Submitted:

29 August 2024

Posted:

30 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

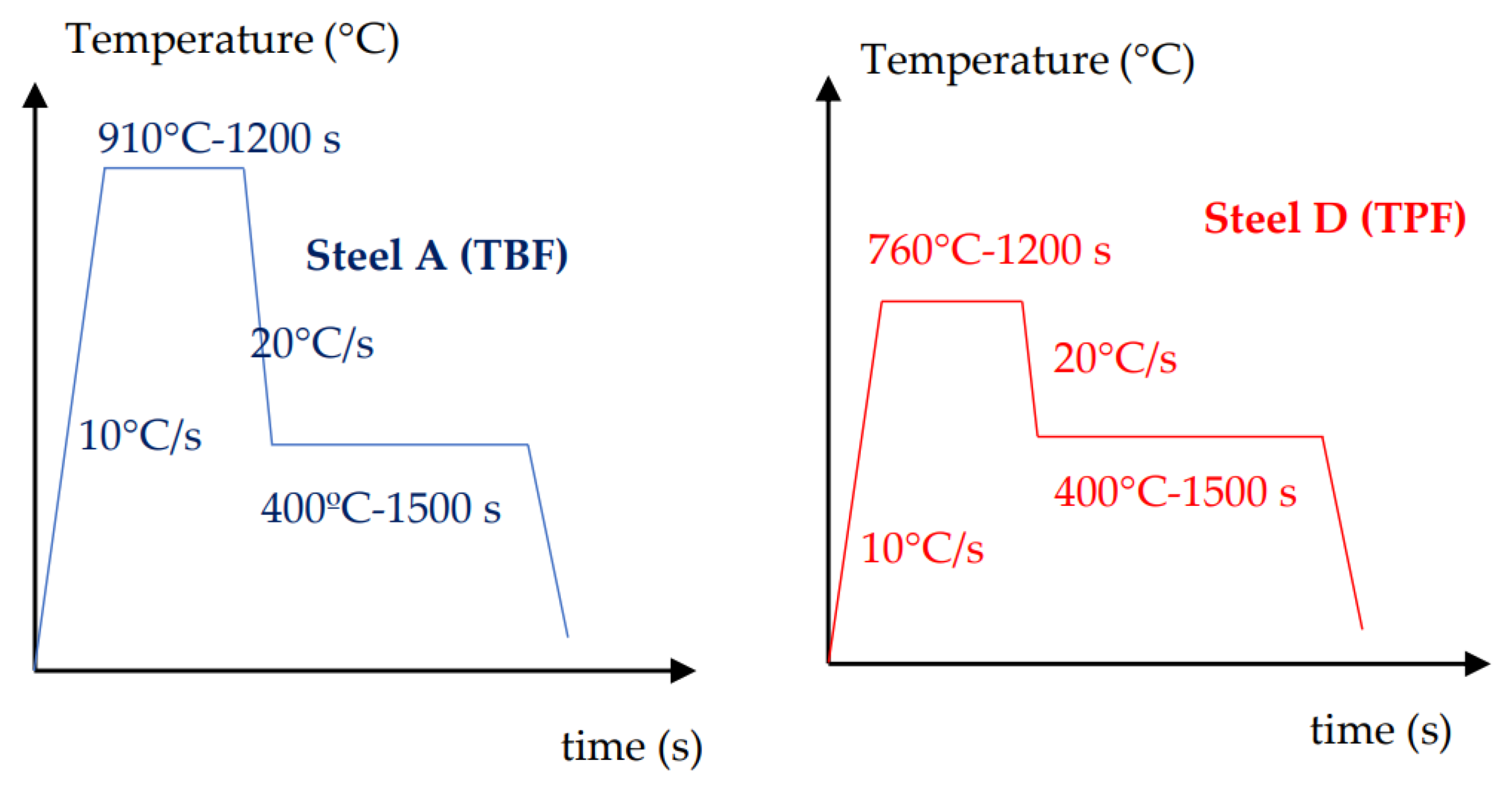

2. Materials and Experimental Results

2.1. Retained Austenite

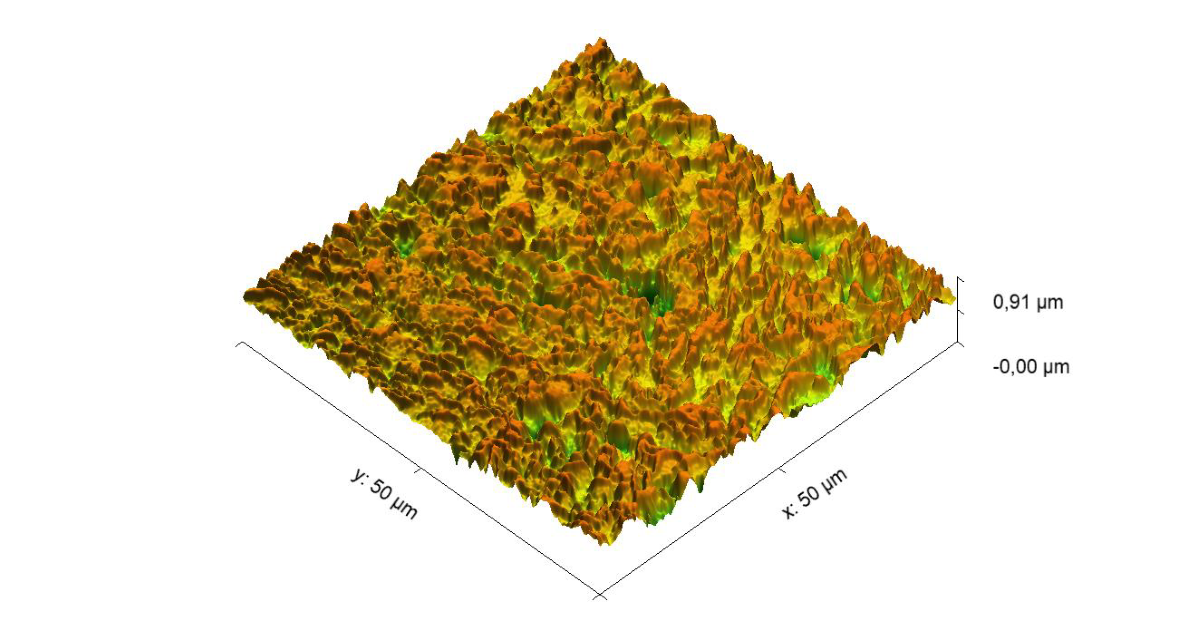

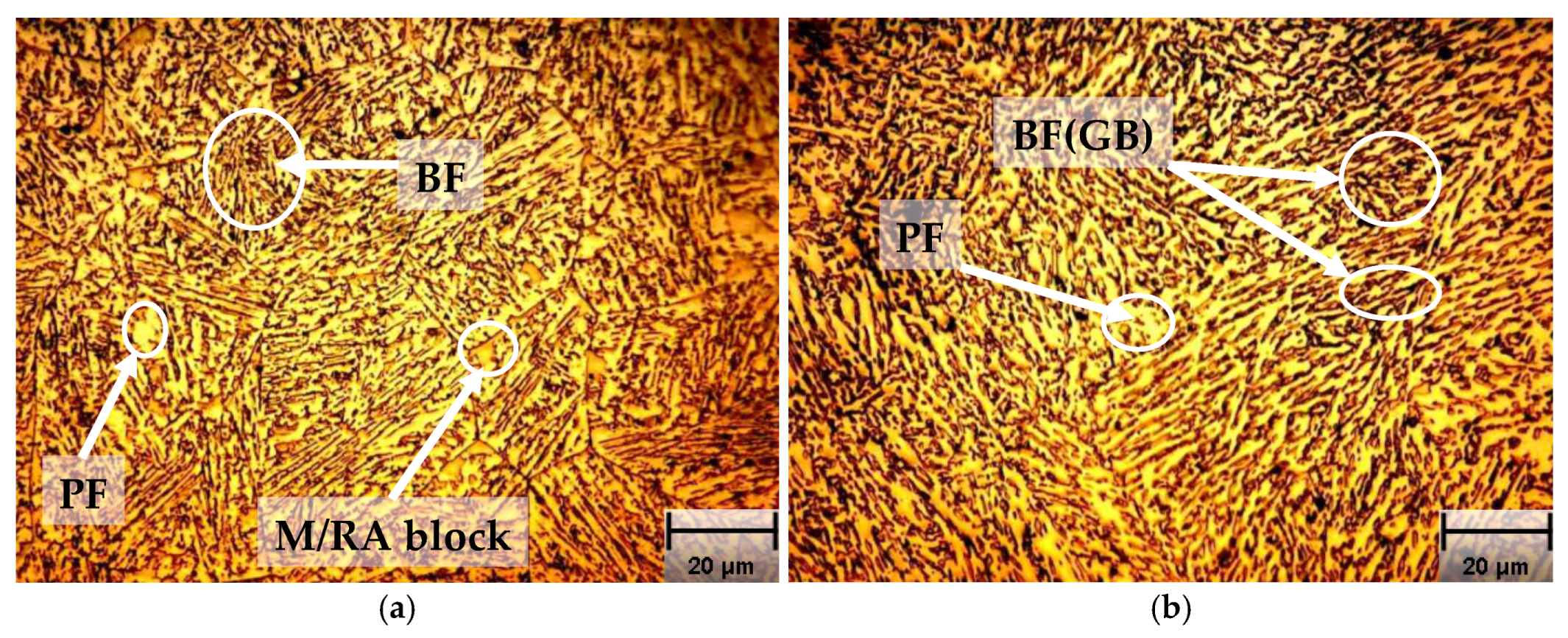

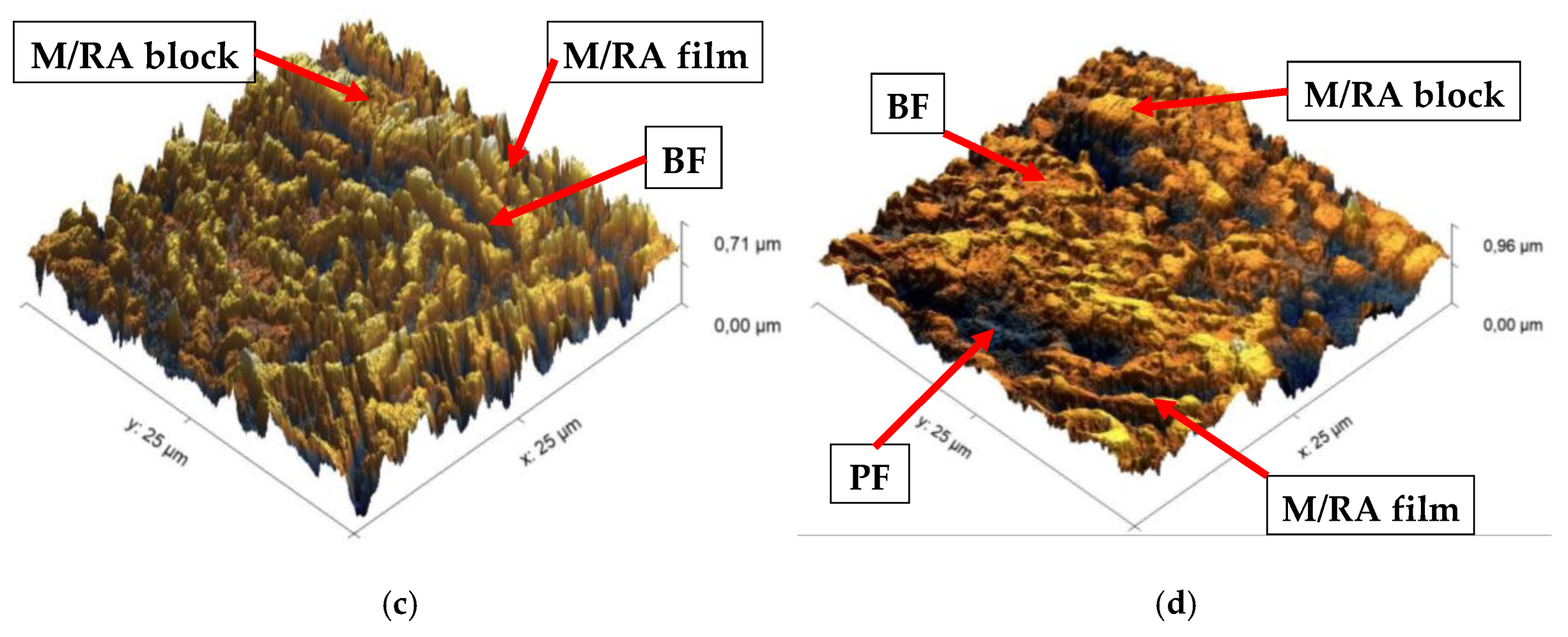

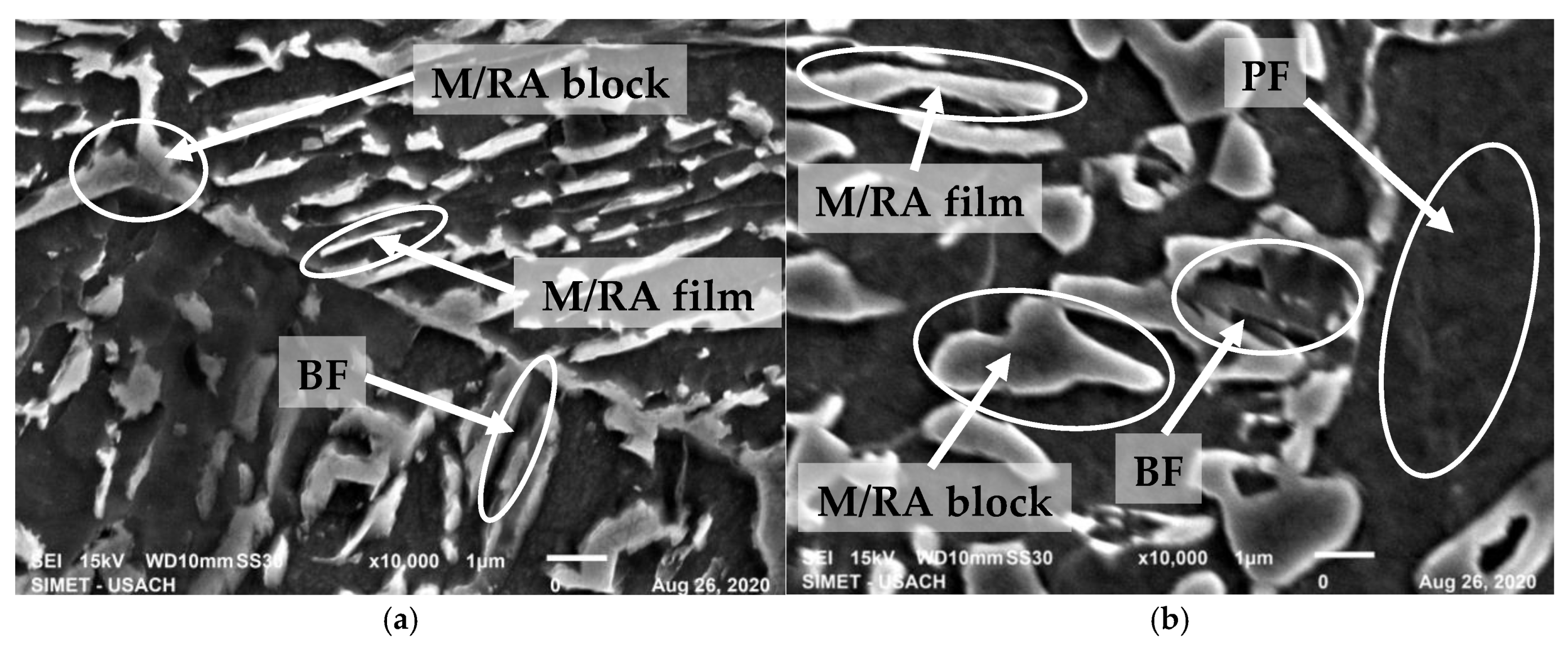

2.2. Metallographic Analysis

