1. Introduction

Spacecraft recovery and landing technology plays a crucial role in the field of spaceflight, providing the necessary support and guarantee for the successful implementation of space missions. In this process, the role of parachute is crucial, which can effectively slow down the descending speed of the spacecraft and realize a smooth and safe landing [

1].

Although spacecraft recovery often employs a staged parachute opening system[

2], there are a number of limitations. A staged parachute opening system requires the deployment sequence and the number of the parachutes to be determined in advance, which may limit the adaptability under different atmospheric conditions and flight states. In addition, the design and control of the staged parachute opening system is relatively complex and requires precise planning and execution, which also increases the weight and cost of the system. To solve the limitations of the staged parachute opening systems, the stepless parachute opening system has become a highly sought-after alternative with greater flexibility and adaptability. It is capable of adjusting the angle and degree of parachute deployment according to real-time environmental conditions and flight status, improving the success rate and safety of spacecraft recovery.

To realize the stepless parachute opening system, the parachute dynamic load must be accurately measured. At present, there are some shortcomings in the traditional measurement program, such as the large size of the measurement instrument and the need for wiring, which is difficult to meet the demand for real-time and accurate measurement. The existing parachute cords dynamic load measurement method is also not directly applicable to the parachute opening process of the cords dynamic load measurement[

3].

To solve this problem, this paper proposes a wireless strain load measuring instrument, which consists of an elastomer structure and an signal acquisition system, and can be integrated into the parachute system without damage[

4]. The instrument is able to measure the dynamic load of the cords during parachute opening in real time and accurately, and transmit the data to the upper computer through wireless transmission, so as to monitor the changes of the parachute cords load in real time. This technology can not only provide reliable data for verifying the technical parameters of parachute cords, but also give important support for the design of stepless cords deployment in the future. Its application scope can also be extended to the research, development and testing of aviation parachutes and sports parachutes, which has great social and economic value.

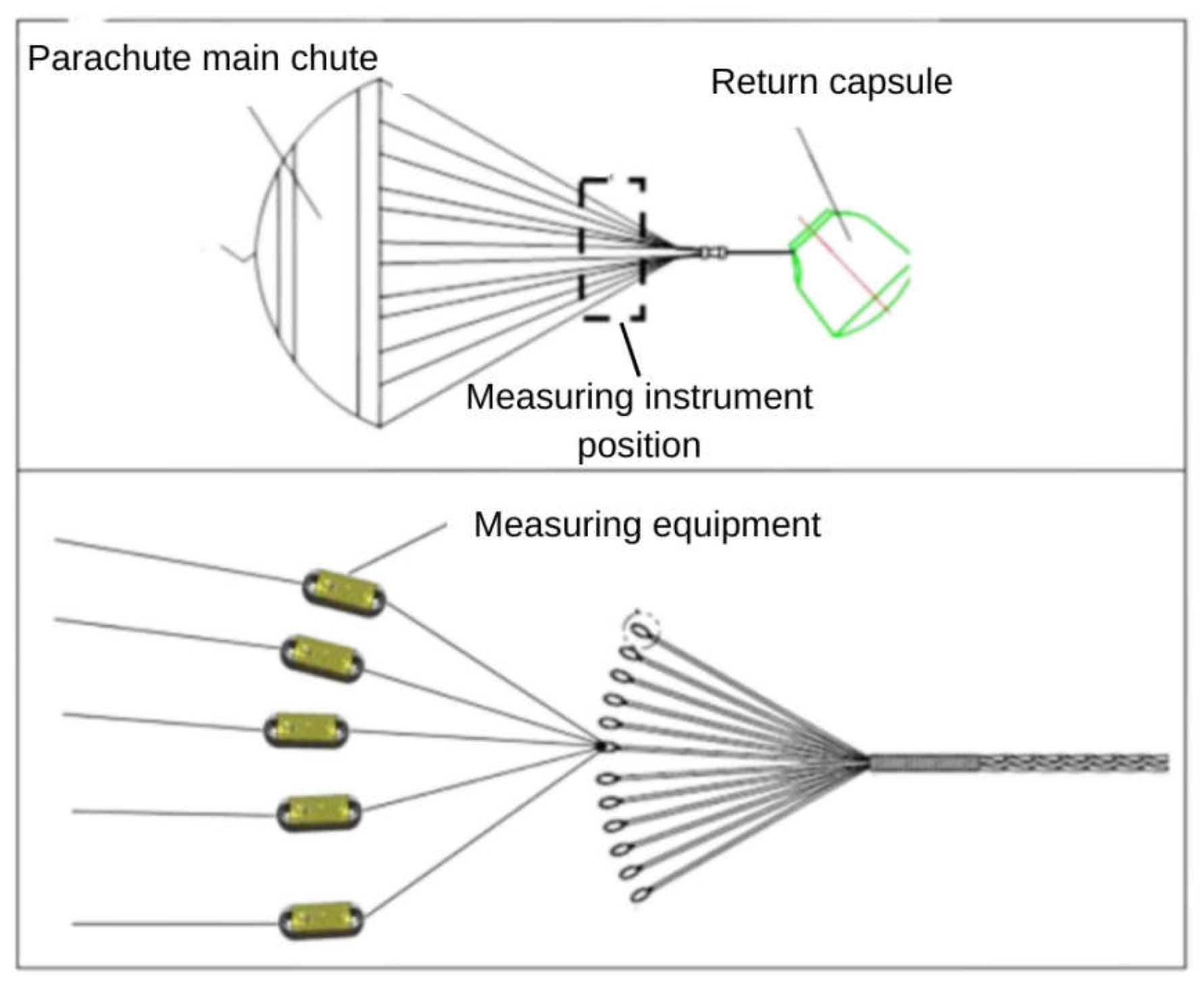

Figure 1.

Schematic of miniature measuring instrument installed in a parachute.

Figure 1.

Schematic of miniature measuring instrument installed in a parachute.

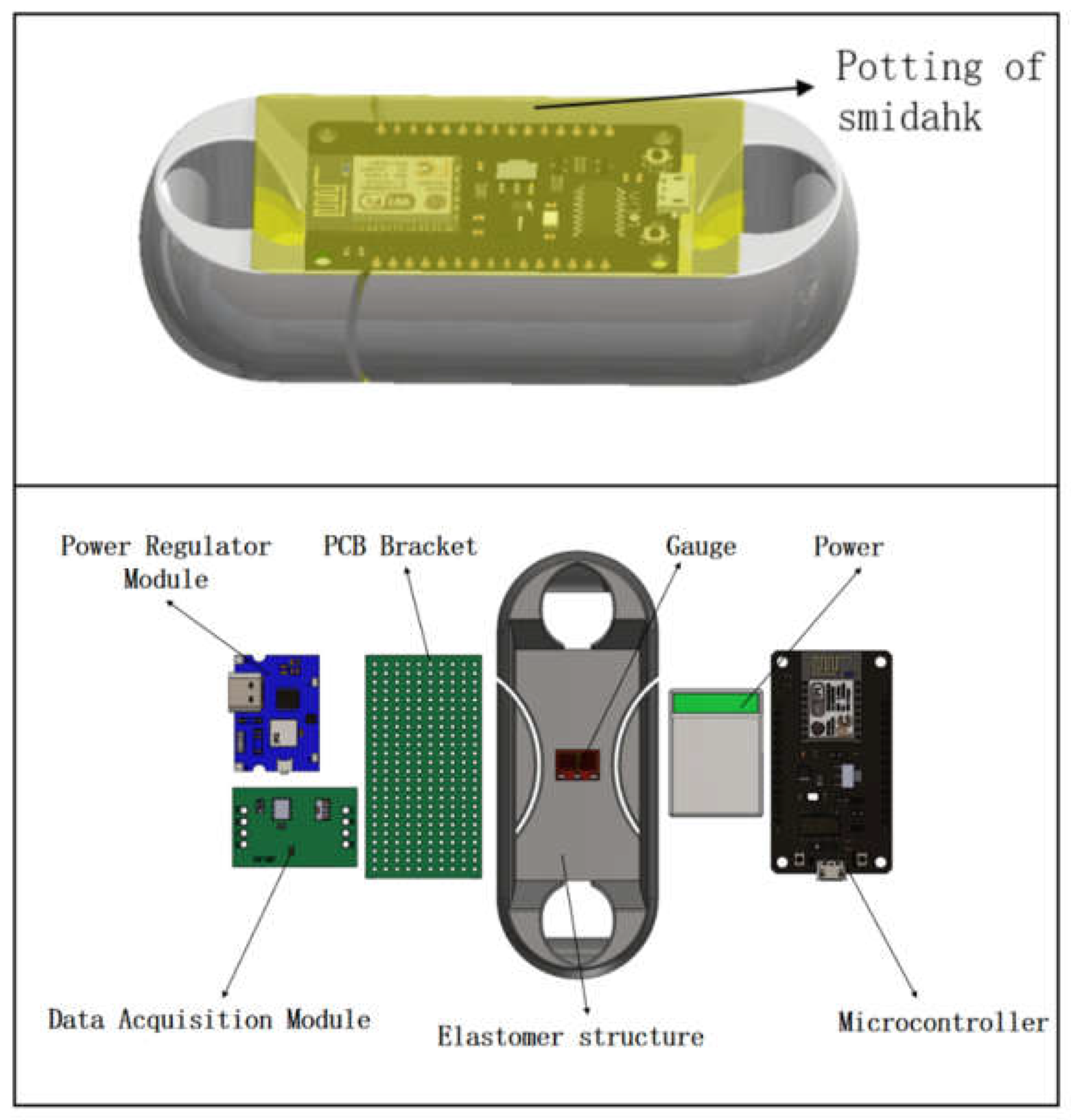

Figure 2.

Schematic of miniature measuring instrument.

Figure 2.

Schematic of miniature measuring instrument.

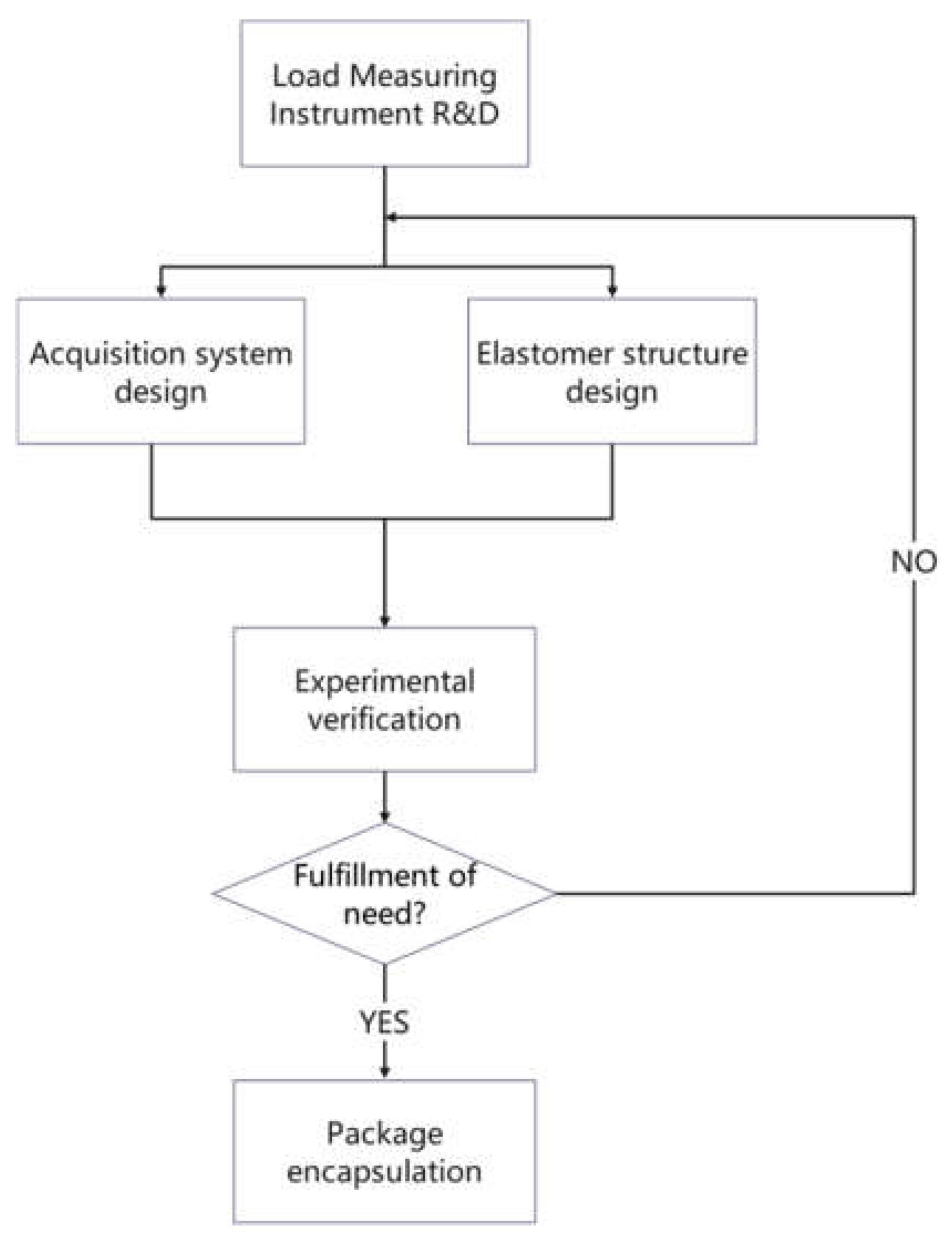

Figure 3.

Parachute Cords Dynamic Load Measuring Instrument R&D Program.

Figure 3.

Parachute Cords Dynamic Load Measuring Instrument R&D Program.

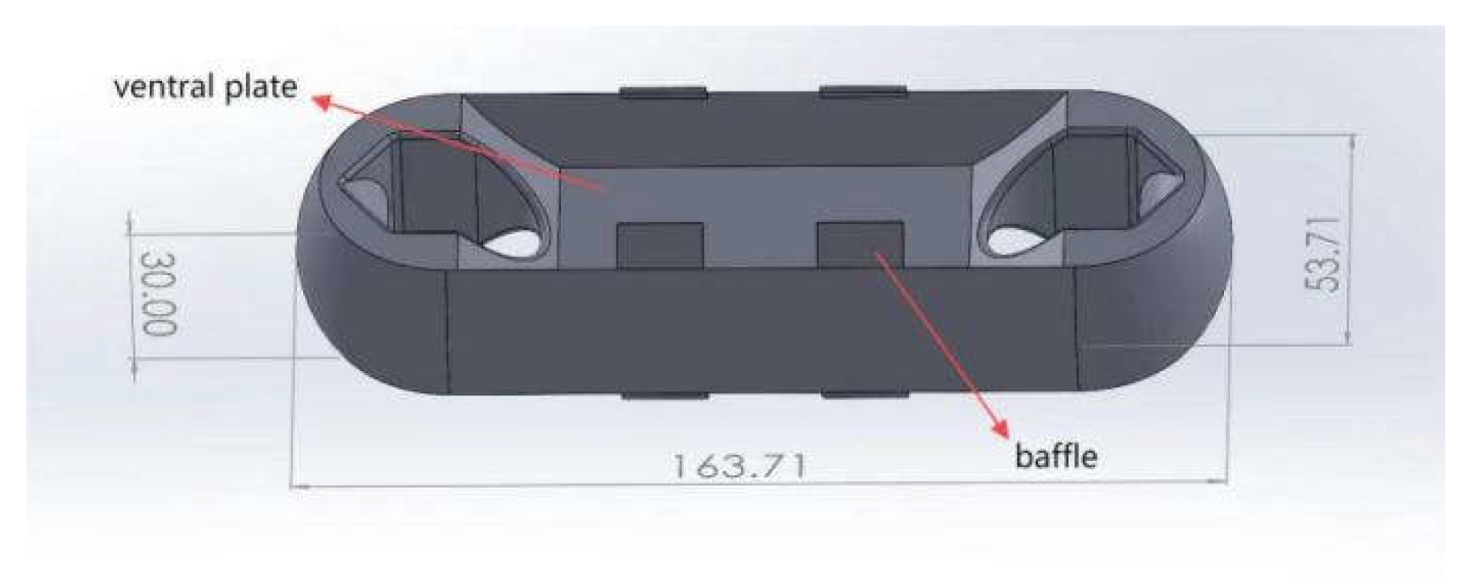

Figure 4.

Design of Elastomer Structure Scheme I.

Figure 4.

Design of Elastomer Structure Scheme I.

Figure 5.

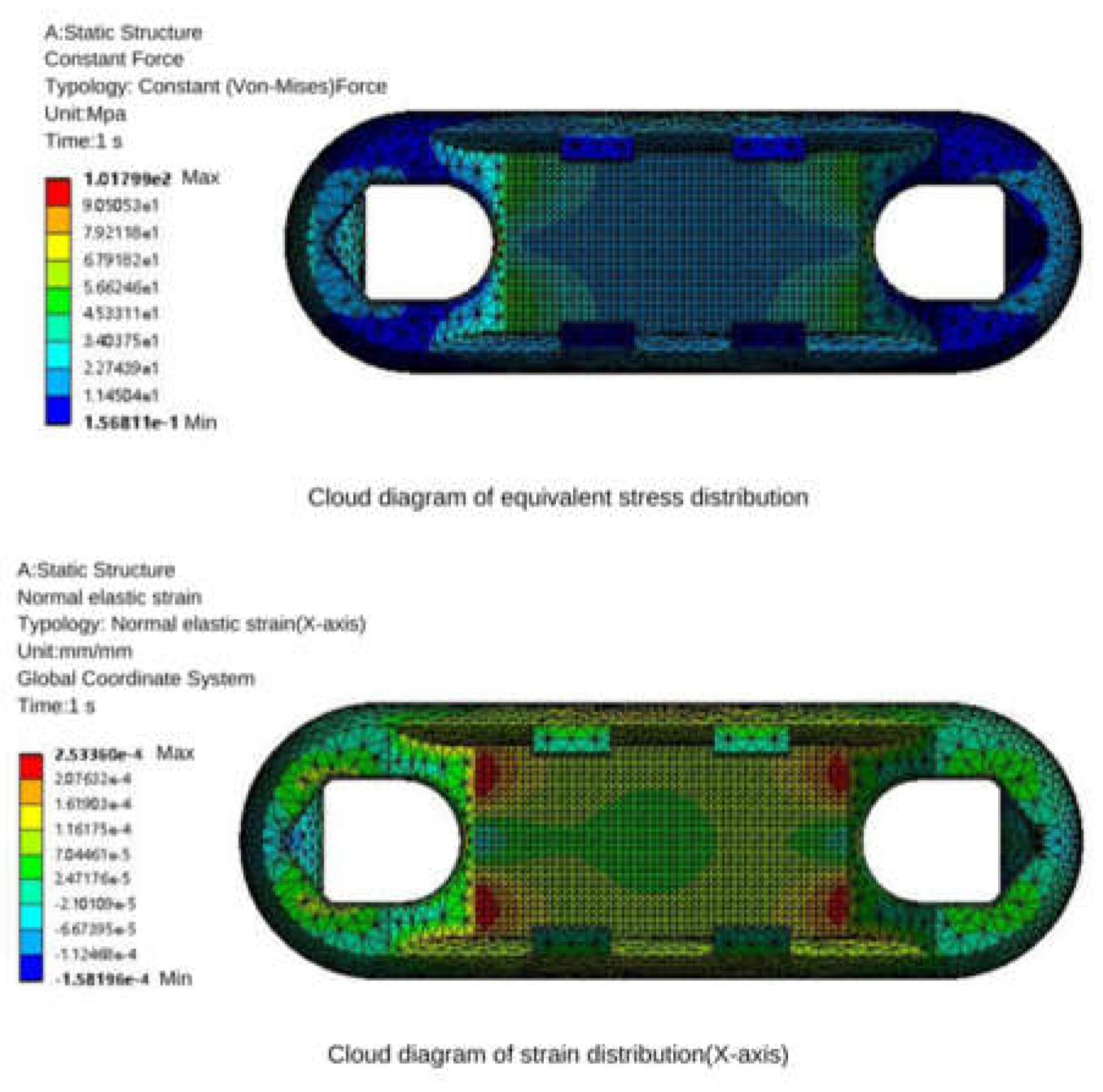

Strain diagram of Elastomer Structure Scheme I.

