Submitted:

24 July 2024

Posted:

25 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

1.1. Foam Dyeing Mechanism

1.2. Types of Foam

1.3. Properties of Foam

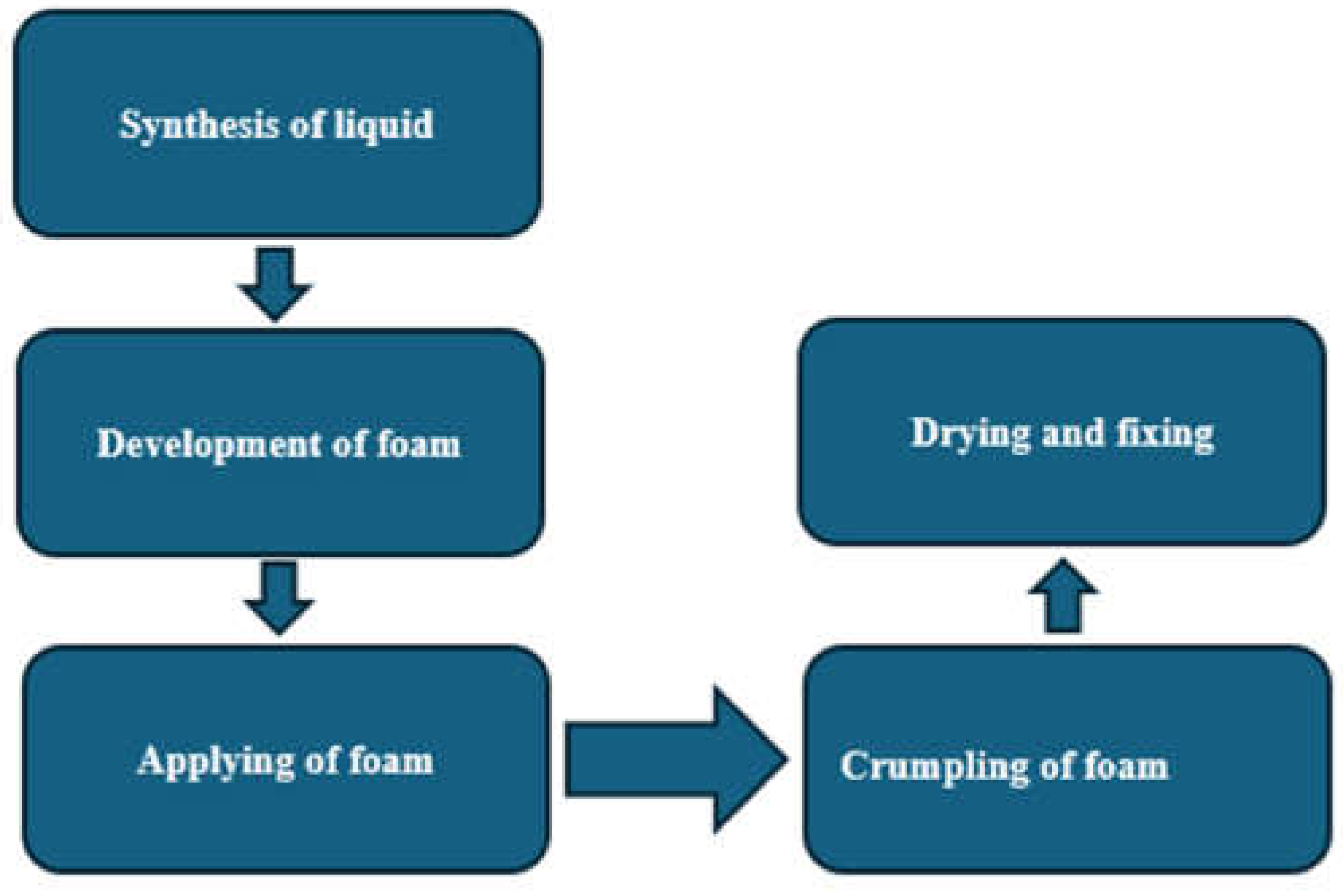

1.4. Steps of Foam Processing

1.4.1. Liquor Preparation

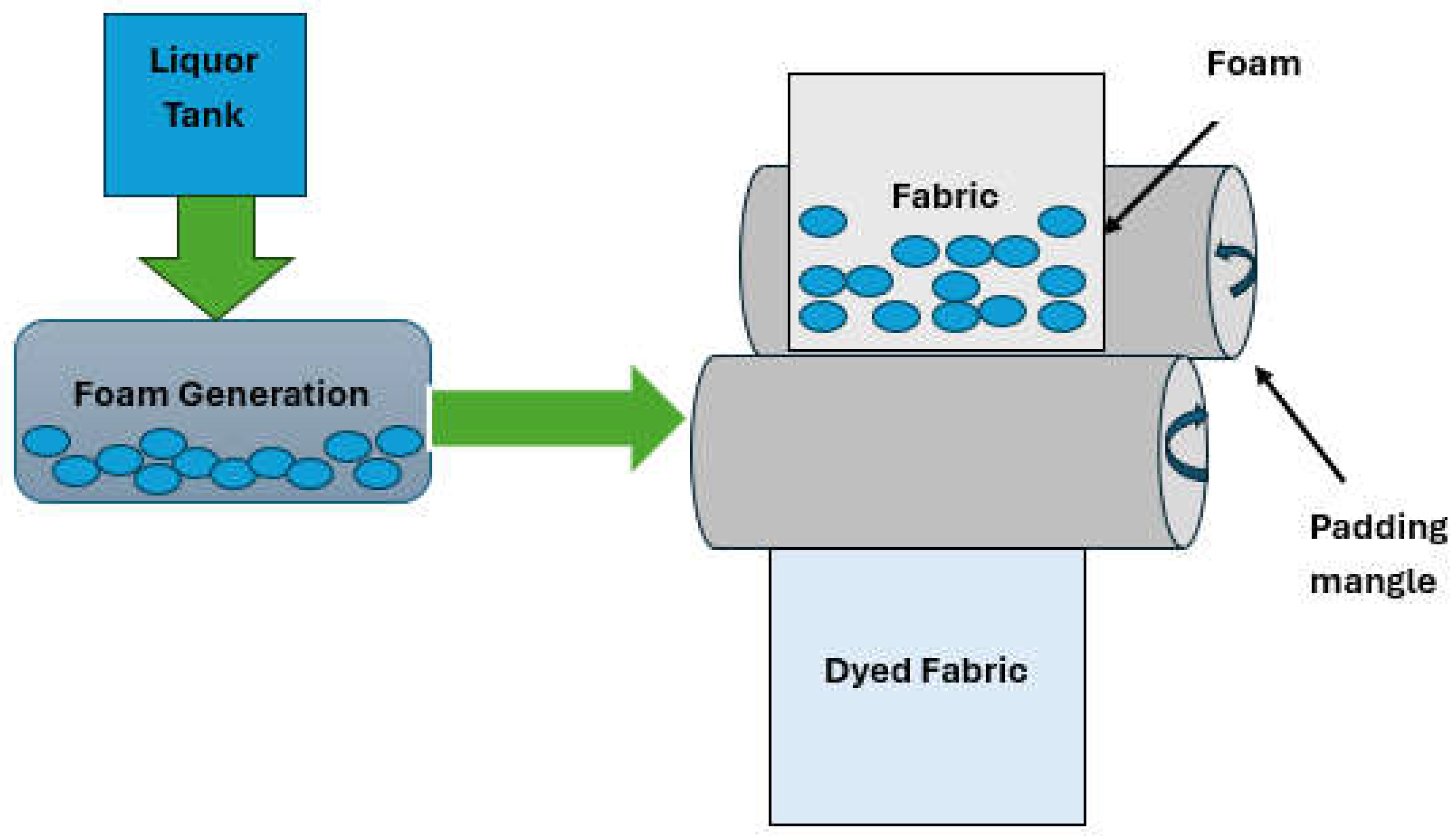

1.4.2. Development of Foam

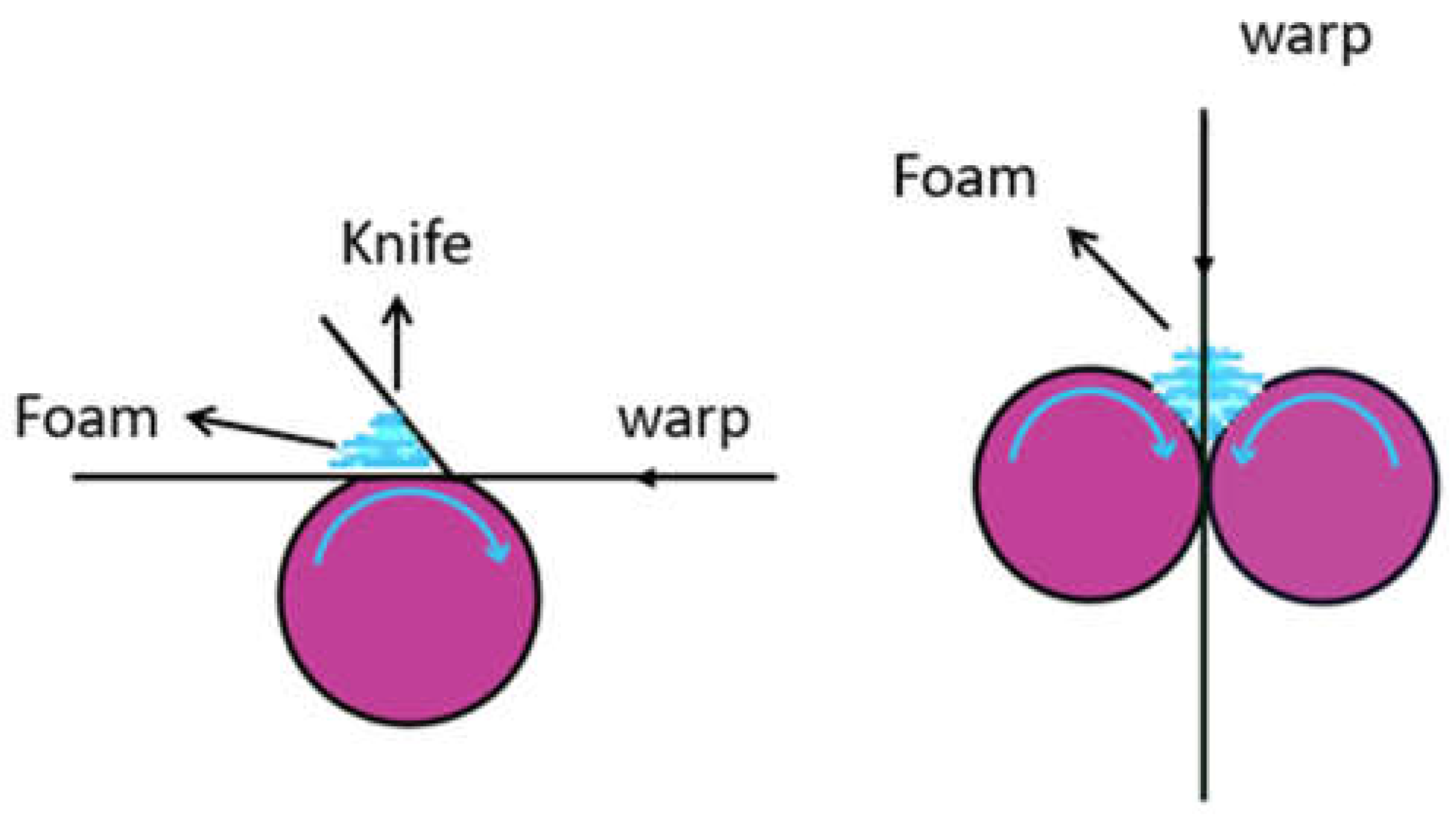

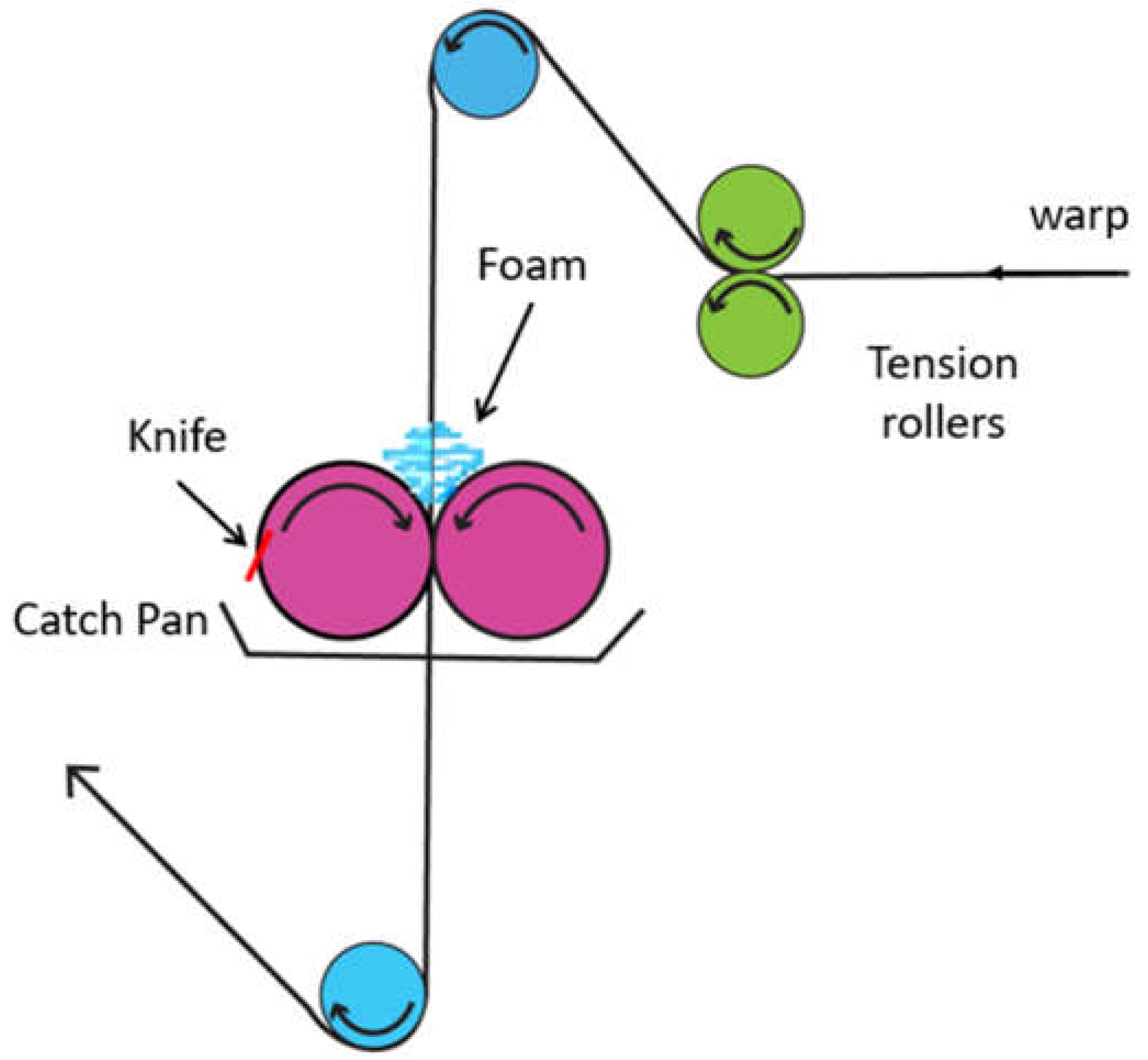

1.4.3. Foam Application Methods in Textiles

1.4.4. Crumpling of Foam

- i.

- Utilization of temperature: Enhancement in drying temperature might cause decline in viscosity, increment in molecular movements in bubble that may cause loss in foaming attributes due to which formation of foam can be prevented.

- ii.

- Addition of defoaming agent: these agents are useful in disappearance of foam to avoid foam in bubbles.

- iii.

- Application of pressure: The bursting of bubbles under extreme pressure

