Submitted:

25 October 2024

Posted:

28 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Application of the AMORMS tool to identify key factors that enhance asset performance through the use of maintenance management optimization and reliability engineering techniques, integrated within an Asset Management Model.

- Evaluation of the critical processes of the proposed Maintenance Management Model (MMM), under the reference framework of an Asset Management process (related standards: UNE 16646 and ISO 55001).

- Proposal for the creation of a Reliability Engineering support group, oriented to implement the actions proposed from the application of the MMM.

- Analysis of the overall results obtained from the application of the AMORMS diagnostic tool and proposed action plans addressing various key aspects: maintenance organization, RAM indicators, maintenance software (SAP-PM), reliability and risk tools (CA, RCA, RCM, LCC), Industry 4.0, etc., in a pilot area of the SINEA PERU plant.

2. Materials and Methods

2.1. Maintenance strategies

- Obtaining, from the corporate business objectives, maintenance objectives and policies at the highest level. These objectives may include, for example, estimated and realistic values for the following variables: equipment availability, reliability, safety, risk, maintenance budget, etc.; in turn, these objectives should be communicated to all personnel involved in maintenance, including third parties.

- Determination of the current performance of production facilities.

- Determination of the Key Performance Indicators (KPIs) to be considered for the evaluation of the performance of the facilities. The improvements to be pursued will be based on this set of metrics accepted by operations and maintenance management.

- Establishment of a set of principles that will drive the implementation of the strategy, and that will condition the subsequent planning, execution, evaluation, monitoring and analysis for the continuous improvement of maintenance activities.