3. Model Description

3.1. Retained Austenite to Martensite: Olson and Cohen Model

3.2. Mecking-Kocks Model

3.3. Retained Austenite

3.4. Rodriguez-Gutierrez Model for Martensite

3.5. Mixture Law and Partition Coefficient

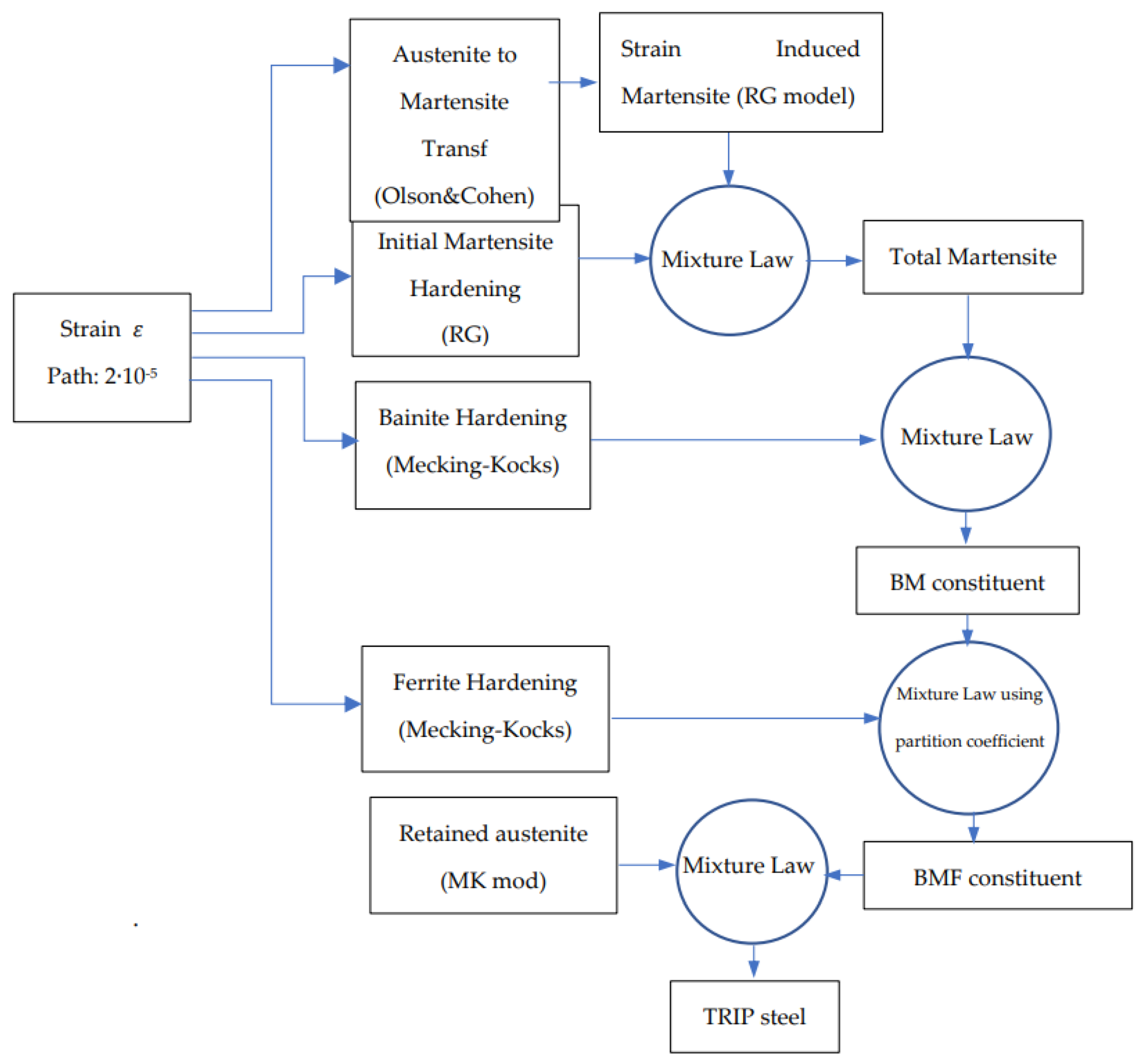

4. Implementation of the Constitutive Model

- (a)

- The starting parameter is the plastic strain . The model assumes an increment of in this parameter.

