Submitted:

05 August 2024

Posted:

06 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Hybrid Energy Storage System (HESS)

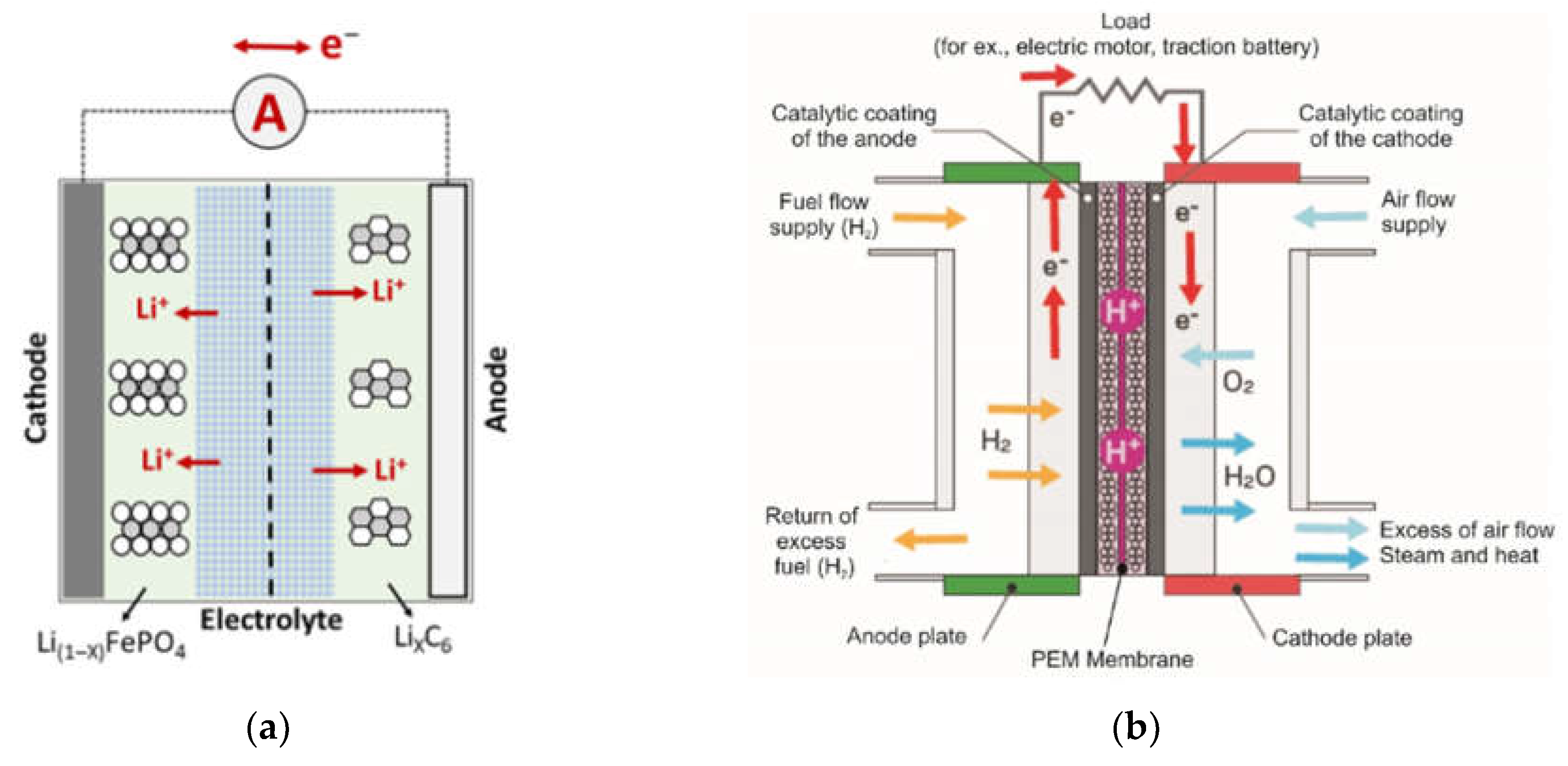

2.1 Battery (BT)

2.2 Fuel Cell (FC)

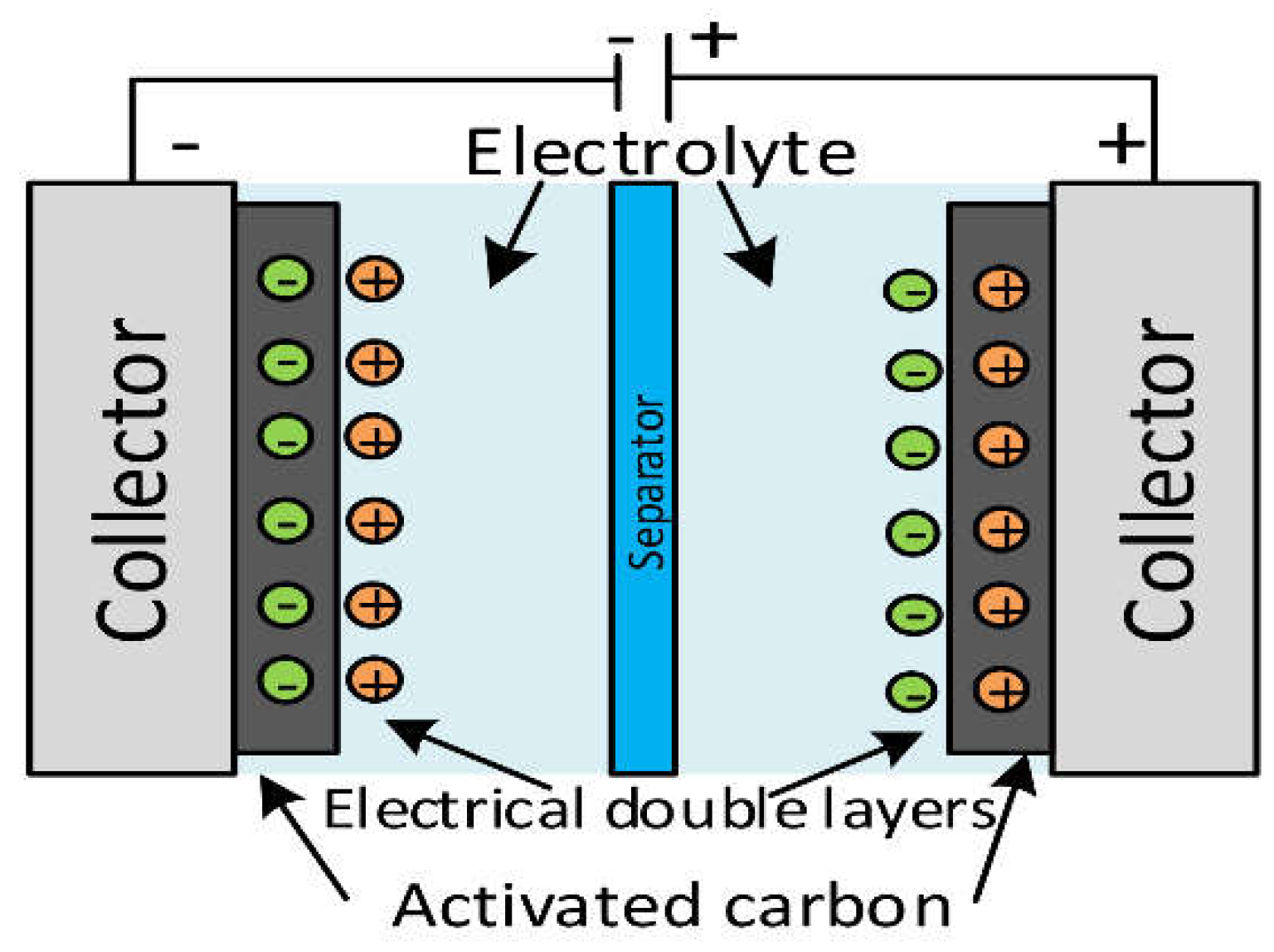

2.3 Supercapacitor (SC)

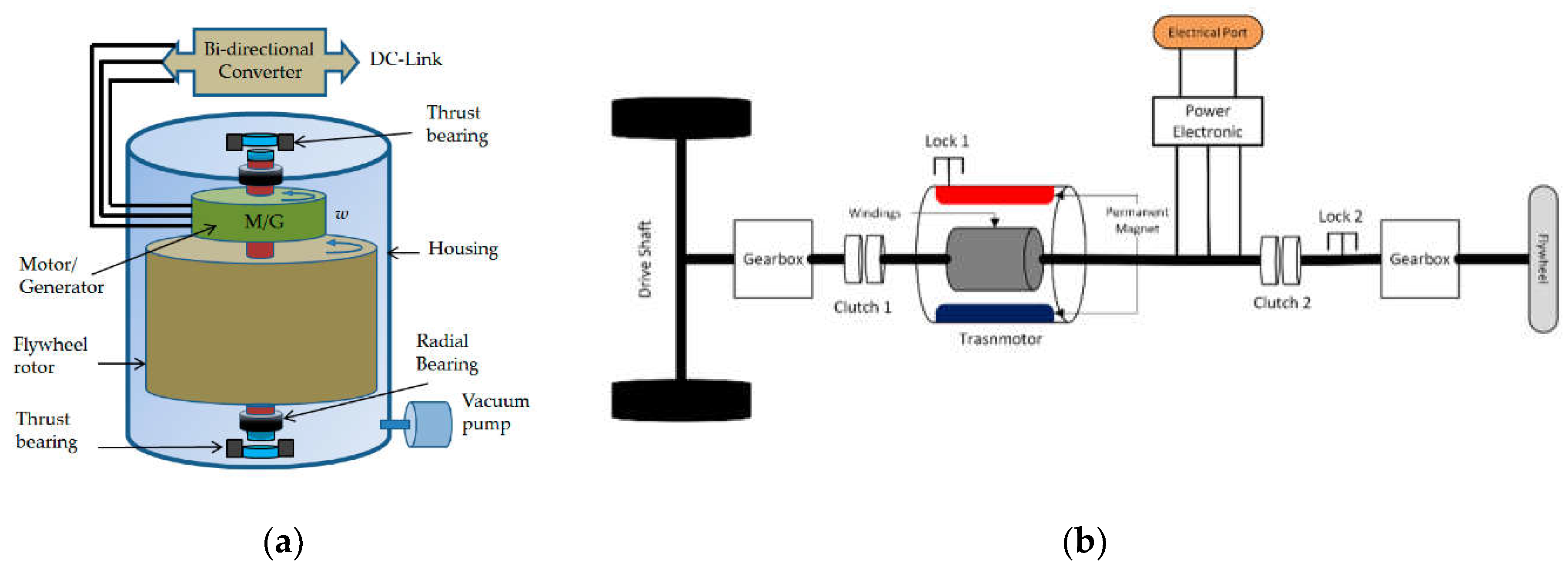

2.3 Flywheel (FW)

3. Transmotor

- elec refers to the electrical port;

- ir refers to the inner rotor;

- or refers to the outer rotor.

- is the electrical frequency of the currents applied to the windings;

- is the number of pole pairs of the Transmotor;

- is the rotating speed of the inner rotor;

- is the rotating speed of the outer rotor;

- is the electrical Torque;

- is the inner rotor’s Torque;

- is the outer rotor’s Torque;

- is the electromotive force induced in the conductor;

- is the velocity of the conductor’

- is the Magnetic field;

- is the length vector of the conductor.