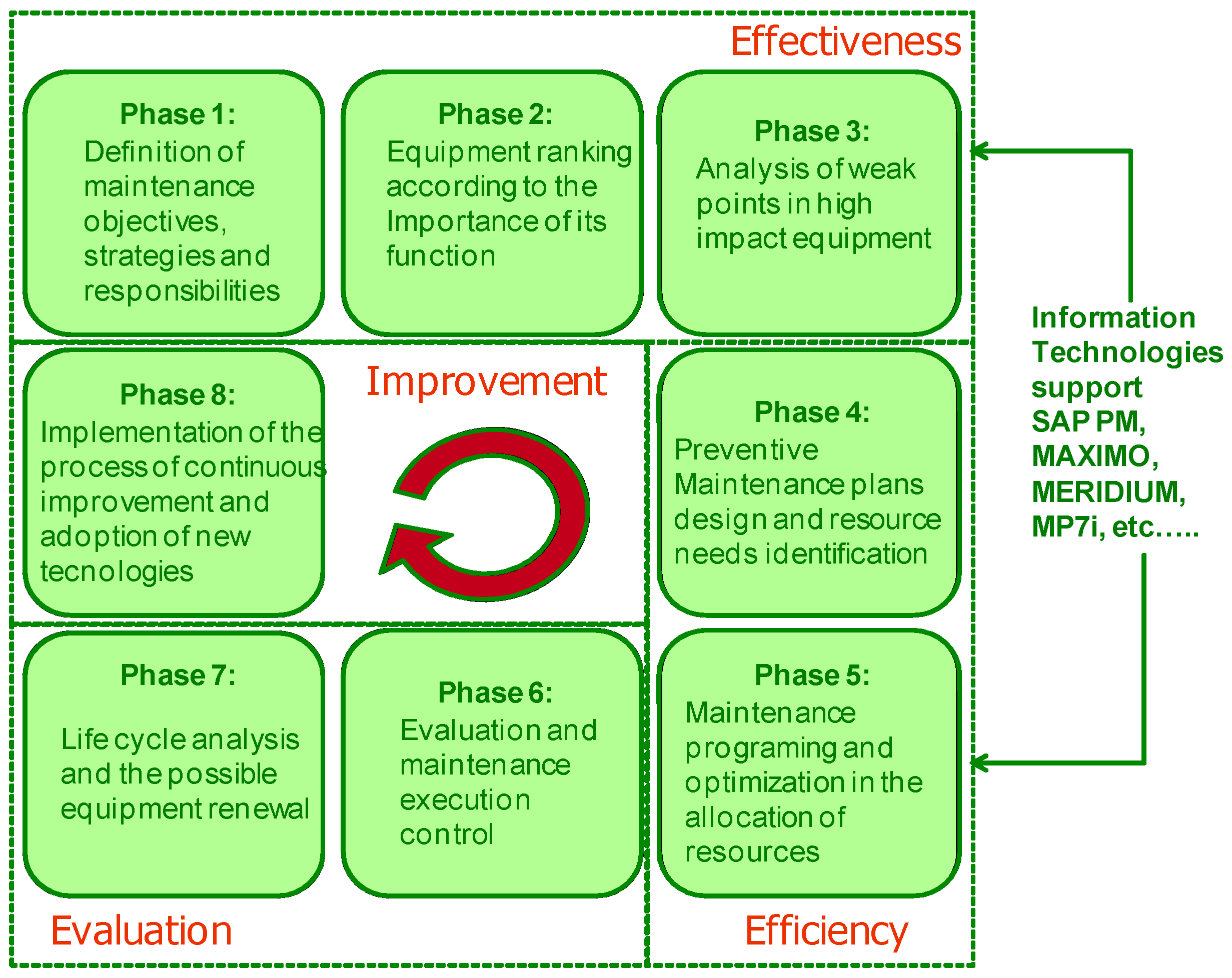

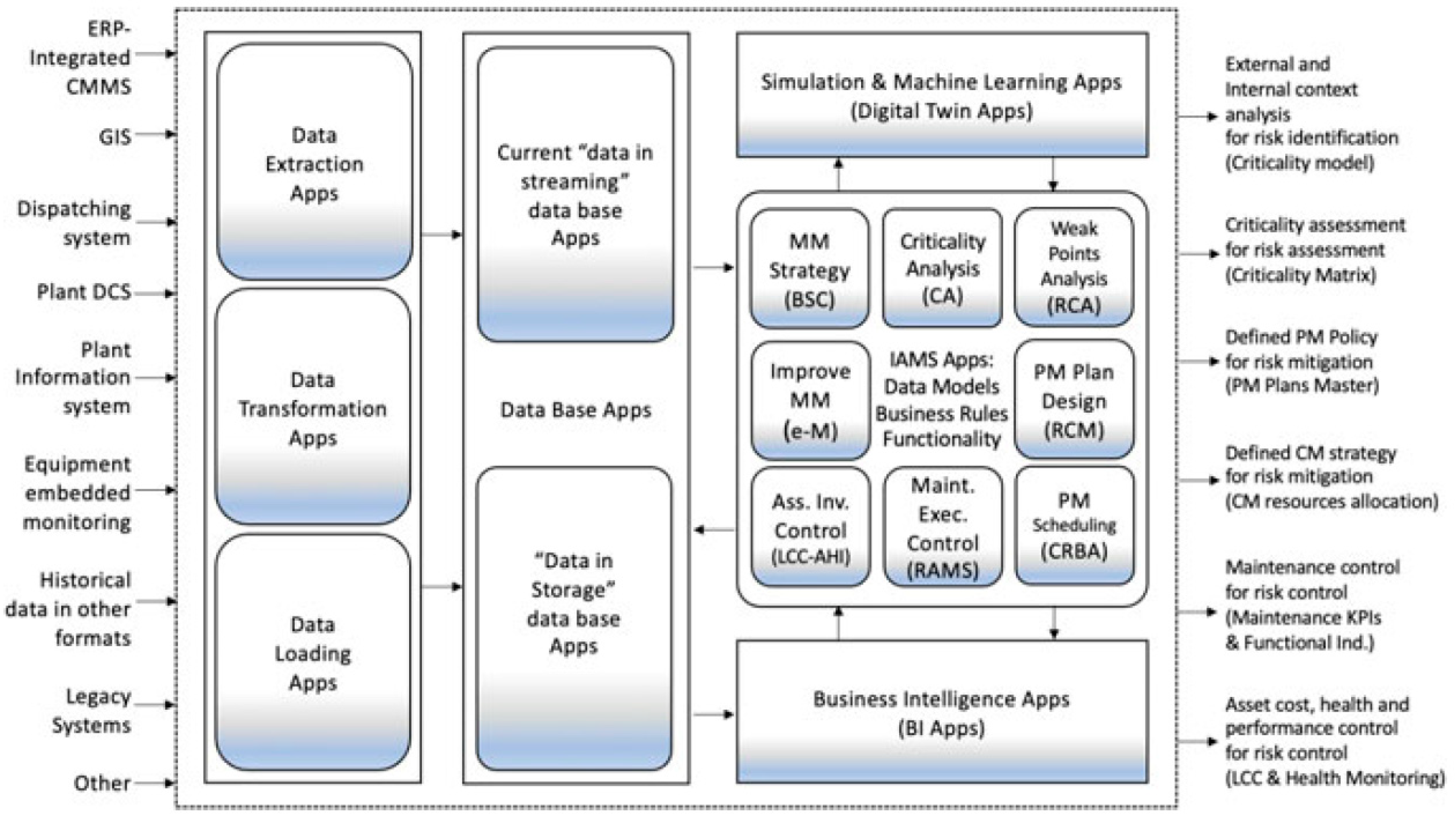

2.2. Management Model

3. Results

3.1. Case Study Scenario

3.2. General AMORMS Audit Implementation Procedure

- Asset Management, Business Objectives (KPIS) and support organization

- Risk-based Ranking Models (criticality of equipment)

- Problem analysis (fault management)

- Programming and planning processes

- Resource allocation, IT and logistical support processes

- Control processes and analysis of technical indicators RAM

- Life cycle cost analysis process

- Review and continuous improvement processes

3.3. Overall results of the AMORMS Audit at the SINEA Peru - SMI Plant

- (i)

- Sample 16 persons different areas, sample standard deviation 0.19);

- (ii)

- Average score obtained: 2.032 out of a maximum of 5 points;

- (iii)

- Category obtained: Average standard process (5 categories, category 2 - 3 was obtained).

- -

- # Is there a process for assessing the economic impact of Reliability in the life cycle of assets? (score: 1.39)

- -

- # 6.1.2. Are improvement analyses efficiently carried out on the historical information of failures and operation of the equipment? (score: 1.47)

- -

- # 3.1.4. Is the failure analysis process carried out by interdisciplinary teams to validate the causes found with real facts? (score: 1.52)

- -

- # Is there an efficiently implemented standard indicator analysis program? (score: 1.71)

- -

- # 8.1.1. Is there an efficient quality management model within the maintenance area? (score: 2.39)

- -

- # 5.1.1. Is there an efficient IT support system for maintenance? (score: 2.37)

-

Asset Management, Business Objectives (KPIS) and supporting organization (score: 2.16)Worst rated questions:

- -

- # 1.5.2. Are the financial control processes implemented based on the analysis of key KPIS on an ongoing basis and not on an ad hoc basis? (score: 1.86)

- -

- # Is the process of analysis and control of the financial KPIS integrated with the analysis of the technical and economic indicators of the maintenance and reliability areas (value: 1.82)? (score: 1.82)

Best rated question:- -

- # 1.4.1. Is there a generally well-defined organizational structure? (score: 2.21)

-

Risk-based Ranking Models (criticality of equipment) (score: 2.23)Worst rated question:

- -

- # 2.2.3. Is the information used to estimate the frequency of failures taken from a reliable and accurate source? (score: 1.98)

Best rated question:- -

- # 2.3.2. Have staff been made aware of the potential consequences of events that may affect safety, health and the environment? (score: 2.25)

-

Problem analysis (fault handling) (score: 1.96)Worst rated question:

- -

- # 3.1.4. Is the failure analysis process carried out by interdisciplinary teams to validate with real facts the causes found? (score: 1.52)

Best rated question:- -

- # Is there an efficient communication process between the organization’s management and the rest of the administrative levels? (score: 2.12)

-

Programming and planning processes (score: 1.87)Worst rated question:

- -

- # Are maintenance planning and scheduling strategies analyzed and are the results of the implementation of these strategies audited? (score: 1.76)

Best rated question:- -

- # Does the organization have a support group in charge of managing and facilitating Reliability and Maintenance tools? (score: 2.16)

-

Resource allocation processes, IT and logistical support (score: 2.19)Worst rated question:

- -

- # Does the maintenance IT support system automatically generate technical and economic indicators, which are widely used by the whole organization to improve decision making? (score: 1.81)

Best rated question:- -

- # 5.1.1. Is there an efficient IT support system for maintenance? (score: 2.37)

-

Control processes and analysis of technical indicators RAM (score: 1.89)Worst rated questions:

- -

- # 6.1.2. Are improvement analyses efficiently carried out on the historical information of failures and operation of the equipment? (score: 1.47)

- -

- # Is there an efficiently implemented standard indicator analysis programmed? (score: 1.71)

Best rated question:- -

- # 6.3.2. Are operational processes related to all production activities? (score: 2.12)

-

Life cycle cost analysis process (score: 1.78)Worst rated question:

- -

- # Is there a process for assessing the economic impact of Reliability in the life cycle of assets (Woodward, Willians and Scott models, etc.)? (score: 1.39)

Best rated question:- -

- # 7.3.1. Are major shutdowns implemented in an orderly manner under a major plant shutdown management model? (score: 2,01)

-

Processes of review and continuous improvement (score: 2.18)Worst rated question:

- -

- # 8.2.4. Is the Continuous Improvement process a common practice in the areas of maintenance and reliability? (score: 1.74)

Best rated question:- -

- # 8.1.1. Is there an efficient quality management model within the maintenance area? (score: 2.39)

4. Discussion

4.1. Key issues related to the organizational structure of maintenance area

- Area assessed: 1. Asset Management, Objectives and Organizational Structure. Grade obtained: 2.16 = Average / Maximum level = 5

- -

- UNE-EN 60300-1:2015. Reliability Management. Guidelines for its management and application

- -

- EN 15628:2014. Maintenance - Qualification of Maintenance Personnel (German Version)

- -

- EN 16646:2014. Maintenance within physical asset management

- -

- EN 17007-2017-MAN.1. Maintenance process and associated indicators (establish the maintenance and reliability policy, strategy and development actions)

- Participate in the development of a comprehensive reliability and maintenance management policy and align it with business objectives.

