Submitted:

29 August 2024

Posted:

03 September 2024

You are already at the latest version

Abstract

Keywords:

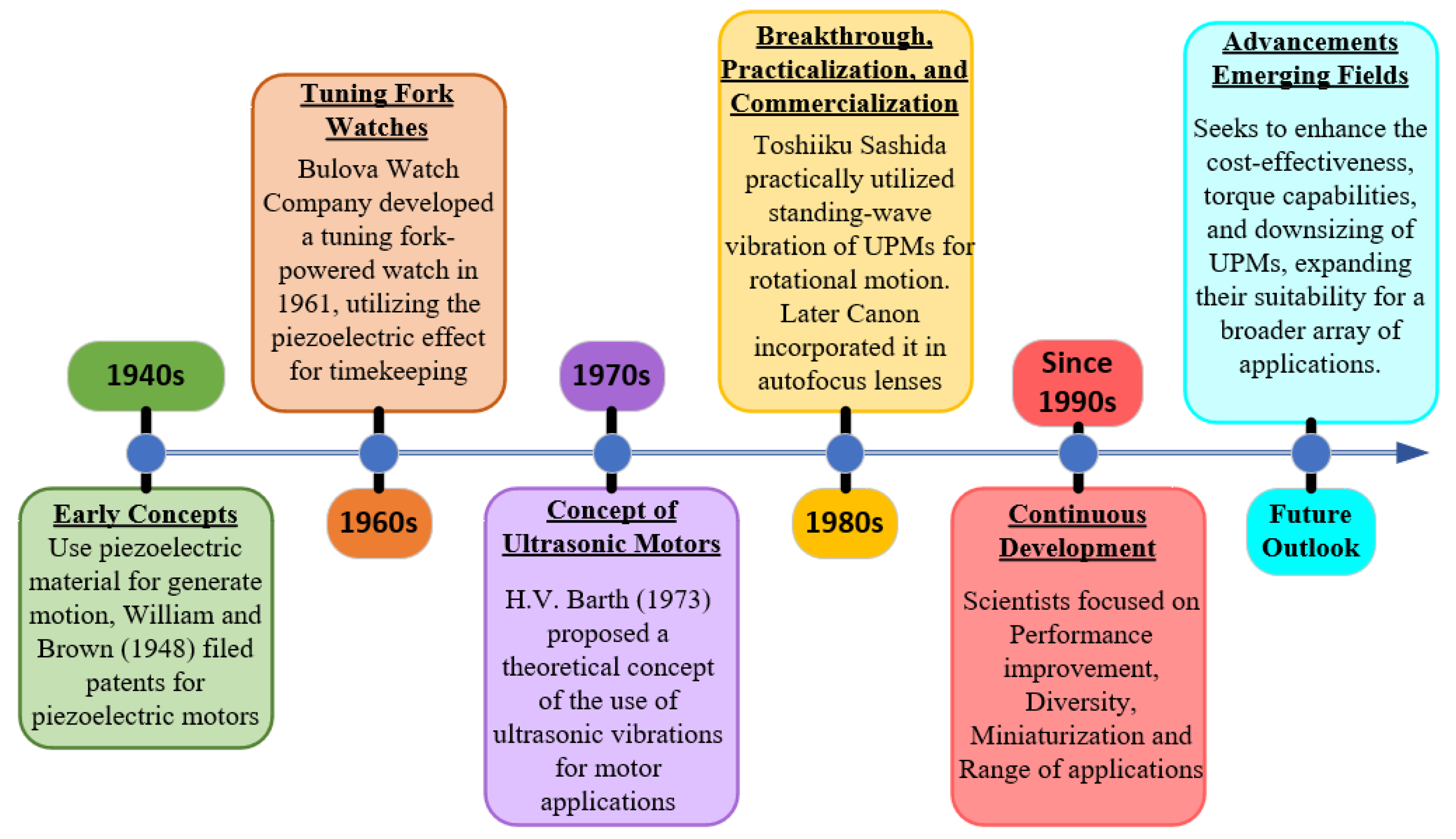

Introduction

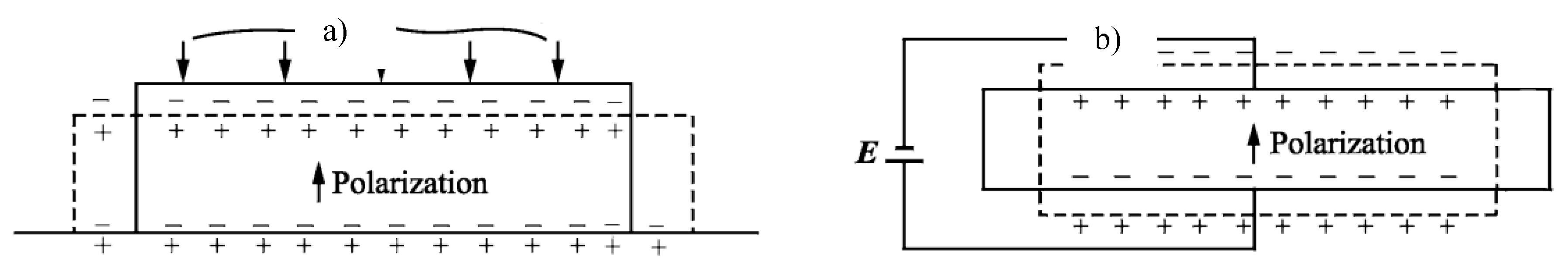

1.1. Application of Piezoelectric Materials to USMs

1.2. Piezoelectric USMs:

| Feature | Piezoelectric Ultrasonic Motor | Electromagnetic Motor | Electrostatic Motor | Thermal Mechanical Motor | Electro-Conjugate Fluid Motor |

|---|---|---|---|---|---|

| Voltage(I/P) | Lower voltage | Lower voltage | High voltage required | Moderate voltage | Moderate voltage |

| Size & Weight | Compact and lightweight | Bulky due to magnets and coils | Can be bulky and heavy | Can be bulky | Can be complex |

| Suitable Environment | Works in air and vacuum | Affected by magnetic fields | Limited by air breakdown | Sensitive to temperature | Sensitive to leaks |

| Noise | Silent operation | Can be noisy (brushes/gears) | May generate noise | May generate noise | May generate noise |

| Electromagnetic Interference (EMI) | No EMI | Generates EMI | May generate EMI | No EMI | No EMI |

| Low-Speed Torque | High torque at low speeds | Torque decreases at low speeds | Limited torque at low speeds | Limited torque at low speeds | Generally lower torque |

| Response Time | Very fast response time | Can be slow depending on design | Slower response time | Slowest response time | Slower response time |

| Motor Complexity | Simple design | Complex design with moving parts | Complex design | Complex heating/cooling system | Complex fluid dynamics |

| Temperature | Stable performance across a wide range | Performance may be affected | Performance may be affected | Performance may be affected | Performance may be affected |

| Motor Efficiency | High efficiency, especially at low speeds | Varies depending on design | Lower efficiency | Lower efficiency | Lower efficiency |

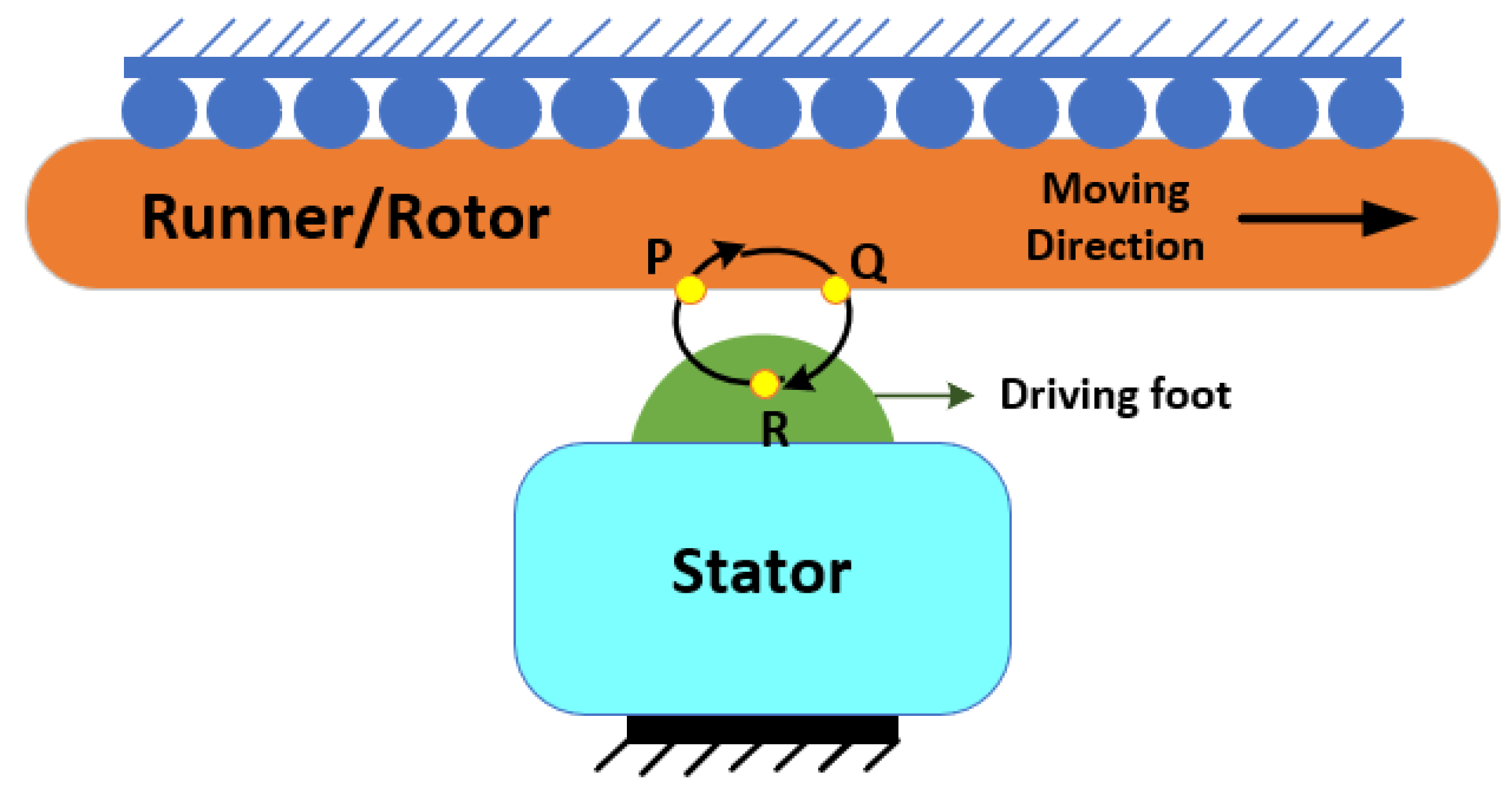

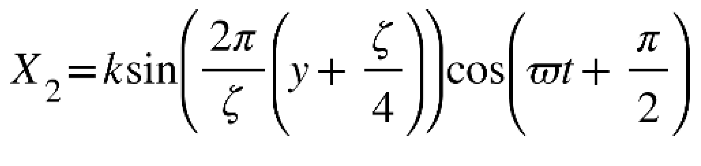

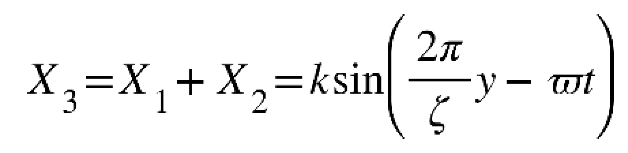

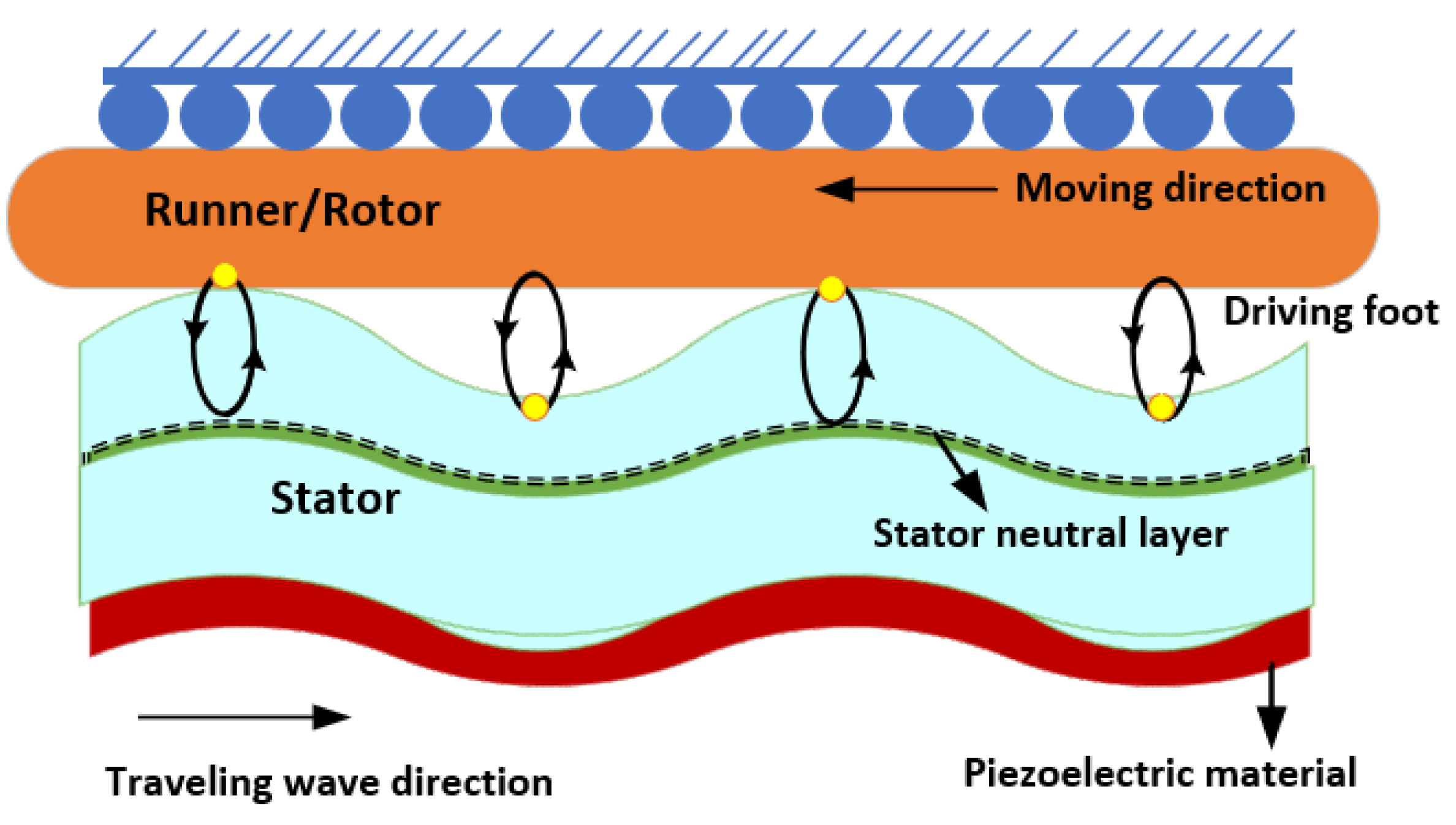

1.3. Basic Operating Principle of USMs:

1.4. Characteristics of USMs:

-

Advantages

- USMs have the benefits of nano/micro-structure and allows variety of flexible designs. Because of the piezoelectric material characteristic that can produce many forms of vibration, involving bending, longitudinal, and torsional vibrations. The torque density of USMs is greater than conventional motors.