- Scenario A: The vehicle aims to accelerate. When the inner rotor (FW) spins faster than the outer rotor (drive shaft), the transmotor's clutch function engages to transfer kinetic energy from the FW to the drive shaft. Simultaneously, its generator function converts excess kinetic energy from the FW into electrical energy, charging the BT. As a result, the vehicle accelerates using mechanical energy from the FW, enhancing the BT ‘s charge. Interestingly, this topology is unique as it charges the BT instead of draining it during acceleration demands.

- Scenario B: The vehicle also intends to accelerate, but in this scenario, the outer rotor (drive shaft) moves faster than the inner rotor (FW). Here, the transmotor's clutch function aids in managing power transfer from the BT to the drive shaft, and its electric motor function converts electrical energy from the BT into mechanical energy, assisting in drive shaft acceleration. Consequently, the vehicle harnesses additional power from the BT for acceleration.

- Scenario C: The vehicle decelerates with the outer rotor (drive shaft) moving faster than the inner rotor (FW). The transmotor engages its clutch to manage the deceleration process and transfer excess kinetic energy from the drive shaft to the FW. Its generator function then converts this excess kinetic energy into electrical energy, recharging the BT. The outcome is vehicle deceleration accompanied by BT charging.

- Scenario D: The vehicle needs to decelerate, and the inner rotor (FW) is spinning faster than the outer rotor (drive shaft). The transmotor's clutch function engages to manage the power transfer from the BT, providing braking power. Then the transmotor will work as a generator charging the BT system.

4. Multisource EVs

4.1 Topologies of HESS

4.1.1. BEV

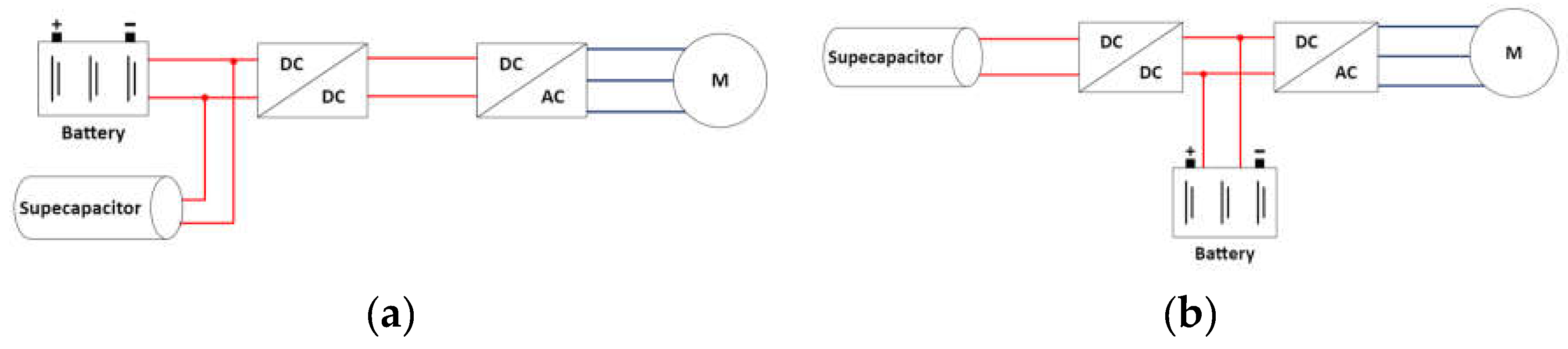

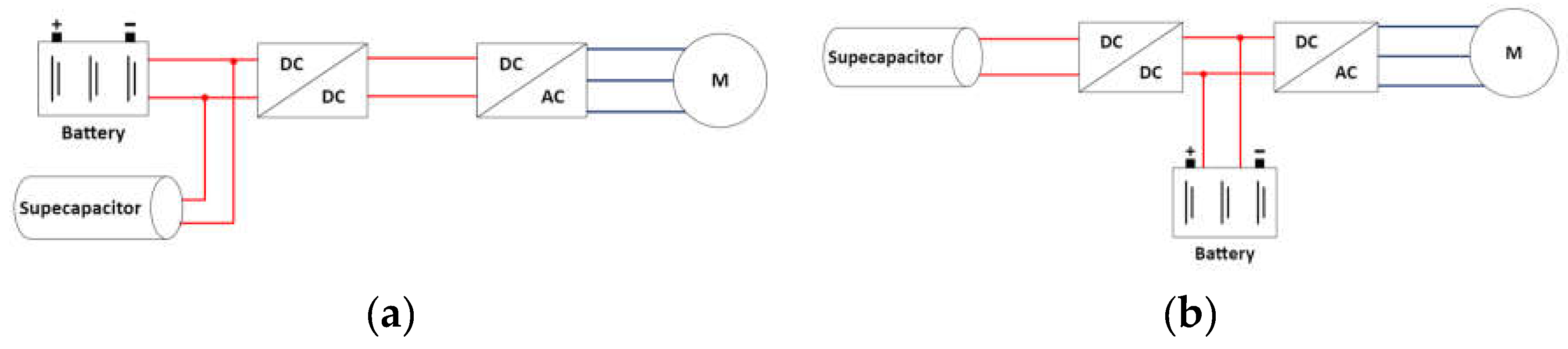

- Passive cascade BT and SC configuration: In this setup, SCs are connected in parallel with the BT as depicted in Figure 4.a to enhance the power performance capability of the system. A bidirectional converter links the SCs to the DC-link, controlling the power flow either sourced from or fed into the SCs. Despite significant voltage fluctuations at the SC terminals, the voltage at the DC-link is maintained nearly constant due to the regulation by the bidirectional converter. However, the BT voltage is equal to the DC-link voltage, as there is no control mechanism between the BT and the SC. The current from the BT must both charge the SC and provide power to the load. A major disadvantage of this placement is its inefficiency in utilizing the stored energy in the SC [8,13,26,40,53].

- Active Cascade System (Active cascade UC/ BT configuration: Similar to (1), this system includes a DC/DC current converter between the BT array and the SC as shown in Figure 4.b, allowing for lower SC voltage relative to the BT, which matches the DC-link voltage. This setup enhances the system's maximum power output but is plagued by frequent BT charging and discharging cycles and inefficient storage of energy from regenerative braking in the SC [8,26,40,53].

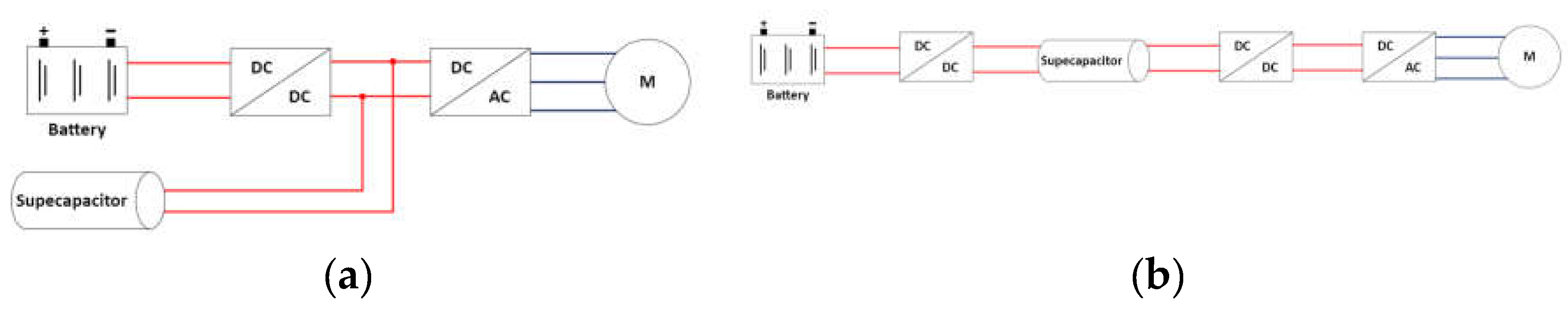

- Active Cascade System with Reverse BT -SC Connectivity (Active cascade BT/UC configuration): In this configuration, presented in Figure 5.a, the BT voltage is lower than that of the SC, which aligns with the DC-link voltage. The BT voltage is boosted to a higher level, allowing for a reduction in current which reduces the BT's capacity requirements and, consequently, the cost of the application. Additionally, this setup allows more efficient control of the BT current compared to setup (1). The BT provides average power, while the SC handles instantaneous demands and captures energy quickly from regenerative braking. The downside is that the BT cannot be charged from the braking energy or from the SC due to the one-way boost converter [8,26,40,53].

- Parallel Passive Cascade System with Two DC–DC Converters: In this system, the SC and the ΒΤ are connected in parallel to the DC-link through bidirectional converters, as seen in Figure 5.b, allowing the SC to deliver 100% of its stored energy. Unlike previous configurations, the BT and SC voltages, which are lower than the DC-link voltage, are adjusted based on power requirements. This setup permits separate control of power flow to and from each storage unit, enhancing flexibility in power management. The converters moderate fluctuations in BT current, significantly reducing strain. Integrating the two DC/DC converters into a single unit could further reduce cost, size, and control complexity [8,13,26,40,53].

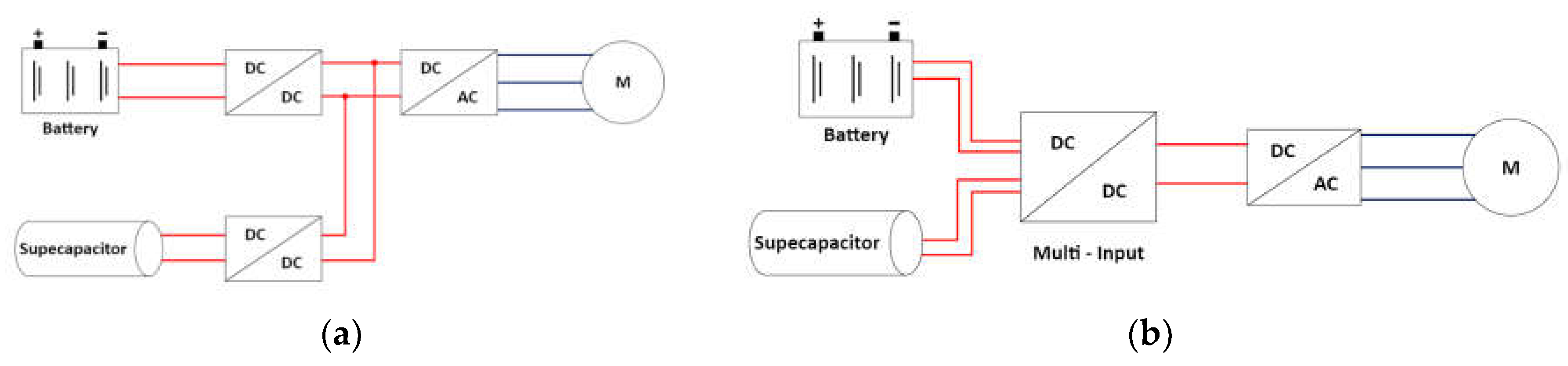

- Multiple Converter Configuration: This configuration, explained at Figure 6.a, employs individually controlled DC-DC converters to link each energy source to the DC-link, requiring the voltages of the BT and SC to match the DC-link voltage. This setup, however, necessitates two full-power converters, substantially increasing the application's cost and size [8,26,40,53].

- Multi-Input Converter Configuration: This configuration aims to reduce the costs associated with the multiple converters in (5). It connects the BT and SC to a common inductor with parallel switches, each paired with a diode to prevent short-circuit. A bidirectional DC/DC current converter controls power flow between the inputs and loads, operating in boost mode when powering loads and in buck mode during energy recovery from braking. The setup demonstrated in Figure 6.b uses a common inductor for all energy sources if additional inputs are present. It addresses the disadvantages of previous topologies by reducing costs and weight while enhancing performance, though it involves a more complex control and power management strategy [8,13,26,40,53].