- Justify and define the reliability policy within the organization and establish the requirements for that policy.

- Provide examples of how reliability aspects are integrated into a comprehensive asset management strategy.

- Formulate maintenance optimization policies aimed at improving the reliability of production assets.

- Design and establish reliability and maintenance goals, as well as technical and economic indicators.

- Guide the organization in selecting different reliability and maintenance optimization methods.

- Organize reliability activities and design the administrative structure that best suits the organization's needs (for SINEA PERÚ Plant, a centralized and horizontally integrated structure with other business areas is recommended).

- Describe and develop the skills of human resources involved in reliability optimization processes.

- Design a human resources development policy for the reliability area.

- Determine the human and material resources necessary to implement various reliability optimization techniques (e.g., support software, training, tools and materials, technical documentation).

- Integrate reliability activities with safety, hygiene, and environmental processes.

- Identify the different conditions of production equipment that may pose health, safety, and environmental risks (inside and outside the company) and describe the possibility of preventing such incidents through reliability activities, including cooperation with other company departments and external parties.

- Design and/or select methods and techniques to achieve optimized results in reliability activities, including economic, safety, and environmental aspects.

- Define the strategy for selecting and implementing different reliability and maintenance optimization methods (e.g., CA: Criticality Analysis, RCA: Root Cause Analysis, TPM: Total Productive Maintenance, RCM: Reliability Centered Maintenance, CRBA: Cost Risk Benefit Analysis, etc.).

- Develop and analyze key indicators used to control economic aspects related to the application of reliability engineering techniques.

- Develop the procedure for applying LCC (Life Cycle Costs) methods and evaluate the economic impact of reliability.

- Describe how LCC concepts can be applied in the different stages of the asset lifecycle.

- Support the optimization process for spare parts and inventory logistics (material handling and storage, methods for calculating maximum/minimum spare parts, shortage costs, storage costs, quality control, delivery systems, etc.).

- Measure and analyze the results of reliability activities, such as efficiency and cost-effectiveness, to describe different methods for evaluating the outcomes of reliability activities, their advantages and disadvantages, and how economic aspects are considered.

- Know and apply the most important standards related to reliability processes.

- Evaluate and propose different economic models related to maintenance and reliability, and understand the basic principles regarding economic outcomes for the organization.

- Participate in defining maintenance activities during the development and acquisition of new production equipment.

- Explain the importance of analyzing reliability, maintainability, and availability at every stage of the asset lifecycle: development, design, installation, commissioning, operation, and replacement.

- Evaluate the future reliability needs of a company to understand the important factors for reliability activities and how they might change in the future (e.g., new requirements related to goals, strategies, and outcomes).

4.2. Key issues related to SAP PM maintenance support software

- Area assessed: 2. Ranking Models and Criticality Analysis process. Grade obtained: 2.23 = Average / Maximum level = 5

- Area assessed: 6. Process of control and analysis of technical and economic indicators. Grade obtained: 1.89 = Below Average / Maximum Level = 5

- -

- UNE-EN-ISO 14224:2016. Petroleum, petrochemical and natural gas industries. Collection and exchange of equipment maintenance and reliability data.

- -

- UNE-EN 60300-1:2015. Reliability Management. Guidelines for its management and application

- -

- EN 17007-2017-MAN.1. Maintenance process and associated indicators (establish the maintenance and reliability policy, strategy and development actions)

- Improve work order data collection formats in SAP PM (problem description, symptoms, failure modes (associated with maintainable items)).

- Improve the process of data capture and analysis of the information generated by the SAP PM software, this process presents a great opportunity for improvement, additionally, the use of this management tool is very limited to only a minimum group of people in the maintenance area, it is necessary to transmit more efficiently the information of the impact of the planning and scheduling process to the operational areas, In addition, the use of SAP PM needs to be much more widely disseminated and the interpretation and decision-making process needs to be improved based on the analysis of the information (technical and economic) that can be generated within the maintenance process (the use of the installed version of SAP PM has not been consolidated).

