Submitted:

26 July 2024

Posted:

26 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Theory and Composite Sensor Design

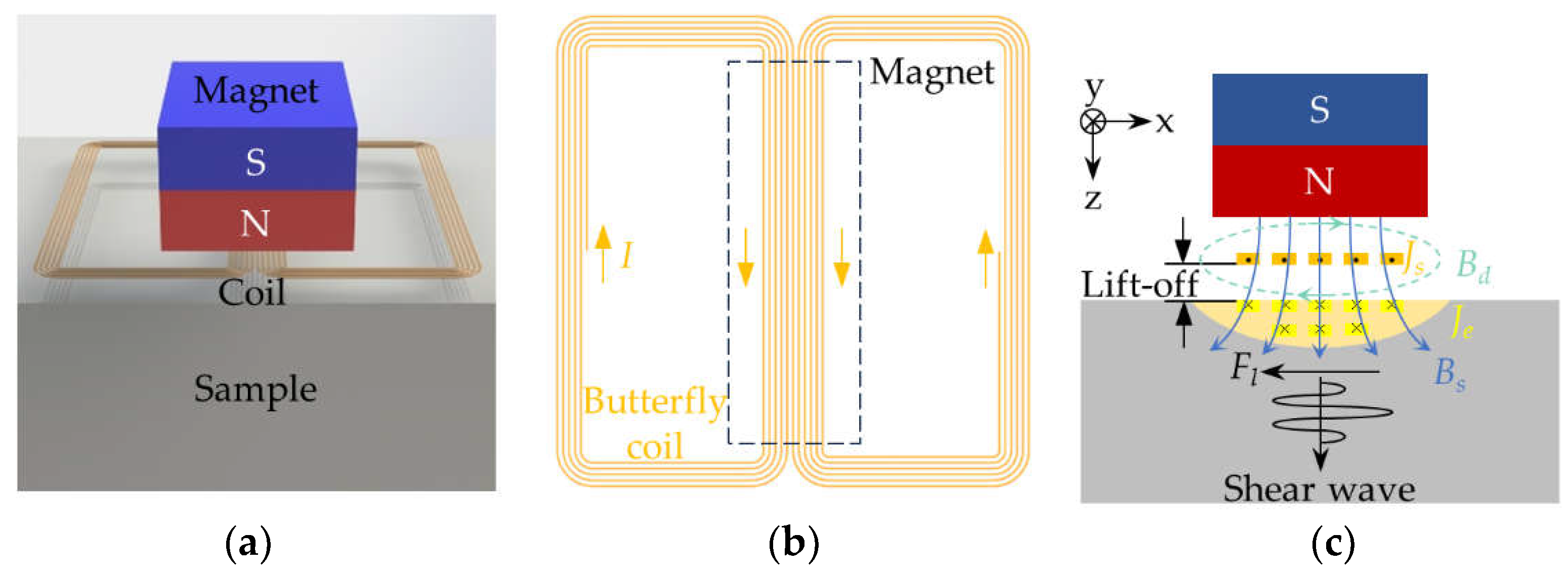

2.1. Principle of bulk wave EMAT

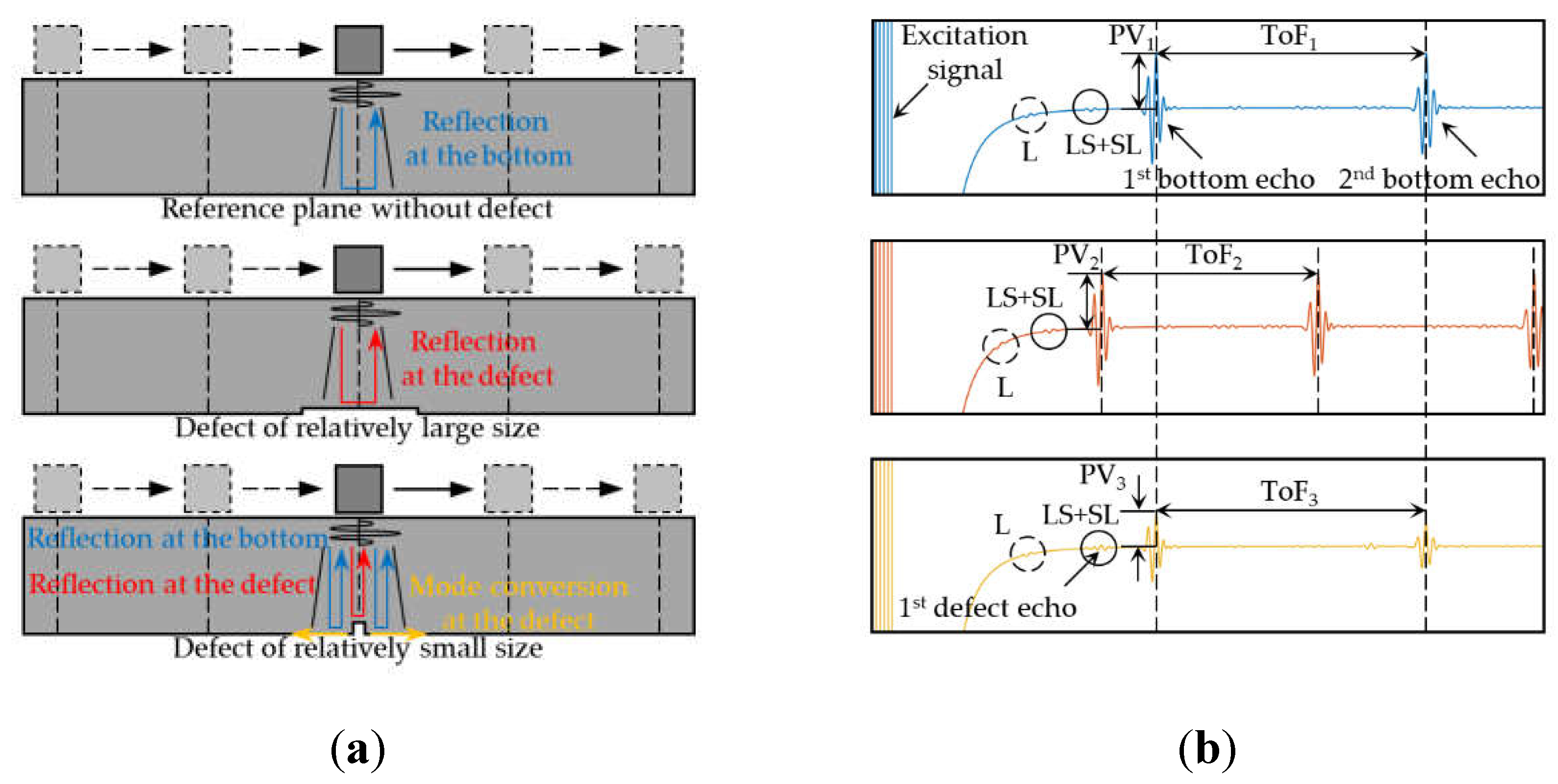

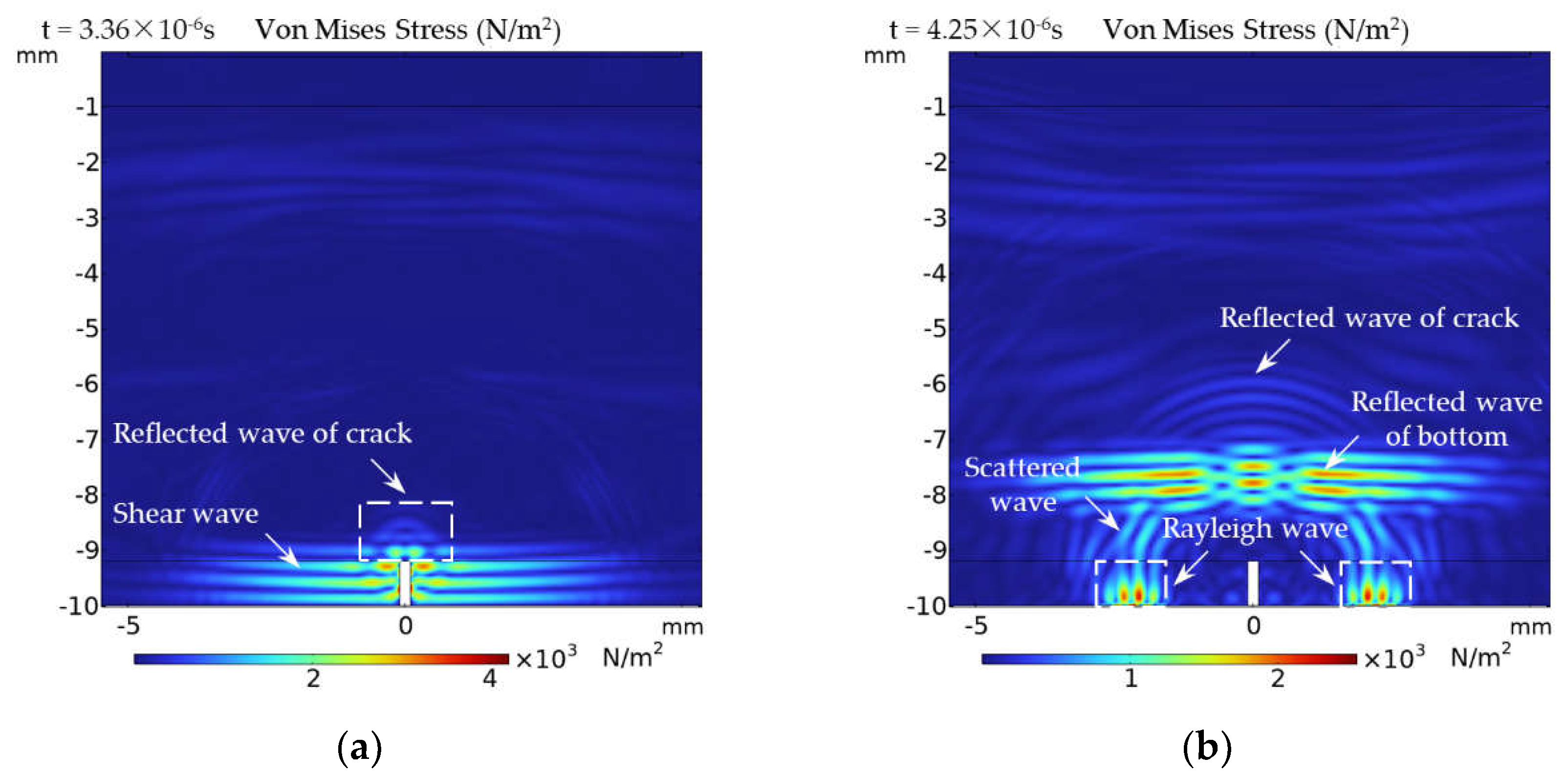

- When there are no defects on the bottom, the excited shear wave is reflected at the bottom, showing several echoes in the time-domain signal. This configuration of EMAT also excites less longitudinal wave, which occurs reflection and mode conversion at the bottom to form reflected longitudinal waves, shear-longitudinal (SL) and longitudinal-shear (LS) converted waves. They are located between adjacent echoes due to their propagation speed, which are considered as noise signals, affecting defect detection. While the ToF1 of adjacent echoes can be used to evaluate the wall thickness of the sample;

- When there are relatively large defects to the probe on the bottom, the beam width of the shear wave excited by EMAT is smaller than the defect width, and a large portion is reflected by the defect, thus showing a changed ToF2;

