Submitted:

03 July 2024

Posted:

04 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature review

2.1. Industrial robots

2.2. Labor productivity

2.3. Quality

2.4. Exports

2.5. Sustainability

2.6. Research hypothesis formulation

3. Materials and Methods

4. Results

4.1. Descriptive results

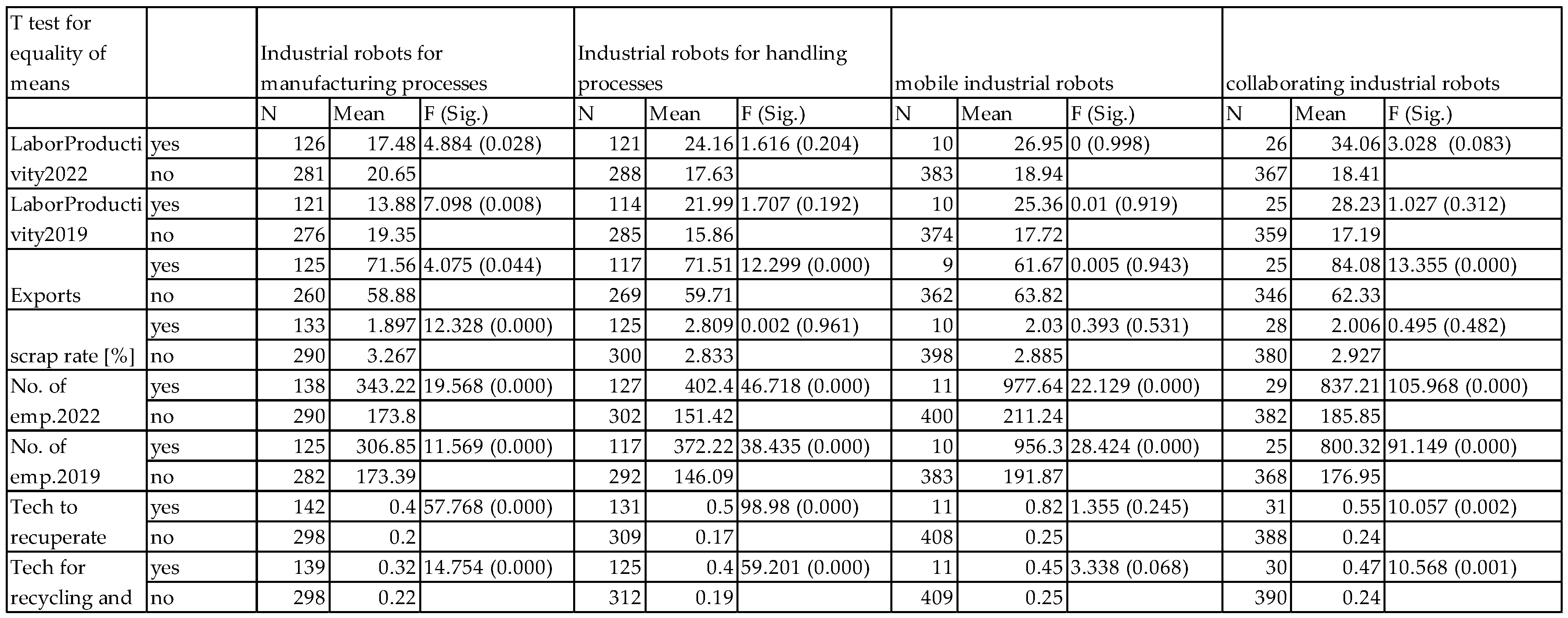

4.2. Hypotheses testing

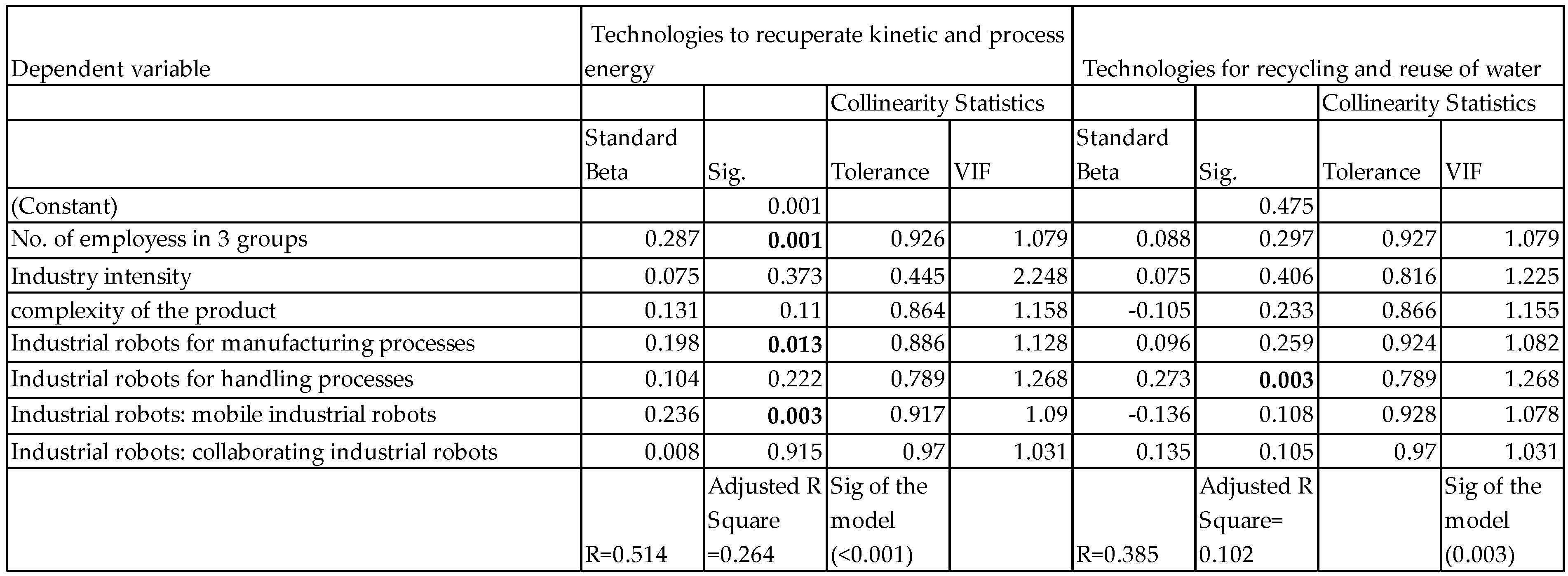

4.3. Regression analysis

4.4. Summary of findings

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- IFR World Robotics 2023 – Industrial Robots; Frankfurt, 2023.

- Duan, D.; Chen, S.; Feng, Z.; Li, J. Industrial Robots and Firm Productivity. Structural Change and Economic Dynamics 2023, 67, 388–406. [Google Scholar] [CrossRef]

- Acemoglu, D.; Restrepo, P. Robots and Jobs: Evidence from US Labor Markets. Journal of Political Economy 2019, 128, 2188–2244. [Google Scholar] [CrossRef]

- Aggogeri, F.; Pellegrini, N.; Taesi, C. Towards Industrial Robots’ Maturity: An Italian Case Study. Robotics 2024, 13, 42. [Google Scholar] [CrossRef]

- Klenert, D.; Fernández-Macías, E.; Antón, J.-I. Do Robots Really Destroy Jobs? Evidence from Europe. Economic and Industrial Democracy 2022, 44, 280–316. [Google Scholar] [CrossRef]

- Acemoglu, D.; Lelarge, C.; Restrepo, P. Competing with Robots: Firm-Level Evidence from France. In Proceedings of the AEA papers and proceedings; American Economic Association 2014 Broadway, Suite 305, Nashville, TN 37203, 2020; Vol. 110, pp. 383–388.