- (b)

-

From the incremental value assumed in (a), the model computes:b.1) The fraction of martensite that appears from the strain-induced transformation of austenite, equation 1.b.2) The strain hardening of ferrite, bainite and retained austenite using the Mecking-Kocks model described in equations 2 (for ferrite and bainite) and 5 (for austenite).b.3) The strain hardening of martensite by means of equation 6.

- (c)

- The total martensite strength is computed by means of a mixture law between initial and strain-induced martensite.

- (d)

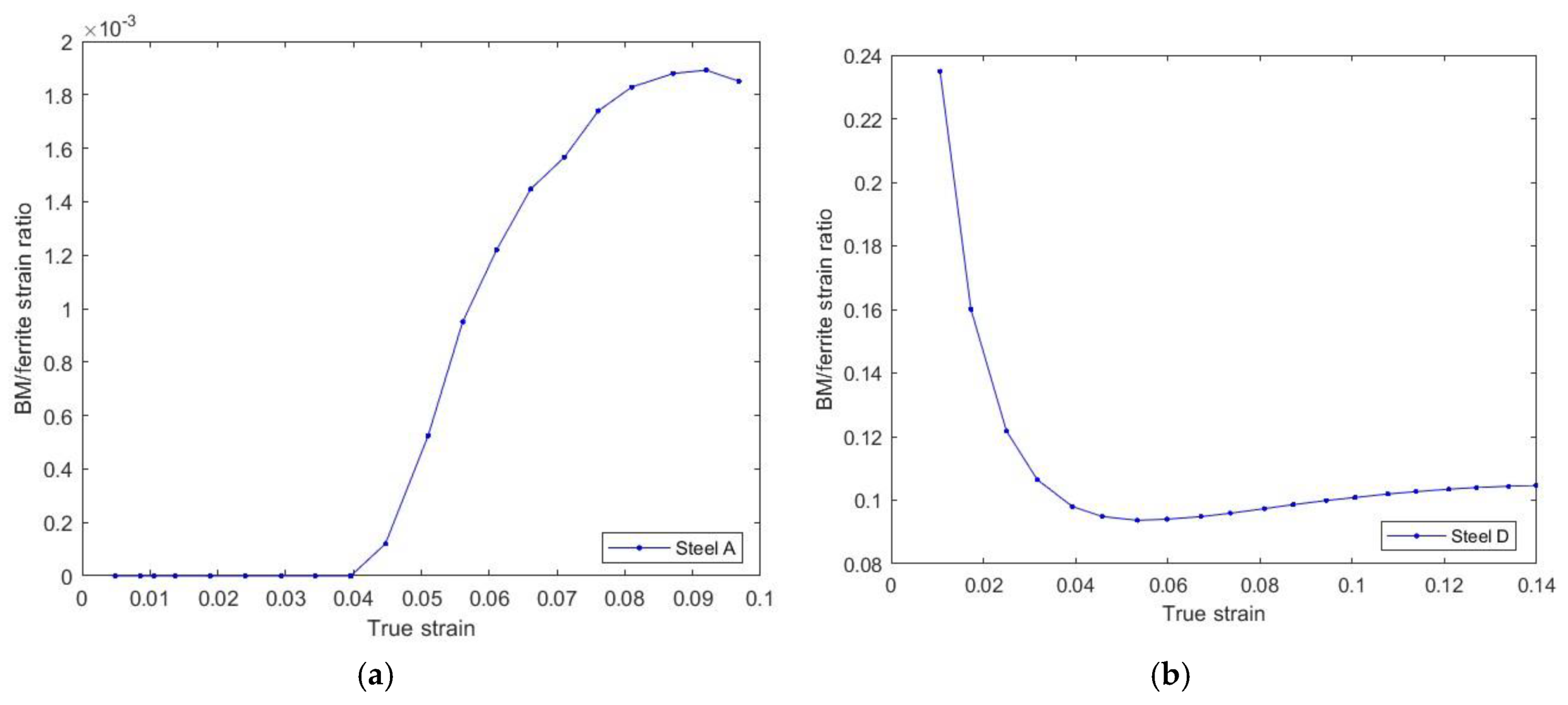

- A mixture law combines the total martensite strength and the bainite strength, obtaining the mechanical strength of the BM (bainite-martensite) constituent.

