Submitted:

09 September 2024

Posted:

10 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Selection of Materials

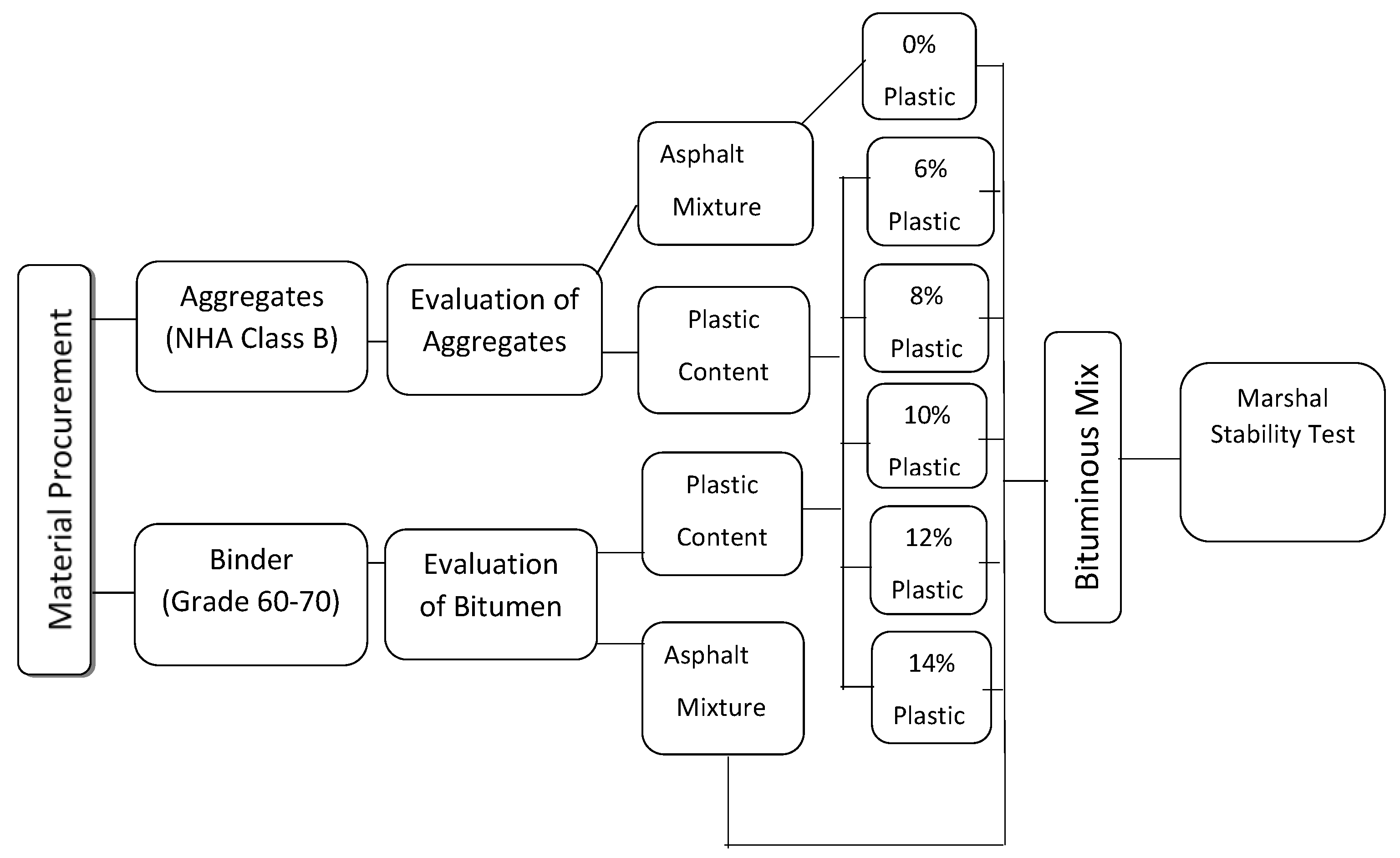

2.2. Methodology

3. Results

- Determining optimum bitumen Content

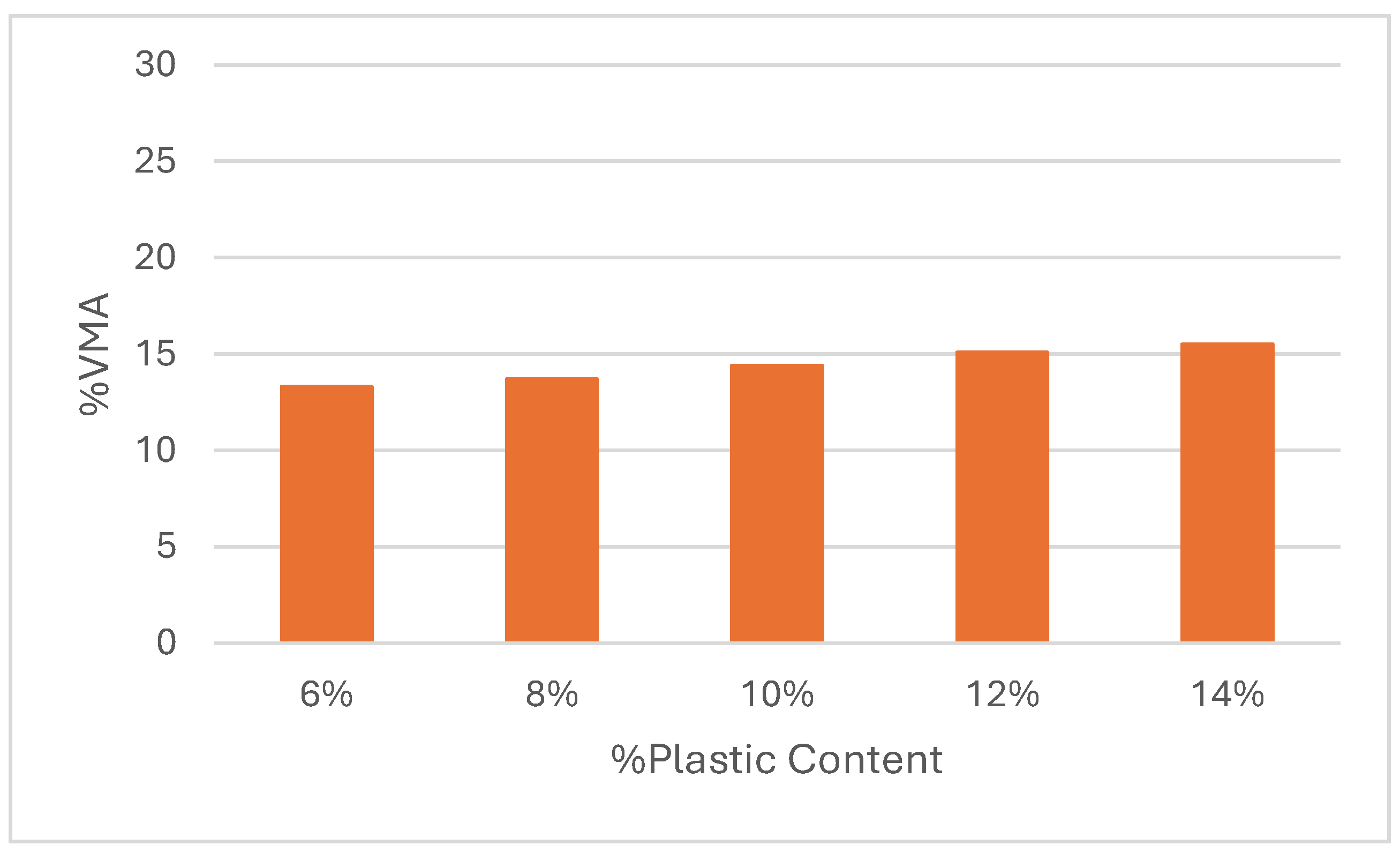

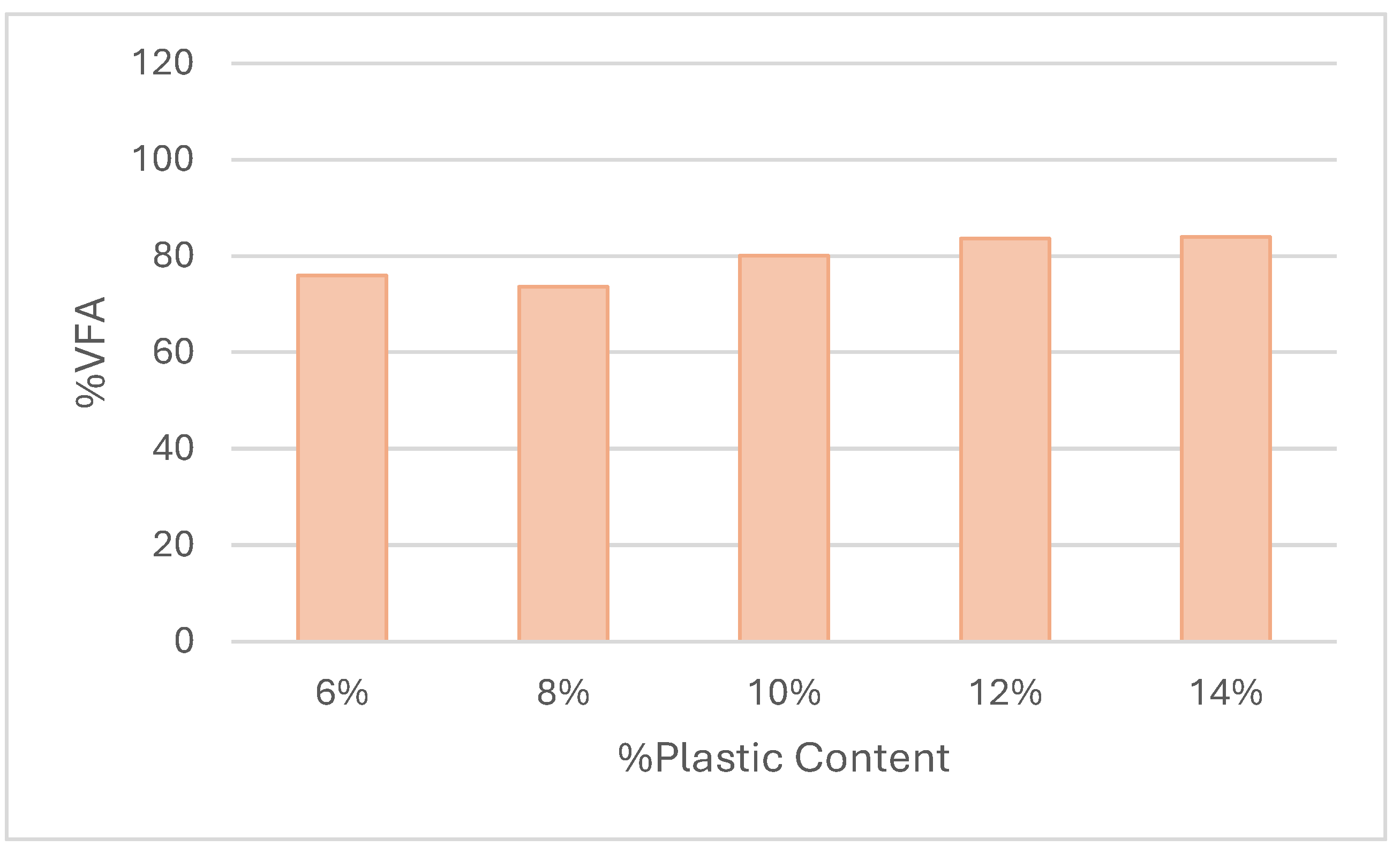

- Determining optimum plastic Content

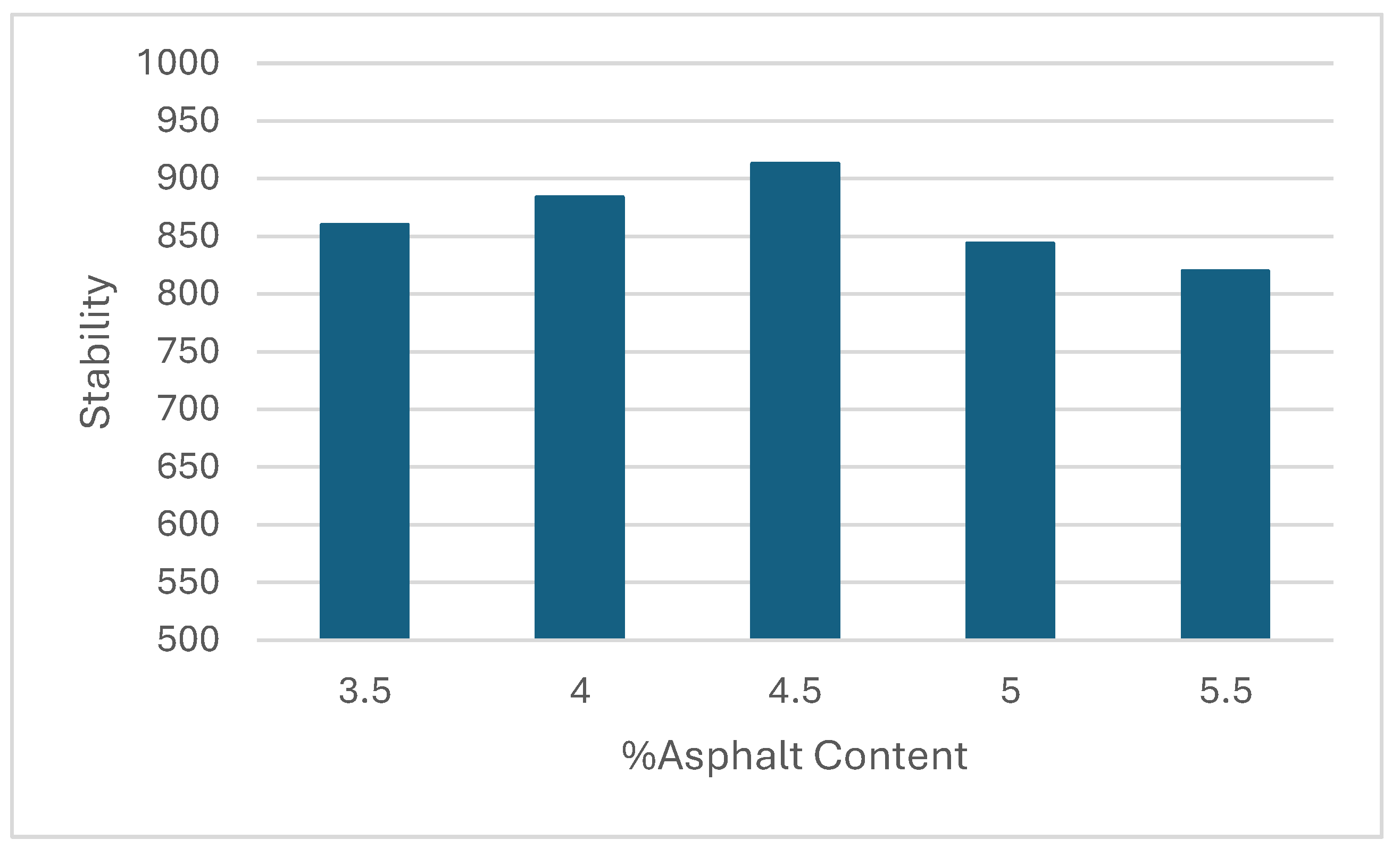

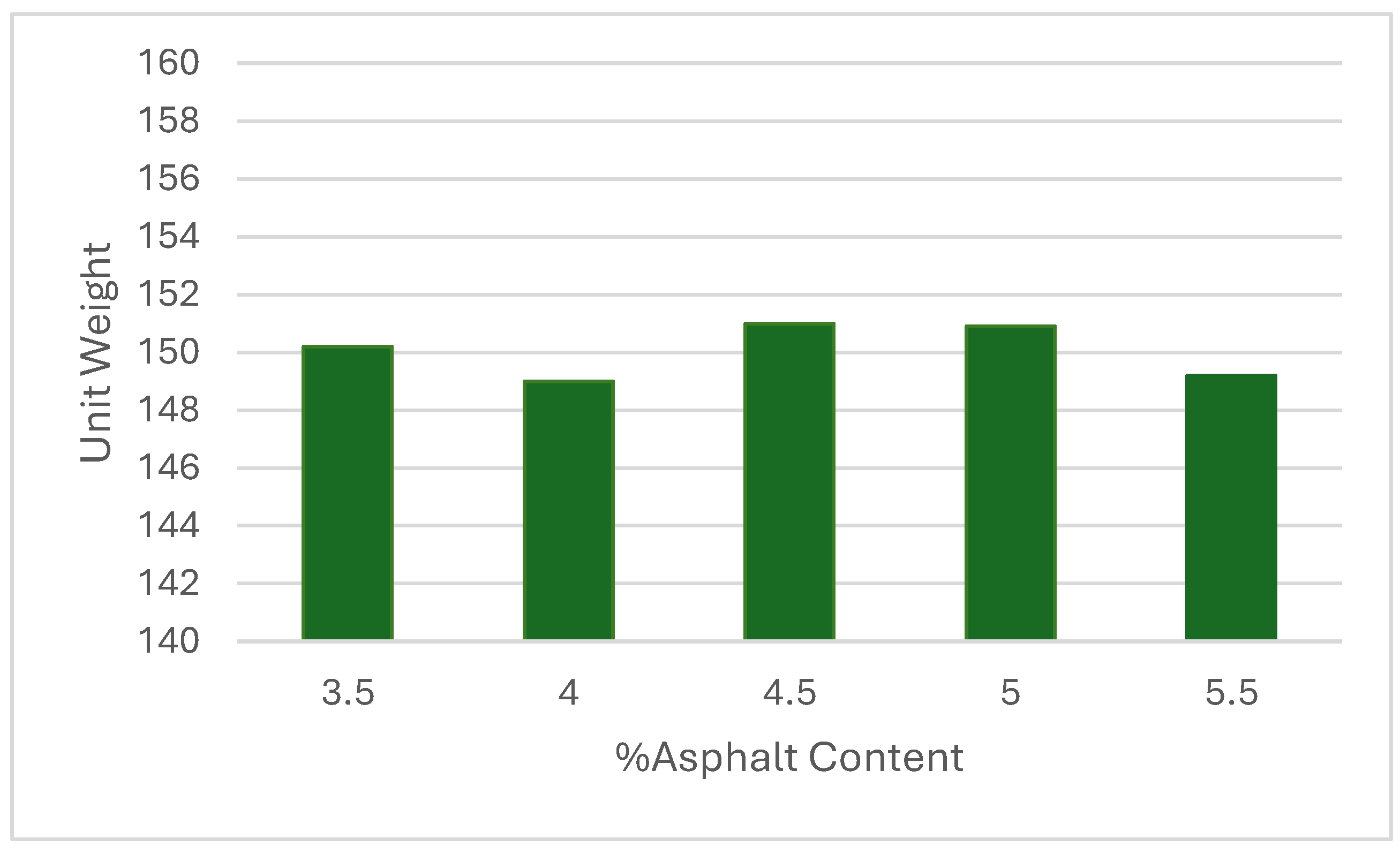

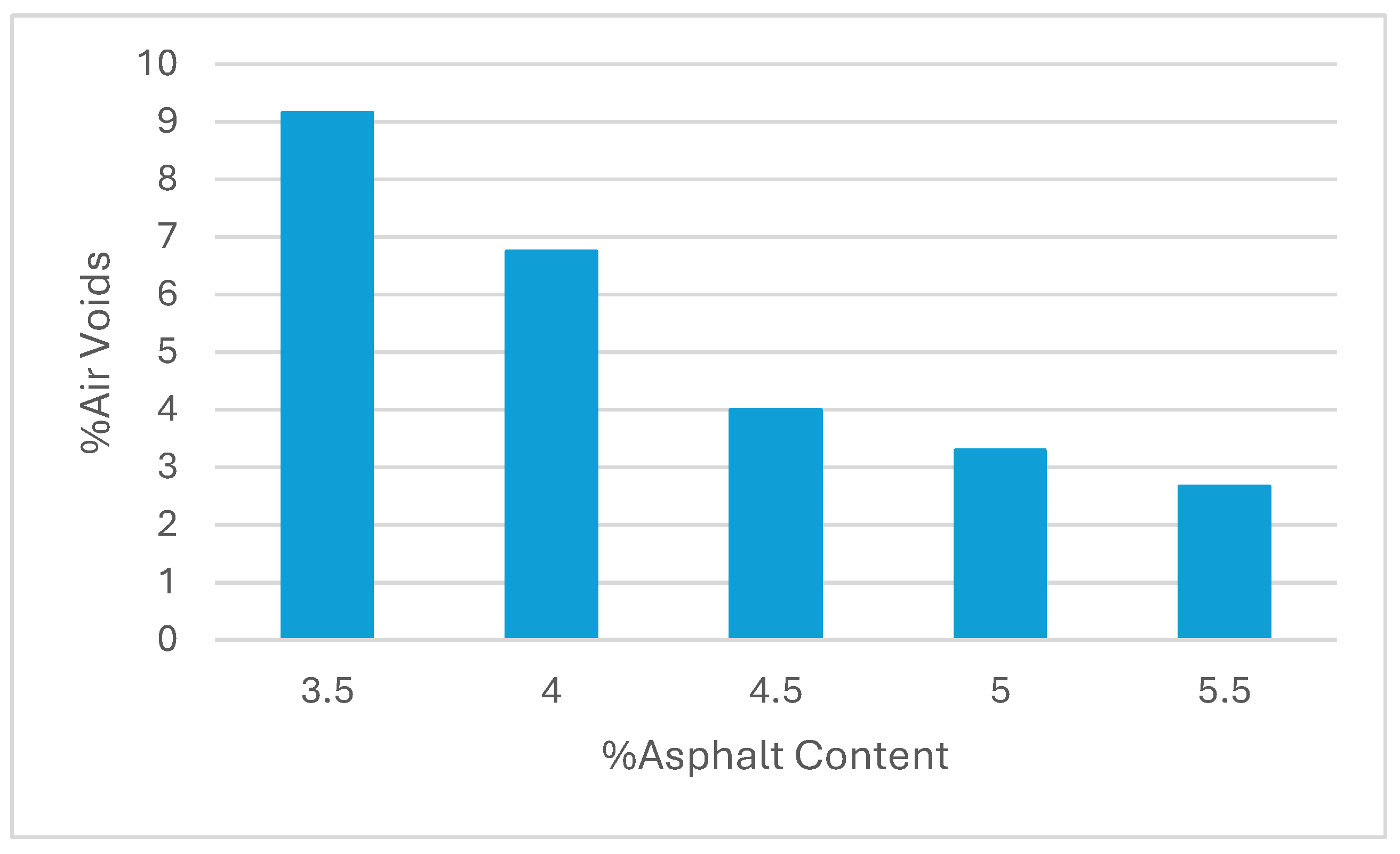

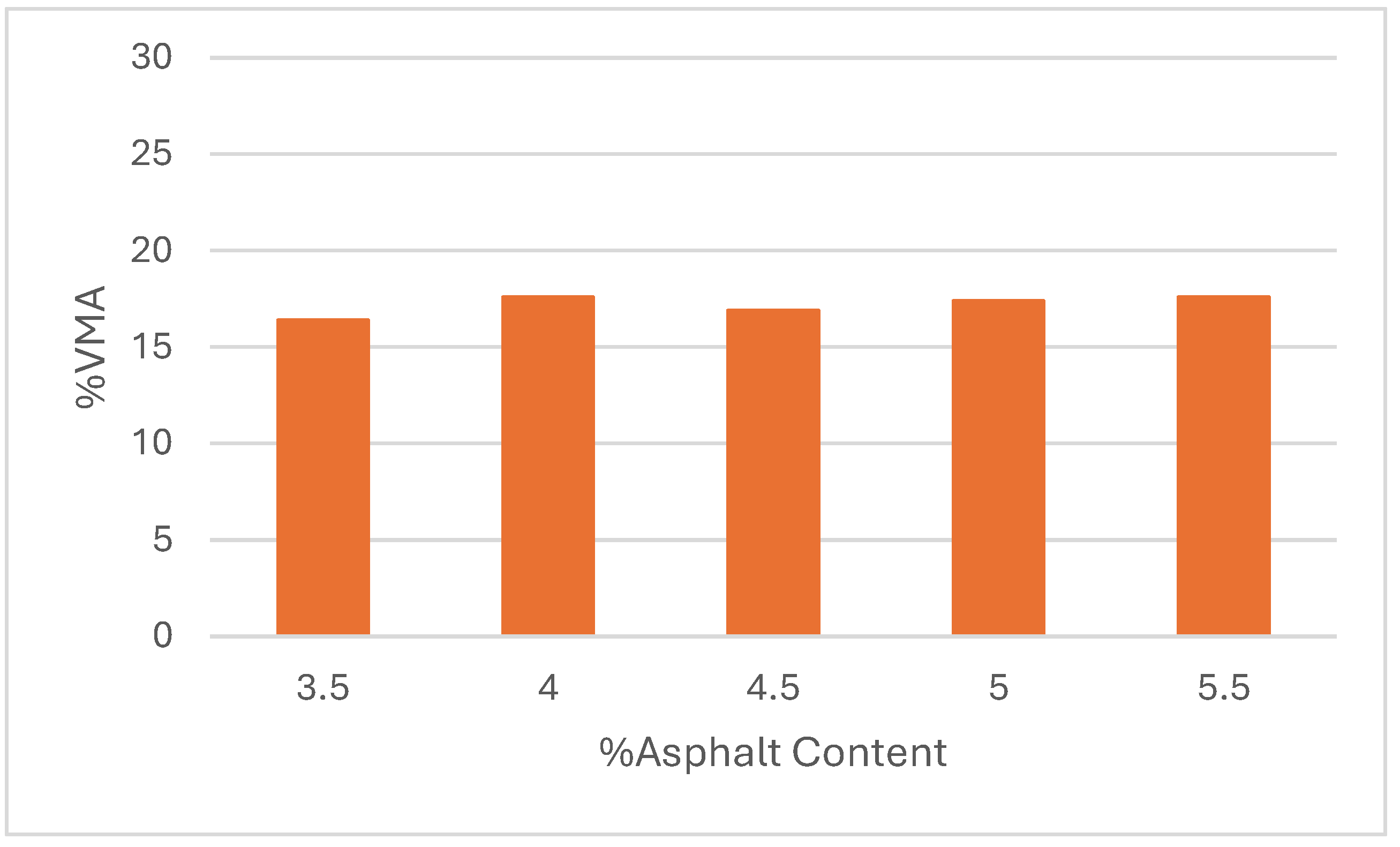

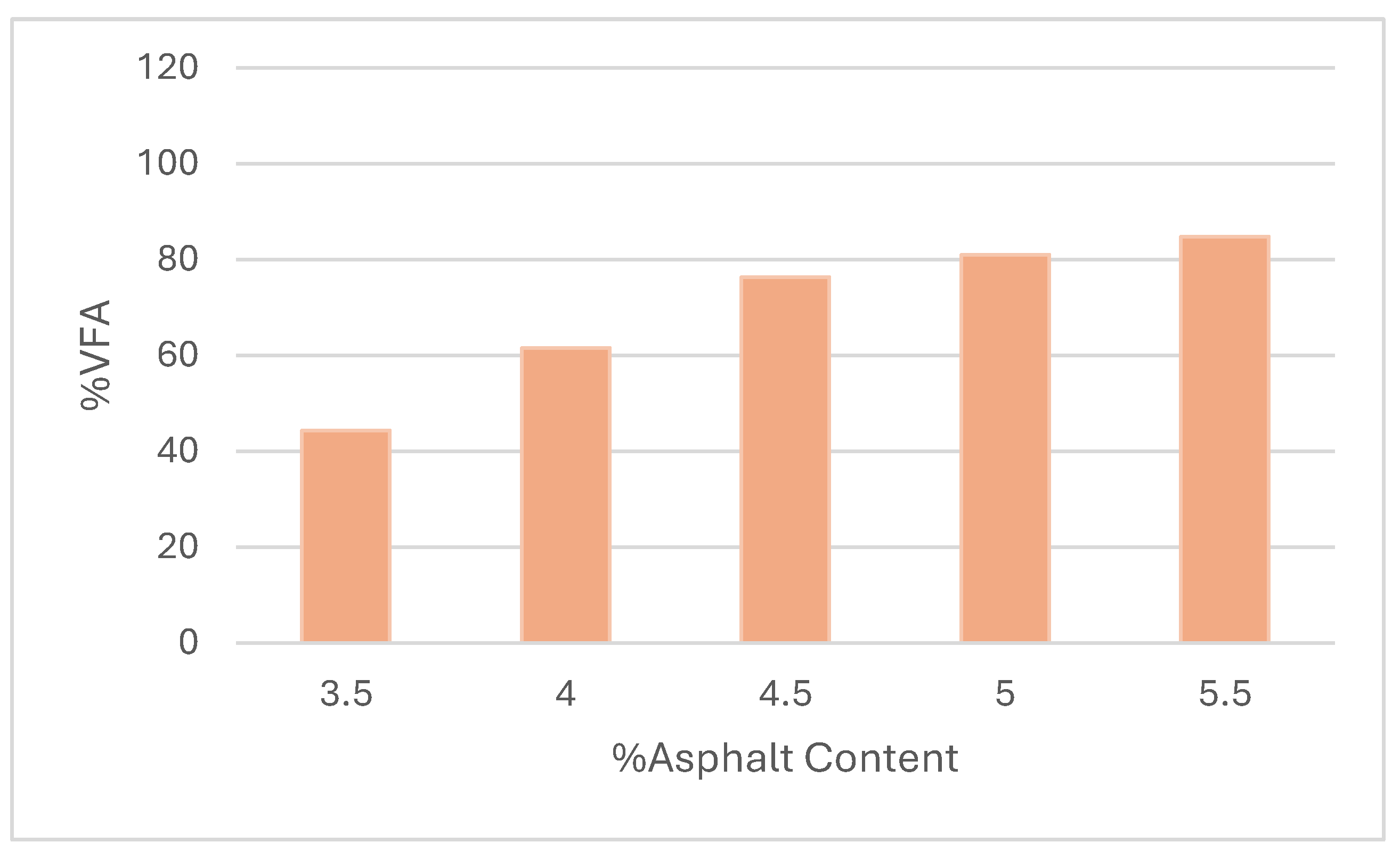

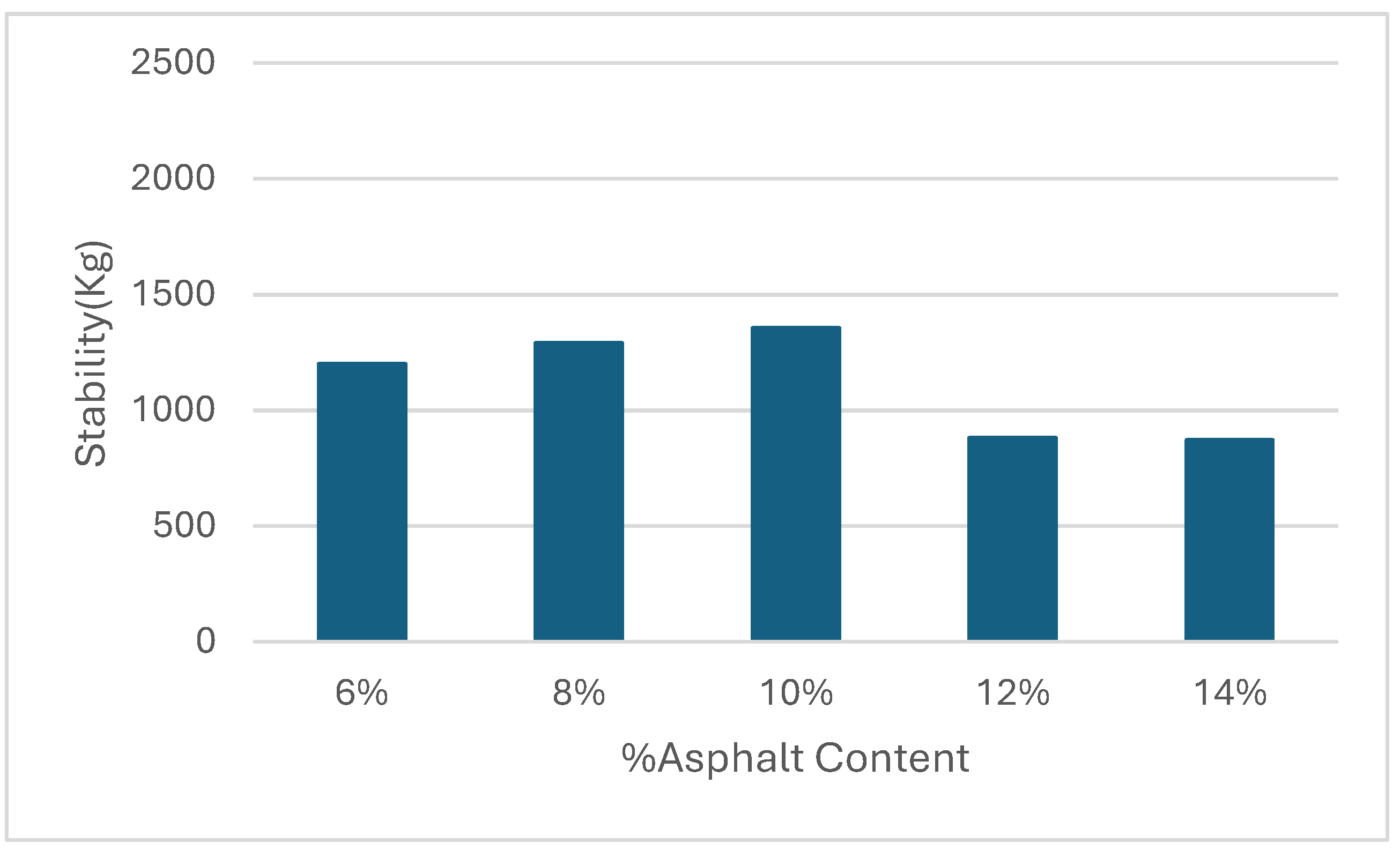

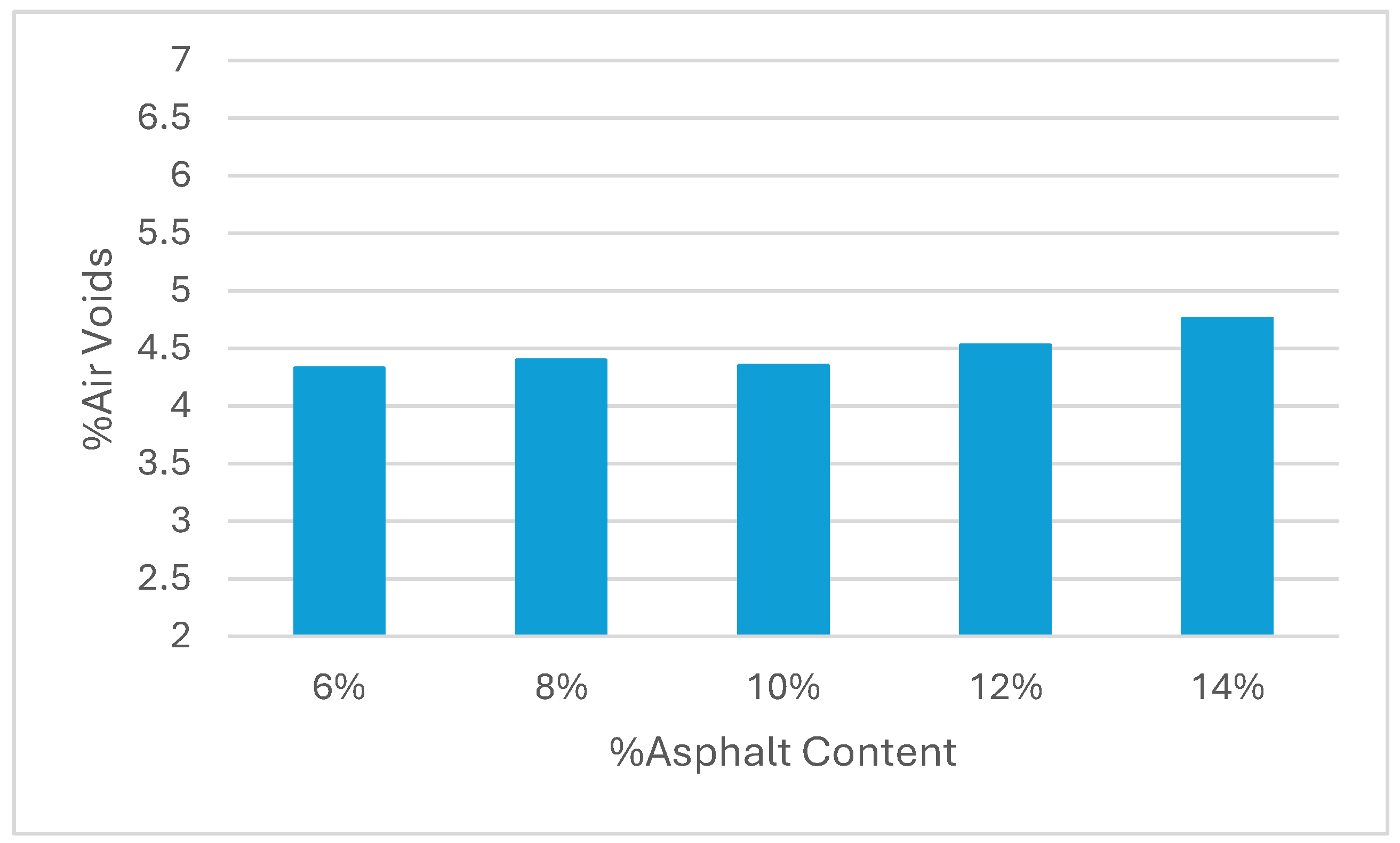

3.1. Determining Optimum Bitumen Content

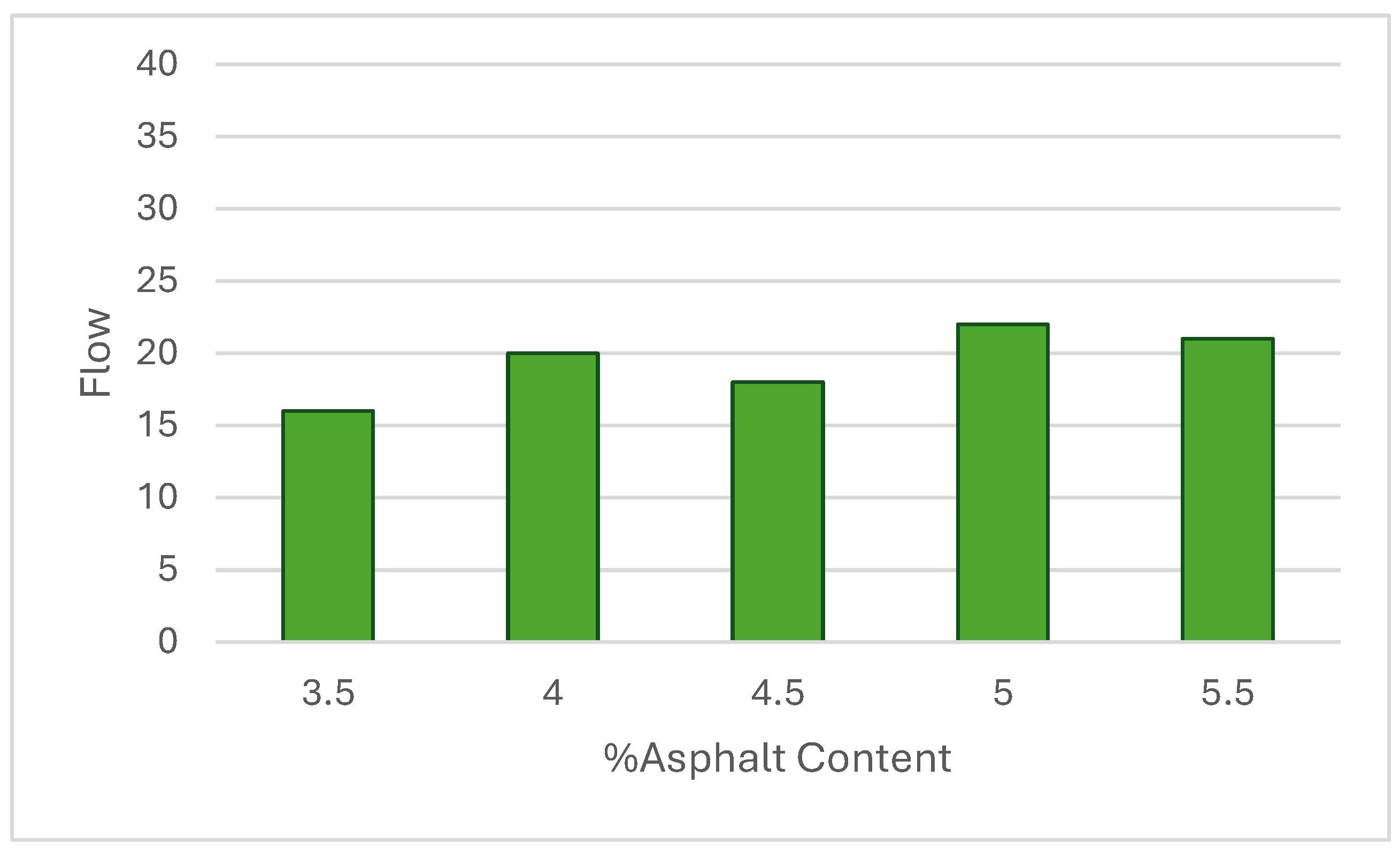

