Submitted:

22 October 2024

Posted:

22 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Background

1.2. Method

- First, this review study examines the diverse applications of 3D printing in smart textiles, providing a detailed analysis of the materials used across various sectors, including wearable technology, medical textiles, and smart fashion design.

- Second, this review paper presents a summary that consolidates this information, offering readers a clear and concise overview of the materials used in 3D printing for smart textiles across these domains, facilitating a quick yet comprehensive understanding of the field.

2. Application of 3D Printing in Smart Textiles

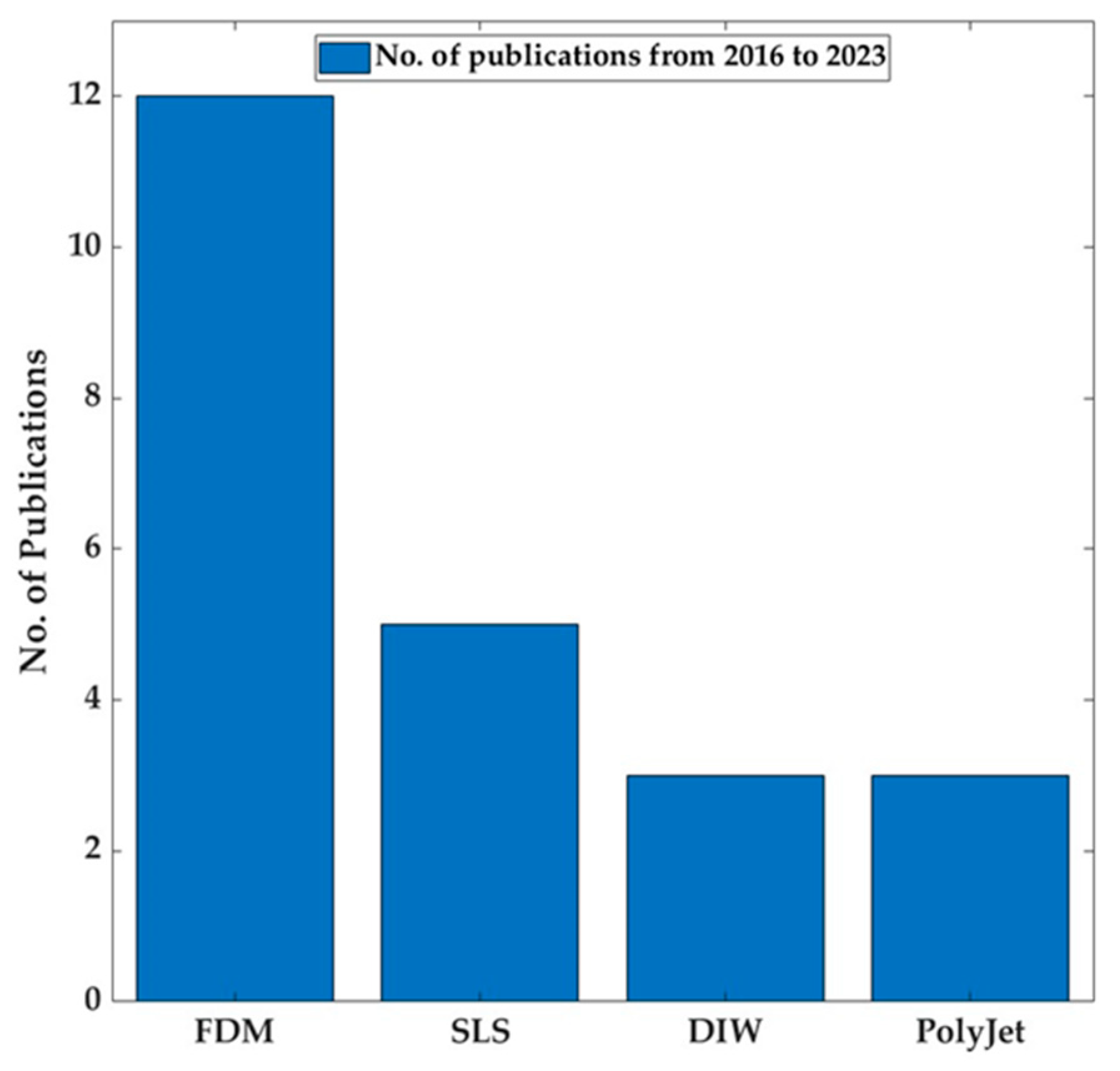

2.1. Fused Filament Fabrication

2.2. Selective Laser Sintering (SLS)

2.3. Direct Ink Writing (DIW)

2.4. PolyJet: Material Jetting

2.5. Summary of 3D-Printed Methods and Materials in Smart Textiles

3. Discussion and Technical Challenges

4. Conclusion and Future Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tuli, N.T.; Khatun, S.; Rashid, A. Bin Unlocking the Future of Precision Manufacturing: A Comprehensive Exploration of 3D Printing with Fiber-Reinforced Composites in Aerospace, Automotive, Medical, and Consumer Industries. Heliyon 2024, 10, e27328. [Google Scholar] [CrossRef] [PubMed]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers (Basel). 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Vanderploeg, A.; Lee, S.-E.; Mamp, M. The Application of 3D Printing Technology in the Fashion Industry. Int. J. Fash. Des. Technol. Educ. 2017, 10, 170–179. [Google Scholar] [CrossRef]

- Pasricha, A.; Greeninger, R. Exploration of 3D Printing to Create Zero-Waste Sustainable Fashion Notions and Jewelry. Fash. Text. 2018, 5, 30. [Google Scholar] [CrossRef]

- Manaia, J.P.; Cerejo, F.; Duarte, J. Revolutionising Textile Manufacturing: A Comprehensive Review on 3D and 4D Printing Technologies. Fash. Text. 2023, 10, 20. [Google Scholar] [CrossRef]

- Takagi, T. Present State and Future of the Intelligent Materials and Systems in Japan. J. Intell. Mater. Syst. Struct. 1999, 10, 575–581. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Cayla, A.; Chen, Y.; Guan, J.; Nierstrasz, V.; Campagne, C. Development of Flexible and Conductive Immiscible Thermoplastic/Elastomer Monofilament for Smart Textiles Applications Using 3D Printing. Polymers (Basel). 2020, 12, 2300. [Google Scholar] [CrossRef]

