Submitted:

04 September 2024

Posted:

04 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

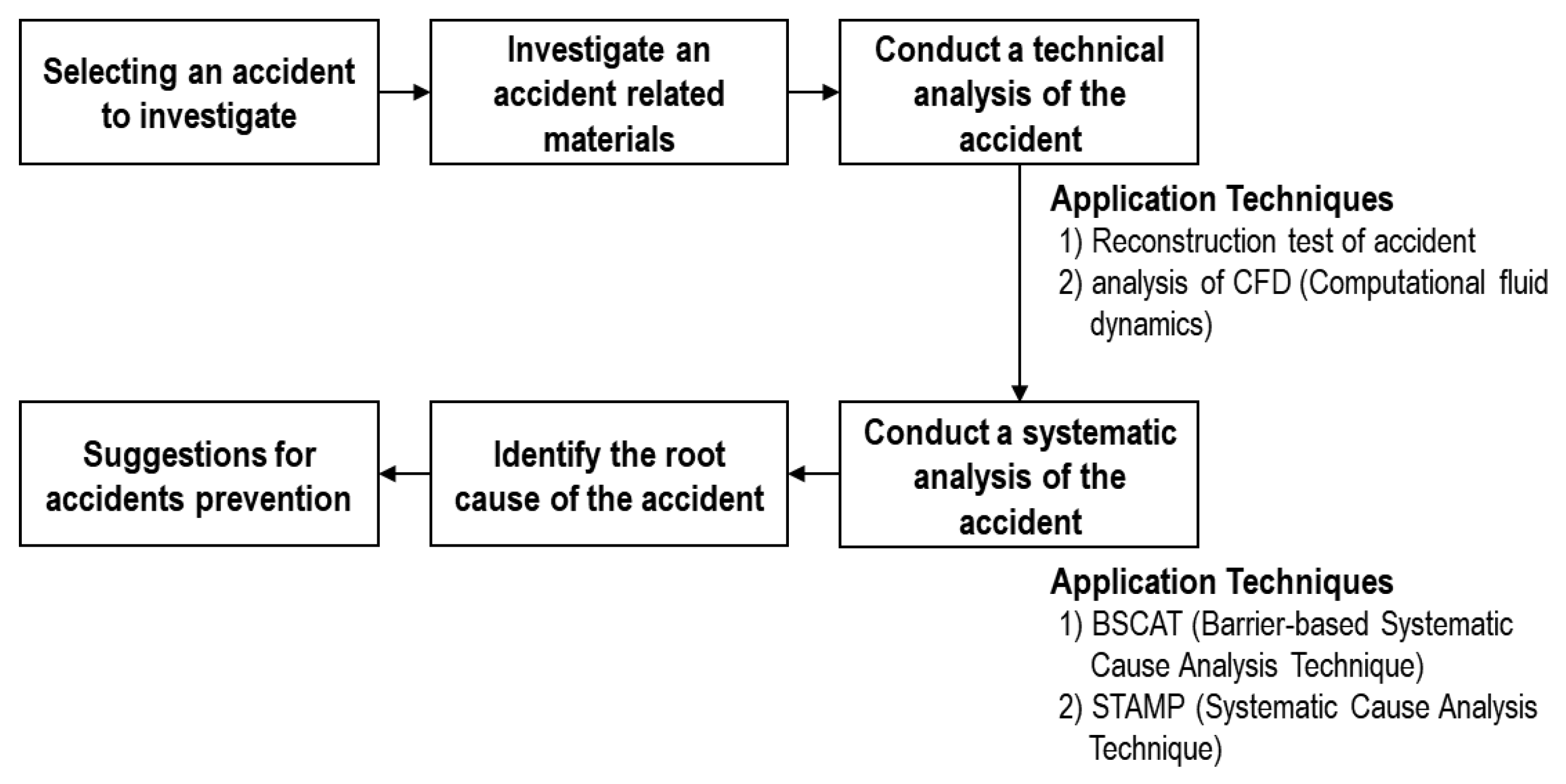

2.2. Methods

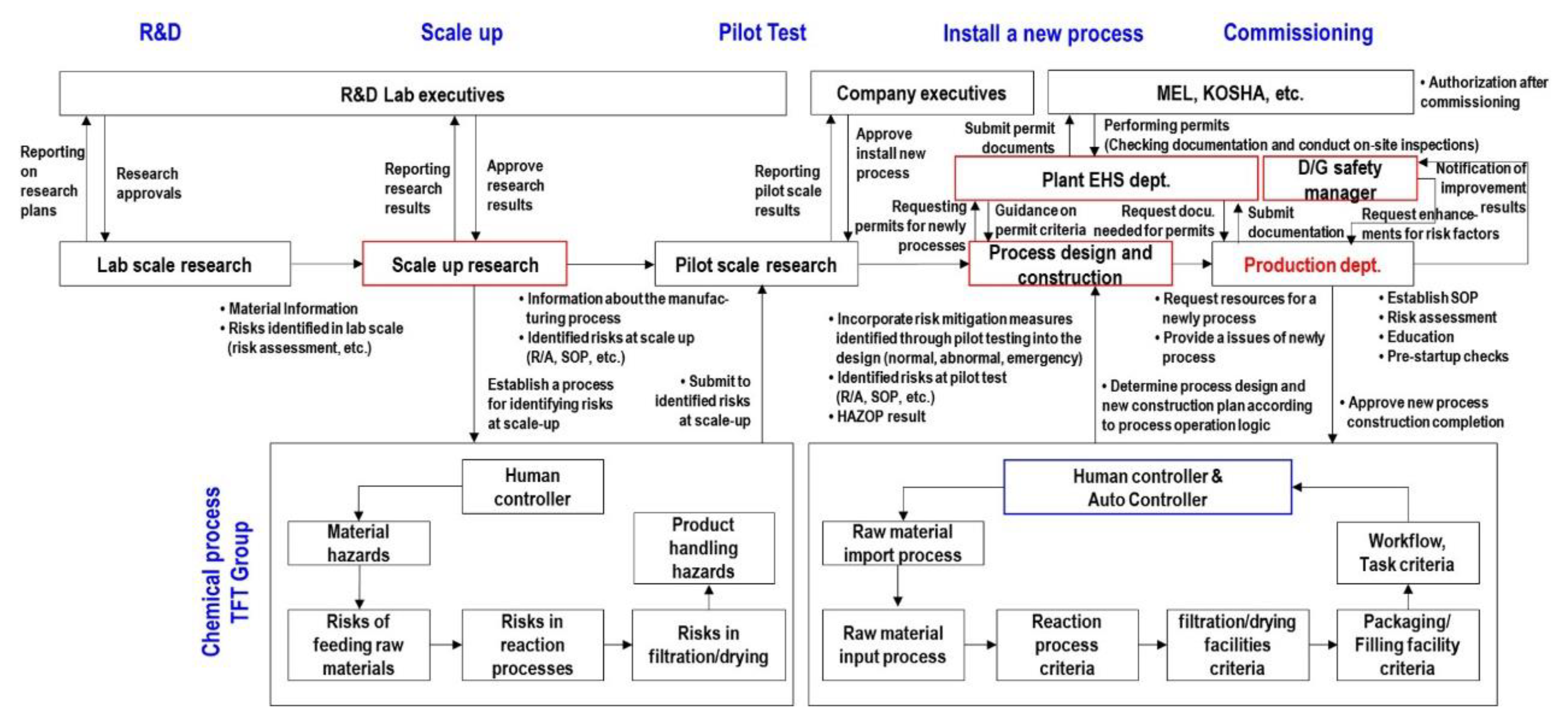

2.2.1. Procedure

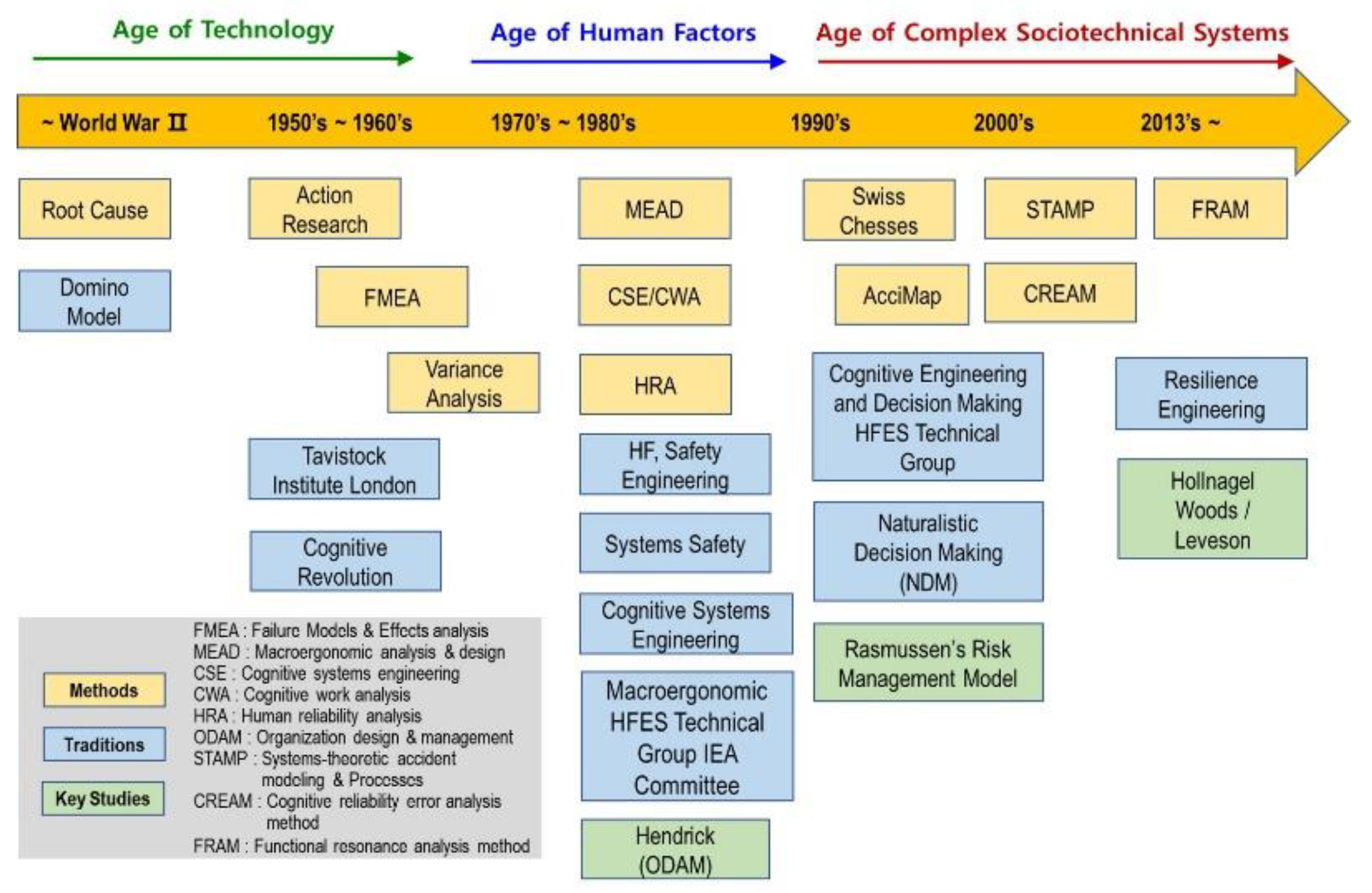

2.2.2. Systematic Accident/Accident Analysis

3. Results

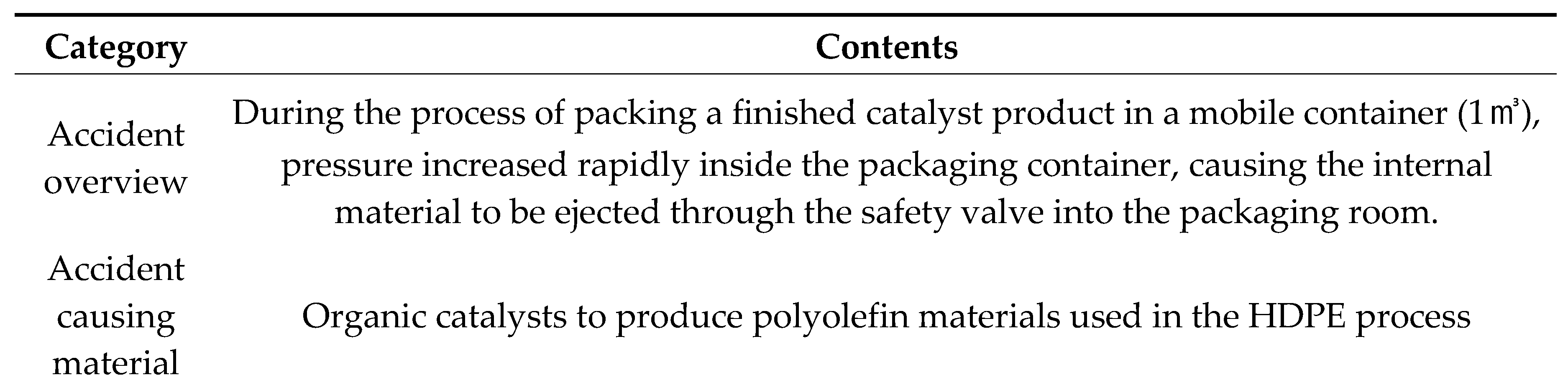

3.1. Technical Analysis Results

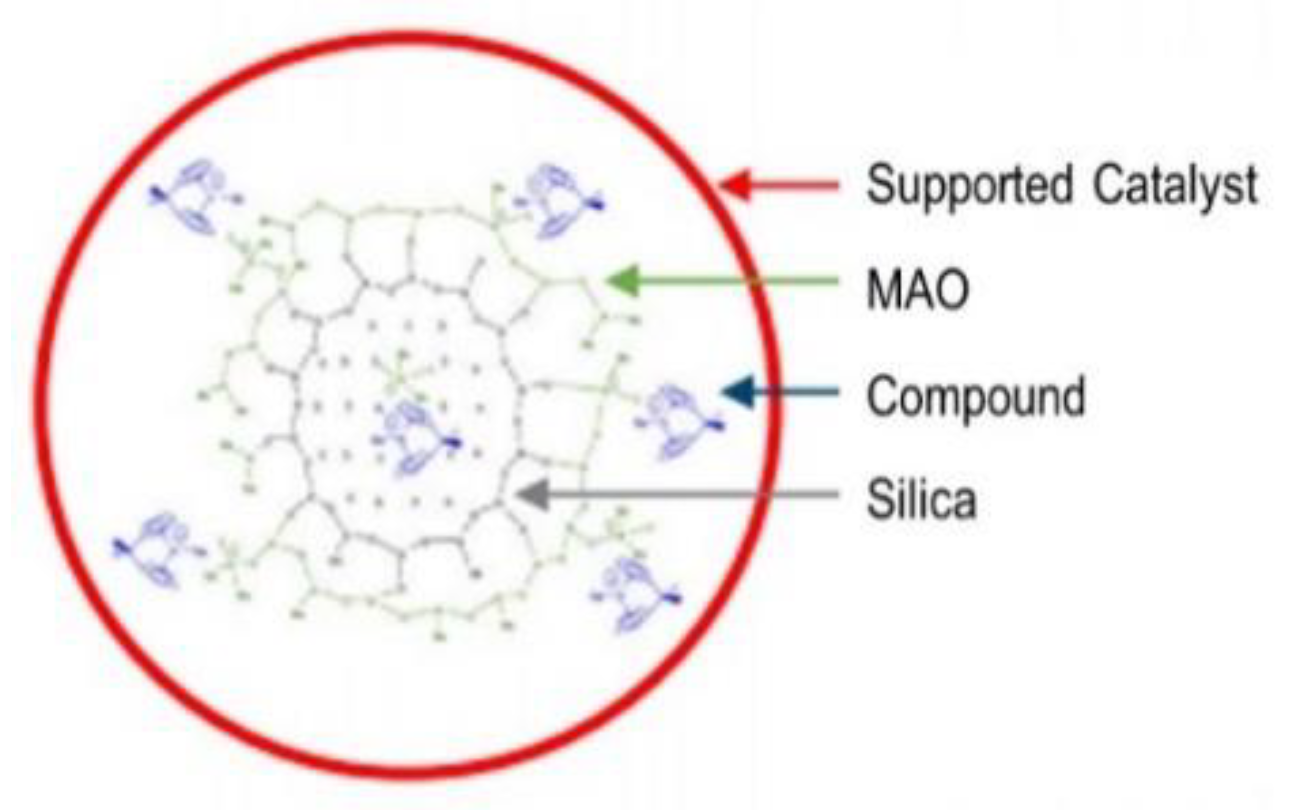

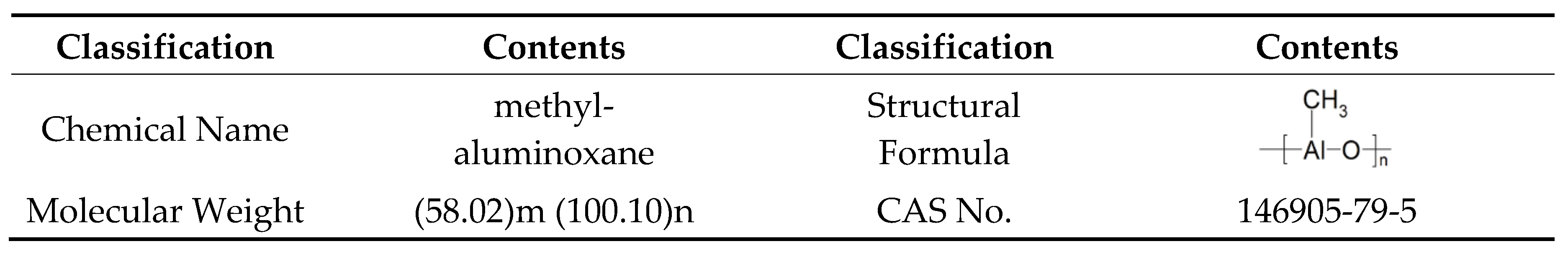

3.1.1. Material Characteristics/ Properties Analysis

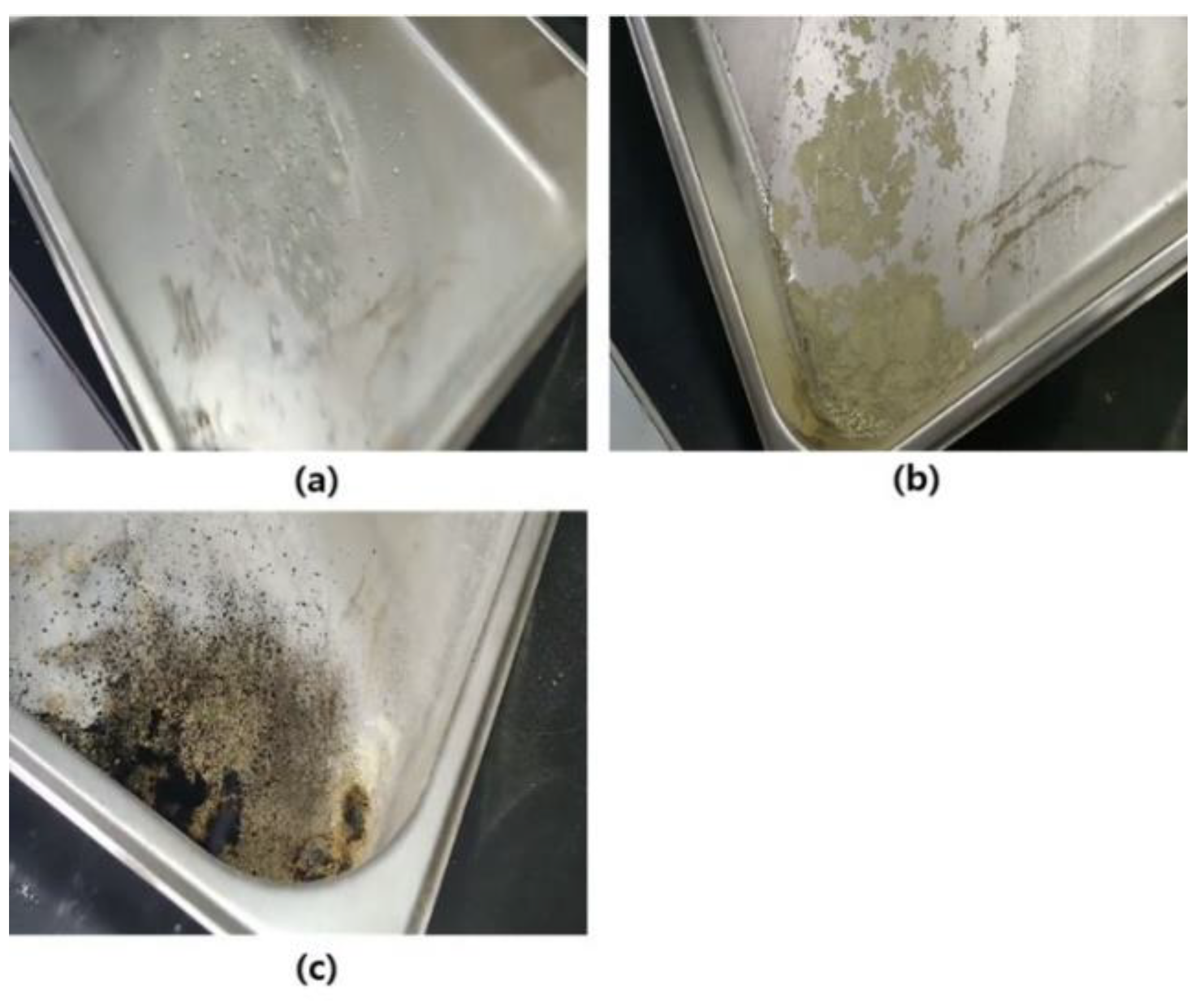

3.1.2. Evaluation on Reactivity with Air

3.1.3. Assessment on Air Introduction during Packaging Process

3.2. Systematic Analysis by Accident

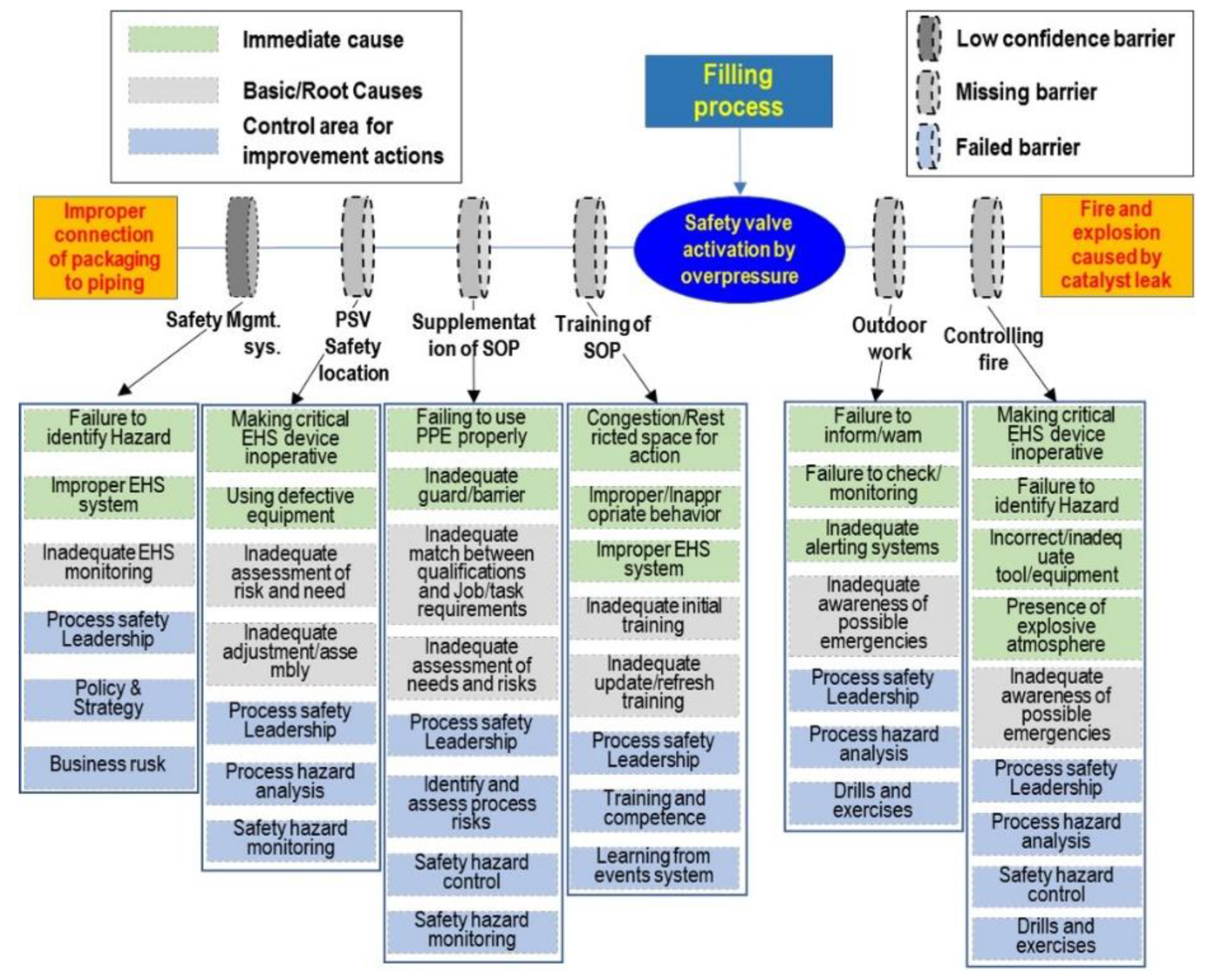

3.2.1. BSCAT Analysis

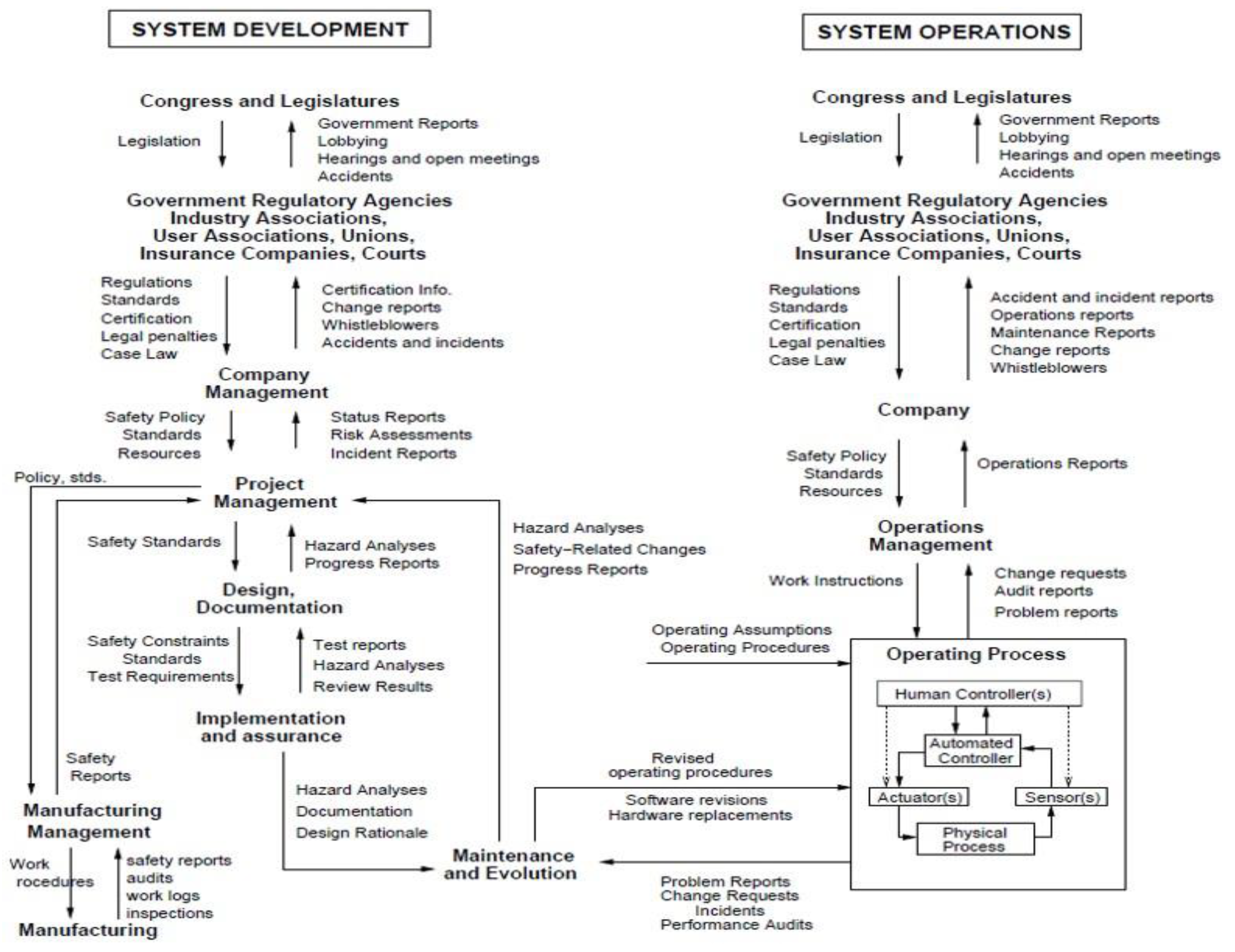

3.2.2. STAMP Analysis

4. Discussion

5. Conclusions

Institutional Review Board Statement

Informed Consent Statement

References

- Winterton, N. Green Chemistry: Deliverance or distraction? Clean Technol. Environ. Policy 2016, 18, 991–1001. