Submitted:

01 October 2024

Posted:

02 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. EVR Measures of LWRs

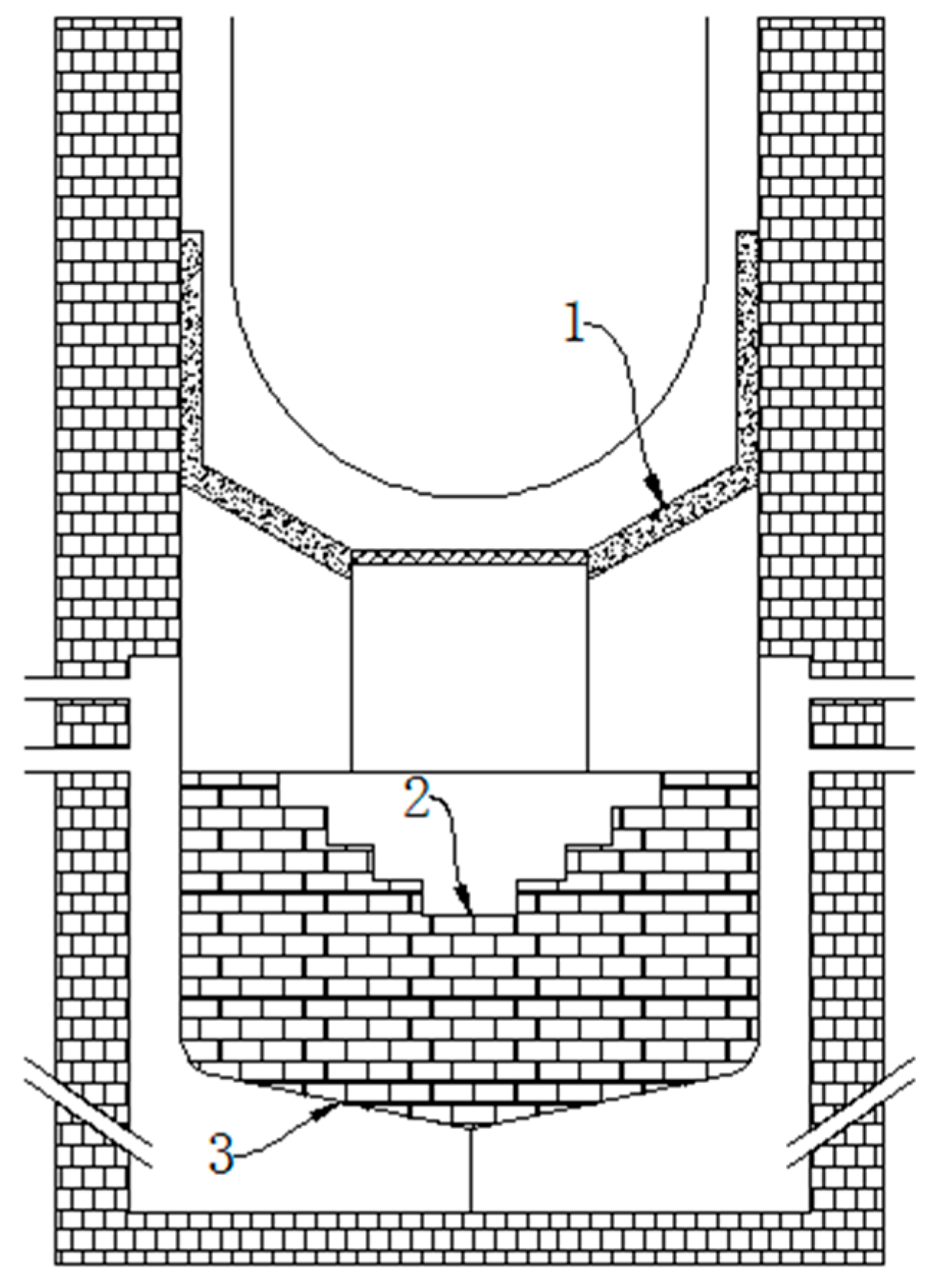

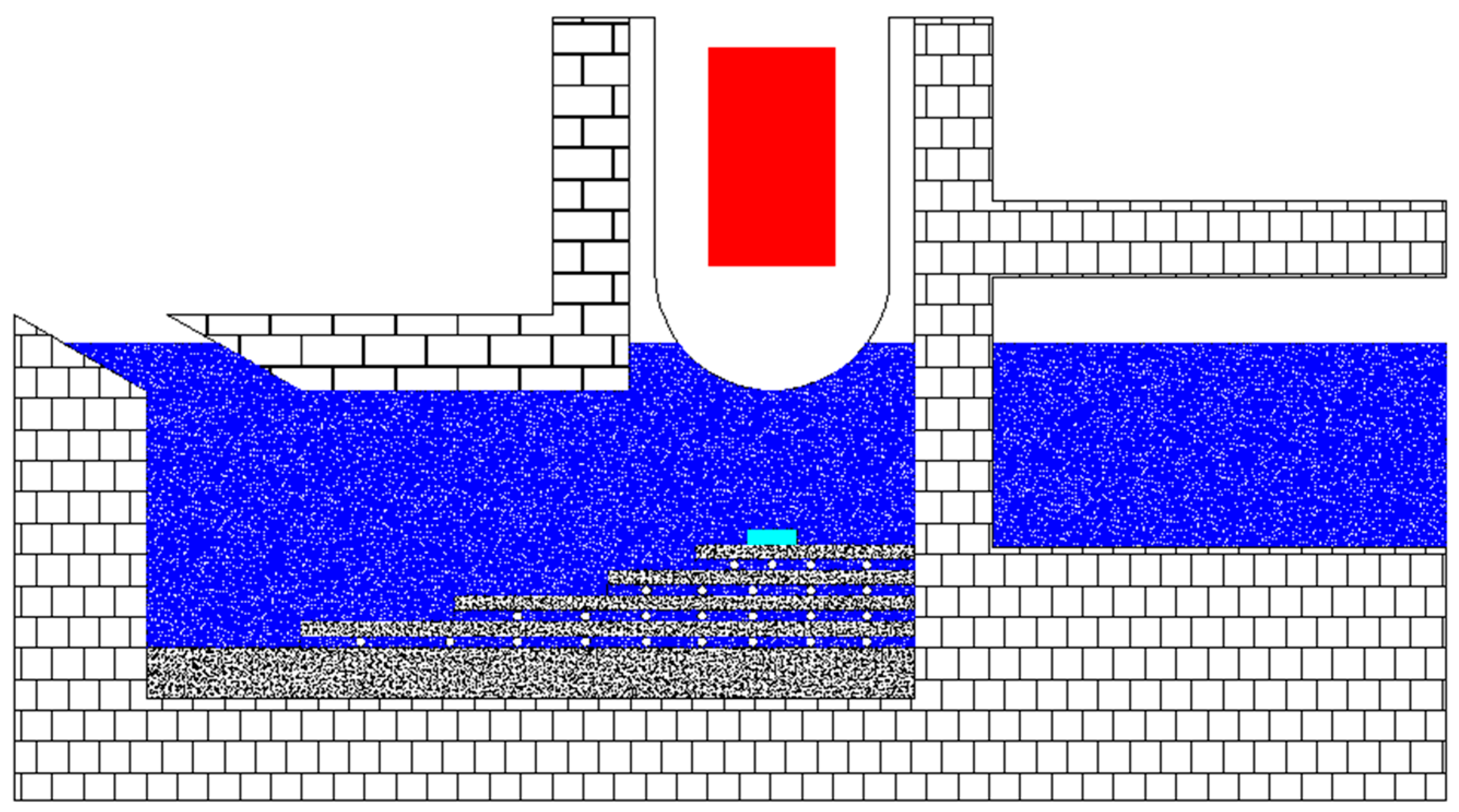