- (e)

- The ferrite and BM component are combined using a mixture law in order to obtain the BMF (bainite-martensite-ferrite) strength.

- (f)

- Finally, the retained austenite and BMF component are combined through a mixture law, obtaining the mechanical strength of the TRIP steel.

4.1. Parameters Used in the Model

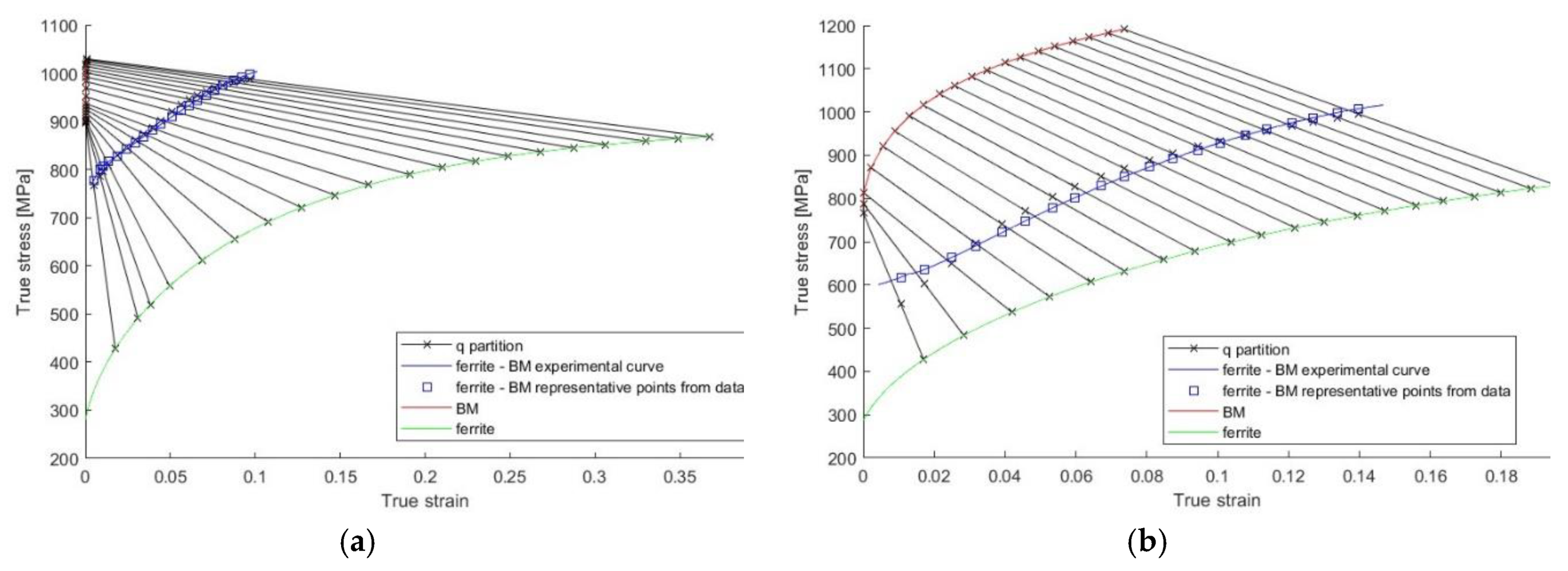

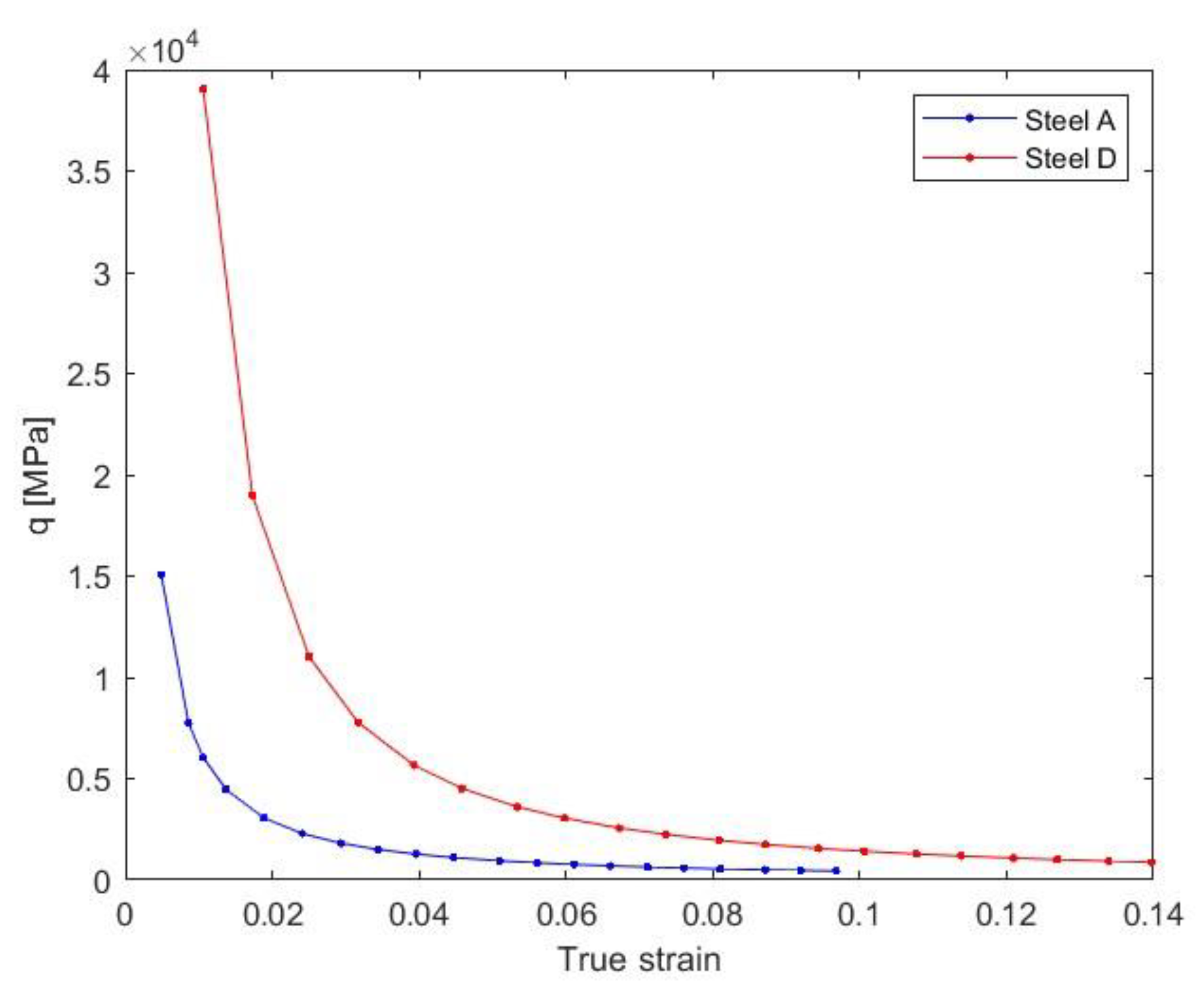

5. Discussion

6. Conclusions

- The model used includes constitutive equations that represent the different phenomena that appear during the deformation process. These equations have calibration parameters and constants whose values are intrinsic to each phase.

- In both cases, the agreement between experimental and modeling data were satisfactory. The relative errors in the stress for steels TBF (TRIP Bainitic Ferrite) and TPF (TRIP Polygonal Ferrite) were 0.8 and 1.6% respectively.

- The model based on partition coefficient shows a great adaptability because it accurately describes the behavior of both steels, taking into account the differences in their characteristics, especially the main hard microconstituents, that is martensite and bainite.

- Three modifications of the original Bouquerel´s model were included in this work: (a) the presence of initial martensite, not considered in the original model; (b) the assumption that austenite is a microconstituent with moderate hardness, whereas Bouquerel considered it a hard phase; (c) the constants and , both related to strain hardening, are affected by TRIP effect. These are the most important novelties of this work.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bouaziz, O.; Zurob, H.; Huang, M. Driving Force and Logic of Development of Advanced High Strength Steels for Automotive Applications. Steel Res. Int. 2013, 84, 937–947. [Google Scholar] [CrossRef]

- De Cooman, B. Structure–properties relationship in TRIP steels containing carbide-free bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 285–303. [Google Scholar] [CrossRef]