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, H.; Li, X.; Zhang, H. Individual factors influencing risk perceptions of hazardous chemicals in China. Environ Res. 2020, 186, 109523. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Ma, X.; Zhang, J.; Yang, Q.; Wei, K. Identifying the Weaker Function Links in the Hazardous Chemicals Road Transportation System in China. Int. J. Environ. Res. Public Health. 2021, 18, 7039. [Google Scholar] [CrossRef] [PubMed]

- Carson, P.; Mumford, C. Hazardous Chemicals Handbook, 1st ed.; Butterworth-Heinemann: Clifton Park, NY, USA, 2013; pp. 11–30. [Google Scholar]

- Li, X.; Liu, T. Community participation effects on preparedness behaviour through risk perception: Empirical data of hazardous chemicals from China. Int. J. Disaster Risk Reduct. 2020, 44, 101421. [Google Scholar] [CrossRef]

- Carpenter, D.O.; Arcaro, K.; Spink, D.C. Understanding the human health effects of chemical mixtures. Environ. Health Perspect. 2002, 110, 25–42. [Google Scholar] [CrossRef]

- Lee, D.J.; Lee, T.H.; Shin, C.H. Study on Improvement Measures for Prevention and Countermeasure of Chemical Accident. Fire Sci. Eng. 2016, 30, 137–143. [Google Scholar] [CrossRef]