Figure 5.

Strain diagram of Elastomer Structure Scheme I.

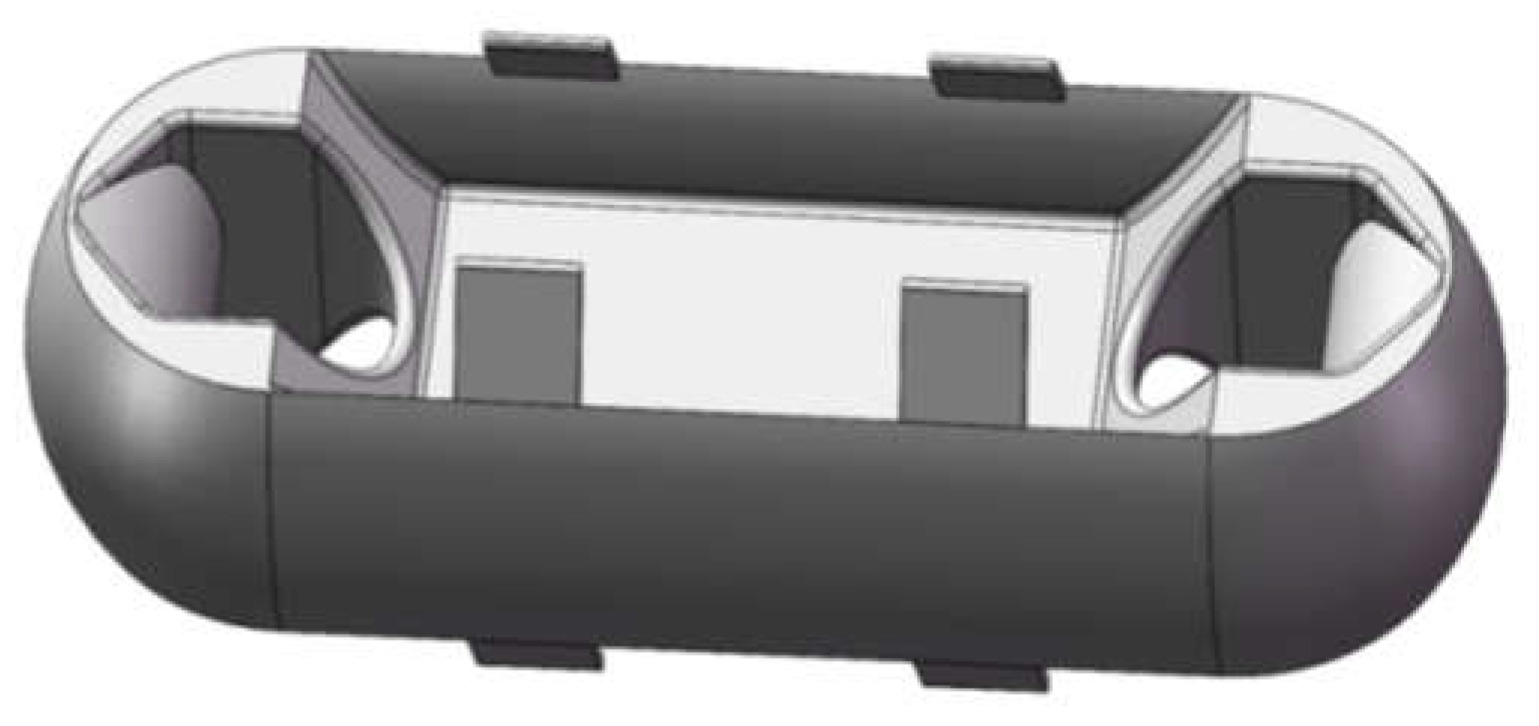

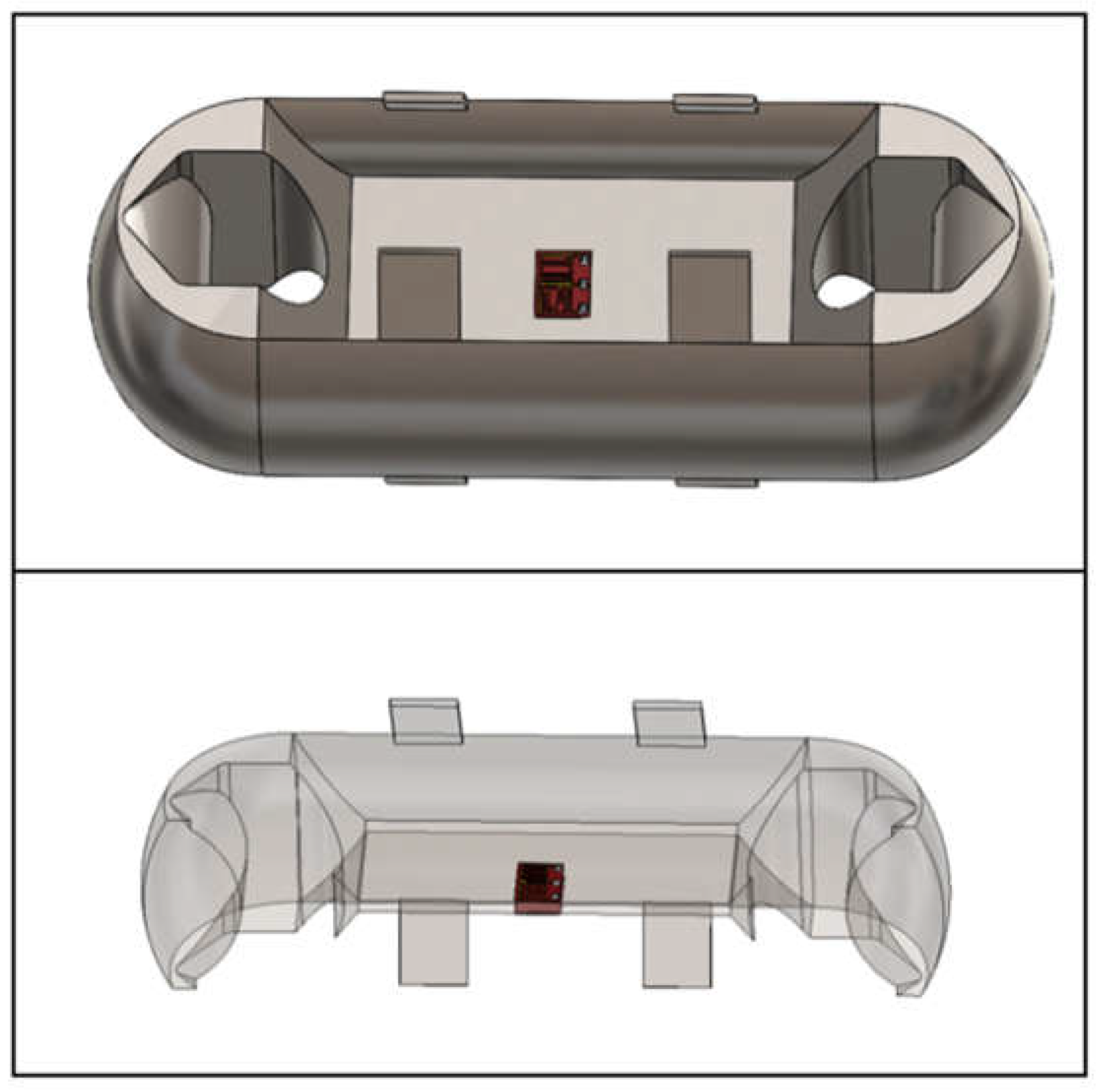

Figure 6.

Elastomer Structure Scheme II.

Figure 6.

Elastomer Structure Scheme II.

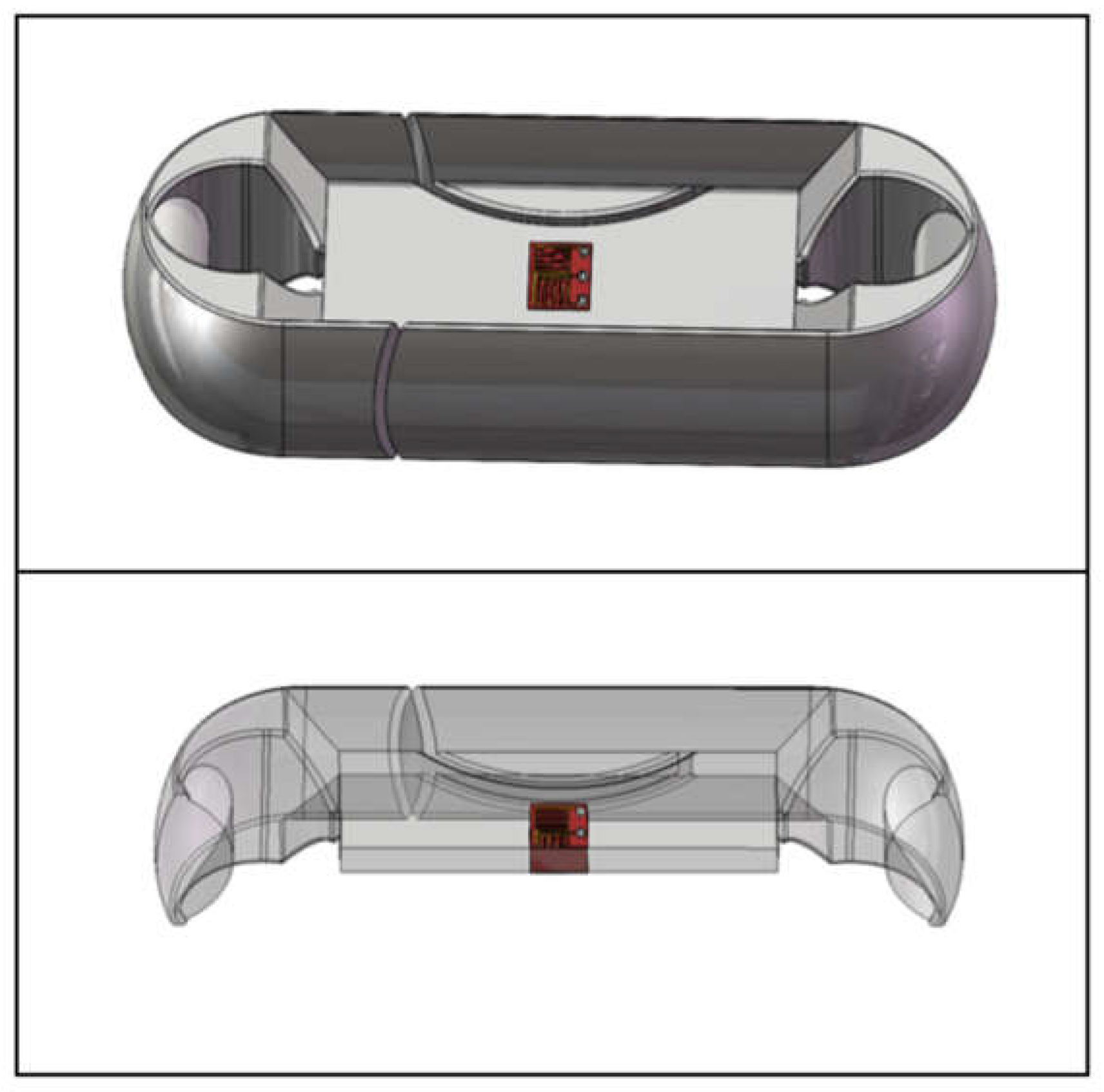

Figure 7.

Elastomer Structure Scheme III.

Figure 7.

Elastomer Structure Scheme III.

Figure 8.

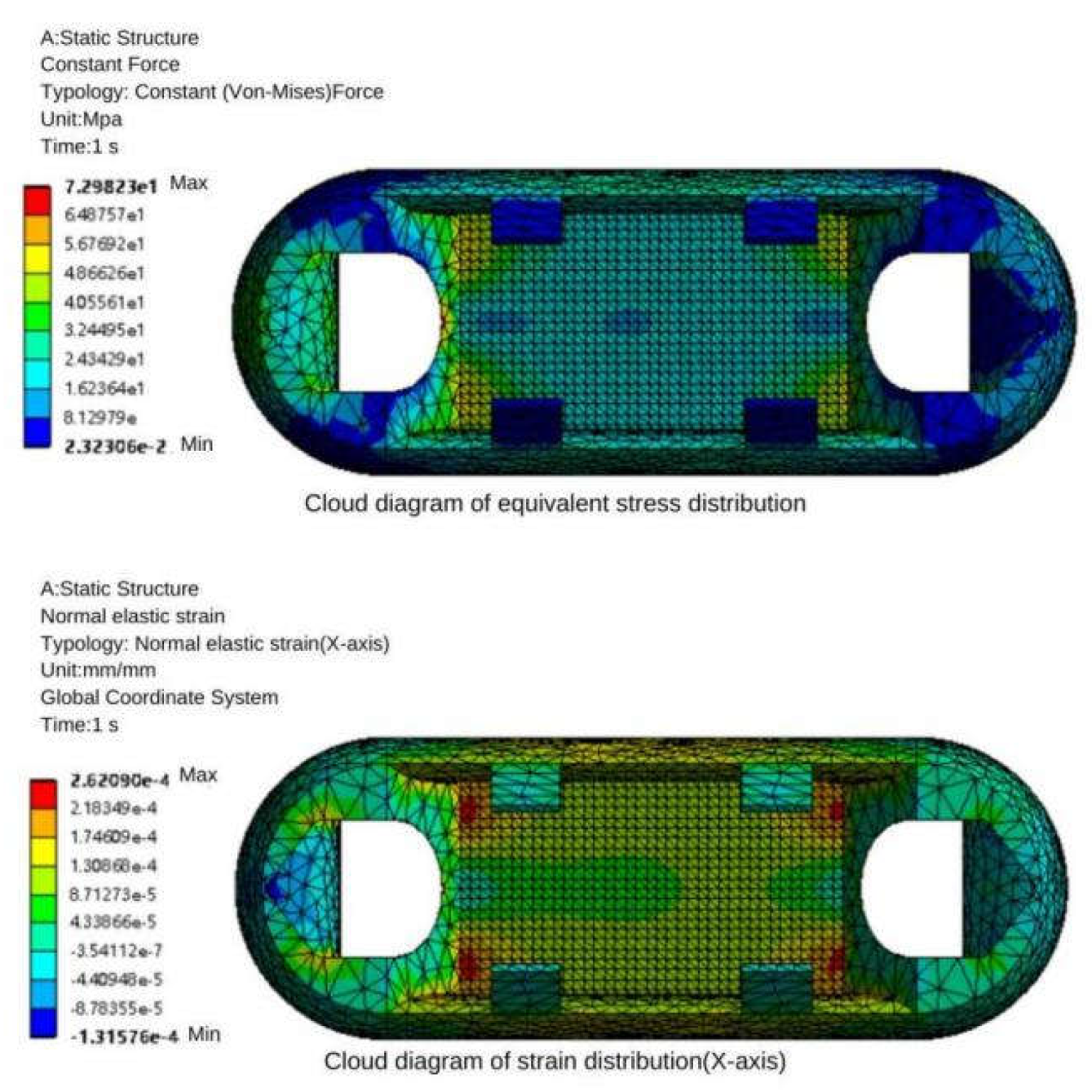

Static analysis of elastomer structure scheme II.

Figure 8.

Static analysis of elastomer structure scheme II.

Figure 9.

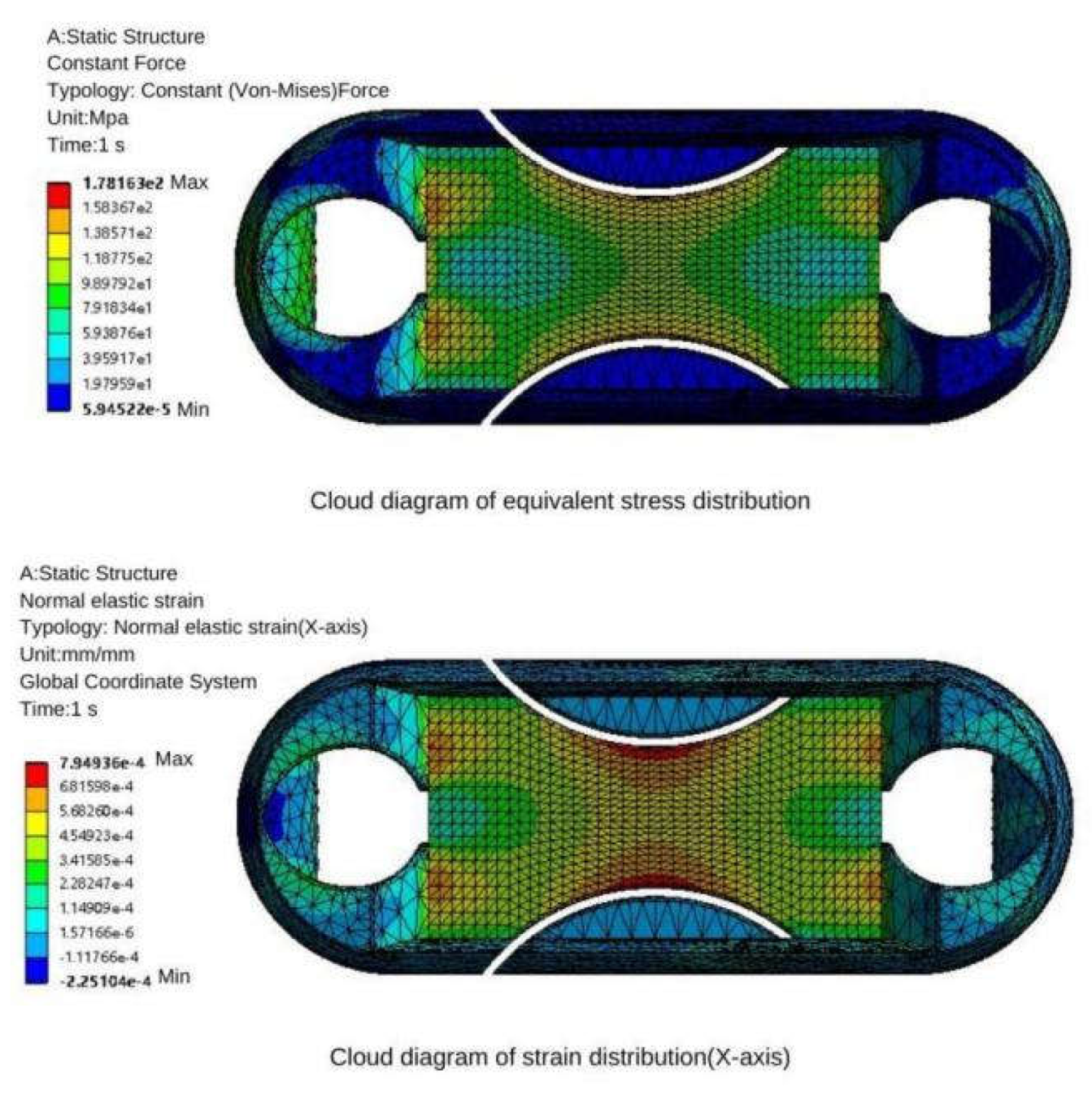

Static Analysis of Elastomer Structure Scheme III.

Figure 9.

Static Analysis of Elastomer Structure Scheme III.

Figure 10.

Strain gage pasting position in elastomer structure scheme II.

Figure 10.

Strain gage pasting position in elastomer structure scheme II.

