Submitted:

02 July 2024

Posted:

03 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Research Methodology

2.1. Theoretical Background

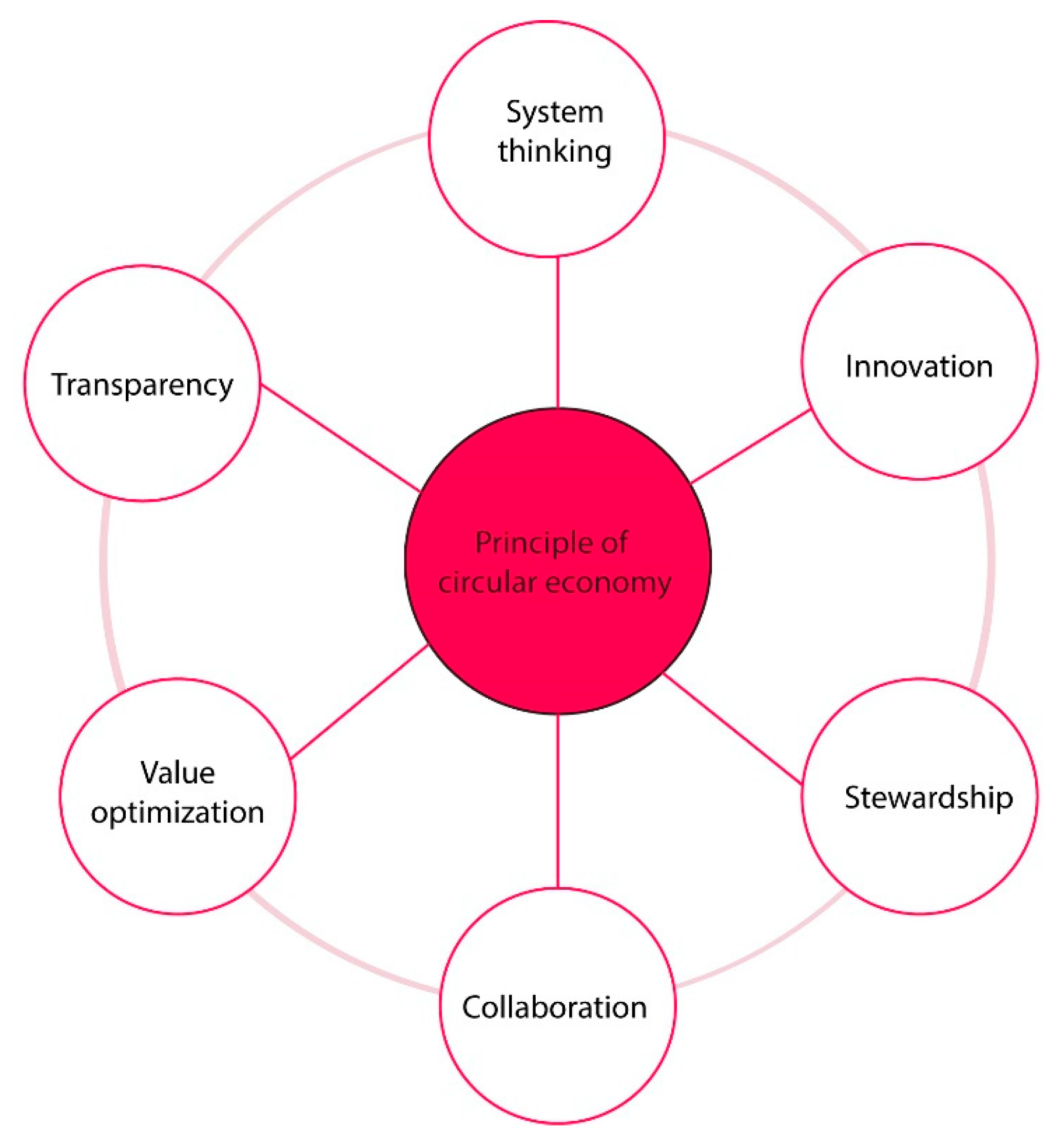

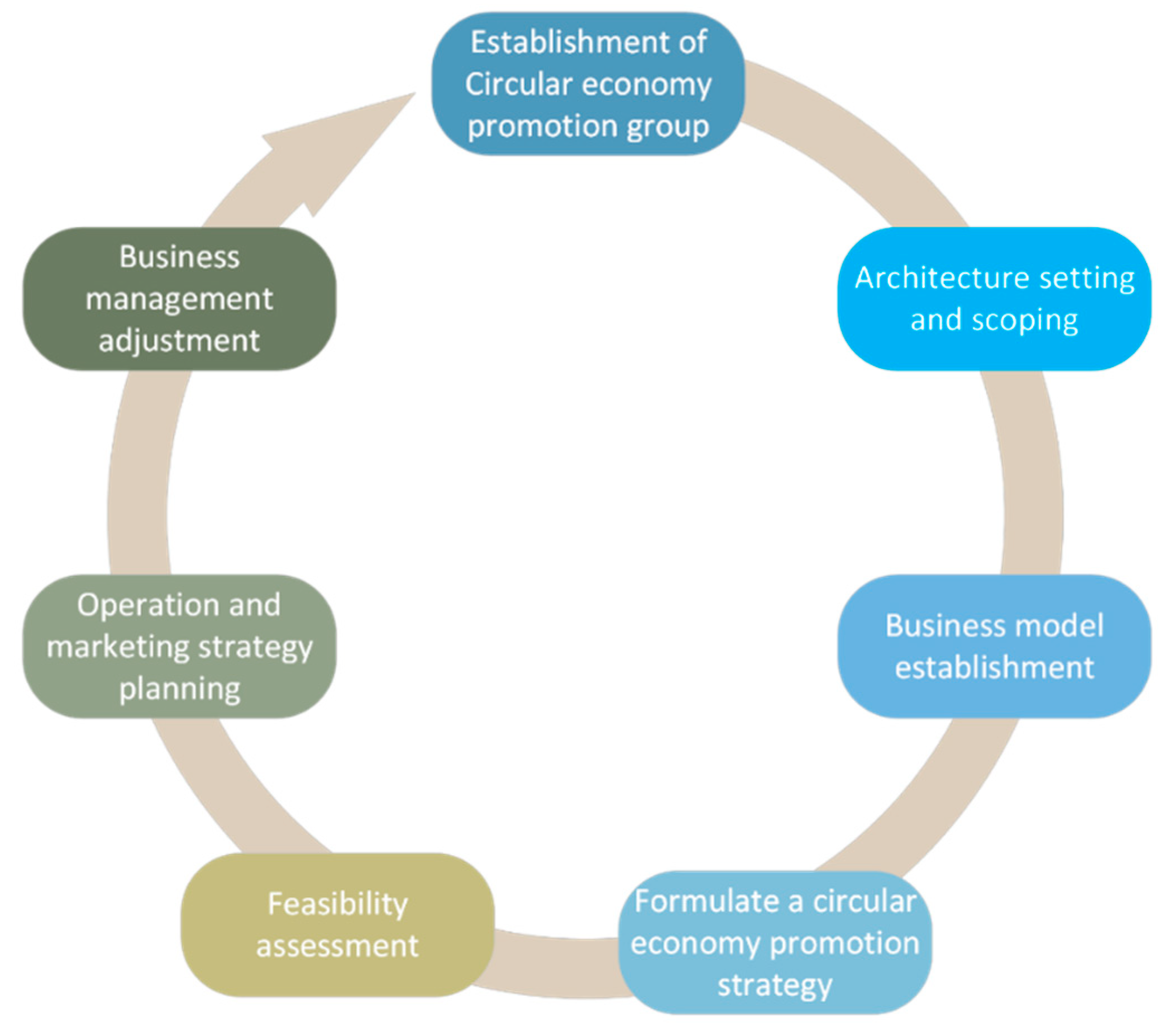

2.2. Implementation of Circular Economy

2.3. Research Procedure

3. Research Background and Information