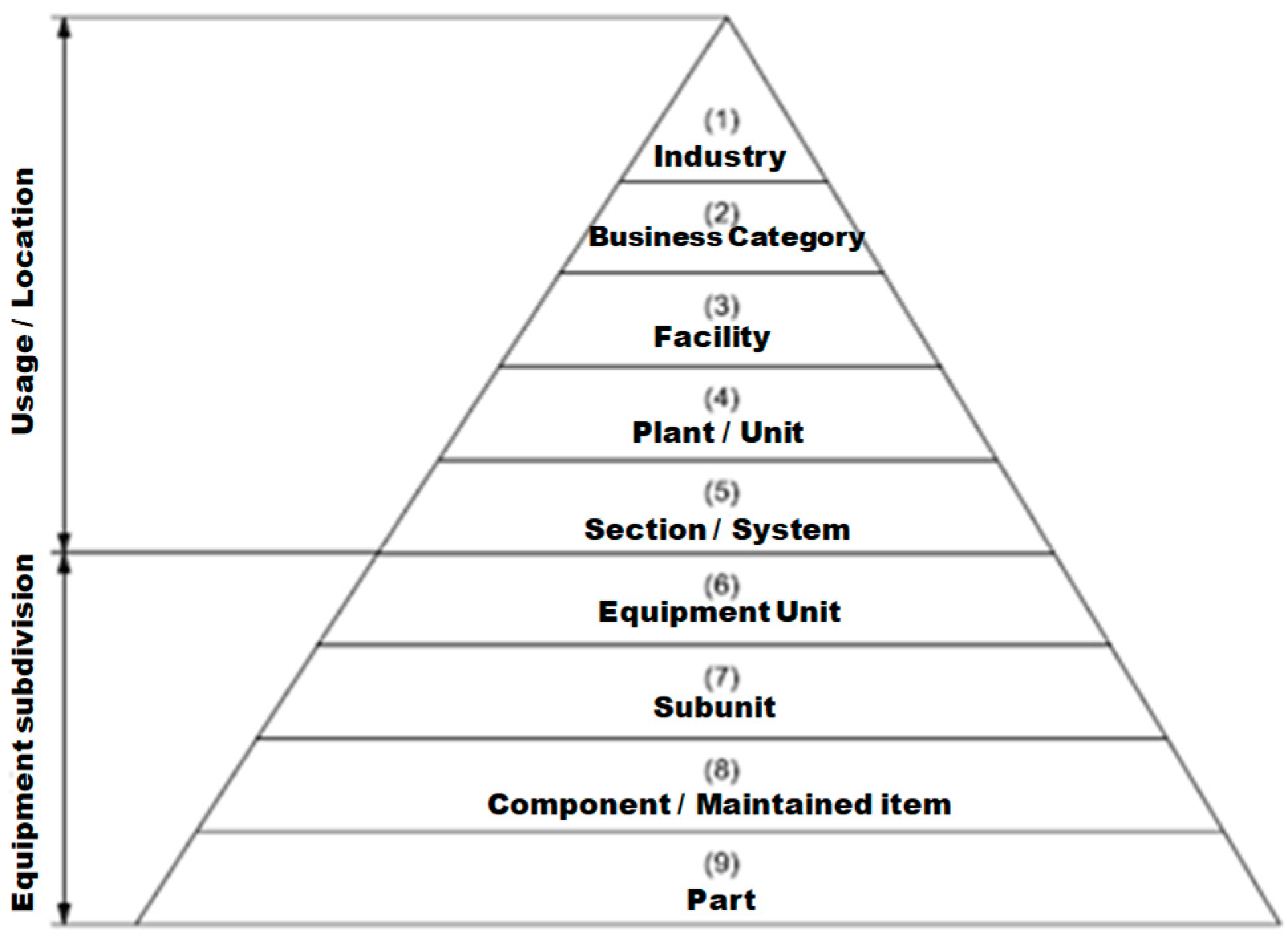

- Develop and automatically generate within the SAP PM at the different hierarchical levels (Plant, Process, System, Equipment and reach the maintainable item, according to the ISO 14224 approach), the technical management indicators (MTTF: mean time to failure, MDT: mean down time, FF: frequency of failures and Costs due to unavailability by failures: CUF). In the medium term, the proposed indicator (CUF) can be related to other indicators such as: Back log, % maintenance activities executed vs. planned, Preventive vs. corrective.

- Promote within SAP PM, a standard model of criticality assessment of failure modes associated with the maintainable item, based on the indicator "CUF: Costs of unavailability due to failures" (frequency of failures (failures/year) x consequences ($/failures) = $/year). This model should be accepted by the whole organization and should also be the criteria for prioritizing the processes of planning, execution of maintenance activities and definition of critical spare parts (internal developments within SAP PM could help to improve this part of the maintenance management process).

- Correct the calculation of the Reliability indicator; the indicator that is currently calculated is a calculation of Availability associated with failures. The correct calculation of Reliability (Rt, probability of operation) should be carried out with statistical techniques, for example, with the Weibull Distribution.

- Promote greater interest in the use of SAP PM at the level of the different maintenance departments (greater commitment to the use of SAP PM) and make decisions based on the use of the technical and economic indicators generated from SAP PM (show the added value of the use of the SAP PM tool).

- Promote a cultural change in SAP PM users, in relation to the management process of the technical and economic data to be entered in SAP PM (guarantee a good level of quality and veracity of the data).

- Use SAP PM to promote improvements in the planning and scheduling processes of maintenance strategies, use the proposed CUF indicator, at the maintainable item level, to drive the PM preventive maintenance optimization process and improve annual maintenance budgets.

- Review and adjust detailed preventive maintenance execution procedures for critical equipment (review step-by-step maintenance and inspection plans for critical failure modes).

- Review the work order prioritization process within SAP PM (it is recommended to use the indicator CUF: Unavailability costs due to failures, to adjust the prioritization of work orders for preventive and corrective activities).

- Set the stage for work orders to be generated within SAP PM by the people who are closest to the equipment (parameterize SAP PM to make it simple and user-friendly).

- Design standard formats or improve existing formats within SAP PM), so that the following information can be recorded: failure modes (catalogue of failures associated with maintainable items, obtained from RCM applications), average operating times, average out-of-service times, economic impact (direct costs of failures plus penalty cost).

- Design a procedure within SAP PM, which allows the integration of the criteria between logistics and maintenance with the aim of being able to establish optimal maximum and minimum spare parts based on the risk factor.

- Disseminate the information generated by SAP PM; and not limit it only to maintenance personnel (take advantage and introduce operations personnel to start correcting the process of defining failure modes, especially start requiring the creation of the failure mode database).

- Develop a procedure within SAP PM to automatically prioritize equipment and preventive and corrective maintenance activities according to the potential impact of failure modes in the operational context.

- Develop a basic training program of technical indicators of Reliability and Maintenance, integrated with the training process in the use of the SAP PM tool, in which field personnel are involved, both operators and maintainers, not limiting the knowledge and use of the indicators to be generated by SAP PM, only to the group of people who make up the Maintenance area, it is necessary to involve the operations personnel.

- Promote in the medium and long term, the development within SAP PM of Root Cause Analysis (RCA) and Reliability Centered Maintenance (MCC) tools, as integrated modules within SAP PM, which directly feed the processes of planning, scheduling and the development of annual maintenance budgets.

-

MTTF = Mean Time to Failure (Average Operational Time Until Failure). Unit of measurement: Time (hours, days, months, etc.)MTTF = ΣTTF / nWhere:TTF = operational times until failuren = total number of failures in the evaluated periodNote: This is a technical indicator and serves as a basic measure of Reliability.

-

FF = Failure FrequencyUnit of measurement: Failures per time (failures/year, failures/month, failures/week, failures/hour)Where:FF= 1 /MTTFNote: This technical indicator measures the rate of increase or decrease in failures and is a basic measure of Reliability.

-

MDT = Mean Down Time (Average Time Out of Service)Unit of measurement: Time (hours, days, weeks, etc.)MDT = ΣDT / nWhere:DT = time out of servicen = total number of failures in the evaluated periodNote: This technical indicator represents Maintainability and measures the increase or decrease in downtime during restoration processes.

-

CUF = Cost of Unavailability Due to FailuresUnit of measurement: Money per time (dollars/year, dollars/month, etc.)CUF = FF × MDT × (CD + CP)Where:FF = failure frequency (failures/month, failures/year, etc.)MDT = average downtime (hours/failure)CD = direct cost of correction per failure hour ($/hour), including material and labor costsCP = penalty cost per hour ($/hour), including opportunity costs caused by failure events (plant shutdowns, production deferral, low quality, rework, safety, and environmental impacts)Note: This is an economic technical indicator representing the Economic Risk Value, measuring the economic impact of failures per unit of time.

-

A = AvailabilityUnit of measurement: % (ratio of operational time)A = ( (MTTF+MDT) / MTTF ) × 100%Where:MTTF = mean time to failure (average operational time until failure)MDT = mean down time (average time out of service)Note: This is a technical indicator used to measure the availability of a system, representing the percentage of time the system is operational relative to the total time (operational time + downtime).

4.3. Key aspects related to the Criticality Analysis process

- Area assessed: 2. Ranking Models and Criticality Analysis process. Grade obtained: 2.23 = Average / Maximum level = 5

- -

- ISO 31000 (Risk-Management-Principles-and-Guidelines)

- -

- NORZOK Z-008:2017 (Risk based maintenance and consequence classification)

- -

- UNE-EN-ISO 14224:2016. Petroleum, petrochemical and natural gas industries. Collection and exchange of equipment maintenance and reliability data.

- Update and confirm the key factors that currently make up the criticality analysis process (criticality processes developed in the RCA and RCM pilot applications). It is important that the factors included in the Risk Matrix help management and technical levels to make more efficient decisions, correctly directing both economic and human resources in the processes related to the operation and maintenance of industrial assets at the SINEA PERU Plant.

