1. Introduction

Compressive strength is the primary criterion for concrete quality control, as it effectively reflects the integrity of its internal structure and is a relatively straightforward technical test. Since World War II, there has been significant interest in methods for rapidly assessing in-situ concrete strength by monitoring temperature changes over time. The theoretical foundations and experimental results of these methods have been extensively documented in various studies, including review publications [

1,

2]. The literature on concrete maturity contains numerous studies on predicting early-age strength [

12], as well as many investigations into predicting late-age strength using modified maturity models [

22]. Several models have been developed addressing two key issues: the maturity index-temperature-time relationship and the strength-maturity relationship (

Table 1).

In general, when modeling the strength-maturity relationship in concrete, some researchers have prioritized creating simplified mathematical descriptions, while others have focused on minimizing estimation errors through regression analysis of test data [

1,

20]. Many authors [

20,

21,

22] have also proposed the use of correction factors to improve the accuracy of these models.

The Hansen and Petersen function [

8] is regarded as one of the most advanced models, linking concrete strength to the maturity measure, represented as the equivalent maturing time (te). This function, similar to the Arrhenius function, includes a parameter called activation energy (Ea), which reflects a cement’s sensitivity to curing temperature. While this concept is straightforward, it is unlikely that a single parameter can fully capture the complexities of a material as intricate as cement.

Various analyses of theoretical and experimental results often yield differing conclusions regarding the value of the Ea coefficient. This value depends not only on the type of cement but also on the water-to-cement ratio (e.g., OPC vs. HPC concrete), temperature [

14][V-H], and the presence of additives and admixtures.

The Ea coefficient can be determined through strength tests [

29] or by calorimetric measurements of the heat released during hydration [

15]. Wirtquin [

15,

16] proposed a method for determining activation energy by measuring cement hydration heat. Earlier, Venuant [

17] demonstrated a strong correlation between hydration heat and mortar strength. Similarly, Kurdowski and Pichniarczyk [

18] found a strong correlation between the hydration heat of various CEM I cements and their strength after 2 and 28 days.

For more complex relationships, an alternative to traditional statistical methods (where the functional form is known) is the use of artificial neural networks (ANNs). These "black box" methods have been successfully applied for over 30 years to solve various material and technological challenges [

23]. ANN analysis has been used to model the relationship between mortar strength and various compositional factors [

24,

25,

26,

27,

28].

In this paper, a different approach is explored to address strength-maturity relationships. An ANN model was developed as an implicit form of the regression function to encompass the entire problem. The research aimed to answer the following questions:

- a)

Can the ANN method produce a model that accurately describes the relationship between mortar strength, temperature, and time?

- b)

Does incorporating two predictive parameters—heat of hydration (Q) and activation energy (Ea)—into the model improve its description of mortar strength development, both at early and late ages?

- c)

How can the ANN-based model, fc%-f(Q, E, T, t), be used to calculate the relative strength of mortar as it depends on variations in curing temperature and time?

2. Materials and Methods

The research programme (

Table 2) involved measuring the compressive strength of the mortar cured at three different temperatures: 5 ° C, 20 ° C and 35 ° C. Six series of samples were prepared using six different cements (

Table 2). Based on the strength tests, the activation energy (Ea) for each cement was determined, and in the calorimetric tests, the amount of heat of hydration (Q) after 48 hours of hydration was measured. The data collected formed a dataset used to develop a regression model through artificial neural network (ANN) analysis. The development of the ANN-fc%=f(Q, E, T, t) model aimed to predict the of the mortar of the strength development by considering two cement parameters (Q and E) in relation to the temperature history (T) over time (t). The proposed approach sought to create a model that covers a broader range of predictive parameters (Q, E) that characterise different cements. This single model would address both the maturity index and the strength-maturity relationships.

2.1. Materials

The mortars were prepared using the following materials:

- Standard sand (0-2 mm grain size) in accordance with CEN PN-EN 196-1.

- Six different cements: five Portland cements (CEM I) and one slag cement (CEM III/A).

- A plasticiser.

The characteristics of the cements used are presented in

Table 2.

In addition, calorimetric tests were conducted on the six cements using an isothermal calorimeter to determine the amount of heat released during hydration at 20 ° C.

Table 3 shows the recorded heat (Q) after 48 hours of testing.

2.2. Mixture Proportions and Sample Preparation

Mortar tests were carried out according to the procedure described in ASTM C1074-04 [

29]. The reference material was structural concrete with a water to cement ratio (W/C) of 0.45 and a cement content (C) of 378 kg. The proportions of the mortar mixture were kept constant, using the same fine aggregate-to-cement ratio, W/C ratio, and plasticiser-to-cement amounts as in the concrete mix. The mixing and preparation of the samples were carried out at room temperature (approximately 22°C).

Six series of samples were prepared using different cements, with the series labelled according to the cement used, designated by letters A to F. In each case, a batch of mortar, approximately 15 dm³ in volume, was mixed and formed into 15 moulds, each containing three beams measuring 40x40x160 mm, totalling 45 samples. The samples were divided into three groups of five moulds, which were immediately placed in water bath. The samples were first placed in water bath with water temperatures of 5 ° C and 35°C, followed by 20 ° C. The metal moulds were partially submerged in water, about halfway up their height, to ensure rapid temperature stabilisation of the mortar. After 1-2 days, the samples were demolded and placed back into the water, where they were stored until compressive strength testing. The water in the bath was continuously circulated and kept at the specified temperature.

2.3. Compressive Strength

The compressive strength tests for the hardened mortar were performed according to PN-EN 196-1 standards. For each mortar type, strength was measured after 1, 3, 7, 14, 28, 56, and 90 days of curing at 5°C, 20°C, and 35 ° C. The samples were stored in water baths at the corresponding temperatures until compressive tests were performed. For further analysis, the compressive strength was taken as the average of four measurements.