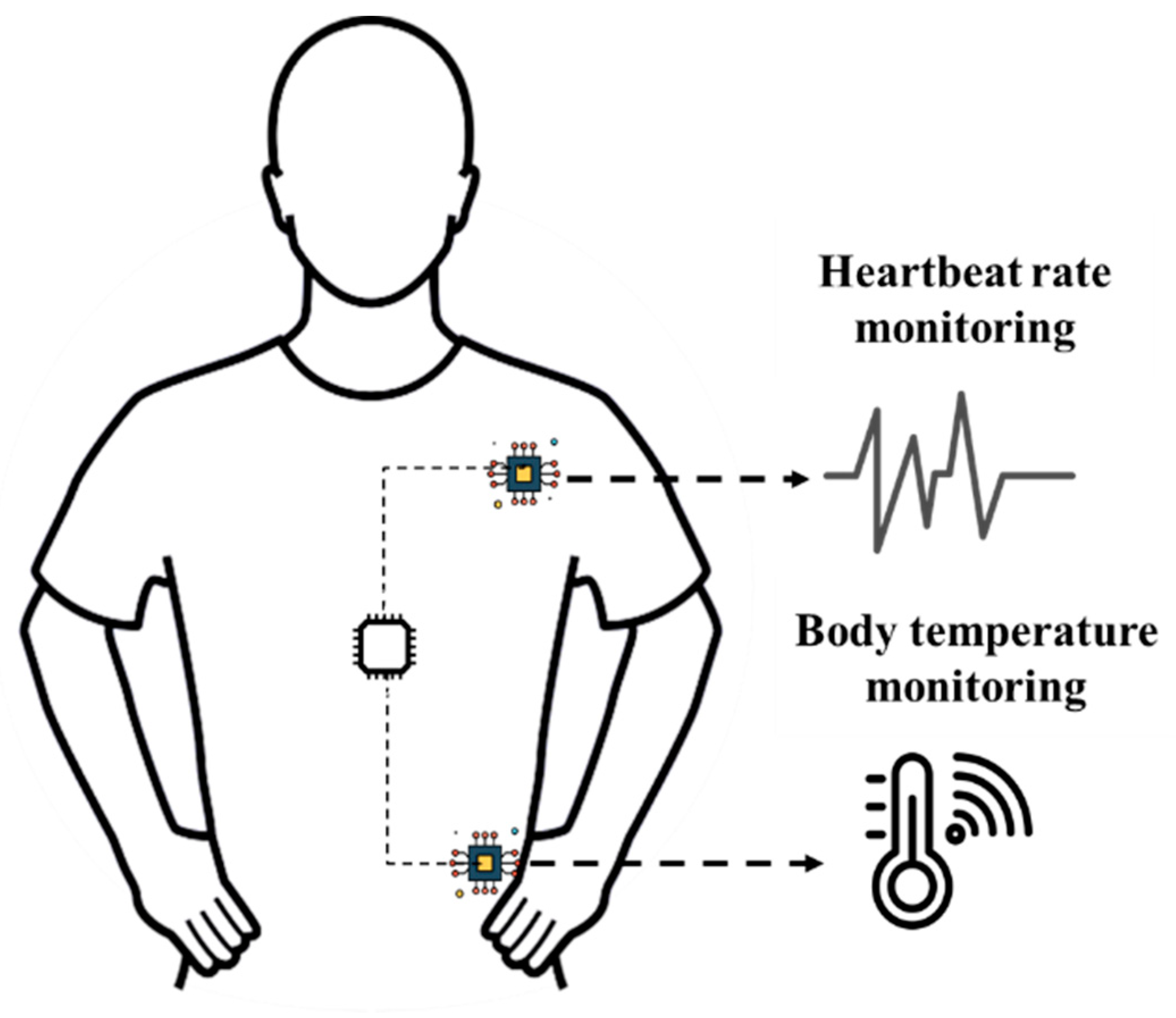

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef]

- Xu, D.; Ouyang, Z.; Dong, Y.; Yu, H.-Y.; Zheng, S.; Li, S.; Tam, K.C. Robust, Breathable and Flexible Smart Textiles as Multifunctional Sensor and Heater for Personal Health Management. Adv. Fiber Mater. 2023, 5, 282–295. [Google Scholar] [CrossRef]

- Bunea, A.-C.; Dediu, V.; Laszlo, E.A.; Pistriţu, F.; Carp, M.; Iliescu, F.S.; Ionescu, O.N.; Iliescu, C. E-Skin: The Dawn of a New Era of On-Body Monitoring Systems. Micromachines 2021, 12, 1091. [Google Scholar] [CrossRef]

- Xiao, Y.-Q.; Kan, C.-W. Review on Development and Application of 3D-Printing Technology in Textile and Fashion Design. Coatings 2022, 12, 267. [Google Scholar] [CrossRef]

- Komolafe, A.; Zaghari, B.; Torah, R.; Weddell, A.S.; Khanbareh, H.; Tsikriteas, Z.M.; Vousden, M.; Wagih, M.; Jurado, U.T.; Shi, J.; et al. E-Textile Technology Review–From Materials to Application. IEEE Access 2021, 9, 97152–97179. [Google Scholar] [CrossRef]

- Tan, W.S.; Suwarno, S.R.; An, J.; Chua, C.K.; Fane, A.G.; Chong, T.H. Comparison of Solid, Liquid and Powder Forms of 3D Printing Techniques in Membrane Spacer Fabrication. J. Memb. Sci. 2017, 537, 283–296. [Google Scholar] [CrossRef]

- Muthuram, N.; Sriram Madhav, P.; Keerthi Vasan, D.; Mohan, M.E.; Prajeeth, G. A Review of Recent Literatures in Poly Jet Printing Process. Mater. Today Proc. 2022, 68, 1906–1920. [Google Scholar] [CrossRef]