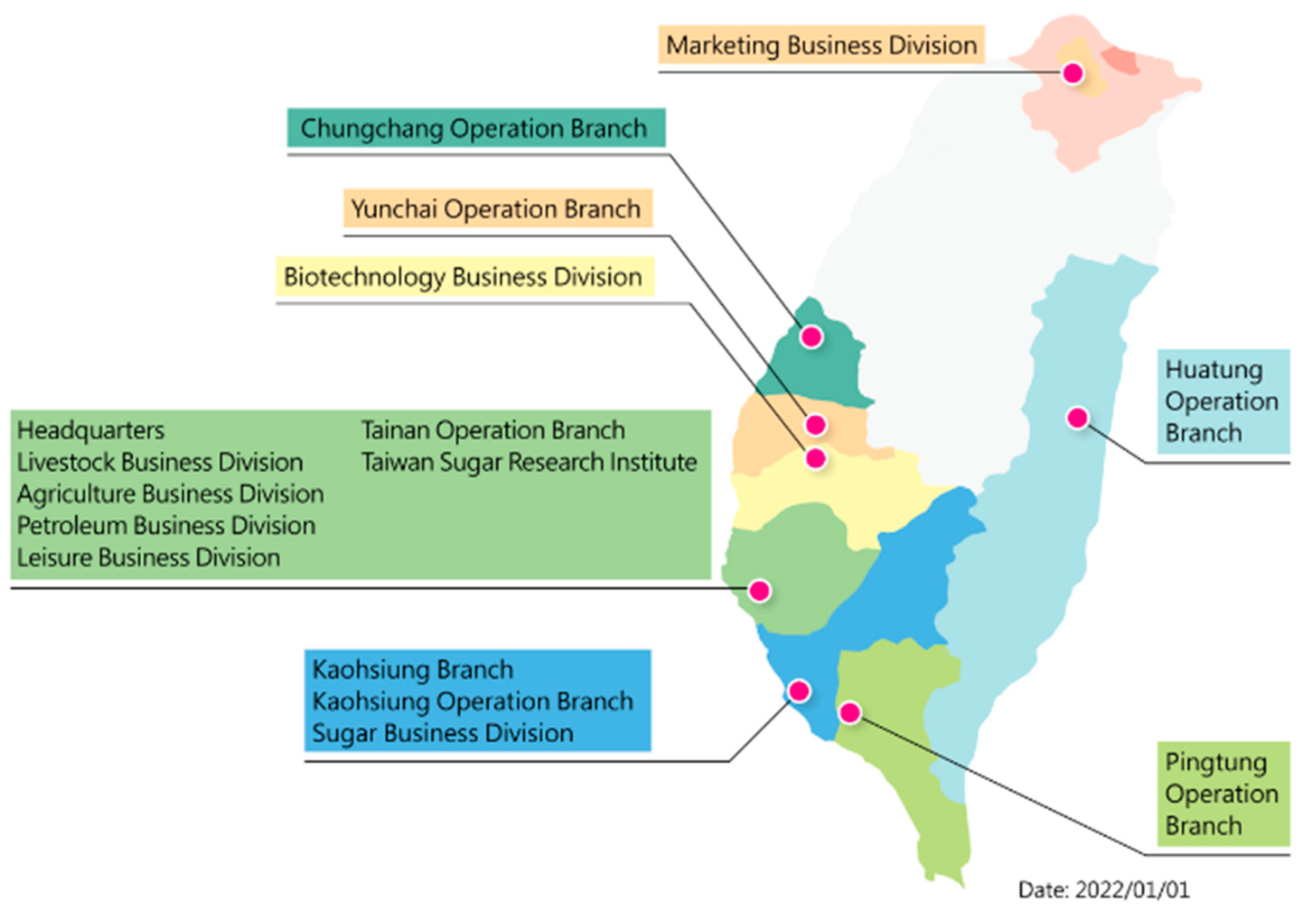

3.1. Taiwan Sugar Company

| Company name | Taiwan Sugar Corporation |

| Equity status/market type | State-owned enterprise under the Ministry of Economic Affairs(The government holds 96.51% of shares, private 3.49%; for related shareholding structure). |