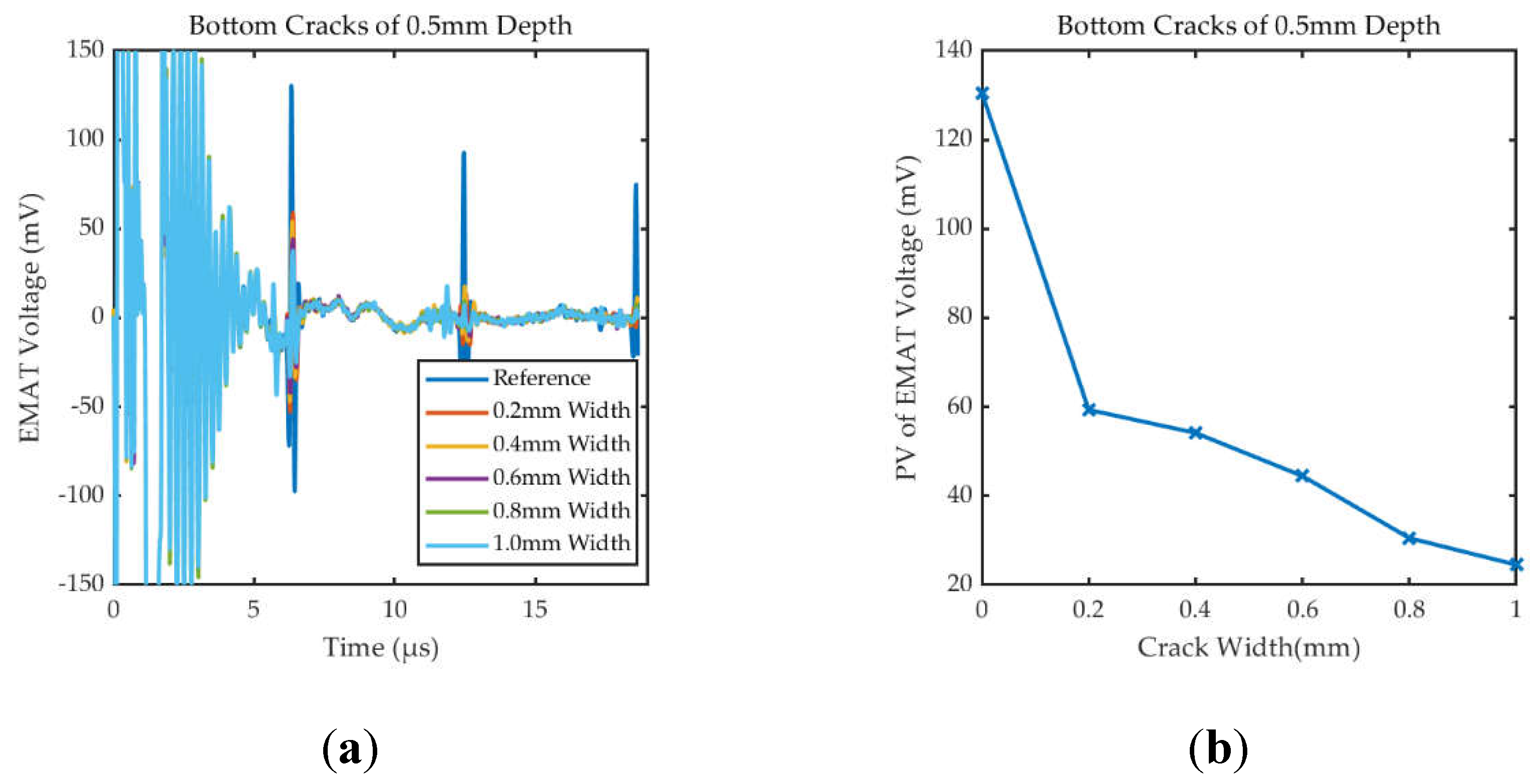

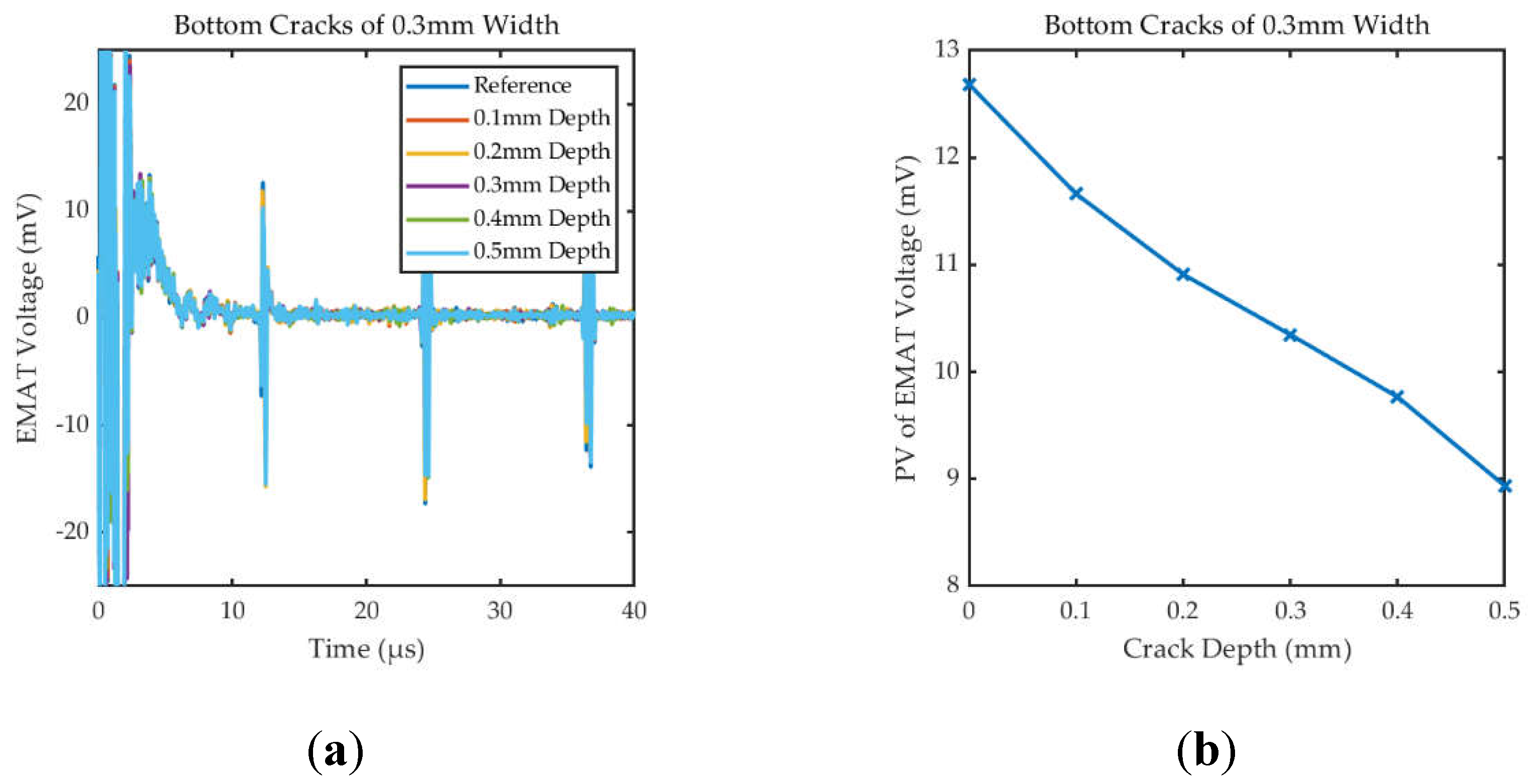

- When there are relatively small defects to the probe on the bottom, such as cracks, the beam width is larger than the defect width, and only a small portion is reflected at the interface of the defect. The rest is reflected at the bottom or affected by the side of the defect to produce scattered waves in other directions, thus showing a changed peak value (PV) of 1st bottom echo.