- de Albuquerque, T.L.; Marques Júnior, J.E.; de Queiroz, L.P.; Ricardo, A.D.S.; Rocha, M.V.P. Polylactic Acid Production from Biotechnological Routes: A Review. Int. J. Biol. Macromol. 2021, 186, 933–951. [Google Scholar] [CrossRef]

- Franco Urquiza, E.A. Advances in Additive Manufacturing of Polymer-Fused Deposition Modeling on Textiles: From 3D Printing to Innovative 4D Printing—A Review. Polymers (Basel). 2024, 16, 700. [Google Scholar] [CrossRef]

- Goncu-Berk, G. 3D Printing of Conductive Flexible Filaments for E-Textile Applications. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1266, 012001. [Google Scholar] [CrossRef]

- Hart, K.R.; Wetzel, E.D. Fracture Behavior of Additively Manufactured Acrylonitrile Butadiene Styrene (ABS) Materials. Eng. Fract. Mech. 2017, 177, 1–13. [Google Scholar] [CrossRef]

- Awasthi, P.; Banerjee, S.S. Fused Deposition Modeling of Thermoplastic Elastomeric Materials: Challenges and Opportunities. Addit. Manuf. 2021, 46, 102177. [Google Scholar] [CrossRef]

- Arioli, M.; Puiggalí, J.; Franco, L. Nylons with Applications in Energy Generators, 3D Printing and Biomedicine. Molecules 2024, 29, 2443. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers (Basel). 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Wilson, S.; Laing, R. Fabrics and Garments as Sensors: A Research Update. Sensors 2019, 19, 3570. [Google Scholar] [CrossRef] [PubMed]

- Mwema, F.M.; Akinlabi, E.T.; Mwema, F.M.; Akinlabi, E.T. Basics of Fused Deposition Modelling (FDM). Fused Depos. Model. Strateg. Qual. Enhanc. 2020, 1–15. [Google Scholar]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of Fused Deposition Modeling Process Parameters: A Review of Current Research and Future Prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P.; Iuliano, L.; Fino, P. Overview on Additive Manufacturing Technologies. Proc. IEEE 2017, 105, 593–612. [Google Scholar] [CrossRef]

- Mogan, J.; Harun, W.S.W.; Kadirgama, K.; Ramasamy, D.; Foudzi, F.M.; Sulong, A.B.; Tarlochan, F.; Ahmad, F. Fused Deposition Modelling of Polymer Composite: A Progress. Polymers (Basel). 2022, 15, 28. [Google Scholar] [CrossRef]

- Čuk, M.; Bizjak, M.; Muck, D.; Kočevar, T.N. 3D Printing and Functionalization of Textiles. Int. Symp. Graph. Eng. Des. 2020, 499–506. [Google Scholar] [CrossRef]

- Morehead, S.; Oliver, R.; O’Connor, N.; Stevenson-Keating, P.; Toomey, A.; Wallace, J. The Power of ‘Soft’. MRS Adv. 2016, 1, 69–80. [Google Scholar] [CrossRef]

- Gowthaman, S.; Chidambaram, G.S.; Rao, D.B.G.; Subramya, H.V.; Chandrasekhar, U. A Review on Energy Harvesting Using 3D Printed Fabrics for Wearable Electronics. J. Inst. Eng. Ser. C 2018, 99, 435–447. [Google Scholar] [CrossRef]