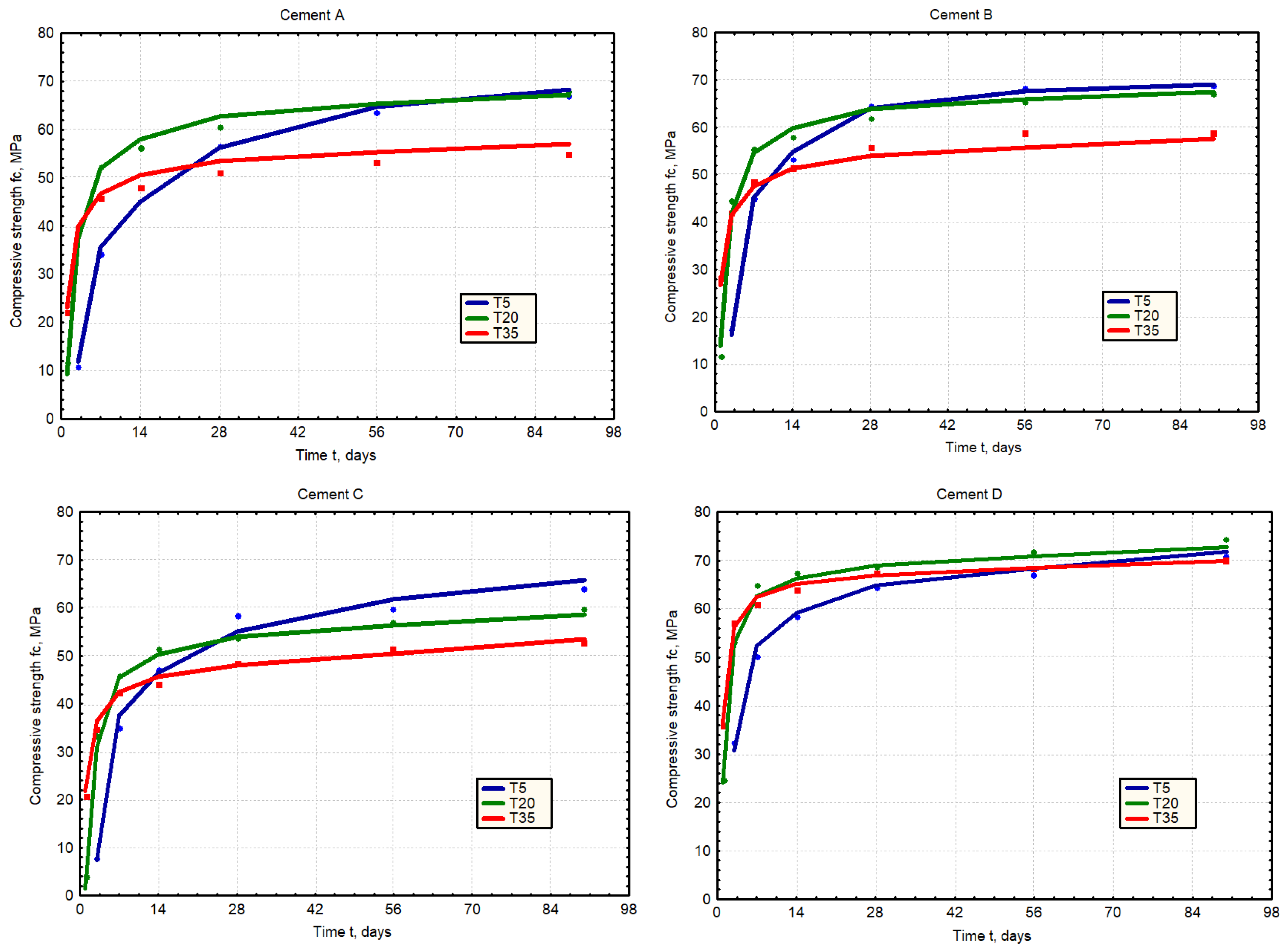

The results were plotted as points on figure 1. In the next stage of the calculations, the relative strength of the mortar was analysed as the ratio of the measured strength at a given time and the strength achieved by that mortar after 90 days of curing at 20 ° C.

On the basis of the strength tests, the activation energy (Ea) of the six cements was determined using the procedure described in ASTM C1074. For further analysis, the parameter referred to as the "activation temperature" (E), which is the activation energy divided by the gas constant, was used. The calculation results are presented in

Table 3.

Figure 1.

Relationships between the Compressive Strength of Mortars (Series A- F), the cure temperature (5 ° C, 20 ° C and 35 ° C) and time. The results of the compressive strength tests are marked as points, while the solid lines correspond to the values approximated by the ANN-fc model.

Figure 1.

Relationships between the Compressive Strength of Mortars (Series A- F), the cure temperature (5 ° C, 20 ° C and 35 ° C) and time. The results of the compressive strength tests are marked as points, while the solid lines correspond to the values approximated by the ANN-fc model.

3. Results and Discussion

3.1. ANN-Model for Prediction of Strength Development

The complex nature of the relationships between the factors under investigation makes it challenging to develop an analytical model that accurately describes their effects on the strength of the material. Therefore, an attempt was made to use artificial neural network (ANN) analysis for this purpose, utilising the QNET'97 software [

32]. In this approach, the ANN method serves as an alternative to multidimensional regression analysis. The developed neural network represents an implicit non-linear function (a "black box" relationship).

Backpropagation neural networks require that all training targets be normalised between 0 and 1, as the output node signals are restricted to this range. QNET also requires input normalisation to enhance training performance. The software automatically performs data normalization, ensuring that all input data and training targets are scaled between 0.15 and 0.85. The network outputs are then automatically adjusted to the appropriate range.

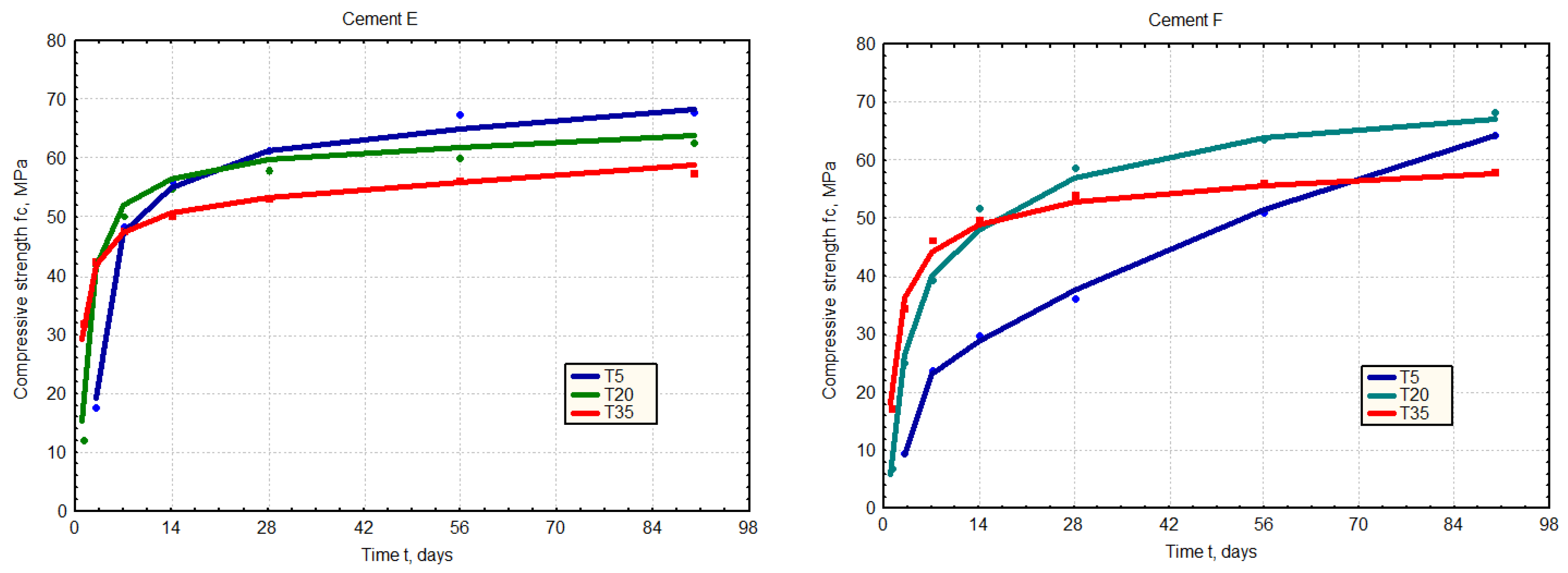

The analysis focused on the influence of four input factors on the development of compressive strength in hardened mortar (fc%):

- -

Q: Hydration heat of the cement after 48 hours, J/g,

- -

E: Activation temperature of the cement, °C,

- -

T: Temperature of the mortar, °C,

- -

t: Curing time, days.