- USMs provide strong torque at low speeds and are capable of driving loads directly with no gear requirement. This advantage improves positioning accuracy as well as response speed by reducing additional weight and volume imposed by the gearbox, transmission-induced position error, vibrations, noise, and energy loss.

- USM's rotor possesses tiny inertia, rapid response at the microsecond level, self-locking, and high holding torque. They may reach a stable speed in a few milliseconds and stop even faster due to friction between the rotor and stator.

- The Position and velocity control of USMs is great with good displacement resolution. Because the stator operates at a high frequency and the rotor or slider is at low frequency. They are capable of controlling precision of microns or even nanoseconds in a servo system and hence responds quickly.

- USMs have distinct characteristics from regular motors as they generate no magnetic fields and are resistant to electromagnetic interference when operating.

- They are environmentally friendly devices due to low noise. USMs typically operate at frequencies greater than 20kHz, which are beyond human hearing. Furthermore, the noise generated by the gearbox to decrease the speed is eliminated because the motor can directly drive loads.

- USMs can operate under harsh environmental circumstances may be in vacuum and high/low temperature with selecting proper design, fractional part, and piezoelectric material.

-

Disadvantages

- USMs usually generate small power with low efficiency as they involve two step energy conversion techniques. The first approach uses the reverse piezoelectric effect to transform electrical power into mechanical energy. The second mechanism converts the stator's vibration.

- into macro one-directional motion of the rotor via friction between its rotor and stator, which cause energy loss. Hence the overall effectiveness of USMs is reduced.

- It has a limited functional life and is not appropriate for continuous operation for long period. Friction and wear issues emerge at the stator-rotor interfaces during friction drive. Furthermore, high-frequency vibration can cause fatigue damage to the rotor and piezoelectric materials, particularly when the power output is large and the ambient temperature is high which cause reduced the performance.

- It has a limited functional life and is not appropriate for continuous operation for long period. Friction and wear issues emerge at the stator-rotor interfaces during friction drive. Furthermore, high-frequency vibration can cause fatigue damage to the rotor and piezoelectric materials, particularly when the power output is large and the ambient temperature is high which cause reduced the performance.

- The USMs have specific criteria of excitation/drive signals for the amplitude, frequency, and phase in order to activate the stator's resonance. Whenever the motor temperature varies, the frequency of excitation signals for piezoelectric devices must be adjusted appropriately to ensure output performance stability. Thus, the circuitry for USMs drivers is sophisticated as well.

1.5. Organization

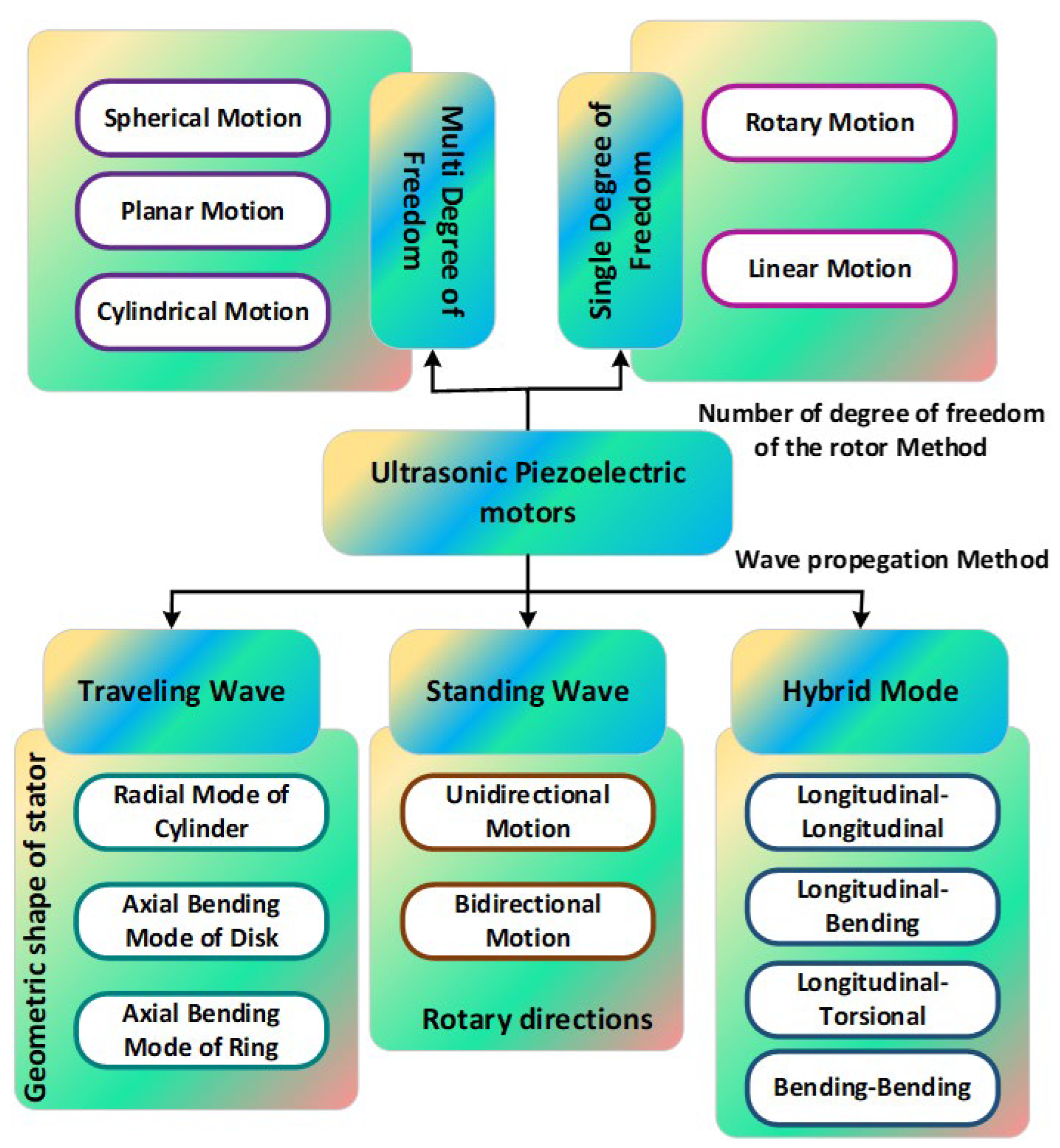

Classification of USMs

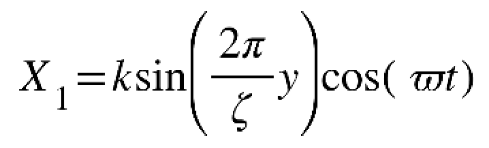

Traveling Wave Motor.

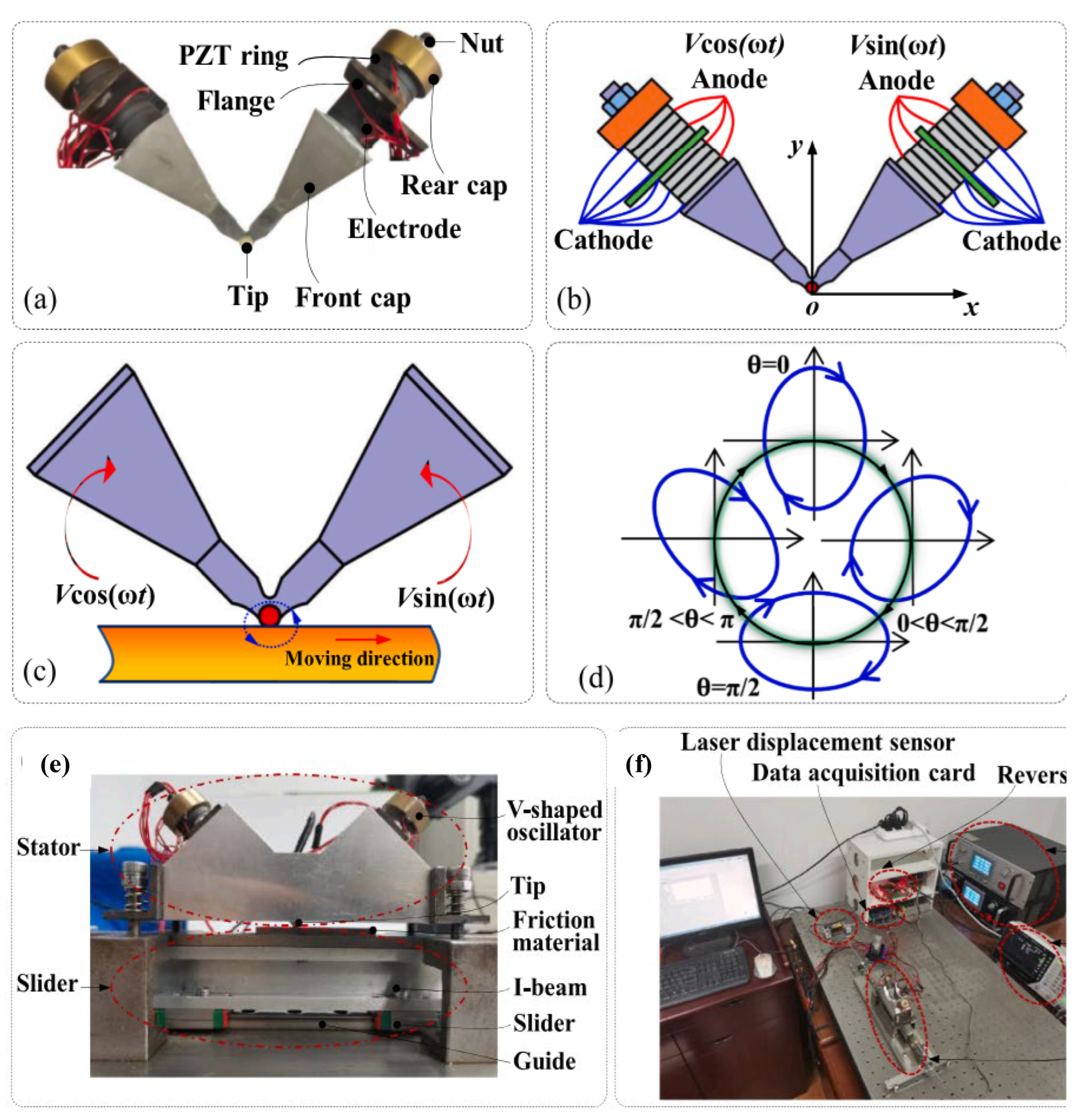

2.2. Standing Wave USMs

| Reference | Year | Vibrator | Stator shape | Voltage | Velocity/Speed | Frequency | Force |

|---|---|---|---|---|---|---|---|

| [95] | 2023 | - | V-shaped | 90V | 0.2m/s | 32.2kHz | 10N |

| [94] | 2023 | linear | V-shaped | 80Vrms | 0.23m/s | 33kHz | 20N |

| [96] | 2023 | linear | V-shaped | 150V | - | 39.1kHz | - |

| [97] | 2021 | linear | V-shaped | 400Vrms | 0.53m/s | 39kHz | 30N |

| [98] | 2020 | linear | V-shaped | 350Vrms | 1.27m/s | 38.6kHz | 80N |

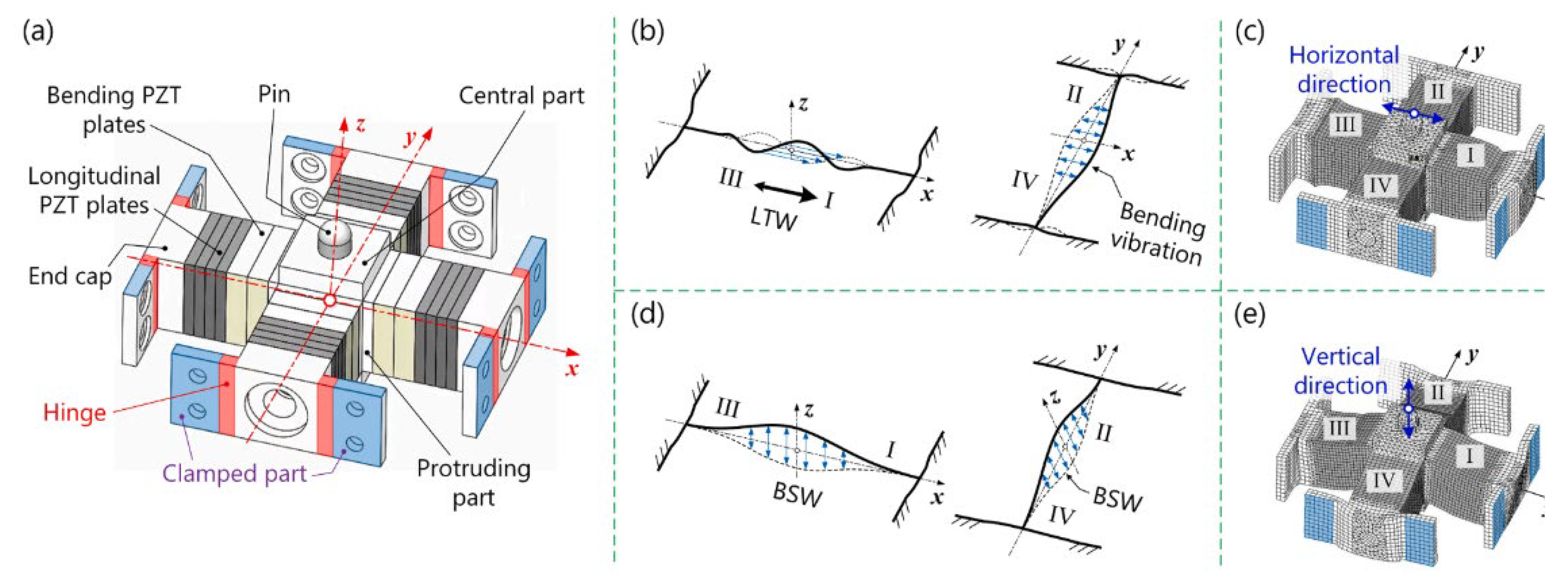

2.3. Hybrid Modes USMs

| Reference | Year | Motion/Vibration | Stator structure |

Prototype Size | Voltage | Velocity/Speed | Frequency | Force |

|---|---|---|---|---|---|---|---|---|

| [100] | 2022 | Longitudinal Bending | tuning fork | - | 320Vpp | 88.67mm/s | 80.2kHz | 99mN |