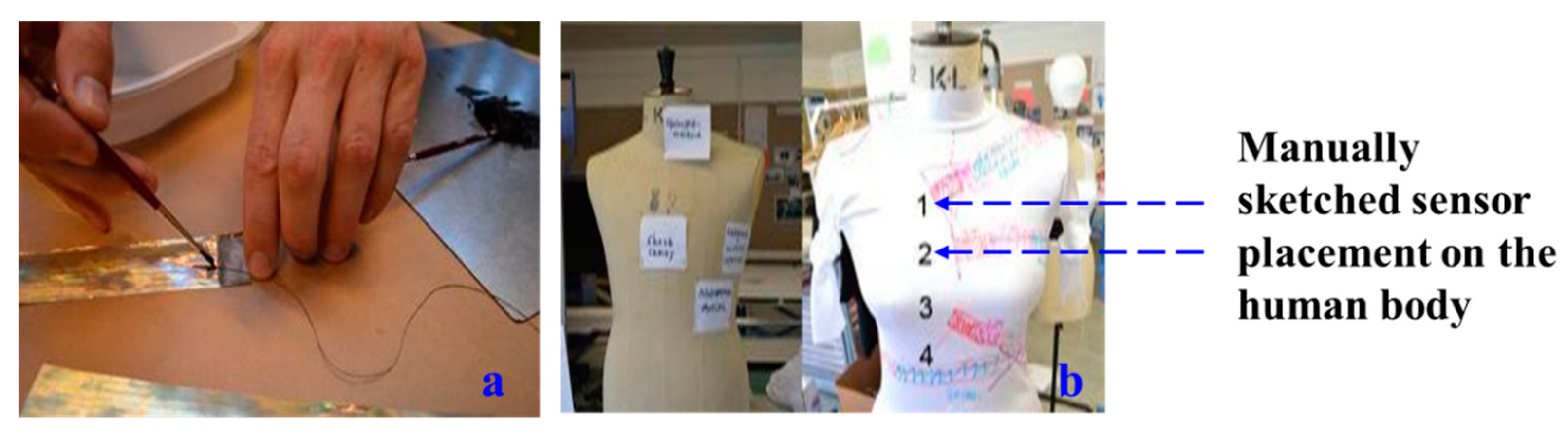

- Grimmelsmann, N.; Martens, Y.; Schäl, P.; Meissner, H.; Ehrmann, A. Mechanical and Electrical Contacting of Electronic Components on Textiles by 3D Printing. Procedia Technol. 2016, 26, 66–71. [Google Scholar] [CrossRef]

- Leist, S.K.; Gao, D.; Chiou, R.; Zhou, J. Investigating the Shape Memory Properties of 4D Printed Polylactic Acid (PLA) and the Concept of 4D Printing onto Nylon Fabrics for the Creation of Smart Textiles. Virtual Phys. Prototyp. 2017, 12, 290–300. [Google Scholar] [CrossRef]

- Ly, S.T.; Kim, J.Y. 4D Printing – Fused Deposition Modeling Printing with Thermal-Responsive Shape Memory Polymers. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 267–272. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.; Cayla, A.; Campagne, C.; Zeng, X.; Nierstrasz, V. Optimization of Adhesion of Poly Lactic Acid 3D Printed onto Polyethylene Terephthalate Woven Fabrics through Modelling Using Textile Properties. Rapid Prototyp. J. 2019, 26, 390–401. [Google Scholar] [CrossRef]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.; Cayla, A.; Campagne, C.; Zeng, X.; Nierstrasz, V. Stress, Strain and Deformation of Poly-Lactic Acid Filament Deposited onto Polyethylene Terephthalate Woven Fabric through 3D Printing Process. Sci. Rep. 2019, 9, 14333. [Google Scholar] [CrossRef] [PubMed]

- Eutionnat-Diffo, P.A.; Chen, Y.; Guan, J.; Cayla, A.; Campagne, C.; Nierstrasz, V. Study of the Wear Resistance of Conductive Poly Lactic Acid Monofilament 3D Printed onto Polyethylene Terephthalate Woven Materials. Materials (Basel). 2020, 13, 2334. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Kim, J. 4D-Printing — Fused Deposition Modeling Printing and PolyJet Printing with Shape Memory Polymers Composite. Fibers Polym. 2020, 21, 2364–2372. [Google Scholar] [CrossRef]

- Hofmann, A.I.; Östergren, I.; Kim, Y.; Fauth, S.; Craighero, M.; Yoon, M.-H.; Lund, A.; Müller, C. All-Polymer Conducting Fibers and 3D Prints via Melt Processing and Templated Polymerization. ACS Appl. Mater. Interfaces 2020, 12, 8713–8721. [Google Scholar] [CrossRef]