1.4.5. Drying and Fixing

2. Application of Foam Technology in Textile Wet Processing

2.1. Pretreatment Processes

2.2. Coloration Processes

2.2.1. Dyeing of Natural Fiber Substrates

2.2.2. Yarn Dyeing by Foaming Indigo

2.2.3. Dyeing of Synthetic Fiber Substrates

2.3. Comparison of Conventional Processing vs. Foam Processing

2.4. Traditional Dyeing versus Foam Dyeing of Synthetic Fibers

2.5. Foam Finishing

3. Benefits of Foam Dyeing

4. Conclusions

Funding

Conflicts of Interest

References

- Anon, “No Title,” ibisworld.com. Global apparel manufacturing – market size 2005–2027,. Accessed: Aug. 24, 2023. [Online]. Available: https://www.ibisworld.com/global/%0Amarket-size/global-apparel-manufacturing/.

- Low, W.; Thin, T.; Yong, L.Y.; Huei, L.Y.; Nee, T.S. Assessment of red and white clay evaporative rate in simulating perspiration with textile. J. Eng. Sci. Technol. 2023, 18, 3128–3139. [Google Scholar]

- Meena, J.S.; Choi, S.B.; Jung, S.; Kim, J.W. Electronic textiles: New age of wearable technology. Mater. Today Bio 2023, 19, 100565. [Google Scholar]

- al Peng, X. Biopolymers-based microencapsulation technology for sustainable textiles development: A short Review. Case Stud. Chem. Environ. Eng. 2023, 7, 100349. [Google Scholar] [CrossRef]

- Manaia, J.; Cerejo, F.; Duarte, J. Revolutionising textile manufacturing: a comprehensive review on 3D and 4D printing technologies. Fash. Text. 2023, 10, 20. [Google Scholar] [CrossRef]

- Tsolis, A.; Bakogianni, S.; Angalaki, C.; Alexandridis, A. A Review of Clothing Components in the Development of Wearable Textile Antennas: Design and Experimental Procedure. Sensors 2023, 23, 3289. [Google Scholar] [CrossRef] [PubMed]

- Alkaya, E.; Demier, G.N. Sustainable Textile Production: a case study from a woven fabric manufacturing mill in Turkey. J Clean Prod 2014, 14, 595–603. [Google Scholar] [CrossRef]

- Maheshwari, U. A review on adsorption process for removal of dyes fro textile industry effluent. in AICHE annual meeting, virtual 2013; paper no 395 ax. San Francisco, CA USA, 2013.

- Shafiq, F.; et al. Extraction of natural dye from aerial parts of argy wormwood based on optimized taguchi approach and functional finishing of cotton fabric. Materials (Basel) 2021, 14, 19. [Google Scholar] [CrossRef] [PubMed]

- Dobilaitė, V.; Ališauskienė, V.; Sacevičienė, M. Study of Textile Waste Generation and Treatment in Lithuania. Fibres Text. East. Eur 2017, 2017, 8–13. [Google Scholar] [CrossRef]

- P. Morrison, J., Morikawa, M., Murphy, M., Schulte, “No Title,” Water Scarcity Clim. Chang. Grow. Risks Businesses Investors. Ceres 60., 2009.