- Hua, W.; Chen, J.; Qin, Q.; Wan, Z.; Song, L. Causation analysis and governance strategy for hazardous cargo accidents at ports:Case study of Tianjin Port’s hazardous cargo explosion accident. Mar. Pollut. Bull. 2021, 173 Pt B, 113053. [Google Scholar] [CrossRef]

- Samar, A.H.; Hassan, R.D.; Stefania, M.; Haytham., K.; Firas, K.; Ralph, G.D. Beirut Ammonium Nitrate Blast: Analysis, Review, and Recommendations. Policy and Practice Reviews article 2021, 9, 1–11. [Google Scholar]

- Hartmann, S.; Klaschka, U. Interested consumers’ awareness of harmful chemicals in everyday products. Environ. Sci. Eur. 2017, 29, 29. [Google Scholar] [CrossRef]

- Dong, R.; Wang, J.; Weng, S.; Yuan, H.; Yang, L. Field determination of hazardous chemicals in public security by using a hand-held Raman spectrometer and a deep architecture-search network. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 258, 119871. [Google Scholar] [CrossRef]

- White-Hunt, K.; Makower, M. The Encouragement of Technological Change; Technological Economics Research Unit, University of Stirling: Stirling, Scotland, 1981. [Google Scholar]

- Belke, J.C.; Dietrich, D.Y. The post-Bhopal and post-9/11 transformations in chemical emergency prevention and res/ponse policy in the United States. J. Loss Prev. Process Ind. 2005, 18, 375–379. [Google Scholar] [CrossRef]

- Wang, W.S.; Jeonggue, P.; Sun-yeong, G. A Study on Improvement Plans for Chemical Accident Policies and Industry Support Plans in the Chemicals Control Act (II). Basic Res. Rep. 2017, 2017, 1–163. [Google Scholar]

- Leveson, N.; Daouk, M.; Dulac, N.; Marais, K. Applying STAMP in Accident Analysis, Massachusetts Institute of Technology. Engineering Systems Division, 2003, ESD-WP-2003-02.

- Leveson, N. A New Accident Model for Engineering safer Systems. Safety Science 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Lundberg, J.; Rollenhagen, C.; Hollnagel, E. The Consequences of Underlying Accident Models in Eight Accident Investigation Manuals. Safety science 2009, 47, 1297–1311. [Google Scholar] [CrossRef]

- Qureshi, Z.H. A Review of Accident Modelling Approaches for Complex Critical Sociotechnical Systems, DSTO-TR-2094, Defence Science and Technology Organization, 2008.