2.1. VVER-1000

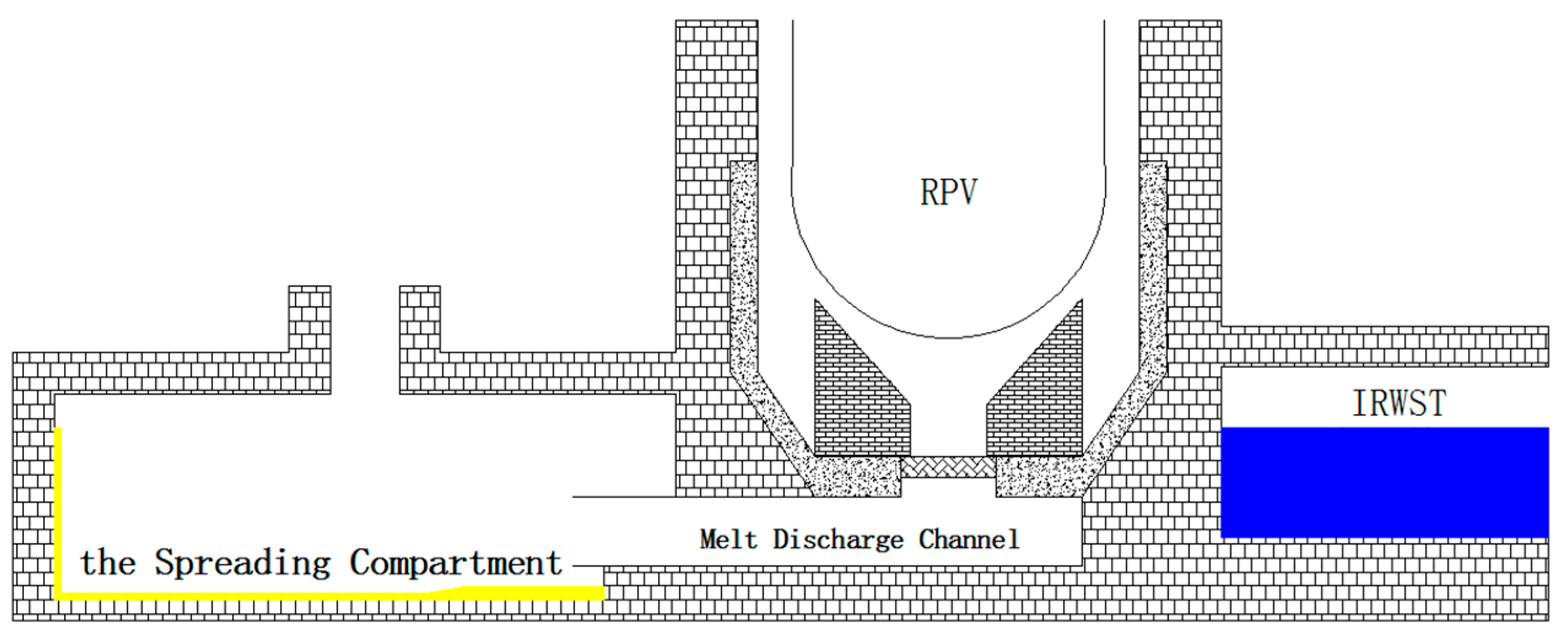

2.2. EPR

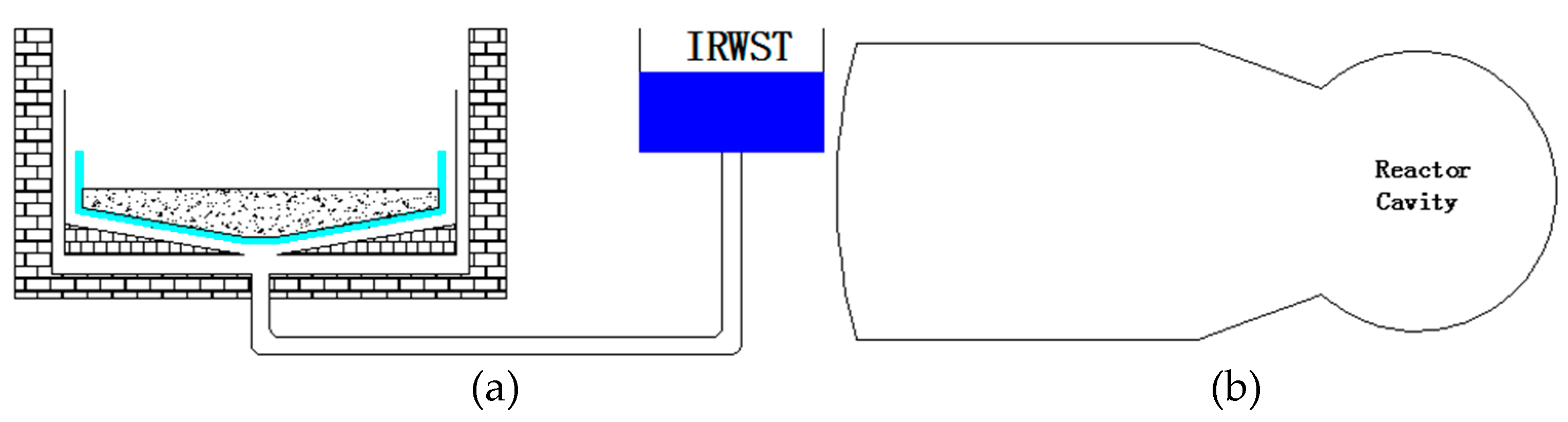

2.3. ESBWR

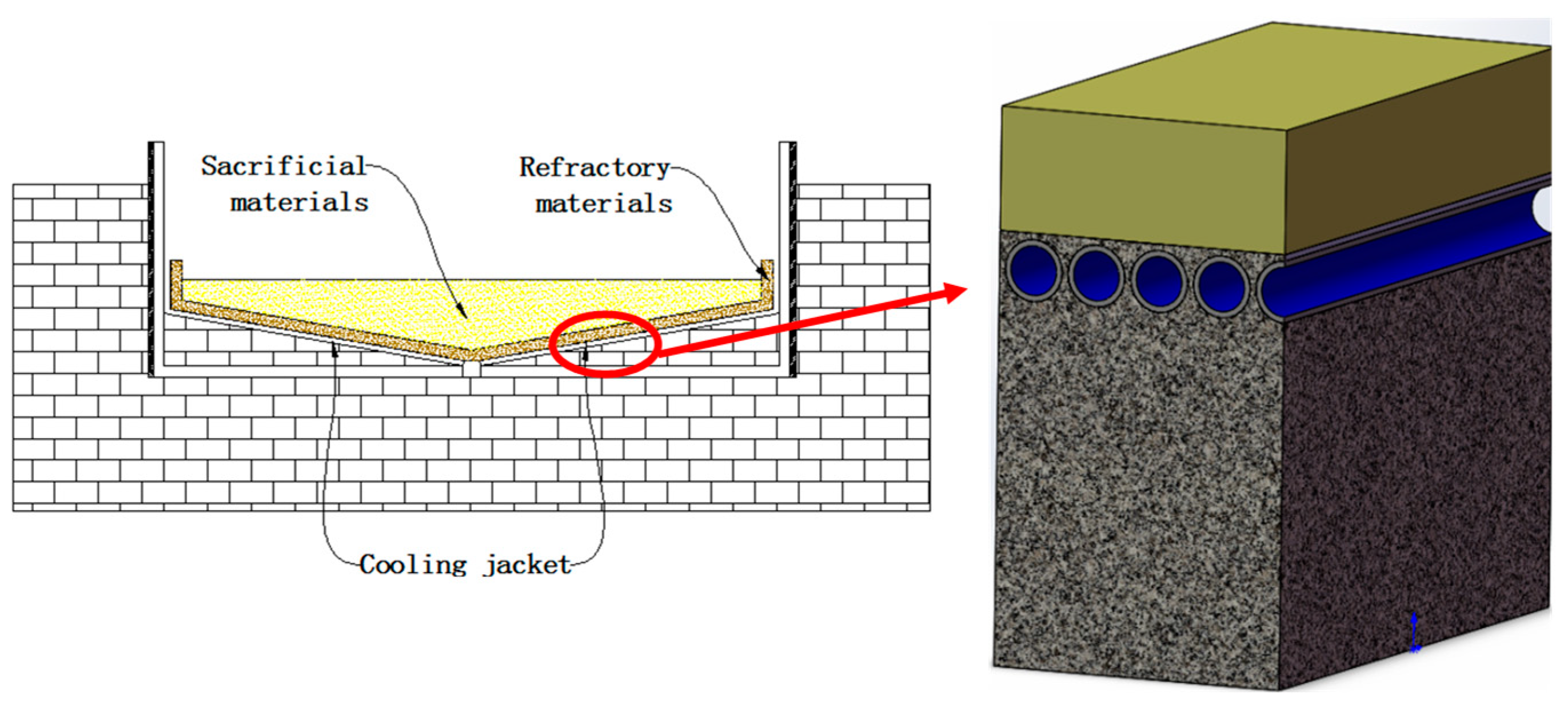

2.4. EU-APR1400

2.5. APWR

3. Pros and Cons of EVR Measures

3.1. EVR versus IVR

3.2. Comparisons of EVR Measures

4. Remaining Issues and Uncertainties

4.1. Dry Reactor Cavity

4.2. Wet Reactor Cavity

- 1)

- The pressure pulse formed by the steam explosion damages the structure of the reactor cavity or core catcher, causing the core melt retention device to fail prematurely, and the transfer of the corium is uncontrolled.