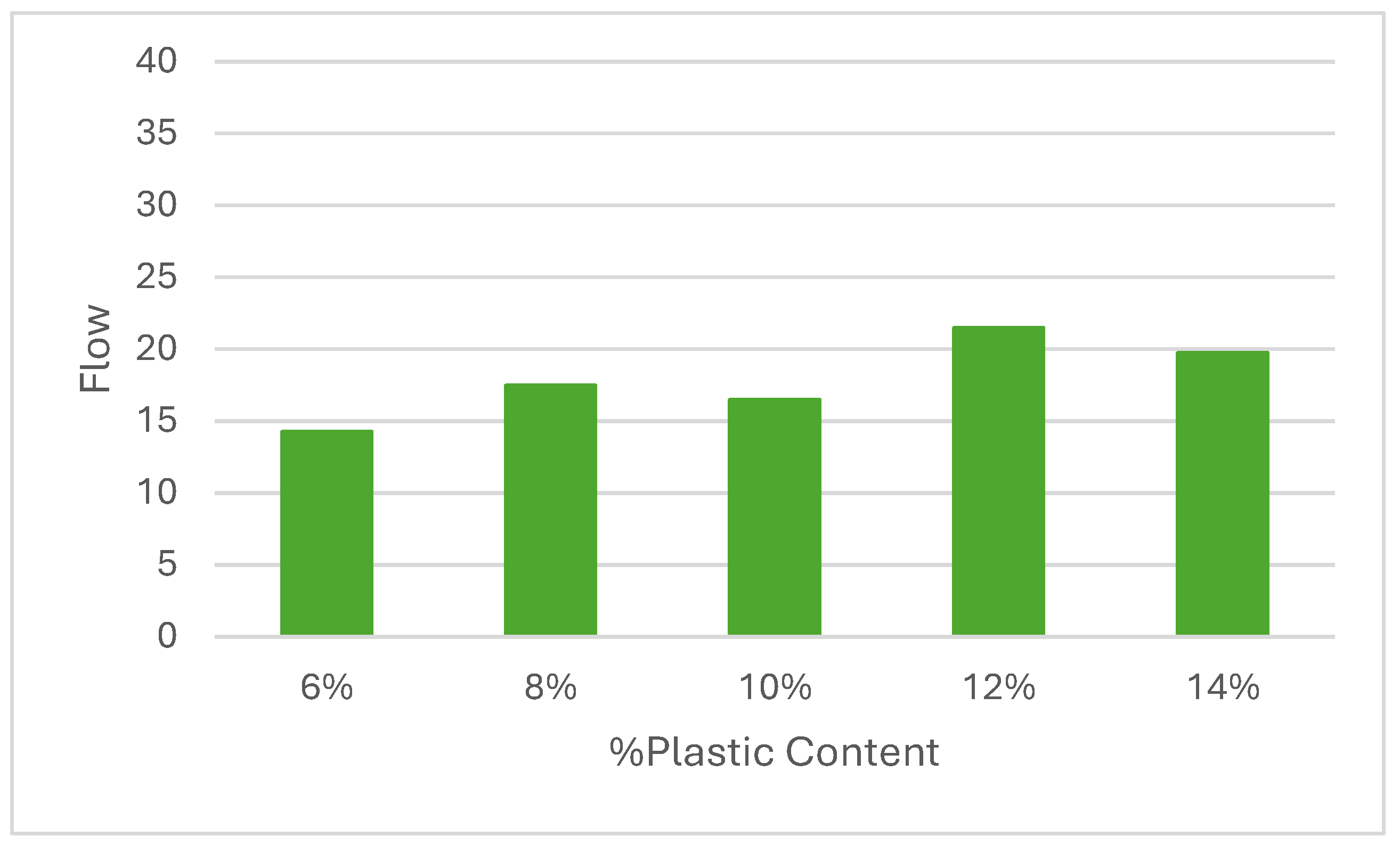

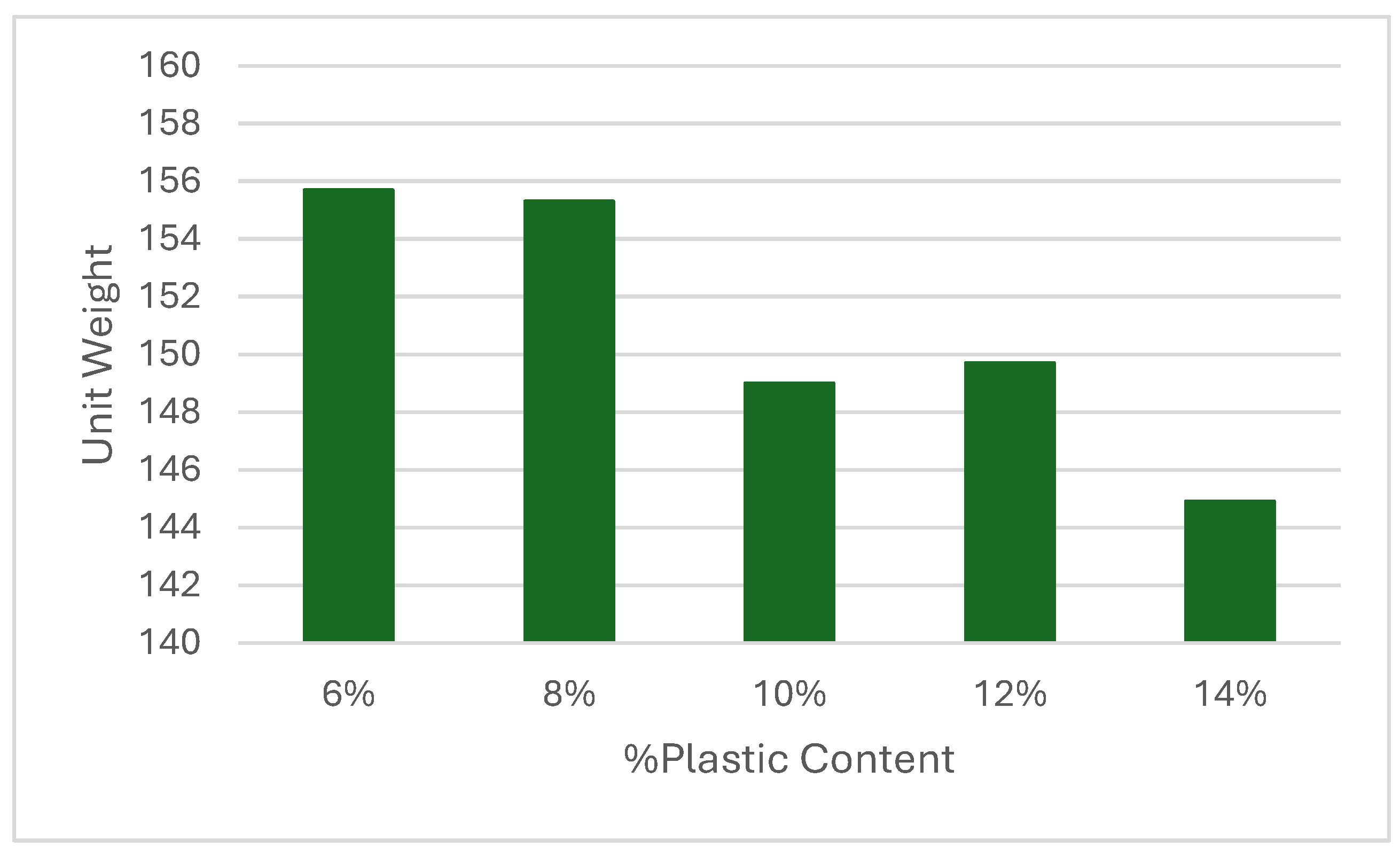

3.2. Determining Optimum Plastic Content

4. Conclusion

- Recycled plastic trash is a useful addition to asphalt mixtures, improving their performance and contributing to the sustainable management of plastic waste.

- Because it results in the best stability and 4% air spaces, 10% by weight of the ideal bitumen content is the ideal amount of plastic to be employed as a modifier in asphalt mixtures.

- When compared to conventional asphalt mixes, asphalt mixtures with 10% plastic by weight of the ideal bitumen content exhibit a roughly 30% increase in stability.