- Ertuna, I.; Güngör, Y.; Karaoğlu, F.; Dindar, N.; Topçu, U.C.; Çaliş, G.; Göde, D.D.C. Design and Production of Smart Wearable Textile Products Using Layered Manufacturing Technology with Photovoltaic Energy. South Florida J. Dev. 2021, 2, 1636–1644. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, Y.; Jia, S.; Zhang, C.; Li, P.; Zhang, Y.; Li, Q. 3D-Printed Flexible Phase-Change Nonwoven Fabrics toward Multifunctional Clothing. ACS Appl. Mater. Interfaces 2022, 14, 7283–7291. [Google Scholar] [CrossRef]

- Kruth, J.P.; Wang, X.; Laoui, T.; Froyen, L. Lasers and Materials in Selective Laser Sintering. Assem. Autom. 2003, 23, 357–371. [Google Scholar] [CrossRef]

- Kim, S.; Seong, H.; Her, Y.; Chun, J. A Study of the Development and Improvement of Fashion Products Using a FDM Type 3D Printer. Fash. Text. 2019, 6, 9. [Google Scholar] [CrossRef]

- Kruth, J.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding Mechanisms in Selective Laser Sintering and Selective Laser Melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- Rosenkrantz, J.; Louis-Rosenberg, J. Dress/Code Democratising Design Through Computation and Digital Fabrication. Archit. Des. 2017, 87, 48–57. [Google Scholar] [CrossRef]

- Bloomfield, M.; Borstrock, S. Modeclix. The Additively Manufactured Adaptable Textile. Mater. Today Commun. 2018, 16, 212–216. [Google Scholar] [CrossRef]

- Beecroft, M. Digital Interlooping: 3D Printing of Weft-Knitted Textile-Based Tubular Structures Using Selective Laser Sintering of Nylon Powder. Int. J. Fash. Des. Technol. Educ. 2019, 12, 218–224. [Google Scholar] [CrossRef]

- Ukobitz, D.; Faullant, R. Leveraging 3D Printing Technologies: The Case of Mexico’s Footwear Industry. Res. Manag. 2021, 64, 20–30. [Google Scholar] [CrossRef]

- Paek, S.W.; Balasubramanian, S.; Stupples, D. Composites Additive Manufacturing for Space Applications: A Review. Materials (Basel). 2022, 15, 4709. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Busolo, T.; Kar-Narayan, S.; Stachewicz, U. Wear-Resistant Smart Textiles Using Nylon-11 Triboelectric Yarns. ACS Appl. Mater. Interfaces 2023, 15, 56575–56586. [Google Scholar] [CrossRef]

- Sharma, V.; Roozbahani, H.; Alizadeh, M.; Handroos, H. 3D Printing of Plant-Derived Compounds and a Proposed Nozzle Design for the More Effective 3D FDM Printing. IEEE Access 2021, 9, 57107–57119. [Google Scholar] [CrossRef]

- Nocheseda, C.J.C.; Fazley Elahee, G.M.; Santos, M.F.A.; Cheng, X.; Espera, A.H.; Advincula, R.C. On the 3D Printability of One-Part Moisture-Curable Polyurethanes via Direct Ink Writing (DIW). MRS Commun. 2023, 13, 647–656. [Google Scholar] [CrossRef]

- Hou, Z.; Lu, H.; Li, Y.; Yang, L.; Gao, Y. Direct Ink Writing of Materials for Electronics-Related Applications: A Mini Review. Front. Mater. 2021, 8, 1–8. [Google Scholar] [CrossRef]

- Wan, X.; Luo, L.; Liu, Y.; Leng, J. Direct Ink Writing Based 4D Printing of Materials and Their Applications. Adv. Sci. 2020, 7, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Palanisamy, S.; Tunakova, V.; Militky, J. Fiber-Based Structures for Electromagnetic Shielding – Comparison of Different Materials and Textile Structures. Text. Res. J. 2018, 88, 1992–2012. [Google Scholar] [CrossRef]

