1. Introduction

The deteriorating environmental situation in the world causes a tightening of requirements not only for various industries, but also for the materials they produce, as even newly developed products are not always environmentally friendly for humans and the environment. Among such materials, protective polymer coatings play an important role. It is known [

1,

2,

3] that in many industries paint and varnish materials based on organic solvents, which are toxic to humans, are used, which leads to the search for an alternative method of protection of structures and buildings. One such option is the use of water-based paints and varnishes - water-dispersion.

Creation of environmentally friendly polymer protective composite materials resistant to external factors is one of the priority directions of researchers. It is known that currently the most common and available way to solve this problem is the use of water-based filled acrylic compositions [

4,

5,

6,

7,

8].

Modifying target additives and natural fillers play an important role in obtaining protective composite coatings [

9,

10]. In this regard, the aim of this work was to study the influence of mineral fillers of different nature and shape of particles on the physical-mechanical and operational properties of coatings (P

C), for the protection of concrete and metal surfaces.

There are large reserves of diatomite in Kazakhstan, which makes it possible to use them in paint and varnish formulations. According to the data of geological prospecting works, siliceous rocks within the Aktobe region of the Republic of Kazakhstan have an extensive distribution.

The aim of the research work is to obtain polymer-based composites with modified diatomite (water-dispersion paint on acrylic binder) with improved performance properties and low cost.

Scientific novelty in obtaining water-dispersion paint and varnish composition on acrylic base with diatomite content; estimation of economic efficiency of this technology in comparison with existing analogues.

2. Materials and Methods

2.1. Materials

The following materials were used as the object of the study.

Filler: Diatomite is a loose or weakly cemented siliceous sedimentary rock composed mainly of the shells of diatom algae and is white, grey or pinkish in color. In the natural state diatomite’s have a large uniformly distributed porosity, reaching 80-85%. Silica in diatomite’s is in amorphous state and makes up 78-95%.

Binder: Akremos-115A aqueous dispersion is a copolymer of styrene and acrylic monomers obtained by emulsion method. It is used as a binder to produce colors that are suitable for exterior and interior painting. The composition

“Akremos-115A

” does not contain organic solvents and belongs to low hazardous substances (4th class of hazard) [

11,

12,

13].

The polymer dispersion “Arakril ADC 777” is an aqueous dispersion of styrene copolymer and acrylic acid esters with high dry residue, obtained by emulsion method. Dispersion of high quality styrene-acrylic copolymer in water, specially formulated for the production of general purpose paints, with high to medium pigment volume concentration (PVC). The product contains finer copolymer particles (less than 0.1 µm) compared to standard grades of styrene-acrylic dispersions.

Pigment: rutile P-02 grade titanium dioxide (mass fraction of rutile titanium dioxide - 95%). Titanium dioxide is a white dense powder, insoluble under normal conditions in alkalis, solutions and acids.

2.2. Methods

Sampling was carried out according to GOST 9980.2 (GOST – Government standard) [

14]. To prepare the middle sample for research according to GOST 28196 item 4.2 [

15], the film was removed from the surface of the material, then the test material was thoroughly mixed to a homogeneous state.

It is allowed to determine the color and appearance of the film on the samples after testing by the indicator

“Coverage of dried film

” according to GOST 28196 item 4.3 [

15]. The covering power of the dried film can be determined by two methods, namely:

1. Plotting the material on a laboratory chart;

2. Application on a glass plate according to GOST 8784 section 1 [

16].

To identify this characteristic, method No.1 was used: the test sample, 250 µm thick, was applied to the laboratory card on the left side using a rakley in a single layer; on the right is the control sample. After drying, visual comparison of the tested sample with the control sample was carried out for one hour under natural daylight in a room at air temperature (20±2) °C.

Determination of the covering power of the coating according to method No. 2 consists in applying layers of coating material on a glass plate (glass for photographic plates of size 9 x 12-1.2) until the contours of a black-and-white contrasting plate or a checkerboard placed under the glass plate become invisible. To determine the hiding power, the coating material is diluted to the working viscosity. On a glass plate prepared according to GOST 8832 and weighed to the fourth decimal place, one or two layers of coating material are applied. A glass plate with the coating material is placed on a contrasting plate and observed in diffused daylight whether the white and black fields are translucent.

The dynamic viscosity of the resulting paint will be measured using a Haake VT 24 rotary viscometer.

Test procedure: The material sample is thoroughly mixed to a homogeneous mass, avoiding the formation of air bubbles. The tests are carried out at air temperature (20±2) °С. The pin of the rotating body is immersed in a plastic cup with the sample to be tested up to the mark, then the motor is started. After one minute, a reading of the measured value is taken from the scale of the Haake viscometer. After the measurement is completed, the rotating body pin is gently rinsed with water to prevent damage to the rotating body pin. Each test shall be carried out twice and the test result will be taken as the arithmetic mean.

To determine the pH range, we used a pH-meter with a glass electrode, measurement error not more than 0.1, a plastic beaker (volume 240 ml, height 8.0 cm, upper diameter 6.7 cm, lower diameter 5.2 cm), distilled water according to GOST 6709 [

17]. All tests are carried out in accordance with GOST 52020 item 9.4 [

18].

