoted in the field of geothermal drilling.

5. Conclusions

In this paper, aiming at the problem of the edge tooth fracture of the drill bit in the high-strength formation of large-diameter geothermal drilling, the failure mode, failure mechanism and common solutions of the drill bit are studied and analyzed. A cluster air drill bit with edge teeth is innovated and designed, and the field test application is carried out, which significantly improves the life of the drill bit. The conclusions of this paper are as follows:

The tooth breaking mechanism of large-diameter high-strength DTH hammer drill hammer bit is that the rotation speed is too high relative to the impact frequency and the diameter of the spherical teeth is small, resulting in a large distance between the rock mass at the bottom of the hole and a large rock ridge at the bottom of the hole, and the strong shear of the spherical teeth caused by high-strength residual rock ridge.

The cluster design of the edge teeth of the bit is innovatively proposed to increase the equivalent diameter of the edge teeth and remove the restriction that the low gear rotation speed of the drill is too high. Under the conventional rotation speed, the drilling life of the bit with the cluster design of the edge teeth is significantly improved in the high-strength formation.

The field application shows that the life of large-diameter drill hammer drill in high-strength formation drilling has been increased from 71 m-89 m to more than 365 m, which is about 4 times the life of the original drill bit, reducing the drilling cost and improving the drilling efficiency.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “Conceptualization, Hongyu Ye and Haoyu Yu; methodology, Hongyu Ye and Haoyu Yu; validation, Hongyu Ye, Xiuhua Zheng and Changgen Bu; formal analysis, Shengyu He and Longjun Tian; investigation, Haoyu Yu, Shengyu He and Longjun Tian; resources, Hongyu Ye and Xiuhua Zheng; data curation, Haoyu Yu and Changgen Bu; writing—original draft preparation, Hongyu Ye; writing—review and editing, Hongyu Ye, Haoyu Yu and Shengyu He; visualization, Longjun Tian and Longjun Tian; supervision, Xiuhua Zheng and Changgen Bu; project administration, Hongyu Ye; funding acquisition, Xiuhua Zheng. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Project (2022XAGG0500) supported by Xiong'an New Area Science and Technology Innovation Special Project of the Ministry of Science and Technology; Project (42172342) supported by the National Natural Science Foundation of China.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang Kexin. Development of new energy industry from the perspective of the “14th Five-Year Plan” for renewable energy development[J]. Zhongguancun, 2022, (7): 32-33.

- Zheng K. Purpose of geothermal development should be the maximizing benefits[C]. Proceedings World Geothermal Congress 2023, Beijing, China, 2023.

- Inga M., Rolf B., Josef W… The energy transition from fossil fuels to geothermal energy-a German case study[C]. Proceedings World Geothermal Congress 2021, Reykjavik, Iceland, 2021.

- Tester J. W., Anderson B. J., Batchelor A. S., et al. The future of geothermal energy-impact of enhanced geothermal systems (EGS) on the United States in the 21st Century[R]. Boston: Massachusetts Institute of Technology, 2006.

- Zheng Xiuhua, Li Feiyue, Duan Chenyang, et al. Progress of EGS projects worldwide and its implications for China[J]. Resources and Industries, 2014, 16(6): 29-35.

- Vivas C., Salehi S., Tuttle J. D., et al. Challenges and opportunities of geothermal drilling for renewable energy generation[C]. GRC Transactions, 2020, 44: 904-918.

- Li Yachen, Duan Chenyang, Zheng Xiuhua. Best practices for high-temperature geothermal drilling. Geology and Exploration. 2016, 52(1): 173-182.

- C. Song, J. Chung, J.-S. Cho, and Y.-J. Nam, “Optimal design parameters of a percussive drilling system for efficiency improvement,” Advances in Materials Science and Engineering,vol. 2018, Article ID 2346598, 13 pages, 2018. [CrossRef]

- Lu Yubei. Application research of air DTH hammer in fast drilling process in Yunnan red beds. Geology and Exploration, 2011, 47(02): 309-315.

- Zhao Huaxuan, Wang Yujun, Chen Tao, et al. Application research of air DTH hammer drilling technology in deep geothermal wells in Guizhou clastic rocks. Geology and Exploration, 2016, 52(05): 942-949.

- Song Jiwei, Jiang Guosheng, Su Ning, Yu Lixin, Li Qilong, Wang Hu, Zhao Huaxuan. Drilling technology for deep geothermal wells in complex formations in Guizhou Province. Geology and Exploration, 2018, 54(5): 1024-1037.

- Luo Hongbao, Li Junping, Wu Jinsheng. Design of DTH bit for high-temperature hard rock. Drilling Engineering, 2021, 48(04): 60-65.