- Saxena, A.; Raja, S.; Arputharaj, A. Challenges in wet processing of Textiles. Text. Cloth. Sustain 2017, 43–79. [Google Scholar]

- De Moraes, S.G.; Freire, R.S.; Duran, N. Degradation and toxicity reduction of textile effluent by combined photocatalytic and ozonation processes. Chemosphere 2000, 40, 2000. [Google Scholar] [CrossRef]

- Ahmad, S.; Ashraf, M.; Abid, S.; Jabbar, M.; Shafiq, F.; Siddique, A. Recent developments in laser fading of denim: A critical review. J. Nat. Fibers 2022, 1–11. [Google Scholar] [CrossRef]

- Tong, O.; Shao, S.; Zhang, Y.; Chen, Y.; Liu, S.L.; Zhang, S.S. An AHP-Based water- Conservation and waste-Reduction indicator system for cleaner production of textile- Printing industry in China and technique integration. Clean Technol. Environ. Policy 2012, 14, 857–868. [Google Scholar] [CrossRef]

- Petek, J.; Glavic, P. An integral approach to waste minimization in process industries. Conserv. Recycl. 1996, 17, 169–188. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, J.; Yan, J.; Zheng, L. An industrial scale multiple supercritical carbon dioxide apparatus and its eco-friendly dyeing production. J. CO2 Util 2016, 16, 272–281. [Google Scholar] [CrossRef]

- Hussain, A.W.T. A critical review of the current water conservation practices in textile wet processing. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Lu, X.; Liu, L.; Liu, R.; Chen, J. Textile wastewater reuse as an alternative water source for dyeing and finishing processes: A case study. Desalination 2010, 258, 229–232. [Google Scholar] [CrossRef]

- Christie, R.M. Environmental Aspects of Textile Dyeing, First ed. ed.; Woodhead Publishing: Manchester, 2007. [Google Scholar]

- Vandevivere, P.C.; Bianchi, R.; Verstraete, W. Review Treatment and Reuse of Wastewater from the Textile Wet-Processing Industr y : Review of Emerging Technologies. J. Chem. T echnol. Biotechnol 1998, 72, 289–302. [Google Scholar] [CrossRef]

- Kant, R. Textile dyeing industry an environmental hazard. Nat. Sci. 2012, 4, 22–26. [Google Scholar] [CrossRef]

- Pang, Y.L.; Abdullah, A.Z. Current status of textile industry wastewater management and research progress in Malaysia: A review. Clean - Soil, Air, Water 2013, 41, 751–764. [Google Scholar] [CrossRef]

- Tüfekci, N.; Sivri, N.; Toroz, I. Pollutants of Textile Industry Wastewater and Assessment of its Discharge Limits by Water Quality Standards. Turkish J. Fish. Aquat. Sci. 2007, 103, 97–103. [Google Scholar]

- Birk, M.; Schoeberi, P.; Chamam, B.; Braun, R.; Fuchs, W. Advanced treatment of textile wastewater towards reuse using a membrane bioreactor. Process Biochem. 2006, 41, 1751–1757. [Google Scholar] [CrossRef]

- Robinson, T.; McMullan, G.; Marchant, R.; Nigam, P. Remediation of dyes in textile effluent: A critical review on current treatment technologies with a proposed alternative. Bioresour. Technol. 2001. [Google Scholar] [CrossRef] [PubMed]

- Hasanbeigi, A. Energy-Efficiency Improvement Opportunities for the Textile Industry. Lawrence Berkeley Natl. Lab. 2010, 136, 000. [Google Scholar]

- Gleick, P.H.; et al. Waste Not, Want Not: The Potential for Urban Water Conservation. California, 2003.

- Avnir, D.; Kaufman, V.R.; Reisfeld, R. Organic fluorescent dyes trapped in silica and silicatitania thin films by the sol-gel method. Photophysical, film and cage properties. J. Non. Cryst. Solids 1985, 74, 395–406. [Google Scholar] [CrossRef]

- Chao, C.; Guan, H.; Zhang, J.; Liu, Y.; Zhao, Y.; Zhang, B. Immobilization of laccase onto porous polyvinyl alcohol/halloysite hybrid beads for dye removal. Water Sci. Technol. 2017. [Google Scholar] [CrossRef] [PubMed]

- Laing, I.G. The impact of effluent regulations on the dyeing industry. Rev. Prog. Color. Relat. Top. 1991, 21, 56–71. [Google Scholar] [CrossRef]

- Smith, J.; Rucker, B. Water And Textile Wet Processing - Part I. Am. Dye. Report. 1987, 17–23. [Google Scholar]

- Schmid, P. Process for ungumming. silk. Patent 848605-A, USA, 1907. [Google Scholar]

- Schmid, P. Apparatus for ungumming silk fabrics. Patent 83 1997, 1906. [Google Scholar]

- Gregorian, R.S.; Bafford, R.A.; Namboodri, C.G. The Utilization of foams in the wet processing of textiles. ACS Symp. Ser. 1979, 107, 155. [Google Scholar]

- Abadte, M.T.; Tadese, M.G. Airflow, Foam, and Supercritical Carbon Dioxide Dyeing Technologies. In Innovative and Emerging Technologies for Textile Dyeing and Finishing; Scrivener Publishing LLC, 201AD; pp. 137–164.