Figure 11.

Strain gage pasting position in elastomer structure scheme III .

Figure 11.

Strain gage pasting position in elastomer structure scheme III .

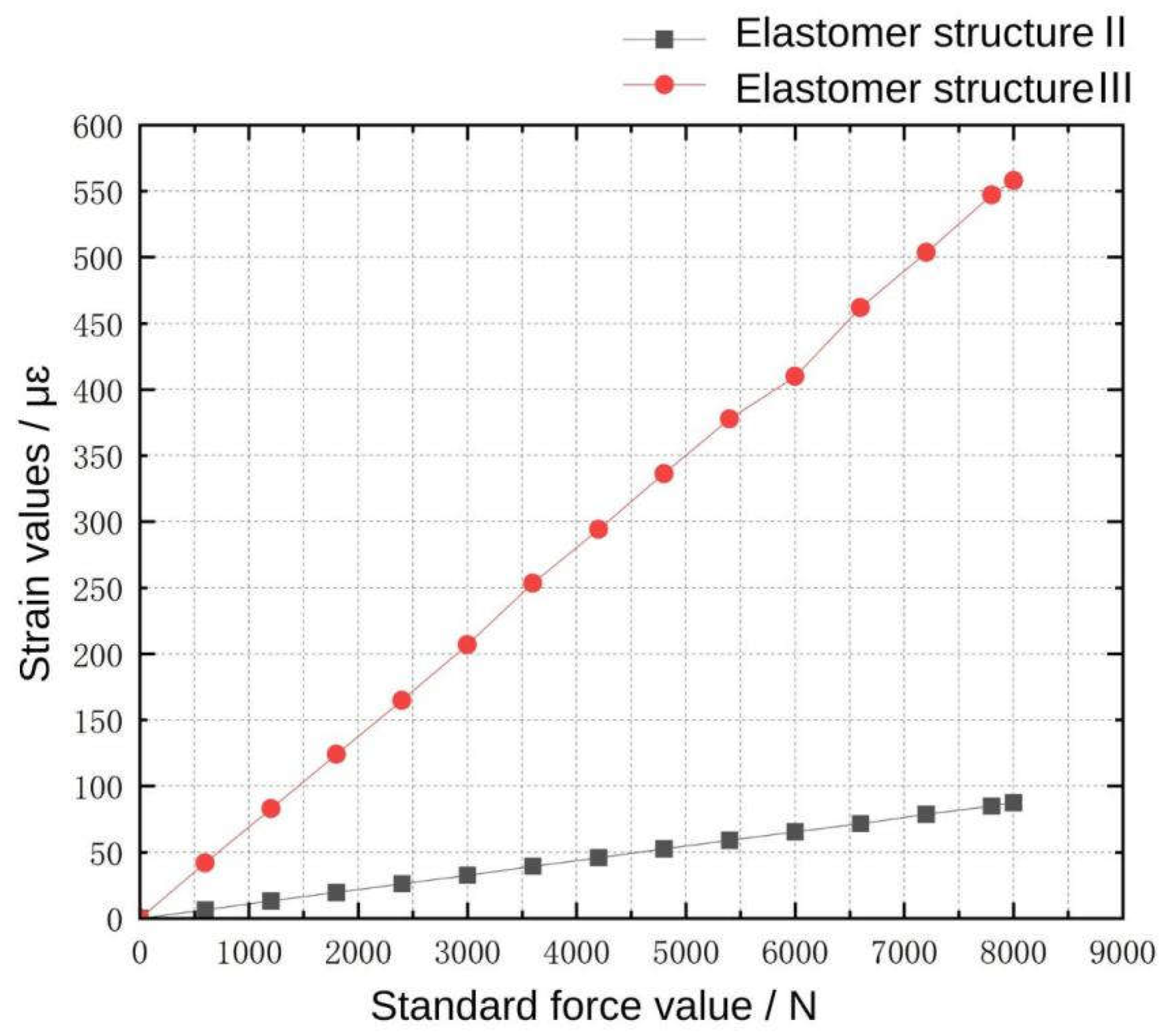

Figure 12.

Axial strain at the center of elastomer structure scheme II and scheme III.

Figure 12.

Axial strain at the center of elastomer structure scheme II and scheme III.

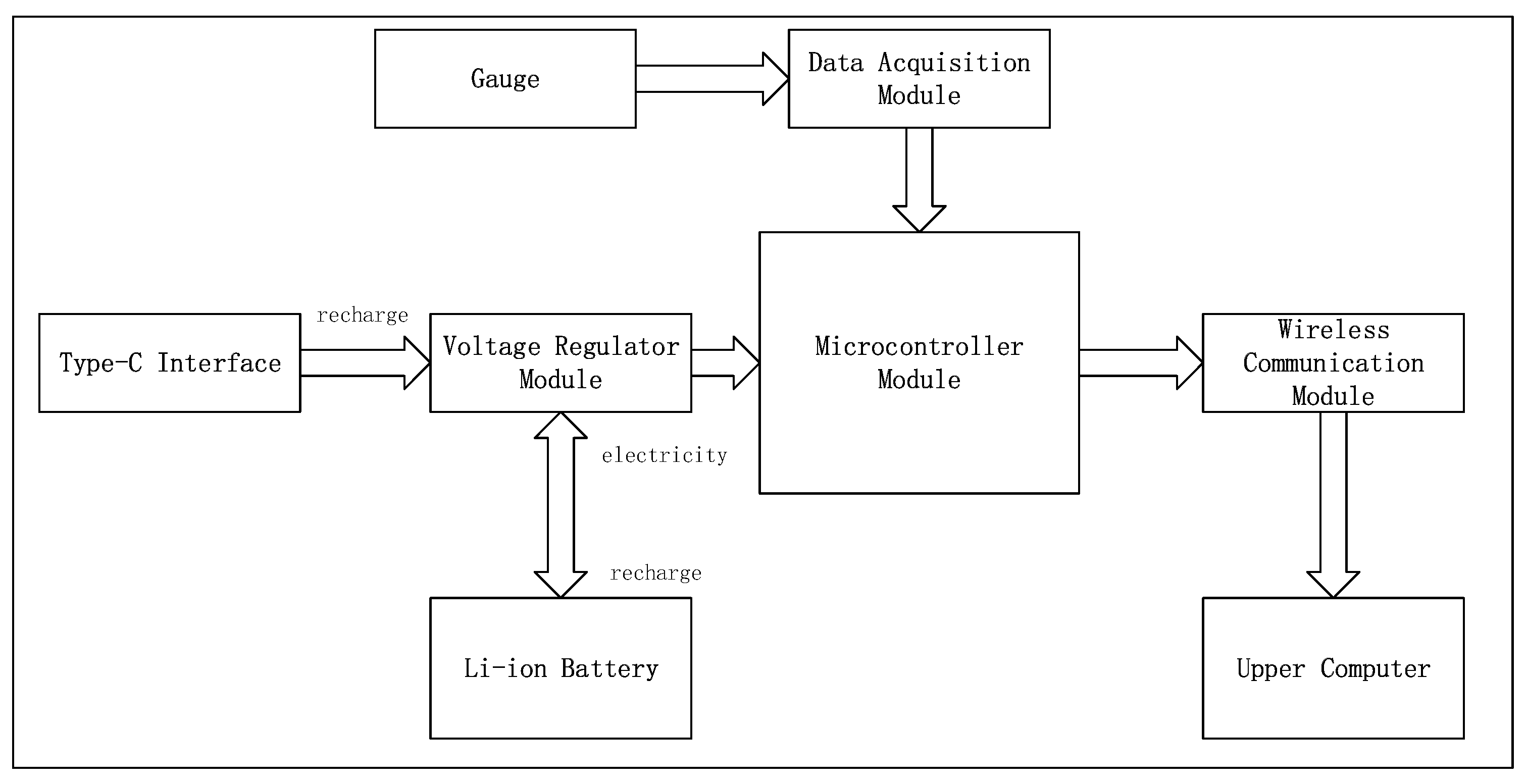

Figure 13.

Schematic diagram of signal acquisition system.

Figure 13.

Schematic diagram of signal acquisition system.

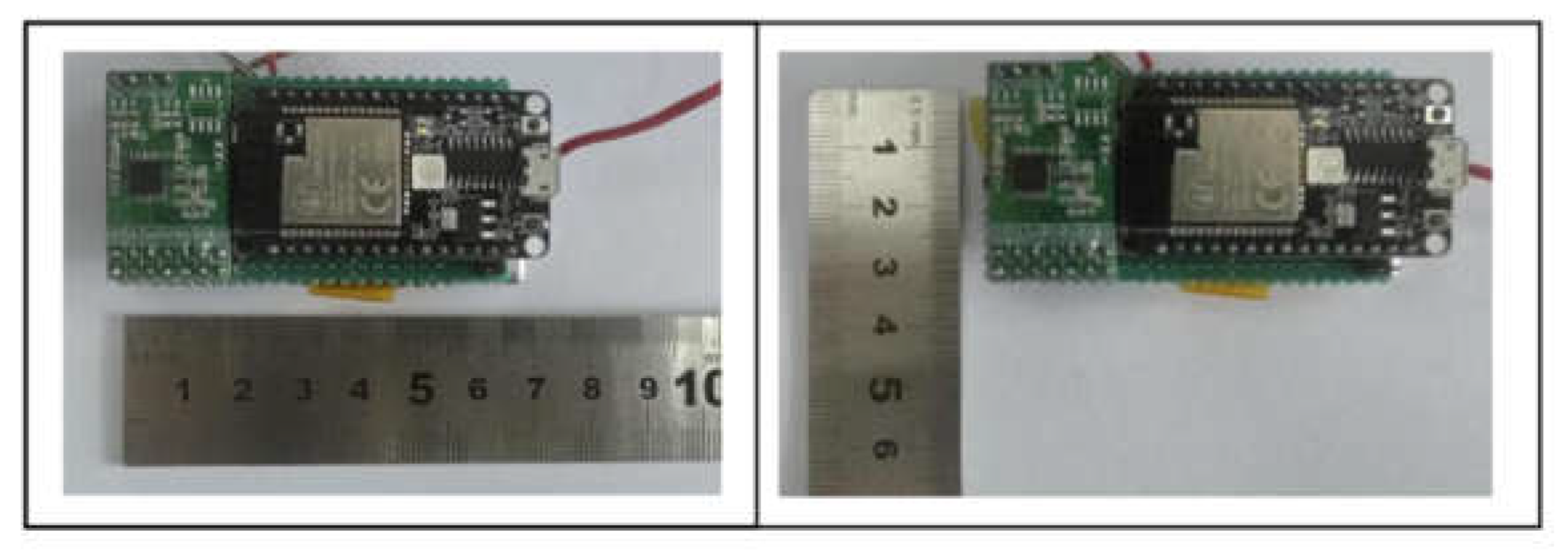

Figure 14.

Photos of signal acquisition system hardware module Ⅰ.

Figure 14.

Photos of signal acquisition system hardware module Ⅰ.