- Proposed Hybrid ESS Configuration: According to Ref. [8], a hybrid topology is proposed where a higher-voltage SC directly connected to the DC-link to cover maximum power demands, while a lower-voltage BT is connected through a power diode or a controlled switch. This system operates in four modes: low power, high power, braking, and acceleration. During low load conditions, the SC primarily powers the load, with the BT contributing when greater power is needed. Energy generated from regenerative braking can be directed solely to the SC for rapid charging, or it can be distributed to both the BT and SC for a more thorough charge

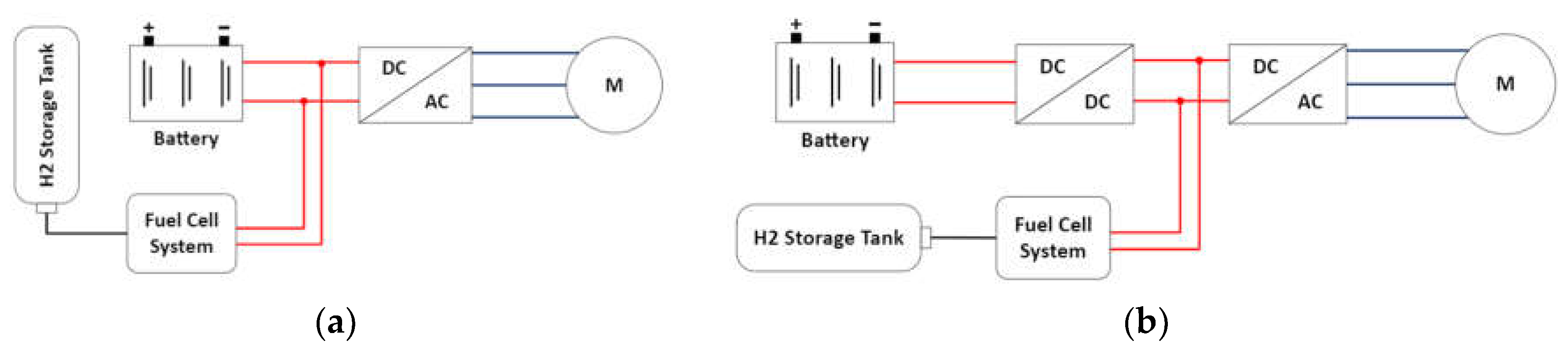

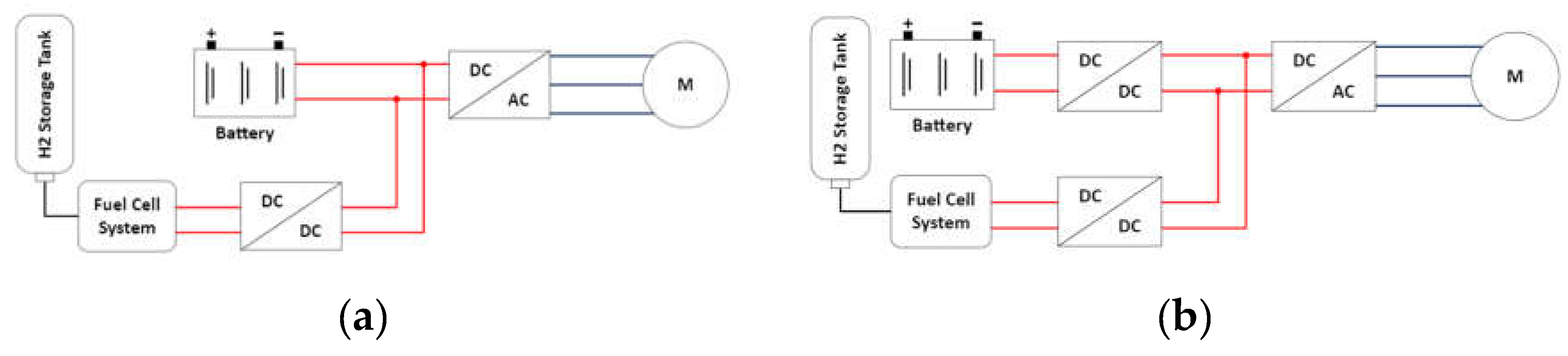

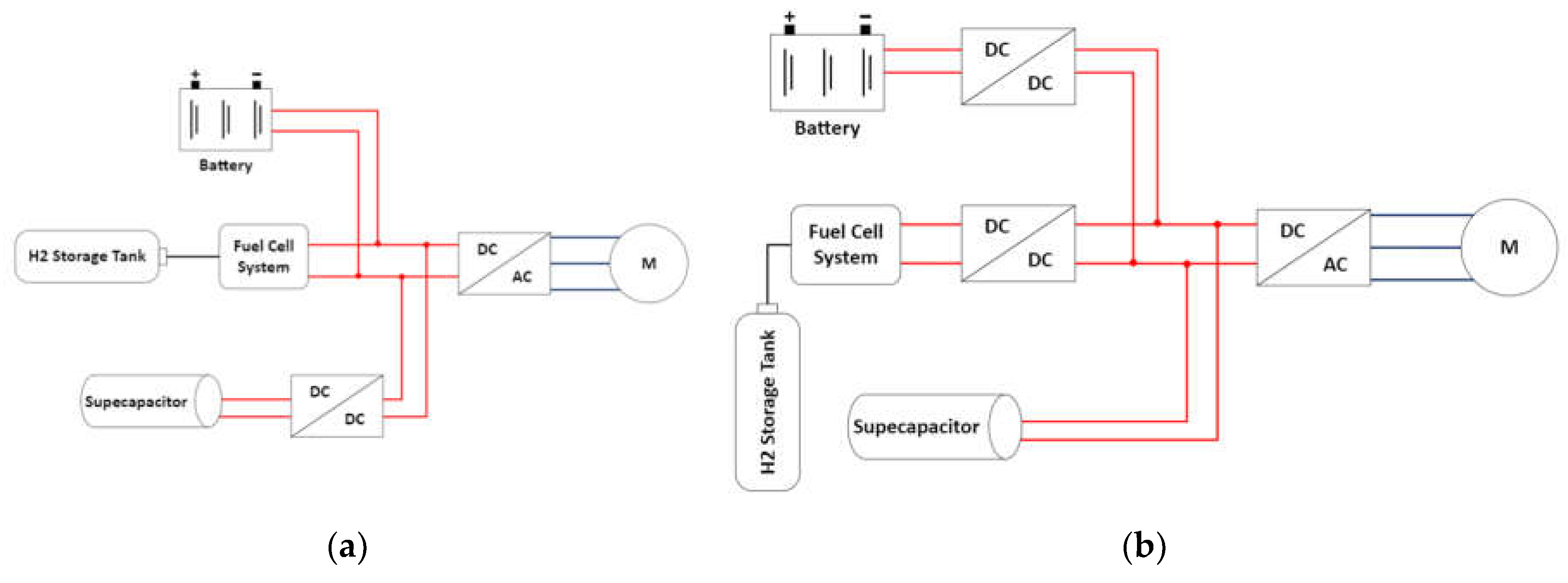

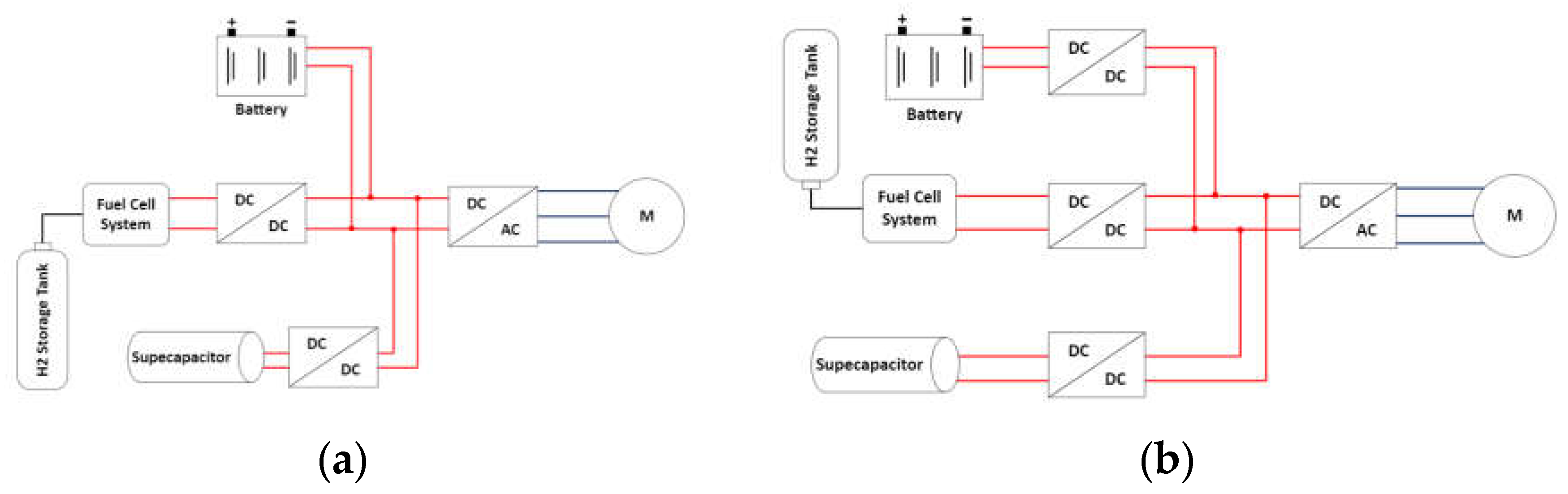

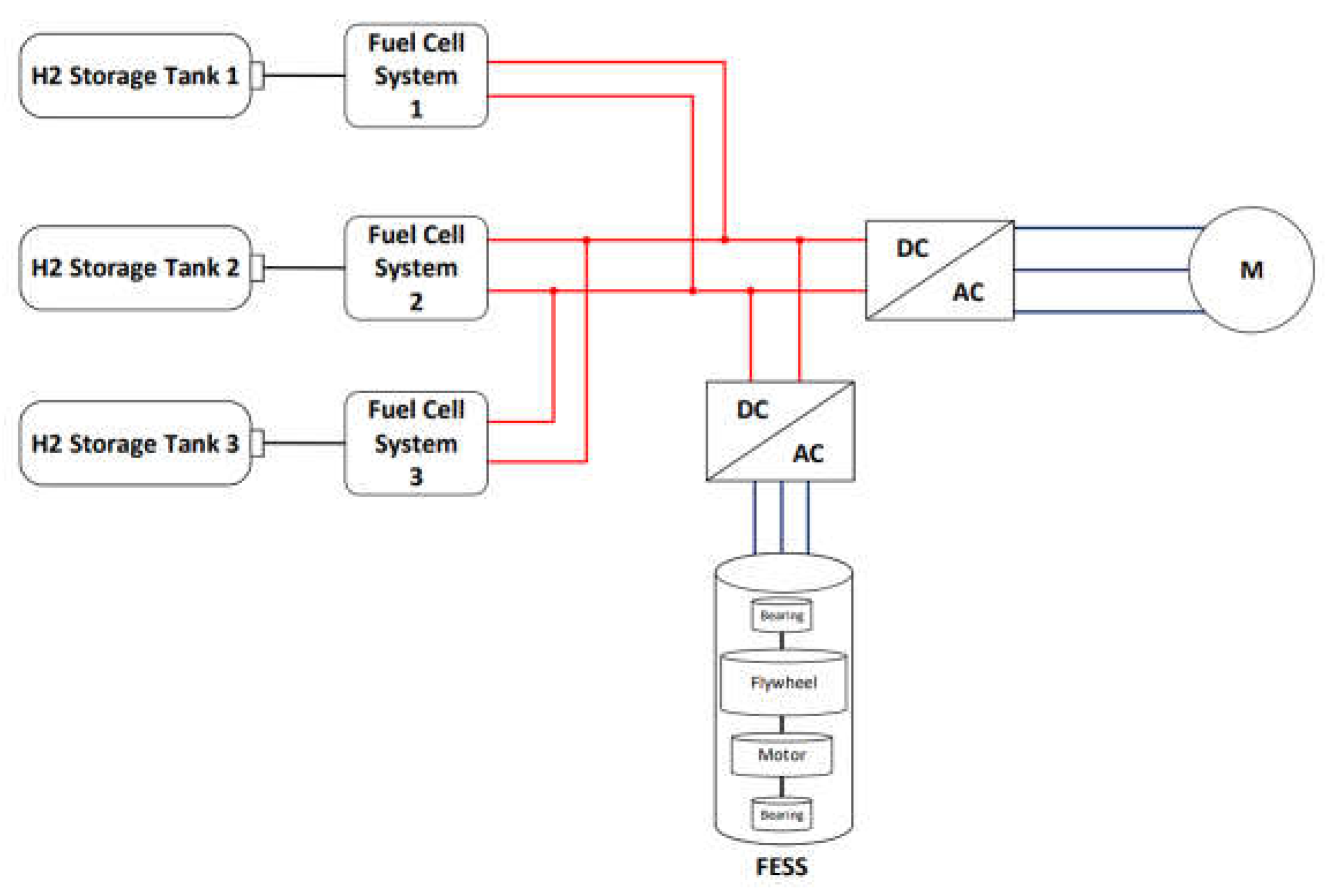

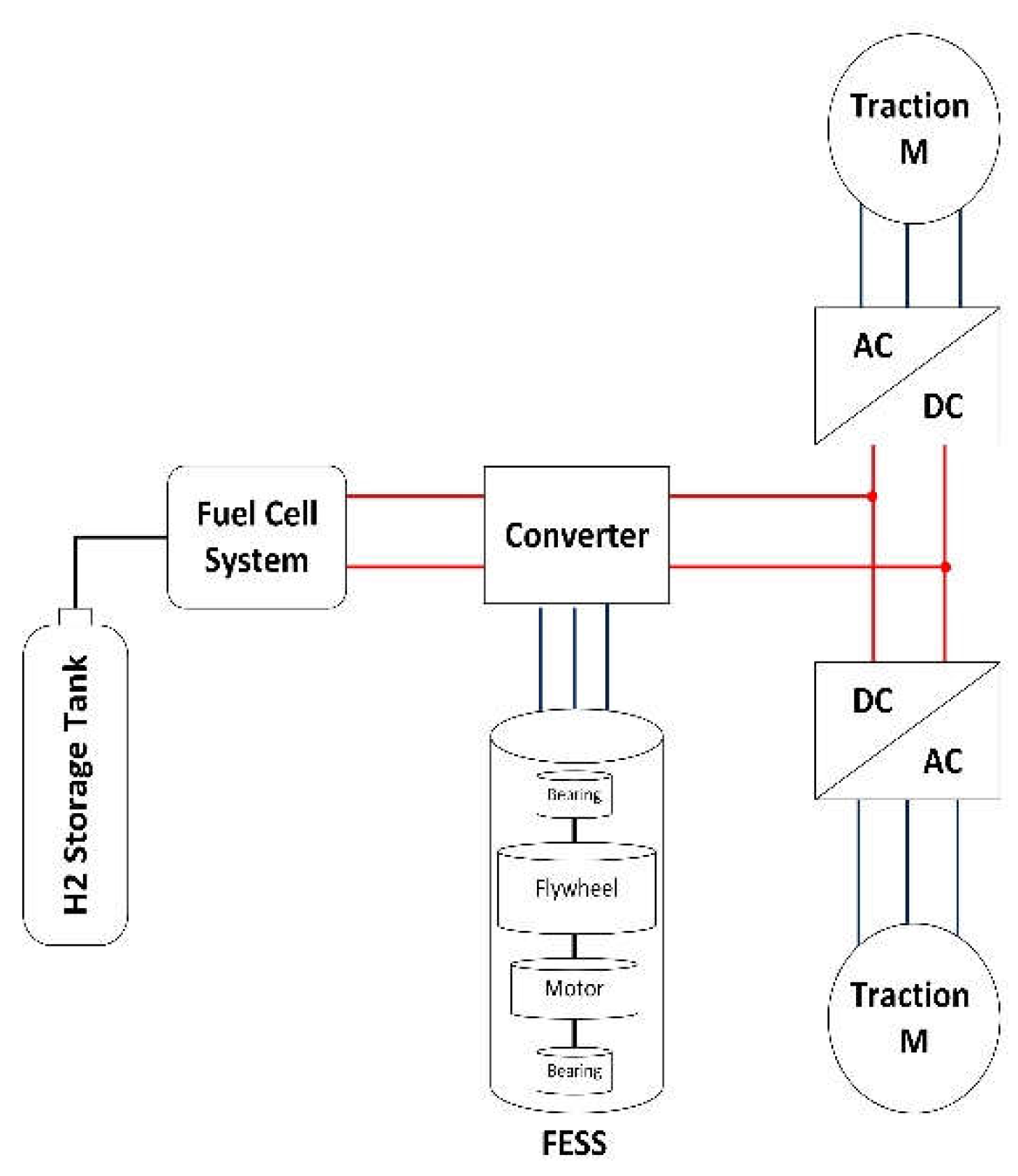

4.1.2. Fuel Cell Electric Vehicle (FCEV)

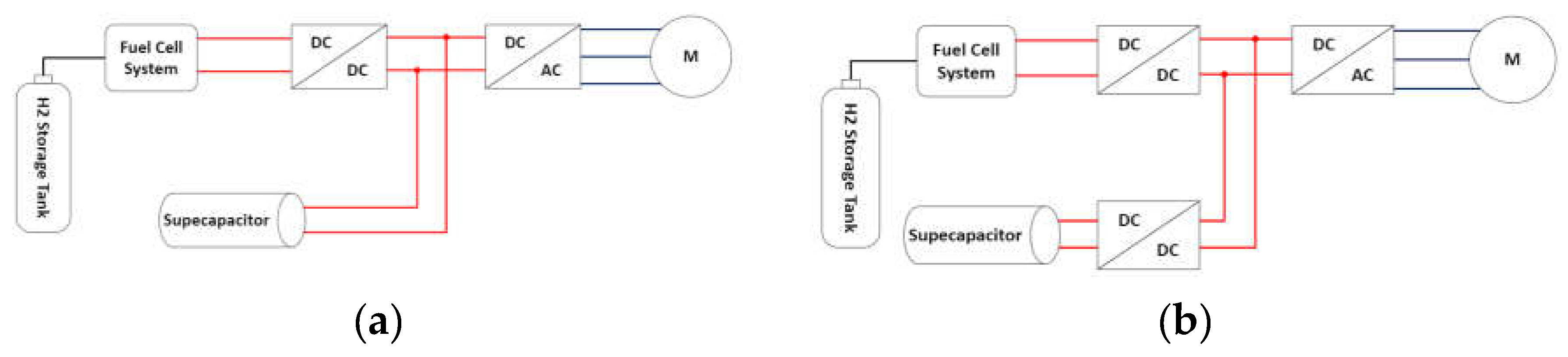

- Direct Parallel Connection/Semi-active Topology: In this setup, the SC is connected directly to the DC-link without a DC/DC converter while the FC is connected to the DC-link with a non-bidirectional DC/DC converter as depicted in Figure 7.a. This direct connection simplifies the circuitry and control strategies, enhancing cost-effectiveness by eliminating the need for a DC/DC converter and enabling faster response times to power demands. However, this arrangement can lead to a voltage mismatch between the SC and the DC-link, particularly as the SoC of the SC changes. There is no precise control of the power flow between the SC and the system, which could lead to instability under varying operational conditions and increased wear, ultimately reducing their lifespan [58,59,60].

- Indirect Parallel Connection/Active Topology: In this configuration, Figure 7.b, the SC is connected through a DC/DC converter to the DC-link, while the FC is connected to the DC-link with a non-bidirectional DC/DC converter. This arrangement allows for voltage regulation, ensuring optimal charging/discharging of SCs and maintaining a stable system voltage, a necessity given the voltage variation of SC according to its SoC [60]. Precise control of the power flow is achievable, using SCs under optimal conditions and ensuring their longevity. The converters can act as a buffer, protecting SCs from sudden voltage spikes. On the other hand, the complexity of the systems increases the requirement of sophisticated management algorithms, while converters raise the manufacturing cost [26,58,59].

- Direct Parallel Connection of both: In this configuration, Figure 8.a, both the BT and the FC are connected directly to the DC-link without any DC/DC converters. Clearly, this setup is the most cost-effective, simplest, and easiest to implement in a FCEV. However, the risks associated with backward current flow due to the uncontrollable DC voltage at the DC-link, and the limitations in controlling power flow, are significant drawbacks that render this topology unsuitable for implementation in an FCEV [59,60]. The issue of backward current flow can be mitigated by using diodes, but this solution reduces the overall efficiency [62]. Finally, regenerative braking is not feasible with this topology.