- Dawson, T.L. Foam dyeing and printing of carpets. J. Soc. Dye. Colour. 1981, 97, 262. [Google Scholar] [CrossRef]

- Bickerman, J.J.; Foams, J.J. New York Inc: Springer-Verlag,.

- Capponi, M.; Flister, A.; Hasler, R.; Oschatz, C.; Robert, G.; Robinson, T.; Stakelbeck, H.P.; Tschudin, P.; Vierlina, J.P. Foam technology in textile processing. Rev. Prog. Color. 1982, 12, 48. [Google Scholar] [CrossRef]

- Elbadawi, A.M.; Pearson, J.S. Foam technology in textile finishing. Text. Prog. 2003, 33, 1. [Google Scholar] [CrossRef]

- Lunkenheimer, K.; Tcholakova, S.; Brinkova, N.P. Physicochemical control of foam properties. Curr Opin Colloid Interface Sci 2020, 50, 101376. [Google Scholar]

- Lunkenheimer, K.; Malysa, K. Simple and generally applicable method of determination and evaluation of foam properties. J surfactants Deterg 2003, 6, 69–74. [Google Scholar] [CrossRef]

- Ashby, M. The properties of foams and lattices. Pjilosophical Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 15–30. [Google Scholar] [CrossRef] [PubMed]

- Ergun, M.; Ergun, H. Influence of activated carbon concentration on foam material properties: Design and optimization. Arab J Sci. 2024, 49, 4877–4888. [Google Scholar] [CrossRef]

- et al Mohsin. Performance enhancement of water and energy efficient foam dyeing and finishing though different foaming agents. J. Nat. Fibers 2023, 20. [Google Scholar]

- Vidalis, T. Continuous foam dyeing apparatus and method. US Patent 5168731; assigned to Vidalis Laura MA 1698 Laurelwood Place Gloucester Orleans Ontario Canada K1C 6Y4 Vidalis Serge E 1698 Laurelwood Place Gloucester Orleans Ontario Canada K1C 6Y4, 1698. [Google Scholar]

- Denkov, N.D. Mechanisms of foam destruction by oil-based antifoams. Langmuir 2004, 20, 463. [Google Scholar] [CrossRef] [PubMed]

- Koh, J. Dyeing of cellulosic fibres. In Handbook of textile and industrial dyeing; Clark, M., Ed.; Woodhead Publishing Limited: Cambridge, 2011; pp. 129–146. [Google Scholar]

- Chequer, F.D.; de Oliveira GA, R.; Ferraz, E.A.; Cardoso, J.C.; Zanoni, M.B.; de Oliveira, D.P. Textile dyes: dyeing process and environmental impact. In Eco-Friendly Textile Dyeing and Finishing; Gunay, M., Ed.; Intech: London, 2013; pp. 151–176. [Google Scholar]

- Faber, L.D.R.; Carroll, C.J. Method of treating textile materials and the like. Patent 194 8568, 1934. [Google Scholar]

- Lister, G.H. water conservation—an alternative to solvent dyeing? J Soc Dye. Colour 1972, 88, 9–14. [Google Scholar] [CrossRef]

- Perkins, W.S.; Walker, R.P. Foam sizing. Text Res J 1982, 52, 547–554. [Google Scholar] [CrossRef]

- Turner, J.D.; Blanton, W.A.; Kravetz, L. Foam mercerization. Text Res J 1982, 52, 73–76. [Google Scholar] [CrossRef]

- Namboodri, C.G. Foam sizing of cotton and blend yarns: slashing trials. Text Res J 1986, 56, 87–92. [Google Scholar] [CrossRef]

- Yu, H.; Wang, Y.; Zhong, Y. Foam properties and application in dyeing cotton fabrics with reactive dyes. Color Technol 2014, 130, 266–272. [Google Scholar] [CrossRef]

- Lambart, A.H.; Harper, R.J. Cross linking Single side Cotton, via foam finishing to produce garment dyeable fabrics. J Coat Fabr 1990, 19, 169–180. [Google Scholar] [CrossRef]

- Bhavsar, P.S.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Mossotti, R.; Giansetti, M.; Rovero, G.; Maier, S.S.; Muresan, A.; Tonin, C. Superheated Water Hydrolyzed Keratin: A New Application as a Foaming Agent in Foam Dyeing of Cotton and Wool Fabrics. ACS Sustain. Chem. Eng. 2017. [Google Scholar] [CrossRef]

- Shaoyu, C.; Chaoxia, W.; Liang, F. A novel strategy for realizing environmentally friendly pigment foam dyeing using polyoxyethylene surfactant C14EO5 as foam controller. Color Technol. 2017, 133, 253–261. [Google Scholar]

- Farias, L.T. Progress in chemical foam technology for dyeing applications. AATCC Rev 2013, 13, 36–41. [Google Scholar]