- Review and adjust the Physical Assets Risk Matrix model, so that it allows for a systemic and comprehensive assessment of the following parameters: Reliability, Maintainability, Costs due to unavailability, Quality, Safety, Health, Environment, Security, Vulnerability and Reputation, aligned with the objectives of a comprehensive Asset Management process.

- Understand that the semi-quantitative method of prioritization by Risk generates a high level of uncertainty, so great care must be taken with the criteria to be evaluated and with the decisions to be taken based on the criticality results to be obtained with this methodology (it is recommended that at least once a year, the criteria included in the Risk-based criticality matrix be reviewed and updated).

- Consolidate the execution of the recommendations obtained from the criticality analysis process, promoting the real and effective implementation of the actions to be proposed from the application of the Reliability and Risk methods: RCA (Root Cause Analysis), RCM (Reliability Centered Maintenance), etc.., compare at least once a year, how the criticality levels of the equipment move within the Risk matrix, once the recommended action plans have been implemented (relate the level of importance of the systems obtained from the criticality matrix with the CUF indicator, proposed in the previous session, compare the CUF before and after the implemented recommendations).

- Ensure the veracity of the information available in the process of defining the factors of the frequencies and consequences of failures (key aspect, having people who are "experts" in the factors to be evaluated in the risk matrix), to such an extent that, if "expert" personnel are not available, high- impact risk factors may be omitted, generating erroneous or incomplete criticality results, which generate inefficient solutions with little added value.

-

Risk = FF x CWhere:FF = Failure frequency (number of failures over a specific period)C = Consequences of failures to safety, environment, quality, production, etc.

4.4. Key aspects related to the failure analysis process

- Area assessed: 3. Problem analysis and fault management. Grade obtained: 1.96 = Below Average / Highest Level = 5

- -

- UNE EN 62740:2015 (RCA: Root Cause Analysis)

- -

- ISO 31000 (Risk-Management-Principles-and-Guidelines)

- Quantify in detail the improvements obtained from the implementation of the recommendations generated by the RCA process. It is proposed to calculate and analyze (before and after the implementation of RCA), technical indices such as: average operating times, average downtimes and the frequency of failures.

- Introduce the CUF indicator (Costs of Unavailability due to Failures), calculate this indicator before the implementation of the RCA and compare it with the one obtained after the implementation of the recommendations generated from the RCAs, to measure the real values of savings or losses obtained.

- Design standard RCA formats for the entire organization (ideally include this format within the SAP PM software). The formats to be developed should record the following information: failure modes and their root causes (most important), average operating times, average out-of-service times, economic impact (CUF indicator). Use as a basis for the design of the formats, the one used in the implemented RCA applications.

- Use the experiences and results obtained from the RCAs (in the pilot applications), to create a shared knowledge database (ideally this database should remain within the SAP PM, in the future all RCAs can be digitized, and Industry 4.0 tools can be integrated, e.g. application of Digital Twins in the failure analysis processes).

- Facilitate the exchange of information and the analysis of resolved RCA cases among the staff of the different maintenance and operations areas (take advantage of the analysis of previous RCAs). Generate lessons learned: "it is not necessary to make mistakes twice".

- Disseminate the information generated by the RCA results; and not limit it only to maintenance personnel (use the information collected for the creation of the failure modes database).

- Develop a basic Failure Analysis training program, involving all operations and maintenance personnel, not limiting the knowledge of the RCA technique only to the maintenance group, it is necessary to involve operations, production, projects and logistics (purchasing) personnel.

- Assign responsible parties for the implementation of the proposed recommendations (define implementation dates for each of the recommendations developed and establish a work plan to implement the recommendations in a period of less than 6 months).

- Formation of work teams. The first step in the methodology is to form a multidisciplinary team responsible for analyzing the problem. This team should include individuals with different perspectives and specialized knowledge about the area or process being investigated. The purpose is to ensure that all relevant aspects are covered.

- Definition and prioritization of problems. The team must identify and clearly define the problems or incidents that have been observed. It is important to have a clear and agreed-upon understanding of the problem in order to proceed effectively. Then, the problems are prioritized, focusing on those with the most significant impact or urgency.

- Definition and prioritization of failure modes. Once the problems have been identified, the next step is to identify the different failure modes that may have caused the problem. These are the various failures in components or processes that contributed to the overall problem. The failure modes are then prioritized based on their criticality and impact.

- Definition and validation of hypotheses. Based on the analysis of possible causes, the team develops hypotheses about what may be causing the problem. These hypotheses must be tested or validated using additional data or analysis to ensure that they accurately represent the root cause.

- Definition of root causes: physical, human, and latent. This is the core of Root Cause Analysis. Here, the team investigates the underlying causes of the problems. Root causes can be physical (equipment or material failures), human (operational errors, lack of training), or latent (systemic factors that are not immediately apparent, such as poor policies or lack of supervision).

- Identification and implementation of solutions. With the root cause validated, the team works on solutions to eliminate or mitigate it. These solutions may include process changes, improvements in training, technical enhancements, or adjustments in policies. It is essential that the solutions are practical and applicable.

- Evaluation of the effectiveness of the solutions. After implementing the solutions, an evaluation is conducted to measure their effectiveness. The team monitors whether the initial problems are resolved and whether the failure modes do not reoccur. This step is crucial to ensure that the solutions not only address the symptoms of the problem but eliminate the root cause.

4.5. Key aspects related to the process of optimisation of maintenance and inspection plans (RCM)

- Area assessed: 4. Process of planning, scheduling and optimization of maintenance plans. Grade obtained: 1.87 = Below Average / Highest Level = 5

- Area assessed: 5. Resource allocation and logistical support process Grade obtained: 2.19 = Average / Maximum level = 5

- -

- SAE 1011-1012 RCM (Reliability Centered Maintenance)

- -

- UNE-EN-ISO 14224:2016. Petroleum, petrochemical and natural gas industries. Collection and exchange of equipment maintenance and reliability data.

- -

- ISO 31000 (Risk-Management-Principles-and-Guidelines)

- -

- EN 17007-2017-MAN.1. Maintenance process and associated indicators (establish the maintenance and reliability policy, strategy and development actions)

- Continue with RCM applications (based on the method used in the pilot applications) on all critical equipment in the Plant and carry out a detailed review of the current maintenance and inspection programs (use the CUF indicator to assess the economic risk factor for each failure mode and adjust the maintenance and inspection plans).

- Code failure modes and generate work orders with the failure modes obtained from RCM applications (include these failure modes as functional locations in the catalogue within the SAP PM at maintainable item level, ISO 14224).

- Develop for the failure modes and critical deterioration processes obtained from the RCM, a cost risk benefit analysis process (apply the reliability optimization techniques: Weibull and Log Normal methods integrated to the CUF optimization indicator.

- Update the effectiveness of the maintenance and inspection plans generated from the RCM; and analyze before and after, the performance of the following technical indicators (MTTF: mean time to failure and MDT: mean down time) and cost indicators (preventive, corrective, predictive maintenance and the CUF: costs due to unavailability due to failures).

- Adjust the internal review procedure of the maintenance and inspection plans defined under the RCM methodology approach to control the average operating times, repair times, failure frequencies and costs per failure unavailability (CUF), at least once every 12 to 18 months.