- Tay, R.Y.; Song, Y.; Yao, D.R.; Gao, W. Direct-Ink-Writing 3D-Printed Bioelectronics. Mater. Today 2023, 71, 135–151. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, Z.; Ouyang, R.; Zheng, R.; Jiang, Z.; Bai, H.; Xue, H. 3D Printed Stretchable Smart Fibers and Textiles for Self-Powered e-Skin. Nano Energy 2021, 84, 105866. [Google Scholar] [CrossRef]

- Zhang, C.; Ouyang, W.; Zhang, L.; Li, D. A Dual-Mode Fiber-Shaped Flexible Capacitive Strain Sensor Fabricated by Direct Ink Writing Technology for Wearable and Implantable Health Monitoring Applications. Microsystems Nanoeng. 2023, 9. [Google Scholar] [CrossRef]

- Badar, F.; Vandi, L.-J.; Carluccio, D.; Redmond, M.; Novak, J.I. Preliminary Colour Characterisation of a Stratasys J750 Digital Anatomy Printer with Different Fillings and Face Orientations. Prog. Addit. Manuf. 2024, 9, 1277–1287. [Google Scholar] [CrossRef]

- Farahi, B. Caress of the Gaze: A Gaze Actuated 3D Printed Body Architecture. ACADIA 2016 Posthuman Front. Data, Des. Cogn. Mach. - Proc. 36th Annu. Conf. Assoc. Comput. Aided Des. Archit. 2016, 352–361. [CrossRef]