Table 4.

Provides information on the range of variability for each of these factors.

Table 4.

Provides information on the range of variability for each of these factors.

| Input/Output |

Unit |

|

Min |

Max |

| Q |

J/g |

X1 |

173 |

302 |

| E |

°C |

X2 |

2760 |

4800 |

| T |

°C |

X3 |

5 |

35 |

| t |

days |

X4 |

1 |

56 |

| fc |

MPa |

Y1 |

3.8 |

74.3 |

| fc% |

% |

Y2 |

6.6 |

110.3 |

After conducting a series of trials, a network with a 4-[5-4]-1 structure was developed (

Figure 2).

Initially, the parameters for the neural network were determined, and the calculated compressive strength values (fc) are presented as solid lines in

Figure 1. Then, following the suggestion of Tang and Carino, the relative strength values of the mortar were calculated by dividing the compressive strength by the corresponding strength at 90 days of curing at a temperature of T=20°C (fc% = fci/fc90).

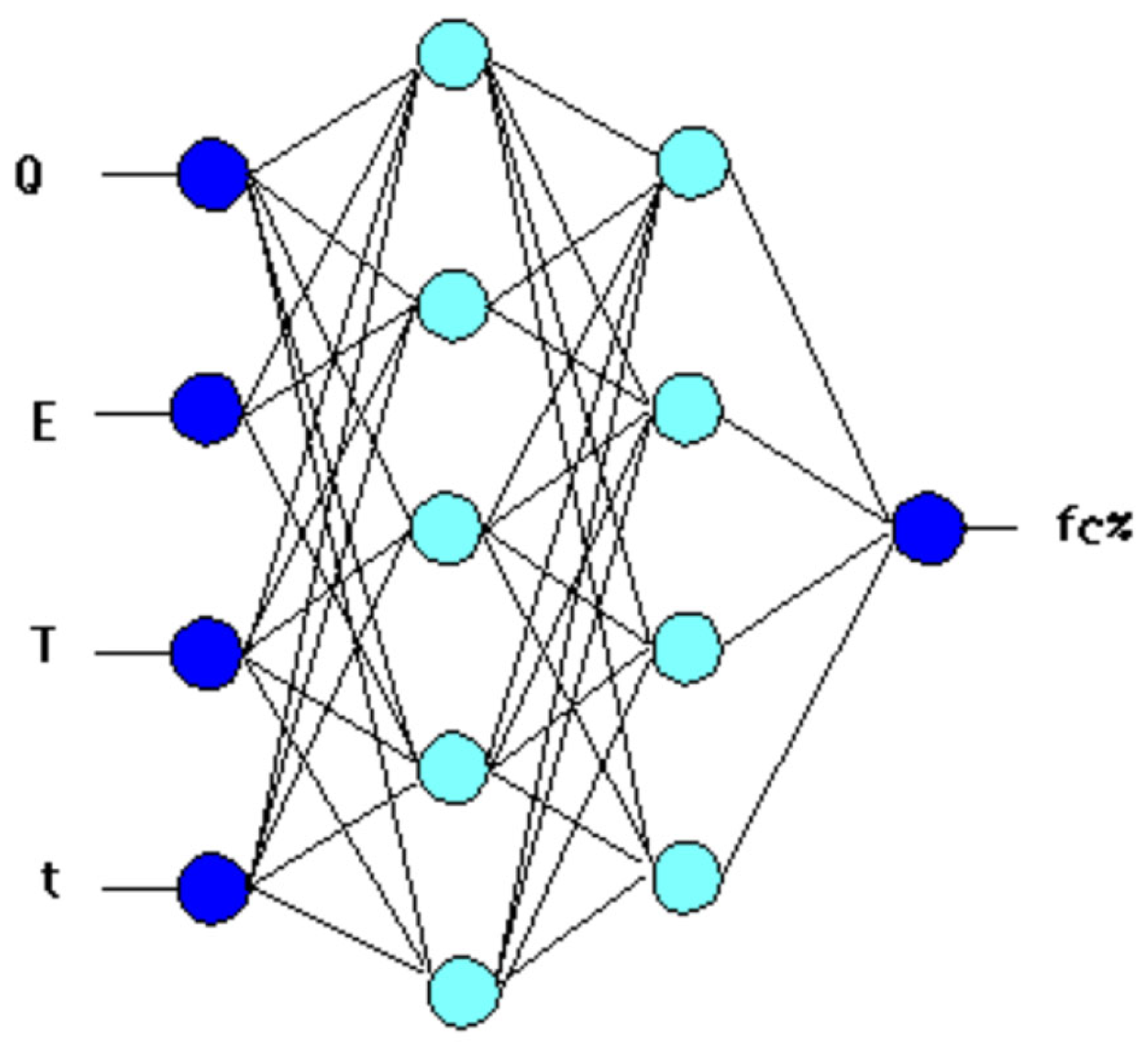

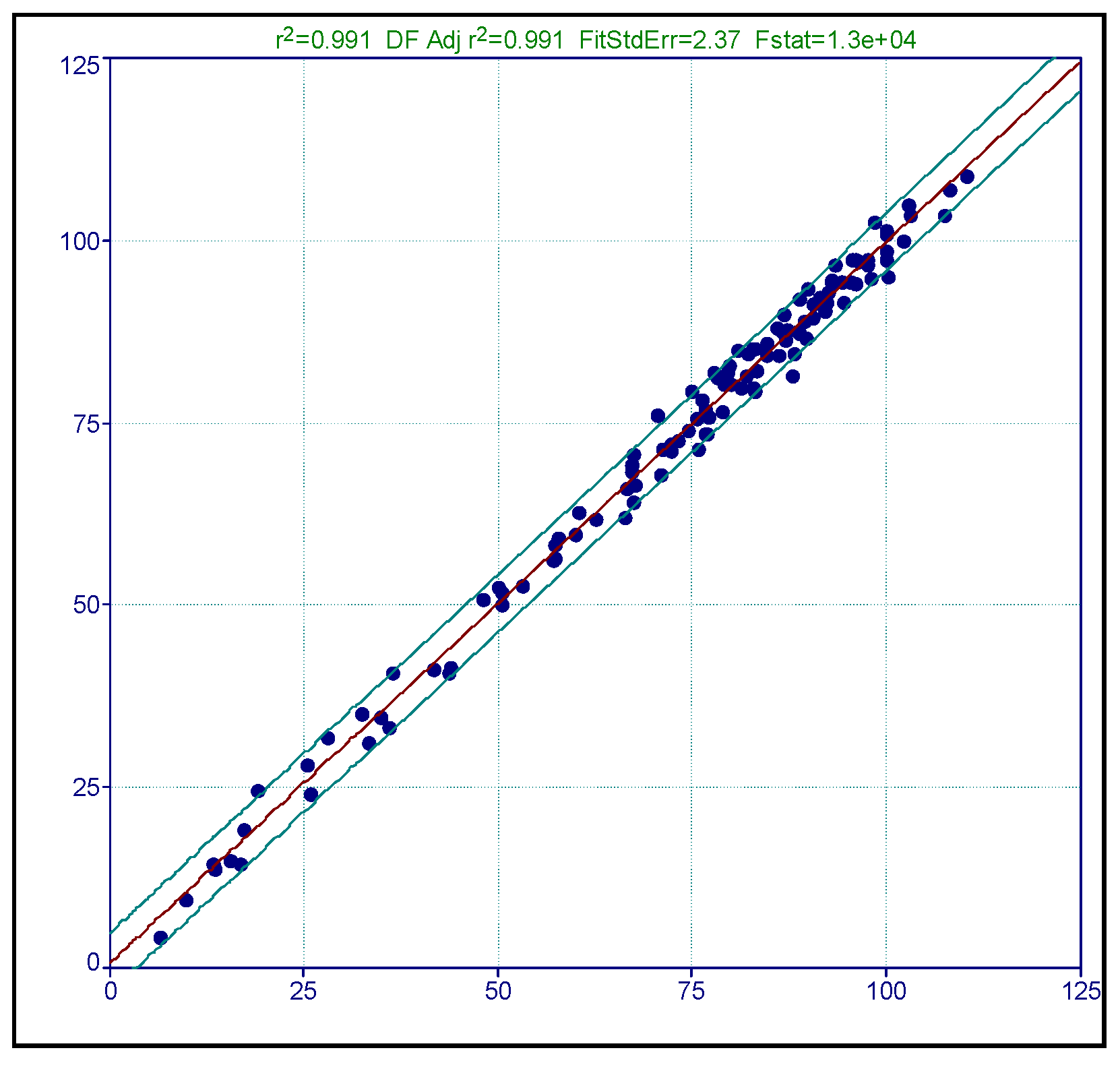

A comparison of the target and network outputs versus the pattern sequence is shown in

Figure 3. The comparison between the measured strengths and the fc% values determined using the ANN-fc% network is illustrated in

Figure 4.

The precision of the estimation related to the training and testing of the data set is presented in

Table 2.

Table 5.

Estimation of ANN-fc% model errors.

Table 5.

Estimation of ANN-fc% model errors.

| |

N |

Max. Error |

RMS Error |

Correlation |

| Training set |

104 |

6.03 |

0.0181 |

0.994 |

| Test set |

15 |

5.30 |

0. 0137 |

0.956 |

Analysing the influence of input data on the output value of fc%, we can be concluded that the most significant factors are the curing time (t), temperature (T), followed by the heat of hydration (Q), and finally, the activation parameter (E).