- 2)

- Damage to the containment structure, such as the pressure pulse formed by the steam explosion may cause the melt to splash or other ejected objects, all of which can threaten the integrity of the containment. In addition, significant displacement of some equipment (such as the collapse of the equipment support structure or direct impact by the pressure pulse) can exert a large pulling force on the pipelines connected to it, which may damage the integrity of the containment through the pipelines that penetrate the containment wall, leading to the release of radioactive materials.

- 1)

- Due to the lack of a more robust phenomenological model to rationalize the observed differences in erosion behavior between the two types of concrete used in experiments, there is still some uncertainty in extrapolating the results to prototype conditions.

- 2)

- The simplicity on a well-mixed core melt pool in the presence of concrete decomposition gases contrasts with the complexity of the concrete ablation mechanism, in which the evolving melt-concrete interface gradually integrates into the melt. From a modeling perspective, this remains difficult to observe and capture through experiments.

- 3)

- MCCI experiments conducted with prototype materials have relatively short durations. The Fukushima nuclear power plant accident has shown that longer transients are likely to occur, and it has been found in accident analysis that the termination of MCCI is significantly affected by the differences in melt pouring conditions predicted by different programs at the time of reactor vessel failure. These findings question the analytical results that predict long-term MCCI, especially in the presence of water. Therefore, if experimental data from short-duration experiments cannot be extrapolated to reactor conditions with high confidence, it is necessary to obtain experimental data from longer durations.

- 4)

- The limitations of experimental techniques present significant challenges. The experiments are conducted under high-temperature (the actual experimental temperature of the core melt being around 2500K) condition, which substantially increases the difficulty of the experiments. This includes limitations in acquiring plenty of data, constraints on measurement accuracy, and the difficulty in estimating heat losses. Additionally, the experiments involve phenomena that are hard to quantify, such as material ejection and the positioning of the crust. However, inspections of the debris in the damaged Fukushima reactors may yield more data and information, thereby enhancing the understanding of the MCCI phenomena under conditions that are large-scale and fully prototypic. This would provide greater credibility for the application of simulation tools in existing power plants, offer a technical foundation for better containment design in future plans, and optimize the severe accident management strategies for both current and future plans.

- 5)

- The MCCI under wet cavity conditions is even more complex.

5. Concluding Remarks and Recommendations

References

- Kymäläinen, H. Tuomisto, T.G. Theofanous, In-vessel retention of corium at the Loviisa plant. Nucl. Eng. Des. 1997, 169, 109–130. [Google Scholar] [CrossRef]

- T. G. Theofanous, C. Liu, S. Additon, S. Angelini, O. Kymäläinen, T. Salmassia, In-vessel coolability and retention of a core melt. Nucl. Eng. Des. 1997, 169, 1–48. [Google Scholar] [CrossRef]

- Esmaili and M. Khatib-Rahbar, Analysis of in-vessel retention and ex-vessel fuel coolant interaction for AP1000, NUREG/CR-6849, ERI/NRC-04-201, August 2004.

- S. S. Lee, S.H. Kim, K.Y. Suh, The design features of the advanced power reactor 1400. Nucl. Eng. Technol. 2009, 41, 995–1004. [Google Scholar] [CrossRef]

- J. Xing, D.Y. Song, Y.X. Wu, HPR1000: Advanced pressurized water reactor with active and passive safety. Engineering 2016, 2, 79–87. [Google Scholar] [CrossRef]

- M. G. Zheng, J.Q. Yan, S.T. Jun, L. Tian, X.J. Wang, Z.M. Qiu, The general design and technology innovations of CAP1400. Engineering 2016, 2, 97–102. [Google Scholar]

- M. Fischer M, P. Levi, The severe accident control strategy of the KERENA BWR, Proc. of ICAPP ’10, San Diego, CA, USA, June 13-17, 2010.

- M. Fischer, The severe accident mitigation concept and the design measures for core melt retention of the European Pressurized Reactor. Nuclear Engineering and Design 2004, 230, 169–180. [Google Scholar] [CrossRef]

- V. Bezlepkin, I.V. Kukhtevich, Yu.G. Leont’ev, S. Bechta, The concept of overcoming severe accidents at nuclear power stations with VVER reactors. Thermal Engineering 2004, 51, 115–123. [Google Scholar]

- Jong Ho Lee, Ji Hwan Kim, Corium Retention and Cooling by an Ex-vessel Core-catcher for Nuclear Power Plants, Transactions of the Korean Nuclear Society Autumn Meeting Jeju, Korea, October 21-22, 2010.

