Submitted:

05 November 2024

Posted:

06 November 2024

You are already at the latest version

Abstract

Keywords:

Laboratory Safety

- Always wear proper personal protection equipment (PPE) for the task you are carrying out (e.g. lab coat or coveralls, safety glasses or prescription glasses with side shields, gloves, face shield, respirator, aspirator, ear buds, etc.); see below for further details.

- Always know the hazardous properties of materials being use

- Always wash hands thoroughly before leaving the laboratory

- Never smoke in the building

- Never eat, drink, store food or apply cosmetics in laboratories

- Never perform unauthorized experiments

- Never engage in pranks, practical jokes or other acts of mischief

- Do not block access to emergency exits and emergency equipment

- Cell phones should not be used in the laboratory as they may become contaminated.

- Headphones are not allowed in the laboratory as they interfere with communication.

- Mouth pipetting is prohibited. Always attach and use a rubber suction bulb for transferring the solution if using a pipette, or use a mechanical pipetting device.

1. Introduction

2. Feed Analysis

- Name of sample

- Code number of sample

- Date of procurement

- Date of sampling

- Batch number in case of processed feeds

- Signature with date

2.1. Determination of Moisture in Feedstuffs

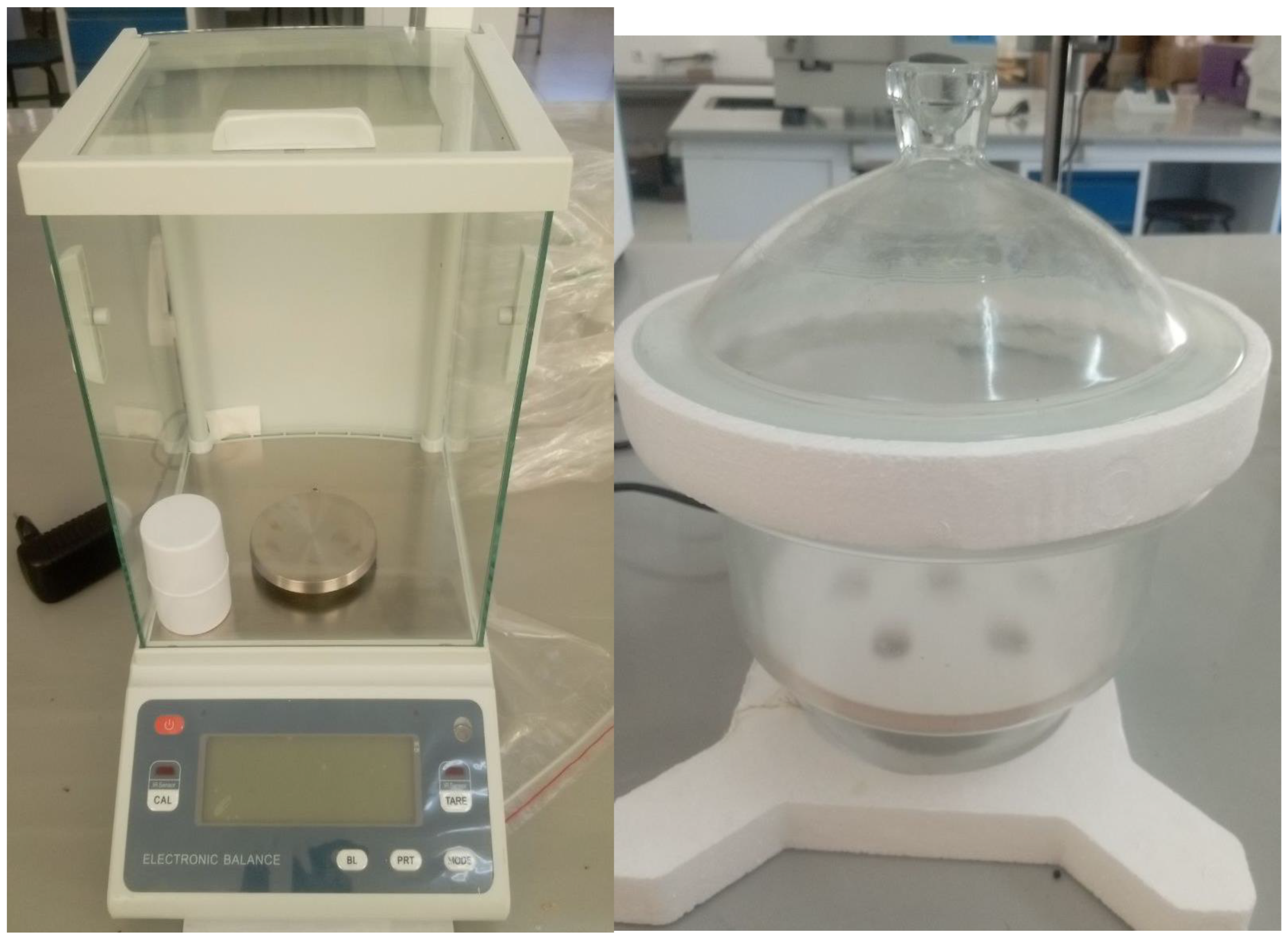

2.1.1. Apparatus and Equipment

- Metal Tong

- Heat resistant gloves

- Spatula

- Permanent markers

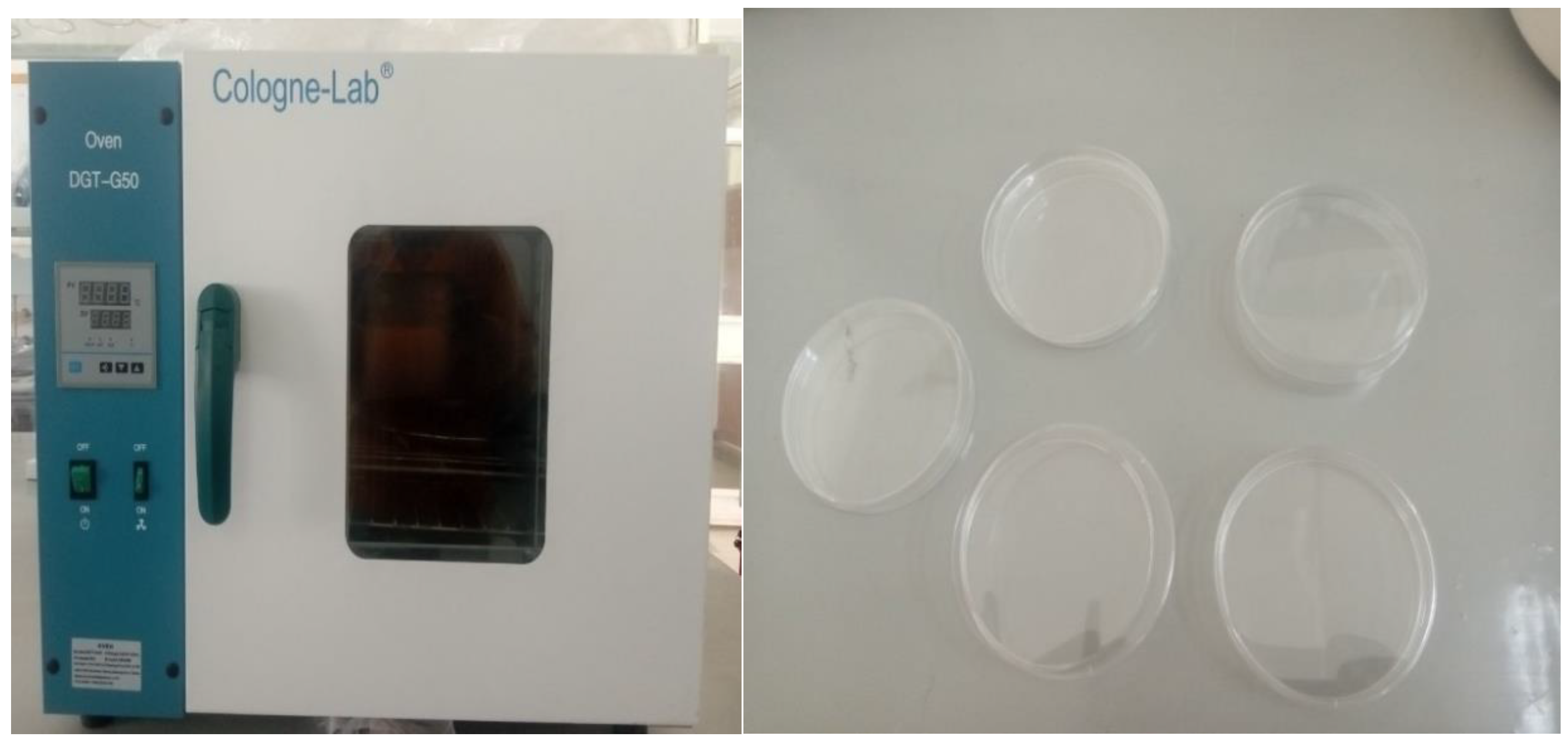

- Hot air oven

- Petri-dish

- Desiccators

- Balance machine

2.1.2. Procedure

2.2. Determination of Dry Matter (DM)

2.2.1. Equipment

- Silica crucibles

- Desiccators

- Hot air oven

- Balance machine

2.2.2. Procedure

- ✓ Dried and grinding samples

- ✓ Dry empty crucibles or container overnight at 105 °C

- ✓ Cool samples in desiccators to room temperature

- ✓ Measure oven-dry crucible (Wt)

- ✓ Add approximately 2g of ground sample; record weight (Ws)

- ✓ Dry overnight at 105 °C for 24hr

- ✓ Allow the desiccators to cool down to room temperature

- ✓ Weight oven dry crucible and sample = (W0)

2.3. Determination of Ash

2.3.1. Equipment

- Sensitive balance (Figure 2)

- Muffle furnace (550 °C) (Figure 6)

- Desiccator (Figure 2)

- Porcelain or silica crucibles (Figure 5)

2.3.2. Procedure

- Ignite dry matter samples overnight at 550 °C for 2:30hr in muffle furnace

- Allow the desiccators to cool down to room temperature

- Weigh ignited crucible and sample (Wa)

- Weight oven dry crucible and sample = (W0)

- Weight oven-dry crucible (Wt)

2.3.3. Precaution

- The ash is highly hygroscopic and thus weighing should be done quickly

2.4. Determination of Organic Dry Matter (ODM)

2.5. Determination of Crude Protein

2.5.1. Equipment

2.5.2. Chemicals/Reagent Preparation

- Clean everything what you need to prepare the catalyst

- Use clean and separated spatula for weighting different reagent/chemicals

- Transfer into same mixer chamber to mix catalysts

- Close the mixer chamber tightly with lid

- Mix all the tree chemicals using the mixer machine

- Take weight of 40g of NaOH pellet

- Transfer the weighted NaOH into the flask and shake slightly to mix

- Take 80ml of distilled water into the flask

- Label the flask with 40% NaOH, the wait too dissolve all the pellets and cool at room temperature