- Because waste plastic has a low density by nature, adding waste plastic to asphalt mixtures causes the bulk density to decrease as the percentage of plastic increases.

- As the plastic component rises, plastic-modified asphalt mixtures show higher flow values, which also causes the modified mix to become stiffer.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jafar JJ. Utilisation of waste plastic in bituminous mix for improved performance of roads. KSCE Journal of Civil Engineering. 2016;20(1):243-249. doi:10.1007/S12205-015-0511-0/METRICS. [CrossRef]

- Ziari H, Kaliji AG, Babagoli R. Laboratory evaluation of the effect of waste plastic bottle (PET) on rutting performance of hot mix asphalt mixtures. Pet Sci Technol. 2016;34(9):819-823. doi:10.1080/10916466.2016.1169290. [CrossRef]

- Ahmadinia E, Zargar M, Karim MR, Abdelaziz M, Shafigh P. Using waste plastic bottles as additive for stone mastic asphalt. Mater Des. 2011;32(10):4844-4849. doi:10.1016/J.MATDES.2011.06.016. [CrossRef]

- Modarres A, Hamedi H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater Des. 2014;61:8-15. doi:10.1016/J.MATDES.2014.04.046. [CrossRef]

- Baghaee Moghaddam T, Karim MR, Syammaun T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr Build Mater. 2012;34:236-242. doi:10.1016/J.CONBUILDMAT.2012.02.054. [CrossRef]

- Abdo AMA, Khaimah A. INVESTIGATION THE EFFECTS OF ADDING WASTE PLASTIC ON ASPHALT MIXES PERFORMANCE. 2017;12(15). Accessed May 25, 2024. www.arpnjournals.com.