| [101] | 2022 | Bending Longitudinal | - | 45.7*30mm | 180Vp | 1103mm/s | 30.2kHz | 392mN |

| [102] | 2020 | Transverse-Shear | disk | 2*10*4mm | 300Vpp | 169.4mm/s | 24.7kHz | 7.5N |

| [103] | 2020 | Longitudinal-torsional | cylinder | 10*10*55mm | 400Vpp | 483rpm | 56kHz | 22N |

| [104] | 2019 | Bending-Bending | planar | 20*44*30mm | 400Vpp | 300µm/s | 40Hz | 1.47N |

| [99] | 2023 | Longitudinal Bending | disk | 68*68*28mm3 | 250V | 877mm/s | 27.4kHz | 40.2N |

| [105] | 2019 | Longitudinal- Bending | disk | 40*112*38mm | 400Vpp | 124.2mm/s | 1.4kHz | 105N |

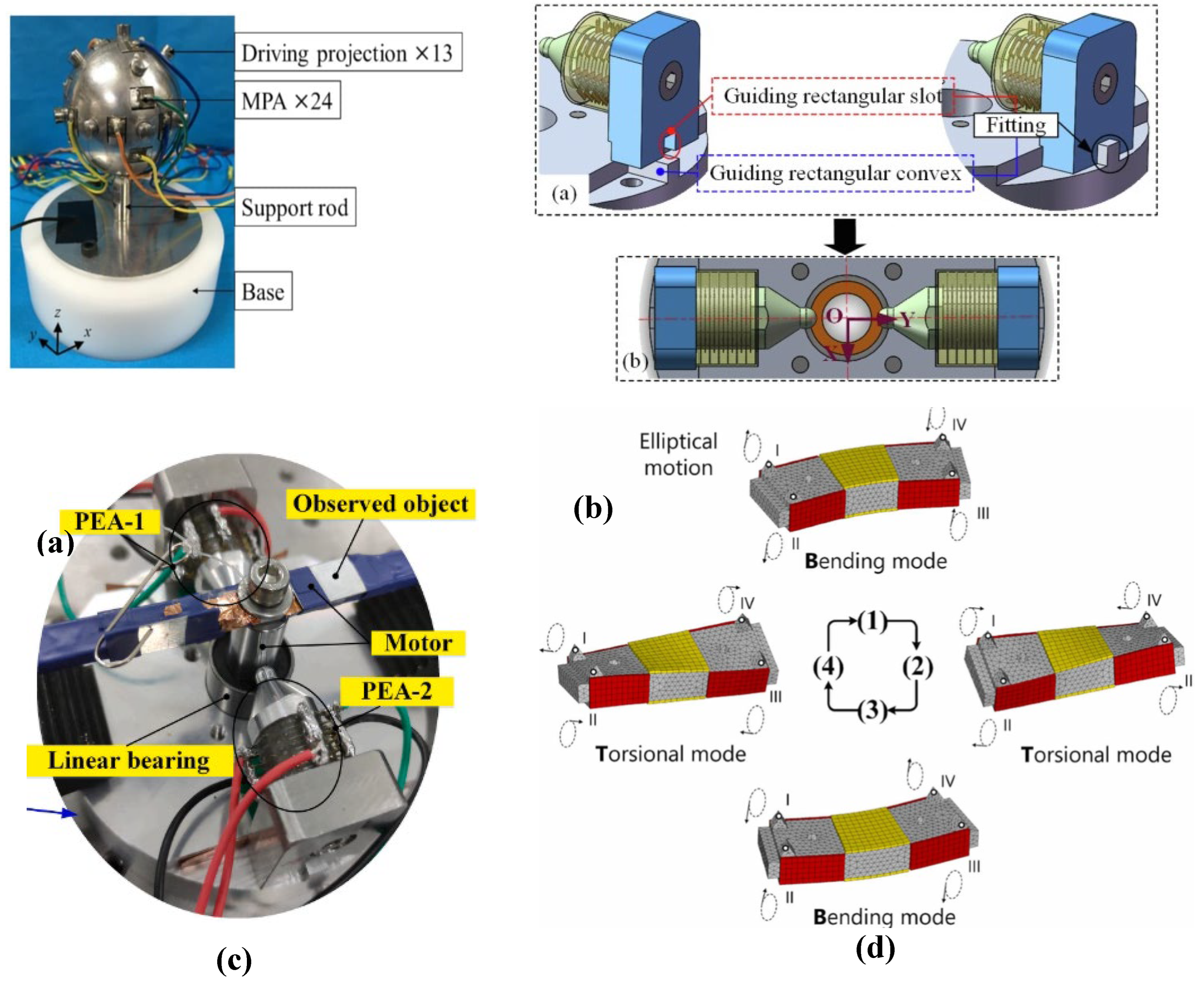

2.4. Multi-DOF Piezoelectric Ultrasonic Motor

2.4.1. Spherical USMs

2.4.2. Rotary-linear USMs

2.4.3. Planar USMs

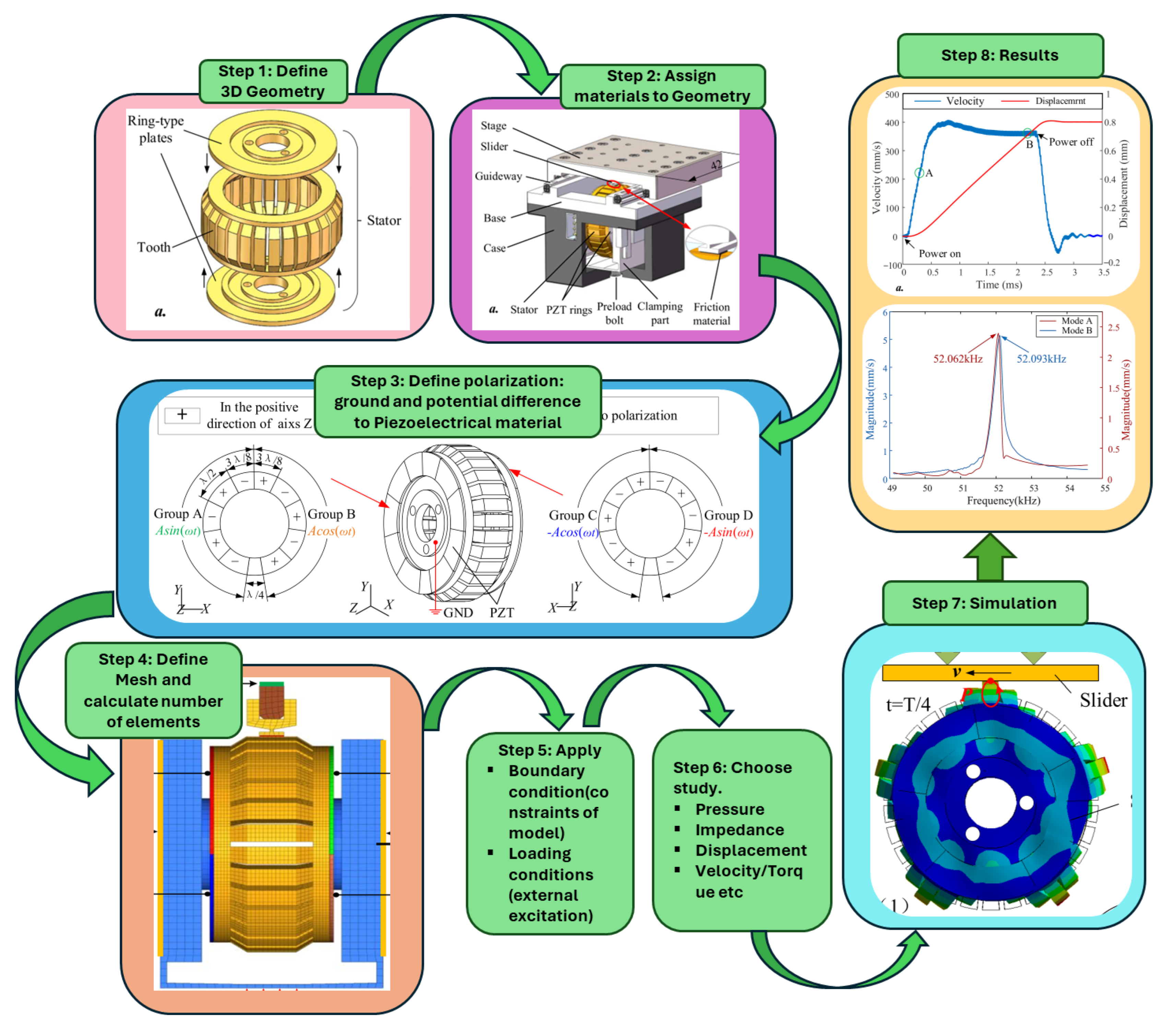

Finite Element Modeling of USMs

Fabrication Methods of USMs

Conventional Fabrication Methods of USMs

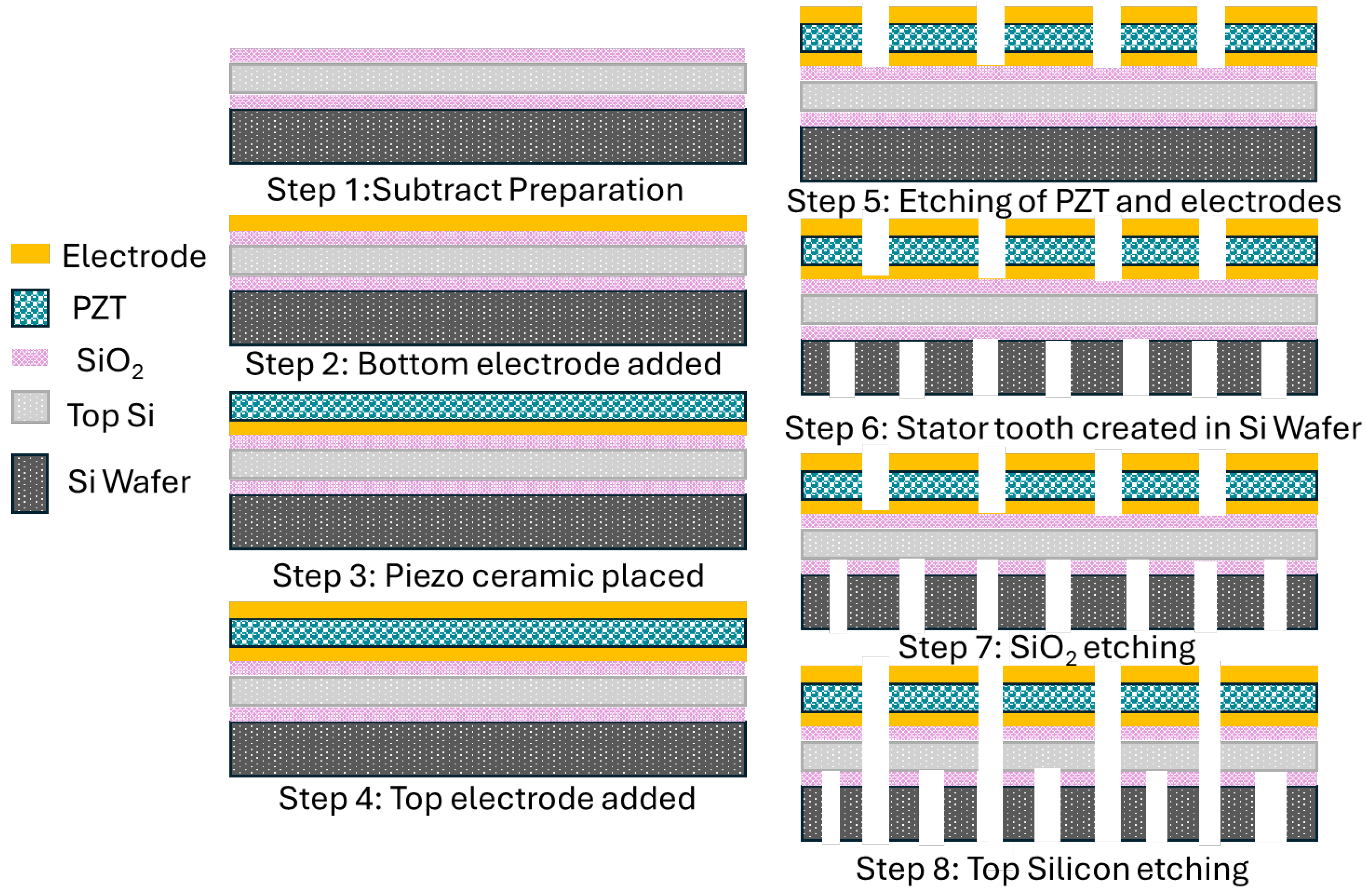

Micro and Nano Fabrication Methods of USMs

| Method | Techniques | Considerations | Advantages |

|---|---|---|---|

| Thin-Film, Deposition |

|

Cost, Performance of thin films, Dedicated apparatus |

Complex designs, Miniaturization, Remove the need of bonding process |

| LGA |

|

Expert tools, Complex process, limited materials |

Good quality surface, Raised proportions of aspects of metal structures |

| Micromachining |

|

Surface roughness, Multi-step process, residual stress |

Intricate characteristics, Combines thin-film deposition processes |

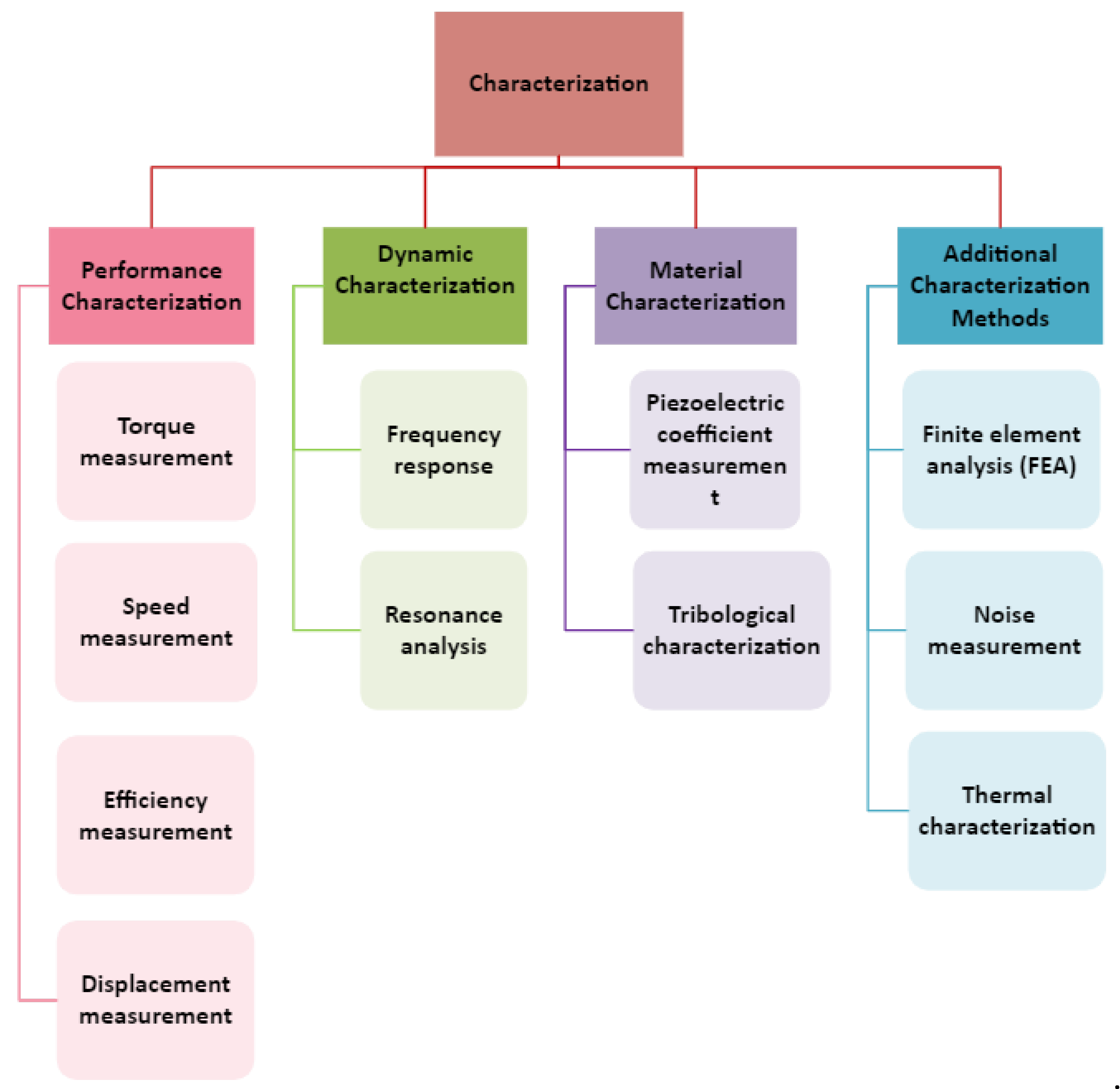

Characterizations of USMs

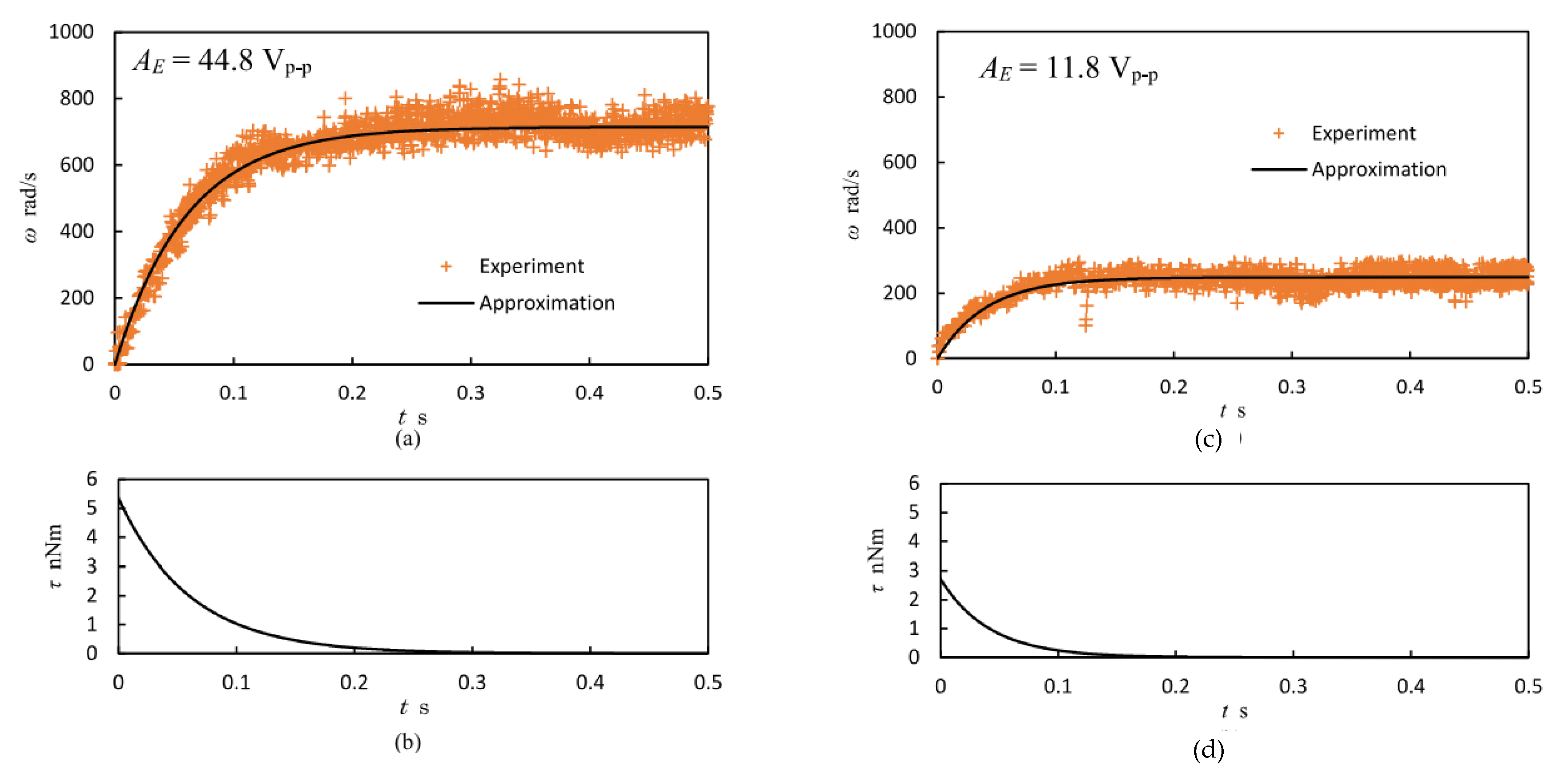

Performance Characterization

Material Characterization

Dynamic Characterization

| Characteristic | Equipment | Technique |

|---|---|---|

| Torque | Torque meter, Load Cell [130,134] |

Static or Dynamic Load Application, [132] Pre-Load mechanisms Custom test configuration |

| Speed Velocity |

Tachometer, Laser doppler vibrometer, [133] encoders |

Transient characterization method [130,135] Direct Measurement, Frequency Sweep Techniques |

| Efficiency | Power Supply, Load Cell, Tachometer, Multimeter |

Calculation of Mechanical Output Power / Electrical Input Power, Frequency Sweep Techniques Torque*angular speed/ Input power [136] |

| Vibration | Accelerometer, Laser Scanner Vibrometer |

Measurement of Vibration Levels and Patterns [131] |

| Strain | Strain Gauge, Digital Image Correlation, Interferometry |

Non-contact optical method High-precision technique |

| Temperature | Thermocouple or Thermistor |

Monitoring Temperature Distribution |

| Noise | Sound Level Meter | Measurement of Acoustic Noise |

| Electric parameters |

Multimeter | Direct measurement of current and voltage |

| Friction and Wear | Tribometer | Simulation of Operating Conditions |

| Piezoelectric coefficient |

Berlincourt Meter, d33 Meter, Laser Interferometry |

Quasi-static method |

| Holding Force | Load Cell | Measurement of Maximum Static Load |

| Frequency Response |

Signal Generator, Power Amplifier, laser Doppler vibrometer, Spectrum Analyzer |

Inputting Varying Frequency Signals and Measuring Response |

| Resonance | Signal Generator, Power Amplifier, laser Doppler vibrometer, Spectrum Analyzer |

Identification of Resonant Frequencies and Mode Shapes, Frequency Sweep Techniques |

| Impedance | Impedance analyzer[138], LCR meter, Network analyzer, Oscilloscope |

Direct Measurement, Vectorial Measurements, S-Parameters[139] |

| Displacement Angular acceleration |

linear variable differential transformer, Laser Triangulation sensor, laser displacement sensor, laser interferometer, linear encoder |

Measurement of Linear or Angular Displacement[131] Newton second law[135] |

| Quality factor | Bode plot | Bode plot[131] |

Applications of USMs

Surgical Robots Based on USMs

Laparoscopic Surgery

Neurosurgery

Cardiovascular Surgery

| Characteristic | Importance | Fields | Applications |

|---|---|---|---|

| High Precision & Resolution | Allows precise and intricate motions, allowing for accurate placement and providing manipulation at the micrometer scale. | Minimally invasive surgery | Instrument control |

| Aerospace | Antenna pointing, Telescope adjustment |

||

| Biomedical engineering | Drug delivery, Microfluidic devices |

||

| Industrial automation | Robotic assembly, Laser cutting |

||

| Fast Response & Speed | Enables fast operating and swift adjustments in position through the use of speedy start-stop and motion functions. | Industrial automation | Assembly lines, Material handling |