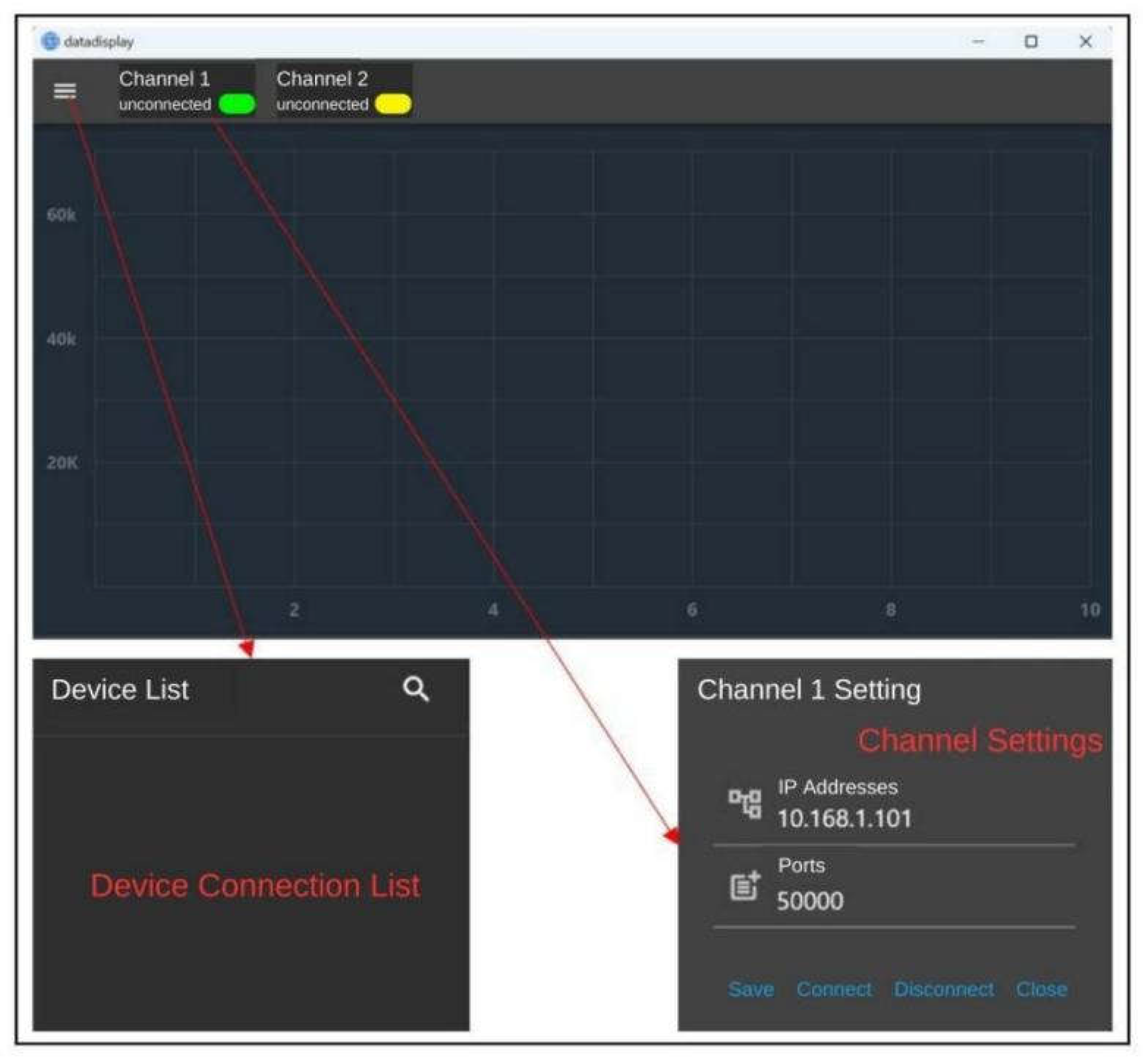

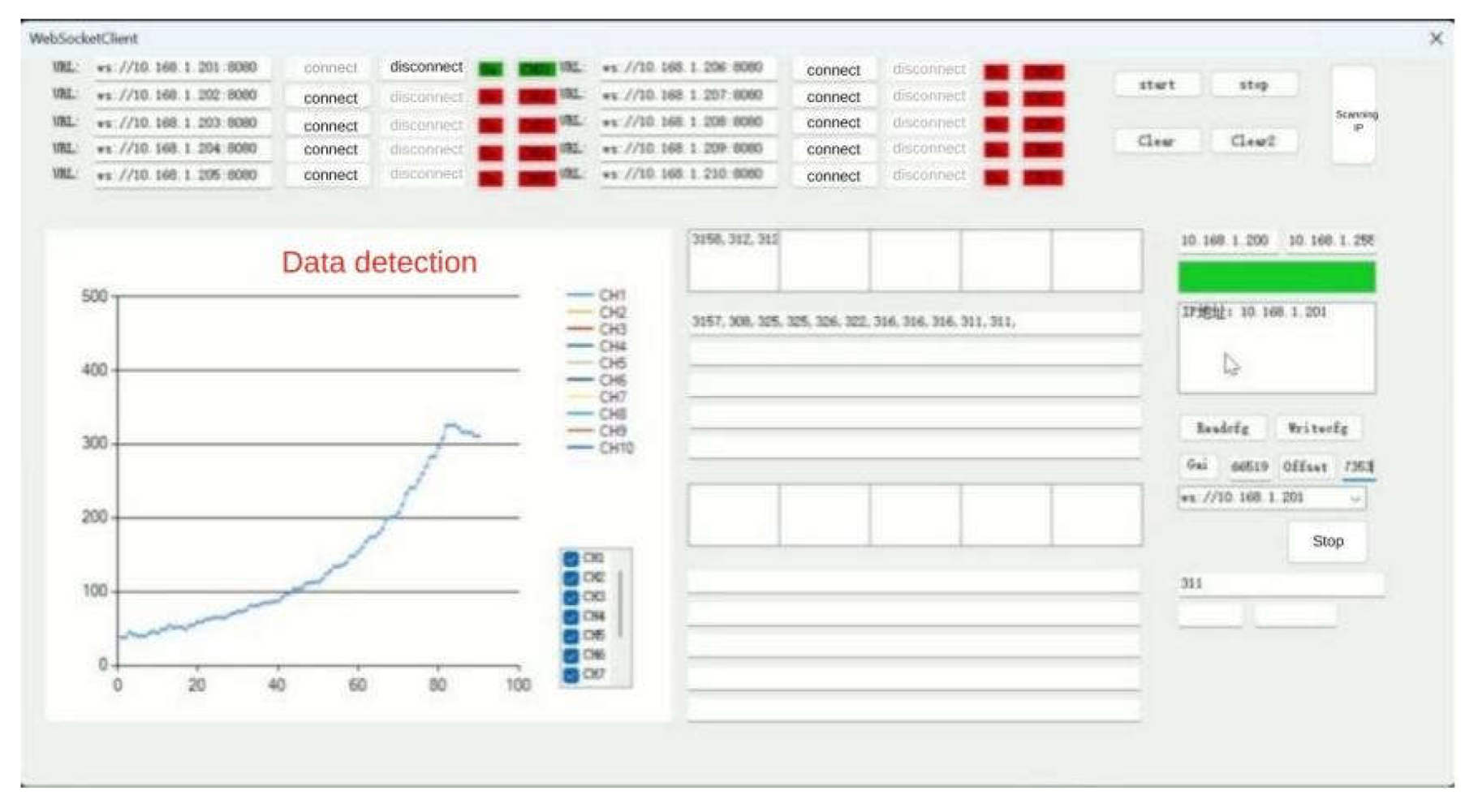

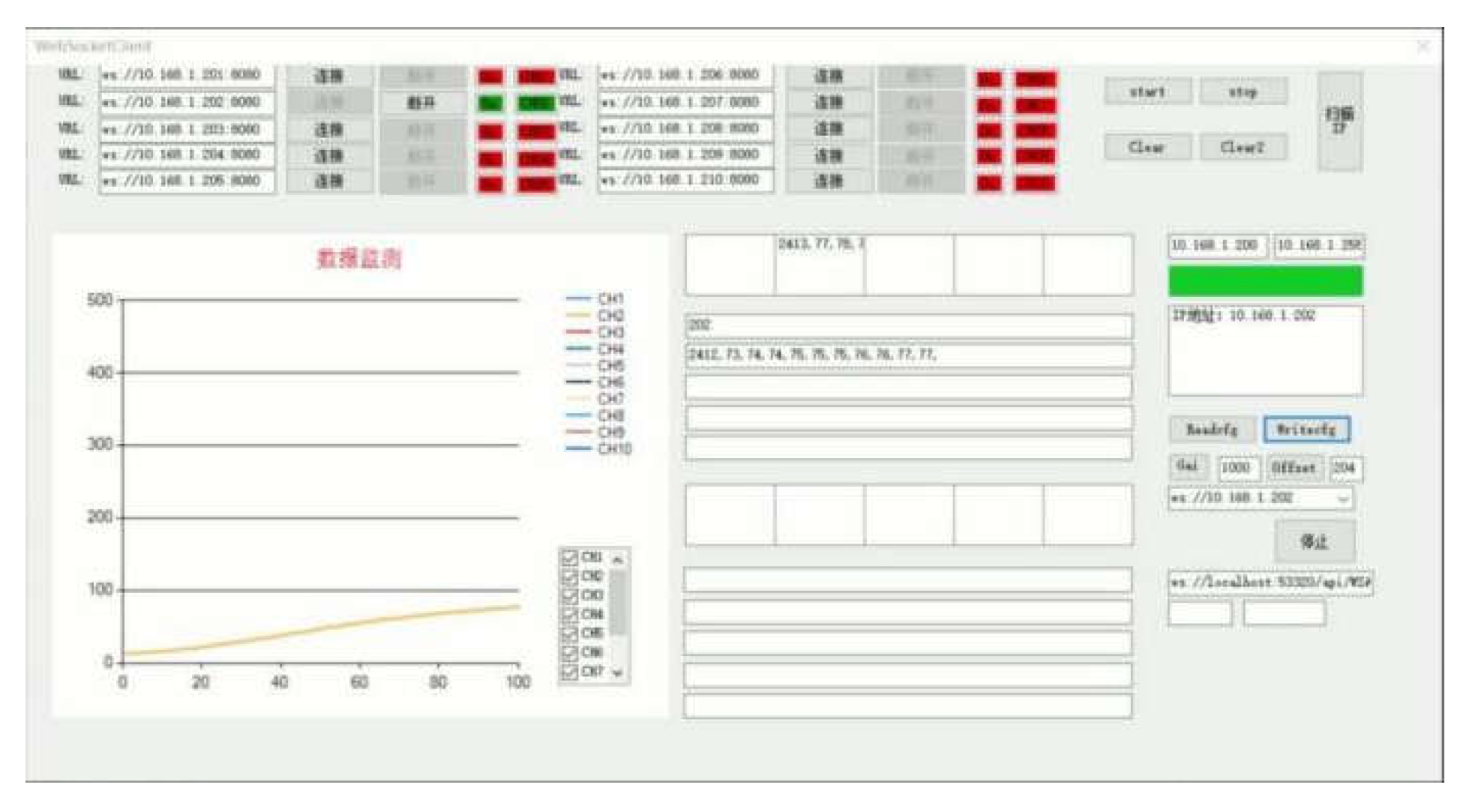

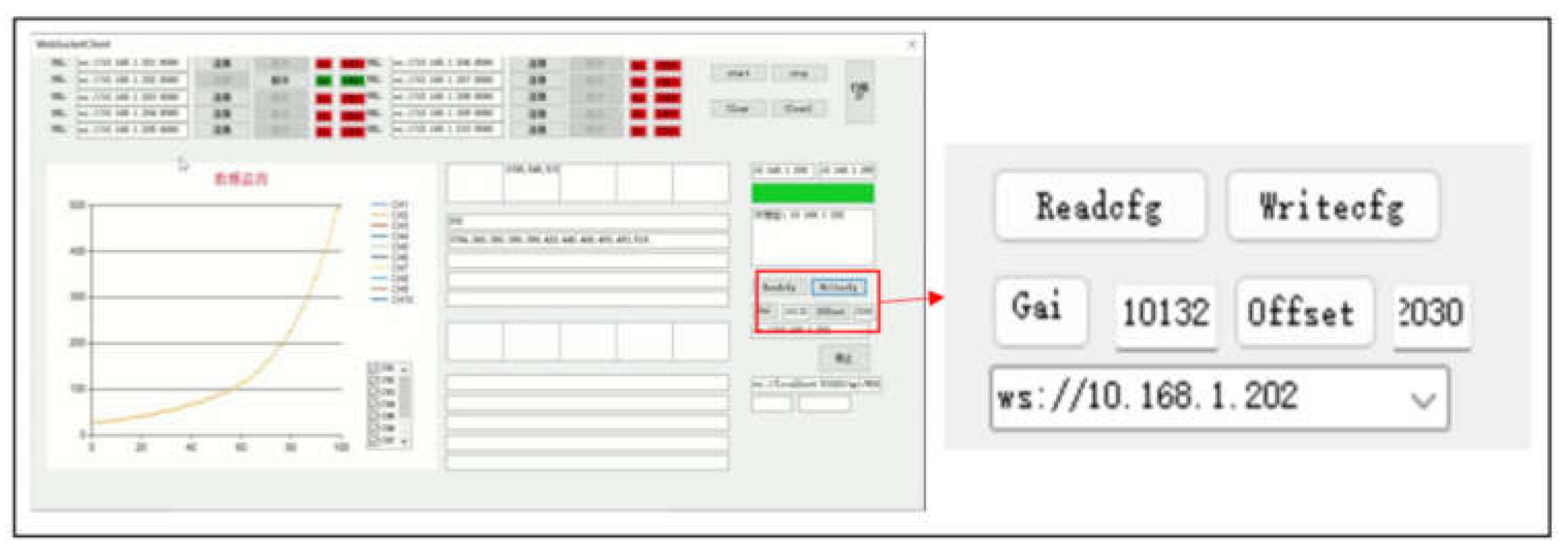

Figure 15.

Signal acquisition system software interface.

Figure 15.

Signal acquisition system software interface.

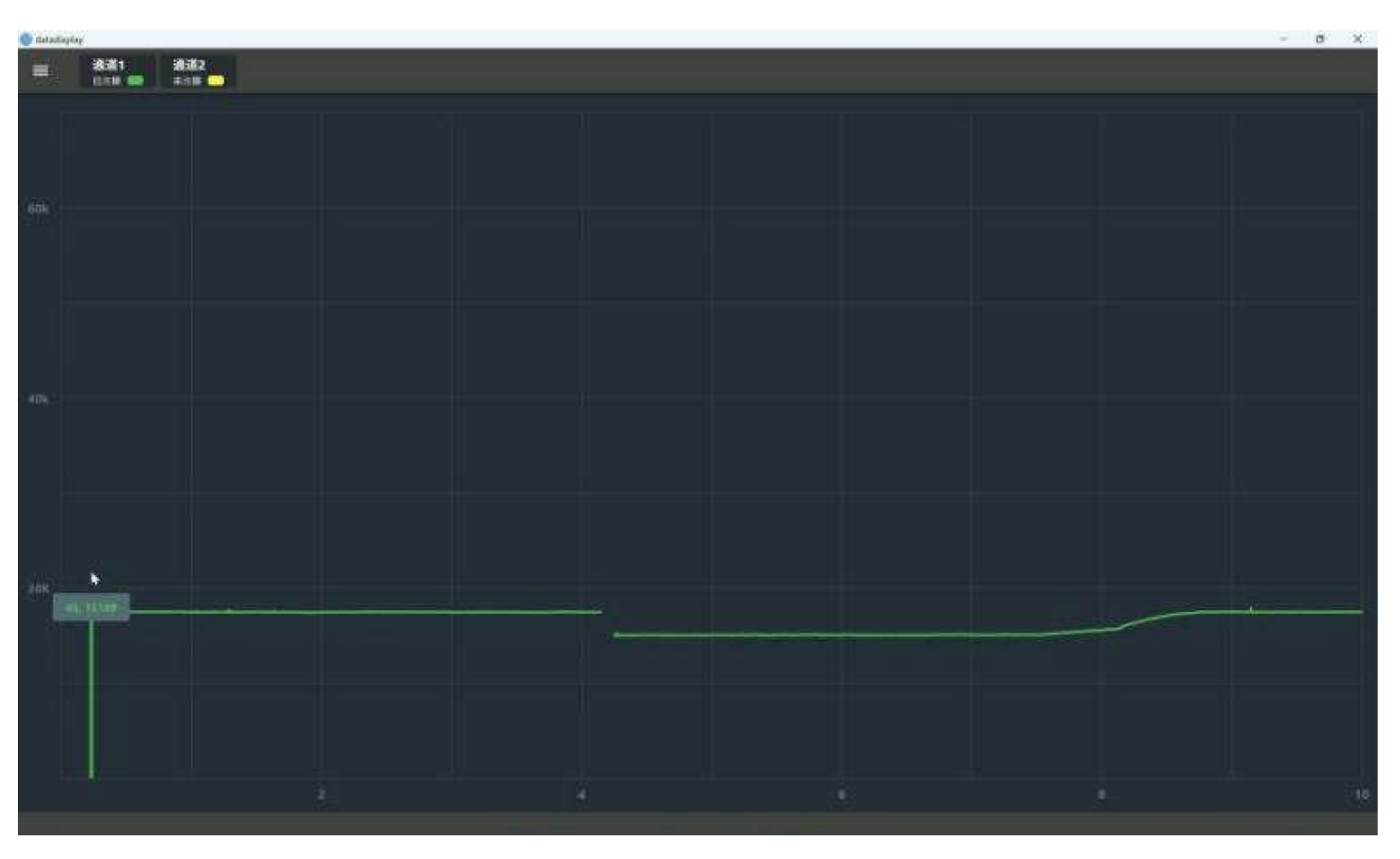

Figure 16.

Upper computer software displaying waveforms.

Figure 16.

Upper computer software displaying waveforms.

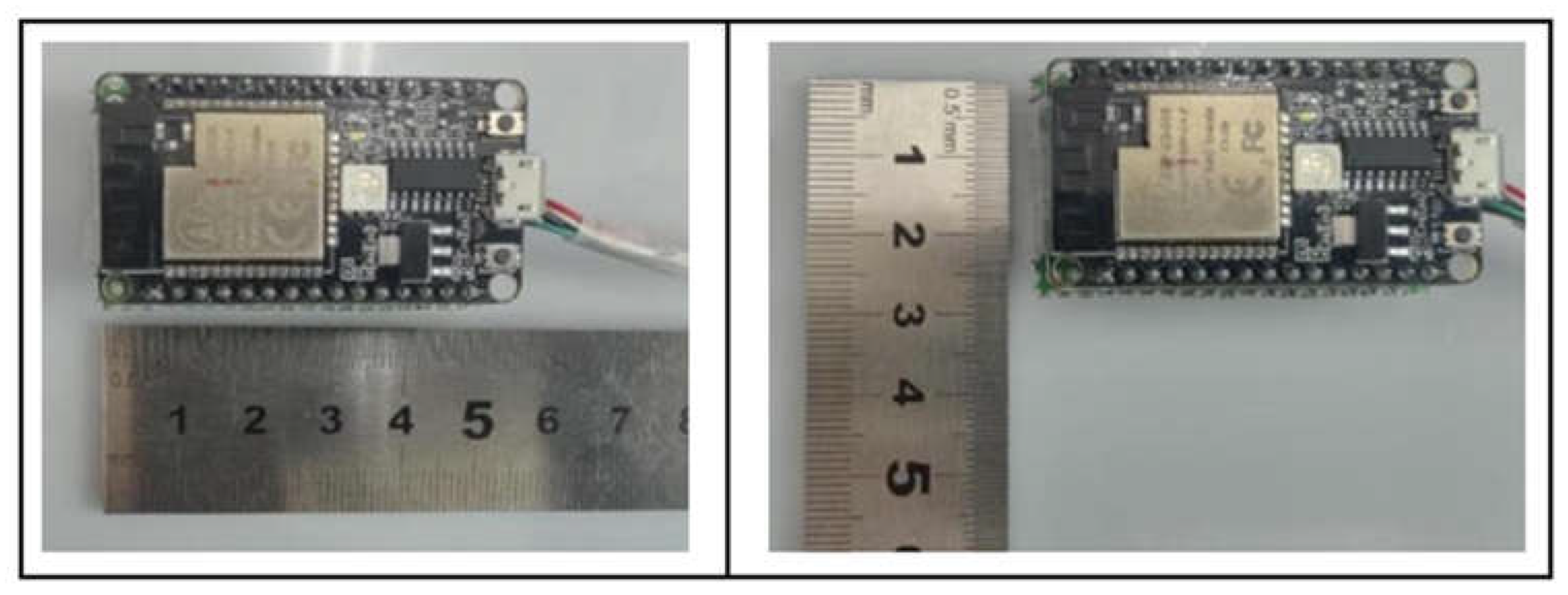

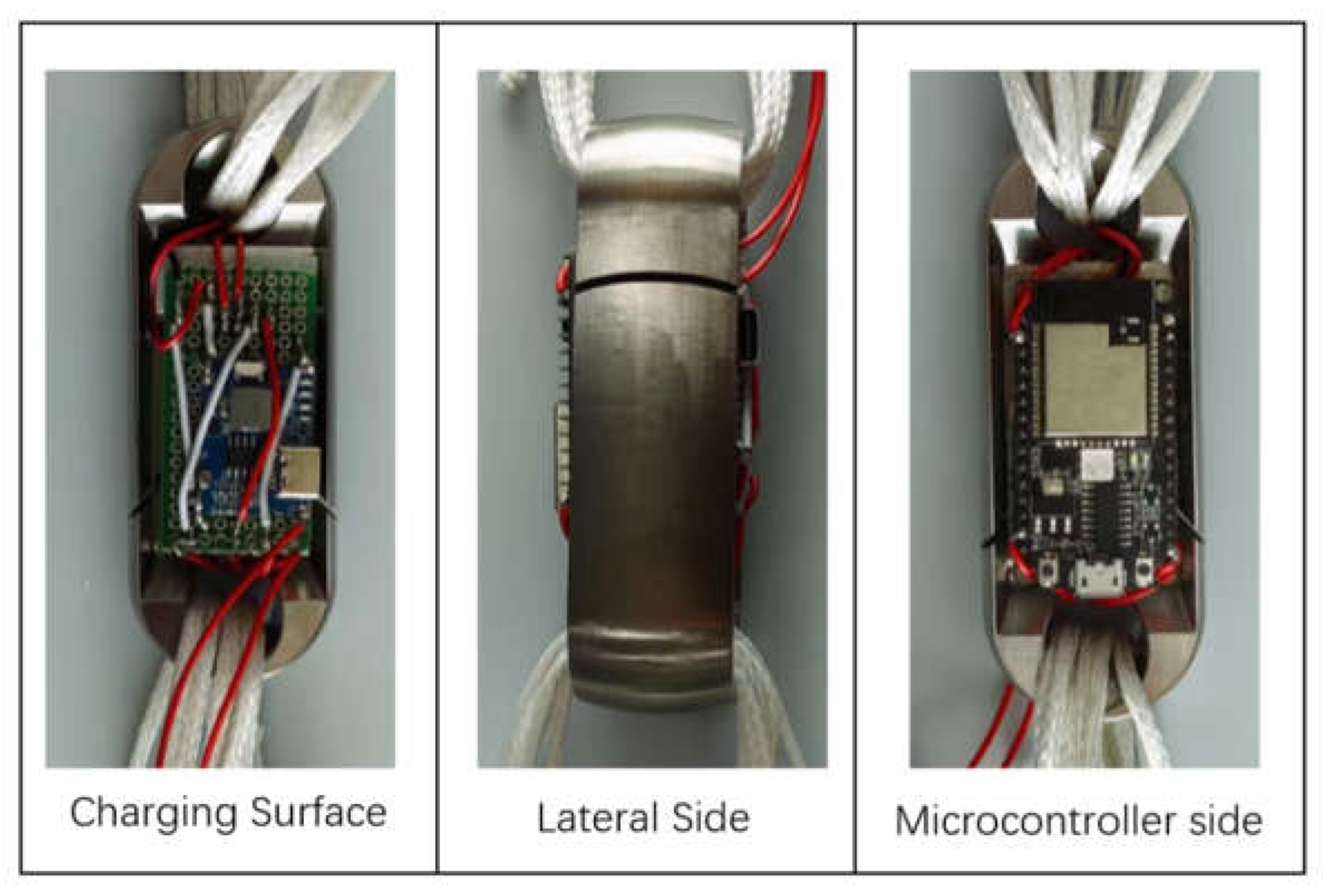

Figure 17.

Photos of signal acquisition system hardware module Ⅱ.

Figure 17.

Photos of signal acquisition system hardware module Ⅱ.

Figure 18.

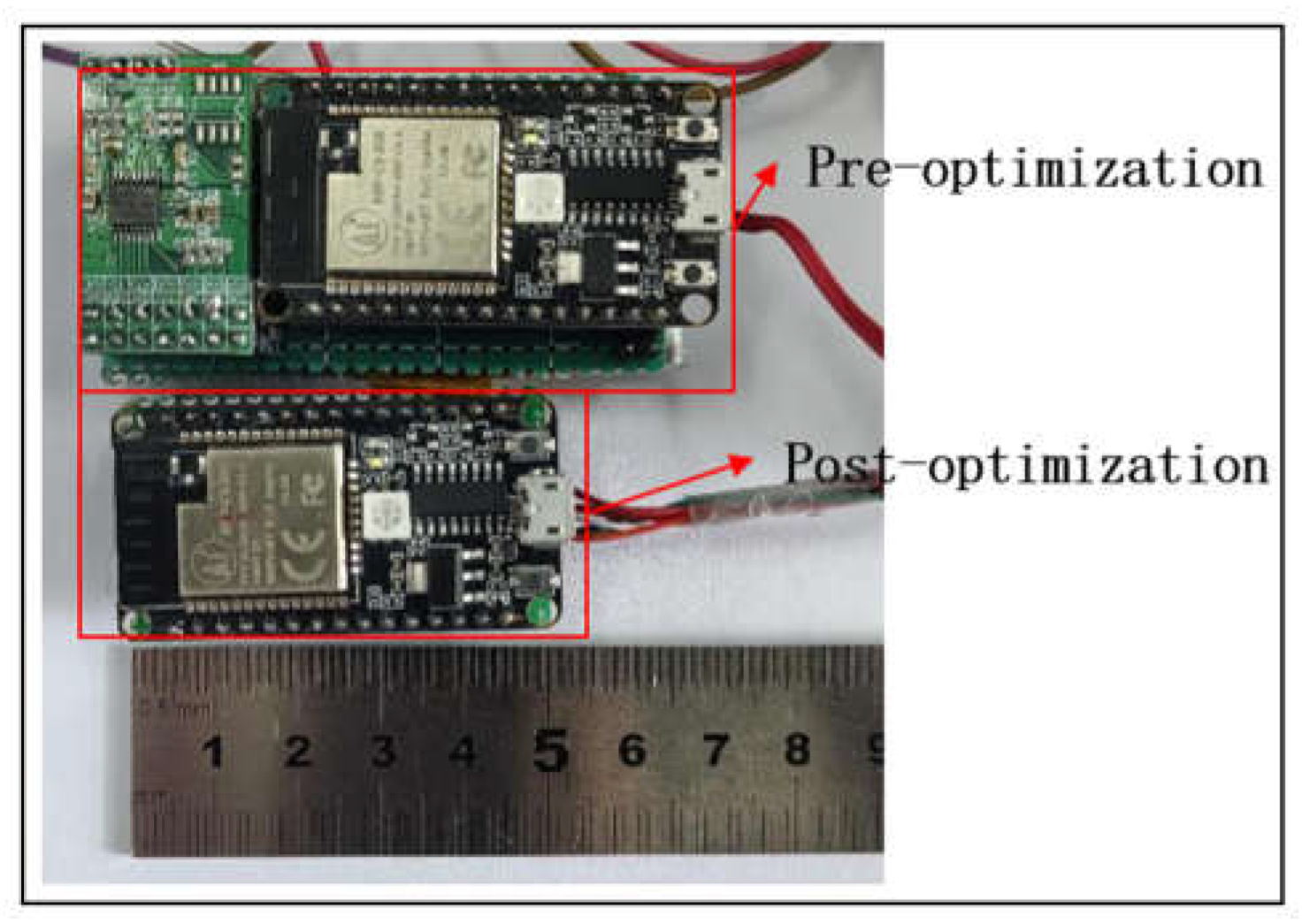

Comparison of the signal acquisition system hardware before and after optimization.