- Direct Parallel Connection of FC: In this setup, the BT is connected through a bidirectional DC/DC converter to the DC-link, while the FC is connected directly to the DC-link [60], as depicted in Figure 8.b. The FC regulates the DC-link voltage, which can exhibit significant variations due to the stochastic nature of the vehicle. This variability can reduce the overall performance of the vehicle [62]. The DC/DC converter facilitates the capture of energy from regenerative braking [59], which helps to offset the efficiency reduction incurred by the implementation of the DC/DC converter.

- Direct Parallel Connection of BT: In this configuration, Figure 9.a, the FC is connected through a non-bidirectional DC/DC converter to the DC-link, while the BT is connected directly to the DC-link [51]. Contrasting with scenario (2), voltage fluctuations at the DC-link are now reduced due to the DC/DC converter and the stable voltage behavior of the BT, which does not vary significantly in comparison to FC behavior. This stability enhances the overall efficiency of the powertrain. The BT also controls the DC-link voltage, and its characteristics play a significant role in maintaining the voltage within acceptable limits [62]. However, this topology does not support capturing energy from regenerative braking [60]. According to a comparison of FCEV topologies in ref. [58], this setup is the most cost-effective one, owing to its efficiency capabilities.

- Indirect Parallel Connection of both: In this topology, FC and BT are connected through a DC/DC converter to the DC-link, while the BT connection is supporting a bidirectional power flow [51,58], as shown in Figure 9.b. This configuration is more complicated than the previous ones, it presents ripple currents that damage the BT system and require a larger filter, which along with the dual DC/DC converters makes this system the costliest. Voltage regulation achieves a stable DC-link voltage [59], alleviating the need of matching power source characteristics. Regenerative braking is enabled in this configuration [60].

- 5.

- BT and FC Parallel Direct Connection: In this topology, both the FC and the BT are directly connected to the DC-link, while the SC is connected through a bidirectional DC/DC converter [63], as depicted in Figure 10.a. The SC enhances energy recovery from regenerative braking, improving overall efficiency. The FC manages the average load, while the BT handles only high-power demands. This method requires a simple control strategy and features reduced complexity in power electronics. The direct connection of the FC is crucial for managing rapid changes in voltage and current in the DC bus [62]. However, the lack of control over the BT and FC does not explicitly yield the best efficiency from the power sources, and could potentially shorten their lifespan.