- Shi Jingjing, Zhang Hailin, Su Yuanyuan, et al. Application of air DTH hammer drilling technology in deep geothermal wells in Shunhuangshan. Drilling Engineering, 2021, 48(10): 36-42.

- Wu Ye, Lu Yubei, Chen Ying. Air drilling experimental research in the Tengchong volcanic geothermal structure. Geology and Exploration, 2013, 49(03): 528-533.

- Hu Gui, Meng Qingkun, Wang Xiangdong, Huang Xueqin, Shi Libao. of gauge protection technology for air hammer bit. Petroleum Machinery, 2010, 38(02): 66-69+7.

- Song Jiwei, Zhao Huaxuan, Su Ning, Li Qilong. Analysis of typical accidents and countermeasures for air DTH hammer drilling. Exploration Engineering (Geotechnical and Drilling Engineering), 2018, 45(05): 22-28.

- Sebastian H. Custom PDC Bits Significantly Increase Drilling Performance in Tauhara Geothermal Drilling Project[C]. Proceedings World Geothermal Congress 2020+1, Reykjavik, Iceland, 2021.

- Terence C, Adrian A. Case studies of PDC bits in deep geothermal drilling[C]. Proceedings World Geothermal Congress 2020+1, Reykjavik, Iceland, 2021.

- Xie Han, Kuang Yuchun, Qin Chao. Finite element simulation and experiment of rock breaking by non-planar PDC cutters [J]. Petroleum Drilling Techniques, 2019, 47(05): 69-73.

- Liu Weiji, Yang Feilong, Dong Hongduo, et al. Research on characteristics of granite crushing by mixed cutting with special-shaped PDC teeth [J]. Engineering Mechanics, 2022, 39:1-12.

- Chen Xin. Research on tooth loss mechanism of cone bit in high temperature geothermal well [D]. Southwest Petroleum University, 2014.

- Jing Yihao. Research on tooth strength of cone bit in geothermal drilling [D]. Southwest Petroleum University, 2015.

- Ren Haitao, Tian Haiping, Yu Hongbo, et al. Research and application of tricone bit in high temperature geothermal Wells [J]. Natural Gas Industry, 2021, 41(10): 95-100.

- Wu Haidong. Experimental Research on diamond bit drilling under high temperature [D]. Jilin University, 2017.

- I wish the effect of China, but Zhaowang. Numerical simulation of dry hot rock broken by PDC cutters [J]. Natural Gas Industry, 2019, 39(04): 125-134.

- Zhang Zhaofeng. Application prospect of high temperature geothermal drilling technology in Kenya in the development of hot dry rock resources in China [J]. Reservoir Evaluation and Development, 2022, 12(6): 833-842.

- Jiann S, David W. Raymond and Somuri Prasad. Advanced Percussive Drilling Technology for Geothermal Exploration and Development DE-FOA-EE0005502[C]. GRC Transactions, 2017, 41.

- Li Shimin. Discussion on the optimal rotational speed of DTH hammer drilling. Exploration Engineering (Geotechnical and Drilling Engineering), 1991, (6): 33-32.

- Du Xianglin, Zhang Maoju, Li Dunbao. Pneumatic DTH hammer drilling technology[m]. Beijing: Geological Publishing House, 1988.

- Geng Ruilun. Design and effect of air DTH hammer bit abroad. Exploration Engineering Compilation, 1998, (3): 1-6.

- Yang Da, Chen Baoyi, Cao Hongyu, et al. Study on rock fragmentation mechanism of hard alloy ball teeth based on impact load. Drilling Engineering, 2022, 49(01): 142-152.

- Shi CS (Shi, Changshuai), Zhu XH (Zhu, Xiaohua), Luo H (Luo, Heng). Study of DTH Bit–Rock Interaction Numerical Simulation method and DTH Bit Properties Evaluation(Article)[J]. Arabian Journal for Science and Engineering, 2017, Vol.42(5): 2179-2190.

- Bu Changgen, Qu Yegao, Cheng Zhiqiang, Liu Baolin. Numerical simulation of impact on pneumatic DTH hammer percussive drilling[J]. Journal of Earth Science, 2009, 20(5): 868-878.

- Yang Qiuming, Zhou Jing, Wang Yu, et al. Numerical simulation and tooth layout optimization of pneumatic DTH hammer for rock fragmentation based on ABAQUS[J]. Drilling Engineering, 2024, 51(01): 40-50.

- Wuhan Geological College (Ed.). Drilling Technology [m]. Beijing: Geological Publishing House, 1981.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).