Figure 18.

Comparison of the signal acquisition system hardware before and after optimization.

Figure 19.

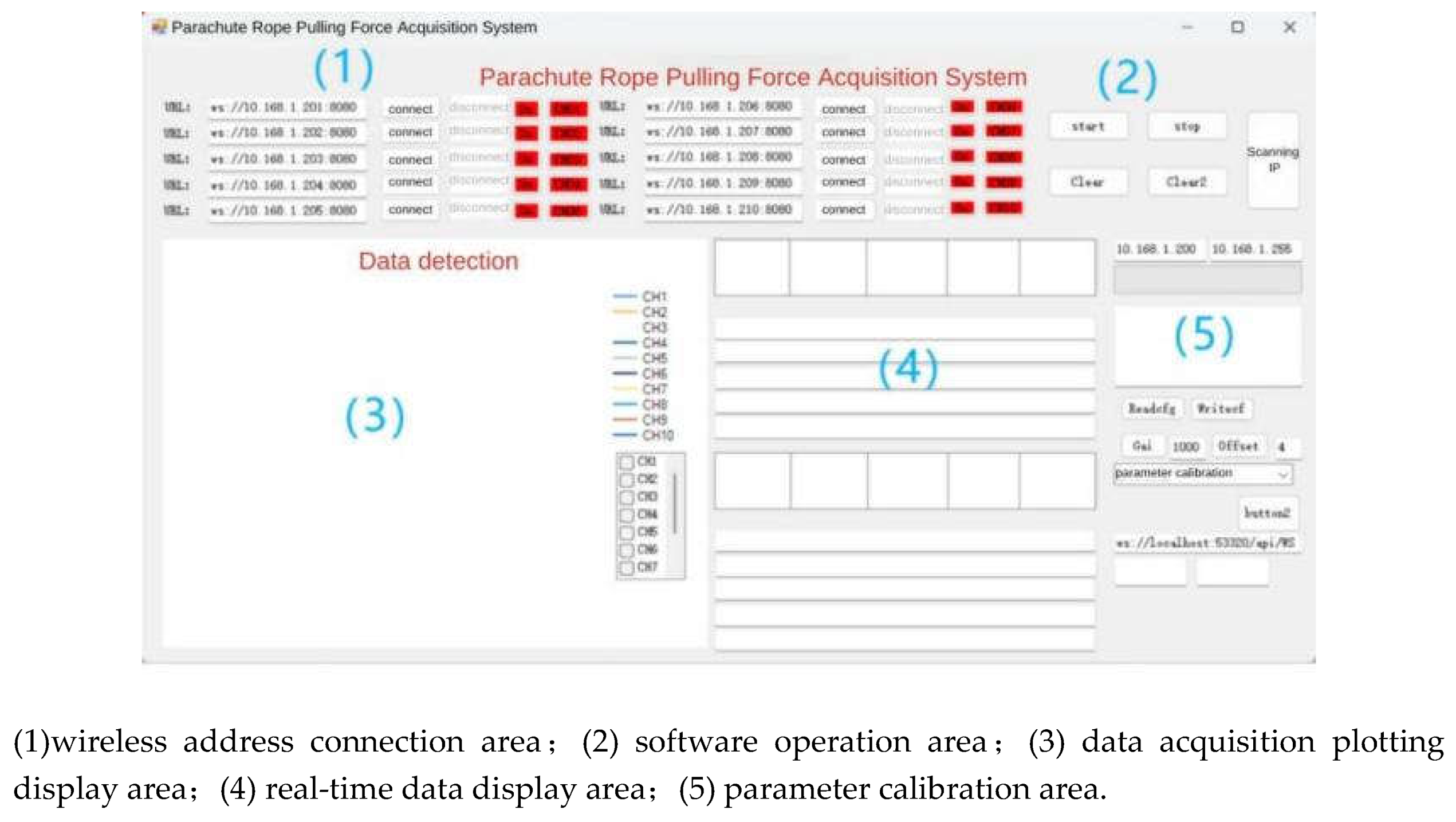

Upper computer software main interface area division.

Figure 19.

Upper computer software main interface area division.

Figure 20.

Miniature measuring instrument fixed to the elastomeric structure.

Figure 20.

Miniature measuring instrument fixed to the elastomeric structure.

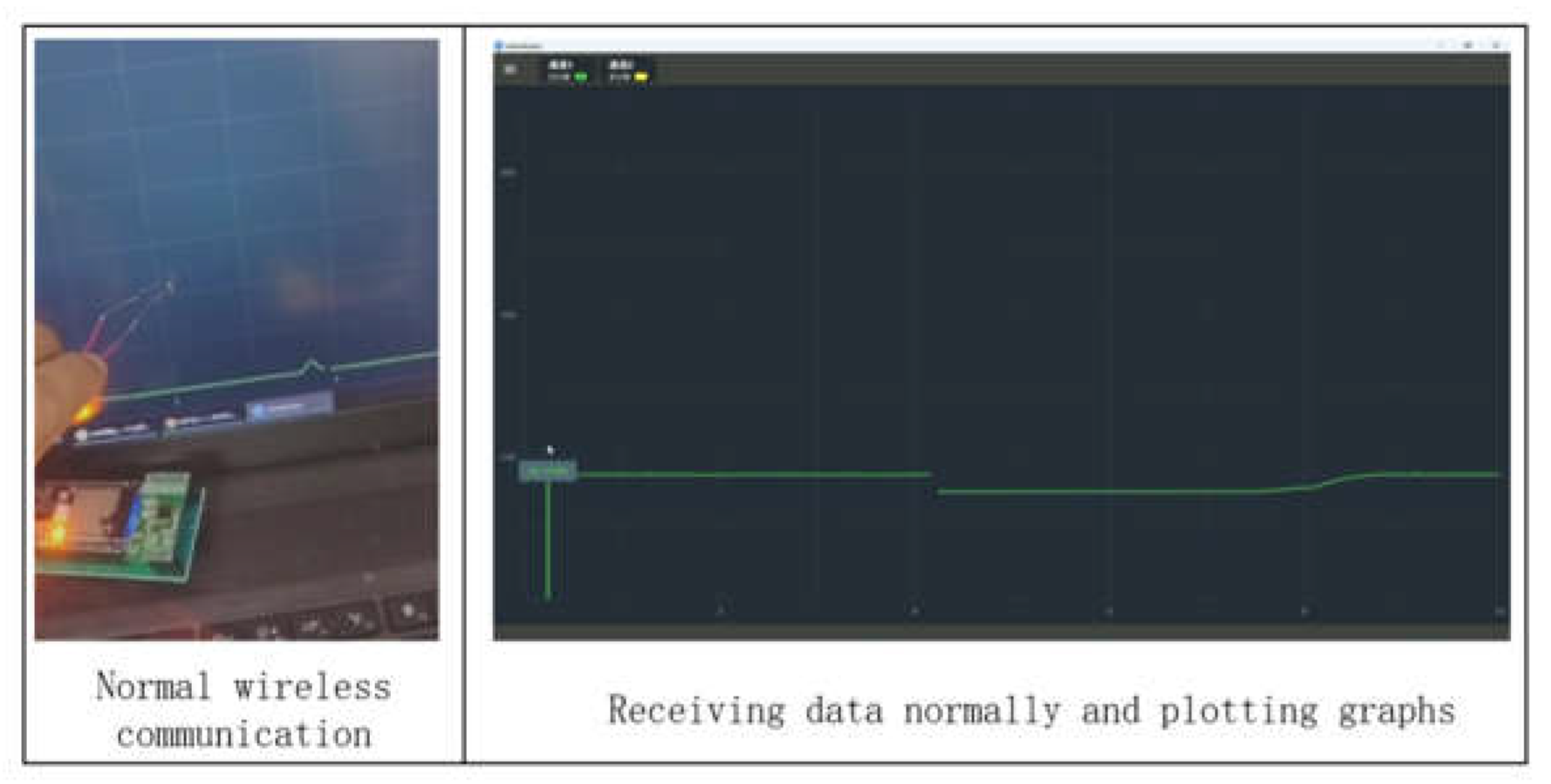

Figure 21.

Signal acquisition system module Ⅱ and wireless communication test of cords tension acquisition system.

Figure 21.

Signal acquisition system module Ⅱ and wireless communication test of cords tension acquisition system.

Figure 22.

Normal working condition of parachute cords tension acquisition system.

Figure 22.

Normal working condition of parachute cords tension acquisition system.

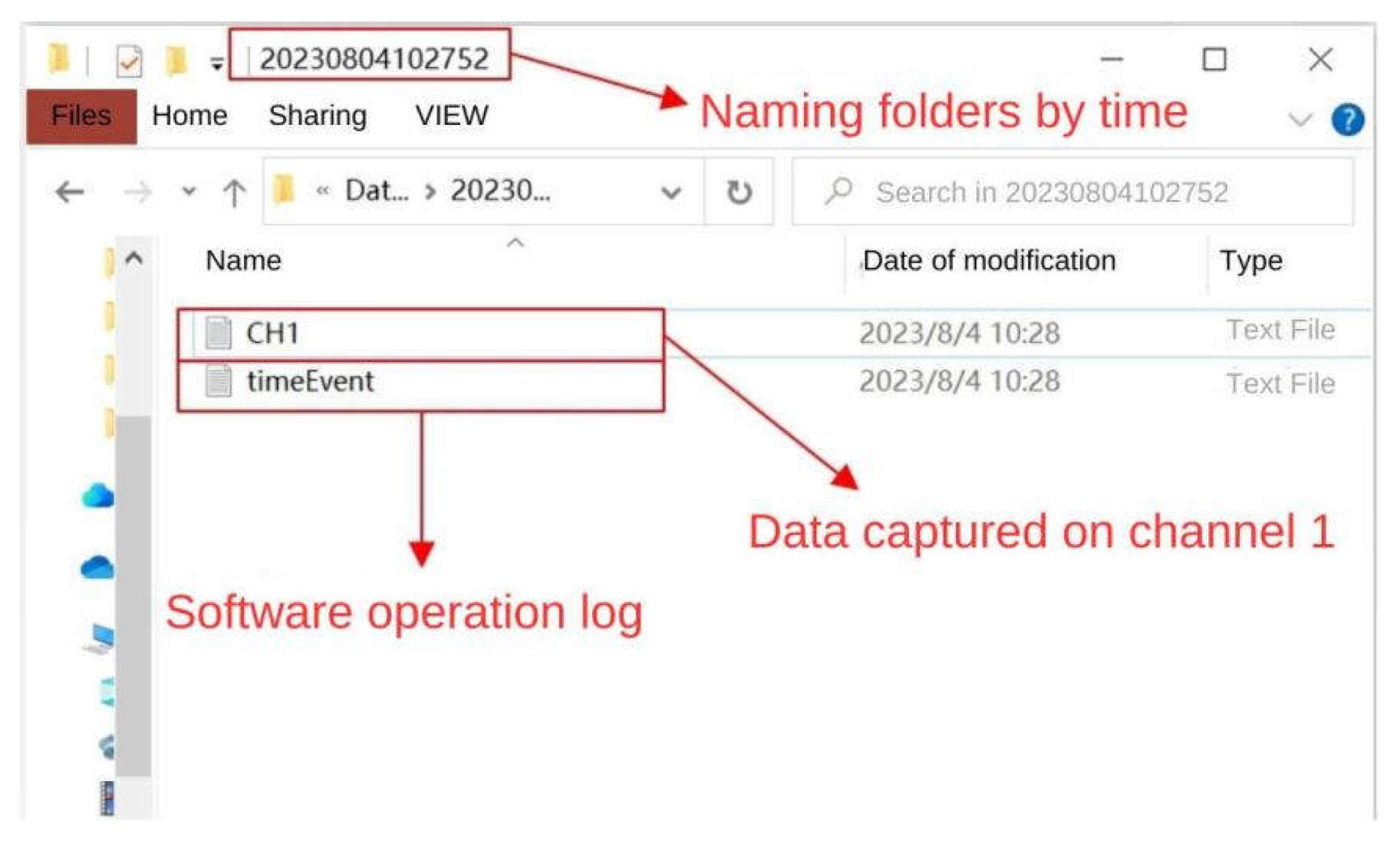

Figure 23.

Data saving for parachute cords tension acquisition syst.

Figure 23.

Data saving for parachute cords tension acquisition syst.

Figure 24.

Photo of the test parachute cords.

Figure 24.

Photo of the test parachute cords.

Figure 25.

Elastomer Structure I Strain Gage Pasting.

Figure 25.

Elastomer Structure I Strain Gage Pasting.

Figure 26.

Elastomer structure Ⅰ static experimental test.

Figure 26.

Elastomer structure Ⅰ static experimental test.

Figure 27.

Waveforms displayed on upper computer software.

Figure 27.

Waveforms displayed on upper computer software.