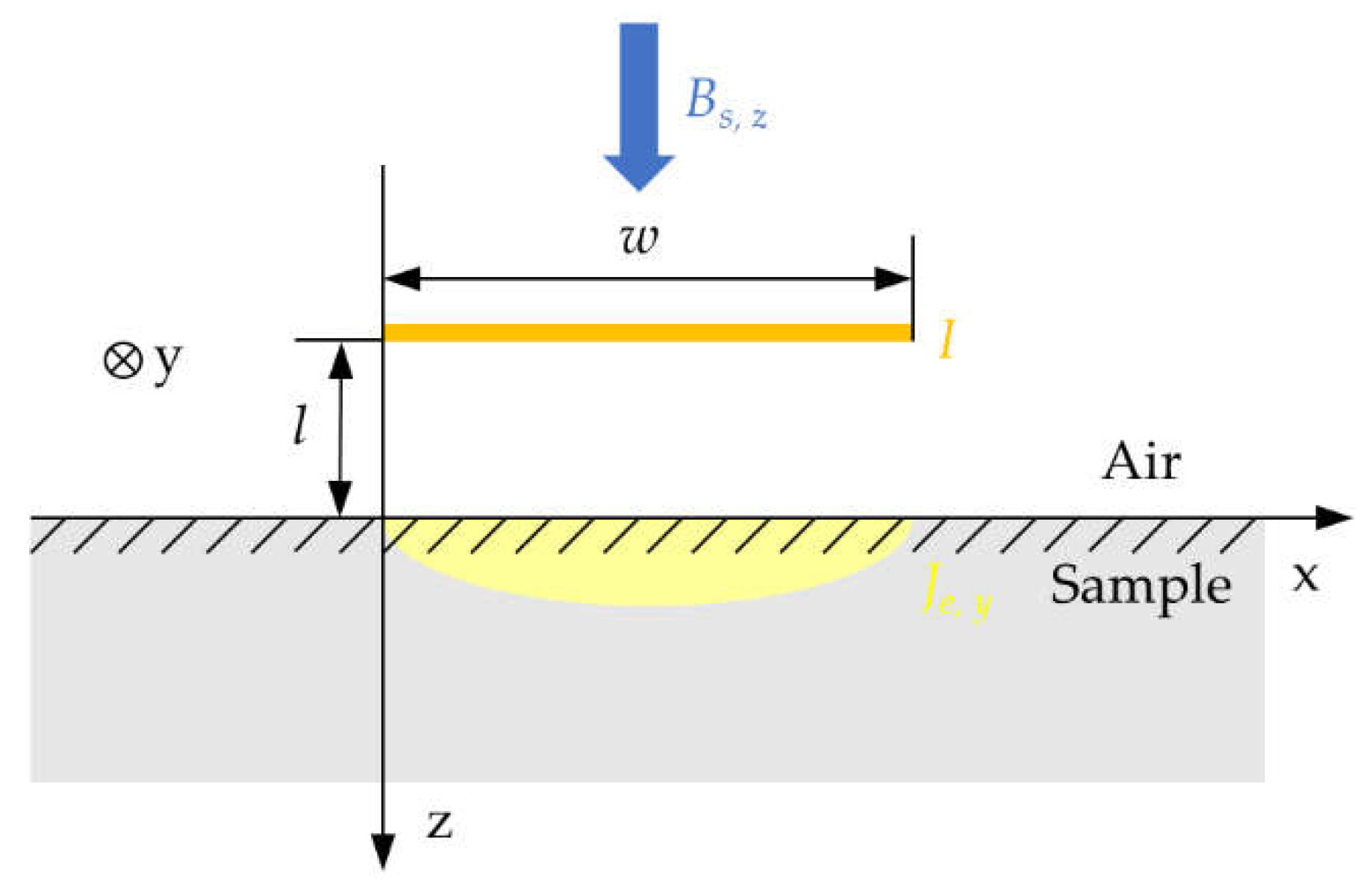

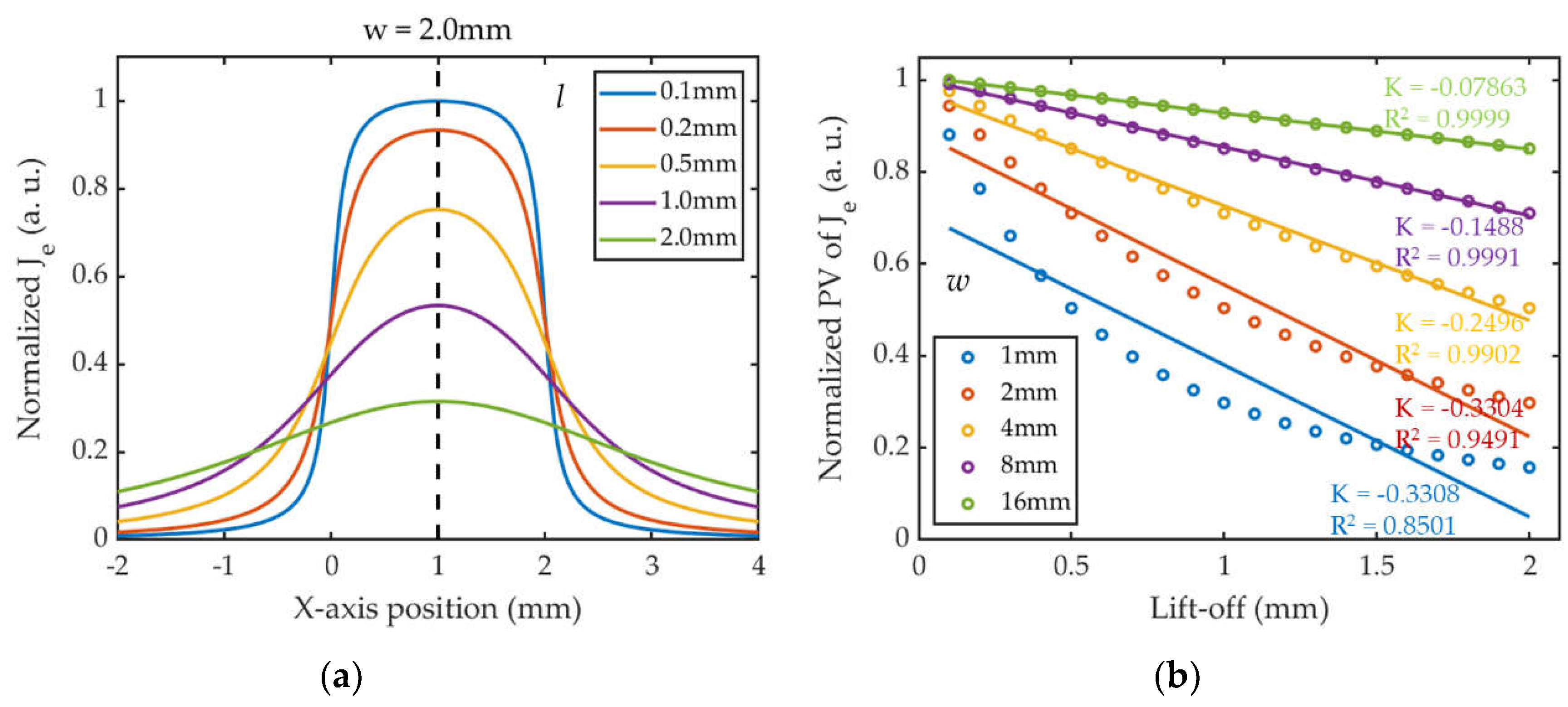

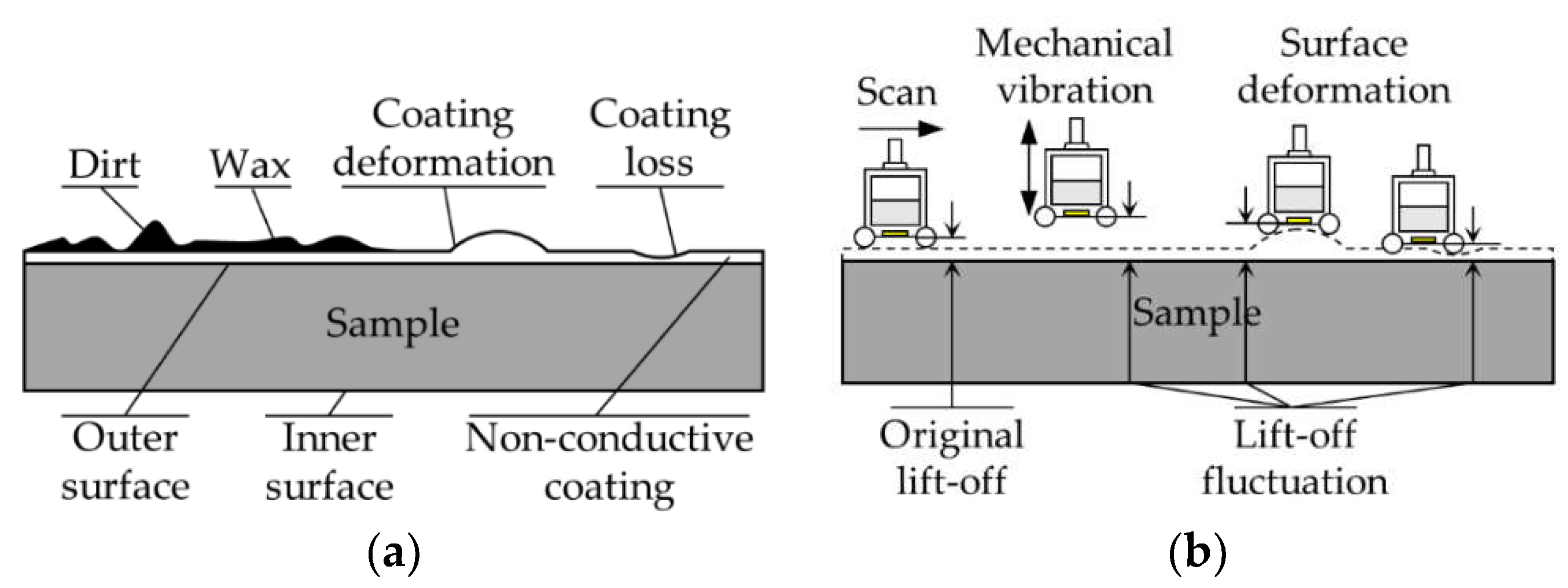

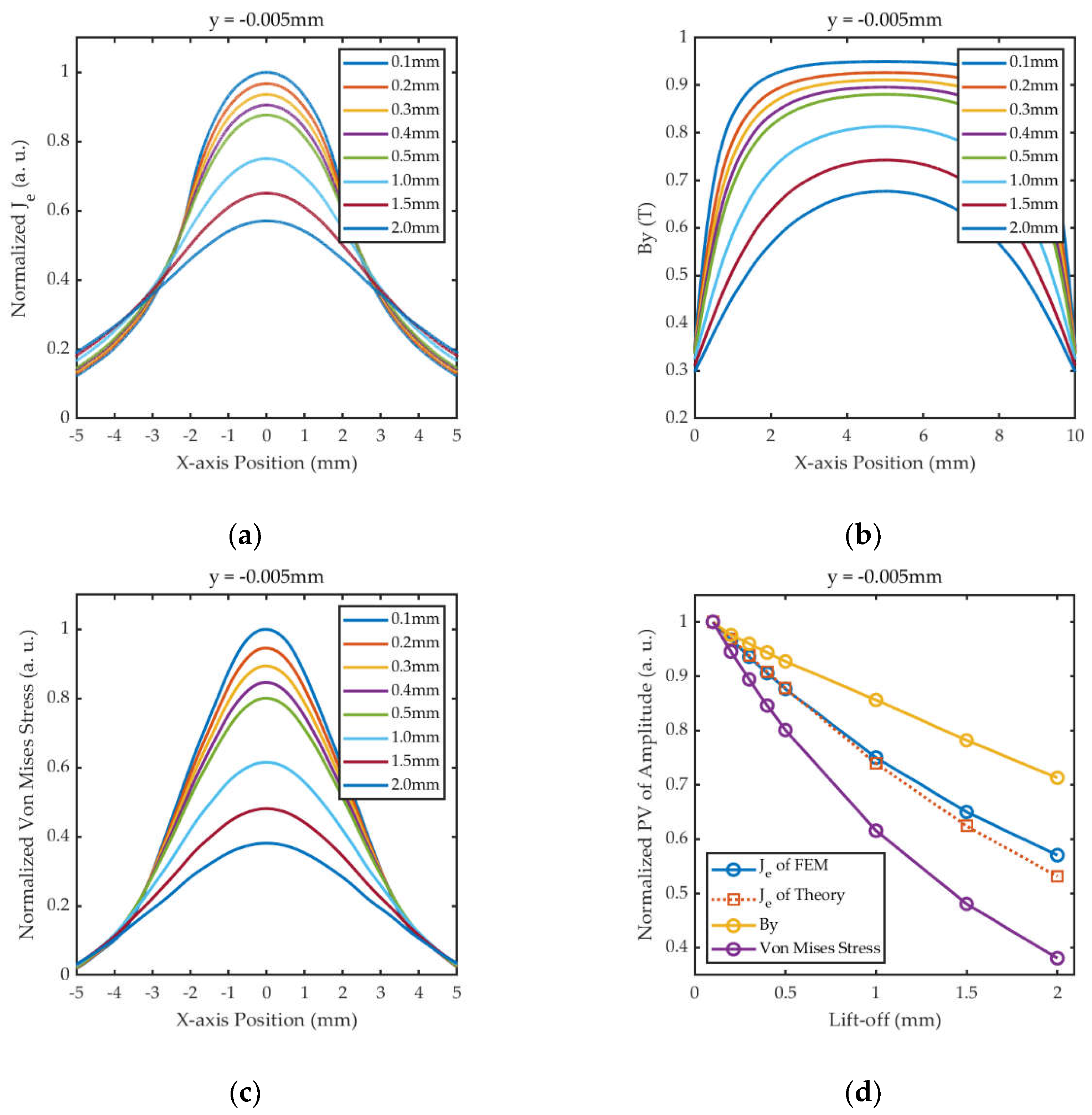

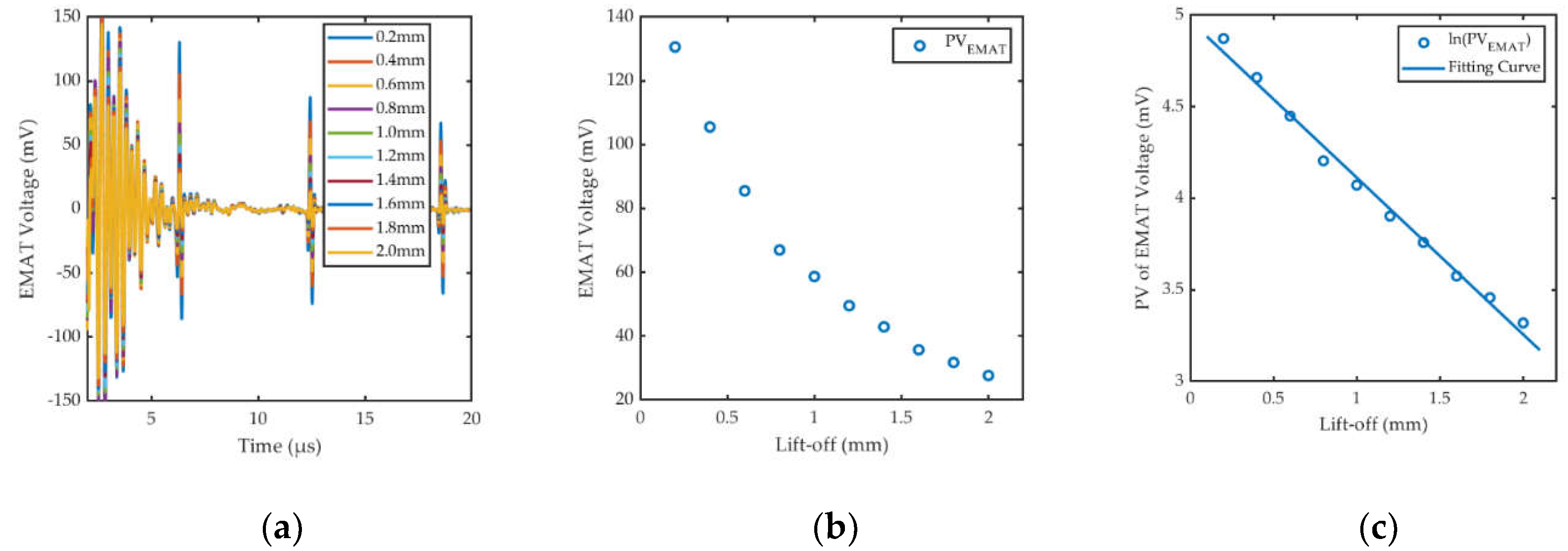

2.2. Effect of Lift-Off on Lorentz Force of Bulk Wave EMAT

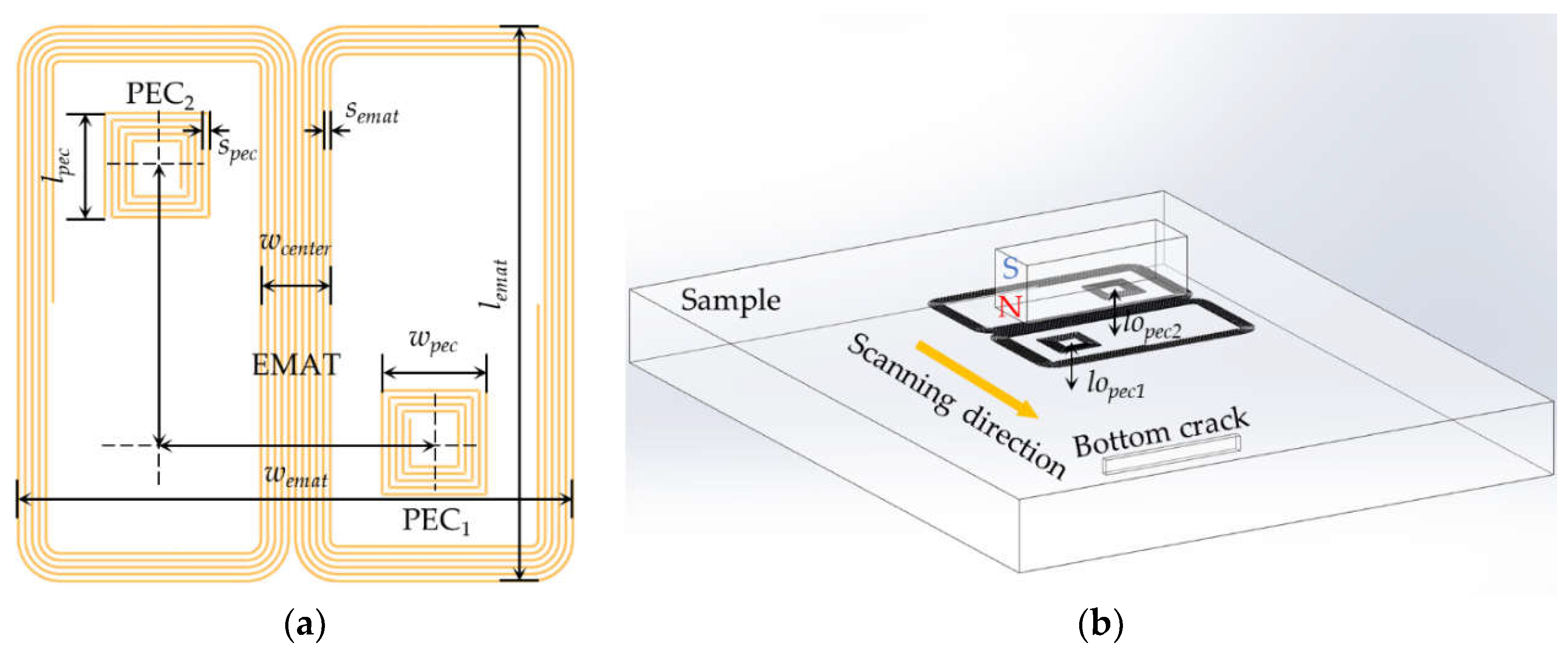

2.3. EMAT-PEC Composite Sensor Design

- The butterfly coil can produce unidirectional and uniform shear wave with a small divergence angle, which has a good detection ability for tiny cracks perpendicular to the polarization direction;

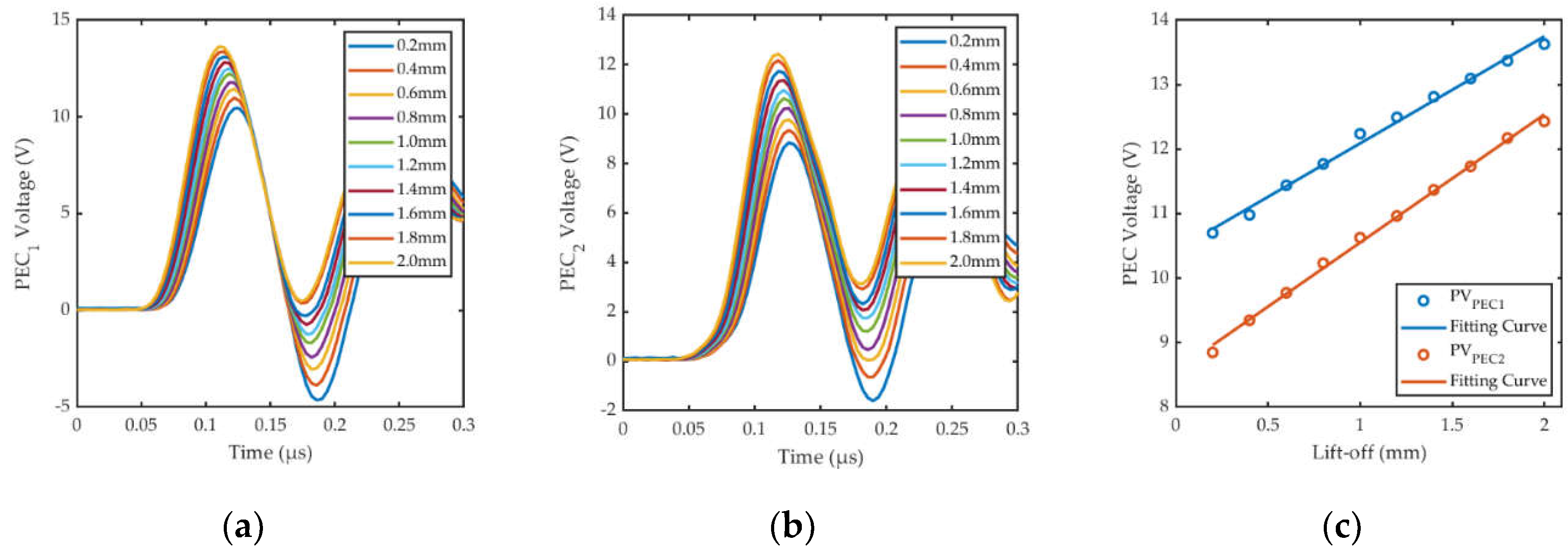

- The symmetric rectangular coils are used to measure the average lift-off of the probe, which can effectively improve the accuracy of the measurement in special industrial scenarios such as probe tilting, and achieve better applicability.

- In each cycle, the PEC and EMAT signals originate from the same excitation signal, so it is easier to synchronize the acquisition of the PEC and EMAT signals and match them compared to the addition of other displacement sensors, which has positive implications for subsequent signal fusion and correction.

- The proposed composite sensor uses only a single excitation signal to avoid crosstalk between multiple signals and improve energy utilization of EMAT. The use of one transmitter and multiple receivers reduces the complexity of the circuit system, and the PEC signals can be extracted through a low-pass filter in the appropriate frequency band.