- Meng, X.; Chen, G.; Shi, J.; Zhu, G.; Zhu, Y. STAMP-based analysis of deepwater well control safety. Journal of loss prevention in the process industries 2018, 55, 41–52. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, C.; Guo, W.; Dai, J.; Zhao, Z. Systems theoretic accident model and process (STAMP): A literature review. Safety science. 2022, 152, 105596. [Google Scholar] [CrossRef]

- Erick, H.; Josephine, S. Study on Developments in Accident Investigation Methods: A Survey of the “State-of-the-Art”. SKI Report 2008, 2008, 50. [Google Scholar]

- Reason, J. Human error: models and management. British Medical Journal. 2000, 320, 768–770. [Google Scholar] [CrossRef]

- Hollnagel, H. Understanding accidents-from root causes to performance variability. Proceedings of the IEEE 7th Conference on Human Factors and Power Plants:1-6. 2002.

- Underwood, P.; Waterson, P. Accident analysis models and methods: guidance for safety professionals, Loughborough University. 2013.

- Hollnagel, H. FRAM: The Functional Resonance Analysis Method. Farnham, UK: Ashgate. 2012.

- Belmonte, F.; Schoen, W.; Heurley, L.; Capel, R. Interdisciplinary safety analysis of complex socio-technological systems based on the functional resonance accident model: An application to railway traffic supervision. Reliability Engineering and System Safety. 2011, 96, 237–249. [Google Scholar] [CrossRef]

- Waterson, P.; Robertson, M.M.; Cooke, N.J.; Militello, L.; Roth, E.; Stanton, N.A. Defining the methodological challenges and opportunities for an effective science of sociotechnical systems and safety. Ergonomics. 2015, 58, 565–599. [Google Scholar] [CrossRef]

- Seo, D.H.; Gae, G.W.; Choi, Y.R.; Han, O.S. Analysis of a Fire Accident during a Batch Reactor Cleaning with AcciMap, STAMP and FRAM. Journal of the Korean Society of Safety. 2021, 36, 62–70. [Google Scholar]

- Koo, C.C.; Seo, D.H.; Lee, P. H. Analysis of Explosion Accidents in a Chemical Plant using STAMP, a Systematic Cause-and-effect Analysis Technique. Korean Institute of Fire Science & Engineering 2021, 35, 17–23. [Google Scholar]

- Kee, D.H. Review and Comparison of Systemic Accident Analysis Techniques based on Literature Survey. Journal of the Ergonomics Society of Korea. 2021, 40, 55–63. [Google Scholar] [CrossRef]

- Patriarca, R.; Bergstrőm, J.; Di Gravio, G. Defining the functional resonance analysis space: Combining Abstraction Hierarchy and FRAM. Reliability Engineering and System Safety. 2017, 165, 34–46. [Google Scholar] [CrossRef]

- Cho, C.H.; Choi, S.W.; Kim, I.K.; Lee, S.H.; Kim, T.W. Study on the Chemical Accidents Investigation and Effective Response System in Korea 2020. Korean Journal of Hazardous Materials. 2020, 9, 68–75. [Google Scholar] [CrossRef]

- Wienen, H.C.A.; Bukhsh, F.A.; Vriezekolk, E.; Wieringa., R.J. Accident Analysis Methods and Models - A Systematic Literature Review, 2017.

- SEO, D.H.; Park, J.H.; Hyun, J.S.; Kim, J.H. Application Review of a Systemic Accident Analysis Method in the Field of Occupational Health -Focused on the Analysis of Methanol Poisoning Accidents Using STAMP-. Journal of Korean Society of Occupational and Environmental Hygiene. 2023, 33, 188–205. [Google Scholar]

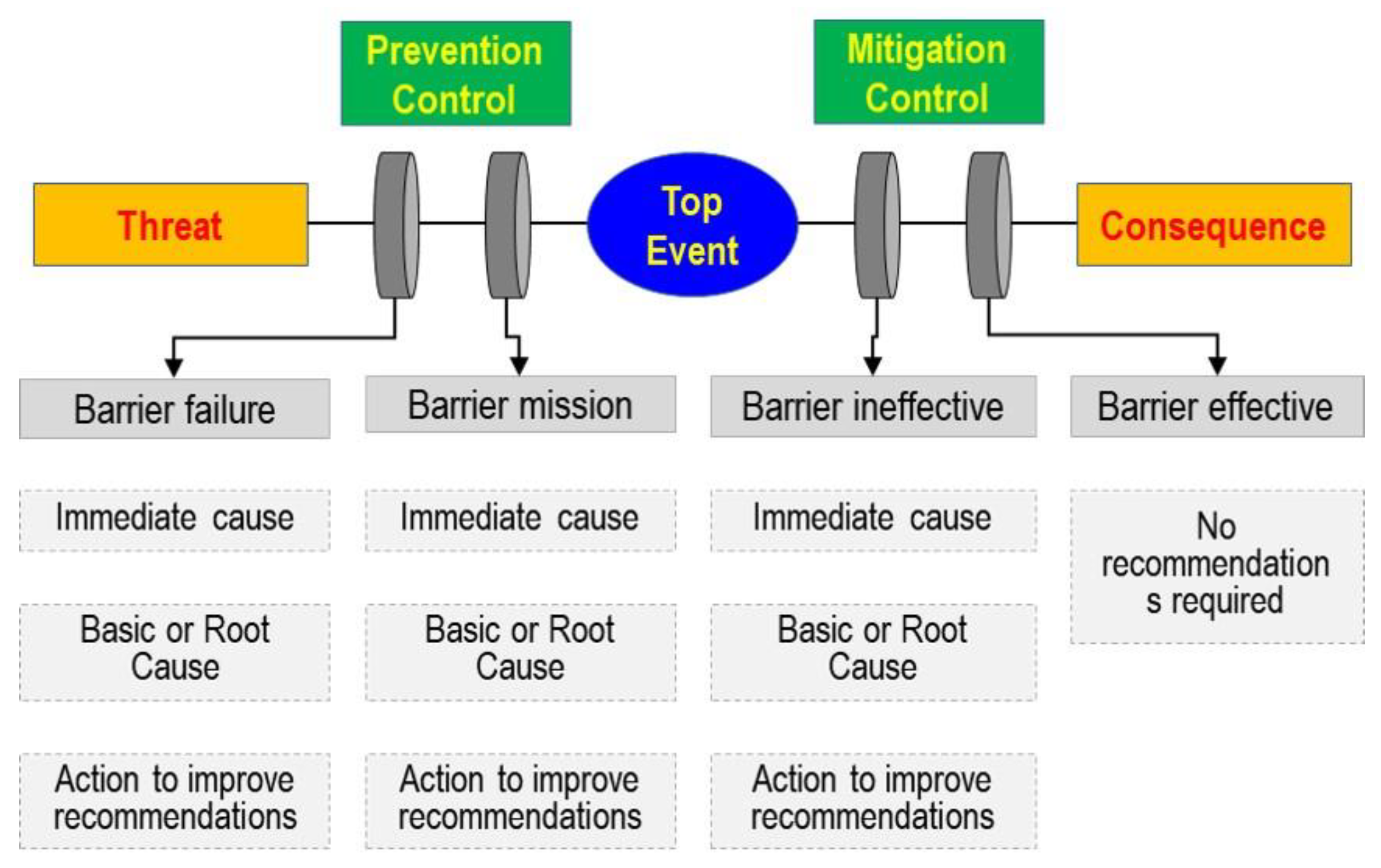

- Robin, P.; Tony, P.; Mark, F.; Stuart, G.F. A Method for Barrier-Based Incident Investigation. Process Safety Progress. 2015, 34, 328–334. [Google Scholar]

- National Fire Information Center E-Fire Statistics. 2018.