- Integrate RCM results within SAP PM, to have a common database of optimized maintenance and inspection plans.

- INITIAL PHASE

- a. Formation of the natural work team. In this stage, a multidisciplinary team is selected and organized. This team usually consists of individuals who have direct experience with the system or asset being analyzed. The team should include operators, maintainers, engineers, supervisors, and any other relevant personnel. It is important that all team members understand the objectives of RCM and the tools that will be used throughout the process. The purpose of this phase is to ensure that the team is aligned and ready to carry out the reliability analysis efficiently and effectively.

- b. System selection and definition of the operational context. In this stage, the system or asset to be analyzed is selected. This step is crucial as it defines the boundaries of the analysis, the scope of the study, and which parts of the system will be considered.

- The operational context is also defined, which describes the conditions under which the system is expected to operate. Factors such as the environment, load capacity, operating duration, environmental conditions, safety standards, among others, are considered. This helps to understand how the system should behave under normal and extreme conditions. It is essential to have a clear understanding of the system, its limits, and its role in the overall process.

- 2.

- RCM IMPLEMENTATION PHASE

- a. Failure Modes and Effects Analysis (FMEA). FMEA is a critical step where the different modes in which a system can fail and the impact of those failures on the overall system performance are identified and analyzed. The analysis is developed through several sub-steps:

- i. Definition of functions. In this sub-phase, the primary and secondary functions of the system or asset are defined. It outlines what is expected of the system under normal conditions and any additional roles it may have. For example, the primary function of a pump in a plant might be to pump water at a certain pressure and flow rate. It may also have secondary functions, such as preventing overheating or ensuring system safety.

- ii. Detection of functional failures. In this stage, the functional failures of the system are identified, meaning those situations in which the system fails to perform its functions as expected. A functional failure can be total (the system does not function at all) or partial (the system operates inefficiently or deviates from its operational standard). Continuing with the pump example, a functional failure could be the pump not reaching the required pressure or failing to start when needed.

- iii. Identifying failure modes. Here, the different failure modes that may cause functional failures are identified. Failure modes are the specific reasons why a functional failure occurs. These modes can be caused by mechanical, electrical, human, or environmental factors. In the case of the pump, a failure mode could be a blockage in the pipes, a failure in the electric motor, or excessive wear of components.

- iv. Effects and consequences of failures. This sub-phase focuses on analyzing and documenting the effects and consequences of the identified failures. Effects describe what happens when a failure occurs (e.g., the pump does not provide enough pressure). Consequences may include damage to other equipment, production interruptions, or even safety risks. This information is crucial to prioritize failures and design mitigation strategies.

- 3.

- APPLICATION OF RCM - DECISION FLOWCHART FOR SELECTING THE OPTIMAL MAINTENANCE STRATEGY

- Once the failure modes and their consequences have been identified, RCM - Decision Flowchart is used to make decisions about the most appropriate type of maintenance to prevent or mitigate the failures. Options may include preventive, predictive, corrective maintenance, or even the decision to do nothing if the associated risk is low. In this phase, factors such as failure criticality, associated costs, and safety are evaluated to determine the optimal maintenance approach. The ultimate goal is to ensure that maintenance tasks are aligned with the critical functions of the system and that system reliability is maximized.

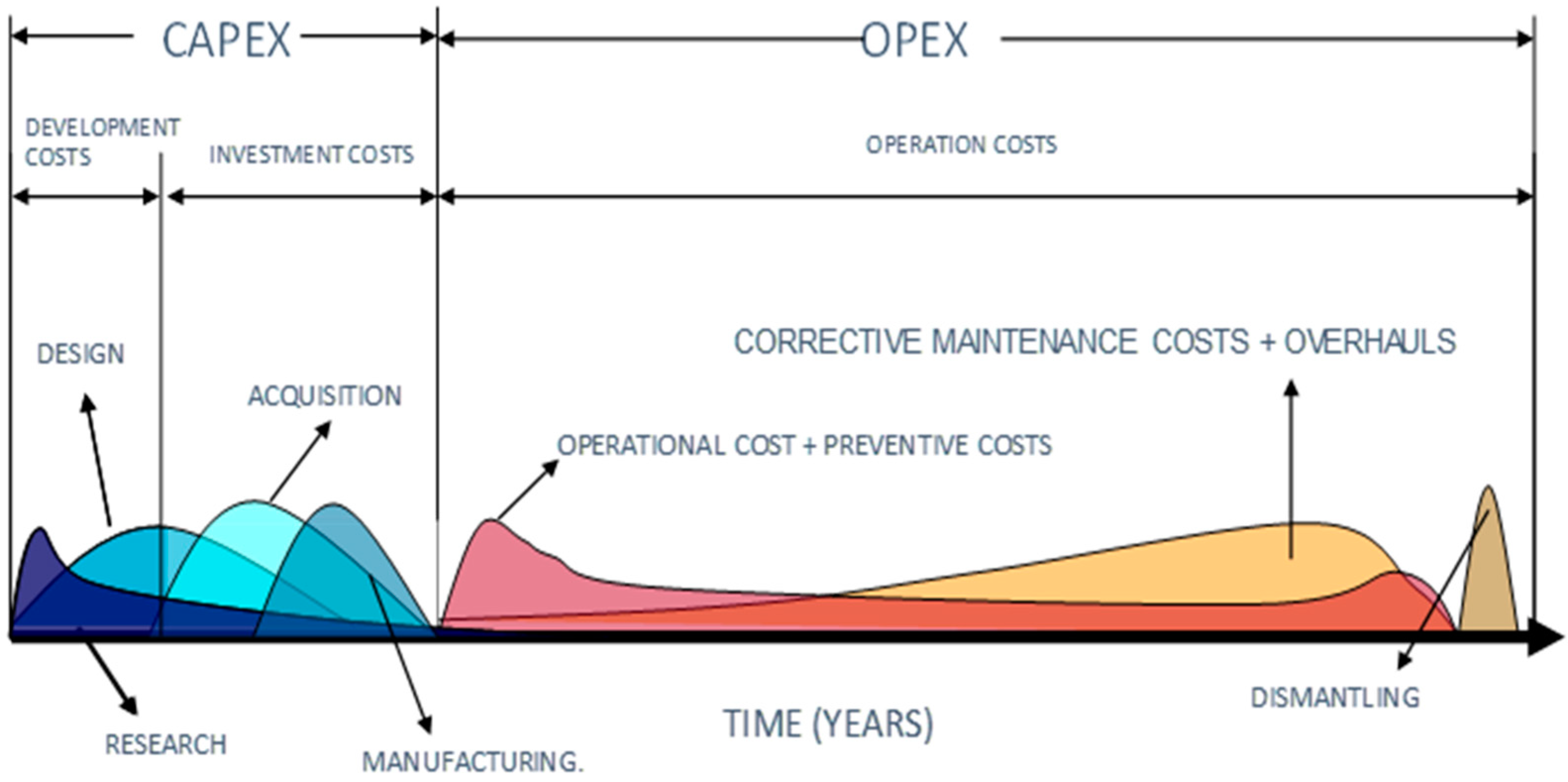

4.6. Key issues related to the Life-Cycle Cost Analysis (LCCA) process

- Area assessed: 7. Life Cycle Cost Analysis Processes. Grade obtained: 1.78 = Below Average / Maximum Level = 5

- -

- ISO 15663:2021 (Petroleum, petrochemical and natural gas industries - Life cycle costing)

- -

- ISO 31000 (Risk-Management-Principles-and-Guidelines)

- Establish the operational conditions of the system. Describe the modes of operation of the system (full load, half load, no load) and the production capacities to be satisfied.