| Establishment date | May 1, 1946 |

| Capital | NTD 56,367 million |

| Total assets | NTD 659,780 million (as of December 31, 2021) |

| Chairman | Chao-Yih Chen |

| President | Kuo-Hsi Wang |

| Number of employees | 3,241 (as of December 31, 2021) |

| TSC Headquarters | No. 68, Shengchan Road, East District, Tainan City |

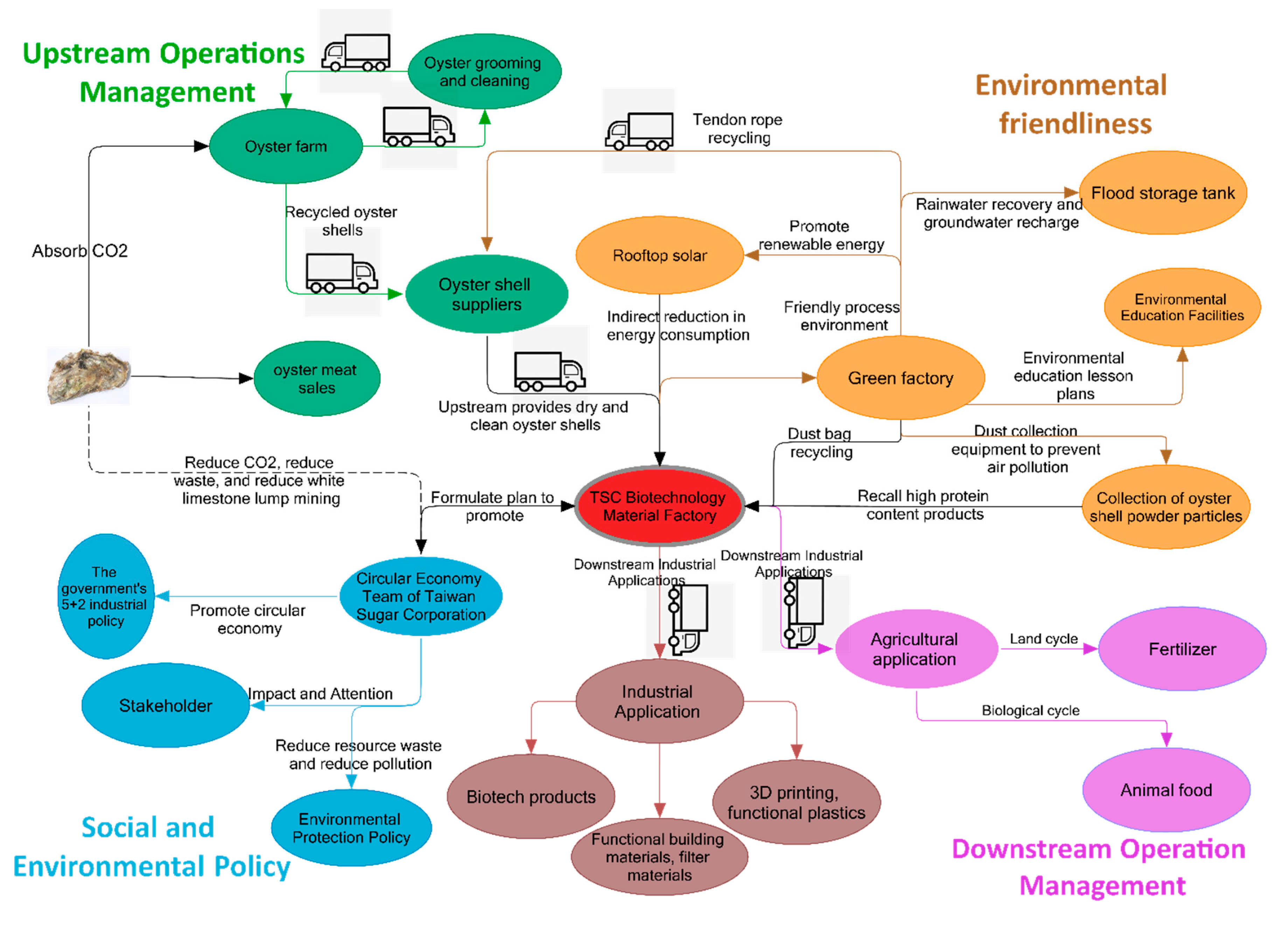

3.2. TSC’s Circular Economy Concept and Planning

- (a)

- Mission: To promote the sustainable development of the economy, society, and environment through a circular economy.

- (b)

- Vision: Create a zero-waste/zero-pollution energy and resource recycling model internally, create opportunities for recycling cooperation externally, and increase enterprise output value.

- (c)

- Strategy: In the short term, check the material flow first to improve the efficiency of resource use; in the medium term, strengthen energy efficiency and create a low-carbon operating model; in the long term, promote diversified development, increase performance revenue, and establish an industrial symbiosis structure to improve the circular economic system.

3.3. Promote the Circular Economy Process of Oyster Shells

3.4. Short, Medium, and Long-Term Goals of Oyster Shell Circular Economy

3.4.1. Short-Term Goals for 2018-2020

3.4.2. Mid-Term Goals for 2021-2023

3.4.3. Long-Term Goals for 2024-2026

3.5. Business Objectives and Business Strategies

3.5.1. Utilization of Oyster Shell Raw Materials

- (a)

- The purchased oyster shells are brought into the site as dry materials

- (b)

- The oyster shells are first crushed and screened by the coarse crusher and then sent to the rotary calciner for calcination. The surface area of the coarsely crushed oyster shells increases, which can improve the calcination efficiency.

- (c)

- To save energy, the calcination temperature is controlled within 300 degrees. At this time, the oyster shells are dried and sterilized after high-temperature treatment. After calcination, the oyster shells are crushed with a fine crusher. Adjust and sieve the aperture to provide oyster shell powder products with different particle sizes to meet the needs of different customers.