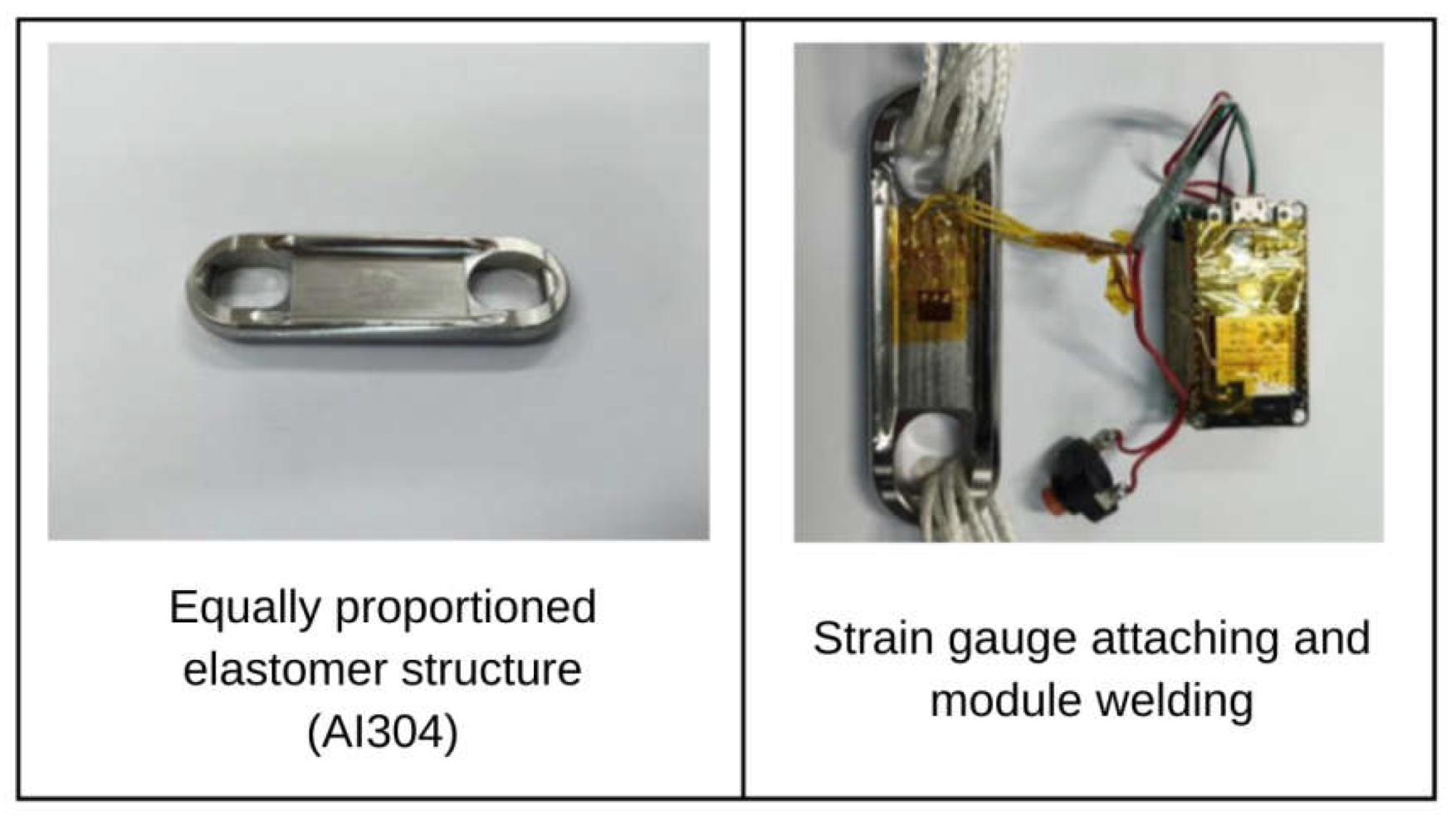

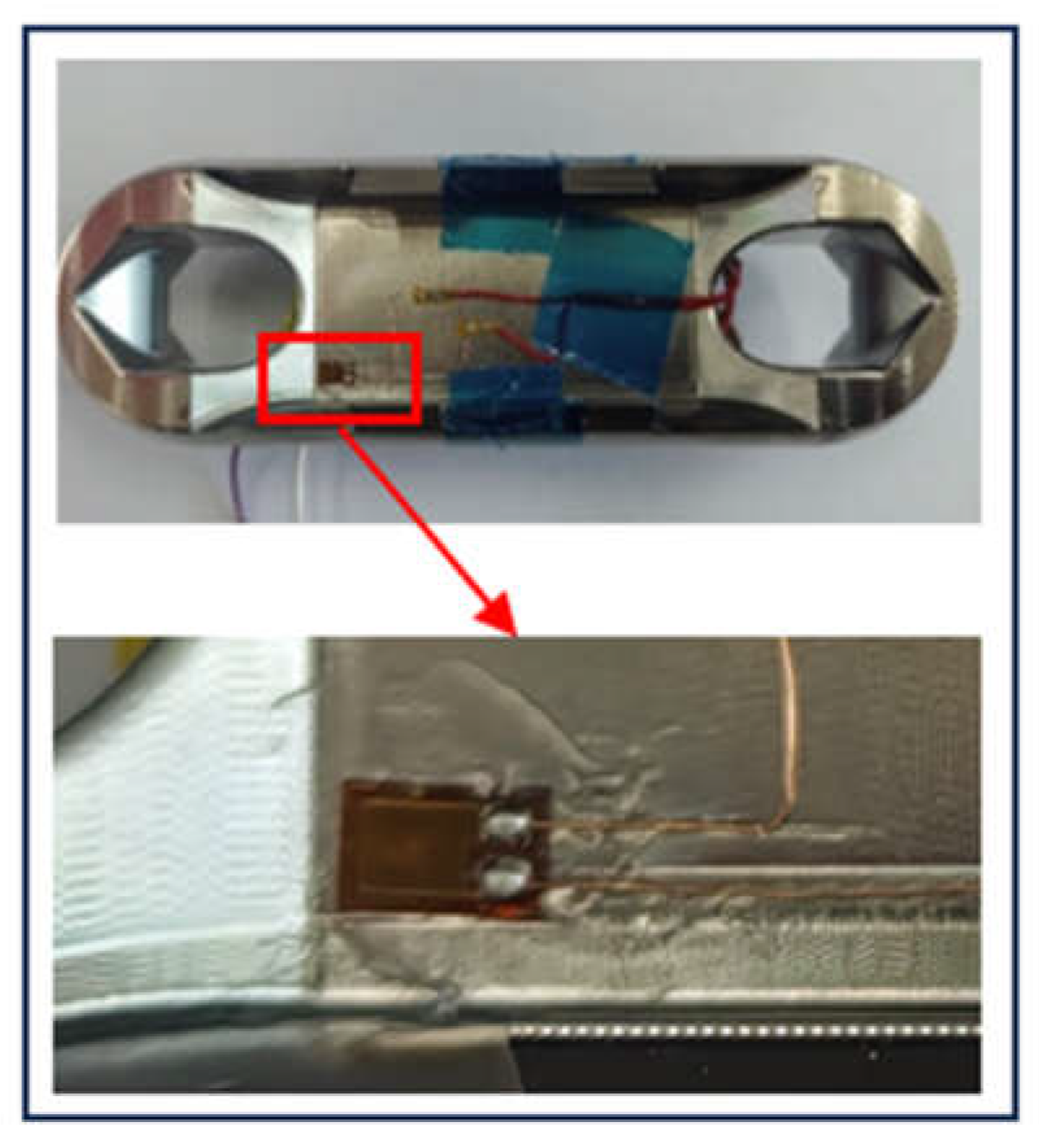

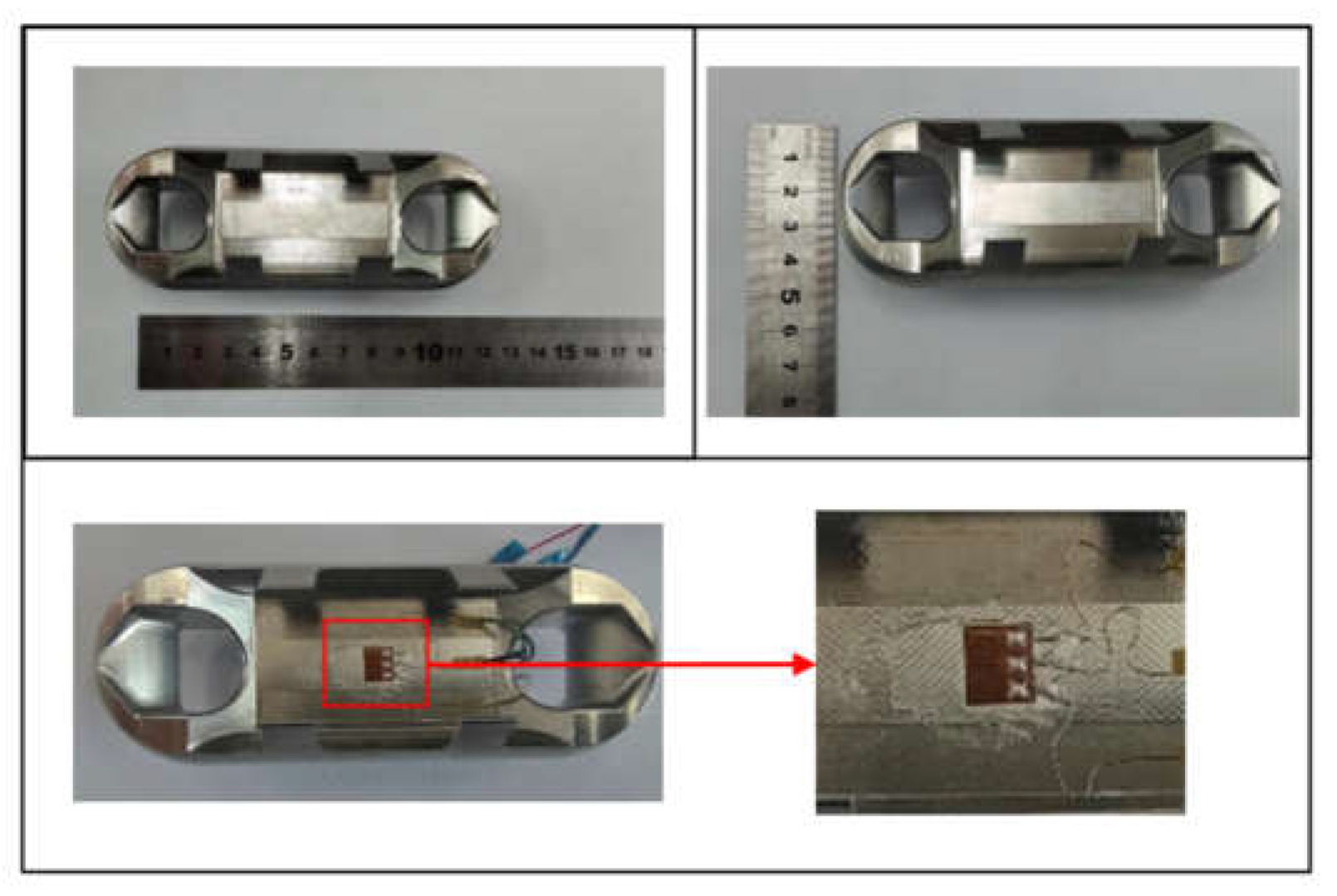

Figure 28.

Physical object and strain gage pasting in elastomer structure scheme II.

Figure 28.

Physical object and strain gage pasting in elastomer structure scheme II.

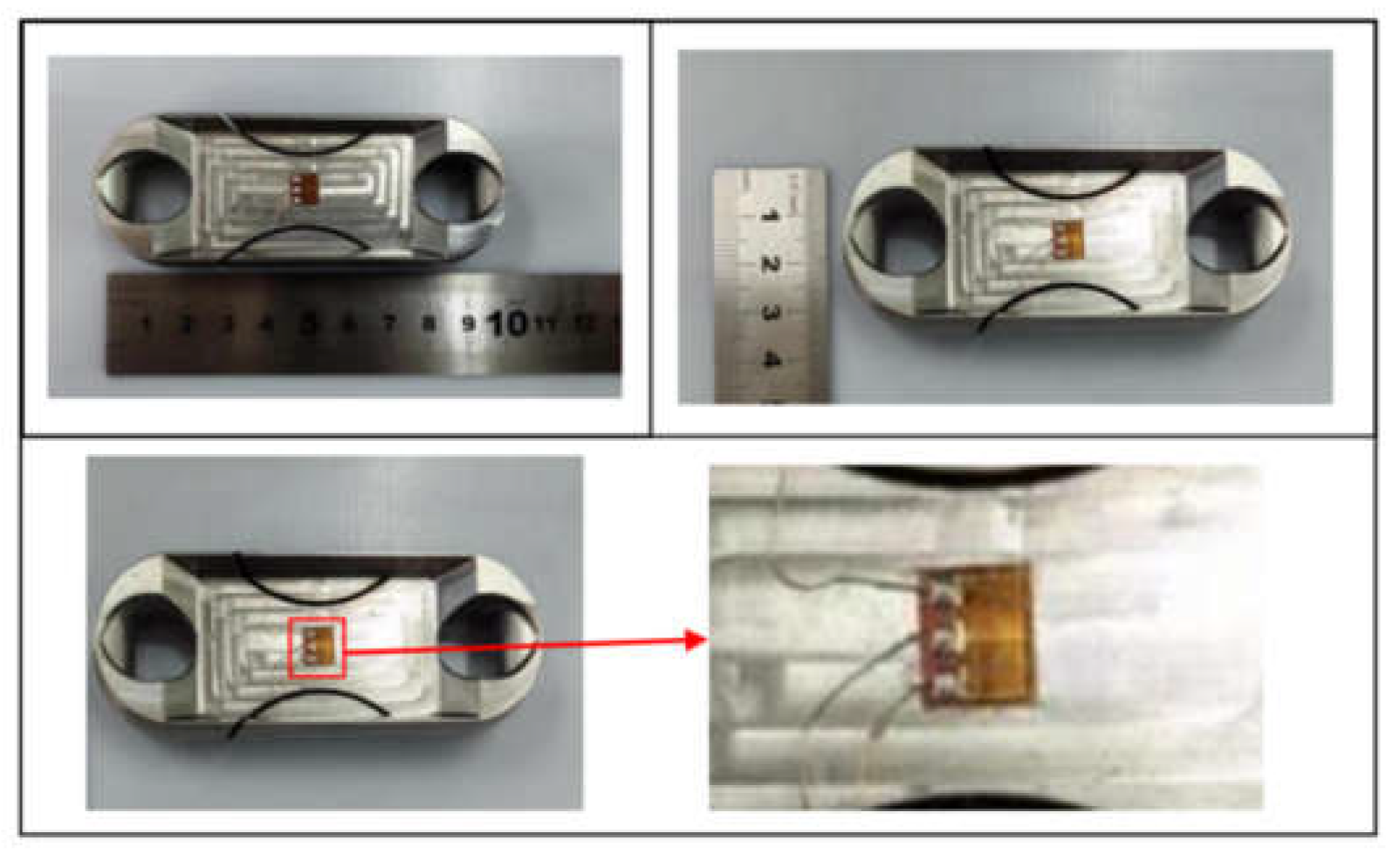

Figure 29.

Physical object and strain gage pasting in elastomer structure scheme III.

Figure 29.

Physical object and strain gage pasting in elastomer structure scheme III.