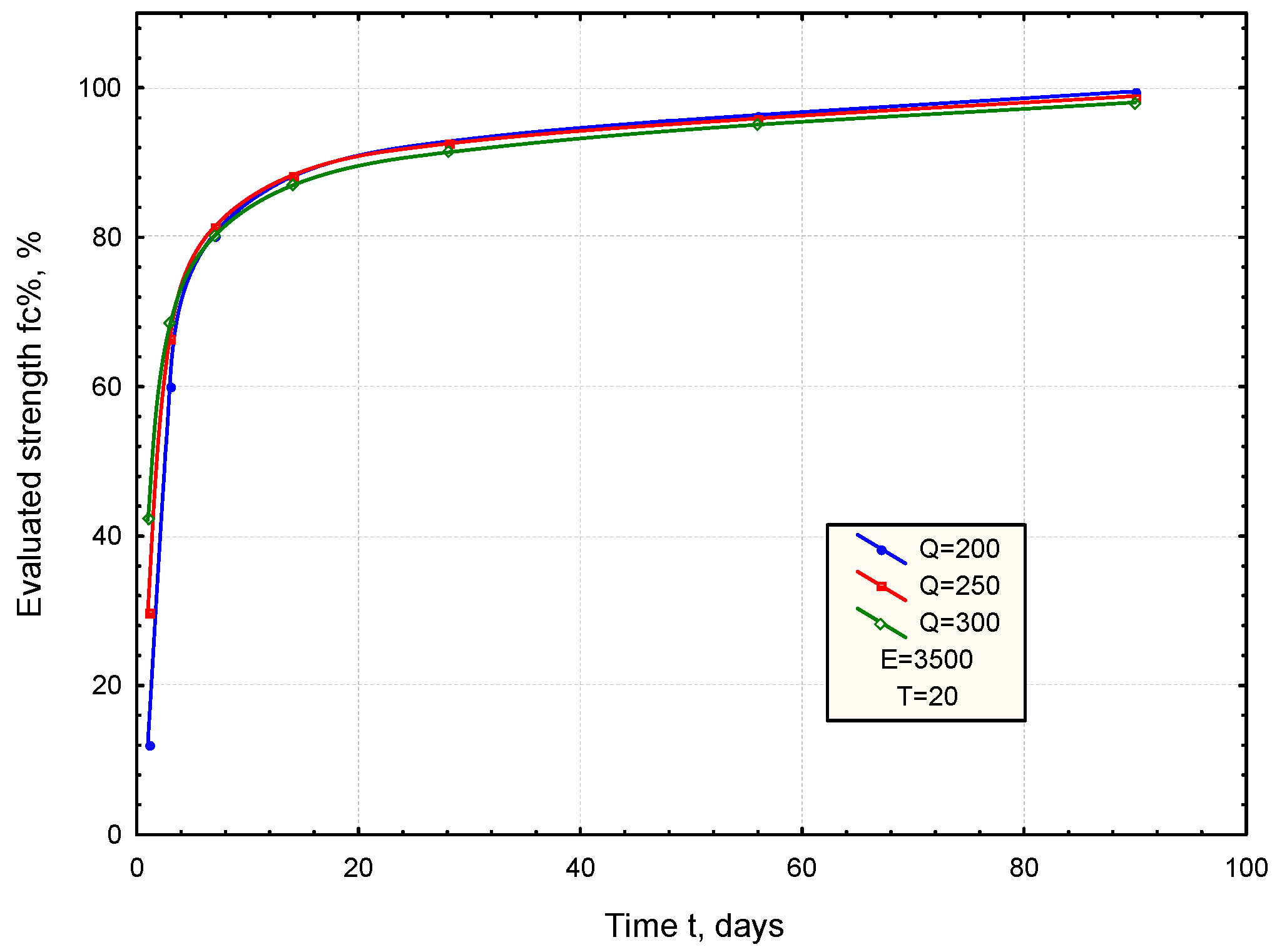

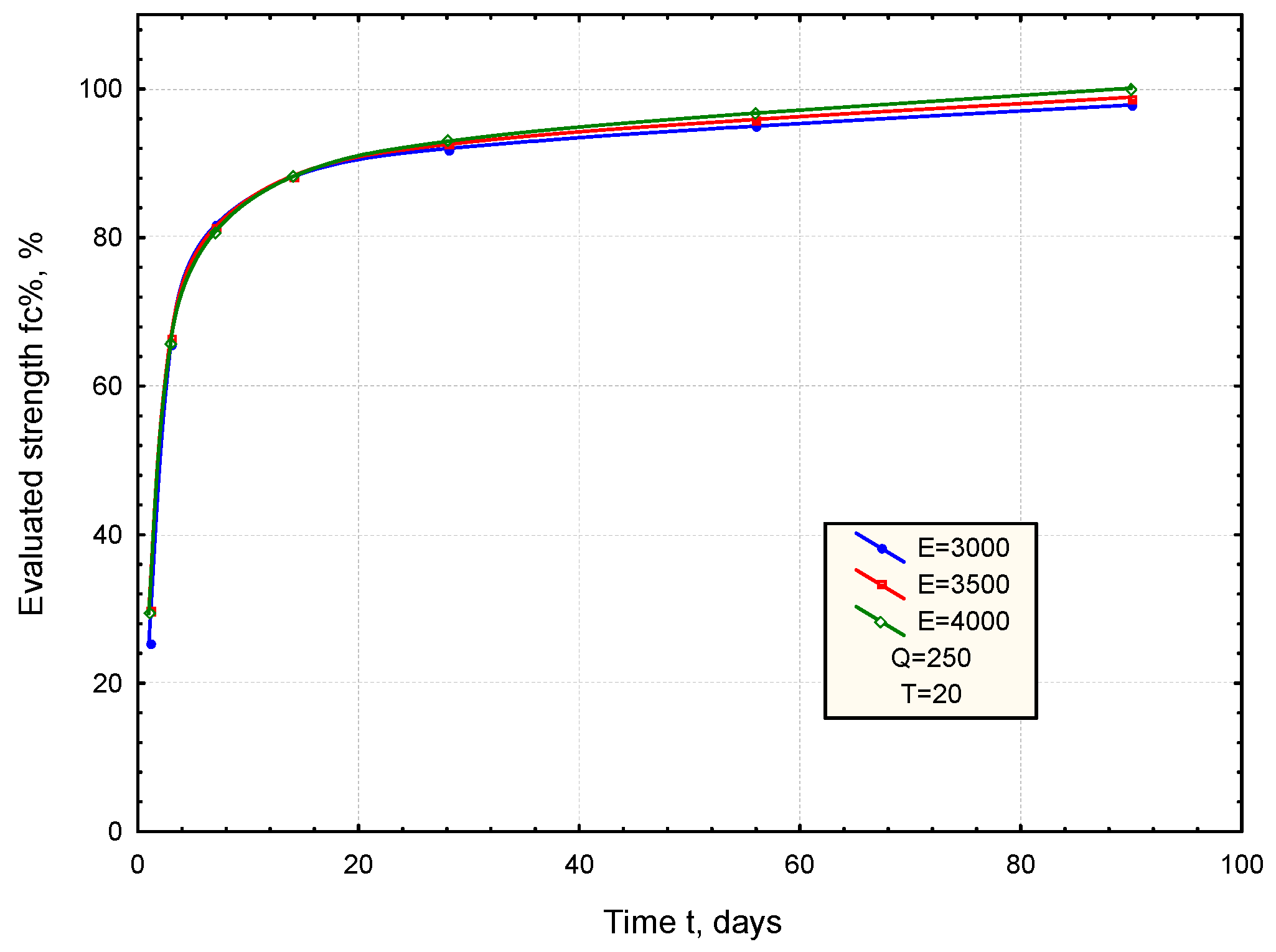

An analysis of the model was performed to evaluate the effect of cement parameters (Q, E) on the development of the mortar strength at constant temperature (T=20°C). Varying the value of Q (hydration heat) within the range of 200-300 J/g, while keeping the E constant at 3500°C, shows a significantly higher increase in early strength (

Figure 5). On the other hand, varying the parameter E from 3000 to 4000°C, assuming a Q value of 250 J/g, reveals a notable influence of the E parameter during the later stages of mortar curing (

Figure 6).

From the analysis of the relationships obtained, it can be inferred that the Q parameter (hydration heat) has a greater influence on early strength gain during the initial curing period, while the E parameter (activation temperature) impacts the development of the strength in the later stages of curing.

This paper provides an example of the direct application of the developed model to calculate the strength of a given mortar, depending on the temperature and the curing time. The approach presented in this study can be applied to predict concrete strength in both early and later stages of curing. The results demonstrate that the ANN analysis method is an effective technique for modelling such complex problems and allows for estimating relative compressive strength (fc%) with sufficient accuracy.