- 6.

- SC Parallel Direct Connection: In this topology, as shown at Figure 10.b both the FC and the BT are connected through DC/DC converters, with the BT being bidirectional, while the SC is directly connected to the DC-link [64]. In this arrangement, the BT captures energy from regenerative braking, and the SC provides immediate power for dynamic demands due to its direct connection, thus protecting the BT and FC. This setup integrates high power and high energy sources [59]. However, it involves more complex power electronics, while a sophisticated control strategy is required. The cost is higher than in the first topology, and the FC and BT might respond to load changes in delay [62].

- 7.

- BT Parallel Direct Connection: In this configuration, both the FC and the SC are connected through DC/DC converters, as depicted in Figure 11.a, with the SC being bidirectional, while the BT is directly connected to the DC-link [60]. The regenerative braking energy is captured by the SC and the lifespan of the FC is enhanced due to the stabilization that is provided by the DC/DC converter. The BT handles steady-state and low dynamic loads but experiences more stress due to the absence of a DC/DC converter [62].

- 8.

- Parallel Indirect Connection of BT, SC and FC: As presented Figure 11.a in this topology, all power sources are connected to the DC-link, with the SC and BT connected through a bidirectional converter [60]. This configuration allows for the most effective control of energy due to the management of all power sources, thereby improving overall system efficiency [51]. The system can dynamically balance power among the SoC of each power source and regulate the DC-link voltage [59]. For example, both BT and SC can support regenerative braking, depending on which source has the capacity to absorb it. Additionally, given the multiple power sources, in the event of a failure of one source, the system can maintain its performance. However, a highly sophisticated control strategy is required to effectively use this system, and it is the most cost-effective topology. Considering a multi-input converter, as in the Multi-Input Converter Configuration, is surmised to be worthwhile to undergo a financial analysis.

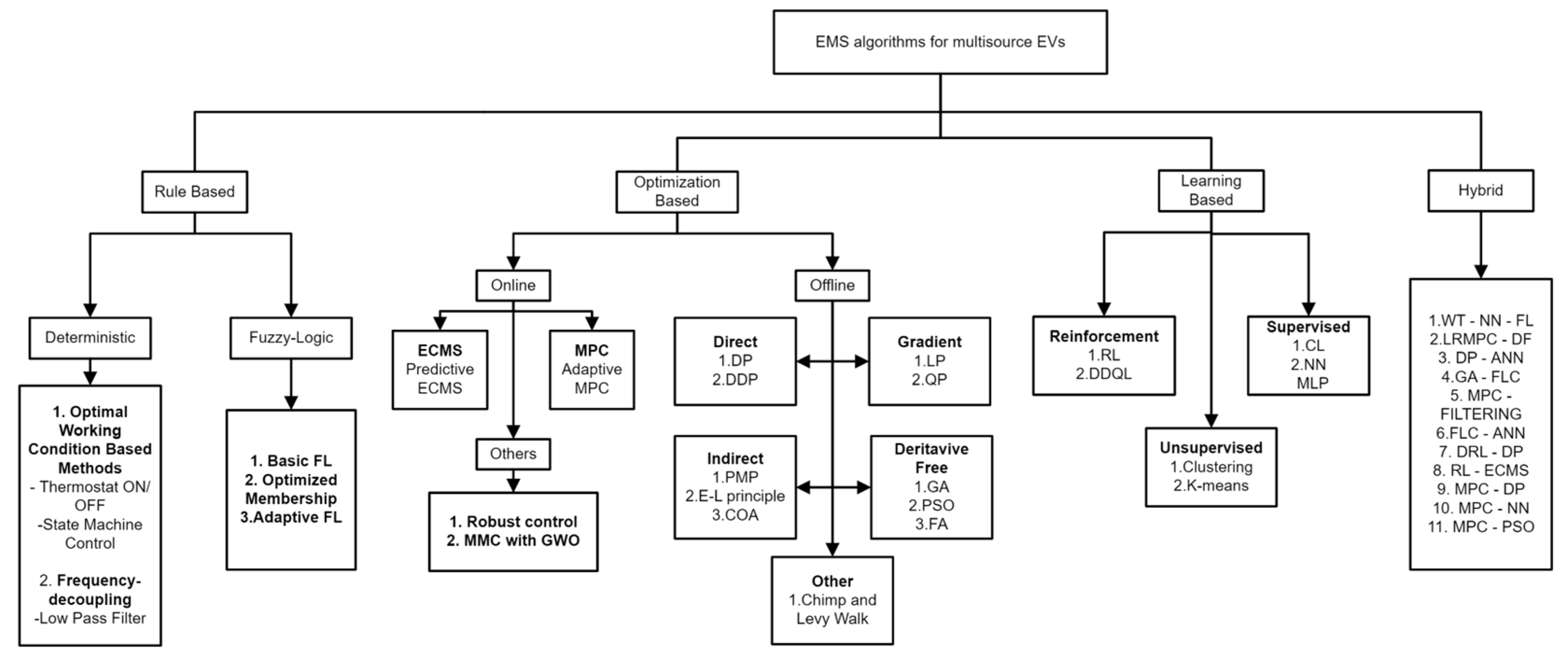

5. Energy Management Algorithms for Multisource EVs

5.1 Energy Management System (EMS)

- Electrical management: Manages the charging and discharging processes to avoid voltage and current inequalities between cells, tailored to the parameters of each energy storage system.

- Thermal management: Ensures the balance of temperature among cells, maintaining the correct operating temperature for all components.

5.2 Optimization Control Strategies of a Multisource EV

- Rule-based algorithms

- Optimization algorithms

- Artificial intelligence-based algorithms

5.3 Rule Based Algorithms

5.3.1. Deterministic Rules

- Optimal working condition-based methods

- 2.

- Frequency-Decoupling Method

5.3.2. Fuzzy-Logic

- 1.

- Basic Fuzzy Logic (BFL):

- 2.

- Optimized Membership:

- 3.

- Adaptive Fuzzy Logic Control:

- 4.

- Predictive Fuzzy Logic Control:

5.4 Optimization Based Algorithms

5.4.1. Online Algorithms

- 1.

- Equivalent Consumption Minimization Strategies (ECMS):

- 2.

- Model Predictive Control Strategy with Differential Evolution:

- 3.

- Others:

5.4.2. Offline Algorithms

- 1.

- Direct Algorithms:

- 2.

- Derivative-Free Algorithms (DFAs)

- 3.

- Indirect Algorithms:

- 4.

- Gradient Algorithms:

- 5.

- Other Algorithms:

5.5 Learning Based

- 1.

- Reinforcement Learning (RL):

- 2.

- Supervised Learning

- 3.

- Unsupervised Learning:

- 4.

- Hybrid

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Denton, T. Electric and Hybrid Vehicles; 711 Third Avenue, New York, 2016. [CrossRef]

- Stephanie Brinley US EV Sales Grew Nearly 52% in 2023. So Why Are Automakers Slowing EV Investments? Available online: https://www.spglobal.com/mobility/en/research-analysis/us-ev-sales-grew-nearly-52-in-2023.html (accessed on 1 August 2024).

- Jerry A. Madrid Electric and Hybrid Vehicle Battery Technologies: Advancements and Challenges. International Journal of Advanced Research in Science, Communication and Technology 2023, 803–807, doi:10.48175/ijarsct-11960. [CrossRef]

- Larminie, James.; Lowry, J. Electric Vehicle Technology Explained; 2nd ed.; John Wiley & Sons: The Atrium, Southern Gate, Chichester, West Sussex, PO19 8SQ, United Kingdom, 2012; ISBN 9781119942733.

- Verma, S.; Mishra, S.; Gaur, A.; Chowdhury, S.; Mohapatra, S.; Dwivedi, G.; Verma, P. A Comprehensive Review on Energy Storage in Hybrid Electric Vehicle. Journal of Traffic and Transportation Engineering (English Edition) 2021, 8, 621–637. [CrossRef]

- Xie, Y.; Zhao, X.; Cai, W.; Qi, G.; Wang, Z.; Zhang, Y.; Yang, Y. Design and Optimisation of Oil Injection Pipe Cooling Structure for Permanent Magnet Synchronous Motors in Hybrid Electric Vehicles. IET Electr Power Appl 2024, 18, 345–355, doi:10.1049/elp2.12393. [CrossRef]

- Bauman, J.; Kazerani, M. A Comparative Study of Fuel-Cell-Battery, Fuel-Cell-Ultracapacitor, and Fuel-Cell-Battery-Ultracapacitor Vehicles. IEEE Trans Veh Technol 2008, 57, 760–769, doi:10.1109/TVT.2007.906379. [CrossRef]

- Khaligh, A.; Li, Z. Battery, Ultracapacitor, Fuel Cell, and Hybrid Energy Storage Systems for Electric, Hybrid Electric, Fuel Cell, and Plug-in Hybrid Electric Vehicles: State of the Art. IEEE Trans Veh Technol 2010, 59, 2806–2814, doi:10.1109/TVT.2010.2047877. [CrossRef]

- Farrokhzad Ershad, N.; Mehrjardi, R.T.; Ehsani, M. Electro-Mechanical EV Powertrain with Reduced Volt-Ampere Rating. IEEE Trans Veh Technol 2019, 68, 224–233, doi:10.1109/TVT.2018.2881385. [CrossRef]

- Tie, S.F.; Tan, C.W. A Review of Energy Sources and Energy Management System in Electric Vehicles. Renewable and Sustainable Energy Reviews 2013, 20, 82–102. [CrossRef]

- Salmasi, F.R. Control Strategies for Hybrid Electric Vehicles: Evolution, Classification, Comparison, and Future Trends. IEEE Trans Veh Technol 2007, 56, 2393–2404, doi:10.1109/TVT.2007.899933. [CrossRef]

- Doucette, R.T.; McCulloch, M.D. A Comparison of High-Speed Flywheels, Batteries, and Ultracapacitors on the Bases of Cost and Fuel Economy as the Energy Storage System in a Fuel Cell Based Hybrid Electric Vehicle. J Power Sources 2011, 196, 1163–1170, doi:10.1016/j.jpowsour.2010.08.100. [CrossRef]

- Ju, F.; Zhang, Q.; Deng, W.; Li, J. Review of Structures and Control of Battery-Supercapacitor Hybrid Energy Storage System for Electric Vehicles; 2014; ISBN 9781479952830. [CrossRef]

- Sulaiman, N.; Hannan, M.A.; Mohamed, A.; Majlan, E.H.; Wan Daud, W.R. A Review on Energy Management System for Fuel Cell Hybrid Electric Vehicle: Issues and Challenges. Renewable and Sustainable Energy Reviews 2015, 52, 802–814. [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Mohamed, A.; Ayob, A. Review of Energy Storage Systems for Electric Vehicle Applications: Issues and Challenges. Renewable and Sustainable Energy Reviews 2017, 69, 771–789. [CrossRef]

- Habib, A.K.M.A.; Hasan, M.K.; Mahmud, M.; Motakabber, S.M.A.; Ibrahimya, M.I.; Islam, S. A Review: Energy Storage System and Balancing Circuits for Electric Vehicle Application. IET Power Electronics 2021, 14, 1–13. [CrossRef]

- Energy Agency, I. Review 2021 Assessing the Effects of Economic Recoveries on Global Energy Demand and CO 2 Emissions in 2021 Global Energy; 2021;

- Iqbal, M.; Benmouna, A.; Becherif, M.; Mekhilef, S. Survey on Battery Technologies and Modeling Methods for Electric Vehicles. Batteries 2023, 9. [CrossRef]

- Piatkowski, P.; Michalska-Pozoga, I.; Szczepanek, M. Fuel Cells in Road Vehicles. Energies (Basel) 2022, 15, doi:10.3390/en15228606. [CrossRef]

- Salado, M.; Gonçalves, R.; Costa, C.M.; Lanceros-Méndez, S. Lithium-Ion Batteries: Electrodes, Separators, and Solid Polymer Electrolytes. In Sustainable Energy Storage in the Scope of Circular Economy: Advanced Materials and Device Design; John Wiley and Sons Ltd, 2023; pp. 43–68 ISBN 9781119817703.