3. Simulation Analysis and Method

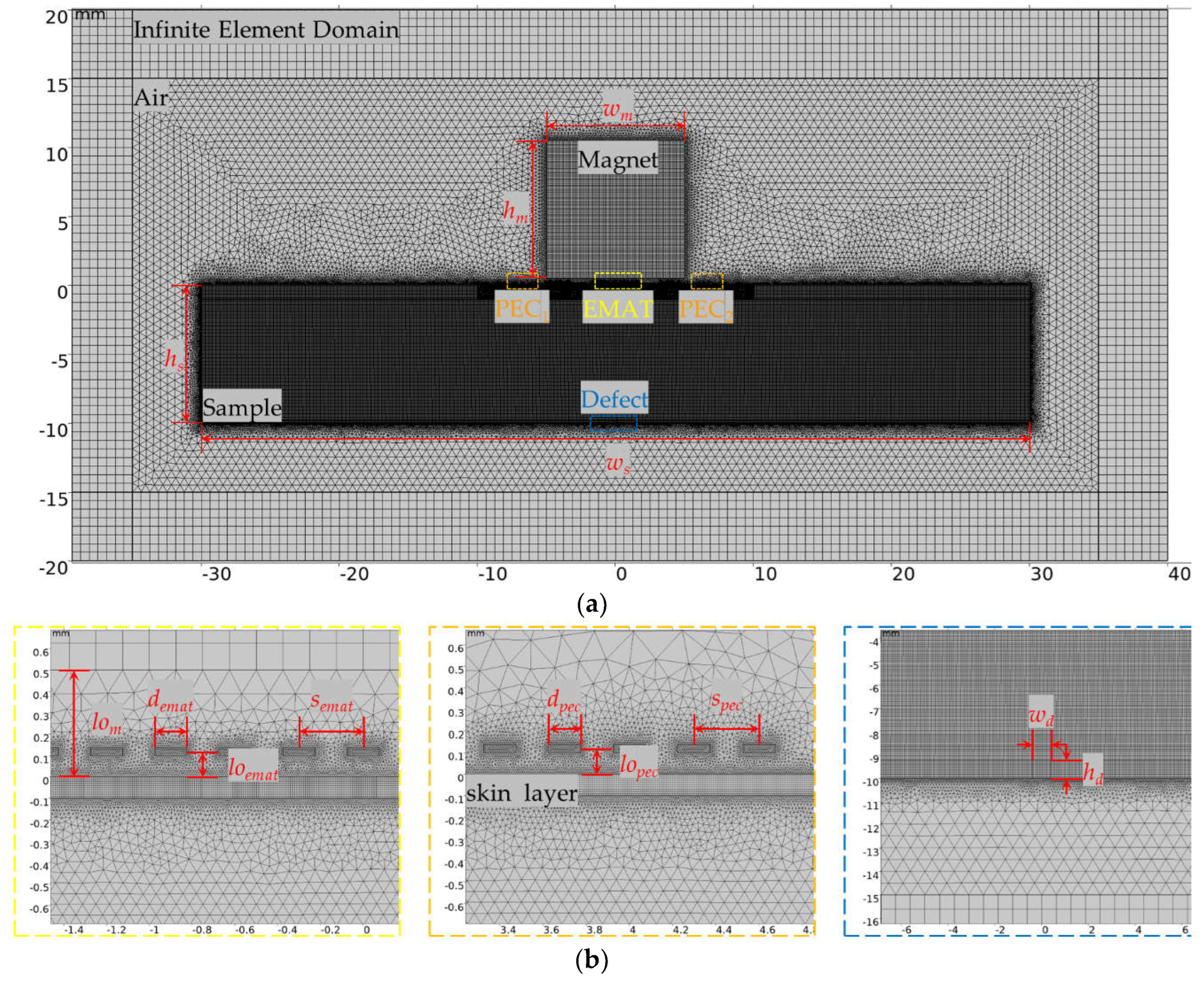

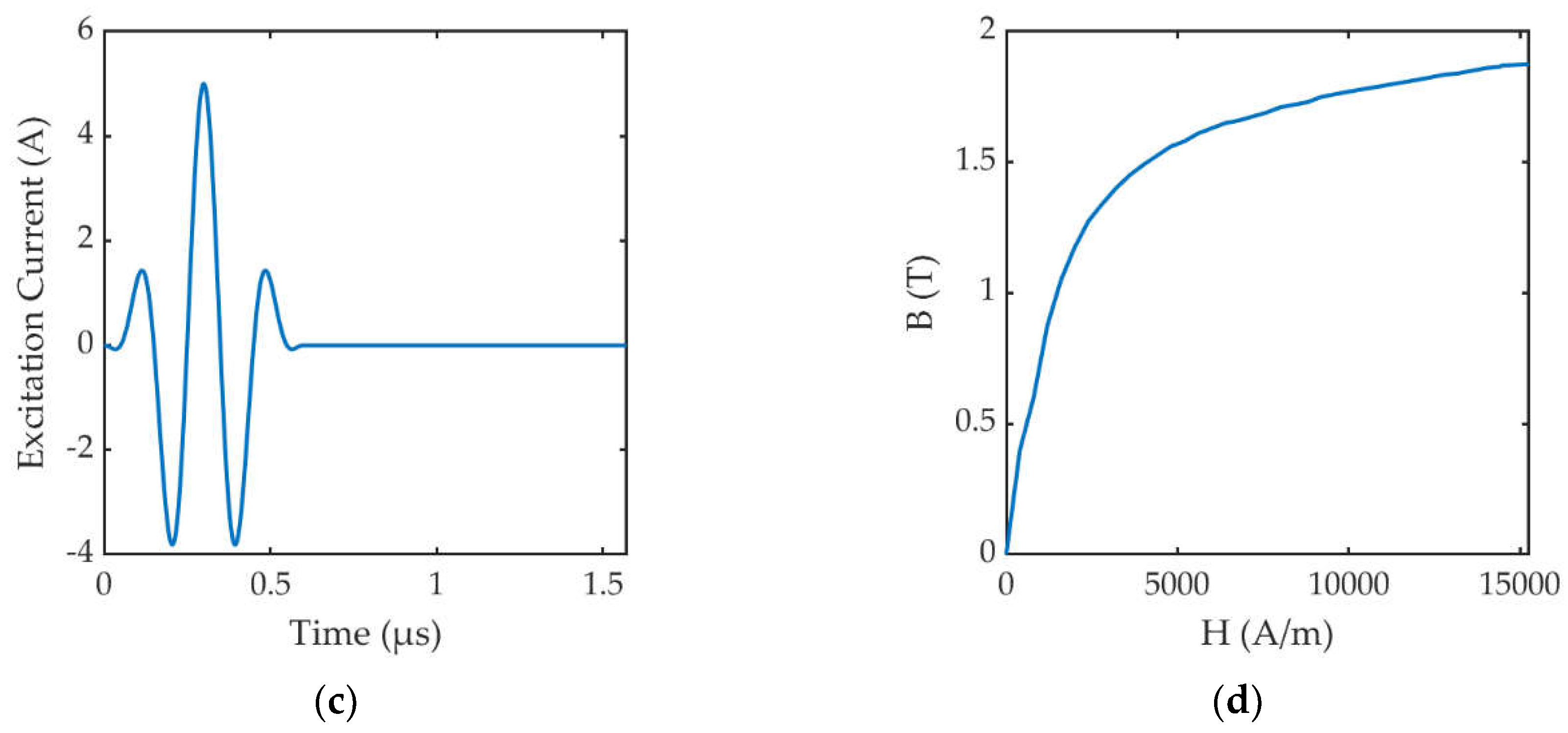

3.1. Finite Element Modeling

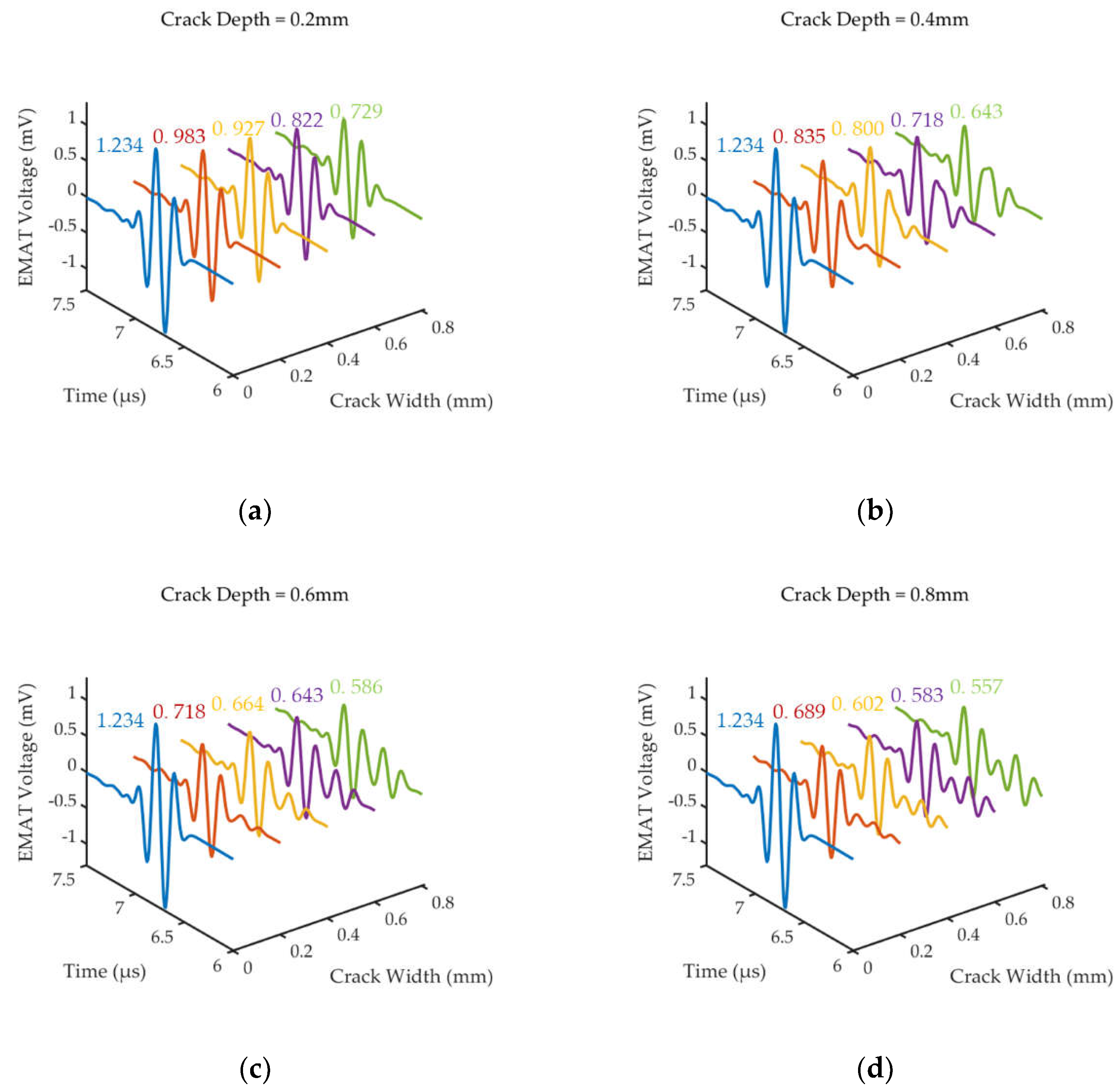

3.2. Crack Detection with Different Sizes

- The feature of the 1st bottom echo amplitude is easily extracted and the ToF between adjacent echoes can be used to synchronize the thickness measurement of the sample;

- The amplitude of bottom echo is much larger than the amplitude of small-size crack echo, and a better SNR can be achieved;

- Due to the complex reflection, scattering and mode conversion at crack-like defects, the crack echo is difficult to be completely recorded by EMAT. Based on the inversion perspective, the amplitude attenuation of the bottom echo reflects the interaction of shear wave with the crack at bottom. The rate of change on bottom echo amplitude due to the crack is larger than on defect echo amplitude, and a higher detection sensitivity can be achieved.