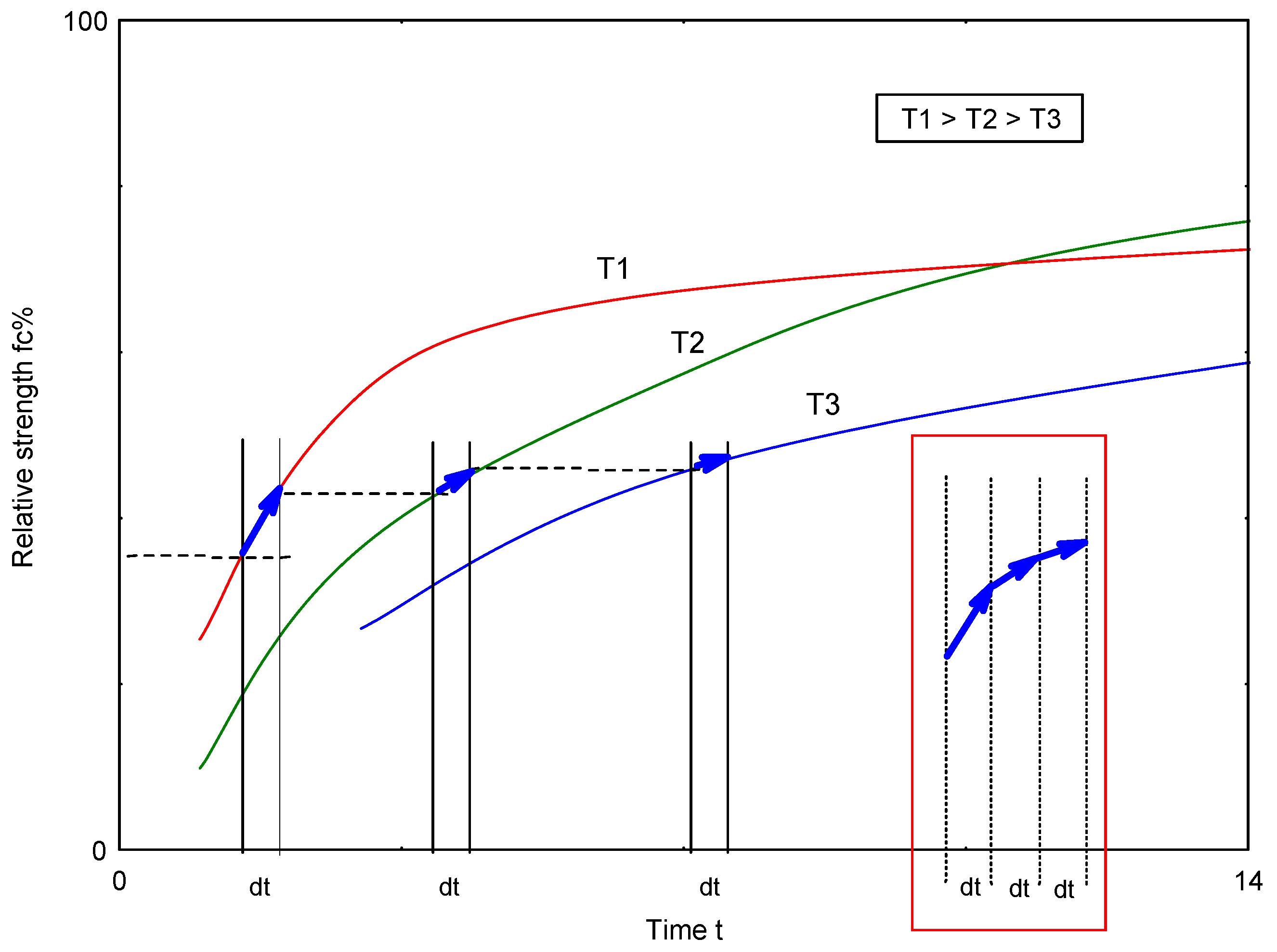

3.2. Application of the Developed ANN-fc% Network for Predicting Hardened Mortar Strength

The determination of ANN-fc% parameters enables the prediction of the relative strength of mortar depending on temperature and curing time. The method to determine fc% is performed iteratively, as illustrated in the conceptual diagram (

Figure 7):

Calculations are performed for a fixed time step dt.

- -

Within the interval dt at a given temperature, the strength increment is dYi (%).

- -

After time t = n *dt, the strength level is Y at the current temperature T1.

- -

If the temperature changes to T2 in the next time step, the time at which the strength level Y is reached at this temperature must be calculated, along with the strength increment dY2.

- -

In subsequent time steps, further strength increments dYi are calculated.

- -

The increase in strength with changing temperature cannot be negative dY≥0.

- -

The final strength Y after a certain time t is the sum of the individual increments dYi, as shown in the lower right corner of the diagram.

- -

The process is repeated until the final time is reached.

A simple calculation programme was prepared as a macro in Statistica (visual basic STB) to perform these calculations. Initially, input data characterising the cement, such as heat of hydration (Q) and the activation parameter (E), and the mortar temperature history (T) during curing (t). On the basis of this data, the QNET programme is called to calculate the fc% value, which is then transferred to the Statistica spreadsheet.

The data collected in the spreadsheet is used to generate a plot showing the development of relative mortar strength (fc%) during curing at variable temperature.