- Kromann, L.; Malchow-Møller, N.; Skaksen, J.R.; Sørensen, A. Automation and Productivity—a Cross-Country, Cross-Industry Comparison. Industrial and Corporate Change 2020, 29, 265–287. [Google Scholar] [CrossRef]

- Graetz, G.; Michaels, G. Robots at Work. Review of Economics and Statistics 2018, 100, 753–768. [Google Scholar] [CrossRef]

- Cheng, H.; Yuan, L. Robot Use, Process Innovation and Quality Improvement-Empirical Evidence from the China Enterprise General Survey (CEGS). Southern Economy,(01) 2020, 46–59. [Google Scholar]

- Cross, P.; Cameron, G. The Importance of Exports to GDP and Jobs. Canadian Economic Observer 1999, 12, 3.1–3.5. [Google Scholar]

- Ogbemhe, J.; Mpofu, K.; Tlale, N.S. Achieving Sustainability in Manufacturing Using Robotic Methodologies. Procedia Manuf 2017, 8, 440–446. [Google Scholar] [CrossRef]

- Knoppen, D.; Knight, L. Pursuing Sustainability Advantage: The Dynamic Capabilities of Born Sustainable Firms. Bus Strategy Environ 2022, 31, 1789–1813. [Google Scholar] [CrossRef]

- Eder, A.; Koller, W.; Mahlberg, B. The Contribution of Industrial Robots to Labor Productivity Growth and Economic Convergence: A Production Frontier Approach. Journal of Productivity Analysis 2024, 61, 157–181. [Google Scholar] [CrossRef]

- Makulavičius, M.; Petkevičius, S.; Rožėnė, J.; Dzedzickis, A.; Bučinskas, V. Industrial Robots in Mechanical Machining: Perspectives and Limitations. Robotics 2023, 12, 160. [Google Scholar] [CrossRef]

- DeStefano, T.; Timmis, J. Robots and Export Quality. J Dev Econ 2024, 168, 103248. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Optimization of Energy Consumption in Industrial Robots, a Review. Cognitive Robotics 2023, 3, 142–157. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Liu, Y.; Wu, H. Can Industrial Robots Reduce Carbon Emissions? Based on the Perspective of Energy Rebound Effect and Labor Factor Flow in China. Technol Soc 2023, 72, 102208. [Google Scholar] [CrossRef]

- Panda, B.K.; Panigrahi, S.S.; Mishra, G.; Kumar, V. Chapter Thirteen - Robotics for General Material Handling Machines in Food Plants. In Transporting Operations of Food Materials Within Food Factories; Jafari, S.M., Malekjani, N., Eds.; Woodhead Publishing, 2023; pp. 341–372 ISBN 978-0-12-818585-8.

- Farooq, M.U.; Eizad, A.; Bae, H.-K. Power Solutions for Autonomous Mobile Robots: A Survey. Rob Auton Syst 2023, 159, 104285. [Google Scholar] [CrossRef]

- Grover, A.K.; Ashraf, M.H. Leveraging Autonomous Mobile Robots for Industry 4.0 Warehouses: A Multiple Case Study Analysis. The International Journal of Logistics Management 2023. [Google Scholar] [CrossRef]

- Löffler, M.; Boysen, N.; Schneider, M. Human-Robot Cooperation: Coordinating Autonomous Mobile Robots and Human Order Pickers. Transportation science 2023, 57, 979–998. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, X.; Lin, Q.; Shan, J.; Jia, S.; Ye, W. A High-Accuracy Positioning Method for Mobile Robotic Grasping with Monocular Vision and Long-Distance Deviation. Measurement 2023, 215, 112829. [Google Scholar] [CrossRef]

- Borboni, A.; Reddy, K.V.V.; Elamvazuthi, I.; AL-Quraishi, M.S.; Natarajan, E.; Azhar Ali, S.S. The Expanding Role of Artificial Intelligence in Collaborative Robots for Industrial Applications: A Systematic Review of Recent Works. Machines 2023, 11, 111. [Google Scholar] [CrossRef]

- Zhang, L.; Gan, T.; Fan, J. Do Industrial Robots Affect the Labour Market? Evidence from China. Economics of Transition and Institutional Change 2023, 31, 787–817. [Google Scholar] [CrossRef]

- Prettner, K. Stagnant Wages in the Face of Rising Labor Productivity: The Potential Role of Industrial Robots. Financ Res Lett 2023, 58, 104687. [Google Scholar] [CrossRef]