- Jacques, P.; Furnémont, Q.; Lani, F.; Pardoen, T.; Delannay, F. Multiscale mechanics of TRIP-assisted multiphase steels: I. Characterization and mechanical testing. Acta Mater. 2007, 55, 3681–3693. [Google Scholar] [CrossRef]

- De Meyer, M.; Vanderschueren, D.; De Cooman, B.C. The Influence of the Substitution of Si by Al on the Properties of Cold Rolled C-Mn-Si TRIP Steels. ISIJ Int. 1999, 39, 813–822. [Google Scholar] [CrossRef]

- Airod, A.; Petrov, R.; Colás, R.; Houbaert, Y. Analysis of the Trip Effect by Means of Axisymmetric Compressive Tests on a Si-Mn Bearing Steel. ISIJ Int. 2004, 44, 179–186. [Google Scholar] [CrossRef]

- Choi, I.D.; Bruce, D.M.; Kim, S.J.; Lee, C.G.; Park, S.H.; Matlock, D.K.; Speer, J.G. Deformation Behavior of Low Carbon TRIP Sheet Steels at High Strain Rates. ISIJ Int. 2002, 42, 1483–1489. [Google Scholar] [CrossRef]

- Dan, W.; Zhang, W.; Li, S.; Lin, Z. A model for strain-induced martensitic transformation of TRIP steel with strain rate. Comput. Mater. Sci. 2007, 40, 101–107. [Google Scholar] [CrossRef]

- De Meyer, M.; Mahieu, J.; De Cooman, B.C. Empirical microstructure prediction method for combined intercritical annealing and bainitic transformation of TRIP steel. Mater. Sci. Technol. 2002, 18, 1121–1132. [Google Scholar] [CrossRef]

- SugimotoK. -I.; SatoS.-H.; KobayashiJ.; SrivastavaA.K. Effects of Cr and Mo on Mechanical Properties of Hot-Forged Medium Carbon TRIP-Aided Bainitic Ferrite Steels. Metals 2019, 9, 1066. [Google Scholar] [CrossRef]

- Turteltaub, S.; Suiker, A. Transformation-induced plasticity in ferrous alloys. J. Mech. Phys. Solids 2005, 53, 1747–1788. [Google Scholar] [CrossRef]

- Iwamoto, T. Multiscale computational simulation of deformation behavior of TRIP steel with growth of martensitic particles in unit cell by asymptotic homogenization method. Int. J. Plast. 2004, 20, 841–869. [Google Scholar] [CrossRef]

- Iwamoto, T.; Tsuta, T. Computational simulation on deformation behavior of CT specimens of TRIP steel under mode I loading for evaluation of fracture toughness. Int. J. Plast. 2002, 18, 1583–1606. [Google Scholar] [CrossRef]