- Establish the utilization factors. These factors should indicate the operating status within each mode of operation.

- Identify the different options to be evaluated. Select the existing alternatives that can meet the required production needs.

- Identify for each alternative all basic cost categories: initial investment, development, acquisition, planned maintenance, replacement.

- Determine for each alternative the Total Cost of Reliability (TCPF). Identify the main types of failures and the frequency of occurrence over time, which will be a constant value throughout the life cycle of the asset.

- Determine critical costs. Identify the cost categories with the highest impact and analyze the drivers of high costs (propose control strategies).

- Calculate all costs in present value (P) for each alternative. Define the discount factor and the expected lifetime and estimate the total present value costs for each alternative evaluated.

- Select the winning alternative. Compare the total costs of the evaluated alternatives and select the option that generates the lowest cost for the expected lifetime.

- (P) = Present value.

- CTCV(P) = Total life-cycle costs in present value (P), for a discount rate (i) and an expected lifetime (T).

- IC = Initial acquisition and installation cost, usually given in present value. CO = Operational costs, usually given as an Annualized value**.

- CMP = Preventive Maintenance Costs, usually given as an Annualized value**.

- CMC = Corrective Maintenance Costs (failure costs), usually given as an annualized value. In this case a constant failure rate is assumed, so the cost impact is the same in all years **.

- CMM = Major Maintenance Costs - Special, usually given as a Future value**.

- RV = Replacement Value, usually given as a Future value**.

4.7. Key aspects related to the process of continuous improvement

- Area assessed 8: Review and continuous improvement processes. Grade obtained: 2.18 = Average / Maximum level = 5

- -

- EN 16646:2014 (Maintenance within physical asset management)

- -

- ISO 55001:2014 (Asset Management - Management Systems - Requirements)

- -

- ISO 31000 (Risk-Management-Principles-and-Guidelines)

5. Conclusions

- -

- Adjust the process of measuring the execution of the recommendations obtained from the criticality analysis process, promoting the effective implementation of the proposed actions based on the application of the improvement methods: RCA (Root Cause Analysis) and RCM (Reliability Centered Maintenance). Develop within SAP PM, the indicator "CUF: Costs of unavailability due to failures" (frequency of failures (failures/year) x consequences ($/failures) = $/year), at the level of equipment and failure modes.

- -

- To consolidate the profile of the Integral Reliability Engineer, who can facilitate and develop applications of the following methodologies: CA: Criticality Analysis, RCA: Root Cause Analysis, TPM: Total Productive Maintenance, RCM: Reliability Centered Maintenance, CRBA: Cost Risk Benefit Analysis, LCC: Life Cycle Cost.

- -

- Update and review in detail the actual impact of maintenance and inspection plans for critical systems. Now, the maintenance plans are based on the manufacturer's recommendations and on the experience of the SMI/SINEA/PERU organization’s maintenance and operations personnel. It is time to update the maintenance and inspection plans (taking advantage of the use of RCA and RCM methodologies). Initially consider critical and medium criticality failure modes and apply cost risk benefit optimization techniques to adjust maintenance and inspection frequencies (the CUF indicator can help in this process).

- -

- Quantify the impact of maintenance and reliability improvement actions in terms of financial indicators. It is important to consider that the continuous improvement process encompasses action plans throughout all phases of the life cycle of physical assets (from conceptual engineering, design, selection, purchase, installation, operation, maintenance and decommissioning).

- -

- Consolidate a process in SAP PM that integrates technical indicators with cost risk benefit optimization indicators at the maintainable item level (providing the scenario to analyze the economic impact that failures could generate in the medium and long term within the operational process).

- -

- Develop a comprehensive process to evaluate systemic indicators of Reliability, Maintainability and Availability and analyze the economic impact of these indicators on the total life cycle costs of critical assets.

- -

- Promote that the Reliability Engineering Management applies in an orderly manner the Maintenance and Reliability Management Model (MMM), explained in Figure 3, orientate the roles and functions of the Reliability personnel, to cover the 8 phases of the MMM, having as final objective to help maximize the value of SMI/SINEA/PERU's assets. To cover this recommendation, "the human resources management together with the Asset Integrity Management", should evaluate the possibility of executing a pilot project to implement the MMM, covering the 8 phases of the model (estimated execution time 2- 3 years).

- a)

- To frame the use of the different Reliability and Maintenance optimization methodologies within an integral process of improvement of the Asset Management of the whole organization, and not as an isolated initiative of the maintenance area.

- b)

- The success of the implementation of Reliability and Maintenance optimization methodologies will depend fundamentally on the human resources involved, which is why special care must be taken in the induction process and in the training of the personnel who will participate in this process. "Assets are designed to do things, people make things happen. Technical aspects alone are not enough to reach the full potential of organizations. It is necessary to strengthen the human aspects: human reliability, motivation, training, natural work teams, communication, etc.

- c)

- The process of improving maintenance and reliability management should not be limited to mere fads, the organization should turn the process of implementing reliability and maintenance techniques into routine working practices that help to optimize decision making throughout the life cycle of industrial assets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Crespo Márquez, A. (2007). The maintenance management framework. Models and methods for complex systems maintenance. London: Springer Verlag.

- Woodhouse, J. Standards in asset management: PAS 55 to ISO 55000. Infrastructure Asset Management 2014, 1, 1–3. [Google Scholar] [CrossRef]

- Parra, C., and Crespo, A. (2015). Ingeniería de Mantenimiento y Fiabilidad aplicada en la Gestión de Activos. Segunda edición. INGEMAN, Escuela Superior de Ingenieros Industriales, Sevilla, España. [CrossRef]

- Crespo Márquez, P. Moreu de León, J. F. Gómez Fernández, C. Parra Márquez and M. López Campos. “The maintenance management framework”. Journal of Quality in Maintenance Engineering 2009, 15, 167–178. [Google Scholar] [CrossRef]

- Campbell JD, Jardine AKS. (2001). Maintenance excellence. New York: Marcel Dekker.

- Kaplan RS, Norton DP. The Balanced Scorecard - measures that drive performance. Harv. Bus. Rev. 1992, 70, 71–9.

- Woodhouse, J. (1996). Managing Industrial Risk. Chapman Hill Inc, London.

- Prasad Mishra, R.; Anand, D.; Kodali, R. Development of a framework for world-class maintenance systems. J. Adv. Manuf. Syst. 2006, 5, 141–165. [Google Scholar] [CrossRef]

- Roda, I.; Macchi, M. A framework to embed Asset Management in production companies. Proc. Inst. Mech. Eng. Part O: J. Risk Reliab. 2018, 232, 368–378. [Google Scholar] [CrossRef]

- Reyes-Picknell, J. (2007). An introduction to PAS 55 - Optimal Management of Physical Assets. Works Management Tutorial, London.