| Biomedical engineering | Pumps, Microfluidic devices |

||

| Silent Operation | Essential for locations that are sensitive to noise by producing minimum noise. | Minimally invasive surgery | Improved Patient Comfort, Quieter surgical environment, Improved Communication and Collaboration of surgical teams |

| Biomedical engineering | Medical pumps, Diagnostic Equipment, Implantable Devices |

||

| Aerospace | Minimizing acoustic disturbances, Microgravity Experiments, |

||

| No electromagnetic interference (EMI) | Ensures optimal performance in the proximity of delicate electronic devices while preventing electromagnetic interference (EMI) disturbances. | Biomedical engineering | Implantable devices |

| Industrial automation | Environments with sensitive electronics, Medical Device Production and Assembly, Applications Requiring Sparks or Flammable Materials |

||

| Aerospace | Safeguarding sensitive Electronics, Compatibility with scientific Equipment, Reduced Risk of Signal Interference |

||

| Compact Size & Lightweight | Enables the reduction in size of instruments and decreases the total weight. | Minimally invasive surgery | Surgical tools |

| Aerospace | Spacecraft design | ||

| Biomedical engineering | Implantable devices | ||

| Harsh Environment Tolerance | Capable of functioning in harsh conditions such as severe temperatures, radiation, and vacuum, making it indispensable for space operations. | Aerospace | Satellite components, Deployment mechanisms |

| Low Power Consumption | Conserves energy and prolongs battery lifespan in circumstances with limited resources. | Aerospace | Spacecraft design |

| Biomedical engineering | Implantable devices |

Industrial Applications

Aerospace Applications

Biomedical Applications

Piezoelectric USMs Trends and Future Developments

Material Advancements

- New piezoelectric materials: Researchers are now working on creating new piezoelectric materials that possess enhanced characteristics such as increased efficiency, a broader range of operating temperatures, and improved resistance to fatigue. This will result in USMs that have improved performance and a broader range of uses.

- Composite materials: Ongoing research is being conducted on composite materials that integrate the piezoelectric effect with additional advantageous characteristics such as lightweight construction or stiffness. These composite materials have the potential to enable the development of USMs with distinct and specialized capabilities.

Miniaturization and integration

- Micro-USMs: Miniaturizing USMs, especially for use in micro-robots, healthcare equipment, and hydrodynamic systems, is a significant current development. The invention of micromachining and fabrication processes will facilitate the production of increasingly miniature and accurate USMs.

- Integration with other technologies: USMs are being combined with other microelectromechanical systems (MEMS) devices and sensors to form more intricate and versatile systems. These advancements will create opportunities for the development of new applications in fields like as biotechnology and aviation.

Improved Control and Performance

- Advanced control algorithms: The growth of advanced control algorithms will enable the more accurate and efficient functioning of USMs. This will enhance their productivity and empower them to tackle more intricate tasks.

- Higher torque and speed: USMs are continuously enhanced to attain greater torque and speed characteristics. This will increase their potential for use in areas such as manufacturing automation and robotics.

- Self-sensing USMs: Ongoing research is being conducted on USMs that possess the ability to perceive their own internal state and adapt their functioning accordingly. This would improve the quality and durability in a wide range of applications.

New Application Areas

- Medical devices: Miniaturized USMs show potential for application in surgical instruments, pharmaceutical delivery devices, and precise manipulation duties inside the human body.

- Nanotechnology: USMs have the potential to manipulate and position items at the nanoscale, which could lead to significant improvements in nanorobotics and material science.

- Energy harvesting: USMs serve as energy harvesters, transforming surrounding vibrations into electrical energy. This technology has the potential to be used in powering low-energy devices such as wearable electronics and wireless sensor networks.