3.5.2. The Operation and Management of the Whole Plant Are Moving towards the Three Zero Goals of "Zero Pollution", "Zero Waste" and "Zero Accident"

- (a)

- There are three sets of environmental protection dust collection equipment in the factory area. The total removal rate of granular matter can reach 99.91%. Through the remote control of the central control room, the dust in the processing and production process - coarse crushing, calcining, fine crushing, and packaging stages is collected and reused.

- (b)

- The rotary calciner uses natural gas for combustion, which is more environmentally friendly than traditional heavy oil combustion.

- (c)

- The calcining and heating equipment adopts proportional control, which saves energy and is more efficient.

3.5.3. Items and Specifications of the Biotechnology Material Factory

- (a)

- Items: oyster shell powder (agricultural use) and oyster shell powder (industrial use)

- (b)

- Packing specifications: 20 kg bag and 1 metric ton space bag.

3.5.4. Multiple Applications of Calcium Carbonate Produced from Oyster Shells

- (a)

- Recycling discarded oyster shells can not only reduce the disturbance of waste to the local area but also contribute to the ecological environment. It can also turn waste into resources and increase employment opportunities.

- (b)

- To expand the multiple applications of calcium carbonate processed from oyster shells, which is the best interpretation of the domestic practice of "circular economy" and "new agriculture".

3.5.5. Concretely Realize the Concept of Circular Economy and Establish a Model of Industrial Innovation

- (a)

-

The goal is to use the role of "innovation leader" to bring this circular resource industry to a healthier field of developmentInitially, a biotechnology factory will be built to produce raw materials in accordance with regulations to meet the needs for fertilizer and feed in the market. During the second phase, oyster shell powder is utilized to produce industrial-grade calcium carbonate raw materials, leading to the development of high-value multi-application pipelines and setting a benchmark for domestic and international production capacity and technology.

- (b)

-

Import substitution to make up for the short and broken chain of raw materials caused by the epidemic.The outbreak of COVID-19 in China has led to a severe shortage of essential raw materials like imported limestone or locally excavated minerals needed to produce calcium oxide (CaO), calcium carbonate (CaCo3), and other vital resources for daily life. This aligns with the factory's commencement of production, aiming to address material shortages, supply chain disruptions, and emerge as a cornerstone industry within the nation's six new strategic sectors. Aligned with the principles of green environmental protection and ecological sustainability, it promises a sustainable future for production and livelihoods.