- Chung, J.; Lee, Y.S. The Evolving Impact of Robots on Jobs. ILR Review 2022, 76, 290–319. [Google Scholar] [CrossRef]

- Yuan, W.; Lu, W. Research on the Impact of Industrial Robot Application on the Status of Countries in Manufacturing Global Value Chains. PLoS One 2023, 18, e0286842. [Google Scholar] [CrossRef] [PubMed]

- Acemoglu, D.; Koster, H.R.A.; Ozgen, C. Robots and Workers: Evidence from the Netherlands; Cambridge, MA, 2023.

- DeStefano, T.; Timmis, J. Robots and Export Quality. J Dev Econ 2024, 168, 103248. [Google Scholar] [CrossRef]

- Yang, S.; Liu, F. Impact of Industrial Intelligence on Green Total Factor Productivity: The Indispensability of the Environmental System. Ecological Economics 2024, 216, 108021. [Google Scholar] [CrossRef]

- Azamfirei, V.; Granlund, A.; Lagrosen, Y. Lessons from Adopting Robotic In-Line Quality Inspection in the Swedish Manufacturing Industry. Procedia Comput Sci 2023, 217, 386–394. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, Q.; Wu, H. Robot Adoption and Export Performance: Evidence from Chinese Industrial Firms. Journal of Manufacturing Technology Management 2023, 34, 896–916. [Google Scholar] [CrossRef]

- Li, L.; Ding, Y.-N.; Fan, J.-C. Industrial Robots and Export Growth: A Cross-Country Analysis. Appl Econ Lett 2024, 1–5. [Google Scholar] [CrossRef]

- Qi, J.; Zhang, Z. Robot Application and Adjustment of Export Product Scope: Can We Have Both Efficiency and Quality? China Finance and Economic Review 2023, 12, 67–88. [Google Scholar]

- Yang, C.-H. Exports and Innovation: The Role of Heterogeneity in Exports. Empir Econ 2018, 55, 1065–1087. [Google Scholar] [CrossRef]

- Zhu, H.; Sang, B.; Zhang, C.; Guo, L. Have Industrial Robots Improved Pollution Reduction? A Theoretical Approach and Empirical Analysis. China & World Economy 2023, 31, 153–172. [Google Scholar] [CrossRef]

- Eurostat Exports of Goods and Services in % of GDP; Brussels, 2023.

- Fraunhofer-Institut für System- und Innovationsforschung European Manufacturing Survey (EMS) - Project Description. Available online: https://www.isi.fraunhofer.de/en/themen/wertschoepfung/fems.html (accessed on 29 May 2024).

- The Institute for Social Research (ISR) Overview of Survey Methodology.

- Prester, J.; Bikfalvi, A.; Palčič, I. The Effect of Product Complexity on Servitization and Deservitization: A Multi-Country Quantitative Analysis. Sustainability 2022, 14, 1–16. [Google Scholar] [CrossRef]

- Armstrong, J.S.; Overton, T.S. Estimating Nonresponse Bias in Mail Surveys. Journal of marketing research 1977, 14, 396–402. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. Journal of Applied Psychology 2003, 88. [Google Scholar] [CrossRef] [PubMed]

- Eurostat Aggregations of Manufacturing Based on NACE Rev. 2; Brussels, 2024.

- Grau, A.; Indri, M.; Bello, L. Lo; Sauter, T. Robots in Industry: The Past, Present, and Future of a Growing Collaboration With Humans. IEEE Industrial Electronics Magazine 2021, 15, 50–61. [Google Scholar] [CrossRef]

- Picco, E.; Miglioretti, M.; Le Blanc, P.M. Sustainable Employability, Technology Acceptance and Task Performance in Workers Collaborating with Cobots: A Pilot Study. Cognition, Technology & Work 2024, 26, 139–152. [Google Scholar]

- Song, J.; Chen, Y.; Luan, F. Air Pollution, Water Pollution, and Robots: Is Technology the Panacea. J Environ Manage 2023, 330, 117170. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, F.; Mai, Q. Robot Adoption and Green Productivity: Curse or Boon. Sustain Prod Consum 2022, 34, 1–11. [Google Scholar] [CrossRef]