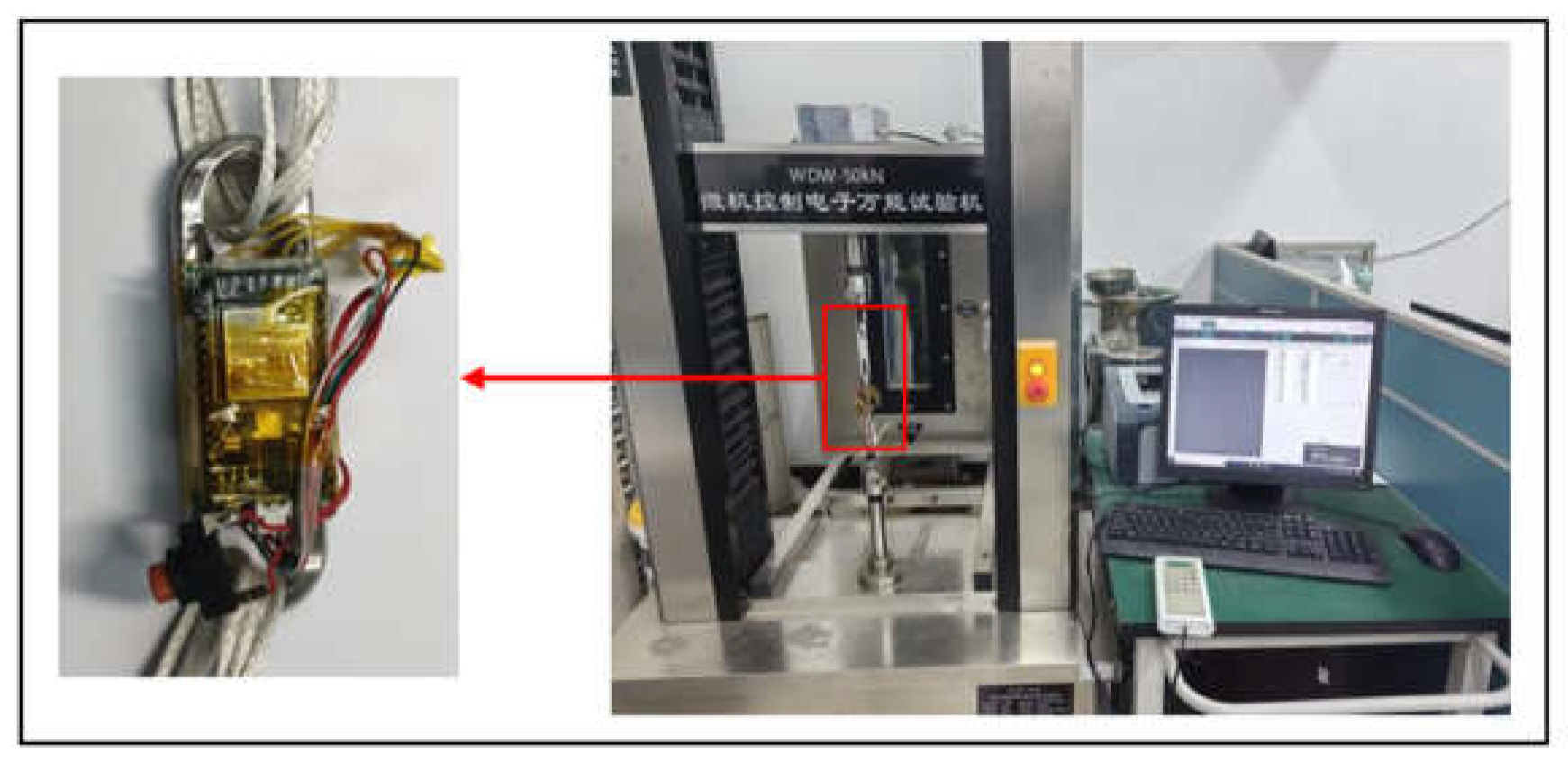

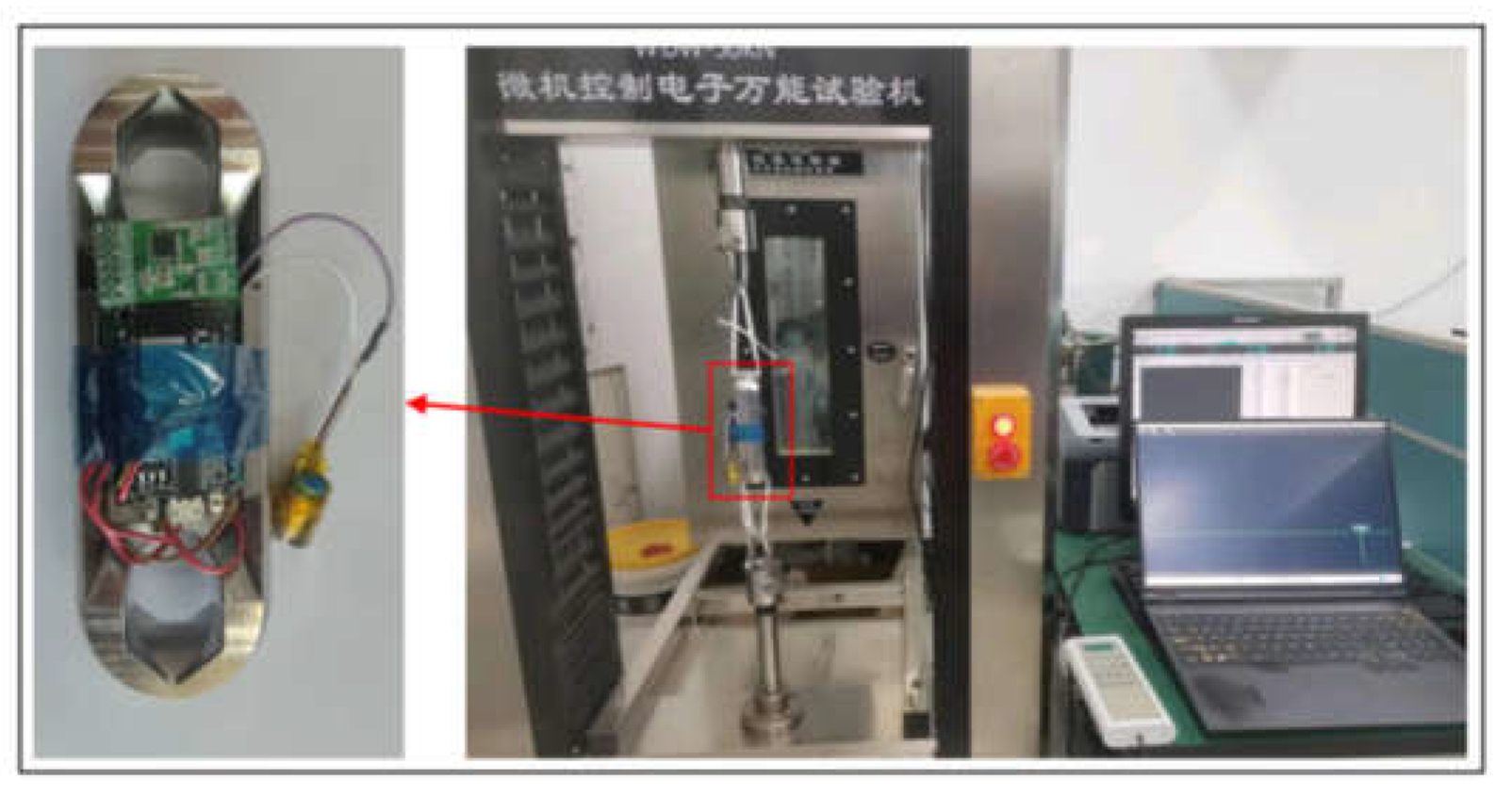

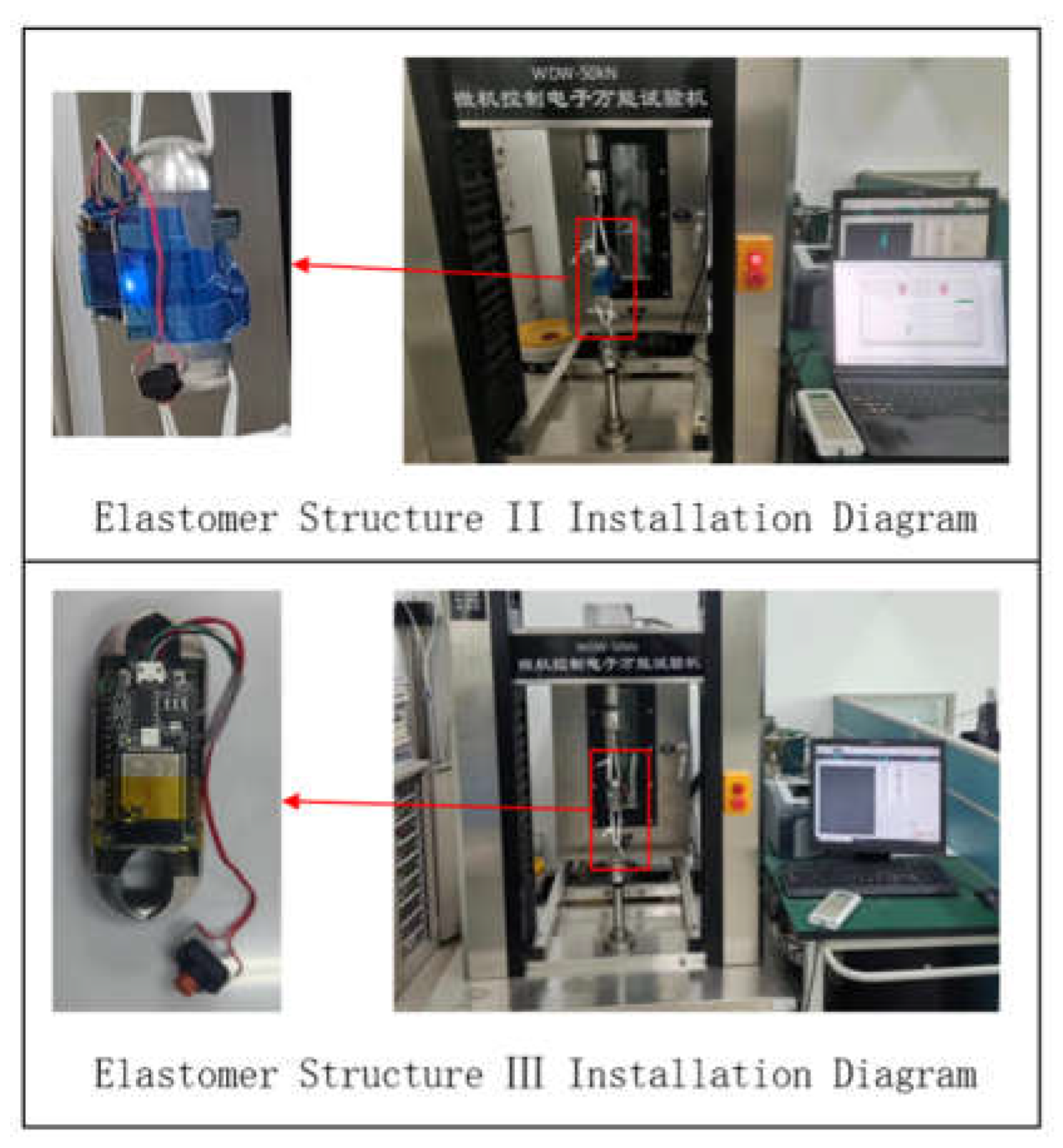

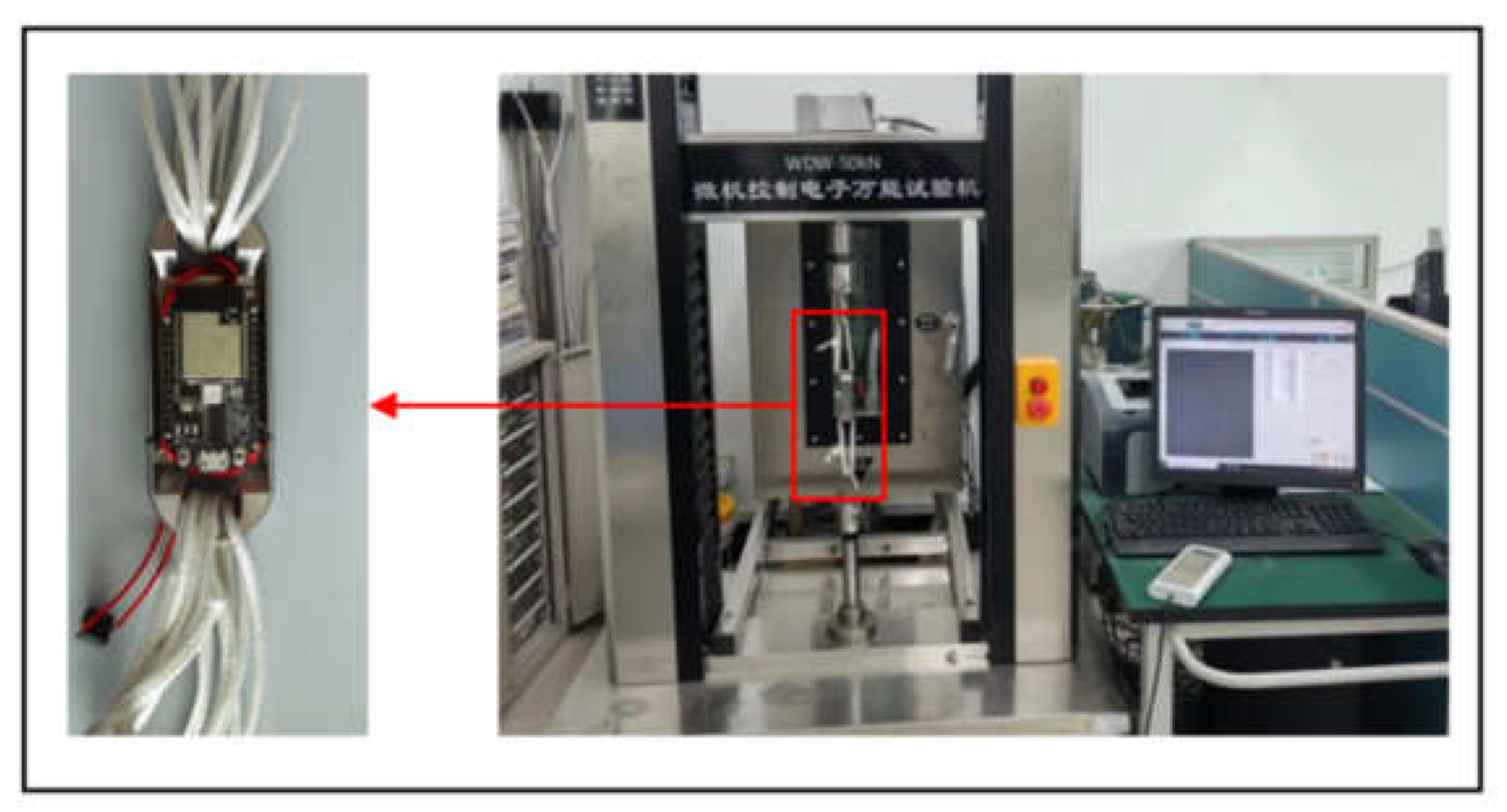

Figure 30.

Mounting of the elastomer structures to the universal testing machines.

Figure 30.

Mounting of the elastomer structures to the universal testing machines.

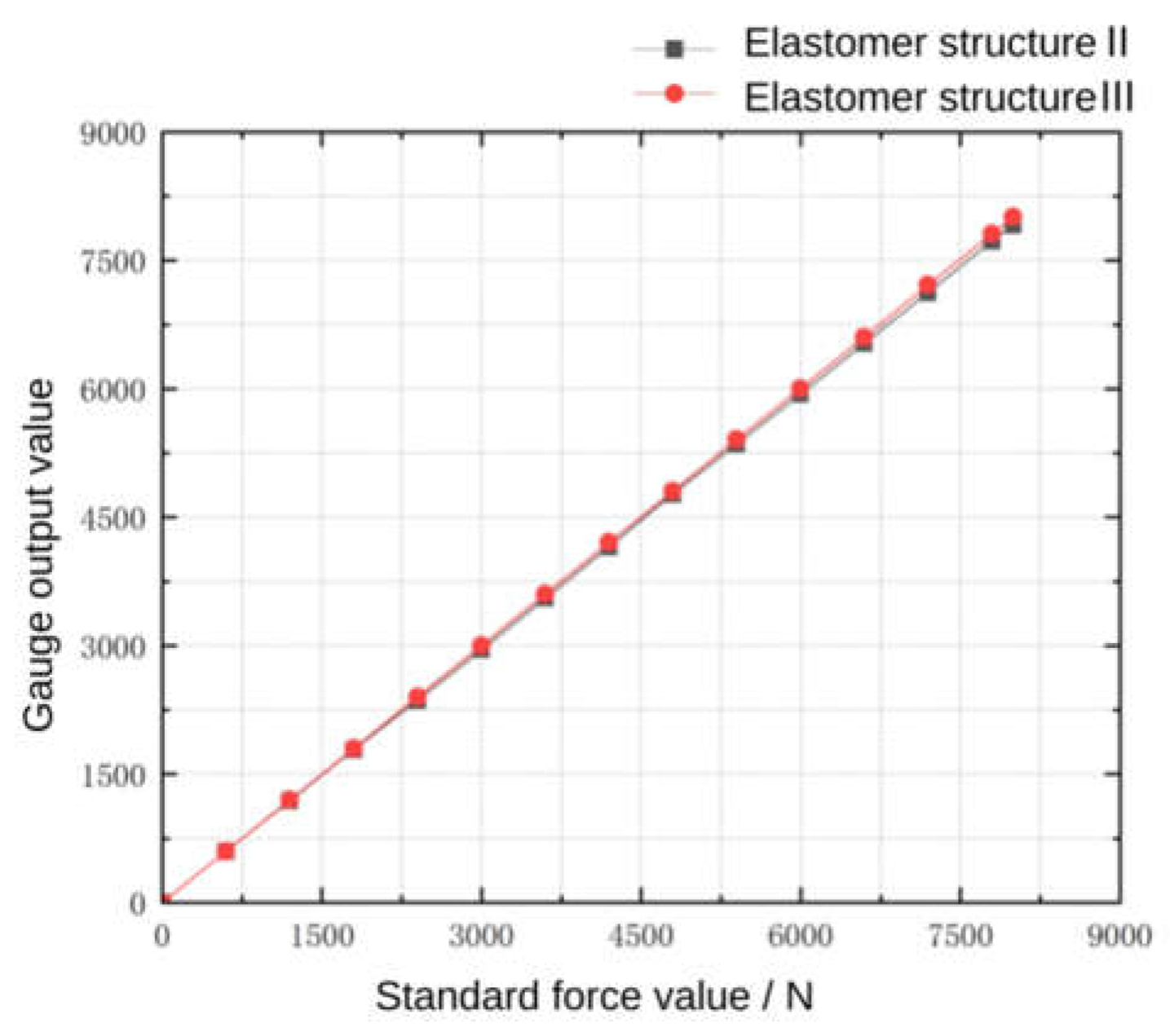

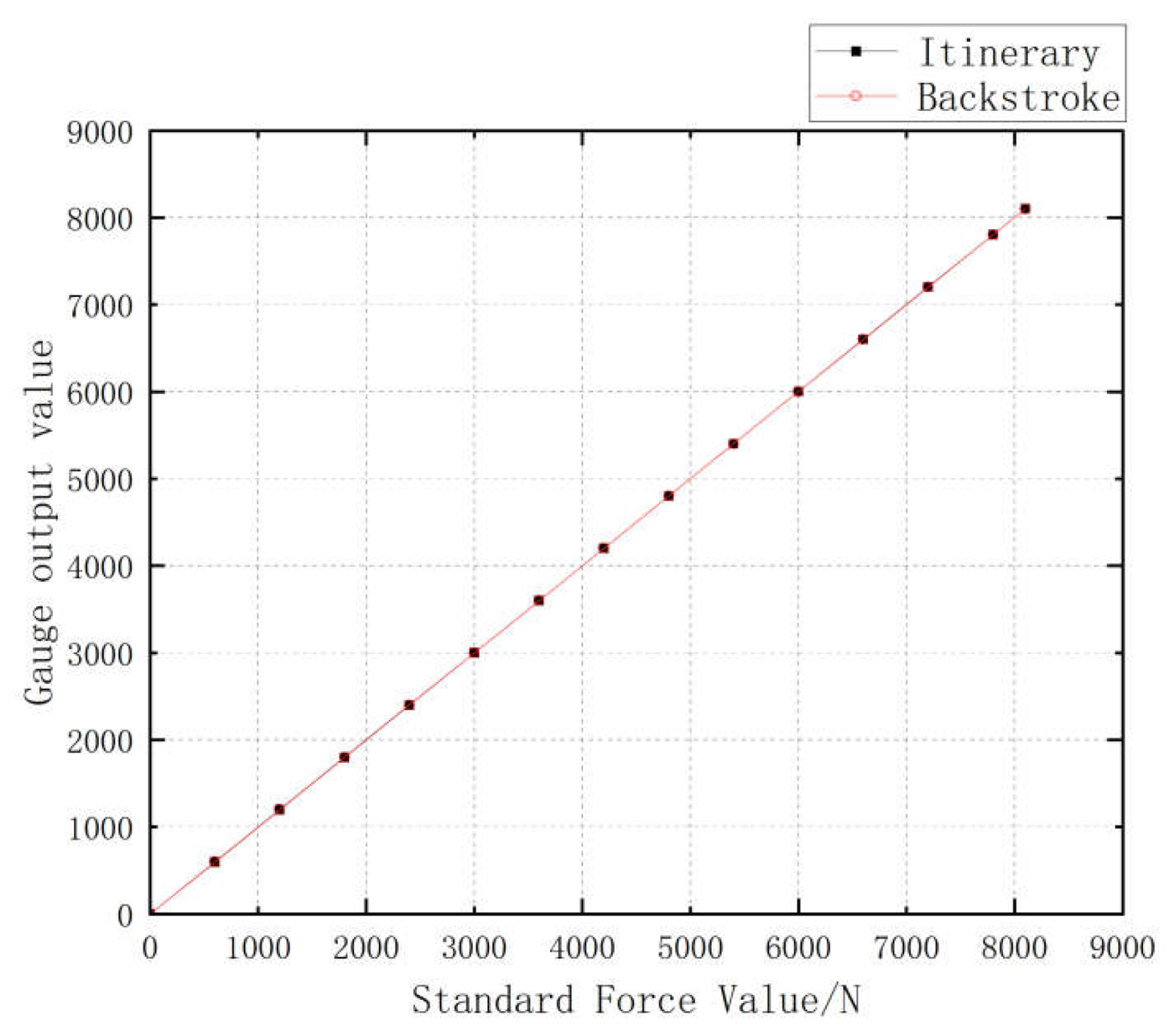

Figure 31.

Elastomer structure test data versus standard force value.

Figure 31.

Elastomer structure test data versus standard force value.

Figure 32.

Miniature Measuring Instrument Prototype.

Figure 32.

Miniature Measuring Instrument Prototype.

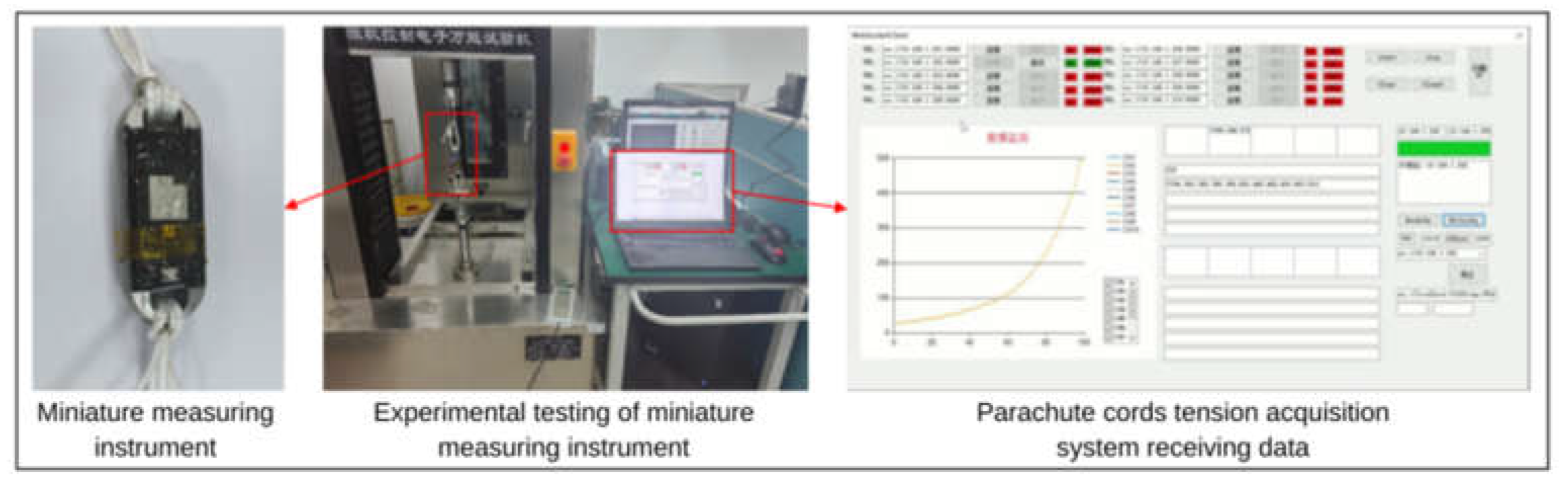

Figure 33.

Joint debugging experiment.

Figure 33.

Joint debugging experiment.

Figure 34.

Data collected by the parachute cords tension acquisition system.

Figure 34.

Data collected by the parachute cords tension acquisition system.

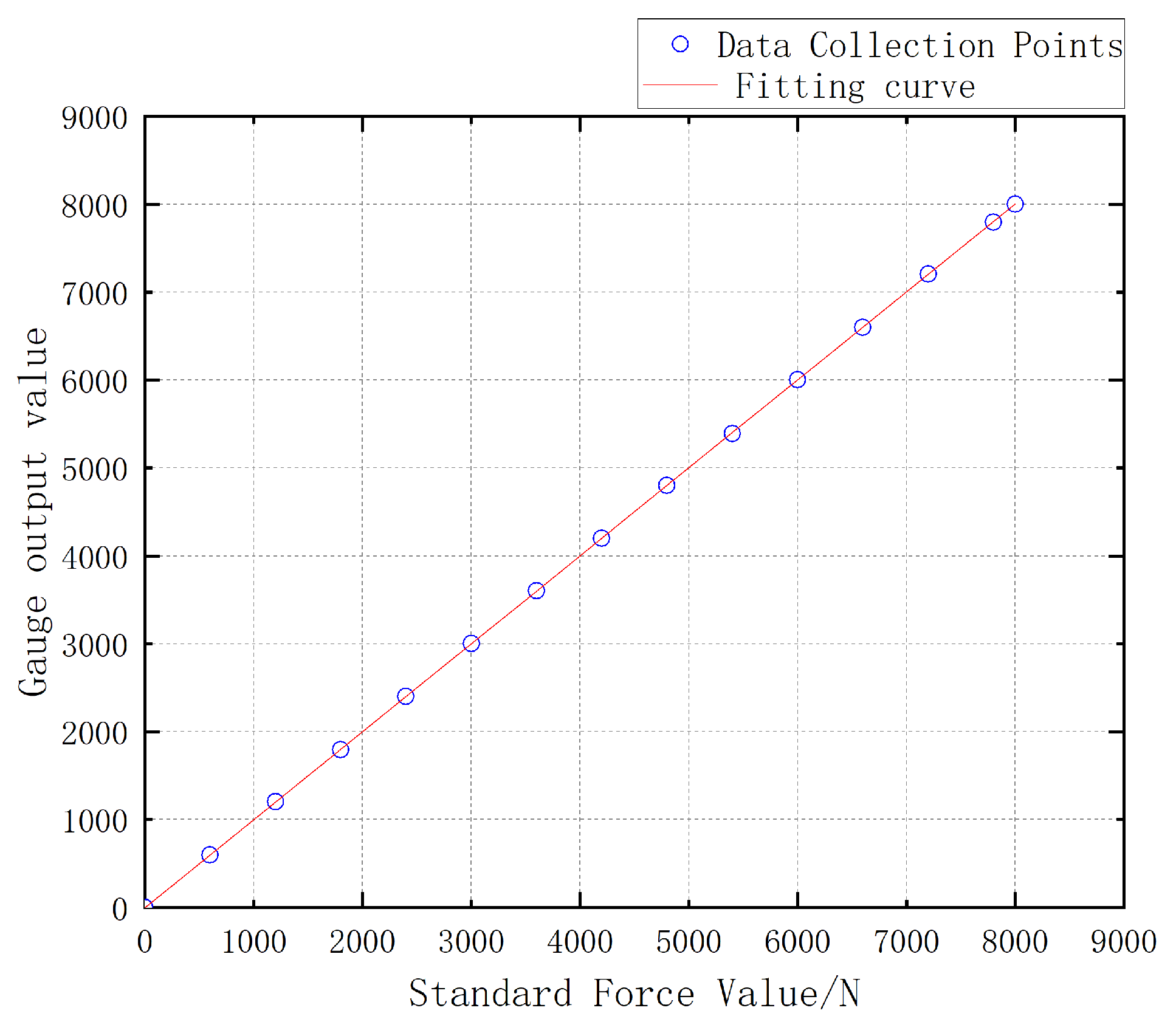

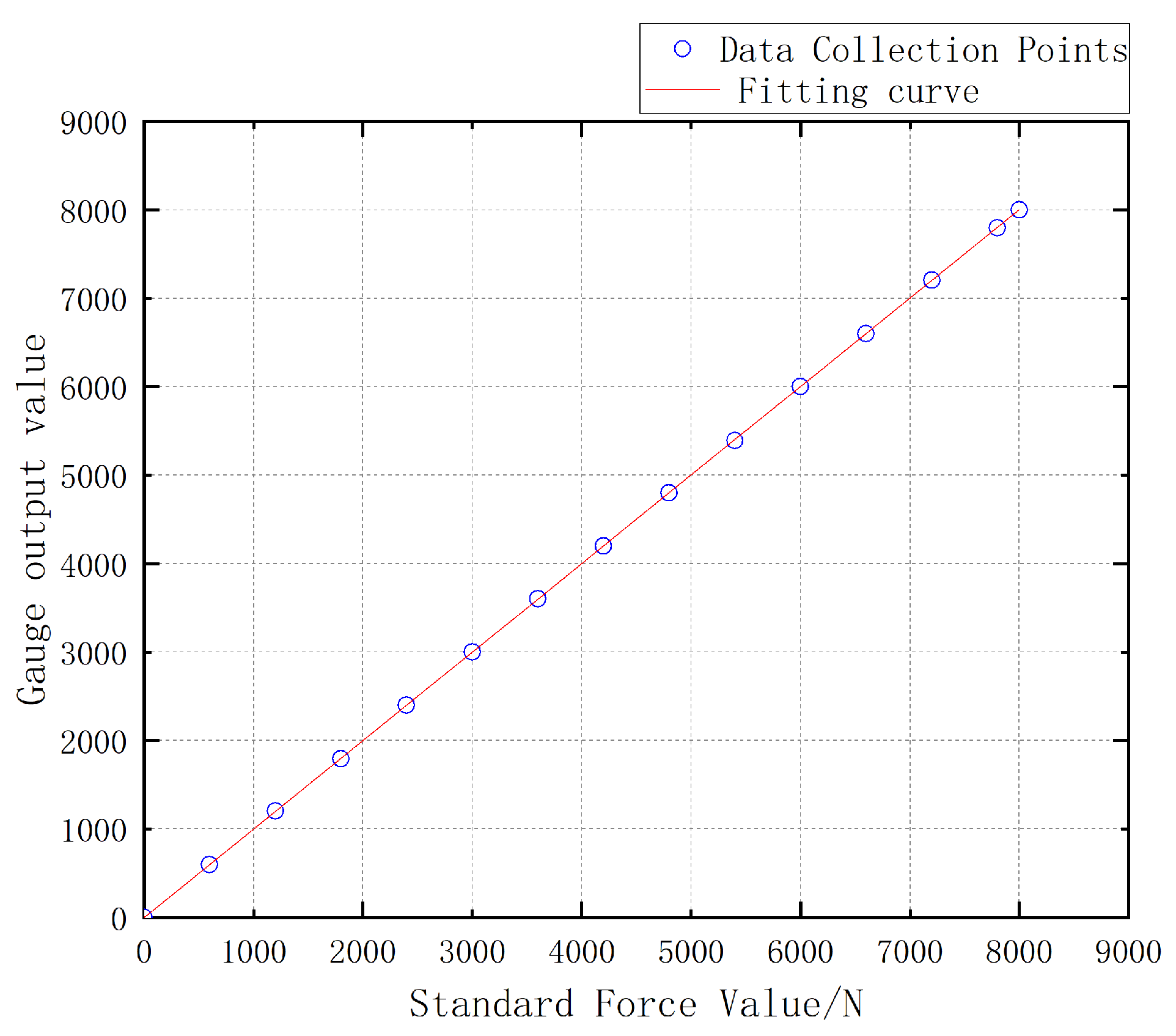

Figure 35.