4. Assessment and Results

4.1. Stakeholder Investigation and Analysis

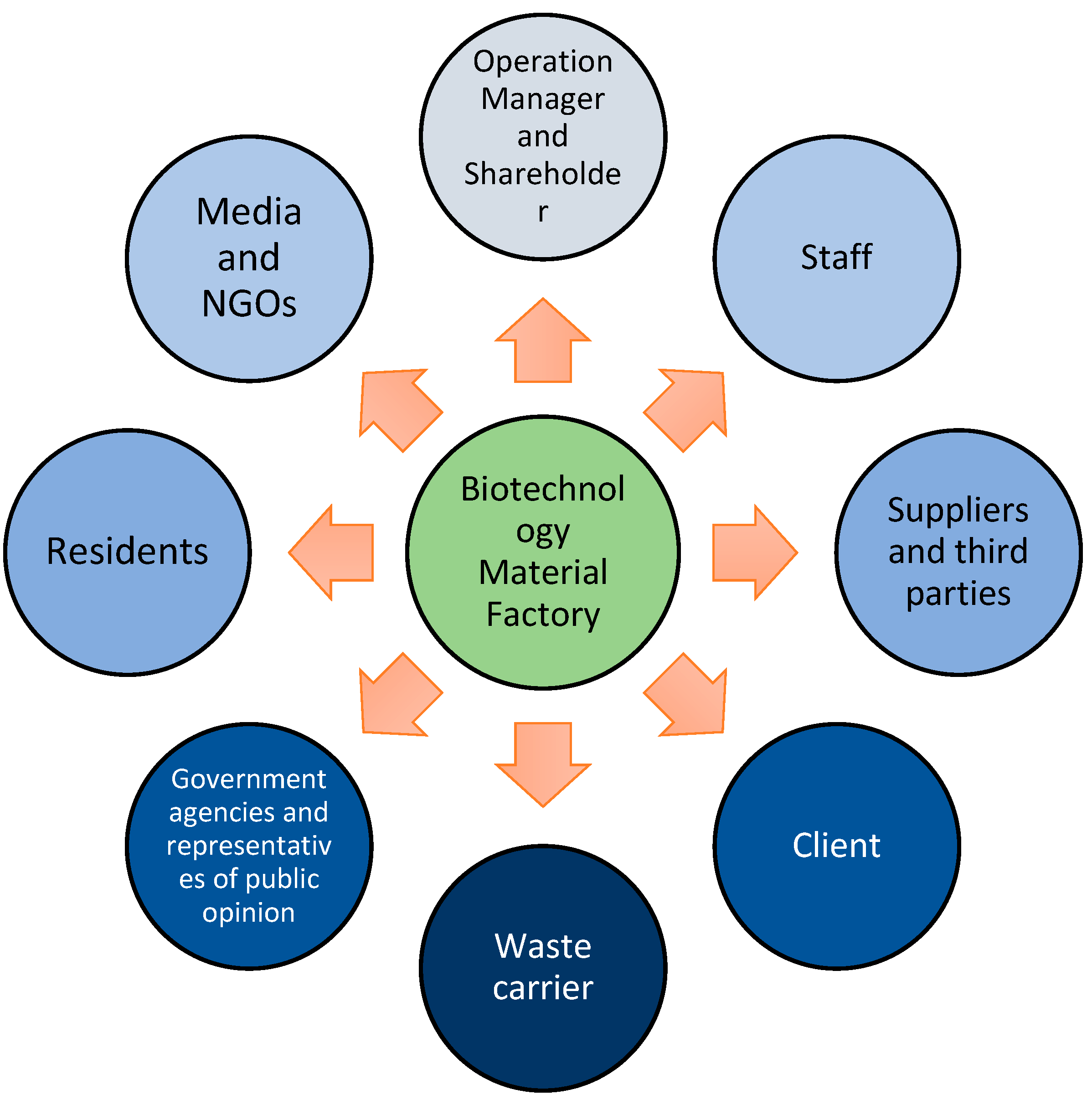

4.1.1. Identification of Interested Parties

4.1.2. Stakeholder Communication

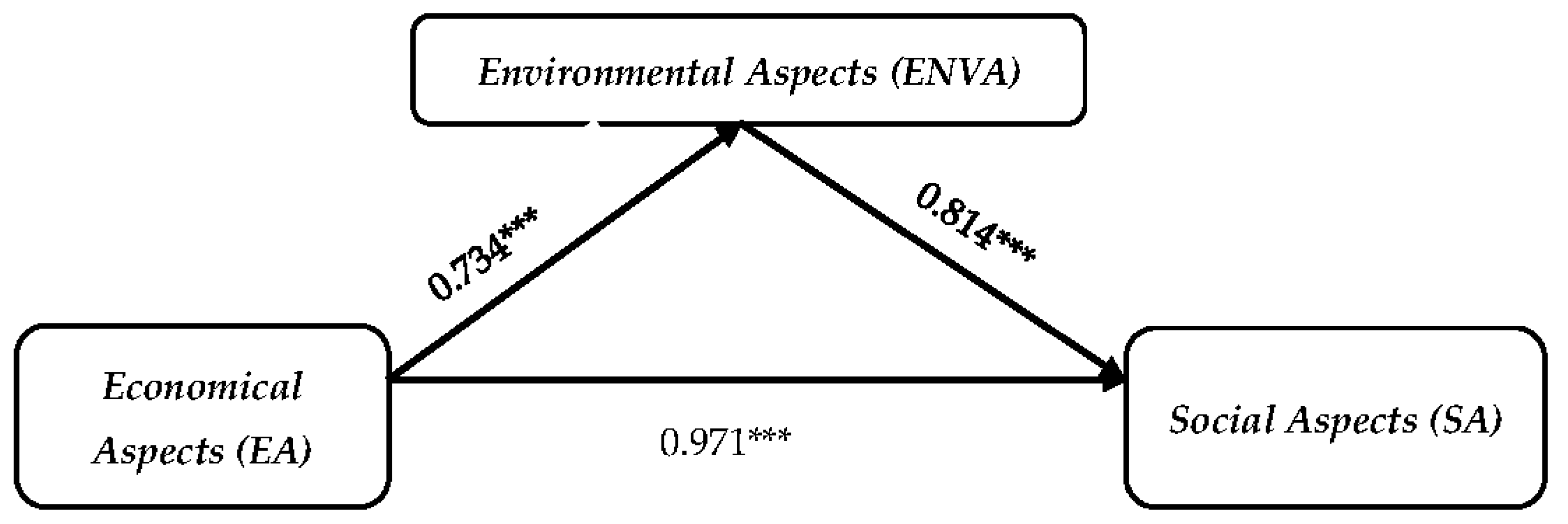

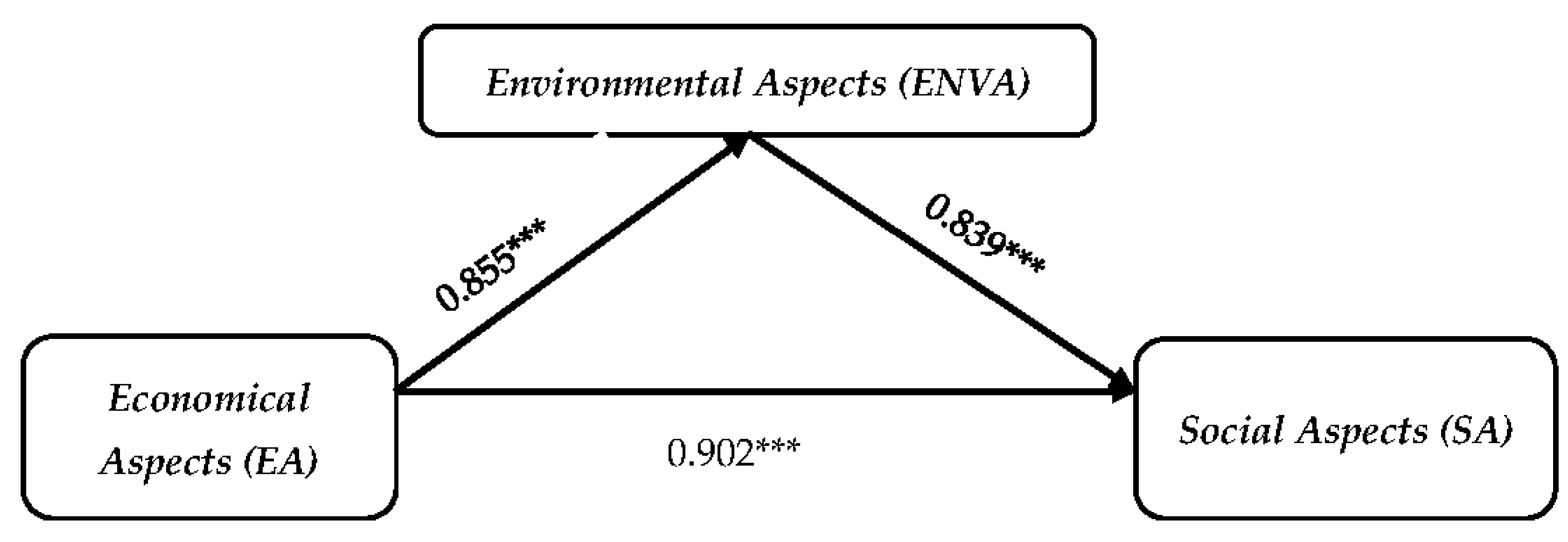

4.1.3. Structural Model Assessment

| Hypothesis | Regression Weights | Beta Coefficient | R2 | P value | Result |

|---|---|---|---|---|---|

| H1(a) | EA→ENVA | 0.855 | 0.730 | 0.000 | Supported |

| H2(a) | ENVA→SA | 0.839 | 0.814 | 0.000 | Supported |

| H3(a) | EA→SA | 0.902 | 0.703 | 0.000 | Supported |

| Hypothesis | Regression Weights | Beta Coefficient | R2 | P value | Hypothesis Result |