- After cooling, add water to make the final 100ml volume

- Weight 4g of boric acid powder

- Transfer the boric acid powder into 40ml of some hot distilled water

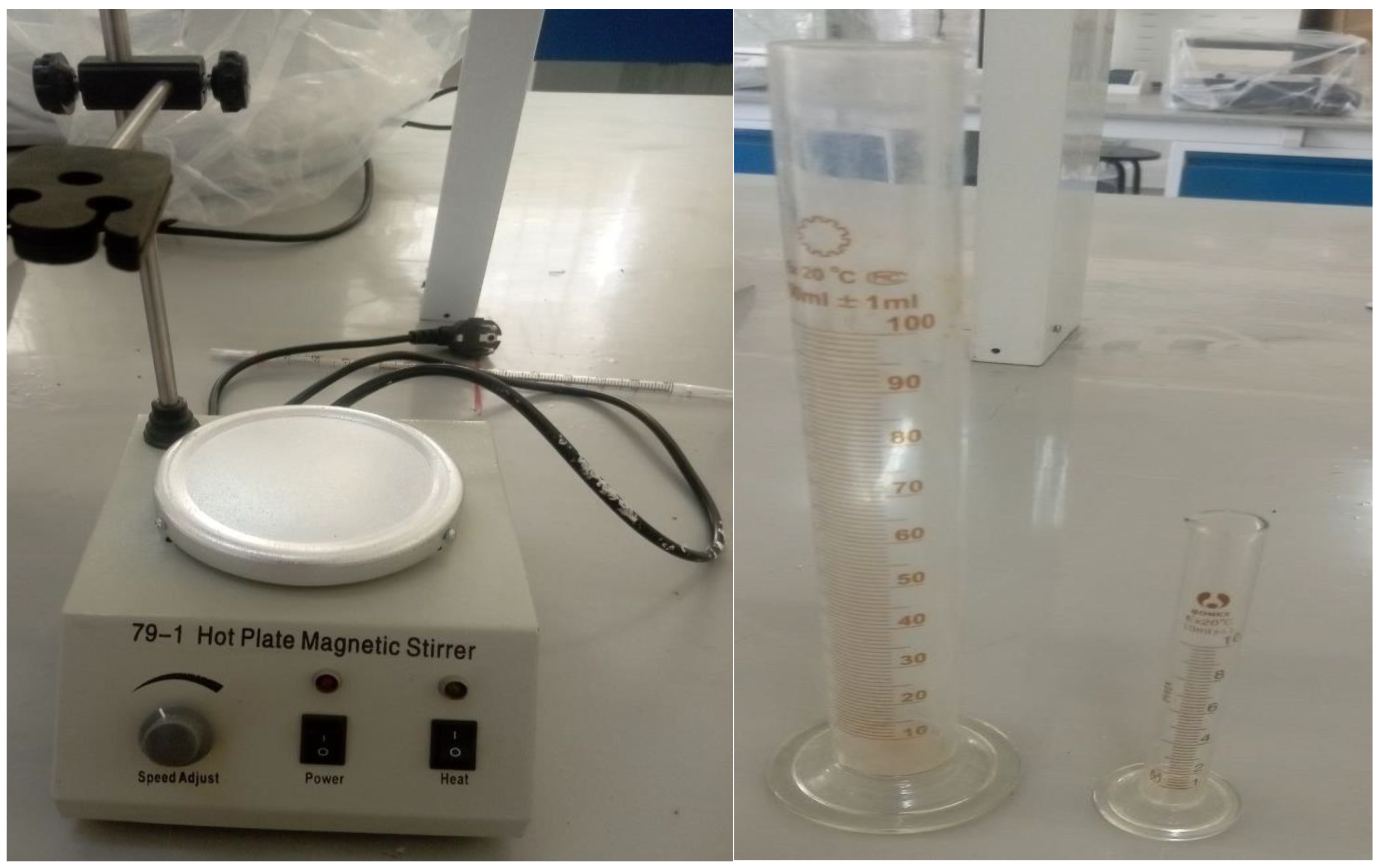

- Stir with a clean glass rod to dissolve boric acid well. Tur off the hot plate and cool the boric acid solution

- Label a 100ml volumetric flask with 4% boric acid solution

- Take the cooled boric acid solution into the volumetric flask

- Add distilled water to volume up to 100ml, and then rotate the flask to mix 4% of boric acid solution.