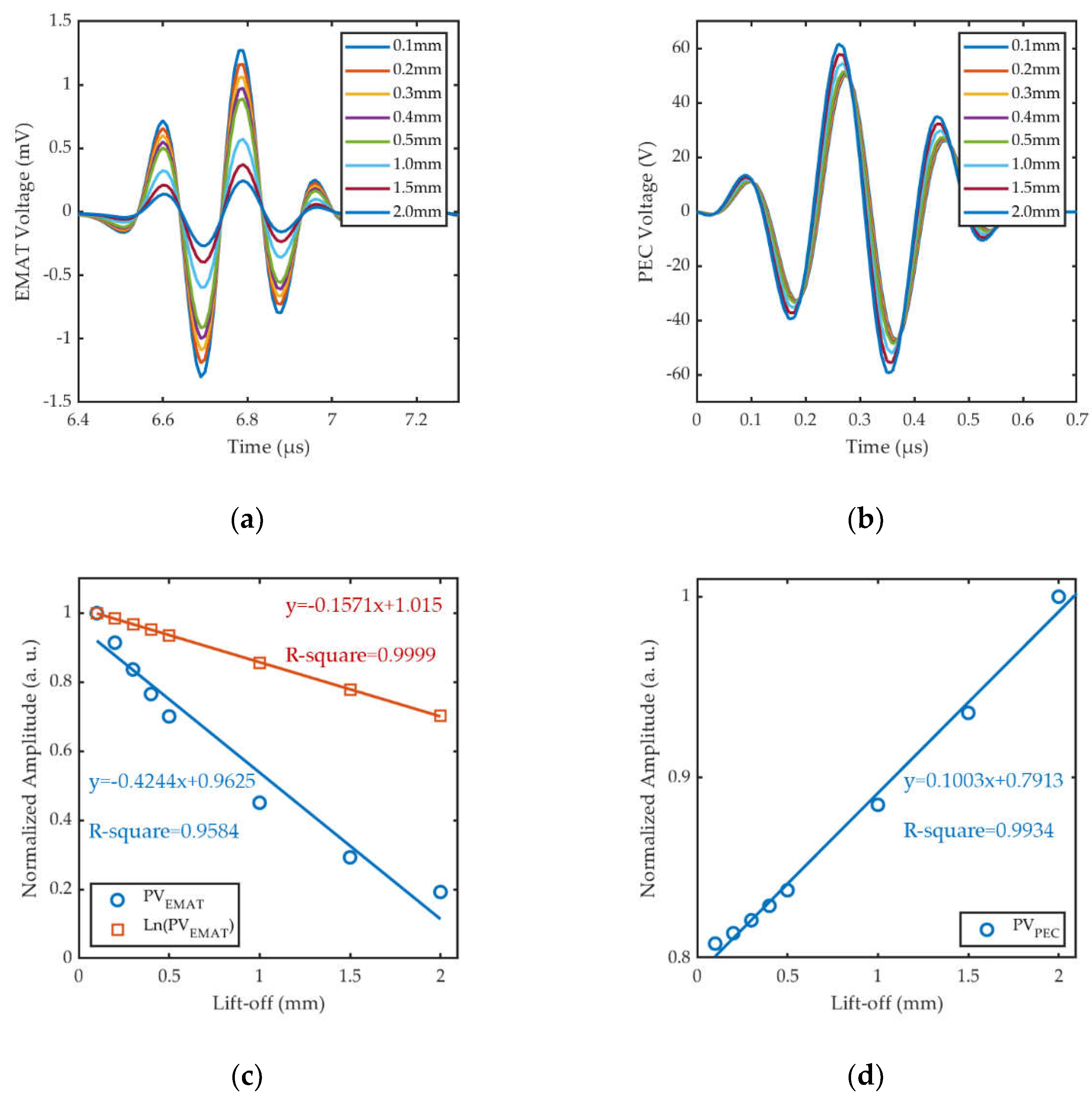

3.3. Effect of Lift-Off on EMAT and PEC Signals

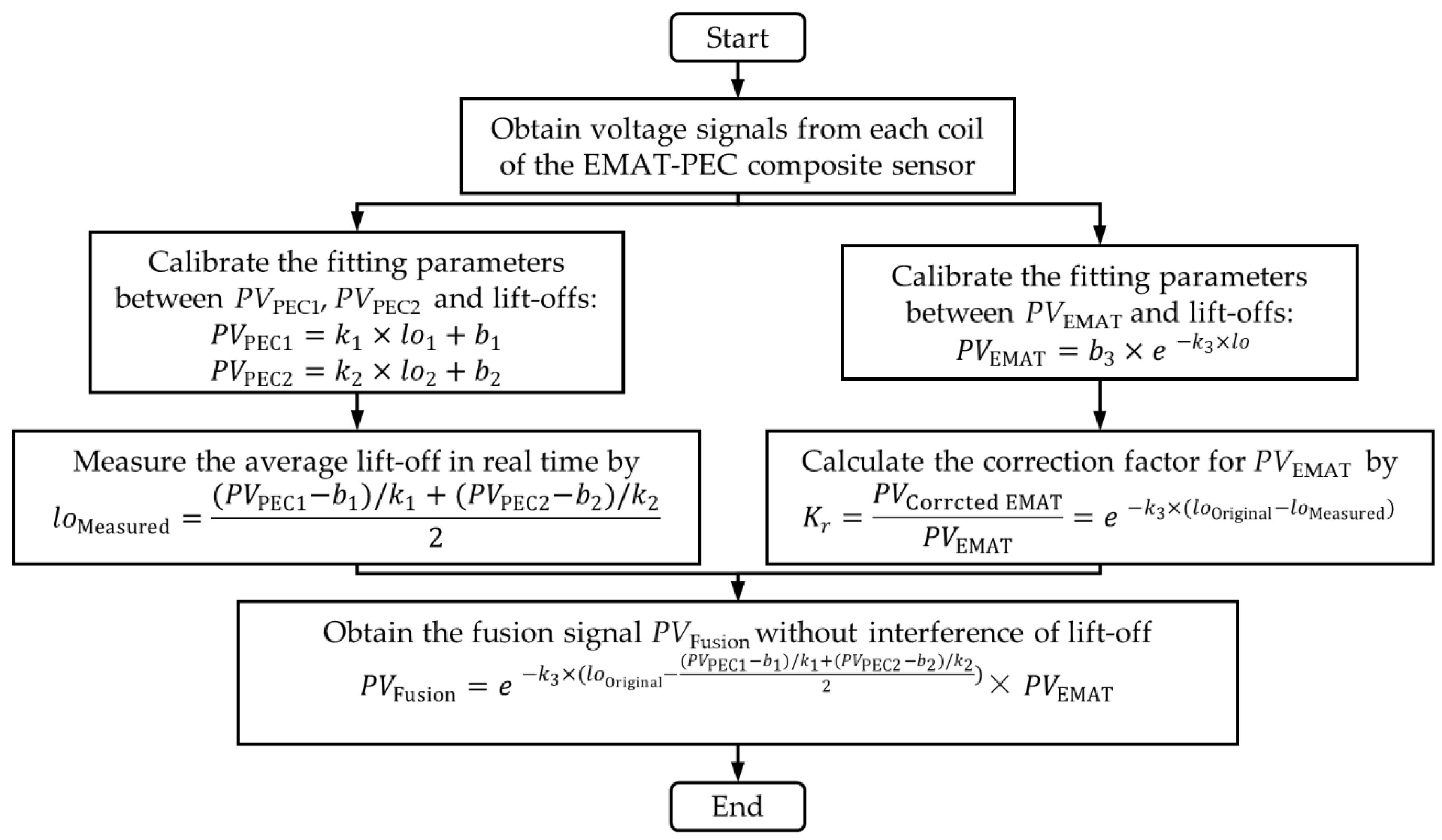

3.4. Real-Time Signal Correction and Fusion Method

- Step 1 is calibration. At the reference plane of the tested sample, a set of EMAT signals and PEC signals under the known lift-offs are extracted using the composite sensor to plot the fitting curves between each signal and lift-offs and determine the fitting parameters.

- Step 2 is the measurement of lift-off. During the crack detection, the peak value of PEC signals PVPEC1 and PVPEC2 picked up by PEC1 and PEC2 coils are substituted into the calibrated fitting curves to calculate the average lift-off of the composite sensor in real time.

- Step 3 is the correction of detection signals. Based on the fitting curve between EMAT signal and lift-offs, the formula for the signal correction factor can be get, and then the measured lift-off is substituted into the formula to calculate the value of correction factor, and finally the correction factor is multiplied by PVEMAT to obtain the crack detection signal without interference of lift-off.

- Step 4 is the fusion of detection signals. Combining the measurement and correction processes of steps 2 and 3, we can fuse the PVPEC1, PVPEC1 and PVEMAT signals to form a new fusion signal which is unaffected by lift-offs.