|---|---|---|---|---|---|

| H1(b) | EA→ENVA | 0.734 | 0.538 | 0.000 | Supported |

| H2(b) | ENVA→SA | 0.814 | 0.663 | 0.000 | Supported |

| H3(b) | EA→SA | 0.942 | 0.971 | 0.000 | Supported |

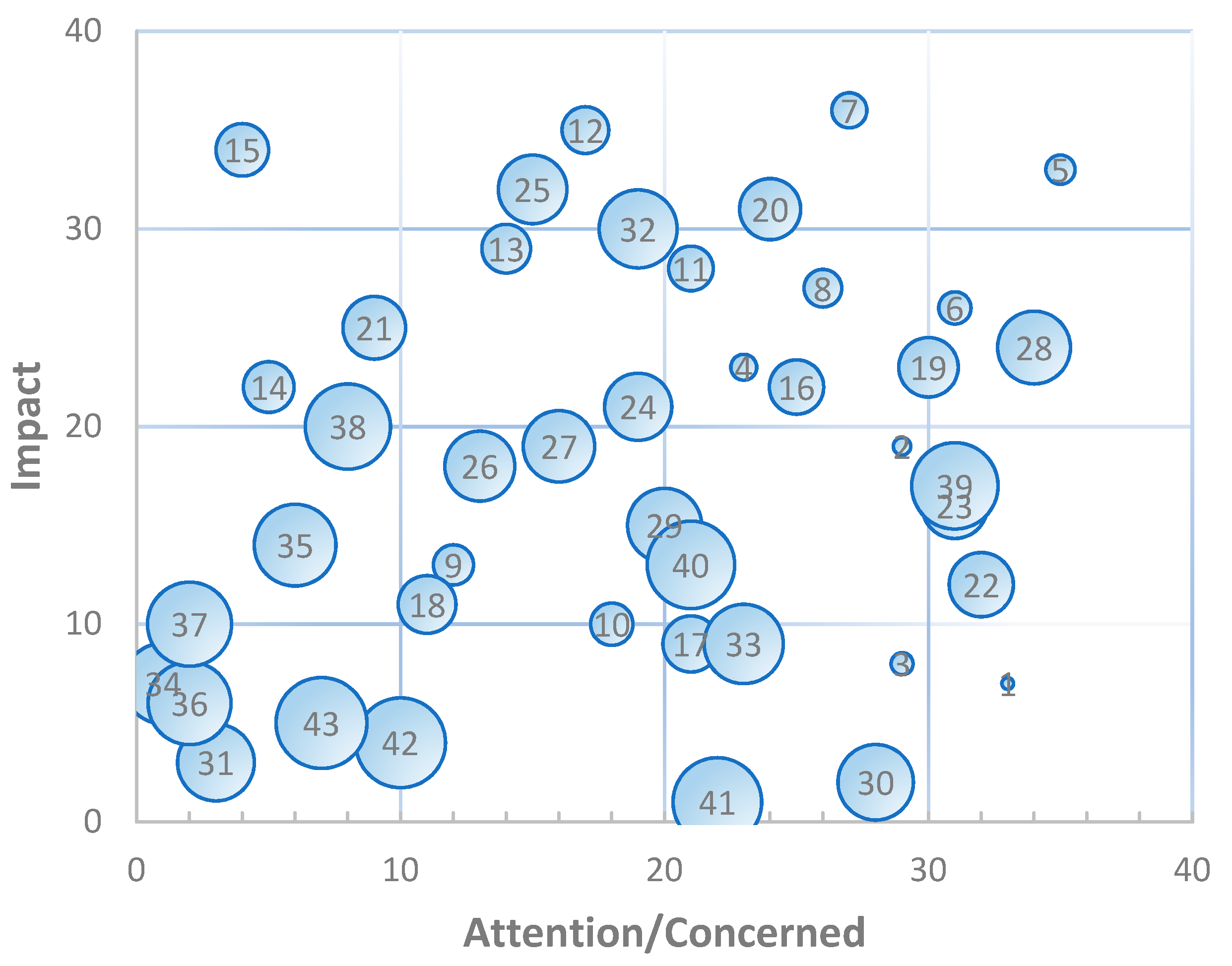

4.1.4. Identify the Degree of Attention and Impact

| Basic information | Economic aspect | Environmental aspect | Social aspect | Most concerned issue |

|---|---|---|---|---|

| Staff | 3.54 | 3.89 | 3.69 | 42 |

| Suppliers/partners/waste disposal | 2.96 | 3.43 | 2.55 | 9 |

| Client | 3 | 3.72 | 3.33 | 9 |

| Residents | 3.16 | 3.83 | 2.93 | 14 |

| Media and NGOs | 4.69 | 4.4 | 4.52 | 37 |

| Shareholder | 3.88 | 4 | 4 | 43 |

| Operation manager | 4.88 | 5 | 4.74 | 43 |

| Government agencies and representatives of public opinion | 4.69 | 4.4 | 4.52 | 41 |

| Average | 30.8 | 32.67 | 30.28 |

4.2. Feasibility Assessment

4.2.1. SWOT Analysis of TSC Biotech Material Factory

- A.

- By partnering with agricultural and fishery groups, academic institutions, and industry partners, the company can help farmers and fishermen turn local agricultural and fishery products into high-value health foods using biotechnology and equipment from Taiwan Sugar Biotechnology. This boosts the value of these products and supports public health.