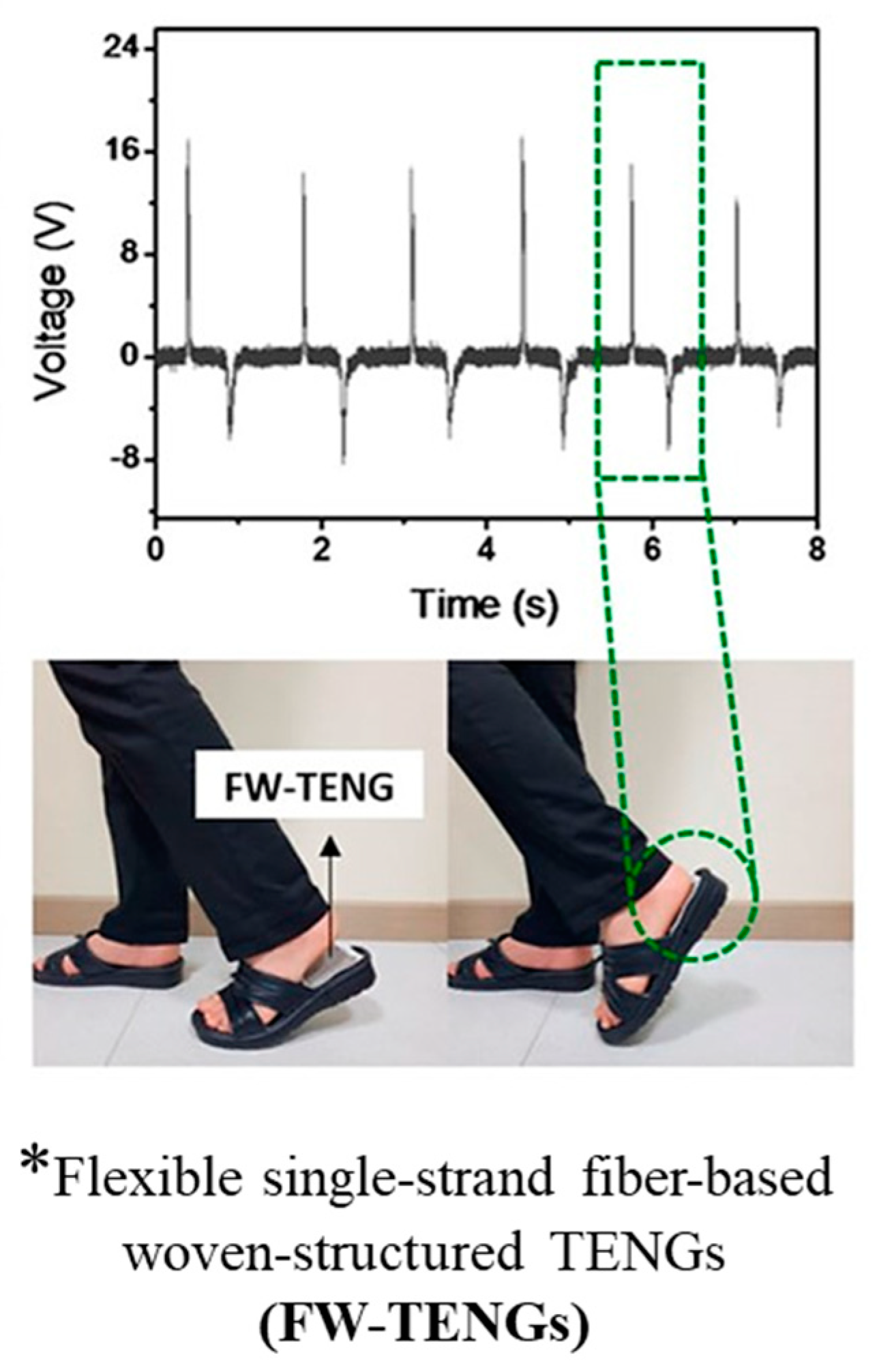

- Park, J.; Kim, D.; Choi, A.Y.; Kim, Y.T. Flexible Single-Strand Fiber-Based Woven-Structured Triboelectric Nanogenerator for Self-Powered Electronics. APL Mater. 2018, 6. [Google Scholar] [CrossRef]

- Diatezo, L.; Le, M.Q.; Tonellato, C.; Puig, L.; Capsal, J.F.; Cottinet, P.J. Development and Optimization of 3D-Printed Flexible Electronic Coatings: A New Generation of Smart Heating Fabrics for Automobile Applications. Micromachines 2023, 14. [Google Scholar] [CrossRef]

- Kočevar, T.N. 3D Printing on Textiles – Overview of Research on Adhesion to Woven Fabrics. Tekstilec 2023, 66, 164–177. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers (Basel). 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

- Dias, D.; Paulo Silva Cunha, J. Wearable Health Devices—Vital Sign Monitoring, Systems and Technologies. Sensors 2018, 18, 2414. [Google Scholar] [CrossRef] [PubMed]

| 3D printing Methods | Materials | Applications in smart textiles |

|---|---|---|

| FDM | Dielectric Electroactive Polymer |

Wearable smart sensor for monitoring deep breathing [28]. |

| Not specified | Energy-harvesting fabric [29]. | |

| PLA, Nylon, conductive PLA | Smart textiles with thermal shape memory behavior [31]. Conductive PLA to create conductive wires [30]. |

|

|

Polyurethane-based SMP, LDPE |

Thermal-responsive smart textiles [26]. Developed conductive and flexible monofilaments for integration into smart textiles [7]. |