- Serri, J.; Martiny, M.; Ferron, G. Finite element analysis of the effects of martensitic phase transformation in TRIP steel sheet forming. Int. J. Mech. Sci. 2005, 47, 884–901. [Google Scholar] [CrossRef]

- Delannay, L.; Jacques, P.; Pardoen, T. Modelling of the plastic flow of trip-aided multiphase steel based on an incremental mean-field approach. Int. J. Solids Struct. 2008, 45, 1825–1843. [Google Scholar] [CrossRef]

- Sierra, R.; Nemes, J. Investigation of the mechanical behaviour of multi-phase TRIP steels using finite element methods. Int. J. Mech. Sci. 2008, 50, 649–665. [Google Scholar] [CrossRef]

- Kouznetsova, V.; Geers, M. A multi-scale model of martensitic transformation plasticity. Mech. Mater. 2008, 40, 641–657. [Google Scholar] [CrossRef]

- Lani, F.; Lani, F.; Furnémont, Q.; Furnémont, Q.; Van Rompaey, T.; Van Rompaey, T.; Delannay, F.; Delannay, F.; Jacques, P.; Jacques, P.; et al. Multiscale mechanics of TRIP-assisted multiphase steels: II. Micromechanical modelling. Acta Mater. 2007, 55, 3695–3705. [Google Scholar] [CrossRef]

- Li, S.; Dan, W.; Zhang, W.; Lin, Z. A model for strain-induced martensitic transformation of TRIP steel with pre-strain. Comput. Mater. Sci. 2007, 40, 292–299. [Google Scholar] [CrossRef]

- Liu, J.-Y.; Lu, H.; Chen, J.-M.; Jullien, J.-F.; Wu, T. Simulation of mechanical behavior of multiphase TRIP steel taking account of transformation-induced plasticity. Comput. Mater. Sci. 2008, 43, 646–654. [Google Scholar] [CrossRef]

- Meftah, S.; Barbe, F.; Taleb, L.; Sidoroff, F. Parametric numerical simulations of TRIP and its interaction with classical plasticity in martensitic transformation. Eur. J. Mech. - A/Solids 2007, 26, 688–700. [Google Scholar] [CrossRef]

- Dan, W.; Li, S.; Zhang, W.; Lin, Z. The effect of strain-induced martensitic transformation on mechanical properties of TRIP steel. Mater. Des. 2008, 29, 604–612. [Google Scholar] [CrossRef]

- Minote, T.; Torizuka, S.; Ogawa, A.; Niikura, M. Modeling of Transformation Behavior and Compositional Partitioning in TRIP Steel. ISIJ Int. 1996, 36, 201–207. [Google Scholar] [CrossRef]

- Valance, S.; Coret, M.; Combescure, A. Strain simulation of steel during a heating-cooling cycle including solid-solid phase change. Eur. J. Mech. - A/Solids 2007, 26, 460–473. [Google Scholar] [CrossRef]

- Wolff, M.; Böhm, M.; Dalgic, M.; Hüßler, I. Evaluation of models for TRIP and stress-dependent transformation behaviour for the martensitic transformation of the steel 100Cr6. Comput. Mater. Sci. 2008, 43, 108–114. [Google Scholar] [CrossRef]

- Yu, H.Y. Strain-hardening behaviors of TRIP-assisted steels during plastic deformation. Mater. Sci. Eng. A 2008, 479, 333–338. [Google Scholar] [CrossRef]

- Papatriantafillou, I.; Agoras, M.; Aravas, N.; Haidemenopoulos, G. Constitutive modeling and finite element methods for TRIP steels. Comput. Methods Appl. Mech. Eng. 2006, 195, 5094–5114. [Google Scholar] [CrossRef]

- Shan, T.; Li, S.; Zhang, W.; Xu, Z. Prediction of martensitic transformation and deformation behavior in the TRIP steel sheet forming. Mater. Des. 2008, 29, 1810–1816. [Google Scholar] [CrossRef]

- Thibaud, S.; Boudeau, N.; Gelin, J. TRIP steel: Plastic behaviour modelling and influence on functional behaviour. J. Mech. Work. Technol. 2006, 177, 433–438. [Google Scholar] [CrossRef]

- Uthaisangsuk, V.; Prahl, U.; Bleck, W. Micromechanical modelling of damage behaviour of multiphase steels. Comput. Mater. Sci. 2007, 43, 27–35. [Google Scholar] [CrossRef]

- Benzing, J.; Liu, Y.; Zhang, X.; Luecke, W.; Ponge, D.; Dutta, A.; Oskay, C.; Raabe, D.; Wittig, J. Experimental and numerical study of mechanical properties of multi-phase medium-Mn TWIP-TRIP steel: Influences of strain rate and phase constituents. Acta Mater. 2019, 177, 250–265. [Google Scholar] [CrossRef]

- Jung, J.; Hur, Y.C.; Jun, S.; Lee, H.-S.; Kim, B.-M.; Kim, J.H. Constitutive Modeling of Asymmetric Hardening Behavior of Transformation-Induced Plasticity Steels. Int. J. Automot. Technol. 2019, 20, 19–30. [Google Scholar] [CrossRef]

- Mulidrán, P.; Spišák, E.; Tomáš, M.; Majerníková, J.; Varga, J. The effect of material models in the fem simulation on the springback prediction of the trip steel. Acta Met. Slovaca 2021, 27, 103–108. [Google Scholar] [CrossRef]

- Polatidis, E.; Haidemenopoulos, G.; Krizan, D.; Aravas, N.; Panzner, T.; Šmíd, M.; Papadioti, I.; Casati, N.; Van Petegem, S.; Van Swygenhoven, H. The effect of stress triaxiality on the phase transformation in transformation induced plasticity steels: Experimental investigation and modelling the transformation kinetics. Mater. Sci. Eng. A 2020, 800, 140321. [Google Scholar] [CrossRef]

- Prüger, S.; Gandhi, A.; Balzani, D. Influence of microstructure morphology on multi-scale modeling of low-alloyed TRIP-steels. Eng. Comput. 2018, 35, 499–528. [Google Scholar] [CrossRef]