- B.

- The company is swiftly utilizing oyster shells to create eco-friendly products and is actively pursuing BS 8001 circular economy certification. This demonstrates a commitment to sustainable practices and environmental education, aligning with global standards.

- C.

- The establishment of an oyster shell biotechnology material factory will improve the quality of life of residents and promote employment opportunities and economic development.

- D.

- The technology of recycling waste oyster shells to produce calcium carbonate can be used in agriculture and industry in multiple ways.

- E.

- Effectively improve the environmental pollution, odor spread, and landscape ecology, and even eliminate the source of germs caused by the random disposal of oyster shells in the western coastal areas.

- F.

- Through recycling technology, discarded oyster shells are transformed into calcium carbonate, serving as a "green mineral" resource for the company's livestock and agricultural operations. This reduces reliance on imported materials and supports domestic manufacturing of feed and fertilizer, fostering self-sufficiency and sustainability.

- A.

- The state-owned enterprise system has long service years employees resulting in high personnel costs, and the average age of employees is aging. Recent retirements and slow recruitment of new staff have led to gaps in manpower and the risk of losing core technical expertise.

- B.

- State-owned enterprises must cooperate with government policies. Production, sales, and quantity are restricted, which affects sales profitability, and restrictions on laws and regulations make raw material procurement and bargaining power weak.

- C.

- The company lacks prior experience in recycling and processing oyster shells, posing challenges in establishing it as a new industry. Despite challenges, securing suitable industrial land near the Biotechnology Division resolves environmental impact assessment concerns for the plant site.

- D.

- People’s awareness of environmental protection is on the rise. To eliminate residents’ doubts about environmental pollution, Taiwan Sugar has increased the depth and frequency of communication with local opinion leaders and residents, emphasizing that the overall planning of the plant is designed by the Industrial Technology Research Institute based on the most stringent environmental and ecological assessment. As a result, the production process will comply with legal norms.

- A.

- The "Agricultural Waste Management Strategy" report prepared by the Environmental Protection Agency of the Executive Yuan in 2013 highlights the potential for innovative utilization of oyster shells, opening direction for new applications.

- B.

- With the advancement of science and technology and the improvement of the environmental protection concept of waste recycling, the development and diversification of related applications of oyster shells will help to increase the added value of oyster shells and promote the sustainable operation of the oyster farming industry.

- C.

- Addressing natural resource scarcity and mitigating long-distance transportation challenges through local utilization of oyster shells reduces carbon emissions and fosters the production of green, eco-friendly products. This trend will encourage to adopt sustainable practices and contributes to environmental conservation efforts.

- D.

- Leveraging oyster shell utilization promotes local economic development and employment opportunities, fostering a mutually beneficial scenario and actualizing the principles of the "circular economy." This not only supports regional growth but also ensures the efficient use of resources within the local ecosystem.

- E.

- TSC Biotech Materials Factory uses discarded oyster shells as raw materials. After high-temperature calcination and fine crushing, it can produce a maximum of 40,000 metric tons of calcium carbonate per year, which can replace the traditional mining of rocks or imported white stones.

- A.

- The accumulation of oyster shells makes it easy to breed mosquitoes and flies, and the odour produced by the heat can pollutes the nearby environment.

- B.

- The added value of oyster shells is low, and the selling price is only about two yuan per kilogram. This means the company can’t make more money from only this practice.

- C.

- National awareness of environmental protection is rising, and environmental protection laws and regulations are becoming more and more stringent. This means the company might have to spend more money on equipment to follow the rules, like setting up three special dust collectors.

4.2.3. Strategy Evaluation and Selection

- A.

- Through the establishment of a cooperative relationship through strategic alliances, TSC Biotechnology cooperates with well-known enterprises and related health food industries to communicate with each other to create healthy and beautiful performances and promote a better environment.

- B.

- The construction of an oyster shell processing facility benefits the environment, economy, and industries by creating employment opportunities and adding value to waste.

- A.

- Integrate company resources and establish friendly environment measures and explanatory resources in the field, to promote and introduce to visiting people from all walks of life, enhance people's concept and knowledge of environmental protection and circular economy, and fulfill corporate social responsibility.

- B.

- Advocate and promote the industrial model of environmental recycling, and actively work towards the goals of waste reduction, zero-emission, carbon reduction, and creation of added value.

- A.

- The company collaborates with universities and researchers on projects related to the environment. It also joins global events about eco-friendly technologies to meet others and work together on making the world greener.

- B.

- The company acknowledges that the circular economy is gaining traction globally and is a fundamental concept for international development. Taking into account Taiwan's agriculture, which generates significant waste, oysters stand out for their ability to absorb carbon dioxide and purify seawater. Additionally, oyster shells present an endlessly recyclable resource. Establishing an oyster shell biotechnology material factory could enable the domestic oyster industry to achieve a closed-loop system, fostering a genuine circular economy. This initiative is not only a sound idea but also a lucrative business opportunity. It will mitigate landscape impact, environmental pollution, disease transmission, and odor associated with haphazard oyster shell disposal, thereby enhancing residents' quality of life and stimulating local economic development.

4.3. TSC Circular Economy Systematic Thinking Framework Output

5. Conclusions

References

- Al Omari MM, H.; Rashid, I.S.; Qinna, N.A.; Jaber, A.M.; Badwan, A.A. (2016). Chapter Two—Calcium Carbonate. In H. G. Brittain (Ed.), Profiles of Drug Substances, Excipients and Related Methodology (Vol. 41, pp. 31–132). Academic Press. [CrossRef]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustainability Science 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Bocken, N.M.P. , de Pauw, I., Bakker, C., & van der Grinten, B. Product design and business model strategies for a circular economy. Journal of Industrial and Production Engineering 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions – a strategy for eco-effective product and system design. Journal of Cleaner Production 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Environmental Impact Assessment: Taiwan’s circular-economy surprises - Taipei Times. (2022, ). (2022, June 8). https://www.taipeitimes.com/News/feat/archives/2022/06/08/2003779537.