- T. G. Theofanous, T.N. Dinh, Application of the risk-oriented accident analysis methodology to the economic, simplified boiling water reactor design. Multiphase Science and Technology 2008, 20, 88–211. [Google Scholar]

- H. Nojiri, Mitsubishi US-APWR and EU-APWR, IAEA Interregional Workshop on Advanced Nuclear Reactor Technology, Vienna, Austria, 4-8 Jul 2011.

- C. C. Chu, J.J. Sienicki, B.W. Spencer, W. Frid, G. Löwenhielm, Ex-vessel melt-coolant interactions in deep water pool: studies and accident management for Swedish BWRs. Nuclear Engineering and Design 1995, 155, 159–213. [Google Scholar] [CrossRef]

- W. M. Ma, T.N. Dinh, The effects of debris bed’s prototypical characteristics on corium coolability in a LWR severe accident. Nuclear Engineering and Design 2010, 240, 598–608. [Google Scholar] [CrossRef]

- W. M. Ma, Y.D. Yuan, B.R. Sehgal, In-vessel melt retention of pressurized water reactors: historical review and future research needs. Engineering 2016, 2, 103–111. [Google Scholar] [CrossRef]

- Gusaro, V.V. et al., Sacrificial materials for safety systems of nuclear power stations: a new class of functional materials. Thermal Engineering 2001, 9, 721–723. [Google Scholar]

- Sidorov, A.S. et al., The device for core melt localization at the Tyan’van nuclear power station with a VVER-1000 reactor. Thermal Engineering 2001, 9, 707–711. [Google Scholar]

- M. Fischer, O. Herbst, H. Schmidt, Demonstration of the heat removing capabilities of the EPR core catcher. Nuclear Engineering and Design 2005, 235, 1189–1200. [Google Scholar] [CrossRef]

- Bouteille, F. Azarian G., Bittermann D., et al., The EPR overall approach for severe accident mitigation. Nuclear Engineering and Design 2006, 236, 1464–1470. [Google Scholar] [CrossRef]

- ADVANCED LIGHT WATER REACTOR UTILITY REQUIREMENTS DOCUMENT,VOLUME III ALWR PASSIVE PLANT,Revision 8, Issued 3/99.

- B.W. Rhee, K.S. Ha, R.J. Park, J.H. Song, A scaling study of the natural circulation flow of the ex-vessel core catcher cooling system of EU-APR1400 for designing a scale-down test facility for design verification, Proc. of ICAPP’12, Chicago, USA, 2012.

- Rae-Joon Park, Kwang-Soon Ha, Bo-Wook Rhee, Hwan Yeol Kim, Detailed evaluation of two phase natural circulation flow in the cooling channel of the ex-vessel core catcher for EU-APR1400. Nuclear Engineering and Design 2016, 298, 33–40. [CrossRef]

- Sehgal, B.R. Nuclear safety of light water reactors: severe accident phenomenology. Waltham: Academic Press; 2012.

- Peng Yu, et al. An assessment of the lumped parameter model for the two-layer melt pool heat transfer. Annals of Nuclear Energy 2023, 180. [Google Scholar]

- Rempe JL, Suh KY, Cheung FB, Kim SB. In-vessel retention strategy for high power reactors. Idaho Falls: Idaho National Engineering and Environmental Laboratory; 2005 Jan. Report No.: INEEL/EXT-04-02561.

- Xiao Zeng, et al. A scoping study on remelting process of a debris bed in the lower head of reactor pressure vessel. Annals of Nuclear Energy 2023, 189. [Google Scholar]

- Vladimir Benzianovich Khabensky, et al., Severe accident management concept of the VVER-1000 and the justification of corium retention in a crucible-type core catcher, Nuclear Engineering and Technology, Vol.41, NO.5, June 2009. 20 June.

- Walter Widmann, Manfred Burger, Gunter Lohnert, Hans Alsmeyer, Walter Tromm, Experimental and theoretical investigations on the COMET concept for ex-vessel core melt retention. Nuclear Engineering and Design 2006, 236, 2304–2327. [CrossRef]

- ourneau, C., Piluso, P., Molten Core Concrete Interation. In Comprehensive Nuclear Materials; Konings, R.J., Ed.; 2012; Volume 2, pp. 635–654.