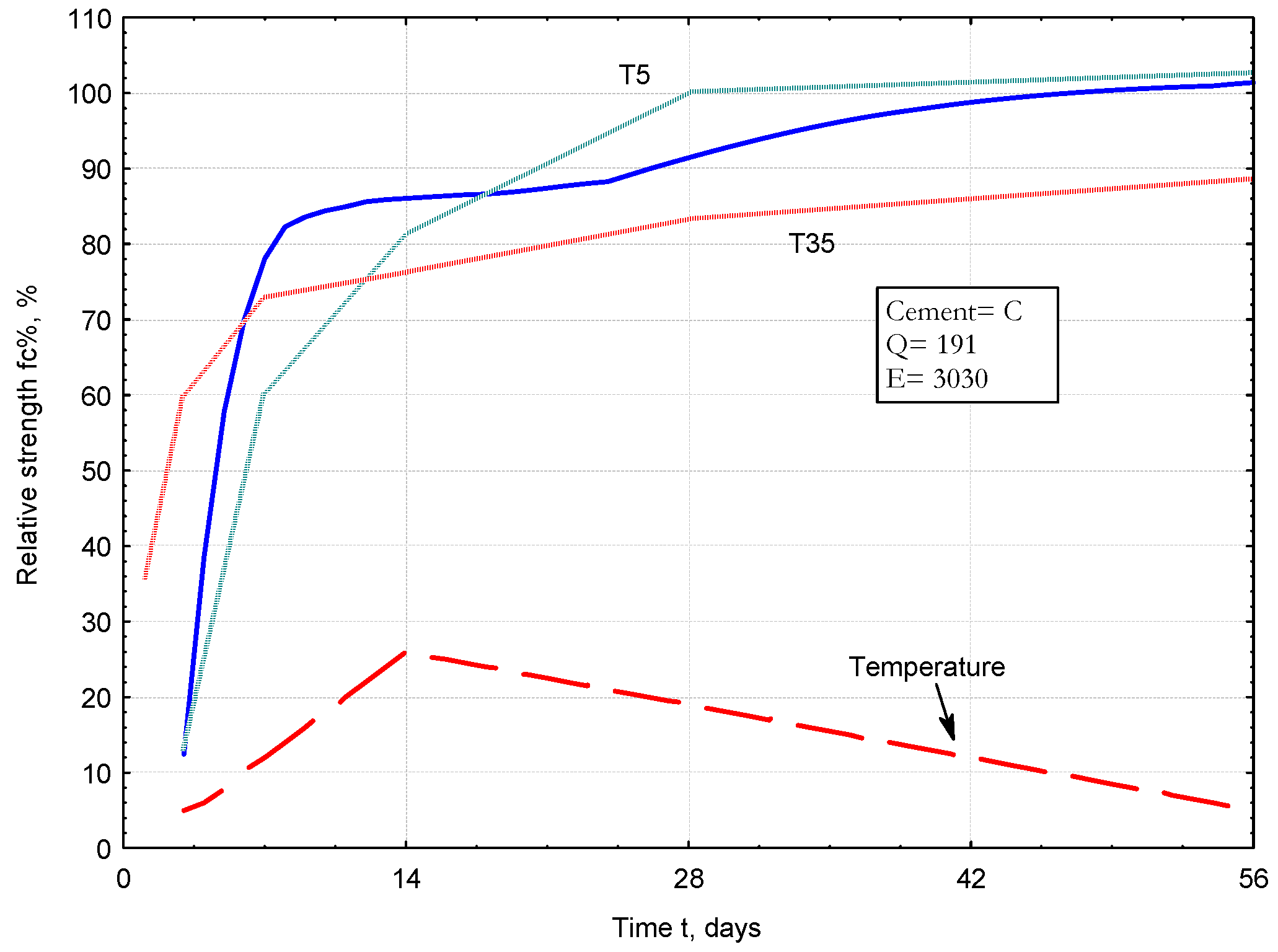

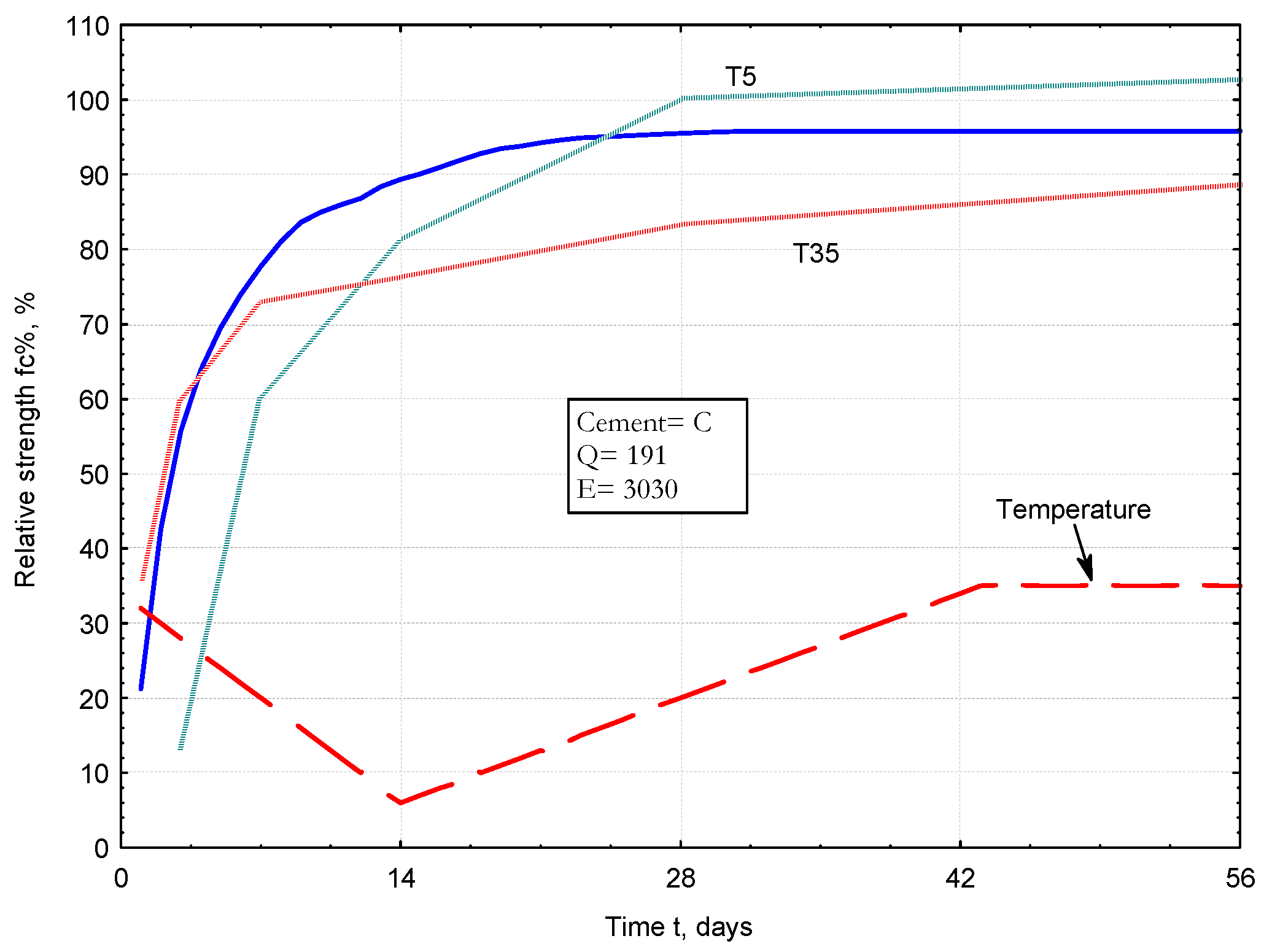

Figure 8 and

Figure 9 show example graphs illustrating changes in relative strength for mortar made with cement characterised by specific Q and E parameters as a result of variable curing temperatures over time.

This study proposes a method for directly calculating fc% using two software programs: Statistica and QNET. Statistica macro is a basic program for calculations and graphical presentation of results using (GUI), while QNET is used to calculate the fc% values.

The appendix attached as

Supplementary Material shows how to perform calculations without using the ANN program detailing the matrix calculations and transformations derived from the sigmoid transfer functions between network layers. By knowing the weight matrices for a given model, calculations can be done without the QNET programme (QNET, which was designed for 32-bit operating systems and not work on newer computers). A script created based on this scheme can be integrated as a subroutine/function in the main calculation program, e.g. Excel or another program.

4. Conclusions

The aim of the research was to develop a new type of model: fc% = f(Q, E, T, t), which allows for estimating the relative strength of mortar, simultaneously taking into account two parameters characterizing the given cement: activation energy (Ea) and heat of hydration measured (Q). To achieve this, the artificial neural network (ANN) method was applied as a technique for multifactor regression analysis. As a result of the analysis, an ANN model was developed, representing an implicit nonlinear "black box" function. The results showed that the ANN analysis method is an efficient technique for modeling such complex problems.

The developed ANN-fc% model has 4 inputs, including heat of hydration (Q), activation energy (Ea), temperature (T) and time (t). In order to collect training data, an extensive mortar testing program was conducted using: 6 cements, curing temperatures 5-35°C, and 90-day strength. The results showed that the ANN analysis method allows for estimating the relative compressive strength with sufficient accuracy. Input nodes analysis showed that hydration heat (Q) influences early strength gain, while activation energy Ea affects later strength development. The method of using the ANN-fc% model to calculate the relative strength of mortar depending on the temperature change during maturation was shown. The approach presented in this paper could be useful for quality control and non-destructive prediction of concrete strength.