- Dissolve 2g phenolphthalein indicator powder into 100ml of ethanol and mix well by shaking

- Label a 100ml volumetric flask with 0.1N HCl

- Drop 80ml of distilled water into 100ml volumetric flask

- Pipette 0.83ml of concentrated HCl (37%) into the flask

- Add distilled water enough to make 100ml of the final volume

- Shake the flask to mix the HCl with distilled water

- Take 0.1N standard NaOH solution into burette

- Take the initial burette reading

- Measure 20ml of newly prepared HCl solution and take into conical flask

- Add 3-4 drops of phenolphthalein indicator into conical flask

- Titrate it with standard 0.1 NaOH solution

- Take final burette reading after the color changed

- Burette reading of NaOH (V2)

- Normality of NaOH (N2)

- Volume of prepared HCl (V1)

- Normality of HCl (N1)

- Dissolve 100mg Methyl red indicator powder into 100ml of methanol and mix well by shaking

2.5.3. Procedures

- 1. Digestion

- ∙

- Label the kjeldahls flask with the sample number

- ∙

- Take the weighted sample into the flask

- ∙

- Again, weight 3g of catalyst

- ∙

- Take the catalyst into the flask to mix sample

- ∙

- Take 20ml of concentrated H2SO4 and pour the acid into the sample flask

- ∙

- Shake the flask gently to mix the acid with sample and catalyst

- ∙

- Place the flask on digestion unit carefully

- ∙

- Turn on the digester power and set the temperature at 2300 c and water circulation open

- ∙

- After 2hr clean green color solution indicates the end of digestion

- ∙

- Turn off the digester and wait to cool the flask

- ∙

- Now, the digested sample diluted with distilled water

- ∙

- Add 20ml of distilled water into the flask, mix and pour the digested sample into 100ml volumetric flask

- ∙

- Add enough water to make the final volume of 100ml

- 2. Distillation

- ∙

- Measure 30ml of 4% boric acid and pour into a conical flask

- ∙

- Place the flask on the distillate collection unit

- ∙

- Take 10ml of digested sample to transfer into distillation flask

- ∙

- Now, add 50ml of 40% NaOH

- ∙

- Add another 50ml of distilled water

- ∙

- Run the distillation at 2000c for 1hr

- ∙

- Turn off the distillation after collect approximately 100ml of distillated

- 3. Titration

- ∙

- Take 0.1N HCl into burette

- ∙

- Note the initial burette reading

- ∙

- Add few drops of methyl red indicator into the conical flask and mix well

- ∙

- Start titration-adding 0.1N HCl

- ∙

- Place a white background at bottom of the flask to transparence colors

- ∙

- Start titration adding 0.1N HCl

- ∙

- Stop the titration if the color is changed into orange

- ∙

- Note final reading of burette

- 4. Calculation

2.6. Determination of Crude Fat or Ether Extract

2.6.1. Apparatus and Equipment

- Soxhlet apparatus

- Soxhlet extractor

- Filter paper

- Measuring cylinder (Figure 8)

- Thimbles

2.6.2. Chemical/Reagent

- n-hexane 95%

2.6.3. Procedure

- Gather everything you need to make a thimble with filter paper

- Make a thimble with filter paper

- Place the thimble on balance machine

- Take weight of a thimbles

- Grind the sample if it is solid

- Put about 4.5g of sample into the thimble.

- Take note weight of the sample

- Place small amount of cotton into thimble in a way that covers the sample

- Fold the thimble to enclose the sample

- Take a cellulose thimble (sample holder)

- Label the thimble contain sample with sample number and put inside the cellulose thimble

- Take a cleaned and dried flat bottom flask

- Take a weight of the flask placing in a balance machine

- Set up soxhlet extraction unit placing the sample in it

- Add sufficient amount of n-hexane

- Run the water through the condenser of soxhlet extractor

- Turn on the power and active for 6hr

- Take out the sample from thimble

- Rotate the flask to evaporate the excess n-hexane

- Place the flask inside the oven to remove moisture and hexane

- Set the temperature at 1100c for 30 minutes

- Take out the dried flask and place in desiccator to cool for 20 minutes

- Measure the final weight of flask after cooling

2.7. Determination of Crude Fiber

2.7.1. Reagents

- Sulfuric acid solution, 0.255N, 1.25 g of H2SO4/100 mL

- Sodium hydroxide solution, 0.313N, 1.25 g of NaOH/100 mL, free of Na2CO3 (concentrations of these solutions must be checked by titration)

- Alcohol - Methanol, isopropyl alcohol, 95% ethanol, reagent ethanol

- Bumping chips or granules - antifoam agent (decaling)

2.7.2. Apparatus

- Digestion apparatus

- Ashing dishes

- Desiccator

- Filtering device

- Suction filter: to accommodate filtering devices. Attach suction flask to trap in line with aspirator or other source of vacuum with valve to break vacuum.