- Report of national research institue of fire and disaster. National Research Institute of Fire and Disaster. Japan. 2018. No.124.

| No. | Industries | Accident Date | Process categorization | Disaster |

|---|---|---|---|---|

| 1 | Pharmaceutical raw materials, petroleum products manufacturing | January. 2016 | Fire in a cleaning process of a raw material concentrator | Death |

| 2 | Pharmaceutical raw materials, petroleum products manufacturing | January. 2016 | Fire in the process of feeding raw materials into a reactor | Death |

| 3 | Chemical and rubber products manufacturing | July. 2016 | Fire from a chemical leak in a reactor | Death |

| 4 | Chemical and rubber products manufacturing | October. 2017 | Dust explosion in a facility during pre-operational inspection | Death |

| 5 | Chemical and rubber products manufacturing | November. 2018 | Fire in the process of adding filler to the mixer | Death |

| 6 | Chemical and rubber products manufacturing | August. 2018 | Fire caused by oil vapor in the process of feeding raw materials into an agitator | Serious injury |

| 7 | Chemical and rubber products manufacturing | November. 2019 | Fire during a chemical splay operation | Serious injury |

| 8 | Chemical and rubber products manufacturing | December. 2019 | Explosion during a reactor internal cleaning | Death |

| 9 | Pharmaceutical raw materials, petroleum products manufacturing | May. 2019 | Fire during filtration of chemicals | Serious injury |

| 10 | Pharmaceutical raw materials, petroleum products manufacturing | February. 2020 | Explosion during a reactor internal cleaning | Serious injury |

| 11 | Chemical and rubber products manufacturing | March. 2020 | Explosion during welding on top of reactor | Death |

| 12 | Chemical and rubber products manufacturing | March. 2020 | Fire while cutting piping connected to a storage tank | Death |

| 13 | Pharmaceutical raw materials, petroleum products manufacturing | April. 2020 | Fire during powder feeding operation | Serious injury |

| 14 | Chemical and rubber products manufacturing | May. 2020 | Fire during flange bolt cutting operation | Serious injury |

| 15 | Chemical and rubber products manufacturing | May. 2020 | Fires and explosions in organocatalyst product packaging operations | Death |

| 16 | Chemical and rubber products manufacturing | June. 2021 | Fire during powdered chemical feed operation | Serious injury |