- Smart cities: USMs have the potential to have a substantial impact on the development of smart cities. Their capabilities extend beyond basic automation, making a significant contribution to the development of a sustainable, customized, and adaptable urban environment. Envision a system of self-repairing infrastructure, where embedded USMs in buildings or roads initiate repairs upon sensing damage, or a network of microfluidic channels driven by USMs that gather real-time environmental data. USMs have the potential to allow building facades to adapt to weather conditions and to generate customized experiences in public spaces using equipment that can be rearranged. USMs could potentially improve waste management by providing the power needed for robotic sorting systems or autonomous collection bots. To create a more peaceful urban environment, USMs could be included into active noise cancellation systems in designated areas or even public transit vehicles. USMs could be advantageous in traffic management by implementing them in dynamic traffic light actuators to enhance traffic flow optimization. The potential is extensive, and as USM technology progresses in conjunction with the idea of optimal smart cities, we may anticipate the development of even more innovative and influential applications.

Challenges and Considerations

- Manufacturing complexity: Advanced manufacturing processes are necessary for the shrinking and integration of USMs, but they can be costly and difficult.

- Material limitations: The characteristics of existing piezoelectric materials impose restrictions on the capabilities of USMs in certain domains. Ongoing investigation into novel materials is essential.

- Cost reduction: Reducing the manufacturing expenses of USMs will be essential for their extensive implementation in many different industries.

- Cryogenic applications: Extreme temperature transducers are necessary to operate in cryogenic conditions that are colder as -230 ˚C and higher up to 125˚C, specifically for aerospace technologies. PMN-PT will be the good option due to its operational flexible rang of cure temperature additionally its multilayer structure will enhance the torque power density of USMs[195,196].

Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- L. Capineri and A. Bulletti, “Ultrasonic Guided-Waves Sensors and Integrated Structural Health Monitoring Systems for Impact Detection and Localization: A Review,” Sensors, vol. 21, no. 9, p. 2929, Apr. 2021. [CrossRef]

- M. Mazalan, A. Noor, Y. Wahab, S. Yahud, and W. Zaman, “Current Development in Interdigital Transducer (IDT) Surface Acoustic Wave Devices for Live Cell In Vitro Studies: A Review,” Micromachines (Basel), vol. 13, no. 1, p. 30, Dec. 2021. [CrossRef]

- H. X. Cao, V. Du Nguyen, J.-O. Park, E. Choi, and B. Kang, “Acoustic Actuators for the Manipulation of Micro/Nanorobots: State-of-the-Art and Future Outlooks,” Micromachines (Basel), vol. 15, no. 2, p. 186, Jan. 2024. [CrossRef]

- D. Mandal and S. Banerjee, “Surface Acoustic Wave (SAW) Sensors: Physics, Materials, and Applications,” Sensors, vol. 22, no. 3, p. 820, Jan. 2022. [CrossRef]

- Z. Guan et al., “A self-powered acoustic sensor excited by ultrasonic wave for detecting and locating underwater ultrasonic sources,” Nano Energy, vol. 104, p. 107879, Dec. 2022. [CrossRef]

- A. Čeponis, V. Jūrėnas, and D. Mažeika, “Low Profile Triangle-Shaped Piezoelectric Rotary Motor,” Micromachines (Basel), vol. 15, no. 1, p. 132, Jan. 2024. [CrossRef]

- Y.-H. Wang, S. C.-S. Tsai, and F. C.-F. Lin, “Reduction of Blood Loss by Means of the Cavitron Ultrasonic Surgical Aspirator for Thoracoscopic Salvage Anatomic Lung Resections,” Cancers (Basel), vol. 15, no. 16, p. 4069, Aug. 2023. [CrossRef]

- J. Zhang, Y. Wang, T. Liu, K. Yang, and H. Jin, “A Flexible Ultrasound Scanning System for Minimally Invasive Spinal Surgery Navigation,” IEEE Trans Med Robot Bionics, vol. 3, no. 2, pp. 426–435, May 2021. [CrossRef]

- D. Zhang et al., “Diagnostic Value of Multi-Mode Ultrasonic Flow Imaging Examination in Solid Renal Tumors of Different Sizes,” J Clin Med, vol. 12, no. 2, p. 566, Jan. 2023. [CrossRef]

- J. Qian et al., “Ultrasound-Assisted Enzymatic Protein Hydrolysis in Food Processing: Mechanism and Parameters,” Foods, vol. 12, no. 21, p. 4027, Nov. 2023. [CrossRef]

- Y. Li et al., “An Ultrasound–Fenton Process for the Degradation of 2,4,6-Trinitrotoluene,” Int J Environ Res Public Health, vol. 20, no. 4, p. 3102, Feb. 2023. [CrossRef]

- M. Salimi et al., “Experimental and Numerical Investigation of the Use of Ultrasonic Waves to Assist Laser Welding,” Materials, vol. 17, no. 11, p. 2521, May 2024. [CrossRef]

- J. Qiu, Y. Yang, X. Hong, P. Vasiljev, D. Mazeika, and S. Borodinas, “A Disc-Type High Speed Rotary Ultrasonic Motor with Internal Contact Teeth,” Applied Sciences, vol. 11, no. 5, p. 2386, Mar. 2021. [CrossRef]

- D. Xu, W. Yang, X. Zhang, and S. Yu, “Design and Performance Evaluation of a Single-Phase Driven Ultrasonic Motor Using Bending-Bending Vibrations,” Micromachines (Basel), vol. 12, no. 8, p. 853, Jul. 2021. [CrossRef]

- A. Zameer, S. Naz, and M. A. Z. Raja, “Parallel differential evolution paradigm for multilayer electromechanical device optimization,” Modern Physics Letters B, Mar. 2024. [CrossRef]

- S. Naz, A. Zameer, M. A. Z. Raja, and K. Muhammad, “Weighted differential evolution heuristics for improved multilayer piezoelectric transducer design,” Appl Soft Comput, vol. 113, p. 107835, Dec. 2021. [CrossRef]

- A. Zameer, S. Naz, M. A. Z. Raja, J. Hafeez, and N. Ali, “Neuro-Evolutionary Framework for Design Optimization of Two-Phase Transducer with Genetic Algorithms,” Micromachines (Basel), vol. 14, no. 9, p. 1677, Aug. 2023. [CrossRef]

- S. Naz, A. Usman, A. Zameer, K. Muhammad, and M. A. Z. Raja, “Efficient multivariate optimization of an ultrasonic transducer with genetic parallel algorithms,” Waves in Random and Complex Media, pp. 1–25, Sep. 2023. [CrossRef]

- S. Naz, M. A. Z. Raja, A. Mehmood, A. Zameer, and M. Shoaib, “Neuro-intelligent networks for Bouc–Wen hysteresis model for piezostage actuator,” The European Physical Journal Plus, vol. 136, no. 4, p. 396, Apr. 2021. [CrossRef]

- S. Naz, M. A. Z. Raja, A. Mehmood, and A. Z. Jaafery, “Intelligent Predictive Solution Dynamics for Dahl Hysteresis Model of Piezoelectric Actuator,” Micromachines (Basel), vol. 13, no. 12, p. 2205, Dec. 2022. [CrossRef]

- Z. Zheng et al., “Micro-Electro-Mechanical Systems Microphones: A Brief Review Emphasizing Recent Advances in Audible Spectrum Applications,” Micromachines (Basel), vol. 15, no. 3, p. 352, Feb. 2024. [CrossRef]

- A. C. Hatfield and T.-B. Xu, “Transparent Piezoelectric LiNbO3-based Surface Acoustic Wave for Dust Mitigation in Space Environment,” in AIAA SCITECH 2023 Forum, Reston, Virginia: American Institute of Aeronautics and Astronautics, Jan. 2023. [CrossRef]

- G. Ali and F. Mohd-Yasin, “Comprehensive Noise Modeling of Piezoelectric Charge Accelerometer with Signal Conditioning Circuit,” Micromachines (Basel), vol. 15, no. 2, p. 283, Feb. 2024. [CrossRef]

- Q.-T. Lai, Q.-J. Sun, Z. Tang, X.-G. Tang, and X.-H. Zhao, “Conjugated Polymer-Based Nanocomposites for Pressure Sensors,” Molecules, vol. 28, no. 4, p. 1627, Feb. 2023. [CrossRef]

- S. Bouhedma, J. Bin Taufik, F. Lange, M. Ouali, H. Seitz, and D. Hohlfeld, “Different Scenarios of Autonomous Operation of an Environmental Sensor Node Using a Piezoelectric-Vibration-Based Energy Harvester,” Sensors, vol. 24, no. 4, p. 1338, Feb. 2024. [CrossRef]

- C. Chen, T.-B. Xu, A. Yazdani, and J.-Q. Sun, “A high density piezoelectric energy harvesting device from highway traffic — System design and road test,” Appl Energy, vol. 299, p. 117331, Oct. 2021. [CrossRef]

- Q. Qiao, X. Wang, W. Liu, and H. Yang, “Defect Detection in Grouting Sleeve Grouting Material by Piezoelectric Wave Method,” Buildings, vol. 14, no. 3, p. 629, Feb. 2024. [CrossRef]

- I. Izadgoshasb, “Piezoelectric Energy Harvesting towards Self-Powered Internet of Things (IoT) Sensors in Smart Cities,” Sensors, vol. 21, no. 24, p. 8332, Dec. 2021. [CrossRef]

- Z. Abdullah, S. Naz, M. A. Z. Raja, and A. Zameer, “Design of wideband tonpilz transducers for underwater SONAR applications with finite element model,” Applied Acoustics, vol. 183, p. 108293, Dec. 2021. [CrossRef]

- L. Shams and T.-B. Xu, “Underwater communication acoustic transducers: a technology review,” in Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2023, Z. Su, M. P. Limongelli, and B. Glisic, Eds., SPIE, Apr. 2023, p. 8. [CrossRef]

- S. Naz, M. A. Z. Raja, A. Kausar, A. Zameer, A. Mehmood, and M. Shoaib, “Dynamics of nonlinear cantilever piezoelectric–mechanical system: An intelligent computational approach,” Math Comput Simul, vol. 196, pp. 88–113, Jun. 2022. [CrossRef]

- A.Kausar, C.-Y. Chang, M. A. Z. Raja, A. Zameer, and M. Shoaib, “Novel design of recurrent neural network for the dynamical of nonlinear piezoelectric cantilever mass–beam model,” The European Physical Journal Plus, vol. 139, no. 1, p. 16, Jan. 2024. [CrossRef]

- F. Qian, T.-B. Xu, and L. Zuo, “Piezoelectric energy harvesting from human walking using a two-stage amplification mechanism,” Energy, vol. 189, p. 116140, Dec. 2019. [CrossRef]

- J. Lin, P. Yuan, R. Lin, X. Xue, M. Chen, and L. Xing, “A Self-Powered Lactate Sensor Based on the Piezoelectric Effect for Assessing Tumor Development,” Sensors, vol. 24, no. 7, p. 2161, Mar. 2024. [CrossRef]

- J. Wang et al., “Design and Analysis of a Cardioid Flow Tube Valveless Piezoelectric Pump for Medical Applications,” Sensors, vol. 24, no. 1, p. 122, Dec. 2023. [CrossRef]

- J. Wallaschek, “Piezoelectric Ultrasonic Motors,” J Intell Mater Syst Struct, vol. 6, no. 1, pp. 71–83, Jan. 1995. [CrossRef]

- M. Hunstig, “Piezoelectric Inertia Motors—A Critical Review of History, Concepts, Design, Applications, and Perspectives,” Actuators, vol. 6, no. 1, p. 7, Feb. 2017. [CrossRef]

- chunsheng zhao, Ultrasonic motors: technologies and applications. . Springer Science & Business Media., 2011. Accessed: May 17, 2024. [Online]. Available: https://books.google.com/books?hl=en&lr=&id=gVbGGkT5emgC&oi=fnd&pg=PR4&dq=ultrasonic+motors+technologies+and+applications+by+chunsheng+zhao&ots=4R_kqVr56E&sig=mPLMjASJ2kyu5IWkW4iA2c6vVqQ#v=onepage&q=ultrasonic%20motors%20technologies%20and%20applications%20by%20chunsheng%20zhao&f=false.

- A.Shuaibu Ahmad, M. Mukhtar Usman, S. Bello Abubakar, and A. Yusuf Gidado, “Review on the application of Piezoelectric materials in the development of ultrasonic motors,” Journal of Advanced Research in Applied Mechanics Journal homepage, vol. 33, no. 1, pp. 9–19, 2017, [Online]. Available: www.akademiabaru.com/aram.html.