- Percival, J.C. Complementarities Between Advanced Manufacturing Technologies. IEEE Trans Eng Manag 2009, 56, 115–128. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, T.; Liu, C. Beyond the Modern Productivity Paradox: The Effect of Robotics Technology on Firm-Level Total Factor Productivity in China. J Asian Econ 2024, 90, 101692. [Google Scholar] [CrossRef]

| Type of robots | Spain | Croatia | Slovakia | Slovenia | Total | Share |

| Industrial robots for manufacturing processes | 17 | 21 | 28 | 77 | 143 | 30.3% |

| Industrial robots for handling processes | 21 | 26 | 28 | 57 | 132 | 28.0% |

| Mobile industrial robots | 0 | 2 | 1 | 8 | 11 | 2.3% |

| Collaborating industrial robots | 7 | 3 | 6 | 15 | 31 | 6.6% |

| Number of companies having at least one type of robot | 25 | 39 | 41 | 90 | 195 | 41.3% |

| Model | Dependent variable: Number of different kinds of robots | Collinearity Statistics | ||||

| Stand. Beta | t | Sig. | Tolerance | VIF | ||

| 1 | (Constant) | 1.412 | 0.16 | |||

| No. of employees in 3 groups | 0.195 | 2.339 | 0.021 | 0.995 | 1.005 | |

| Industry intensity | -0.186 | -2.083 | 0.039 | 0.869 | 1.151 | |

| Product complexity | -0.022 | -0.242 | 0.809 | 0.871 | 1.148 | |

| 2 | (Constant) | 2.086 | 0.039 | |||

| No. of employees in 3 groups | 0.063 | 0.763 | 0.447 | 0.877 | 1.14 | |

| Industry intensity | -0.198 | -2.386 | 0.018 | 0.867 | 1.153 | |

| Product complexity | -0.041 | -0.487 | 0.627 | 0.847 | 1.181 | |

| Technologies to recuperate kinetic and process energy | 0.311 | 3.707 | 0.001 | 0.844 | 1.184 | |

| Technologies for recycling and reuse of water | 0.203 | 2.55 | 0.012 | 0.944 | 1.059 | |

| Model Summary | Change Statistics | |||||

| Model | R | R Square | Δ R Square | Δ Sig. F | ||

| 1 | 0.266 | 0.071 | 0.05 | 0.02 | ||

| 2 | 0.463 | 0.214 | 0.184 | 0.001 | ||

| Small | Medium | Large | |

|---|---|---|---|

| Industrial robots for manufacturing processes | 21% | 32% | 43% |

| Industrial robots for handling processes | 20% | 27% | 45% |

| Industrial robots: mobile industrial robots | 1% | 1% | 8% |

| Industrial robots: collaborating industrial robots | 4% | 5% | 17% |

| Type of robot | Low tech | Medium - low tech | Medium-high tech | High-tech |

|---|---|---|---|---|

| Industrial robots for manufacturing processes | 17.42% | 36.73% | 39.05% | 25.00% |

| Industrial robots for handling processes | 29.55% | 29.08% | 26.67% | 28.57% |

| Mobile industrial robots | 1.52% | 1.02% | 5.71% | 3.57% |

| Collaborating robots | 1.52% | 6.12% | 14.29% | 7.14% |

| Share of companies having at least one robot type | 32.6% | 46.9% | 46.7% | 39.3% |

| Hypotheses | Conclusion |

| H1: In companies that adopted robots we will see higher productivity than non-adopters | Partially confirmed |

| H2: There is no statistically significant difference in number of workers in 2022 and 2019 in companies that have industrial robots. | confirmed |

| H3: Adopters of industrial robots will have statistically significant lower scrap rate than non-adopters. | confirmed |

| H4: Adopters of industrial robots will have statistically significant higher exports than non-adopters. | confirmed |

| H5: Adopters of industrial robots will have statistically significant higher usage of ecological technology than non-adopters. | confirmed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).