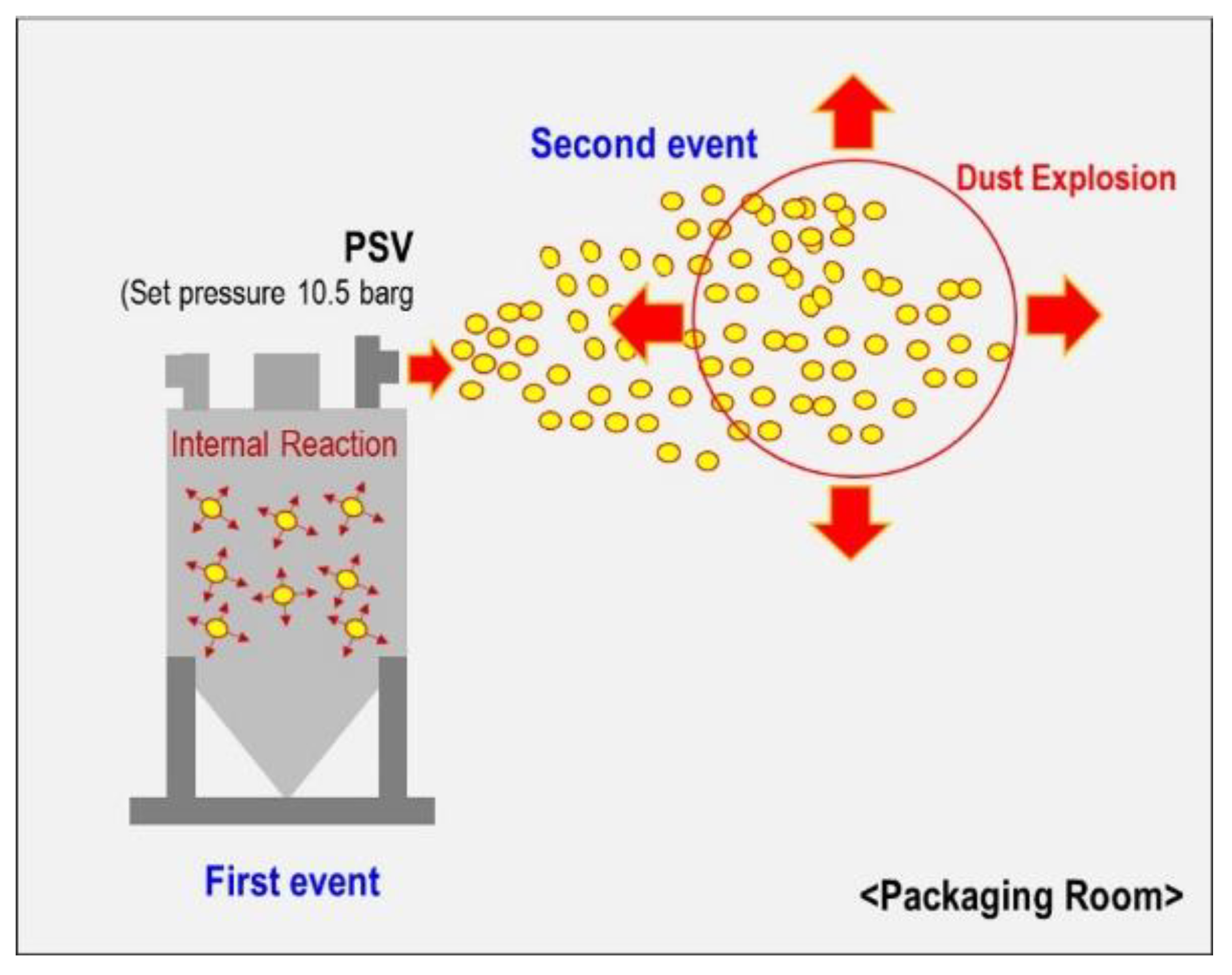

| Sequence of events | Accident cause | Reason for accident | Result |

|---|---|---|---|

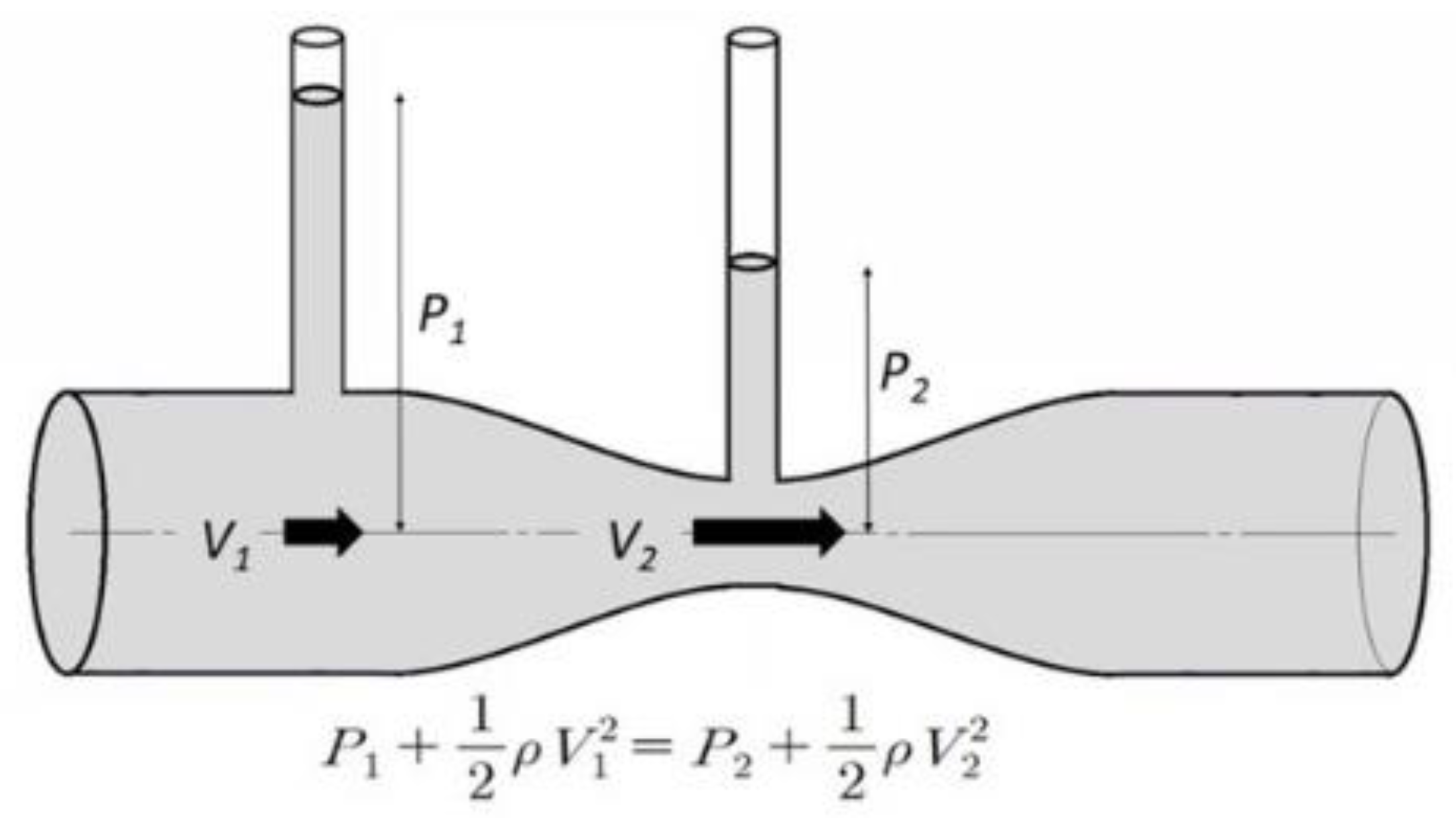

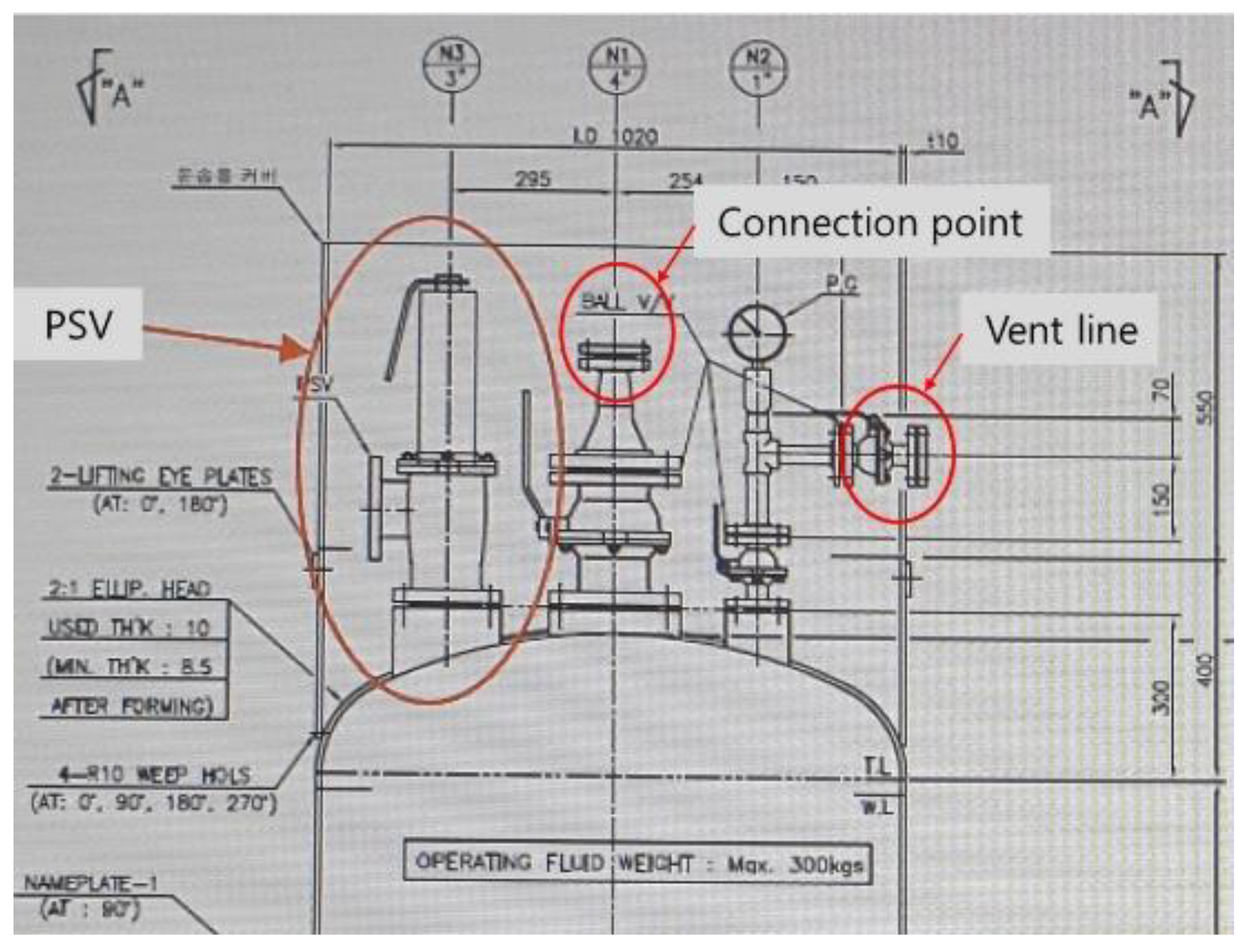

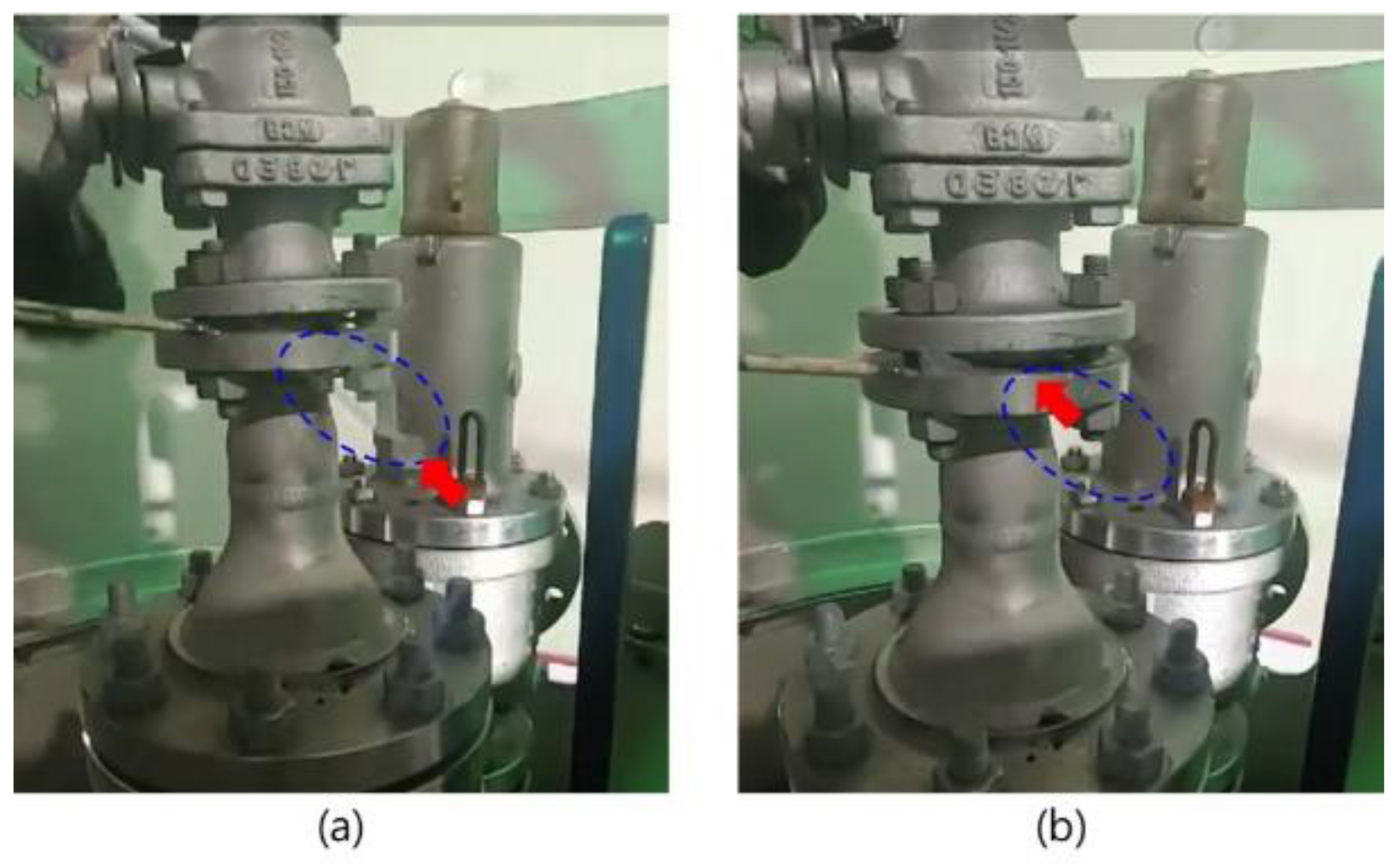

| First Event | Improper connection between container and flange | Air enters between improperly connected flanges and reacts with the catalyst inside the container | Pressure builds up inside the vessel, causing the internal pressure to blow out through the process safety valve (PSV). |

| Second Event | safety valve outlet is not connected to a safety location | Catalyst dust is blowing into the room because the PSV outlet is not connected to a safety location | “Dust explosion” caused by dust released into the packing room |

| Classification | Possible scenario | Investigation result |

|---|---|---|

| Packaging containers |

Moisture residue due to poor container cleaning | Internal analysis of identically handled containers shows no moisture residue |