- Erkman, S. Industrial ecology: An historical view. Journal of Cleaner Production 1997, 5, 1–10. [Google Scholar] [CrossRef]

- European Commission. Directorate General for Environment. (2017). Moving towards a circular economy with EMAS: Best practices to implement circular economy strategies (with case study examples). Publications Office. https://data.europa.eu/doi/10.2779/463312.

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. Journal of Cleaner Production 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Hamester MR, R.; Balzer, P.S.; Becker, D. Characterization of calcium carbonate obtained from oyster and mussel shells and incorporation in polypropylene. Materials Research 2012, 15, 204–208. [Google Scholar] [CrossRef]

- Hanein, T.; Simoni, M.; Long Woo, C.; LProvis, J.; Kinoshita, H. Decarbonisation of calcium carbonate at atmospheric temperatures and pressures, with simultaneous CO 2 capture, through production of sodium carbonate. Energy & Environmental Science 2021, 14, 6595–6604. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resources, Conservation and Recycling 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä; J. Circular Economy: The Concept and its Limitations. Ecological Economics 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Lewandowski, M. Designing the Business Models for Circular Economy—Towards the Conceptual Framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Lyle, J.T. Regenerative Design for Sustainable Development.; John Wiley & Sons, 1996. [Google Scholar]

- MacArthur, E. Towards the circular economy: Vol. Journal of Industrial Ecology 2013, 2, 23–44. [Google Scholar]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; John Wiley & Sons, 2010. [Google Scholar]

- Osterwalder, A.; Pigneur, Y.; Bernarda, G.; Smith, A. Value Proposition Design: How to Create Products and Services Customers Want; John Wiley & Sons, 2015. [Google Scholar]

- Pinheiro MA, P.; Seles BM, R.P.; De Camargo Fiorini, P.; Jugend, D.; Lopes de Sousa Jabbour, A.B.; da Silva HM, R.; Latan, H. The role of new product development in underpinning the circular economy: A systematic review and integrative framework. Management Decision 2019, 57, 840–862. [Google Scholar] [CrossRef]

- Singh, C.; Ford, J.; Ley, D.; Bazaz, A.; Revi, A. Assessing the feasibility of adaptation options: Methodological advancements and directions for climate adaptation research and practice. Climatic Change 2020, 162, 255–277. [Google Scholar] [CrossRef]

- Sinha, E. Identifying enablers and outcomes of circular economy for sustainable development: A systematic literature review. Business Strategy & Development 2022, 5, 232–244. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking circular business: A framework of barriers and drivers. Journal of Cleaner Production, 2019; 212, 90–98. [Google Scholar] [CrossRef]

- Tutuş, A.; Çiçekler, M.; Killi, U.; Kaplan, M. Comparison of GCC and PCC as Coating Material in Paper Production; 2018. [Google Scholar]

| Item | Short-term (2018-2020) | Mid-term (2021-2023) | Long-term (2024-2026) |

|---|---|---|---|

| Oyster shell source |

Chiayi |

Yunlin, Chiayi, Tainan |

All of Taiwan and the outlying islands of Penghu |

| Processing capacity | The design processing capacity is 135 tons/day for 12 hours | The processing capacity of incoming goods is 20,000 tons/year | The processing capacity of incoming goods is 50,000 tons/year |

| Revenue | - | Pre-tax loss of fewer than 5 million yuan/year | Pre-tax profit of more than 2.5 million yuan/year |

| Statutory operating license and certification | Construction license, use license | Factory Registration Certificate, Reuse Organization Permit, Stationary Pollution Source Operation Permit ISO 9001 quality management ISO 45001 Occupational Safety and Health Management System BS 8001 Circular Economy |

ISO 14064 Carbon Inventory ISO 14067 carbon footprint PAS2060 Carbon Neutrality |

| Research and development | ITRI and Nanhua University Promote Cooperation Agreement | Fertilizers, horticultural landscaping, feed, functional building materials, 3D printing, filter materials Increase the Academy of Agricultural Sciences to promote cooperation agreements |

Functional fabrics, ceramics |

| Industrial application | Feed, fertilizer, 3D printing, functional plastics, plastic wood | Functional Building Materials | |

| Environmental friendly | The design and construction meet the green building bronze standard Set up solar energy, flood storage tanks, natural gas as power, and dust collection equipment |

Environmental Education Teaching Plans and Curriculum Obtained the bronze certificate of green building |

Build an exhibition and sales center, and pass environmental education facilities |

| Period | Risk issue | Supporting measures |

|---|---|---|

| Short-term (2018-2020) | Political considerations of local governments, and doubts about environmental sanitation | The original evaluation site was moved from Dongshi to Yongkang District, Tainan City |

| Mid-term (2021-2023) | Low prices for agricultural use and fierce competition | Seek industrial use |

| Industrial use is expensive, low in usage, and slow in development time, and regulations need to be amended | Research and development in cooperation with academic institutions | |

| Long-term (2024-2026) | Applications in various industries require relevant technical documents and materials, and the threshold for use is relatively high | Looking for willing and capable manufacturers to cooperate |

| Category | Subcategory | Communication channel | Frequency of communication |

|---|---|---|---|

| Suppliers and third parties | Oyster shells and packaging materials suppliers | Telephone | Not fixed |

| Third-party | Interview, telephone, E-mail | 1-6 times/month | |

| Client | External customers | Interview, telephone, E-mail | 1-6 times/month |

| Internal customers | Interview, telephone, E-mail | 1-2 times/month | |

| Waste processor | Interview, telephone, E-mail | Not fixed | |

| Government agencies and representatives of public opinion | Interview, telephone, E-mail | 1-2 times/month | |

| Operation Manager and Shareholder | Interview, telephone, E-mail | 1-2 times/month | |

| Media and NGOs | Interview, telephone, E-mail | 1-2 times/month | |

| Residents | Interview, telephone, E-mail | Irregular | |

| Staff | Interview, telephone, E-mail | At any time | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).