- Pintelon, L.M.; Gelders, L.F. Maintenance management decision making. European Journal of Operational Research 1992, 58, 301–317. [Google Scholar] [CrossRef]

- Woodward, D.G. Life Cycle Costing - Theory, Information Acquisition and Application. Int. J. Proj. Manag. 1997, 15, 335–344. [Google Scholar] [CrossRef]

- Van der Duyn Schouten, F.A.; Vanneste, S.G. Maintenance optimization of a production system with buffer capacity. Eur. J. Oper. Res. 1995, 82, 323–338. [Google Scholar] [CrossRef]

- González, J. (2004). Auditoría del Mantenimiento e Indicadores de Gestión. Editorial Fundación Confemetal, Madrid, España.

- Parra-Marquez, C., Viveros-Gunckel, P., Kristjanpoller-Rodriguez, F., Crespo-Marquez, A., Gonzalez-prida-Diaz, V. “AUDIT MODELS FOR ASSET MANAGEMENT, MAINTENANCE AND RELIABILITY PROCESSES. CASE STUDY: ELECTRICITY TRANSMISSION SECTOR”. DYNA Management, 2020, 8. [14 p.]. [CrossRef]

- Crespo Márquez, A. et al. (2020). “Defining Asset Health Indicators (AHI) to Support Complex Assets Maintenance and Replacement Strategies. A Generic Procedure to Assess Assets Deterioration”. In: Crespo Márquez, A., Macchi, M., Parlikad, A. (eds) Value Based and Intelligent Asset Management. Springer, Cham. [CrossRef]

- Serra J., De la Fuente A., Crespo A., Sola A., Guillén A., Candón E., Martínez-Galán P. (2019). “A model for lifecycle cost calculation based on asset health index”. In: International Conference on Smart Infrastructure and Construction 2019 (ICSIC), pp 91–98. ISBN 978-0-7277-6466-9. https://www.icevirtuallibrary.com/. [CrossRef]

- Parra C., González-Prida V., Candón E., De la Fuente A., Martínez-Galán P., Crespo A. (2021). “Integration of Asset Management Standard ISO 55000 with a Maintenance Management Model”. In: Crespo Márquez A., Komljenovic D., Amadi-Echendu J. (eds) 14th WCEAM Proceedings. WCEAM 2019. Lecture Notes in Mechanical Engineering. Springer, Cham. [CrossRef]

- Moubray, J. (1997). Reliability-Centered Maintenance (2nd ed.). Oxford: Butterworth-Heinemann.

- Crespo Márquez, A. (2022). “Asset Health Indexing and Life Cycle Costing. In: Digital Maintenance Management”. Springer Series in Reliability Engineering. Springer, Cham. [CrossRef]

- De la Fuente A, Crespo A, Sola A, Guillén A, Gómez J, Amadi-Echendu JE. (2021). “Planning major overhaul and equipment renovation based on asset criticality and health index”. In: Crespo Márquez A, Komljenovic D, Amadi-Echendu J (eds) 14th WCEAM proceedings, WCEAM 2019. Lecture notes in mechanical engineering. Springer, Cham. [CrossRef]

- Roda, I.; Macchi, M. A framework to embed Asset Management in production companies. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2018, 232, 368–378. [Google Scholar] [CrossRef]

- Carnero, M.C. Auditing model for the introduction of computerized maintenance management systems. Int. J. Data Sci. 2015, 1, 17–41. [Google Scholar] [CrossRef]

- Parra, C., and Crespo, A. (2015). Review of the basic processes of a Maintenance and Reliability Management Model. Project: Design and Construction of the Third Set of Locks in the ACP (AUTORIDAD DEL CANAL DE PANAMÁ). Edit IngeCon – INGEMAN - MWH GLOBAL, Panamá. [CrossRef]

- Parra, C., Pineda, G., López, F., and Crespo, A. (2013). Modelo de Gestión del Mantenimiento (MGM) alineado a un proceso de Gestión de Activos. Área de estudio: Compresión y Transporte de Gas. Editado por INGECON, Colombia. [CrossRef]

- Internet: BSI. British Standard Institution at http://www.bsigroup.com/ [accessed September 2022].

- Internet: IAM. Institute of Asset Management at http://www.theiam.org/ [accessed September 2022].

- Internet: TWPL. The Woodhouse Partnership at http://www.twpl.com/ [accessed October 2018].

- UNE EN 16646 (2014): Maintenance in Physical Asset Management.

- UNE EN 13306 (2002): Maintenance Terminology.

- PAS 55-1, 2004. Asset Management. Specification for the optimized management of physical infrastructure assets. BSI: United Kingdom.

- PAS 55-2, 2004. Asset Management. Guidelines for the application of PAS 55-1. BSI: United Kingdom.

- PAS 55-1, 2008. Asset management. Specification for the optimized management of physical assets. BSI: United Kingdom.

- PAS 55-2, 2008. Asset management. Guidelines for application of PAS 55-1. BSI: United Kingdom.

- ISO 55000: 2014, Asset management - Overview, principles and terminology.

- ISO 55001: 2014, Asset management - Management systems - Requirements.

- ISO 55002: 2014, Asset management - Management systems - Guidelines on the application of ISO 55001.

| AMORMS audit rating scale | |

| 0 - 1 | Very poor process |

| 1 - 2 | Below-average process |

| 2 - 3 | Average standard process |

| 3 - 4 | Process with very good practices |

| 4 - 5 | World Class Process |

| AMORMS Results | |

| 2.16 | Asset Management, Business Objectives (KPIS) and support organization |

| 2.23 | Risk-based Ranking Models (criticality of equipment) |

| 1.96 | Problem analysis (fault management) |

| 1.87 | Programming and planning processes |

| 2.19 | Resource allocation, IT and logistical support processes |

| 1.89 | Control processes and analysis of technical indicatorsRAM |

| 1.78 | Life cycle cost analysis process |

| 2.18 | Review and continuous improvement processes |

| Indicators Technicals/Economics |

Before the implementation of the MMM (2023) | After the implementation of the MMM (2025) |

| MTTF: mean time to failure, hours | 210 hours | 260 hours |

| FF: failure frequency, failures/year | 44 failures/year | 33 failures/year |

| MDT: mean down time, hours/failure | 16 hours/failure | 12 hours/failure |

| A: operational availability, % | 92,9% | 95,5% |

| TDT: total down time/year, hours/year | 704 hours/year | 396 hours/year |

| CM/CP: maintenance costs/production costs, % | 27% | 21% |

| CUF: opportunity costs due to unavailability due to failures, dollars/year | 1.200 dollars/hour x 704 hours/year: 844.800 dollars/year |

1.200 dollars/hour x 396 hours/year: 369.600 dollars/year |

| Project costs/year, dollars/year | 83.000 dollars/year | |

| Savings due to decrease in CUF, dollars/year | (844.800 - 369.600 - 83.000) dollars/year = 392.200 dollars/year |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).