- Xia, Q.; Ren, Y.; Wang, Z.; Yang, D.; Yan, P.; Wu, Z.; Sun, B.; Feng, Q.; Qian, C. Safety Risk Assessment Method for Thermal Abuse of Lithium-Ion Battery Pack Based on Multiphysics Simulation and Improved Bisection Method. Energy 2023, 264, doi:10.1016/j.energy.2022.126228. [CrossRef]

- KURTULMUŞ, Z.N.; KARAKAYA, A. Review of Lithium-Ion, Fuel Cell, Sodium-Beta, Nickel-Based and Metal-Air Battery Technologies Used in Electric Vehicles. International Journal of Energy Applications and Technologies 2023, 10, 103–113, doi:10.31593/ijeat.1307361. [CrossRef]

- Bhuvana, J.; Pandeya, M.; Vishnoi, R. Emerging Battery Technologies for High-Power Electric Vehicles. In Proceedings of the 2024 International Conference on Optimization Computing and Wireless Communication, ICOCWC 2024; Institute of Electrical and Electronics Engineers Inc., 2024.

- Khan, M. Innovations in Battery Technology: Enabling the Revolution in Electric Vehicles and Energy Storage. British Journal of Multidisciplinary and Advanced Studies 2024, 5, 23–41, doi:10.37745/bjmas.2022.0414. [CrossRef]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy Management of Hybrid Electric Vehicles: A Review of Energy Optimization of Fuel Cell Hybrid Power System Based on Genetic Algorithm. Energy Convers Manag 2020, 205. [CrossRef]

- Meyers, R.A.; Elgowainy, A. Encyclopedia of Sustainability Science and Technology Series Editor-in-Chief: A Volume in the Encyclopedia of Sustainability Science and Technology, Second Edition Electric, Hybrid, and Fuel Cell Vehicles; Palm Desert, CA, USA, 2021.

- Deb, N.; Alam, M.Z.; Rahman, T.; Jami, M.S.; Bt. Mansor, M.F.; Tajuddin, H.B.A. Design and Analysis of a Fuel Cell and Batteries in Energy Production for Electric Vehicle. Iranian Journal of Energy and Environment 2023, 14, 301–313, doi:10.5829/ijee.2023.14.03.11. [CrossRef]

- De Wolf, D.; Smeers, Y. Comparison of Battery Electric Vehicles and Fuel Cell Vehicles. World Electric Vehicle Journal 2023, 14, doi:10.3390/wevj14090262. [CrossRef]

- Xu, Z. Hydrogen Fuel-Cell Technology in Electric Vehicles: Current Usage, Materials and Future Applications; 2022; Vol. 2022. [CrossRef]

- Wang, Y.; Leung, D.Y.C.; Xuan, J.; Wang, H. A Review on Unitized Regenerative Fuel Cell Technologies, Part-A: Unitized Regenerative Proton Exchange Membrane Fuel Cells. Renewable and Sustainable Energy Reviews 2016, 65, 961–977. [CrossRef]

- Sharma, S.; Panwar, A.K.; Tripathi, M.M. Storage Technologies for Electric Vehicles. Journal of Traffic and Transportation Engineering (English Edition) 2020, 7, 340–361. [CrossRef]

- Kularatna, N.; Subasinghage, K.; Gunawardane, K.; Jayananda, D.; Ariyarathna, T. Supercapacitor-Assisted Techniques and Supercapacitor-Assisted Loss Management Concept: New Design Approaches to Change the Roadmap of Power Conversion Systems. Electronics (Switzerland) 2021, 10. [CrossRef]

- Şahin, M.E.; Blaabjerg, F. A Hybrid PV-Battery/Supercapacitor System and a Basic Active Power Control Proposal in MATLAB/Simulink. Electronics (Switzerland) 2020, 9, doi:10.3390/electronics9010129. [CrossRef]

- Makuwatsine, T.T.; Gill, A.; Gupta, S.; Chauhan, S. Supercapacitor and Battery Hybrid Energy Storage System for Electric Vehicle. In Proceedings of the 2023 3rd Asian Conference on Innovation in Technology, ASIANCON 2023; Institute of Electrical and Electronics Engineers Inc., 2023.

- Rajagopal, S.; Pulapparambil Vallikkattil, R.; Mohamed Ibrahim, M.; Velev, D.G. Electrode Materials for Supercapacitors in Hybrid Electric Vehicles: Challenges and Current Progress. Condens Matter 2022, 7. [CrossRef]

- Tundwal, A.; Kumar, H.; Binoj, B.J.; Sharma, R.; Kumar, G.; Kumari, R.; Dhayal, A.; Yadav, A.; Singh, D.; Kumar, P. Developments in Conducting Polymer-, Metal Oxide-, and Carbon Nanotube-Based Composite Electrode Materials for Supercapacitors: A Review. RSC Adv 2024, 14, 9406–9439. [CrossRef]

- Laadjal, K.; Marques Cardoso, A.J. A Review of Supercapacitors Modeling, SoH, and SoE Estimation Methods: Issues and Challenges. Int J Energy Res 2021, 45, 18424–18440. [CrossRef]

- Li, H.; Chu, J.; Sun, S. High-Performance Flywheel Hybrid Powertrain. Sustainability (Switzerland) 2022, 14, doi:10.3390/su14138076. [CrossRef]

- Amiryar, M.E.; Pullen, K.R.; Nankoo, D. Development of a High-Fidelity Model for an Electrically Driven Energy Storage Flywheel Suitable for Small Scale Residential Applications. Applied Sciences (Switzerland) 2018, 8, doi:10.3390/app8030453. [CrossRef]

- Ehsani, M.; Singh, K.V.; Bansal, H.O.; Mehrjardi, R.T. State of the Art and Trends in Electric and Hybrid Electric Vehicles. Proceedings of the IEEE 2021, 109, 967–984, doi:10.1109/JPROC.2021.3072788. [CrossRef]

- Lin, Z.; Li, D.; Zou, Y. Energy Efficiency of Lithium-Ion Batteries: Influential Factors and Long-Term Degradation. J Energy Storage 2023, 74, doi:10.1016/j.est.2023.109386. [CrossRef]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy Management of Hybrid Electric Vehicles: A Review of Energy Optimization of Fuel Cell Hybrid Power System Based on Genetic Algorithm. Energy Convers Manag 2020, 205. [CrossRef]

- Verma, S.; Mishra, S.; Gaur, A.; Chowdhury, S.; Mohapatra, S.; Dwivedi, G.; Verma, P. A Comprehensive Review on Energy Storage in Hybrid Electric Vehicle. Journal of Traffic and Transportation Engineering (English Edition) 2021, 8, 621–637. [CrossRef]

- Holtkamp, M.; Alonso, G. RAQ Issue 179: Energy Storage Using Supercapacitors: How Big Is Big Enough?; 2020; Vol. 54;.

- Tafazzoli Mehrjardi, R.; Ershad, N.F.; Ehsani, M. Transmotor-Based Powertrain for High-Performance Electric Vehicle. IEEE Transactions on Transportation Electrification 2020, 6, 1199–1210, doi:10.1109/TTE.2020.2995872. [CrossRef]

- Ershad, N.F.; Mehrjardi, R.; Ehsani, M. Development of a Kinetic Energy Recovery System Using an Active Electromagnetic Slip Coupling. IEEE Transactions on Transportation Electrification 2019, 5, 456–464, doi:10.1109/TTE.2019.2891045. [CrossRef]

- Mehrjardi, R.T.; Ershad, N.F.; Ehsani, M. Transmotor-Flywheel Powertrain Assisted by Ultracapacitor. IEEE Transactions on Transportation Electrification 2022, 8, 3686–3695, doi:10.1109/TTE.2022.3152793. [CrossRef]

- Ershad, N.F.; Mehrjardi, R.T.; Ehsani, M. Efficient Flywheel-Based All-Wheel-Drive Electric Powertrain. IEEE Transactions on Industrial Electronics 2021, 68, 5661–5671, doi:10.1109/TIE.2020.2992942. [CrossRef]

- Raghuwanshi, A.; Ojha, A. An Overview of the Regenerative Braking Technique and Energy Storage Systems in Electric, Hybrid, and Plug-In Hybrid Electric Vehicles. In Proceedings of the 2023 IEEE International Students’ Conference on Electrical, Electronics and Computer Science, SCEECS 2023; Institute of Electrical and Electronics Engineers Inc., 2023.

- Sayed, K.; Abdel-Khalek, S.; Zakaly, H.M.H.; Aref, M. Energy Management and Control in Multiple Storage Energy Units (Battery–Supercapacitor) of Fuel Cell Electric Vehicles. Materials 2022, 15, doi:10.3390/ma15248932. [CrossRef]

- IEEE Staff 2017 IEEE Transportation Electrification Conference and Expo (ITEC).; IEEE, 2017; ISBN 9781509039531.

- Hredzak, B.; Agelidis, V.G.; Jang, M. A Model Predictive Control System for a Hybrid Battery-Ultracapacitor Power Source. IEEE Trans Power Electron 2014, 29, 1469–1479, doi:10.1109/TPEL.2013.2262003. [CrossRef]

- Ehsani Mehrdad; Gao Yimin; Longo Stefano; Ebrahimi Kambiz Modern Electric, Hybrid Electric, and Fuel Cell Vehicles Third Edition; 2018.

- Dhand, A.; Pullen, K. Analysis of Dual Mode Continuously Variable Transmission for Flywheel Energy Storage Systems. In Proceedings of the SAE Technical Papers; SAE International, April 5 2016; Vol. 2016-April.

- Dhand, A.; Pullen, K. Analysis of Continuously Variable Transmission for Flywheel Energy Storage Systems in Vehicular Application. Proc Inst Mech Eng C J Mech Eng Sci 2015, 229, 273–290, doi:10.1177/0954406214533096. [CrossRef]

- Dhand, A.; Pullen, K. Optimal Energy Management for a Flywheel-Assisted Battery Electric Vehicle. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering 2015, 229, 1672–1682, doi:10.1177/0954407014567720. [CrossRef]

- Marzougui, H.; Kadri, A.; Bacha, F. Rule-Based Power Sharing Strategy for a Fuel Cell-Supercapacitor Vehicle. In Proceedings of the 2021 IEEE 2nd International Conference on Signal, Control and Communication, SCC 2021; Institute of Electrical and Electronics Engineers Inc., 2021; pp. 113–118.