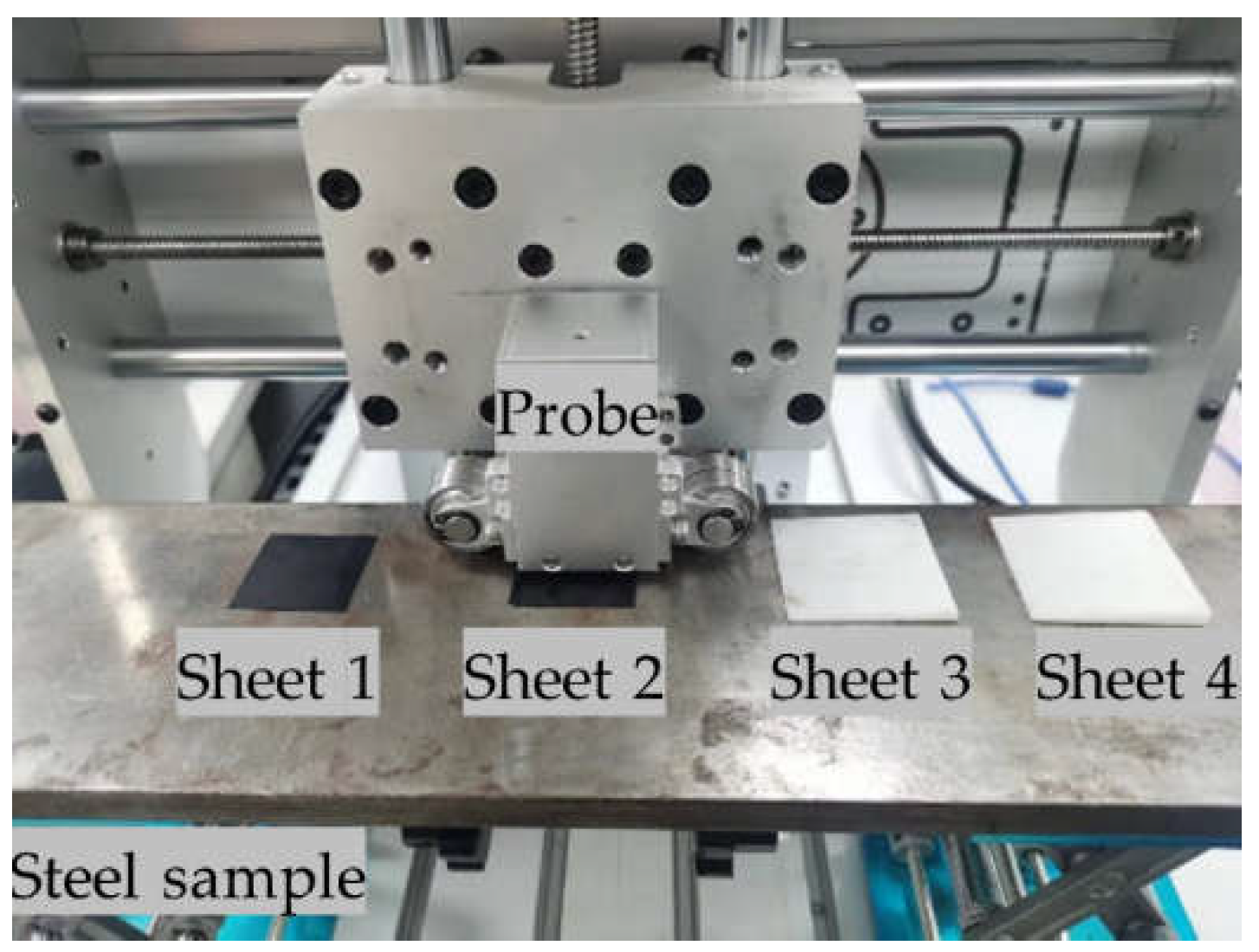

4. Experiment

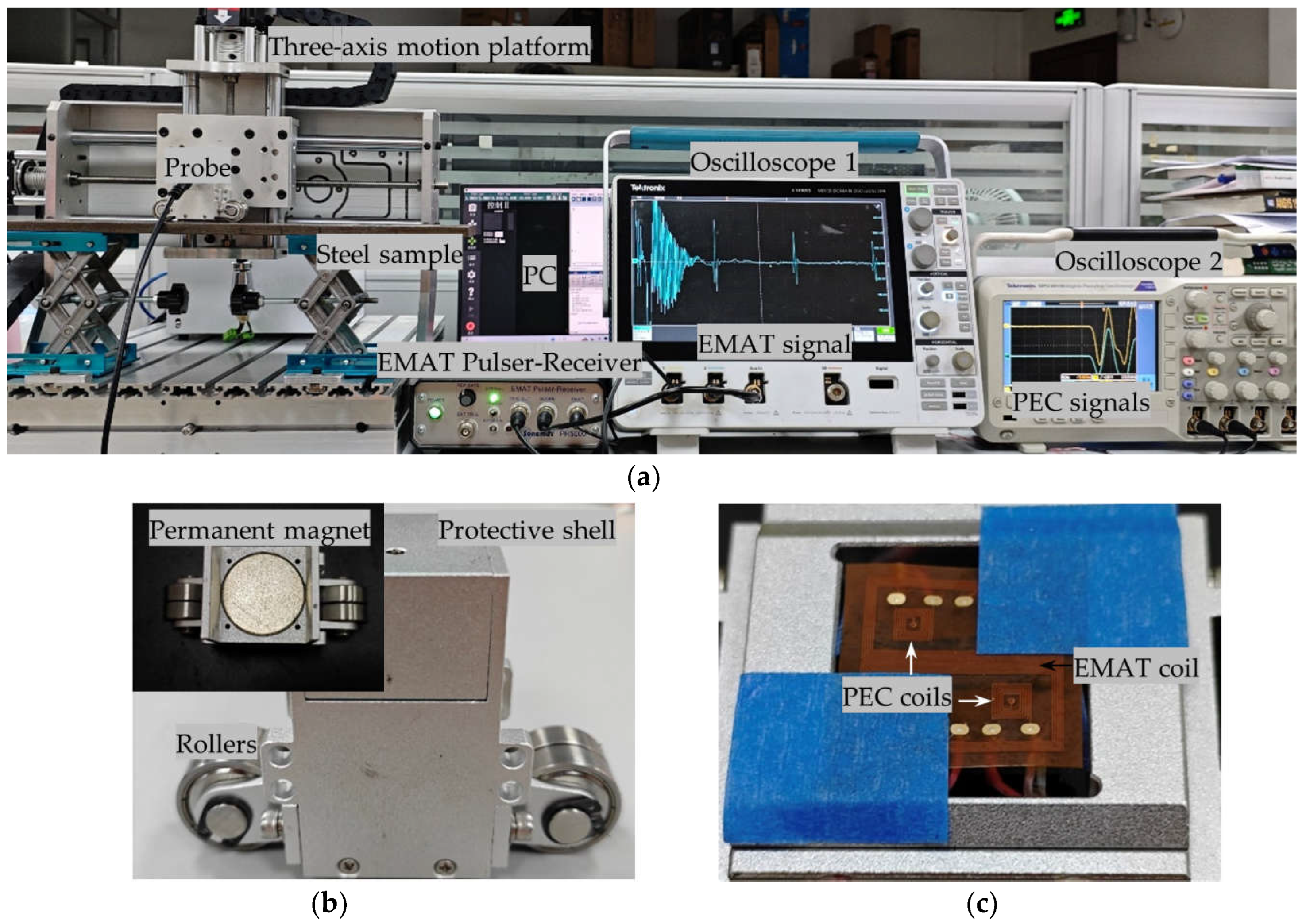

4.1. Experimental Setup

4.2. Results and Discussion

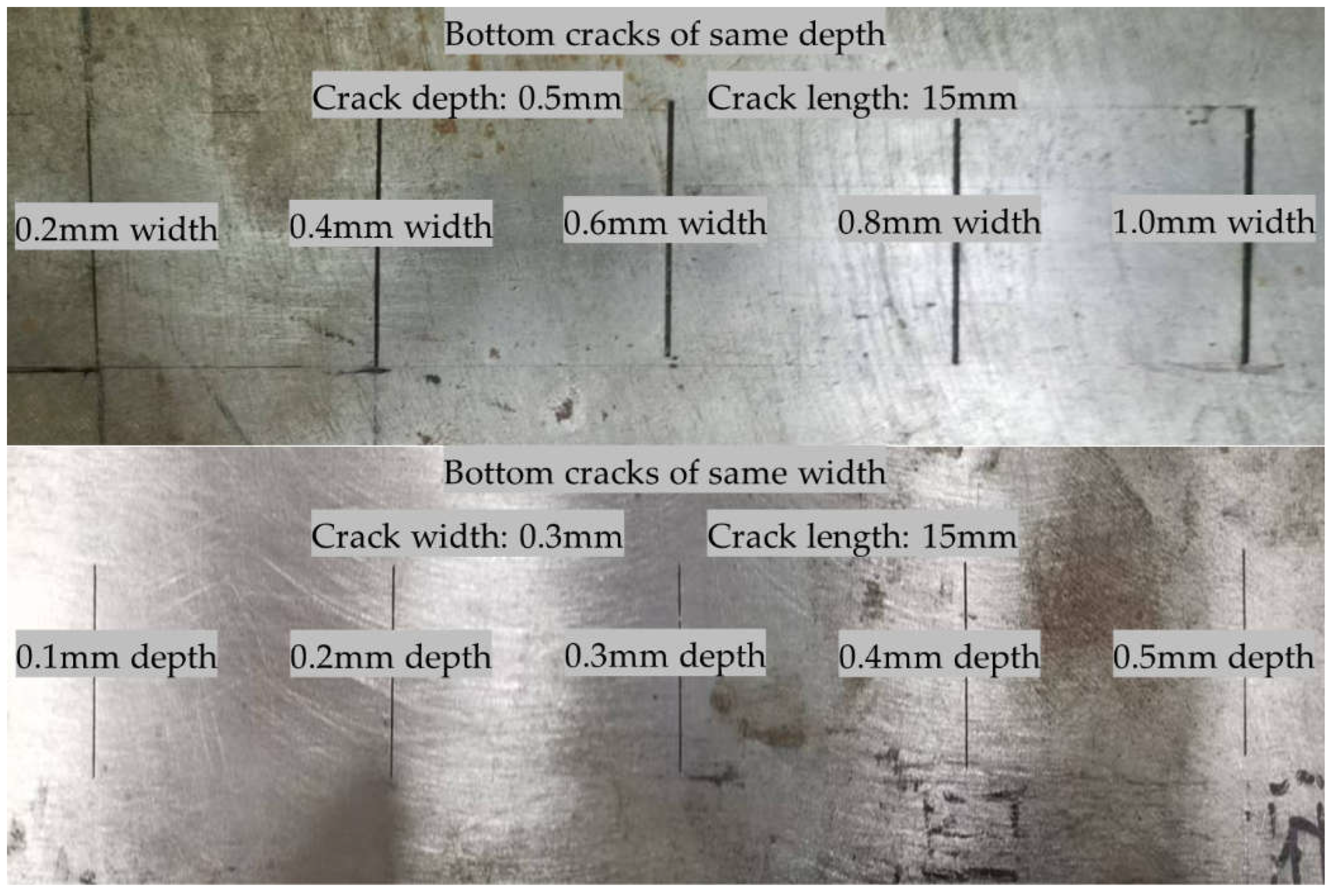

4.2.1. Detection of Bottom Cracks at Different Widths

4.2.2. Detection of Bottom Cracks at Different Depths

4.2.3. Calibration Experiments

4.2.4. Comparison of Lift-Off Measurement between Symmetric PEC Coils and Single PEC Coil

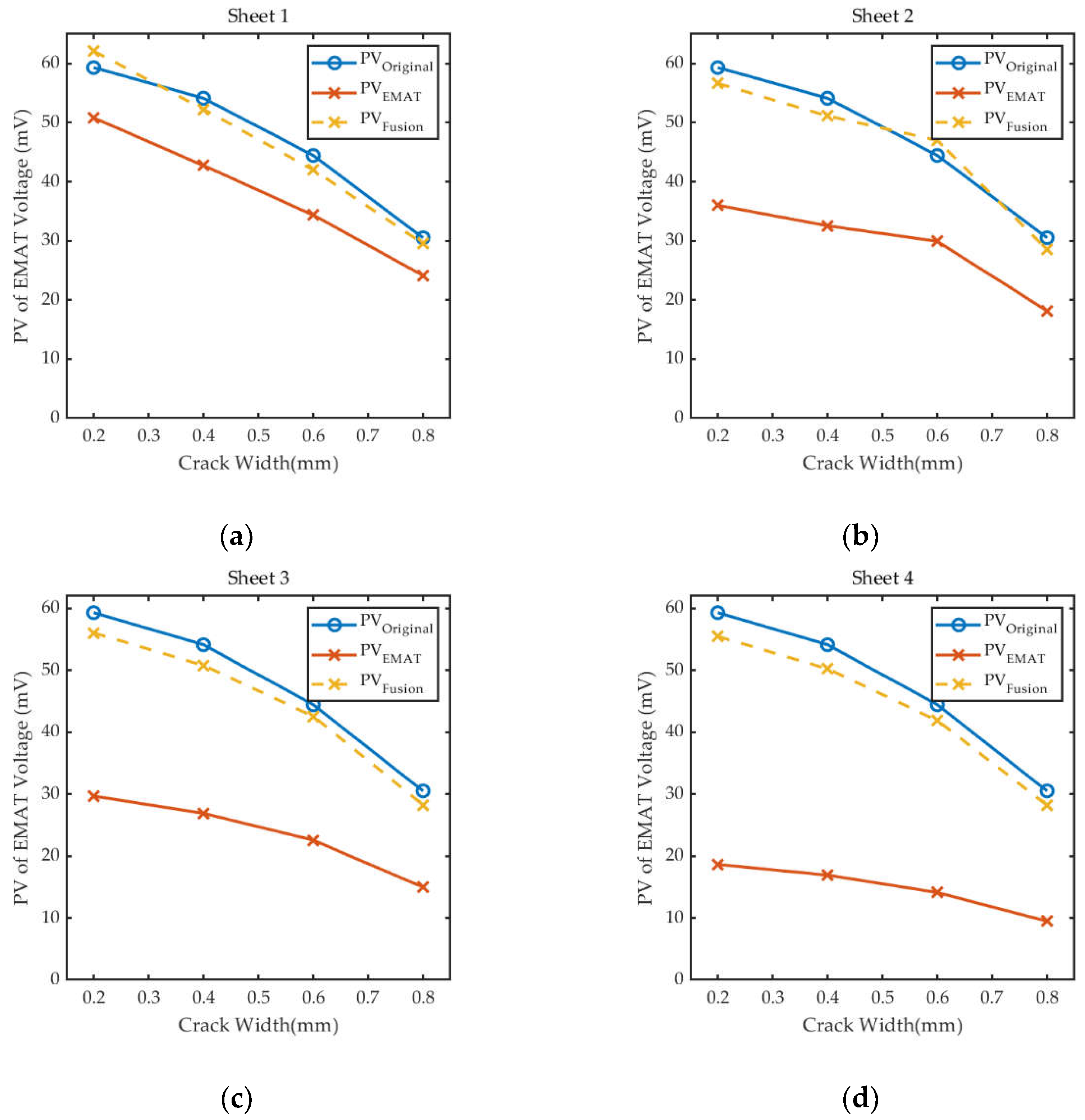

4.2.5. Amplitude Correction Experiment based on Signal Fusion

5. Conclusion and Future Work

5.1. Conclusion

- The optimally designed and arranged probe is capable of exciting unidirectional shear waves with polarization direction perpendicular to the cracks, and the mode conversion occurring at the tiny crack causes the attenuation of the bottom echo amplitude. Compared with focusing on the defect echo, extracting the attenuation of the bottom echo amplitude to invert the defect size can obtain a better SNR and resolution. The experimental results prove that the probe has the ability to detect the bottom crack as small as 0.1*0.3mm;

- The designed composite sensor can synchronously obtain the information of defect in testing sample and probe posture in real time based on EMAT echo signal and PEC signals. The whole system is supported by only one excitation source, which ensures the stability of the system and improves the energy utilization rate. The experimental results validate that symmetrically PEC coils can more accurately measure the average lift-off of the probe than a single PEC coil, with a relative error of less than ±5%.

- The proposed signal fusion method skillfully combines the fitting relationships between the EMAT, PEC signals and the lift-offs to form a fusion signal that is not affected by lift-off, thereby effectively reducing the impact of probe fluctuation on defect detection during actual inspection. The experimental results confirm that the signal fusion method effectively corrects the effect of lift-off on the amplitude of the detection signal, and the error of the corrected signal relative to the reference signal is less than ±8%.