|

| PLA, PET | Stress, Strain and deformation performance in FDM-printed fabrics [33,34]. | |

| PLA monofilament, PET | Conductive smart textiles with wear resistance [35]. | |

| PEDOT | Energy-harvesting smart textiles [37]. | |

| SWNT-embedded hydrophobic filaments |

Phase-change nonwoven fabric for breathable, flexible smart textiles [39]. | |

| SLS | Nylon powder | Convertible petal dress with complex geometric structures [43]. |

| Nylon powder | Flexible textile production without support elements [45]. | |

| Nylon | Prototype development for athletic footwear and gear [46]. | |

| Nylon | Chainmail patterns for apparel [44]. | |

| Metal-woven material | Foldable material for space transportation [47]. | |

| Nylon-11 | Triboelectric yarns for energy harvesting in smart textiles [48]. | |

| DIW | Conductive inks | Enhancing smart textiles’ functionality with color changing capabilities [53]. |

| Not specified | Energy management in smart textiles [54]. | |

| PDMS, graphene, and PTFE | stretchable smart fibers and textiles for self-powered electronic skin (e-skin) [55]. | |

| PolyJet | Photopolymer resins | Interactive textiles responding to eye-gaze [58] |

| Not specified | Self-powered textiles from mechanical movement [59]. | |

| Carbon composite | Smart heating fabrics for heated automobile seats [60]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).