- K. Spanner and B. Koc, “Piezoelectric Motors, an Overview,” Actuators, vol. 5, no. 1, p. 6, Feb. 2016. [CrossRef]

- D. Xu, Y. Liu, S. Shi, J. Liu, W. Chen, and L. Wang, “Development of a Nonresonant Piezoelectric Motor With Nanometer Resolution Driving Ability,” IEEE/ASME Transactions on Mechatronics, vol. 23, no. 1, pp. 444–451, Feb. 2018. [CrossRef]

- M. V. Golub, S. I. Fomenko, P. E. Usov, and A. A. Eremin, “Elastic Waves Excitation and Focusing by a Piezoelectric Transducer with Intermediate Layered Elastic Metamaterials with and without Periodic Arrays of Interfacial Voids,” Sensors, vol. 23, no. 24, p. 9747, Dec. 2023. [CrossRef]

- Y. Wang, S. Wu, W. Wang, T. Wu, and X. Li, “Piezoelectric Micromachined Ultrasonic Transducers with Micro-Hole Inter-Etch and Sealing Process on (111) Silicon Wafer,” Micromachines (Basel), vol. 15, no. 4, p. 482, Mar. 2024. [CrossRef]

- A. U. H. Mohsan et al., “Design and Effect of Resonant Ultrasonic Vibration-Assisted Laser Cladding (R-UVALC) on AlCrFeMnNi High-Entropy Alloy,” Materials, vol. 17, no. 5, p. 969, Feb. 2024. [CrossRef]

- L. Gou et al., “Investigation of New Accelerometer Based on Capacitive Micromachined Ultrasonic Transducer (CMUT) with Ring-Perforation Membrane,” Micromachines (Basel), vol. 15, no. 2, p. 279, Feb. 2024. [CrossRef]

- A. Wellendorf, L. von Damnitz, A. W. Nuri, D. Anders, and S. Trampnau, “Determination of the Temperature-Dependent Resonance Behavior of Ultrasonic Transducers Using the Finite-Element Method,” Journal of Vibration Engineering & Technologies, vol. 12, no. 2, pp. 1277–1290, Feb. 2024. [CrossRef]

- Y. Liu, M. Hafezi, and A. Feeney, “A cascaded Nitinol Langevin transducer for resonance stability at elevated temperatures,” Ultrasonics, vol. 137, p. 107201, Feb. 2024. [CrossRef]

- M. Taşlıyol, S. Öncü, and M. E. Turan, “An implementation of class D inverter for ultrasonic transducer mixed powder mixture,” Ultrason Sonochem, vol. 104, p. 106838, Mar. 2024. [CrossRef]

- V. Ruiz-Díez, J. Hernando-García, J. Toledo, A. Ababneh, H. Seidel, and J. L. Sánchez-Rojas, “Bidirectional Linear Motion by Travelling Waves on Legged Piezoelectric Microfabricated Plates,” Micromachines (Basel), vol. 11, no. 5, p. 517, May 2020. [CrossRef]

- C. Peng, H. Wu, S. Kim, X. Dai, and X. Jiang, “Recent Advances in Transducers for Intravascular Ultrasound (IVUS) Imaging,” Sensors, vol. 21, no. 10, p. 3540, May 2021. [CrossRef]

- W. Li, M. Ge, R. Jia, X. Zhao, H. Zhao, and C. Dong, “Design and Analysis Method of Piezoelectric Liquid Driving Device with Elastic External Displacement,” Micromachines (Basel), vol. 15, no. 4, p. 523, Apr. 2024. [CrossRef]

- K. Uchino, “Piezoelectric ultrasonic motors: overview,” Smart Mater Struct, vol. 7, no. 3, pp. 273–285, Jun. 1998. [CrossRef]

- K. Uchino, S. Cagatay, B. Koc, S. Dong, P. Bouchilloux, and M. Strauss, “Micro Piezoelectric Ultrasonic Motors,” J Electroceram, vol. 13, no. 1–3, pp. 393–401, Jul. 2004. [CrossRef]

- S. Ueha, Y. Hashimoto, M. Kuribayashi, and E. Mori, “Ultrasonic Power Measurement Using Standing Wave Ratio,” Jpn J Appl Phys, vol. 24, no. S1, p. 169, Jan. 1985. [CrossRef]

- Siyuan He, Weishan Chen, Xie Tao, and Zaili Chen, “Standing wave bi-directional linearly moving ultrasonic motor,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 45, no. 5, pp. 1133–1139, Sep. 1998. [CrossRef]

- Y. Liu, S. Shi, C. Li, W. Chen, L. Wang, and J. Liu, “Development of a bi-directional standing wave linear piezoelectric actuator with four driving feet,” Ultrasonics, vol. 84, pp. 81–86, Mar. 2018. [CrossRef]

- X. Dong, M. Hu, L. Jin, Z. Xu, and C. Jiang, “A standing wave ultrasonic stepping motor using open-loop control system,” Ultrasonics, vol. 82, pp. 327–330, Jan. 2018. [CrossRef]

- X. Hou, H. P. Lee, C. J. Ong, and S. P. Lim, “Development and numerical characterization of a new standing wave ultrasonic motor operating in the 30–40kHz frequency range,” Ultrasonics, vol. 53, no. 5, pp. 928–934, Jul. 2013. [CrossRef]

- L. Wang, C. Shu, Q. Zhang, and J. Jin, “A novel sandwich-type traveling wave piezoelectric tracked mobile system,” Ultrasonics, vol. 75, pp. 28–35, Mar. 2017. [CrossRef]

- S. Kondo, H. Yamaura, D. Koyama, and K. Nakamura, “Traveling wave type ultrasonic linear motor using twin bending bars,” Phys Procedia, vol. 3, no. 1, pp. 1053–1058, Jan. 2010. [CrossRef]

- D. Sun, S. Wang, S. Hata, J. Sakurai, and A. Shimokohbe, “Driving mechanism and experimental realization of a cylindrical ultrasonic linear microactuator,” Microelectron Eng, vol. 86, no. 4–6, pp. 1262–1266, Apr. 2009. [CrossRef]

- M. K. Kurosawa, “State-of-the-art surface acoustic wave linear motor and its future applications,” Ultrasonics, vol. 38, no. 1–8, pp. 15–19, Mar. 2000. [CrossRef]

- K. Asai, M. K. Kurosawa, and T. Higuchi, “Novel power circulation methods for a surface acoustic wave motor,” in 1999 IEEE Ultrasonics Symposium. Proceedings. International Symposium (Cat. No.99CH37027), IEEE, 1999, pp. 667–670 vol.1. [CrossRef]

- M. Kurosawa, M. Takahashi, and T. Higuchi, “Ultrasonic linear motor using surface acoustic waves,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 43, no. 5, pp. 901–906, Sep. 1996. [CrossRef]

- M. Kurosawa, M. Takahashi, and T. Higuchi, “Ultrasonic linear motor using surface acoustic waves,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 43, no. 5, pp. 901–906, Sep. 1996. [CrossRef]

- M. Kuribayashi, S. Ueha, and E. Mori, “Excitation conditions of flexural traveling waves for a reversible ultrasonic linear motor,” J Acoust Soc Am, vol. 77, no. 4, pp. 1431–1435, Apr. 1985. [CrossRef]

- M. Guo, S. Pan, J. Hu, C. Zhao, and S. Dong, “A small linear ultrasonic motor utilizing longitudinal and bending modes of a piezoelectric tube,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 61, no. 4, pp. 705–709, Apr. 2014. [CrossRef]

- K. Asumi, R. Fukunaga, T. Fujimura, and M. Kuribayashi Kurosawa, “High speed, high resolution ultrasonic linear motor using V-shape two bolt-clamped Langevin-type transducers,” Acoust Sci Technol, vol. 30, no. 3, pp. 180–186, 2009. [CrossRef]

- M. Kuribayashi Kurosawa, O. Kodaira, Y. Tsuchitoi, and T. Higuchi, “Transducer for high speed and large thrust ultrasonic linear motor using two sandwich-type vibrators,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 45, no. 5, pp. 1188–1195, Sep. 1998. [CrossRef]

- A. Endo, N. Sasaki, and Y. Tomikawa, “Linear type ultrasonic motor using two-dimensionally positioned piezoelectric elements,” Ferroelectrics, vol. 112, no. 1, pp. 165–170, Dec. 1990. [CrossRef]

- K. Uchino, K. Kato, and M. Tohda, “Ultrasonic linear motors using a multilayered piezoelectric actuator,” Ferroelectrics, vol. 87, no. 1, pp. 331–334, Nov. 1988. [CrossRef]

- Z. Xue, K. T. Chau, W. Liu, and T. W. Ching, “Design, Analysis, and Implementation of Wireless Traveling-Wave Ultrasonic Motors,” IEEE Trans Power Electron, vol. 39, no. 4, pp. 1–11, Apr. 2024. [CrossRef]

- S. Guo, L. Wang, J. Jin, and Y. Yang, “A general structural design method, dynamics modeling and application study for built-in sandwich annular traveling wave piezoelectric transducers,” Mech Syst Signal Process, vol. 199, p. 110476, Sep. 2023. [CrossRef]

- C. Jiang, Z. Zhao, D. Lu, Z. Xu, and L. Jin, “Contact analysis and performance evaluation of ring type traveling wave ultrasonic motors based on a surface contact model,” Ultrasonics, vol. 127, p. 106851, Jan. 2023. [CrossRef]

- T. Yang, B. Cao, Y. Chen, X. Li, J. He, and W. Su, “Optimization of three-dimensional traveling wave drive for a PZT thin-film micro-motor based on stiffness tuning of the supporting structure,” Ultrasonics, vol. 134, p. 107066, Sep. 2023. [CrossRef]

- Y. Zhang et al., “Laser-induced microtextured stators coupling with flexible rotors for low-voltage driving rotational piezoelectric motors,” Chemical Engineering Journal, vol. 467, p. 143361, Jul. 2023. [CrossRef]

- G. Wang et al., “Improving output performance of ultrasonic motor by coating MoS2 on the stator,” Tribol Int, vol. 186, p. 108608, Aug. 2023. [CrossRef]

- K. Murai, D. Kong, H. Tamura, and M. Aoyagi, “Hollow cylindrical linear stator vibrator using a traveling wave of longitudinal axisymmetric vibration mode,” Ultrasonics, vol. 129, p. 106910, Mar. 2023. [CrossRef]

- C. Jiang, X. Wu, D. Lu, Z. Xu, and L. Jin, “Contact modeling and performance evaluation of ring type traveling wave ultrasonic motors considering stator teeth,” Ultrasonics, vol. 117, p. 106518, Dec. 2021. [CrossRef]

- X. Ma, J. Liu, J. Deng, Q. Liu, and Y. Liu, “A Rotary Traveling Wave Ultrasonic Motor With Four Groups of Nested PZT Ceramics: Design and Performance Evaluation,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 67, no. 7, pp. 1462–1469, Jul. 2020. [CrossRef]

- N. Chen and D. Fan, “A teeth-discretized electromechanical model of a traveling-wave ultrasonic motor,” Mechanical Sciences, vol. 11, no. 2, pp. 257–266, Jul. 2020. [CrossRef]

- J. Li, S. Zeng, S. Liu, N. Zhou, and T. Qing, “Tribological properties of textured stator and PTFE-based material in travelling wave ultrasonic motors,” Friction, vol. 8, no. 2, pp. 301–310, Apr. 2020. [CrossRef]

- S. Zeng, J. Li, N. Zhou, J. Zhang, A. Yu, and H. He, “Improving the wear resistance of PTFE-based friction material used in ultrasonic motors by laser surface texturing,” Tribol Int, vol. 141, p. 105910, Jan. 2020. [CrossRef]

- X. Liu, J. Song, H. Chen, G. Zhao, J. Qiu, and Q. Ding, “Enhanced transfer efficiency of ultrasonic motors with polyimide based frictional materials and surface texture,” Sens Actuators A Phys, vol. 295, pp. 671–677, Aug. 2019. [CrossRef]

- L. Kang et al., “Design of precision driving control system for standing-wave ultrasonic motor,” in Eighth Symposium on Novel Photoelectronic Detection Technology and Applications, S. Zhu, Q. Yu, J. Su, L. Chen, and J. Chu, Eds., SPIE, Mar. 2022, p. 592. [CrossRef]

- Q. Pan, Y. Wang, A. Wan, C. Li, M. Zhao, and R. Li, “Development of a novel single-mode miniature standing wave ultrasonic motor,” Smart Mater Struct, vol. 32, no. 12, p. 125015, Dec. 2023. [CrossRef]

- Y. Deng, G. Zhao, X. Yi, and W. Xiao, “Contact modeling and input-voltage-region based parametric identification for speed control of a standing wave linear ultrasonic motor,” Sens Actuators A Phys, vol. 295, pp. 456–468, Aug. 2019. [CrossRef]

- Z. Chen, X. Li, P. Ci, G. Liu, and S. Dong, “A standing wave linear ultrasonic motor operating in in-plane expanding and bending modes,” Review of Scientific Instruments, vol. 86, no. 3, Mar. 2015. [CrossRef]

- Y. Shi and C. Zhao, “A new standing-wave-type linear ultrasonic motor based on in-plane modes,” Ultrasonics, vol. 51, no. 4, pp. 397–404, May 2011. [CrossRef]

- Siyuan He, Weishan Chen, Xie Tao, and Zaili Chen, “Standing wave bi-directional linearly moving ultrasonic motor,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 45, no. 5, pp. 1133–1139, Sep. 1998. [CrossRef]

- I. Grybas, R. Bansevicius, V. Jurenas, A. Bubulis, J. Janutenaite, and G. Kulvietis, “Ultrasonic standing waves-driven high resolution rotary table,” Precis Eng, vol. 45, pp. 396–402, Jul. 2016. [CrossRef]

- M. Shafik and L. Makombe, “A Standing Wave Piezoelectric Ultrasonic Motor Using a Single Flexural Vibration Ring Transducer,” Applied Mechanics and Materials, vol. 415, pp. 126–131, Sep. 2013. [CrossRef]

- X. Lu, J. Hu, L. Yang, and C. Zhao, “A novel dual stator-ring rotary ultrasonic motor,” Sens Actuators A Phys, vol. 189, pp. 504–511, Jan. 2013. [CrossRef]

- X. Jin, Y. Zhang, H. Fu, J. Ji, X. Hua, and Y. Fu, “Low-voltage driving linear piezoelectric motors having textured sliders of surface multi-connected vesicle-like microarray,” Int J Mech Sci, vol. 241, p. 107984, Mar. 2023. [CrossRef]

- Q. and P. Q. and Z. Y. and D. X. and F. H. and J. J. and W. P. L. and F. C. and L. J. and Y. Z. Peng, “ Crocodile-Skin-Inspired Surface Microstructures for Friction Regulation of Piezoelectric Motors.,” SSRN, Oct. 2023.