- Li, M.; Yu, P.; Wang, Y.; Sun, Z.; Chen, Z. Topology Comparison and Sensitivity Analysis of Fuel Cell Hybrid Systems for Electric Vehicles. IEEE Transactions on Transportation Electrification 2023, 9, 5111–5121, doi:10.1109/TTE.2022.3218341. [CrossRef]

- Kasimalla, V.K.R.; Naga Srinivasulu, G.; Velisala, V. A Review on Energy Allocation of Fuel Cell/Battery/Ultracapacitor for Hybrid Electric Vehicles. Int J Energy Res 2018, 42, 4263–4283. [CrossRef]

- Yu, P.; Li, M.; Wang, Y.; Chen, Z. Fuel Cell Hybrid Electric Vehicles: A Review of Topologies and Energy Management Strategies. World Electric Vehicle Journal 2022, 13. [CrossRef]

- Kök, C.; Mert, S.O. Energetic and Exergetic Performance Investigation of Different Topologies for Hybrid Fuel Cell Vehicles. Int J Energy Res 2023, 2023, doi:10.1155/2023/7165382. [CrossRef]

- Ragab, A.; Marei, M.I.; Mokhtar, M. Comprehensive Study of Fuel Cell Hybrid Electric Vehicles: Classification, Topologies, and Control System Comparisons. 2023, doi:10.20944/preprints202310.1459.v1. [CrossRef]

- Xie, C.; Xu, X.; Bujlo, P.; Shen, D.; Zhao, H.; Quan, S. Fuel Cell and Lithium Iron Phosphate Battery Hybrid Powertrain with an Ultracapacitor Bank Using Direct Parallel Structure. J Power Sources 2015, 279, 487–494, doi:10.1016/j.jpowsour.2015.01.029. [CrossRef]

- Gao, D.; Jin, Z.; Lu, Q. Energy Management Strategy Based on Fuzzy Logic for a Fuel Cell Hybrid Bus. J Power Sources 2008, 185, 311–317, doi:10.1016/j.jpowsour.2008.06.083. [CrossRef]

- Kuo, J.K.; Hsieh, H.K. Research of Flywheel System Energy Harvesting Technology for Fuel Cell Hybrid Vehicles. Fuel Cells 2013, 13, 1234–1241, doi:10.1002/fuce.201300129. [CrossRef]

- Hearn’, C.S.; Flynn’, M.M.; Lewis’, M.C.; Thompson’, R.C.; Murphy’, B.T.; Longoria2, R.G. Low Cost Flywheel Energy Storage for a Fuel Cell Powered Transit Bus; 2007;

- D’Ovidio G.; Masciovecchio C.; Rotondale N. City Bus Powered by Hydrogen Fuel Cell and Flywheel Energy Storage System; IEEE International Electric Vehicle Conference: Florence, Italy, 2014; ISBN 9781479960750.

- Gino D’Ovidio; Carlo Masciovecchio; Antonio Ometto; Carlo Villante On Design of Hybrid Power Unit with Partitioned Fuel-Cell and Flywheel Energy Sorage System for City Transit Buses; International Symposium on Power Electronics, Electrical Drives, Automation and Motion, 2020; ISBN 9781728170190.

- Rimpas, D.; Kaminaris, S.D.; Aldarraji, I.; Piromalis, D.; Vokas, G.; Papageorgas, P.G.; Tsaramirsis, G. Energy Management and Storage Systems on Electric Vehicles: A Comprehensive Review. Mater Today Proc 2022, 61, 813–819, doi:10.1016/j.matpr.2021.08.352. [CrossRef]

- Rimpas, D.; Kaminaris, S.D.; Aldarraji, I.; Piromalis, D.; Vokas, G.; Papageorgas, P.G.; Tsaramirsis, G. Energy Management and Storage Systems on Electric Vehicles: A Comprehensive Review. Mater Today Proc 2022, 61, 813–819, doi:10.1016/j.matpr.2021.08.352. [CrossRef]

- Farrokhi, E.; Safari, P.; Ghoreishy, H. A Rule-Based Energy Management Strategy with Current Estimation for Controlling Grid Connected Hybrid Energy Storage System. In Proceedings of the 2023 14th Power Electronics, Drive Systems, and Technologies Conference, PEDSTC 2023; Institute of Electrical and Electronics Engineers Inc., 2023.

- Barhoumi, N.; Marzougui, H.; Bacha, F.; Boukhnifer, M. Energy Management Algorithm of Fuel Cell/Supercapacitor System for Electrical Vehicle. In Proceedings of the 2022 8th International Conference on Control, Decision and Information Technologies, CoDIT 2022; Institute of Electrical and Electronics Engineers Inc., 2022; pp. 1415–1420.

- Kraa, O.; Boualem, S.; Kermadi, M. Flow-Chart Power Management for Grid-Connected Hybrid System. EEA - Electrotehnica, Electronica, Automatica 2023, 71, 75–82, doi:10.46904/eea.23.71.1.1108008. [CrossRef]

- Moulik, B.; Söffker, D. Optimal Rule-Based Power Management for Online, Real-Time Applications in Hevs with Multiple Sources and Objectives: A Review. Energies (Basel) 2015, 8, 9049–9063. [CrossRef]

- Hajji, B.; Mellit, A.; Marco Tina, G.; Rabhi, A.; Launay, J.; Eddine Naimi Editors, S. Proceedings of the 2nd International Conference on Electronic Engineering and Renewable Energy Systems; Saidia, Morocco, 2020;

- Trovao, J.P.F.; Roux, M.A.; Menard, E.; Dubois, M.R. Energy- and Power-Split Management of Dual Energy Storage System for a Three-Wheel Electric Vehicle. IEEE Trans Veh Technol 2017, 66, 5540–5550, doi:10.1109/TVT.2016.2636282. [CrossRef]

- Belkhier, Y.; Oubelaid, A.; Shaw, R.N. Hybrid Power Management and Control of Fuel Cells-Battery Energy Storage System in Hybrid Electric Vehicle under Three Different Modes. Energy Storage 2024, 6, doi:10.1002/est2.511. [CrossRef]

- Omakor, J.; Alzayed, M.; Chaoui, H. Particle Swarm-Optimized Fuzzy Logic Energy Management of Hybrid Energy Storage in Electric Vehicles. Energies (Basel) 2024, 17, doi:10.3390/en17092163. [CrossRef]

- Chen, J.; Xu, C.; Wu, C.; Xu, W. Adaptive Fuzzy Logic Control of Fuel-Cell-Battery Hybrid Systems for Electric Vehicles. IEEE Trans Industr Inform 2018, 14, 292–300, doi:10.1109/TII.2016.2618886. [CrossRef]

- Beşkardeş, A.; Hameş, Y.; Kaya, K. A Comprehensive Review on Fuzzy Logic Control Systems for All, Hybrid, and Fuel Cell Electric Vehicles. Soft comput 2024, doi:10.1007/s00500-023-09454-5. [CrossRef]

- Castaings, A.; Lhomme, W.; Trigui, R.; Bouscayrol, A. Energy Management of a Multi-Source Vehicle by λ-Control. Applied Sciences (Switzerland) 2020, 10, doi:10.3390/APP10186541. [CrossRef]

- Huseyin A. Yavasoglu; Chuan Shi, S.M.I.; Kursad Gokce Energy Storage Systems for EVs with Two Propulsion Machines; IEEE: Gebze, Kocaeli Turkey, 2017; ISBN 9781509039531.

- Tang, Y.; Xie, J.; Shen, Y.; Sun, S.; Li, Y. Energy Management Strategy Based on Model Predictive Control-Differential Evolution for Hybrid Energy Storage System in Electric Vehicles. IET Electrical Systems in Transportation 2024, 2024, doi:10.1049/2024/8840942. [CrossRef]

- Yulong, Z.; Weida, W.; Changle, X.; Hui, L.; Langari, R. Research and Bench Test of Nonlinear Model Predictive Control-Based Power Allocation Strategy for Hybrid Energy Storage System. IEEE Access 2018, 6, 70770–70787, doi:10.1109/ACCESS.2018.2876440. [CrossRef]

- Majeed, M.A.; Khan, M.G.; Asghar, F. Nonlinear Control of Hybrid Energy Storage System for Hybrid Electric Vehicles. International Transactions on Electrical Energy Systems 2020, 30, doi:10.1002/2050-7038.12268. [CrossRef]

- Hu, L.; Tian, Q.; Zou, C.; Huang, J.; Ye, Y.; Wu, X. A Study on Energy Distribution Strategy of Electric Vehicle Hybrid Energy Storage System Considering Driving Style Based on Real Urban Driving Data. Renewable and Sustainable Energy Reviews 2022, 162, doi:10.1016/j.rser.2022.112416. [CrossRef]

- Cui, Z.; Guo, Z.; Manthiram, A. Irreparable Interphase Chemistry Degradation Induced by Temperature Pulse in Lithium-Ion Batteries. Angewandte Chemie - International Edition 2023, 62, doi:10.1002/anie.202313437. [CrossRef]

- Ahsan, M.B.F.; Mekhilef, S.; Soon, T.K.; Usama, M.; Binti Mubin, M.; Seyedmahmoudian, M.; Stojcevski, A.; Mokhlis, H.; Shrivastava, P.; Alshammari, O. Optimal Sizing and Cost Analysis of Hybrid Energy Storage System for EVs Using Metaheuristic PSO and Firefly Algorithms. Results in Engineering 2024, 23, doi:10.1016/j.rineng.2024.102358. [CrossRef]

- Zheng, C.; Li, W.; Liang, Q. An Energy Management Strategy of Hybrid Energy Storage Systems for Electric Vehicle Applications. IEEE Trans Sustain Energy 2018, 9, 1880–1888, doi:10.1109/TSTE.2018.2818259. [CrossRef]

- Intidam, A.; Fadil, H. El; Nady, S.; Benzouina, O.; Koundi, M.; Rachid, K. Nonlinear Optimization Technique for Energy Management of HESS in Fuel Cell Electric Vehicle. In Proceedings of the IFAC-PapersOnLine; Elsevier B.V., 2022; Vol. 55, pp. 426–431.

- Mounica, V.; Obulesu, Y.P. An Energy Management Scheme for Improving the Fuel Economy of a Fuel Cell/Battery/Supercapacitor-Based Hybrid Electric Vehicle Using the Coyote Optimization Algorithm (COA). Front Energy Res 2023, 11, doi:10.3389/fenrg.2023.1180531. [CrossRef]

- Li, X.; Li, M.; Habibi, M.; Najaafi, N.; Safarpour, H. Optimization of Hybrid Energy Management System Based on High-Energy Solid-State Lithium Batteries and Reversible Fuel Cells. Energy 2023, 283, doi:10.1016/j.energy.2023.128454. [CrossRef]

- Ranjbaran, P.; Ebrahimi, J.; Bakhshai, A.; Jain, P. Reinforcement Learning-Based Approaches to Energy Management of Hybrid Energy Storage Systems in Electric Vehicles. In Proceedings of the Proceedings of the International Conference on Power Electronics and Drive Systems; Institute of Electrical and Electronics Engineers Inc., 2023; Vol. 2023-August.

- Shuai, Q.; Wang, Y.; Jiang, Z.; Hua, Q. Reinforcement Learning-Based Energy Management for Fuel Cell Electrical Vehicles Considering Fuel Cell Degradation. Energies (Basel) 2024, 17, doi:10.3390/en17071586. [CrossRef]

- Mukhcrjee, N.; Sarkar, S. A Deep Concurrent Learning-Based Robust and Optimal Energy Management Strategy for Hybrid Energy Storage Systems in Plug-in Hybrid Electric Vehicles. In Proceedings of the 2023 IEEE Vehicle Power and Propulsion Conference, VPPC 2023 - Proceedings; Institute of Electrical and Electronics Engineers Inc., 2023.