- Seupel, A.; Kuna, M. Phenomenological modeling of thermomechanical coupling effects of highly alloyed TRIP-steels at different stress states. Procedia Struct. Integr. 2022, 35, 10–17. [Google Scholar] [CrossRef]

- Tzini, M.-I.T.; Aristeidakis, J.S.; Christodoulou, P.I.; Kermanidis, A.T.; Haidemenopoulos, G.N.; Krizan, D. Multi-phase field modeling in TRIP steels: Distributed vs. average stability and strain-induced transformation of retained austenite. Mater. Sci. Eng. A 2021, 833, 142341. [Google Scholar] [CrossRef]

- Burgold, A.; Droste, M.; Seupel, A.; Budnitzki, M.; Biermann, H.; Kuna, M. Modeling of the cyclic deformation behavior of austenitic TRIP-steels. Int. J. Plast. 2020, 133. [Google Scholar] [CrossRef]

- Gui, Y.; An, D.; Han, F.; Lu, X.; Kang, G.; Zhang, X. Multiple-mechanism and microstructure-based crystal plasticity modeling for cyclic shear deformation of TRIP steel. Int. J. Mech. Sci. 2022, 222. [Google Scholar] [CrossRef]

- Mu, W.; Rahaman, M.; Rios, F.L.; Odqvist, J.; Hedström, P. Predicting strain-induced martensite in austenitic steels by combining physical modelling and machine learning. Mater. Des. 2020, 197, 109199. [Google Scholar] [CrossRef]

- Bouquerel, J.; Verbeken, K.; Decooman, B. Microstructure-based model for the static mechanical behaviour of multiphase steels. Acta Mater. 2006, 54, 1443–1456. [Google Scholar] [CrossRef]

- Salinas, Á.; Celentano, D.; Carvajal, L.; Artigas, A.; Monsalve, A. Microstructure-Based Constitutive Modelling of Low-Alloy Multiphase TRIP Steels. Metals 2019, 9, 250. [Google Scholar] [CrossRef]

- ASTM E415, “Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic,” in American Society for Testing and Materials, no. April 1999, 2015, pp. 1–9.

- ASTM E975, “ASTM E975 Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation,” 2009.

- Escobar, J.; Jiménez, J.L.; Artigas, A.; Perez-Ipiña, J.; Monsalve, A. Influence of Cold Deformation on Carbide Precipitation Kinetics in a Fe-22Mn-0.45C TWIP Steel. Materials 2022, 15, 3748. [Google Scholar] [CrossRef] [PubMed]

- Tesser, E.; Silva, C.; Artigas, A.; Monsalve, A. Effect of Carbon Content and Intercritical Annealing on Microstructure and Mechanical Tensile Properties in FeCMnSiCr TRIP-Assisted Steels. Metals 2021, 11, 1546. [Google Scholar] [CrossRef]

- ASTM E18, “ASTM E8 Standard Test Methods for Tension Testing of Metallic Materials,” 2016.

- Samek, L.; De Moor, E.; Penning, J.; De Cooman, B.C. Influence of alloying elements on the kinetics of strain-induced martensitic nucleation in low-alloy, multiphase high-strength steels. Met. Mater. Trans. A 2006, 37, 109–124. [Google Scholar] [CrossRef]

- Alvarez, P.; Muñoz, F.; Celentano, D.; Artigas, A.; Cerda, F.M.C.; Ponthot, J.-P.; Monsalve, A. Modeling the Mechanical Response of a Dual-Phase Steel Based on Individual-Phase Tensile Properties. Metals 2020, 10, 1031. [Google Scholar] [CrossRef]

- Lian, J.; Jiang, Z.; Liu, J. Theoretical model for the tensile work hardening behaviour of dual-phase steel. Mater. Sci. Eng. A 1991, 147, 55–65. [Google Scholar] [CrossRef]

| %C | %Mn | %Si | %Cr | %Al | %Cu | %Mo | %Ni | %P | %S | %Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.166 | 1.872 | 1.534 | 0.242 | 0.343 | 0.0995 | 0.017 | 0.050 | 0.005 | 0.022 | Bal. |

| Phase | Steel A (%) |

Steel D (%) |

Grain Size Steel A (μm) |

Grain Size Steel D (μm) |

|---|---|---|---|---|

| Polygonal Ferrite (PF) | 25.0 | 52.0 | 7.2 | 7.2 |

| Bainitic Ferrite (BF) | 33.0 | 25.0 | 1.5 | 2.0 |

| Martensite (M) | 31.6 | 5.1 | 1.0 | 2.0 |

| Retained Austenite (RA) | 10.4 | 17.9 | 0.7 | 0.7 |

| Transformed Austenite after tension test * | 8.1 | 13.7 | - | - |

| Carbon in RA | 1.4 | 1.4 | - | - |

| Steel | Yield stress (MPa) | UTS (MPa) | Total Elongation (%) |

|---|---|---|---|

| A | 735 | 913 | 18.4 |

| D | 560 | 897 | 22.3 |

| Steel A | Steel D | Reference | |

|---|---|---|---|

| 24 | 26 | This work | |

| 1 | 1.5 | This work | |

| 2 | 2 | [47] | |

| 0.012 | 0.014 | This work | |

| 3.6 | 2.8 | This work |

| Constant | Units | Austenite | Ferrite | Bainite | Martensite | Reference |

|---|---|---|---|---|---|---|

| - | [40] | |||||

| [40] | ||||||

| 225 | 1150 | This work | ||||

| [40] | ||||||

| [40] | ||||||

| [40] | ||||||

| - | [40] | |||||

| [40] | ||||||

| [40] |

| (Mpa) | ||

|---|---|---|

| Steel A | 28.04 | 1.18 |

| Steel D | 48.05 | 1.47 |

| Maximum Stress Difference | Average Stress Difference | |||

|---|---|---|---|---|

| (MPa) | (%) | (Mpa) | (%) | |

| Steel A | 12.77 | 1.58 | 7.40 | 0.84 |

| Steel D | 52.24 | 8.48 | 12.48 | 1.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).