- Arabani M, Tahami SA, Taghipoor M. Laboratory investigation of hot mix asphalt containing waste materials. Road Materials and Pavement Design. 2017;18(3):713-729. doi:10.1080/14680629.2016.1189349. [CrossRef]

- Nouali M, Derriche Z, Ghorbel E, Chuanqiang L. Plastic bag waste modified bitumen a possible solution to the Algerian road pavements. Road Materials and Pavement Design. 2020;21(6):1713-1725. doi:10.1080/14680629.2018.1560355. [CrossRef]

- Kumbhalwar A, Pratap Singh H, Sakale R. INTERNATIONAL JOURNAL OF PROGRESSIVE EXPERIMENTAL STUDY ON THE IMPACT OF USING WASTE PLASTIC AND GLASS ON THE PROPERTIES OF ASPHALT PAVEMENT PRAVIN. Accessed May 25, 2024. www.ijprems.com.

- Al-Fatlawi SA, Al-Jumaili MA, Eltwati A, Enieb M. Experimental-Numerical Model of Permanent Deformation in Asphalt Paving Mixtures Modified with Waste Plastic and Rubber. AIP Conf Proc. 2023;2775(1). doi:10.1063/5.0140884/2904360. [CrossRef]

- Mosa AM. MODIFICATION OF HOT MIX ASPHALT USING POLYETHYLENE THEREPHTHALATE (PET) WASTE BOTTLES. Accessed May 25, 2024. https://www.researchgate.net/publication/319254306.

- Gürü M, Çubuk MK, Arslan D, Farzanian SA, Bilici I. An approach to the usage of polyethylene terephthalate (PET) waste as roadway pavement material. J Hazard Mater. 2014;279:302-310. doi:10.1016/J.JHAZMAT.2014.07.018. [CrossRef]

- Shamim S, Vikram A. Experimental study on usage of (PET) waste plastic incorporating with (TIO2) titanium dioxide for the construction of plastic roads. Mater Today Proc. Published online February 15, 2023. doi:10.1016/J.MATPR.2023.01.320. [CrossRef]

- Leng Z, Padhan RK, Sreeram A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J Clean Prod. 2018;180:682-688. doi:10.1016/J.JCLEPRO.2018.01.171. [CrossRef]

- De Arimateia Almeida E Silva J, De Figueirêdo Lopes Lucena LC, Rodrigues JKG, Carvalho MW, Costa DB. Use of Micronized Polyethylene Terephthalate (Pet) Waste in Asphalt Binder. Pet Sci Technol. 2015;33(15-16):1508-1515. doi:10.1080/10916466.2015.1079538. [CrossRef]

- Shbeeb L, Awwad MT. The Use of Polyethylene in Hot Asphalt Mixtures. Am J Appl Sci. 2007;4(6):390-396.