| Moisture ingress due to improper container storage | ||

| Nitrogen Inlet Line |

Moisture content in nitrogen | The issue did not occur with other products packaged under the same conditions. |

| Moisture in the nitrogen supply line | ||

| Catalyst Filling Line |

Entry of air or moisture during the catalyst packaging line connection process | Nitrogen purging for 5 minutes after packaging line connection removes internal residue |

| Entry of air or moisture during catalyst packaging operations | Need technical analysis | |

| Vent Line | Debris blocks the vent pipe releasing pressure from the packaging container | The pressure inside the packaging container (5 barg) is expelled through the vent pipe during the packing operation |

| Oil inside the pressure gauge installed at the end of the container discharge line enters the packaging container. | Even if oil leaks, it is structured in a way that prevents oil from entering inside the packaging container. | |

| Foreign matter present in the raw material | Foreign matter (such as moisture) in the raw material was mixed in during manufacturing. | The issue did not occur with other products packaged under the same conditions. |

| Reaction Case | Chemical equation | ∆E (kcal/mol) |

비고 |

|---|---|---|---|

| MAO+O2 | 2(CH3AlO) + 3O2 → Al2O3 + 2CO + 3H2O | -55.2 | O2 1 mol |

| MAO+H2O | 2(CH3AlO) + H2O → Al2O3 + 2CH4 | -30.5 | H2O 1 mol |

| <Calculation Tool> ① Software Operations Center : lg chem R&D Center ② Method : Density Functional Theory (DFT) , Becke Exchange Functional & Perdew-Wang 91 Correlation Functional ③ Basis Set : DND(Double-numerical + d Polarization Basis Set) ④ Calculation formula : ΔE°_rxn = [Sum of products for ΔH°_f] – [Sum of reactants for ΔH°_f] | |||

| No. | Barrier | Status | Confidence | Challenge | Performance |

|---|---|---|---|---|---|

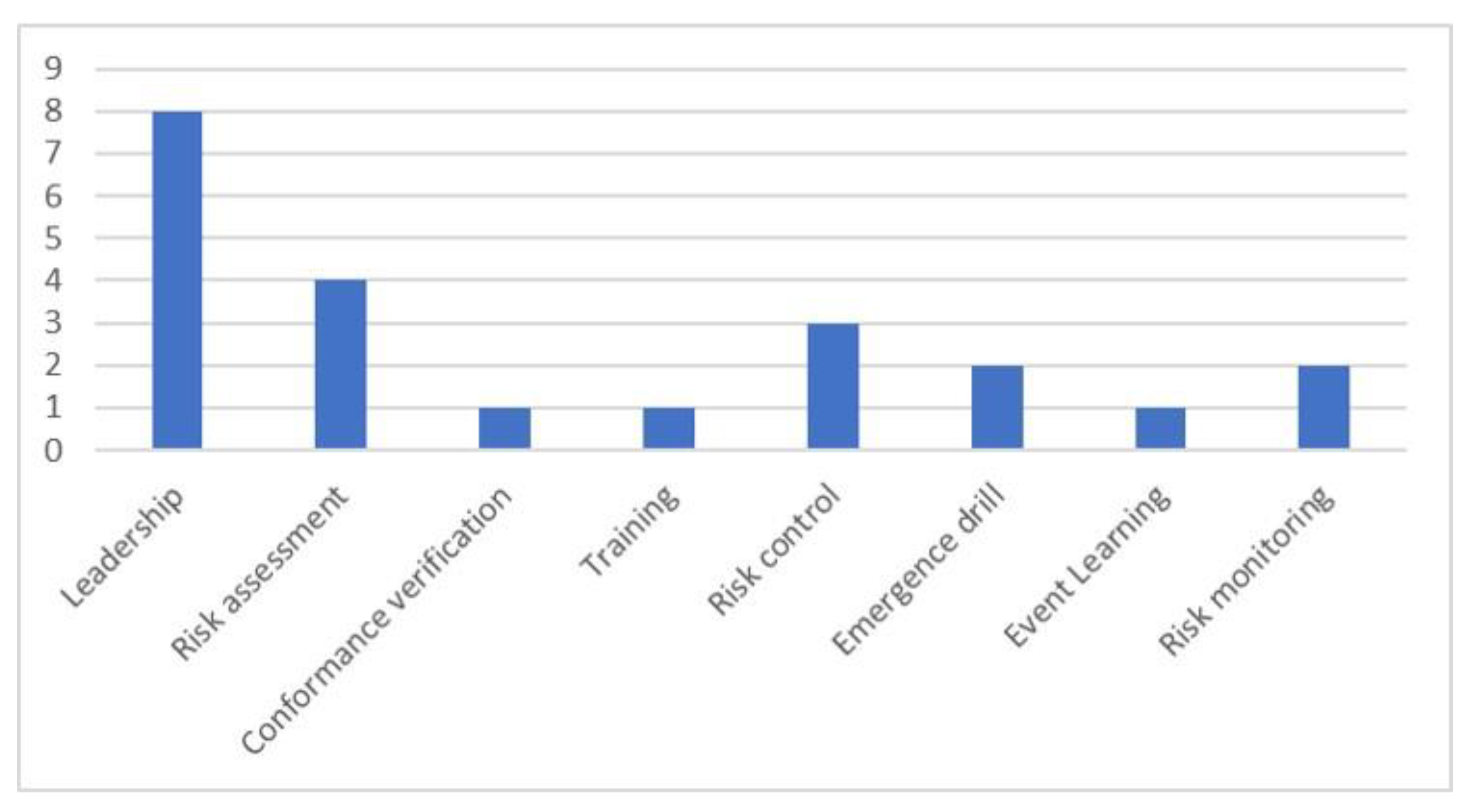

| 1 | Safety Mgmt. Sys. | Low | Contains regulations on procedures and work permits for safe process management | Not working properly |

|

| 2 | Safety valve discharge line connected to combustion/ absorption/capture/recovery facilities. | Missing | Dangerous substances discharged from safety valves must be treated by combustion, absorption, capture, and recovery. | Not operational |

|

| 3 | Supplementation of SOP | Missing | 1) In case the piping is not connected properly, the operator should reconfirm the piping connection on his own or have another operator reconfirm the piping connection Establish a procedure for waiting a certain amount of time after packaging to work on a product because adverse events may occur during packaging |

Not operational |

|

| 4 | Education on standard of procedure (SOP) | Missing | Prevent similar accidents from occurring by training workers on work procedures | Not operational |

|

| 5 | Packaging process organized as an outside work | Missing | Operate catalyst packaging outside to ensure that catalyst dust does not reach explosive dust concentrations even if it is blown outside | Not operational |

|

| 6 | Properly configured fire protection facilities | Missing | Prevent secondary accidents such as fires and explosions by eliminating flammable materials near the workplace or establishing facilities indoors to prevent or respond to dust explosions | Not operational |

| Group | Safety requirements | Improper decision | Defect in organization |

|---|---|---|---|

| MEL/ KOSHA |

1) Enforcement of the safety & health Act 2) Thoroughly review a PSM document |

- | - |

| R&D Center |

1) Establishing safety standards & risk assessment criteria in R&D 2) Establish a safety training program for researchers 3) Establish procedures to identify the risks involved before transferring R&D products to production. |

Underestimating the risk of chemicals and failing to consider the safeguards that should be in place during the scale-up phase. | Enhance the ability to list risks identified in the research phase and clearly communicate them to production and design teams. |

| Production team | 1) Establish procedures to identify key risks before transferring R&D products to production 2) Establish procedures for training workers on key points related to manufacturing new products |

1) Performing piping connections in unsafe locations and conditions without a worker-centric risk assessment. 2) Lack of understanding of what happens when foreign objects are introduced during the packaging process |

Lack of procedure regarding what needs to be reviewed when introducing new products and the ability to worker-centric risk assessments and manage incident cases. |

| EHS Team | 1) Clear cross-functional R&R by PSM element 2) Inventory legal requirements about PSM |

Determined that indoor emissions from PSV lines are not in violation of the law | It is necessary to supplement the function that lists relevant laws and regulations when introducing new products and periodically check them during the construction process. |

| D/G safety manager |

Perform safety management tasks to meet legal requirements when handling hazardous materials | Determining the risk of the pack aging step as low and not participating in the packaging process. | Establish a system to ensure that safety managers are involved in all hazardous materials work |

| Process design team | 1) Establish procedures to incorporate risk factors identified in the research phase into the design. 2) Establish procedures to incorporate accident cases into design |

1) Failure to clearly review legislation during process design 2) Failure to account for human error in process design |

Internal criteria for safe design guidelines (KOSHA Guidelines) must be clarified |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).