2.8. Determination of NFE (Nitrogen Free Extract)

3. Urea Molasses Blocks (UMB)

3.1. Preparation of the Ingredients

- Molasses (34%)

- Urea (10%)

- Cement (15%)

- Wheat bran (25%)

- Noug seed cake (13%) and

- Common salt (3%).

3.2. Apparatus

- Molding instrument

- Ingredients

- Mixing equipment

- Weighing scales.

3.3. Procedure

- Molasses

- Urea

- Cement

- wheat bran

- Noug seed cake

- Common salt

- Ø Feed to ruminants only (sheep, goats and cattle).

- Ø Do not feed to monogastrics, (i.e., horses, donkeys, or pigs).

- Ø Do not feed to young ruminants less than six months of age (kids, lambs)

- Ø Blocks should be used as a supplement and not as the basic ration

- Ø A minimum of coarse forage in the rumen is essential

- Ø Never give blocks to an emaciated animal with an empty stomach. There is the risk of poisoning due to excessive consumption

- Ø The amount of blocks fed to sheep and goats should be limited to 100 grams/day while for cattle it should be limited to 700 grams/day.

- Ø The blocks should never be supplied in ground form or dissolved in water as this can result in over consumption

- Ø Supply sufficient amount of water ad lib

4. Physical Evaluation of Feedstuffs

References

- AOAC (Association of Official Analytical Chemists). 1995. Animal Feed: Sample preparation (950.02). Official methods of analysis, 16th edition.

- AOAC (Association of Official Analytical Chemists). 1995. Ash of Animal Feed (942.05). Official methods of analysis, 16th edition.

- AOAC (Association of Official Analytical Chemists). 1995. Fat (Crude) or Ether Extract in Animal Feed (920.39). Official methods of analysis, 16th Edition.

- AOAC (Association of Official Analytical Chemists). 1995. Fiber (Acid Detergent) and Lignin in Animal Feed (973.18). Official methods of analysis, 16th edition.

- AOAC (Association of Official Analytical Chemists). 1995. Moisture in Animal Feed (930.15). Official methods of analysis, 16th edition.

- AOAC (Association of Official Analytical Chemists). 1995. Laboratory Safety. Appendix B. Official methods of analysis, 18th edition.

- AOAC (Association of Official Analytical Chemists). 1990. Official methods of analysis, 15th edition. Arlington, VA.

- AOAC (Association of Official Analytical Chemists). 2000. AOAC Official Method 970.26. Official methods of analysis, 17th edition.

- AOAC (Association of Official Analytical Chemists). 2000. AOAC Official Method 972.16. Official methods of analysis, 17th edition. Gaithersburg, MD, USA.

- AOAC (Association of Official Analytical Chemists). 2000. Official Method 947.05. Official methods of analysis, 17th edition. Gaithersburg, MD, USA.

- Kunju, P.J.G. (1986). “Urea molasses block lick: A feed supplement for ruminants” Proceedings of the International Workshop, Kandy, Sri Lanka p261.

- L.O. GarcÃa and J.I.R. Restrepo. 1995. Multi-nutrient block handbook. Food and agriculture organization of the United Nations Rome, FAO Economic and Social Development Series No.

- Van Soest, P. J. 1975. Physio-chemical aspects of fibre digestion. In: I. W. McDonald, and AC. I. Warner (Ed.), Digestion and Metabolism in the Ruminant. The Univ. New England Publ. Unit, Armidale, Australia.

- Zaklouta M., Hilali M., Nefzaoui A. and Haylani M. 2011. Animal nutrition and product quality laboratory manual. ICARDA, Aleppo, Syria. viii + 92 pp.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).