- Atta El-Saikaly M, Jendia S. Study of the Possibility to Reuse Waste Plastic Bags as a Modifier for Asphalt Mixtures Properties (Binder Course Layer).

- Genet MB, Sendekie ZB, Jembere AL. Investigation and optimization of waste LDPE plastic as a modifier of asphalt mix for highway asphalt: Case of Ethiopian roads. Case Studies in Chemical and Environmental Engineering. 2021;4:100150. doi:10.1016/J.CSCEE.2021.100150. [CrossRef]

- Lubis AS, Muis ZA, Siregar NA. The effects of low-density polyethylene (LDPE) addition to the characteristics of asphalt mixture. IOP Conf Ser Earth Environ Sci. 2020;476(1):012063. doi:10.1088/1755-1315/476/1/012063. [CrossRef]

- Prahara E, Aswita F, Niluh Putu Shinta ES. The effect of High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) on characteristics of asphalt concrete with dry and wet mixing process. IOP Conf Ser Mater Sci Eng. 2020;852(1):012056. doi:10.1088/1757-899X/852/1/012056. [CrossRef]

- Nisar J, Shafi Mir M, Vivek. Study on optimal preparation and rheological characteristics of waste low density polyethylene (LDPE)/styrene butadiene styrene (SBS) composite modified asphalt binder. Constr Build Mater. 2023;407:133459. doi:10.1016/J.CONBUILDMAT.2023.133459. [CrossRef]

- Abduljabbar N, Al-Busaltan S, Dulaimi A, Al-Yasari R, Sadique M, Nageim H Al. The effect of waste low-density polyethylene on the mechanical properties of thin asphalt overlay. Constr Build Mater. 2022;315:125722. doi:10.1016/J.CONBUILDMAT.2021.125722. [CrossRef]

- Almeida A, Capitão S, Bandeira R, Fonseca M, Picado-Santos L. Performance of AC mixtures containing flakes of LDPE plastic film collected from urban waste considering ageing. Constr Build Mater. 2020;232:117253. doi:10.1016/J.CONBUILDMAT.2019.117253. [CrossRef]

- Setyarini NL, Tajudin A. Characteristics of Asphalt Concrete Mixed Using Aggregates Coated by Low Density Polyethilene (LDPE) Plastic Waste. Published online October 1, 2019:12-15. doi:10.2991/APTE-18.2019.1. [CrossRef]

- Mashaan N, Rezagholilou A, Nikraz H, Mashaan NS, Rezagholilou A, Nikraz H. Waste Plastic as Additive in Asphalt Pavement Reinforcement: A review. Accessed May 25, 2024. https://www.researchgate.net/publication/335541754.

- Jan H, Aman MY, Tawab M, Ali K, Ali B. Performance Evaluation of Hot Mix Asphalt Concrete by Using Polymeric Waste Polyethylene. EAI/Springer Innovations in Communication and Computing. Published online 2018:91-99. doi:10.1007/978-3-319-70542-2_7. [CrossRef]

- Hinislioglu S, Agar E. Use of waste high density polyethylene as bitumen modifier in asphalt concrete mix. Mater Lett. 2004;58(3-4):267-271. doi:10.1016/S0167-577X(03)00458-0. [CrossRef]

- Gibreil HAA, Feng CP. Effects of high-density polyethylene and crumb rubber powder as modifiers on properties of hot mix asphalt. Constr Build Mater. 2017;142:101-108. doi:10.1016/J.CONBUILDMAT.2017.03.062. [CrossRef]

- Tahmoorian F, Liyanapathirana S, Yeaman J, Egwurube J. Performance of Hot-Mix Asphalt and Modified Binders Containing Polyethylene. Journal of Transportation Engineering, Part B: Pavements. 2023;149(1):04023001. doi:10.1061/JPEODX.PVENG-502. [CrossRef]

- Heydari S, Hajimohammadi A, Haji Seyed Javadi N, Khalili N. The use of plastic waste in asphalt: A critical review on asphalt mix design and Marshall properties. Constr Build Mater. 2021;309:125185. doi:10.1016/J.CONBUILDMAT.2021.125185. [CrossRef]

- Haider S, Hafeez I, Jamal, Ullah R. Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures. Constr Build Mater. 2020;235:117496. doi:10.1016/J.CONBUILDMAT.2019.117496. [CrossRef]

- Abdullah ME, Abd Kader SA, Putra Jaya R, Yaacob H, Abdul Hassan N, Che Wan CN. Effect of Waste Plastic as Bitumen Modified in Asphalt Mixture. MATEC Web of Conferences. 2017;103:09018. doi:10.1051/MATECCONF/201710309018. [CrossRef]

- Ma Y, Zhou H, Jiang X, et al. The utilization of waste plastics in asphalt pavements: A review. Cleaner Materials. 2021;2:100031. doi:10.1016/J.CLEMA.2021.100031. [CrossRef]

- Jafar JJ. Utilisation of waste plastic in bituminous mix for improved performance of roads. KSCE Journal of Civil Engineering. 2016;20(1):243-249. doi:10.1007/S12205-015-0511-0/METRICS. [CrossRef]

- Ranieri M, Costa L, Oliveira JRM, Silva HMRD, Celauro C. Asphalt Surface Mixtures with Improved Performance Using Waste Polymers via Dry and Wet Processes. Journal of Materials in Civil Engineering. 2017;29(10):04017169. doi:10.1061/(ASCE)MT.1943-5533.0002022. [CrossRef]

- Cardone F, Spadoni S, Ferrotti G, Canestrari F. Asphalt mixture modification with a plastomeric compound containing recycled plastic: laboratory and field investigation. Materials and Structures/Materiaux et Constructions. 2022;55(3):1-12. doi:10.1617/S11527-022-01954-4/FIGURES/10. [CrossRef]

- Kumar R, Allah Khan M. Use of Plastic Waste Along with Bitumen in Construction of Flexible Pavements. Accessed May 25, 2024. www.ijert.org.

- Dalhat MA, Al-Abdul Wahhab HI. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. International Journal of Pavement Engineering. 2017;18(4):349-357. doi:10.1080/10298436.2015.1088150. [CrossRef]

- Li H, Hao G, Zhou L, et al. Effect of different waste plastic modifiers on conventional asphalt performance: optimal preparation parameters determination and mechanism analysis. Environmental Science and Pollution Research. 2023;30(38):89910-89926. doi:10.1007/S11356-023-28559-W/FIGURES/18. [CrossRef]

- S. Haider, I. Hafeez, Jamal, and R. Ullah, “Sustainable use of waste plastic modifiers to strengthen the adhesion properties of asphalt mixtures,” Constr Build Mater, vol. 235, p. 117496, Feb. 2020, doi: 10.1016/J.CONBUILDMAT.2019.117496. [CrossRef]

| Sieve Size (mm) | Sieve Size (inch) | (% Passing) | (% Retained) | Weight Retained |

|---|---|---|---|---|

| 19 | 3/4 | 100 | 0 | 0 |

| 12.5 | 1/2 | 82 | 18 | 450 |

| 9 | 3/8 | 70 | 12 | 300 |

| 4.75 | No. 4 | 50 | 20 | 500 |

| 2.36 | No. 8 | 30 | 20 | 500 |

| 0.3 | No. 50 | 10 | 20 | 500 |

| 0.075 | No. 200 | 5 | 5 | 125 |

| Pan | Pan | 0 | 5 | 125 |

| Penetration at 25 °C | Softening Point, °C | Flash Point, °C | Fire Point, °C | Solubility, % | Specific Gravity |

|---|---|---|---|---|---|

| 62.3 | 48 | 270 | 290 | 99.2 | 1.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).