- Yavasoglu, H.A.; Tetik, Y.E.; Ozcan, H.G. Neural Network-Based Energy Management of Multi-Source (Battery/UC/FC) Powered Electric Vehicle. Int J Energy Res 2020, 44, 12416–12429, doi:10.1002/er.5429. [CrossRef]

- Jui, J.J.; Ahmad, M.A.; Molla, M.M.I.; Rashid, M.I.M. Optimal Energy Management Strategies for Hybrid Electric Vehicles: A Recent Survey of Machine Learning Approaches. Journal of Engineering Research (Kuwait) 2024. [CrossRef]

- Sun, H.; Tao, F.; Fu, Z.; Gao, A.; Jiao, L. Driving-Behavior-Aware Optimal Energy Management Strategy for Multi-Source Fuel Cell Hybrid Electric Vehicles Based on Adaptive Soft Deep-Reinforcement Learning. IEEE Transactions on Intelligent Transportation Systems 2023, 24, 4127–4146, doi:10.1109/TITS.2022.3233564. [CrossRef]

- Chen, T.C.; Ibrahim Alazzawi, F.J.; Grimaldo Guerrero, J.W.; Chetthamrongchai, P.; Dorofeev, A.; Ismael, A.M.; Al Ayub Ahmed, A.; Akhmadeev, R.; Latipah, A.J.; Esmail Abu Al-Rejal, H.M. Development of Machine Learning Methods in Hybrid Energy Storage Systems in Electric Vehicles. Math Probl Eng 2022, 2022, doi:10.1155/2022/3693263. [CrossRef]

- Sidharthan Panaparambil, V.; Kashyap, Y.; Vijay Castelino, R. A Review on Hybrid Source Energy Management Strategies for Electric Vehicle. Int J Energy Res 2021, 45, 19819–19850. [CrossRef]

- Zhang, Q.; Wang, L.; Li, G.; Liu, Y. A Real-Time Energy Management Control Strategy for Battery and Supercapacitor Hybrid Energy Storage Systems of Pure Electric Vehicles. J Energy Storage 2020, 31, doi:10.1016/j.est.2020.101721. [CrossRef]

- Li, S.; Hou, Z.; Chu, L.; Jiang, J.; Zhang, Y. A Novel Learning-Based Robust Model Predictive Control Energy Management Strategy for Fuel Cell Electric Vehicles. 2022. [CrossRef]

| Storage System | Advantages | Disadvantages | Power Source | Efficiency | Future Trends |

|---|---|---|---|---|---|

| BT [5,18,19,20,21,22,23,24] |

High energy density | High Production costs | Main | 80%+ depending on the technology [41] |

Solid state |

| Effective thermal management | Degradation over time | Nickel-Based | |||

| Availability | Safety risks | Metal-air | |||

| FC [8,26,27,29,30,42,43] |

High efficiency | Expensive due to platinum | Main | Up to 60% | Development of alternative catalysts |

| Longer lifespan than BTs | Slow response time | Scaling up green hydrogen | |||

| Instant resupply | No support of regenerative braking | ||||

| FW [1,7,8,12,26,31,32,34,35,36,37] | High efficiency | High-strength materials required | Supplementary | Up to 85% | Improvement in materials and integration techniques |

| Low maintenance | Complex integration | ||||

| Durability | Safety concerns with high-speed rotation | ||||

| Ideal for regenerative braking | |||||

| SC [10,12,26,38,39,40] |

High power density | Low energy density | Supplementary | Approx. 70-85% [44] | Increasing electrode surface area |

| Fast charge/discharge | High costs | New materials |

| Scenario | Inner Rotor Speed (FW) | Outer Rotor Speed (DS) | Speed Command | Transmotor Role | Power Flow Direction | BT Status |

|---|---|---|---|---|---|---|

| A. Acceleration | Faster | Slower | Increase | Generator & Clutch | Mechanical (FW) -> Electrical (BT) & Mechanical (FW) & Mechanical (DS) | Charging |

| B. Acceleration | Slower |

Faster | Increase | Electric Motor & Clutch | Electrical (BT) -> Mechanical (DS) | Discharging |

| C. Deceleration | Slower | Faster | Decrease | Generator & Clutch | Mechanical (DS) -> Electrical (BT)Mechanical (DS) -> Mechanical (FW) | Charging |

| D. Deceleration | Faster | Slower | Decrease | Electric Motor & Clutch | Mechanical (DS) -> | Charging |

| Electrical (BT) |

| EVs | Power Sources Involved | Topology name | Advantages | Disadvantages | Comments |

|---|---|---|---|---|---|

| BEV [7] |

BT-SC [8,13,26,40,50,51,52,53] |

Passive Cascade BT and SC configuration | Enhanced power performance capability | Significant voltage fluctuations at SC terminals | Inefficient utilization of stored energy in SCs, complex control needed. |

| Active Cascade System | Allows for better maximum power output | Frequent BT charging/discharging cycles, inefficient SC energy storage | Enhances system's power capability but increases wear on BTs. | ||

| Active Cascade System with Reverse BT -SC Connectivity | Efficient control of BT current, reduces BT's capacity requirements | Impossible BT charging from braking energy or from the SC | Provides more efficient control, though limits regenerative capabilities. | ||

| Parallel Passive Cascade System with Two DC-DC converters | Separate control of power flow, enhances flexibility | Requires additional components, increasing complexity and cost | Offers individual control over BTs and SCs. | ||

| Multiple Converter Configuration | Individual control of power flow to each storage unit | High cost, increased complexity | Promising if cost is reduced | ||

| Multi-Input Converter Configuration | Reduces costs and weight, enhances performance | More complex control strategy needed | Common inductor used for all energy sources to manage power flow | ||

| Proposed Hybrid ESS Configuration | Covers maximum power demands with higher-voltage SC, efficient energy distribution during various driving conditions | Relies heavily on control strategy for efficiency | Operates in four modes: low power, high power, braking, and acceleration, optimizing power and energy use | ||

| FCEV | FC-SC [7,12,26,53,57,58,59,60] |

Direct Parallel Connection/Semi-active Topology | Simplifies circuitry, enhances response times | Potential for voltage mismatch, instability | Cost-effective, no DC/DC converter needed |

| Indirect Parallel Connection/Active Topology | Voltage regulation, stable system voltage | Increases system complexity, higher cost | Uses DC/DC converters for precise control | ||

| FC-BT [7,51,58,59,60,61,62] |

Direct Parallel Connection of both | Efficient average load management | Lack of control over BT and FC may reduce efficiency | Simple control strategy, direct connection crucial for rapid changes | |

| Direct Parallel Connection of FC | Manages DC-link voltage, reduces variability | FC regulates DC-link voltage, leading to potential performance issues | DC/DC converter facilitates energy capture from braking | ||

| Direct Parallel Connection of BT | Stabilizes DC-link voltage, enhances powertrain efficiency | Does not support energy capture from regenerative braking | Direct connection stabilizes voltage but stresses BT | ||

| Indirect Parallel Connection of both | Dynamic balance of power among SoC, regulates DC-link voltage | Highly sophisticated control strategy required, most costly | Supports regenerative braking, maintains performance despite failures | ||

| FC-BT-SC [7,12,51,59,60,62,63,64] |

BT and FC Parallel Direct Connection: | Streamlines power management for average loads | Simplistic approach may not yield optimal efficiency | Focuses on managing rapid changes in power demand | |

| SC Parallel Direct Connection | Immediate power for dynamic demands, protects BT and FC | More complex power electronics Sophisticated control required |

Enhances energy recovery from braking, improves overall efficiency | ||

| BT Parallel Direct Connection | Enhances stability of power supply | Limited support for dynamic power management | Prioritizes steady-state and low dynamic loads | ||

| Parallel Indirect Connection of BT, SC and FC | Comprehensive management of energy sources | Requires advanced control systems, increased cost | Maximizes efficiency through sophisticated energy management | ||

| FC-FW [65,66,67,68] |

Independent Control of Multiple FC Stacks in Hybrid Powertrain Topology | Manages load variations effectively, captures braking energy | Complexity in integration, high-speed rotation safety concerns | Reduces FC size, optimizing efficiency | |

| Integrated Hybrid Power System with FC and FESS in Urban Transit Application | Optimizes power usage, reduces operational costs | High initial investment and maintenance expenses | Suitable for applications requiring frequent stops and starts |

| Algorithm Strategy | Learning Approach |

Specific Technique | Advantages | Disadvantages | Comments |

|---|---|---|---|---|---|

| Rule Based | Deterministic [5,57,59,60,71,72,73] |

Optimal working condition based. | High precision in optimal conditions. | Less flexibility, poor at handling unexpected conditions. | Suitable for predictable operations. |

| Frequency Decoupling. | Effective in frequency insolation. | Can be complex to implement. | Enhances control precision but requires detailed parametric adjustments. | ||

| Fuzzy-Logic [5,50,75,76,77,78] |

Basic Fuzzy Logic | Simplifies control, robust to variations. | May not capture complex dynamics. | Used for less complex dynamic systems. | |

| Optimized Membership | Enhances accuracy with tailored functions. | Computationally intensive. | Best for environments that evolve over time. | ||

| Adaptive Fuzzy Logic | Adjusts to dynamic changes, improves with experience. | High cost, increased complexity. | Promising if cost is reduced. | ||

| Optimization Based | Online [52,60,81,82,83,84,85,86] |

ECMS | Real-time optimization of control strategies. | Requires continuous adjustment. | Suitable for dynamic and real-time applications. |

| MPC | Considers future states for decision making. | Computationally intensive. | For systems where future planning is critical. | ||

| Others | Allows for bespoke solutions. | May lack general applicability. | Suitable for unique or niche scenarios. | ||

| Offline [5,88,89,90,91,92] |

Direct | Simplifies problem to direct solutions. | May overlook long-term consequences. | Used for simpler dynamic systems. | |

| Indirect | Can handle complex problems. | Indirect methods may be slower and less intuitive. | Useful for complex operational models. | ||

| Gradient | Efficient path to optimum. | Sensitive to initial conditions. | Requires smooth problem formulations. | ||

| Derivative free | Useful where derivatives are not available. | Often slower and less accurate. | Used where analytical gradients are not available. | ||

| Other | Flexibility in approach. | May not be as well-optimized. | For specialized or less common scenarios. | ||

| Learning based | Supervised Learning [5,60,93,95,100] |

CL | Effective for feature competition and selection. | Requires specific problem structuring, high computation. | Ideal for tasks needing refined feature selection. |

| NN | Excellent for capturing nonlinear relationships in data. | Requires large amounts of data, prone to overfitting. | Suitable for pattern identification and complex modeling. | ||

| Unsupervised [5,60,78,93,96,100] |

MLP | Suited for deep learning tasks. | Computationally intensive. | Used for hierarchical feature extraction | |

| Reinforcement FC-FW [5,60,78,93,94,98,100] |

RL | Adapts based on reward feedback, good for dynamic policies. | Converges slowly, requires significant interaction. | For environments where decision-making is critical. | |

| DDQL | Reduces overestimation of action values. | Complex architecture, needs careful tuning. | Enhances stability and performance in deep RL scenarios. | ||

| Hybrid | Combination [100,101,102] |

1.WT - NN – FL 2. LRMPC – DF 3. DP – ANN 4.GA – FLC 5. MPC - FILTERING 6.FLC – ANN 7. DRL – DP 8. RL – ECMS 9. MPC – DP 10. MPC – NN 11. MPC - PSO |

Integrates strengths of multiple techniques. | More complex to configure and optimize. | For tasks requiring robust, adaptable solutions. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).