- Q. Peng et al., “Mechanical Characteristics Regulation of V-Shaped Standing-Wave Ultrasonic Motors With Minimal Quantity Lubrication,” Tribology Transactions, vol. 66, no. 2, pp. 222–237, Mar. 2023. [CrossRef]

- L. Zhou, Z. Yao, S. Dai, Y. He, and H. Xu, “Modeling and verification of life prediction of a V-shaped linear ultrasonic motor,” Review of Scientific Instruments, vol. 92, no. 4, Apr. 2021. [CrossRef]

- X. Li, Z. Yao, R. Li, and D. Wu, “Dynamics modeling and control of a V-shaped ultrasonic motor with two Langevin-type transducers,” Smart Mater Struct, vol. 29, no. 2, p. 025018, Feb. 2020. [CrossRef]

- J. Wu et al., “A two-DOF linear ultrasonic motor utilizing the actuating approach of longitudinal-traveling-wave/bending-standing-wave hybrid excitation,” Int J Mech Sci, vol. 248, p. 108223, Jun. 2023. [CrossRef]

- H. Qu, C. Liu, L. Zhang, J. Qu, and B. Song, “A Longitudinal-Bending Hybrid Linear Ultrasonic Motor and Its Driving Characteristic,” Shock and Vibration, vol. 2022, pp. 1–14, Jan. 2022. [CrossRef]

- Z. Ding, W. Wei, K. Wang, and Y. Liu, “An Ultrasonic Motor Using a Carbon-Fiber-Reinforced/Poly-Phenylene-Sulfide-Based Vibrator with Bending/Longitudinal Modes,” Micromachines 2022, Vol. 13, Page 517, vol. 13, no. 4, p. 517, Mar. 2022. [CrossRef]

- D. Lu, Q. Lin, B. Chen, C. Jiang, and X. Hu, “A single-modal linear ultrasonic motor based on multi vibration modes of PZT ceramics,” Ultrasonics, vol. 107, p. 106158, Sep. 2020. [CrossRef]

- L. Yang, W. Ren, C. Ma, and L. Chen, “Mechanical simulation and contact analysis of the hybrid longitudinal-torsional ultrasonic motor,” Ultrasonics, vol. 100, p. 105982, Jan. 2020. [CrossRef]

- J. Deng, Y. Liu, J. Liu, D. Xu, and Y. Wang, “Development of a Planar Piezoelectric Actuator Using Bending–Bending Hybrid Transducers,” IEEE Transactions on Industrial Electronics, vol. 66, no. 8, pp. 6141–6149, Aug. 2019. [CrossRef]

- Y. Liu, L. Wang, Z. Gu, Q. Quan, and J. Deng, “Development of a Two-Dimensional Linear Piezoelectric Stepping Platform Using Longitudinal-Bending Hybrid Actuators,” IEEE Transactions on Industrial Electronics, vol. 66, no. 4, pp. 3030–3040, Apr. 2019. [CrossRef]

- J. Leng, L. Jin, Z. Xu, and X. Zhu, “Development of a 3-DOF Cylindrical Ultrasonic Motor Based on Non-Standard Modes,” Applied Sciences, vol. 13, no. 18, p. 10096, Sep. 2023. [CrossRef]

- A. Mizuno, H. Kajiwara, H. Tamura, and M. Aoyagi, “Study on Multidegree-of-Freedom Ultrasonic Motor Using Vibration Mode Rotation of Metal Spherical Stator,” Actuators, vol. 11, no. 1, p. 27, Jan. 2022. [CrossRef]

- Z. Li, Z. Guo, H. Han, Z. Su, and H. Sun, “Design and characteristic analysis of multi-degree-of-freedom ultrasonic motor based on spherical stator,” Review of Scientific Instruments, vol. 93, no. 2, Feb. 2022. [CrossRef]

- J. Leng, L. Jin, X. Dong, H. Zhang, C. Liu, and Z. Xu, “A multi-degree-of-freedom clamping type traveling-wave ultrasonic motor,” Ultrasonics, vol. 119, p. 106621, Feb. 2022. [CrossRef]

- S. Toyama, S. Hatae, and M. Nonaka, “Development of multi-degree of freedom spherical ultrasonic motor,” in Fifth International Conference on Advanced Robotics ’Robots in Unstructured Environments, IEEE, 1991, pp. 55–60 vol.1. [CrossRef]

- S. Toyama, S. Sugitani, Zhang Guoqiang, Y. Miyatani, and K. Nakamura, “Multi degree of freedom spherical ultrasonic motor,” in Proceedings of 1995 IEEE International Conference on Robotics and Automation, IEEE, pp. 2935–2940. [CrossRef]

- R. Liu, L. Wang, J. Jin, and H. Zhao, “A Novel 2-Dof Ultrasonic Motor Design, Simulation, and Experimental Investigation,” in 2022 16th Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), IEEE, Oct. 2022, pp. 77–81. [CrossRef]

- Z. Huang, S. Shi, W. Chen, L. Wang, L. Wu, and Y. Liu, “Development of a novel spherical stator multi-DOF ultrasonic motor using in-plane non-axisymmetric mode,” Mech Syst Signal Process, vol. 140, p. 106658, Jun. 2020. [CrossRef]

- Z. Li, Z. Wang, P. Guo, L. Zhao, and Q. Wang, “A ball-type multi-DOF ultrasonic motor with three embedded traveling wave stators,” Sens Actuators A Phys, vol. 313, p. 112161, Oct. 2020. [CrossRef]

- V. Jūrėnas, G. Kazokaitis, and D. Mažeika, “Design of Unimorph Type 3DOF Ultrasonic Motor,” Applied Sciences, vol. 10, no. 16, p. 5605, Aug. 2020. [CrossRef]

- X. Yang and W.-L. Zhu, “Design, Analysis, and Control of an XY Parallel Nanomanipulator With Multiple Actuation Modes,” IEEE Transactions on Industrial Electronics, vol. 67, no. 9, pp. 7639–7648, Sep. 2020. [CrossRef]

- J. Deng, Y. Liu, S. Zhang, and J. Liu, “Modeling and experiments of a nano-positioning and high frequency scanning piezoelectric platform based on function module actuator,” Sci China Technol Sci, vol. 63, no. 12, pp. 2541–2552, Dec. 2020. [CrossRef]

- D. Mazeika, S. Borodinas, P. Vasiljev, R. Bareikis, A. Struckas, and V. Jurenas, “2DOF LINEAR-ROTARY TYPE ULTRASONIC MOTOR.”.

- Q. Chang, Y. Liu, J. Deng, S. Zhang, and W. Chen, “Design of a precise linear-rotary positioning stage for optical focusing based on the stick-slip mechanism,” Mech Syst Signal Process, vol. 165, p. 108398, Feb. 2022. [CrossRef]

- Y. Sato, A. Kanada, and T. Mashimo, “Self-Sensing and Feedback Control for a Twin Coil Spring-Based Flexible Ultrasonic Motor,” IEEE Robot Autom Lett, vol. 5, no. 4, pp. 5425–5431, Oct. 2020. [CrossRef]

- W. Wei et al., “A linear ultrasonic motor driven by torsional/bending vibrations,” Sens Actuators A Phys, vol. 357, p. 114404, Aug. 2023. [CrossRef]

- H.-K. Guo, Y.-H. Hsu, and C.-K. Lee, “Control of a multi-direction piezoelectric linear motor using a gyroscopic feedback control,” in Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2024, M. P. Limongelli, C. T. Ng, and B. Glisic, Eds., SPIE, May 2024, p. 19. [CrossRef]

- T. Yamabuchi and Y. Kagawa, “Numerical simulation of a piezoelectric ultrasonic motor and its characteristics,” J. Jpn. Soc. Simul. Technol, vol. 8, no. 3, pp. 69–76, 1989.

- T. Maeno, T. Tsukimoto, and A. Miyake, “Finite-element analysis of the rotor/stator contact in a ring-type ultrasonic motor,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 39, no. 6, pp. 668–674, 1992.

- J. W. Krome and J. Wallaschek, “Finite Element Models for the Piezoelectric Actuation in Ultrasonic Traveling Wave Motors,” J Intell Mater Syst Struct, vol. 7, no. 2, pp. 157–161, Mar. 1996. [CrossRef]

- Z. Yin, C. Dai, Z. Cao, W. Li, Z. Chen, and C. Li, “Modal analysis and moving performance of a single-mode linear ultrasonic motor,” Ultrasonics, vol. 108, p. 106216, Dec. 2020. [CrossRef]

- W. Ren, M. Yang, L. Chen, C. Ma, and L. Yang, “Mechanical optimization of a novel hollow traveling wave rotary ultrasonic motor,” J Intell Mater Syst Struct, vol. 31, no. 8, pp. 1091–1100, May 2020. [CrossRef]

- L. Yang et al., “Design and Dynamic Simulation of a Novel Traveling Wave Linear Ultrasonic Motor,” Micromachines (Basel), vol. 13, no. 4, p. 557, Mar. 2022. [CrossRef]

- J. Li, F. Che, J. Deng, W. Chen, J. Liu, and Y. Liu, “A linear ultrasonic motor with a hollowed and symmetrical stator,” Int J Mech Sci, vol. 262, p. 108718, Jan. 2024. [CrossRef]

- T. Kanda, A. Makino, T. Ono, K. Suzumori, T. Morita, and M. K. Kurosawa, “A micro ultrasonic motor using a micro-machined cylindrical bulk PZT transducer,” Sens Actuators A Phys, vol. 127, no. 1, pp. 131–138, Feb. 2006. [CrossRef]

- P. Marter, M. Khramova, F. Duvigneau, R. J. Wood, D. Juhre, and R. Orszulik, “Bidirectional motion of a planar fabricated piezoelectric motor based on unimorph arms,” Sens Actuators A Phys, vol. 377, Oct. 2024. [CrossRef]

- T. Yang et al., “A PZT Thin-Film Traveling-Wave Micro-Motor With Stator Teeth Based on MEMS Technology,” Journal of Microelectromechanical Systems, vol. 33, no. 2, pp. 236–247, Apr. 2024. [CrossRef]

- W. Zhou et al., “A Piezoelectric Microultrasonic Motor With High Q and Good Mode Match,” IEEE/ASME Transactions on Mechatronics, vol. 26, no. 4, pp. 1773–1781, Aug. 2021. [CrossRef]

- S. Cagatay, B. Koc, P. Moses, and K. Uchino, “A piezoelectric micromotor with a stator of φ = 1.6mm and l = 4mm using bulk PZT,” Japanese Journal of Applied Physics, Part 1: Regular Papers and Short Notes and Review Papers, vol. 43, no. 4 A, pp. 1429–1433, 2004. [CrossRef]

- K. Uchino, S. Cagatay, and B. Koc, “Ultrasonic Motors,” 2003. [Online]. Available: https://www.researchgate.net/publication/279377213.

- S. Cagatay, B. Koc, and K. Uchino, “A 1.6-mm, Metal Tube Ultrasonic Motor,” 2003.

- K. Kikuchi, M. Hussain, and T. Mashimo, “Fabrication and characterization of a submillimeter-scale ultrasonic motor,” Sens Actuators A Phys, vol. 360, p. 114524, Oct. 2023. [CrossRef]

- S. Izuhara and T. Mashimo, “Design and characterization of a thin linear ultrasonic motor for miniature focus systems,” Sens Actuators A Phys, vol. 329, p. 112797, Oct. 2021. [CrossRef]

- B. Delibas and B. Koc, “Single crystal piezoelectric motor operating with both inertia and ultrasonic resonance drives,” Ultrasonics, vol. 136, p. 107140, Jan. 2024. [CrossRef]

- N. Chen, J. Zheng, X. Jiang, S. Fan, and D. Fan, “Analysis and control of micro-stepping characteristics of ultrasonic motor,” Frontiers of Mechanical Engineering, vol. 15, no. 4, pp. 585–599, Dec. 2020. [CrossRef]

- Z. Li, Z. Wang, L. Zhao, and P. Guo, “Characteristic analysis and experimental study of spherical ultrasonic motor with multi-degree-of-freedom,” Journal of Applied Science and Engineering, vol. 23, no. 4, pp. 619–626, Dec. 2020. [CrossRef]

- X. Li, Z. Wen, B. Jia, T. Cao, D. Yu, and D. Wu, “A Review of Application and Development Trends in Ultrasonic Motors,” ES Materials & Manufacturing, 2020. [CrossRef]

- L. Zhang, H. Zheng, S. Huang, W. Zhang, F. Li, and D. Liu, “A life test of ultrasonic motors under different torque loads and the analysis of the characteristics of wearing surfaces,” Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, vol. 234, no. 5, pp. 770–777, May 2020. [CrossRef]

- “Ultrasonics: Fundamentals, Technologies, and Applications - Dale Ensminger, Leonard J. Bond - Google Books.” Accessed: May 31, 2024. [Online]. Available: https://books.google.com/books?hl=en&lr=&id=EVnqEAAAQBAJ&oi=fnd&pg=PP1&dq=+ultrasonics+motors+in+Semiconductor+Manufacturing&ots=TIGXh-YtVV&sig=7PVusgeNkbYOJfIhcFwA8ANCvNU#v=onepage&q&f=false.

- K. Guo, J. Lu, and H. Yang, “Simulation Analysis of a Sandwich Cantilever Ultrasonic Motor for a Dexterous Prosthetic Hand,” Micromachines 2023, Vol. 14, Page 2150, vol. 14, no. 12, p. 2150, Nov. 2023. [CrossRef]

- K. Asumi, R. Fukunaga, T. Fujimura, and M. K. Kurosawa, “Miniaturization of a V-shape transducer ultrasonic motor,” Jpn J Appl Phys, vol. 48, no. 7 PART 2, p. 07GM02, Jul. 2009.

- T. Kimmel, S. Stall, D. Porada, C. Kunkel, and A. Kessler, “Comparison of ultrasonic devices for the pretreatment of textiles before washing and analysis of action,” J Eng Fiber Fabr, vol. 18, Jan. 2023.

- C. Dils, S. Hohner, and M. Schneider-Ramelow, “Use of Rotary Ultrasonic Plastic Welding as a Continuous Interconnection Technology for Large-Area e-Textiles,” Textiles 2023, Vol. 3, Pages 66-87, vol. 3, no. 1, pp. 66–87, Jan. 2023. [CrossRef]

- N. M. Zashchepkina, V. G. Zdorenko, N. R. Tierentyeva, O. M. Markina, M. O. Markin, and K. M. Bozhko, “Ultrasonic method of quality control for textile materials,” Archives of Materials Science and Engineering, vol. Vol. 97, no. nr 1/2, pp. 39–49, 2019. [CrossRef]

- J. A. Gallego-Juarez, E. Riera, V. Acosta, G. Rodríguez, and A. Blanco, “Ultrasonic system for continuous washing of textiles in liquid layers,” Ultrason Sonochem, vol. 17, no. 1, pp. 234–238, Jan. 2010. [CrossRef]

- K. Rapouch and Mrázek M, “Use of ultrasound for cleaning of components of historical vehicles in Technical Museum”. [CrossRef]

- F. I. Alzarooni, A. K. Alkharji, A. A. Alsuwaidi, and E. R. Almajali, “Design and implementation of an automated dry solar-panel cleaning system,” 2020 Advances in Science and Engineering Technology International Conferences, ASET 2020, Feb. 2020. [CrossRef]

- T. Kimmel, C. Kunkel, M. Ait Sghir, and A. Kessler, “Potential of ultrasonics for energy saving in the household washing process,” Energy Effic, vol. 16, no. 5, pp. 1–11, Jun. 2023.