- Seiler, J.M. Froment K., Material effects on multiphase phenomena in late phases of severe accidents of nuclear reactor. Multiphase Science and Technology 2000, 12, 117–257. [Google Scholar] [CrossRef]

- P. P. Kulkarni, A.K. Nayak, Study on coolability of melt pool with different strategies. Nuclear Engineering and Design 2014, 270, 379–388. [Google Scholar] [CrossRef]

- V. V. Gusarov, V. I. Almjashev, V. B. Khabensky, S. V. Beshta, etc., Physicochemical Modeling and Analysis of the Interaction between a Core Melt of the Nuclear Reactor and a Sacrificial Material. Glass Physics and Chemistry 2005, 31, 53–66. [Google Scholar] [CrossRef]

- S. M. An, K.S. Ha, B.T. Min, H.Y. Kim, J.H. Song, Ablation characteristics of special concrete due to an impinging zirco-nium-dioxide melt jet. Nuclear Engineering and Design 2015, 284, 10–18. [Google Scholar] [CrossRef]

- Andrei, A. Komlev, Vyacheslav I.Almjashev, etc., New sacrifificial material for ex-vessel core catcher. Journal of Nucle-ar Materials 2015, 467, 778–784. [Google Scholar]

- W。 Tromm, H. Alsmeyer, Experiments for a core catcher concept based on water addition from below. Nuclear Engineering and Design 1995, 157, 437–445. [CrossRef]

- H. Alsmeyer, W. Tromm. The COMET Concept for Cooling Core Melts: Evaluation of the Experimental Studies and Use in the EPR, FZKA 6186, EXV-CSC(99)-D036[R]. 1999.

- H. Alsmeyer, T. Cron, G. Merkel, S. Schmidt-Stiefel, W. Tromm, T. Wenz. Melt Cooling by Bottom Flooding: The Experiments CometPC-H4 and -H5, FZKA 6945, SAM-ECOSTAR-D45[R]. 2004.

- S. Lomperski, M.T. Farmer, Performance testing of engineered corium cooling systems. Nuclear Engineering and Design 2012, 243, 311–320. [Google Scholar] [CrossRef]

- Ö. Yilmaz, G. Pohlner, M. Buck and J. Starflinger C. Journeau (2016), Design Considerations for a Core-Catcher Concept Based on Bottom-Flooding through Porous Concrete, NUTHOS-11[C].

- Huhtiniemi, I. Magallon, D. Insigh into steam explosion with corium melts in KROTOS. Nucl. Eng. Des. 2001, 204, 391–400. [Google Scholar] [CrossRef]

- Magallon, D. Huhtiniemi, I. Corium melt quenching tests at low pressure and subcooled water in FARO. Nucl. Eng. Des. 2001, 204, 369–376. [Google Scholar] [CrossRef]

- Kim, J.H., Park, I.K., Min, B.T., Hong, S.W., Shin, Y.S., Song, J.H., Kim, H.D. An experimental study on intermediate steam explosions experiments with molten zir-conia and corium in the TROI facilities. In: Proceedings of the 10th International Conference on Nuclear Thermal Hydraulics (NURETH-10), Seoul, Korea, 2003; pp. 1–6.

- Min J, Ma W, Zhu G,et al.An experimental study on steam explosion of a small melt jet falling into a water pool[J]. Nuclear engineering and design 2022, 391. [CrossRef]

- Kim, H. Single Droplet Vapor Explosion Experiments, The U. of Wisconsin - Madison, 1986.

- Nelson, L. and Guay, K.P., "Suppression of Steam Explosions in Tin and FeAl2O3 Melts by Increasing the Viscosity of the Coolant," High Temperature-High Pressures, Vol 18, 1986.

- Nelson, L. S. and Duda, P. M., "Steam Explosion Experiments with Single Drops of Iron Oxide Melted with a CO2 Laser. Part II. Parametric Studies," NUREG/CR-2718, SAND-82-1105 R3, Sandia National Laboratory, 1985.

- Becker, K.M. and Lindland, K.P., "The Effects of Surfactants on Hydrodynamic Fragmentation and Steam Explosions," KTH-NEL-50, Royal Institute of Technology, Stockholm, Sweden, 1991.

- Kowal, M.G. and Dowling, M.F. and Abdel-Khalik, S.I., "An Experimental Investigation of the Effects of Surfactants on the Severity of Vapor Explosions," Nucl. Sci. & Eng. Vol 115, pi 85—192, 1993.