- Shang, S.; Hu, E.; Poon, P. Foam dyeing for developing wash out effect on cotton knitted fabrics with pigments. Res J Text Appar 2011, 15, 44–51. [Google Scholar] [CrossRef]

- Magda M, S.S.; Kamel, S. Foam dyeing with vat dyes. Am Dye. Rep 1997, 86, 35–41. [Google Scholar]

- Wang, P.X.Q.; Zhou, W.; Du, S.; Yang, X.; Zhang, M.; Chang, Y.; Cui, S. Application of foam dyeing technology on ultra-fine polyamide filament fabrics with acid dye. Text. Res. J. 2019, 1–9. [Google Scholar] [CrossRef]

- Chen, S.; Fei, L.; Ge, F.; Liu, J.; Yin, Y.; Wang, C. A versatile and recycled pigment foam coloring approach for natural and synthetic fibers with nearly- zero pollutant discharge. J. Clean. Prod 2020, 243. [Google Scholar] [CrossRef]

- Shakra, S.; Hanna, H.L.; Kharadly, E.A. Foam dyeing with reactive dyes and its effect on the fastness properties of dyeings. Am Dye. Rep 78, 60.

- Hoque, E.; Acharya, S.; Shamshina, J.; Abidi, N. Review of foam applications on Cotton Textiles. Text. Res. J. 2022, 1–16. [Google Scholar] [CrossRef]

- Berendt, H.U.; Schafer, P. Process for dyeing or printing cellulose-containing textile material with vat dye. foam. Patent 4613335-A, 1986. [Google Scholar]

- Aurich, C.W.; Zeiffer, D.F.; Neupert, H.A. Apparatus for dyeing textile substrates with foamed dye. Patent 2008/ 147515-AI, 2008. [Google Scholar]

- Malpass, H.; Tharpe, R.; Ethridge, M.D. Indigo dyeing Fabrics, process and apparatus and indigo dyed yarns and made thereby. Patent 10619292-B2, 2020. [Google Scholar]

- Kumins, C.A.; Jerome, F.; Chase, V.L. Process of coloring textile materials. Patent 2971458, 1961. [Google Scholar]

- Hutzler, S.; Cox, S.J.; Wang, G. Foam drainage in two dimensions. Colloid Surf A Physicochem Eng Asp. 2005, 263, 178–183. [Google Scholar] [CrossRef]

- Siva, M.; Ramamurthy, K.K.; Dhamodharan, R. Sodium salt admixtures for enhancing the foaming characteristics of sodium lauryl sulphate. Cem. Concr. Compos 2015, 57, 133–141. [Google Scholar] [CrossRef]

- Sun, L.; Wang, B.; Pu, W. The effect of foam stability on foam flooding recovery. Pet. Sci Technol 2015, 33, 15–22. [Google Scholar] [CrossRef]

- Wang, J.J.; Nguyen, A.V.; Farrokhpay, S. A critical review of the growth, drainage and collapse of foams. Adv Colloid Interface Sci 2016, 228, 55–70. [Google Scholar] [CrossRef] [PubMed]

- Mao, Z.; Yu, H.; Wang, Y. States of Water and Pore Size Distribution of Cotton Fibers with Different Moisture Ratios. Ind 2014, 53, 8927–8934. [Google Scholar] [CrossRef]

- Sarwar, N.; Mohsin, M.; Bhatti, A.A.; Ahmmad, S.W.; Husaain, A. Development of water and energy efficient environment friendly easy care finishing by foam coating on stretch denim fabric. J. Clean. Prod. 2017, 154, 159–166. [Google Scholar] [CrossRef]

- Mohsin, M.; Shaheen, S. Multi-criteria decision analysis for textile pad-dyeing and foam-dyeing based on cost, performance, productivity and sustainability. Cellulose 2019. [Google Scholar] [CrossRef]

- Choudhury, A.R. Dyeing of synthetic fibres. In Handbook of Textile and Industrial Dyeing; Clark, M., Ed.; Woodhead Publishing Limited: Cambridge, 2011; pp. 40–128. [Google Scholar]

- Abrahams, G.A.; Douglas, D.H. Douglas, Foam dyeing process. US Patent 3762860; assigned to Dexter Chemical Corporation, 1973. [Google Scholar]

- Mohsin, M.; Shaheen, S. Development of sustainable and cost efficient textile foamfinishing and its comparison with conventional padding. Cellulose 2020. [Google Scholar] [CrossRef]

- Song, D.C.M.; Hou, J.; Lu, Y.; Lin, J. Performance of Foam and Application in Foam Finishing of Textile. Adv. Mater. Res. 2013, 821–822, 661–664. [Google Scholar] [CrossRef]

- Van Der Walt, G.H.J.; Van Resenburg, N.J.J. Low liquor dyeing and finishing. Text. Prog 2009, 14, 2009. [Google Scholar] [CrossRef]