5.2. Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Yao, Y.; Tung, S.-T.E.; Glisic, B. Crack Detection and Characterization Techniques-An Overview. Structural Control and Health Monitoring 2014, 21, 1387–1413. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Eslami, A.; Egbewande, A. A Review on Pipeline Corrosion, in-Line Inspection (ILI), and Corrosion Growth Rate Models. International Journal of Pressure Vessels and Piping 2017, 149, 43–54. [Google Scholar] [CrossRef]

- Kong, Y.; Bennett, C.J.; Hyde, C.J. A Review of Non-Destructive Testing Techniques for the in-Situ Investigation of Fretting Fatigue Cracks. Materials & Design 2020, 196, 109093. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Li, E.; Deng, Z.; Kang, Y.; Tang, C.; Sunny, A.I. A High-Sensitivity MFL Method for Tiny Cracks in Bearing Rings. IEEE Trans. Magn. 2018, 54, 1–8. [Google Scholar] [CrossRef]

- Ravan, M.; Amineh, R.K.; Koziel, S.; Nikolova, N.K.; Reilly, J.P. Estimation of Multiple Surface Cracks Parameters Using MFL Testing. In Proceedings of the 2010 URSI International Symposium on Electromagnetic Theory; IEEE: Berlin, Germany, August, 2010; pp. 891–894. [Google Scholar]

- Ege, Y.; Bicakcı, S.; Gunes, H.; Citak, H.; Coramik, M. An Application of BRANN and MFL Methods: Determining Crack Type and Physical Properties on M5 Steel Sheets. Measurement 2019, 138, 545–556. [Google Scholar] [CrossRef]

- Hamia, R.; Cordier, C.; Dolabdjian, C. Eddy-Current Non-Destructive Testing System for the Determination of Crack Orientation. NDT & E International 2014, 61, 24–28. [Google Scholar] [CrossRef]

- Dai, L.; Feng, H.; Wang, T.; Xuan, W.; Liang, Z.; Yang, X. Pipe Crack Recognition Based on Eddy Current NDT and 2D Impedance Characteristics. Applied Sciences 2019, 9, 689. [Google Scholar] [CrossRef]

- Yuan, F.; Yu, Y.; Li, L.; Tian, G. Investigation of DC Electromagnetic-Based Motion Induced Eddy Current on NDT for Crack Detection. IEEE Sensors J. 2021, 21, 7449–7457. [Google Scholar] [CrossRef]

- Kim, G.; Seo, M.-K.; Kim, Y.-I.; Kwon, S.; Kim, K.-B. Development of Phased Array Ultrasonic System for Detecting Rail Cracks. Sensors and Actuators A: Physical 2020, 311, 112086. [Google Scholar] [CrossRef]

- Drinkwater, B.W.; Wilcox, P.D. Ultrasonic Arrays for Non-Destructive Evaluation: A Review. NDT & E International 2006, 39, 525–541. [Google Scholar] [CrossRef]

- Wang, K.; Song, Y.; Kang, Y.; Guo, Y.; Ma, H.; Wu, S.; Yang, J. Ultrasonic Detection Method Based on Flexible Capillary Water Column Arrays Coupling. Ultrasonics 2024, 139, 107276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Liu, M.; Jia, X.; Gao, R. Numerical Study and Optimal Design of the Butterfly Coil EMAT for Signal Amplitude Enhancement. Sensors 2022, 22, 4985. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Huang, S.; Zhang, Y.; Zhao, W. Multiphysics Modeling of a Lorentz Force-Based Meander Coil Electromagnetic Acoustic Transducer via Steady-State and Transient Analyses. IEEE Sensors J. 2016, 16, 6641–6651. [Google Scholar] [CrossRef]

- Lunn, N.; Dixon, S.; Potter, M.D.G. High Temperature EMAT Design for Scanning or Fixed Point Operation on Magnetite Coated Steel. NDT & E International 2017, 89, 74–80. [Google Scholar] [CrossRef]

- Gao, H.; Ali, S.; Lopez, B. Efficient Detection of Delamination in Multilayered Structures Using Ultrasonic Guided Wave EMATs. NDT & E International 2010, 43, 316–322. [Google Scholar] [CrossRef]

- Liu, T.; Pei, C.; Cai, R.; Li, Y.; Chen, Z. A Flexible and Noncontact Guided-Wave Transducer Based on Coils-Only EMAT for Pipe Inspection. Sensors and Actuators A: Physical 2020, 314, 112213. [Google Scholar] [CrossRef]

- Pei, C.; Liu, T.; Chen, H.; Chen, Z. Inspection of Delamination Defect in First Wall with a Flexible EMAT-Scanning System. Fusion Engineering and Design 2018, 136, 549–553. [Google Scholar] [CrossRef]

- Tu, J.; Zhong, Z.; Song, X.; Zhang, X.; Deng, Z.; Liu, M. An External through Type RA-EMAT for Steel Pipe Inspection. Sensors and Actuators A: Physical 2021, 331, 113053. [Google Scholar] [CrossRef]

- Felice, M.V.; Fan, Z. Sizing of Flaws Using Ultrasonic Bulk Wave Testing: A Review. Ultrasonics 2018, 88, 26–42. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Urayama, R.; Uchimoto, T.; Takagi, T.; Hashimoto, M. Small Electromagnetic Acoustic Transducer with an Enhanced Unique Magnet Configuration. NDT & E International 2020, 110, 102205. [Google Scholar] [CrossRef]

- Maiyi, Z.; Renwen, C.; Yufeng, Z. Design and Optimization of Electromagnetic Ultrasonic Body Wave Probe Based on Halbach Structure. 39.

- Sun, H.; Huang, S.; Wang, Q.; Wang, S.; Zhao, W. Orthogonal Optimal Design Method for Point-Focusing EMAT Considering Focal Area Dimensions. Sensors and Actuators A: Physical 2020, 312, 112109. [Google Scholar] [CrossRef]

- Jia, X.; Ouyang, Q.; Zhang, X. An Improved Design of the Spiral-Coil EMAT for Enhancing the Signal Amplitude. Sensors 2017, 17, 1106. [Google Scholar] [CrossRef] [PubMed]

- Parra-Raad, J.; Khalili, P.; Cegla, F. Shear Waves with Orthogonal Polarisations for Thickness Measurement and Crack Detection Using EMATs. NDT & E International 2020, 111, 102212. [Google Scholar] [CrossRef]

- Feng, J.; Lu, S.; Liu, J.; Li, F. A Sensor Liftoff Modification Method of Magnetic Flux Leakage Signal for Defect Profile Estimation. IEEE Trans. Magn. 2017, 53, 1–13. [Google Scholar] [CrossRef]

- Wang, S.; Hu, Y.; Duan, Z.; Jiang, C.; Kang, Y.; Feng, B. AC Magnetic Flux Leakage Testing With Real-Time Liftoff Compensation Using Double Layer Parallel-Cable Probe. IEEE Trans. Instrum. Meas. 2024, 73, 1–9. [Google Scholar] [CrossRef]

- Xiang, L.; Dixon, S.; Thring, C.B.; Li, Z.; Edwards, R.S. Lift-off Performance of Electromagnetic Acoustic Transducers (EMATs) for Surface Acoustic Wave Generation. NDT & E International 2022, 126, 102576. [Google Scholar] [CrossRef]

- Feng, B.; Xie, S.; Xie, L.; Deng, K.; Wang, S.; Kang, Y. Analysis of the Lift-Off Effect in Motion-Induced Eddy Current Testing Based on Semi-Analytical Model. IEEE Trans. Instrum. Meas. 2024, 73, 1–8. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, S.; Duan, Z.; Gao, Y. A Method for Compensation of Permanent Magnetic Field Perturbation (PMFP) Testing Signal Based on Lift-off Measurement. Meas. Sci. Technol. 2023, 34, 125129. [Google Scholar] [CrossRef]

- Duan, Z.; Kang, Y.; Chen, Y.; Wan, Z.; Wang, S. Reduction of Lift-off Effect in Pulsed Eddy Current Testing for Surface Hardness Classification of Ferromagnetic Steel. Measurement 2022, 205, 112191. [Google Scholar] [CrossRef]

- Duan, Z.; Guo, Y.; Cheng, S.; Kang, Y.; Hu, Y.; Chen, Y.; Li, Y.; Feng, B. A Lift-off Measurement and Compensation Method Based on a Comprehensive EMAT-PEC Probe. Sensors and Actuators A: Physical 2024, 372, 115319. [Google Scholar] [CrossRef]

- Wang, S.; Li, Z.; Kang, L.; Hu, X.; Zhang, X. Modeling and Comparison of Three Bulk Wave EMATs. In Proceedings of the IECON 2011 - 37th Annual Conference of the IEEE Industrial Electronics Society; IEEE: Melbourne, Vic, Australia, November, 2011; pp. 2645–2650. [Google Scholar]

- Hirao, M.; Ogi, H. Electromagnetic Acoustic Transducers: Noncontacting Ultrasonic Measurements Using EMATs; Springer Series in Measurement Science and Technology; Springer Japan: Tokyo, 2017; ISBN 978-4-431-56034-0. [Google Scholar]

- Harker, A.H. Numerical Modelling of the Scattering of Elastic Waves in Plates. J Nondestruct Eval 1984, 4, 89–106. [Google Scholar] [CrossRef]

- MacLauchlan, D.; Clark, S.; Cox, B.; Doyle, T.; Grimmett, B.; Hancock, J.; Hour, K.; Rutherford, C. Recent Advancements in the appplication of EMATs to NDE. In Proceedings of the Sixteenth World Conf. NDT; 2004; pp. 1154–1161. [Google Scholar]

| Object | Parameter | Symbol | Value |

|---|---|---|---|

| EMAT | width | wemat | 16mm |

| length | lemat | 16mm | |

| lift-off | loemat | 0.1mm | |

| wire diameter | demat | 8mil | |

| wire spacing | semat | 16mil | |

| wire height | hemat | 0.035mm | |

| turns | nemat | 11 | |

| PEC1, PEC2 | width | wpec | 4mm |

| length | lpec | 4mm | |

| lift-off | lopec | 0.1mm | |

| wire diameter | dpec | 8mil | |

| wire spacing | dpec | 16mil | |

| wire height | hpec | 0.035mm | |

| turns | npec | 5 |

| Object | Parameter | Symbol | Value |

|---|---|---|---|

| magnet | width | wm | 10mm |

| height | hm | 10mm | |

| lift-off | lom | 0.5mm | |

| remanent flux density | Bs | 1.21T | |

| sample | width | ws | 60mm |

| thickness | hs | 10mm | |

| density | ρ | 7850kg/m³ | |

| permeability | μ | B-H curve | |

| electrical conductivity | σ | 4.032×106S/m | |

| Young’s modulus | E | 200×109Pa | |

| Passion’s ratio | ε | 0.33 | |

| excitation current | center frequency | fc | 5MHz |

| cycle | n | 3 |

| Fitting Function | R-square |

|---|---|

| ln(PVEMAT) = - 0.8565 × lo + 4.969 | 0.9911 |

| PVPEC1 = 1.659 × lo + 10.43 | 0.9929 |

| PVPEC2 = 1.987 × lo + 8.564 | 0.9971 |

| Sheet No. | PVPEC1 (V) | lo1 (mm) | PVPEC2 (V) | lo2 (mm) | Average lo (mm) | Actual lo (mm) | Relative error |

|---|---|---|---|---|---|---|---|

| Sheet 1 | 11.138 | 0.427 | 9.444 | 0.443 | 0.435 | 0.250+0.2 | -3.33% |

| Sheet 2 | 11.615 | 0.714 | 10.038 | 0.742 | 0.728 | 0.504+0.2 | 3.41% |

| Sheet 3 | 11.784 | 0.816 | 10.686 | 1.068 | 0.942 | 0.702+0.2 | 4.32% |

| Sheet 4 | 12.124 | 1.021 | 12.385 | 1.923 | 1.472 | 1.205+0.2 | 4.77% |

| Sheet No. | Crack width (mm) | PVEMAT (mV) | PVFusion (mV) | PVOriginal (mV) | Relative error |

|---|---|---|---|---|---|

| Sheet 1 | 0.2 | 50.809 | 62.138 | 59.327 | +4.74% |

| 0.4 | 42.747 | 52.278 | 54.135 | -3.43% | |

| 0.6 | 34.361 | 42.022 | 44.455 | -5.47% | |

| 0.8 | 24.142 | 29.525 | 30.517 | -3.25% | |

| Sheet 2 | 0.2 | 36.034 | 56.639 | 59.327 | -4.53% |

| 0.4 | 32.538 | 51.144 | 54.135 | -5.53% | |

| 0.6 | 29.900 | 46.997 | 44.455 | +5.72% | |

| 0.8 | 18.139 | 28.511 | 30.517 | -6.57% | |

| Sheet 3 | 0.2 | 29.685 | 56.046 | 59.327 | -5.53% |

| 0.4 | 26.909 | 50.804 | 54.135 | -6.15% | |

| 0.6 | 22.556 | 42.586 | 44.455 | -4.20% | |

| 0.8 | 14.970 | 28.263 | 30.517 | -7.39% | |

| Sheet 4 | 0.2 | 18.660 | 55.470 | 59.327 | -6.50% |

| 0.4 | 16.908 | 50.262 | 54.135 | -7.15% | |

| 0.6 | 14.093 | 41.894 | 44.455 | -5.76% | |

| 0.8 | 9.4888 | 28.207 | 30.517 | -7.57% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).