- Manfred Fischer, Torsten Keim, Markus Hupp, Super Absorbing Polymers for the Mitigation of Ex-Vessel Core Melt Scenarios in Gen II Plants, Technical Meeting on Ex-Vessel Molten Corium Behaviour and Coolability 14.-17.06.2022.

- PATRICK S, MANFRED G, RUDI K. Basic investigations on debris cooling. Nuclear Engineering and Design 2006, 236, 2104–2116. [Google Scholar] [CrossRef]

- ZOU Xumao, LI Liangxing, KONG Liubo, et al. Two-phase flow resistance and interfacial drag in packed beds. J.Journal of shanghai jiao tong university 2017, 51, 470–475. [Google Scholar]

- ZHANG Zhengzheng, Li Liangxing, MA Weimin, et al. Investigaion on Flow Characteristics in Radial Stratified Debris Bed. Atomic Energy Science and Technology 2022, 56, 2032–2040. [Google Scholar]

- KULKARNI P P, RASHID M, KULENOVIC R, et al. Experimental investigation of coolability behaviour of irregularly shaped particulate debris bed[J]. Nuclear Engineering and Design 2010, 240, 3067–3077. [Google Scholar] [CrossRef]

- LI L X, ZOU X M, WANG H S, et al. Investigations on two-phase flow resistances and its model modifications in a packed bed[J]. International Journal of Multiphase Flow 2018, 101, 24–34. [Google Scholar] [CrossRef]

- Yang Shengxing, Gong Houjun, Fang Yu, et al. Experimental Study on Cooling Characteristics of Mixed Partical Size Debris Bed under Different Water Injection Methods. Nuclear Power Engineering 2023, 44, 247–252. [Google Scholar]

- Magallon D, Huhtiniemi I. Corium melt quenching tests at low pressure and subcooled water in FARO. Nucl Eng Design 2001, 204, 369–376. [Google Scholar] [CrossRef]

- D.H. Thompson, M.T. Farmer, J.K. Fink, D.R. Armstrong, B.W. Spencer, Compilation, analysis and interaction of ACE Phase C and MACE experimental data, Report ACEX TRC-14, Argonne National La-boratory, Chicago, IL, USA, 1997.

- M.T. Farmer, B.W. Spencer, D.J. Kilsdonk, W. Aeschlimann, Status of large scale MACE Core Coolability experiments, OECD Workshop on Ex-Vessel Debris Coolability, Karlsruhe, Germany (1999).

- E.R. Copus, Sustained Uranium dioxide Concrete interaction tests: The SURC test series,2nd OECD (NEA) Spec. Mtg. on Molten Core DebrisdConcrete Interactions, Karlsruhe,Germany (1992).

- E.R. Copus, R.E. E.R. Copus, R.E. Blose, J.E. Brockmann, R.B. Simpson, D.A. Lucero, Core-Concrete Interactions Using Molten Urania With Zirconium on a Limestone Concrete Basemat, The SURC-1 Experiment, Report NUREG/CR-5443, Sandia National Lab. (1992).

- E.R. Copus, R.E. E.R. Copus, R.E. Blose, J.E. Brockmann, R.B. Simpson, D.A. Lucero, Core-Concrete Interactions using Molten UO2 with Zirconium on a Basaltic Basemat: The SURC-2 Experiment, (1990) Sandia Nat. Lab. Report NUREG/CR-5564, SAND90–1022 (1990).

- E.R. Copus, R.E. E.R. Copus, R.E. Blose, J.E. Brockmann, R.D. Gomez, D.A. Lucero, Core-Concrete Interactions using Molten Steel with Zirconium on a Basaltic Basemat: The SURC-4 Experiment, In: NUREG/CR-4994, SAND87–2008, Sandia National Laboratories (1989).

- C. Journeau, P. C. Journeau, P. Piluso, J.F. Haquet, Behaviour of nuclear reactor pit concretes under severe accident conditions, Proc. CONSEC ’07, Concrete under Severe Conditions (2007). Tours, France.

- Fernando Robledo, Mitchel T. Farmer, Mitchel T. Farmer, Claus Spengler, Claus Spengler, Sudhamay Basu, State-of-the-Art Report on Molten Corium Concrete Interaction and Ex-Vessel Molten Core Coolability, NEA/CSNI/R(2016)15, 2017.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).