- Kumar, P.S.; Yaashikaa, P.R. Sustainable dyeing techniques. In Sustainable Innovations in Textile Chemical Processes; Muthu, S., Ed.; Springer: Singapore, 2018; pp. 1–29. [Google Scholar]

| Sr.# | Dye/ pigment /substrate |

Dye/ pigment conc. |

Wet Pick Up | Water consumption | Energy consumption | Dyes and chemicals consumption |

Color strength (K/S) | Rubbing Fastness | Washing fastness | Ref. | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dry | Wet | ||||||||||||||||||||

| Foam dyeing | Conventional (exhaust/continuous) | Foam dyeing | conventional | Foam dyeing | conventional | Foam dyeing | Foam dyeing | Conventional pad dyeing | Foam dyeing | Conventional pad dyeing | Foam dyeing | Conventional pad dyeing | Foam dyeing | Conventional dyeing | |||||||

| 1 | CI Reactive Red 120 | 1.80 o.w.f | 30-40% | - | less | More | Less energy consumption | more | - | 15.0 | 12.0 | 5.0 | 5.0 | 2.0-3.0 | 2.0 | high | low | [55] | |||

| 2 | Reactive orange 16 | 3.0% o.w.f | - | - | - | - | - | - | - | 12.5 | - | - | - | - | - | - | - | [56] | |||

| 3 | Reactive blue 184 | 3.0% o.w.f | - | - | - | - | - | - | - | 18.2 | - | - | - | - | - | - | - | [56] | |||

| 4 | Reactive blue 19 | 3% o.w.f |

- | - | - | - | - | - | - | 9.9 | - | - | - | - | - | - | - | [56] | |||

| 5 | Acid orange 74 | 3.0% o.w.f |

- | - | - | - | - | - | - | 7.4 | - | - | - | - | - | - | - | [56] | |||

| 6 | Intracron Red VS-4BL | 3.0% o.w.f |

- | - | - | - | - | - | - | 12.5 | - | - | - | - | - | - | - | [56] | |||

| 7 | Levafix Navy CA | 1-5.0% o.w.f |

40% | 70 % | Water efficient | - | Energy efficient | - | - | 15.0 | 15.0 | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 | 4.0-5.0 | 4/5 | 4/5 | [57] | |||

| 8 | Nylosan Navy S-3G SGR | 1-5.0% o.w.f |

40% | 70 % | Water efficient | - | Energy efficient | - | - | 21 | 21 | 4/5 | 4-4/5 | 4/5 | 4-4/5 | 4/5-5 | 5 | [57] | |||

| 9 | CI Pigment Red 254 | 6.0% o.w.f |

- | - | Reduced water consumption | - | - | - | - | 7.8 | - | 4.0 | - | 3.0-4.0 | - | - | - | [58] | |||

| 10 | Brand A (Black) | 100.0 g/L |

- | - | - | - | - | - | - | - | - | 3.0 | 5.0 | 3.0 | 2.5 | - | - | [59] | |||

| 11 | Printofix Blue T-K | 100.0 g/L |

- | - | - | - | - | - | - | - | - | 4.0 | - | 4.0 | - | - | - | [60] | |||

| 12 | Printofix Black T-M | 100.0 g/L |

- | - | - | - | - | - | - | - | - | 3.0-4.0 | - | 3.0 | - | - | - | [60] | |||

| 13 | Printofix Navy T-V | 100.0 g/L |

- | - | - | - | - | - | - | - | - | 3.0-4.0 | - | 2.0-3.0 | - | - | - | [60] | |||

| 14 | Printofix Yellow T-G | 100.0 g/L |

- | - | - | - | - | - | - | - | - | 4.0 | - | 2.0 | - | - | - | [60] | |||

| 15 | CI reactive Red 120 | - | 30% | 80% pad steam | 300kg | 1600kg | 23.54 | 122.29 | reduced | Improved | - | Improved | - | Improved | - | - | - | [55] | |||

| 16 | Reactive dye | - | - | - | - | - | - | - | - | Comparable to conventional | - | Comparable to conventional | - | Comparable to conventional | - | - | - | [57] | |||

| 17 | C14[EO]5 Pigment | - | - | - | - | - | - | - | - | Improved | - | - | - | - | - | - | - | [58] | |||

| 18 | Vat dye | - | - | - | - | - | - | - | - | - | - | Comparable to conventional | - | Comparable to conventional | - | - | - | [61] | |||

| 19 | Acid dye on polyamide fikaments | - | - | exhaust | - | - | - | - | - | incraesed | - | - | - | - | - | Comparable | - | [62] | |||

| 20 | Reactive and acid | Wool and cotton | 40% | c40% Pad batch |

- | - | - | - | - | improved | - | comparable | - | comparable | comparable | - | - | [57] | |||

| 21 | Pigment dispersion/cotton, silk and polyester | - | - | Exhaust dyeing | - | - | - | - | - | improved | - | improved | - | improved | improved | - | - | [63] | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).