- J. Huang and D. Sun, “Performance Analysis of a Travelling-Wave Ultrasonic Motor under Impact Load,” Micromachines (Basel), vol. 11, no. 7, p. 689, Jul. 2020. [CrossRef]

- X. Liu, G. Zhao, and J. Qiu, “Improving the performance of ultrasonic motors in low-pressure, variable-temperature environments,” Tribol Int, vol. 160, p. 107000, Aug. 2021. [CrossRef]

- E. T. K. Chiang, T. Urakubo, and T. Mashimo, “Lift Generation by a Miniature Piezoelectric Ultrasonic Motor-Driven Rotary-Wing for Pico Air Vehicles,” IEEE Access, vol. 10, pp. 13210–13218, 2022. [CrossRef]

- J. Zhou et al., “Development of a Δ-Type Mobile Robot Driven by Three Standing-Wave-Type Piezoelectric Ultrasonic Motors,” IEEE Robot Autom Lett, vol. 5, no. 4, pp. 6717–6723, Oct. 2020. [CrossRef]

- Q. Lu, Z. Sun, J. Zhang, J. Zhang, J. Zheng, and F. Qian, “A Novel Remote-Controlled Vascular Interventional Robotic System Based on Hollow Ultrasonic Motor,” Micromachines (Basel), vol. 13, no. 3, p. 410, Mar. 2022. [CrossRef]

- S. Izuhara and T. Mashimo, “Design and characterization of a thin linear ultrasonic motor for miniature focus systems,” Sens Actuators A Phys, vol. 329, p. 112797, Oct. 2021. [CrossRef]

- K. Kikuchi, M. Hussain, and T. Mashimo, “Fabrication and characterization of a submillimeter-scale ultrasonic motor,” Sens Actuators A Phys, vol. 360, Oct. 2023. [CrossRef]

- A. Antoniou et al., “Robotic system for magnetic resonance guided focused ultrasound ablation of abdominal cancer,” The International Journal of Medical Robotics and Computer Assisted Surgery, vol. 17, no. 5, p. e2299, Oct. 2021. [CrossRef]

- X. Bai, M. Hu, T. Gang, and Q. Rong, “A Submerged Optical Fiber Ultrasonic Sensor Using Matched Fiber Bragg Gratings,” Sensors, vol. 18, no. 6, p. 1942, Jun. 2018. [CrossRef]

- J. Tian, X. Dong, S. Gao, and Y. Yao, “Multipoint fiber-optic laser-ultrasonic actuator based on fiber core-opened tapers,” Opt Express, vol. 25, no. 24, p. 29737, Nov. 2017. [CrossRef]

- M. Giannakou et al., “Magnetic resonance image–guided focused ultrasound robotic system for transrectal prostate cancer therapy,” The International Journal of Medical Robotics and Computer Assisted Surgery, vol. 17, no. 3, p. e2237, Jun. 2021. [CrossRef]

- C. Damianou, M. Giannakou, G. Menikou, and L. Ioannou, “Magnetic resonance imaging-guided focused ultrasound robotic system with the subject placed in the prone position,” Digit Med, vol. 6, no. 1, pp. 24–31, Jan. 2020. [CrossRef]

- A. Mustafa, T. Sasamura, and T. Morita, “Robust Speed Control of Ultrasonic Motors Based on Deep Reinforcement Learning of a Lyapunov Function,” IEEE Access, vol. 10, pp. 46895–46910, 2022. [CrossRef]

- Y. J. Mon, “Vision Robot Path Control Based on Artificial Intelligence Image Classification and Sustainable Ultrasonic Signal Transformation Technology,” Sustainability 2022, Vol. 14, Page 5335, vol. 14, no. 9, p. 5335, Apr. 2022. [CrossRef]

- J. Sun, D. Zhou, Y. Liu, J. Deng, and S. Zhang, “Development of a Minimally Invasive Surgical Robot Using Self-Helix Twisted Artificial Muscles,” IEEE Transactions on Industrial Electronics, vol. 71, no. 2, pp. 1779–1789, Feb. 2024. [CrossRef]

- J. Li, H. Liu, J. Li, Y. Yang, and S. Wang, “Piezoelectric transducer design for an ultrasonic scalpel with enhanced dexterity for minimally invasive surgical robots,” vol. 234, no. 7, pp. 1271–1285, Dec. 2019. [CrossRef]

- M. Pavone et al., “Ultrasound-guided robotic surgical procedures: a systematic review,” Surg Endosc, vol. 38, no. 5, pp. 2359–2370, May 2024. [CrossRef]

- R. Y. Hutama, M. M. Khalil, and T. Mashimo, “A Millimeter-Scale Rolling Microrobot Driven by a Micro-Geared Ultrasonic Motor,” IEEE Robot Autom Lett, vol. 6, no. 4, pp. 8158–8164, Oct. 2021. [CrossRef]

- J. Li, Z. Sun, H. Yan, and J. Chen, “Design of a Magnetically Anchored Laparoscope Using Miniature Ultrasonic Motors,” Micromachines 2022, Vol. 13, Page 855, vol. 13, no. 6, p. 855, May 2022. [CrossRef]

- X. Li, T. Stritch, K. Manley, and M. Lucas, “Limits and Opportunities for Miniaturizing Ultrasonic Surgical Devices Based on a Langevin Transducer,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 68, no. 7, pp. 2543–2553, Jul. 2021. [CrossRef]

- Q. Lu, Z. Sun, H. Yan, J. Zhang, J. Zhang, and J. Yang, “A novel laparoscopic surgical robot (LSR) based on double-leg ultrasonic motor (DUM),” J Intell Mater Syst Struct, vol. 34, no. 11, pp. 1276–1288, Jul. 2023. [CrossRef]

- K. Fukushima et al., “A pneumatic rotary actuator for forceps tip rotation,” Sens Actuators A Phys, vol. 333, p. 113222, Jan. 2022. [CrossRef]

- Y. Qin, Y. Shi, L. Wang, H. Wang, and J. Han, “Design, Modeling and Optimization of a Magnetic Resonance Conditional 3-RRR Spherical Parallel Robot for Neurosurgery,” IEEE Trans Med Robot Bionics, vol. 6, no. 2, pp. 556–566, May 2024. [CrossRef]

- F. Ju et al., “A Flexible Surgical Robot with Hemispherical Magnet Array Steering and Embedded Piezoelectric Beacon for Ultrasonic Position Sensing,” Advanced Intelligent Systems, vol. 6, no. 3, Mar. 2024. [CrossRef]

- S. Manjila, B. Rosa, K. Price, R. Manjila, M. Mencattelli, and P. E. Dupont, “Robotic Instruments Inside the MRI Bore: Key Concepts and Evolving Paradigms in Imaging-enhanced Cranial Neurosurgery,” World Neurosurg, vol. 176, pp. 127–139, Aug. 2023. [CrossRef]

- B. Li, L. Yuan, C. Wang, and Y. Guo, “Structural design and analysis of pneumatic prostate seed implantation robot applied in magnetic resonance imaging environment,” The International Journal of Medical Robotics and Computer Assisted Surgery, vol. 18, no. 6, Dec. 2022. [CrossRef]

- M. Li, “Design and stability analysis of a nonlinear controller for MRI-compatible pneumatic motors,” Proc Inst Mech Eng C J Mech Eng Sci, vol. 238, no. 1, pp. 3–17, Jan. 2024. [CrossRef]

- A. L. Gunderman, M. Azizkhani, S. Sengupta, K. Cleary, and Y. Chen, “Modeling and Control of an MR-Safe Pneumatic Radial Inflow Motor and Encoder (PRIME),” IEEE/ASME Transactions on Mechatronics, pp. 1–12, 2023. [CrossRef]

- X. T. Wankhede SP, “ The Roles of Piezoelectric Ultrasonic Motors in Industry 4.0 Era: Opportunities & Challenges.. ,” in Piezoelectric Actuators-Principles, Design, Experiments and Applications, Hu Huang and Jianping Li, Eds., IntechOpen, 2021, ch. 8.

- X. Li et al., “A Design Method of Traveling Wave Rotary Ultrasonic Motors Driving Circuit under High Voltage Using Single-Sided Hertzian Contact Forced Oscillator Model,” Micromachines (Basel), vol. 14, no. 1, p. 64, Dec. 2022. [CrossRef]

- C.-P. Lee, M.-C. Tsai, and Y.-K. Fuh, “Tiny Piezoelectric Multi-Layered Actuators with Application in a Compact Camera Module—Design, Fabrication, Assembling and Testing Issues,” Micromachines (Basel), vol. 13, no. 12, p. 2126, Dec. 2022. [CrossRef]

- X. Xin, X. Gao, J. Wu, Z. Li, Z. Chu, and S. Dong, “A ring-shaped, linear piezoelectric ultrasonic motor operating in E01 mode,” Appl Phys Lett, vol. 116, no. 15, Apr. 2020. [CrossRef]

- R. Niu, H. Zhu, and C. Zhao, “A four-legged linear ultrasonic motor: Design and experiments,” Review of Scientific Instruments, vol. 91, no. 7, Jul. 2020. [CrossRef]

- X. Ma et al., “A novel rotary ultrasonic motor based on multiple Langevin transducers: design, simulation, and experimental investigation,” Smart Mater Struct, vol. 33, no. 5, p. 055001, May 2024. [CrossRef]

- X. Ma, J. Liu, J. Deng, Q. Liu, and Y. Liu, “A Rotary Traveling Wave Ultrasonic Motor With Four Groups of Nested PZT Ceramics: Design and Performance Evaluation,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 67, no. 7, pp. 1462–1469, Jul. 2020. [CrossRef]

- S. Guo, L. Wang, J. Jin, and Y. Yang, “A general structural design method, dynamics modeling and application study for built-in sandwich annular traveling wave piezoelectric transducers,” Mech Syst Signal Process, vol. 199, p. 110476, Sep. 2023. [CrossRef]

- Z. Xue, K. T. Chau, W. Liu, and T. W. Ching, “Design, Analysis, and Implementation of Wireless Traveling-Wave Ultrasonic Motors,” IEEE Trans Power Electron, vol. 39, no. 4, pp. 4601–4611, Apr. 2024. [CrossRef]

- Y. Zhang et al., “Laser-induced microtextured stators coupling with flexible rotors for low-voltage driving rotational piezoelectric motors,” Chemical Engineering Journal, vol. 467, p. 143361, Jul. 2023. [CrossRef]

- L. Yang et al., “A novel traveling wave rotary ultrasonic motor with piezoelectric backup function,” J Intell Mater Syst Struct, vol. 34, no. 20, pp. 2414–2427, Dec. 2023. [CrossRef]

- Z. Wen, X. Li, T. Cao, B. Wang, R. Liu, and D. Wu, “A Low-Voltage Cylindrical Traveling Wave Ultrasonic Motor Incorporating Multilayered Piezoelectric Ceramics,” IEEE Trans Ultrason Ferroelectr Freq Control, vol. 69, no. 6, pp. 2129–2136, Jun. 2022. [CrossRef]

- Y. Liu, Y. Xiong, L. Hua, L. Yang, and W. Zeng, “Mechanical characteristic analysis of a separable stator fabricated by fine-blanking process with numerical and experimental methods,” The International Journal of Advanced Manufacturing Technology, vol. 112, no. 9–10, pp. 2435–2445, Feb. 2021. [CrossRef]

- T.-B. Xu, “Review on PMN-PT Relaxor Piezoelectric Single Crystal materials for cryogenic actuators,” in AIAA SCITECH 2022 Forum, Reston, Virginia: American Institute of Aeronautics and Astronautics, Jan. 2022. [CrossRef]

- T.-B. Xu, L. Tolliver, X. Jiang, and J. Su, “A single crystal lead magnesium niobate-lead titanate multilayer-stacked cryogenic flextensional actuator,” Appl Phys Lett, vol. 102, no. 4, Jan. 2013. [CrossRef]

| Material | Characteristics | Advantages | Disadvantages |

|---|---|---|---|

| Lead Zirconate Titanate (PZT) |

|

|

|

| Single Crystal Piezoelectric Materials (e.g., Lithium Niobate) |

|

|

|

| Lead-Free Piezoelectric Ceramics |

|

|

|

| Piezoelectric Polymers (e.g., PVDF) |

|

|

|

| Reference | Year | Motion | Stator type | Size(piezoceramic) | Voltage | Velocity/Speed | Frequency | Force | Torque |

|---|---|---|---|---|---|---|---|---|---|

| [72] | 2024 | Rotary | Ring | 12*5*2mm | 500Vpp | 62rpm | 40kHz | 10N | 0.94Nm |

| [73] | 2023 | Linear | Disk | 9*1.65*2.7mm | 500Vpp | 19.04rpm | 19kHz | 300N | 1.2Nm |

| [74] | 2023 | - | Ring | 0.5mm | 200Vp | 120rpm | 41kHz | 250N | 1.1Nm |

| [75] | 2023 | - | Radial | 3µm | 6Vpp | >12000rpm | 95.2kHz | 50mN | 14.89µNm |

| [76] | 2023 | Rotary | Disk | <10µm | 80Vp | 158rpm | 41.9kHz | 40N | 73Nmm |

| [77] | 2023 | Rotary | Disk | - | 500V | 153rpm | 36.2kHz | 280N | 1.5Nm |

| [78] | 2023 | Linear | Cylinder | 15*15mm | 60Vpp | 7.9mm/s | 96kHz | - | - |

| [79] | 2021 | - | Ring | 27*2*0.5mm | 200Vp | 128.2rpm | 41kHz | 250N | 0.9Nm |

| [80] | 2020 | Rotary | - | 7.5*4.2*1.5mm | 250Vpp | 53.86rpm | 24.86kHz | 0.69N | 0.11Nm |

| [81] | 2020 | - | - | - | 1.3Vpp | 160rpm | 41.5kHz | - | 1Nm |

| [82] | 2020 | Rotary | Ring | 340*180µm | - | 17.09rpm | 39.6kHz | 250N | 0.35Nm |

| [83] | 2020 | Ring | 60mm | 24Vp | 110rpm | 37.2kHz | 200N | 1.2Nm | |

| [49] | 2020 | Linear | Disk | - | 6Vpp | 1.7mm/s | 19.3kHz | - | - |

| [84] | 2019 | Rotary | Disk | 60mm | 30Vpp | 90rpm | 0-100kHz | 60N | 1.5Nm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).