Elastomer structure AD sampling fitting curve at static state.

Figure 35.

Elastomer structure AD sampling fitting curve at static state.

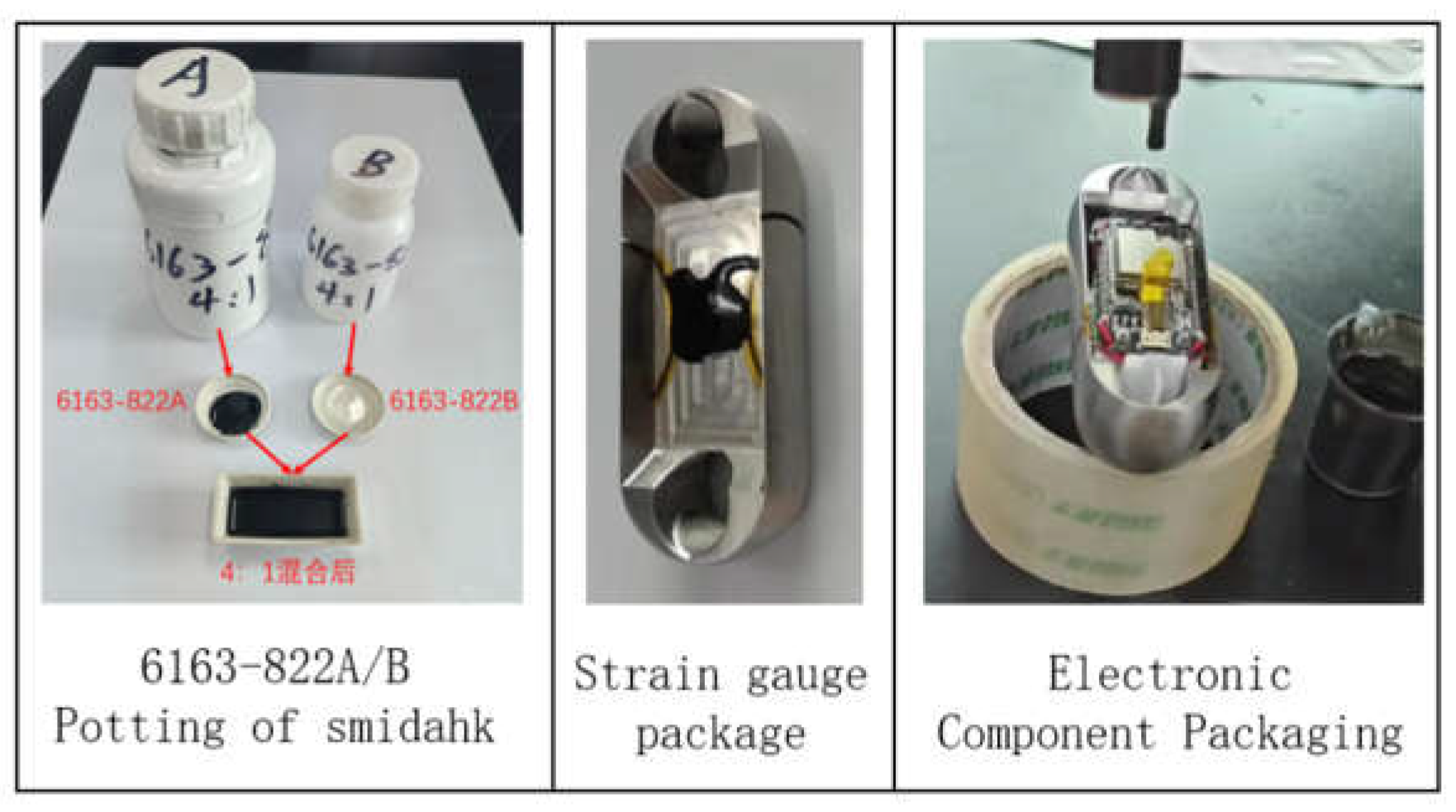

Figure 36.

Miniature measuring instrument encapsulating.

Figure 36.

Miniature measuring instrument encapsulating.

Figure 37.

Miniature measuring instrument after encapsulating and curing.

Figure 37.

Miniature measuring instrument after encapsulating and curing.

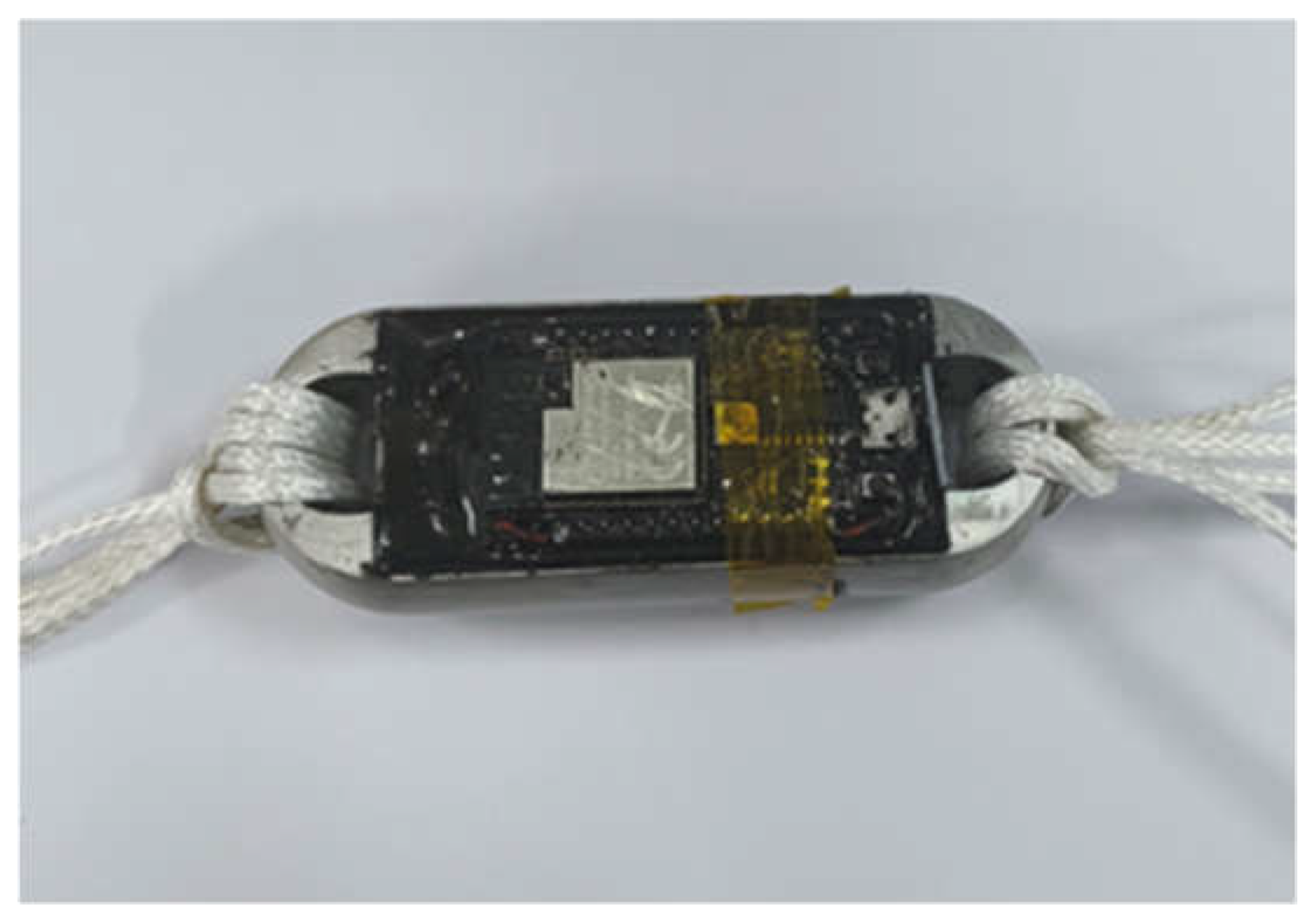

Figure 38.

Miniature measuring instrument experimental testing.

Figure 38.

Miniature measuring instrument experimental testing.

Figure 39.

Miniature measuring instrument calibration.

Figure 39.

Miniature measuring instrument calibration.

Figure 40.

Repeatability test curves for miniature measuring instrument.

Figure 40.

Repeatability test curves for miniature measuring instrument.

Figure 41.

Hysteresis test curve for miniature measuring instrument.

Figure 41.

Hysteresis test curve for miniature measuring instrument.

Figure 42.

Linearity test curve for miniature measuring instrument.

Figure 42.

Linearity test curve for miniature measuring instrument.

Table 1.

Expected indicators for the miniature measuring instrument.

Table 1.

Expected indicators for the miniature measuring instrument.

| Main technical indicators |

Expected parameters |

| Range |

0-8000N |

| Sampling rate |

1000Hz |

| Measurement accuracy |

3%FS |

| Measuring time |

>20 minutes |

| Weight |

<500g |

Table 2.

Selection of hardware module Ⅰ of the acquisition system.

Table 2.

Selection of hardware module Ⅰ of the acquisition system.

| Designation |

Models |

| Microcontroller |

ESP32C3-32S-Kit Development Board |

| A/D Sampling Module |

ADS8689 Module |

| Strain Gage Module |

Single Bridge Strain Gage Module |

| Strain Gage |

BF350-3AA |

| Batteries |

603040 |

| Battery Charging Module |

ETA9742 Module |

Table 3.

Performance Parameters of Signal Acquisition System Hardware Module I.

Table 3.

Performance Parameters of Signal Acquisition System Hardware Module I.

| Technical Indicators |

Technical Parameters |

| Hardware Module Size |

67.8mm×33.84mm×21.63mm |

| Weights |

56.2g |

| A/D Sampling Module Resolution |

16-bit |

| Sampling Rate |

100kHz |

| Channel Number |

8 channels |

| Supply Voltage |

5V analog power supply, 1.65V-5.12V digital power supply |

| Battery Capacity |

800mAh |

Table 4.

Signal Acquisition System Hardware Module II.

Table 4.

Signal Acquisition System Hardware Module II.

| Designation |

Models |

| Microcontroller |

ESP32C3-32S-Kit Development Board |

| A/D Sampling Module |

ADS8689 Module |

| Strain Gage |

BF350-3AA |

Batteries

Battery Charging Module |

603040

ETA9742 Module |

Table 5.

Comparison of technical parameters.

Table 5.

Comparison of technical parameters.

| Technical indicators |

Signal acquisition system hardware module Ⅰ |

Signal acquisition system hardware module Ⅱ |

| Hardware Module Dimensions |

67.8mm×33.84mm×21.63mm |

49.19mm×28.22mm×22.78mm |

| Weight |

56.2g |

30g |

| A/D Sampling Module Resolution |

16 bits |

24 bits |

| Sampling Rate |

100kHz |

1000Hz |

| Number of Channels |

8 channels |

Single Channel

|

| Strain gage |

1/4 bridge strain gage |

Two half-bridge strain gages to form a full bridge |

| Battery Capacity |

800mAh |

400mAh |

Table 6.

Parameters related to parachute cords.

Table 6.

Parameters related to parachute cords.

| Material |

Width |

Thickness |

Tensile Strength |

| Parachute cord |

3.5mm |

1mm |

3KN |

Table 8.

Test data of elastomer structure I and II.

Table 8.

Test data of elastomer structure I and II.

| Standard force value/N |

Elastomer structure II

test data |

Elastomer structure III

test data |

| 0 |

0 |

0 |

| 599 |

599 |

598 |

| 1199 |

1190 |

1200 |

| 1799 |

1785 |

1799 |

| 2399 |

2362 |

2401 |

| 2999 |

2953 |

3003 |

| 3599 |

3554 |

3604 |

| 4199 |

4153 |

4208 |

| 4795 |

4771 |

4804 |

| 5395 |

5354 |

5408 |

| 5995 |

5938 |

6003 |

| 6595 |

6532 |

6604 |

| 7195 |

7123 |

7213 |

| 7795 |

7724 |

7808 |

| 7995 |

7913 |

8006 |

Table 9.

Test data received by the upper computer.

Table 9.

Test data received by the upper computer.

| Standard force value/N |

Test data |

Fitting data |

Bias value of the fit|△Lm| |

Percentage of error% |

| 0 |

0 |

0 |

0 |

0.00% |

| 599 |

598 |

597 |

1 |

0.17% |

| 1199 |

1200 |

1198 |

2 |

0.17% |

| 1799 |

1799 |

1798 |

1 |

0.06% |

| 2399 |

2401 |

2399 |

2 |

0.08% |

| 2999 |

3003 |

3000 |

3 |

0.10% |

| 3599 |

3604 |

3600 |

4 |

0.11% |

| 4199 |

4208 |

4201 |

7 |

0.17% |

| 4799 |

4804 |

4801 |

3 |

0.06% |

| 5399 |

5408 |

5402 |

6 |

0.11% |

| 5999 |

6003 |

6002 |

1 |

0.02% |

| 6599 |

6604 |

6603 |

1 |

0.02% |

| 7199 |

7213 |

7204 |

9 |

0.13% |

| 7799 |

7808 |

7804 |

4 |

0.05% |

| 8000 |

8006 |

8005 |

1 |

0.01% |

Table 10.

Repeatability test experimental data for miniature measuring instrument (gradual increase in pulling force).

Table 10.

Repeatability test experimental data for miniature measuring instrument (gradual increase in pulling force).

| Standard force value/N |

S1 |

S2 |

S3 |

maximum error△Rmax |

Percentage of error% |

| 0 |

0 |

0 |

0 |

0 |

0.00% |

| 599 |

596 |

598 |

597 |

3 |

0.50% |

| 1199 |

1197 |

1202 |

1200 |

3 |

0.25% |

| 1799 |

1800 |

1795 |

1797 |

5 |

0.28% |

| 2399 |

2397 |

2399 |

2398 |

2 |

0.08% |

| 2999 |

2995 |

3003 |

2997 |

4 |

0.13% |

| 3599 |

3597 |

3602 |

3599 |

3 |

0.08% |

| 4199 |

4200 |

4197 |

4198 |

4 |

0.10% |

| 4799 |

4800 |

4799 |

4797 |

3 |

0.06% |

| 5399 |

5400 |

5391 |

5397 |

8 |

0.15% |

| 5999 |

5995 |

6002 |

6000 |

4 |

0.07% |

| 6599 |

6600 |

6597 |

6599 |

3 |

0.05% |

| 7199 |

7200 |

7204 |

7197 |

5 |

0.07% |

| 7799 |

7803 |

7797 |

7807 |

8 |

0.10% |

| 7999 |

8000 |

8002 |

7996 |

8 |

0.10% |

Table 11.

Experimental data for hysteresis test of miniature measuring instrument.

Table 11.

Experimental data for hysteresis test of miniature measuring instrument.

| Standard force value/N |

Positive range test data |

Reverse range test data |

Difference△Hm |

Percentage of error% |

| 0 |

0 |

0 |

0 |

0% |

| 599 |

600 |

601 |

1 |

0.17% |

| 1199 |

1200 |

1202 |

2 |

0.17% |

| 1799 |

1798 |

1801 |

3 |

0.17% |

| 2399 |

2402 |

2403 |

4 |

0.17% |

| 2999 |

3004 |

3007 |

7 |

0.23% |

| 3599 |

3602 |

3604 |

4 |

0.11% |

| 4199 |

4201 |

4202 |

1 |

0.02% |

| 4799 |

4802 |

4803 |

2 |

0.04% |

| 5399 |

5403 |

5405 |

5 |

0.09% |

| 5999 |

6005 |

6006 |

6 |

0.10% |

| 6599 |

6604 |

6606 |

3 |

0.05% |

| 7199 |

7204 |

7205 |

2 |

0.03% |

| 7799 |

7804 |

7805 |

2 |

0.03% |

| 8099 |

8104 |

8105 |

2 |

0.02% |

Table 12.

Experimental data for linearity test of miniature measuring instrument.

Table 12.

Experimental data for linearity test of miniature measuring instrument.

| Standard force value/N |

Test data |

Fitting data |

Bias value of the fit|△Lm| |

Percentage of error% |

| 0 |

0 |

0 |

0 |

0.00% |

| 599 |

598 |

597 |

1 |

0.17% |

| 1199 |

1200 |

1198 |

2 |

0.17% |

| 1799 |

1799 |

1798 |

1 |

0.06% |

| 2399 |

2401 |

2399 |

2 |

0.08% |

| 2999 |

3003 |

3000 |

3 |

0.10% |

| 3599 |

3604 |

3600 |

4 |

0.11% |

| 4199 |

4205 |

4201 |

4 |

0.10% |

| 4799 |

4804 |

4801 |

3 |

0.06% |

| 5399 |

5405 |

5402 |

3 |

0.06% |

| 5999 |

6003 |

6002 |

1 |

0.02% |

| 6599 |

6604 |

6603 |

1 |

0.02% |

| 7199 |

7209 |

7204 |

5 |

0.07% |

| 7799 |

7808 |

7804 |

4 |

0.05% |

| 8000 |

8006 |

8005 |

1 |

0.01% |

Table 13.

Miniature measuring instrument performance indicators.

Table 13.

Miniature measuring instrument performance indicators.

| Performance indicators |

Technical Parameters |

| Instrument Dimensions |

96mm×36mm×29.5mm(L x W x H) |

| Weight |

291g |

| Endurance |

>20min |

| Range |

0~8000N |

| Resolution |

1N |

| Sensitivity |

1mV/V |

| Repeatability |

0.1% |

| Hysteresis |

0.1% |

| Linearity |

0.1% |

| Accuracy |

0.1732% |