When treating the presented research as a preliminary phase, it will be necessary to conduct further studies to verify the relationships obtained based on the testing of concrete samples.

Supplementary Materials

The following supporting information can be downloaded at:

Preprints.Org, The appendix attached as supplementary material shows how to perform calculations without using the ANN program detailing the matrix calculations and transformations derived from the sigmoid transfer functions between network layers.

Funding

There is no external funding for this work.

Acknowledgments

The author thanks his colleagues Adam Kłak and Maciej Lech for their help in preparing samples and testing the strength of mortars.

Conflicts of Interest

The author declare no conflicts of interest.

References

- Carino N.J.: The maturity method: Theory and application. ASTM J. Cem. Concr. Aggreg. 1984, 6, 61–73.

- Nan Ji Jin, Kyu-Seok Yeon, Seung-Ho Min, Jaeheum Yeon: Using the Maturity Method in Predicting the Compressive Strength of Vinyl Ester Polymer Concrete at an Early Age. Advances in Materials Science and Engineering. 2017, 12 pp. [CrossRef]

- A.G.A. Saul, Principles underlying the steam curing of concrete at atmospheric pressure, Mag. Concr. Res. 1951, 2 (6), pp. 127–140.

- Rastrup E.: Heat of hydration in concrete. Mag. Concr. Res. 1954, 6 (17)), pp. 79–92.

- Carino N. J., Lew H. S., and Volz C. K.: Early age temperature effects on concrete strength prediction by the maturity method. ACI Journal Proceedings, 1983, vol. 80, no. 2, pp.93–101.

- J. M. Plowman: Maturity and the strength of concrete. Mag. Concr. Res., 1956, vol.8, no. 22, pp.13–22.

- Carino N.J., Lew N. J.: The maturity method: from theory to application. Proceedings of the 2001 Structures Congress &Exposition, May 2001.

- P. F. Hansen, E. J. Pedersen,: Maturity computer for controlled curing and hardening of concrete. Nordisk Betong, 1977, no. 1, pp. 21–25.

- Lew H. S., Reichard T. W.: Prediction of strength of concrete from maturity. ACI SP 56-14, 1978, pp. 229–248.

- Tank R.C., Carino N.J.: Rate constant functions for strength development of concrete. ACI Mater. J. 1991, 88, pp. 74–83.

- Hansen P. F., Pedersen E. J.: Curing of concrete structures. CEB Information Bulletin, 1985, vol. 166.

- Benaicha M., Burtschell Y., Alaoui A. H.: Prediction of compressive strength at early age of concrete- Application of maturity. Journal of Building Engineering, 2016, vol.6, pp. 119–125. [CrossRef]

- Ohama Y., Demura K., Lee Y. S., Yeon K. S.: Compressive strength prediction of polyester mortars by the maturity method. Proceedings of the International Symposium, Brittle Matrix Composites 6, 2000, pp. 439–448. [CrossRef]

- Vazquez-Herrero C., Martinez-Lange I., Sanchez-Tembleque F.: A new procedure to ensure structural safety based on the maturity method and limit state theory. Construction and Building Materials, 2012, 35, pp.383-398. [CrossRef]

- Wirquin E., Broda M., Duthoit B.: Determination of the apparent activation energy of one concrete by calorimetric and mechanical means Influence of a superplasticizer. Cement and Concrete Research, 2002, 32, pp. 1207–1213.

- D’Aloia L., Chavillard G.: Determination the “apparent” activation energy of concrete Ea- numerical simulations of the heat of hydration of cement. CCR, 2002, Vol. 32, pp 1277-1289.

- Venuant M.: Rev. Mat. Constr., 1961.

- Kurdowski W., Pichniarczyk P.: Problems with the Arrhenius equation in the evaluation of concrete maturity. Cement Wapno Beton, 2016, vol. 21, no. 3, pp. 149-156.

- Hyun-Min Yang, Seung-Jun Kwon, Nosang Vincent Myung, Jitendra Kumar Singh, Han-Seung Lee, Soumen Mandal: Evaluation of Strength Development in Concrete with Ground Granulated Blast Furnace Slag Using Apparent Activation Energy. Materials 2020, 13, 442; [CrossRef]

- Jieying Zhang, Cusson D., Monteiro P., Harvey J.: New perspectives on maturity method and approach for high performance concrete applications. Cement and Concrete Research, 2008, 38, pp. 1438–1446. [CrossRef]

- Lanh Si Ho, Kenichiro Nakarai, Kenta Eguchi, Yuko Ogawa: Difference in Strength Development between Cement-Treated Sand and Mortar with Various Cement Types and Curing Temperatures. Materials 2020, 13, 4999; [CrossRef]

- Yahia A. Abdel-Jawad: The maturity method: Modifications to improve estimation of concrete strength at later ages. Construction and Building Materials, 2006, 20, pp. 893–900.

- Yeh I.-C.: Modeling of strength of high-performance concrete using artificial neural networks. Cement and Concrete Research, 1998,Vol. 28, No. 12, pp. 1797-1808.

- Hamid Eskandari-Naddaf, Ramin Kazemi: ANN prediction of cement mortar compressive strength, influence of cement strength class. Construction and Building Materials, 2017, 138, pp. 1–11. [CrossRef]

- Mulusew Aderaw Getahuna, Stanley Muse Shitotec, Zachary C. Abiero Gariyd: Artificial neural network based modelling approach for strength prediction of concrete incorporating agricultural and construction wastes. Construction and Building Materials, 2018, 190, pp. 517–525. [CrossRef]

- Silva F.A., Delgado J.M., Cavalcanti R.S., Azevedo A.C., Guimarães A.S., Lima A.G.: Use of Nondestructive Testing of Ultrasound and Artificial Neural Networks to Estimate Compressive Strength of Concrete. Buildings 2021, 11, 44. [CrossRef]

- Mostafa Amiri, Farzad Hatami: Prediction of mechanical and durability characteristics of concrete including slag and recycled aggregate concrete with artificial neural networks (ANNs). Construction and Building Materials, 2022, 325, 126839. [CrossRef]

- Abellan-Garcia J., Pacheco-Bustos C.: ANN approach to evaluate the effects of supplementary cementitious materials on the compressive strength of recycled aggregate concrete. Construction and Building Materials, 2023, 402. [CrossRef]

- ASTM C1074-11. Standard Practice for Estimating Concrete Strength by the Maturity Method; ASTM International: West Conshohocken, PA, USA, 2011.

- FIB Model Code 2010, First complete draft, Volume 1, Lausanne, 2010.

- STATISTICA. Statistics Program Package. StatSoft PL.

- QNET’97- Neural Network Modeling for Windows 95/98/NT. Vesta Services Inc. Winnetka II, 1997.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).