Studies to determine the mass fraction of non-volatile substances are carried out in accordance with GOST 31939 [

19].

Density is determined according to GOST R 53654.1 [

20], adhesion of coating is tested according to GOST 31149 [

21], degree of grinding according to GOST 31973-2013 [

22], resistance to static impact of water according to GOST 9.403, method A [

23], resistance to vapour permeability according to GOST 25898 [

24], conditional light resistance of coating according to GOST 21903 [

25].

Evaluation of the appearance of coatings was carried out according to GOST 6992-68 [

26]. The adhesion of paint coatings was determined by the lattice notch method [

21]. The adhesion value (%) is judged by the number of squares of the coating that have not separated. If adhesion is good, the coating material should not lag anywhere on the metal. If adhesion is poor, the film will come away from the metal almost over the entire lattice. The elasticity of the films characterises their bending strength. It was determined using the elasticity scale according to GOST 9.074-77 [

27].

3. Results

3.1. Results of Experimental Research

The results of studies of diatomites of Utesai, Zhalpak and Kirgiz deposits of the Aktobe region of the Republic of Kazakhstan.

The samples of investigated diatomites were finely dispersed powders of greyish-yellowish color, obtained by grinding of slightly cemented rocks of corresponding deposits. The particle size distribution of the dispersed material prepared in this way is shown in

Table 1.

Measurements were carried out using a Shimadzu SALD-3101 fine particle size analyzer with a measurement range of 50 nm to 3 mm. The analysis of the size distribution of natural diatomite particles showed that 99% of their total amount has linear sizes: 0.260 - 0.783 µm (Utesai deposit); 0.260 - 0.504 µm (Zhalpak deposit); 0.260 - 0.789 µm (Kyrgyz deposit). Particle size distributions are close to Gaussian - the most probable values of particle size for dispersed material of Utesai, Zhalpak and Kyrgyz deposits are close to each other and lie in the interval ~ 0.350 - 0.410 μm. Thus, the powders of the studied diatomite’s are ultra-disperse granular systems consisting mainly of submicrometre-sized particles.

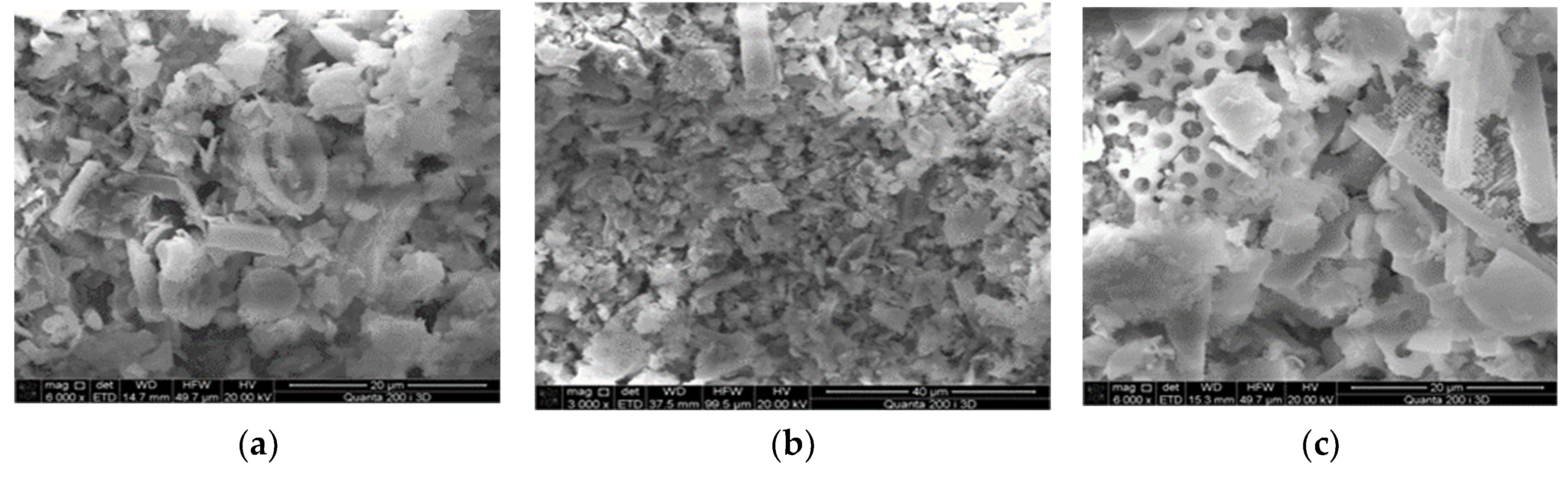

Figure 1 shows electron microscopy images of natural diatomite powders. Remains of shell flaps of diatom algae with regular channels of ~ 300-500 nm diameter, which constitute the life support system of unicellular algae, as well as various in shape and size fragments of dispersed material, are clearly visible. A characteristic feature of granular systems is their significant porosity, reaching even for natural fossil rocks, 70% and more. Free space between particles, as well as inhomogeneities of amorphous silica particles themselves in the form of pores, channels, cracks of nano- and submicrometre sizes form a developed pore structure of different scale levels, which determines many properties of mineral powders.

The processes occurring during heating of diatomite’s were investigated by thermogravimetric analysis [

28].

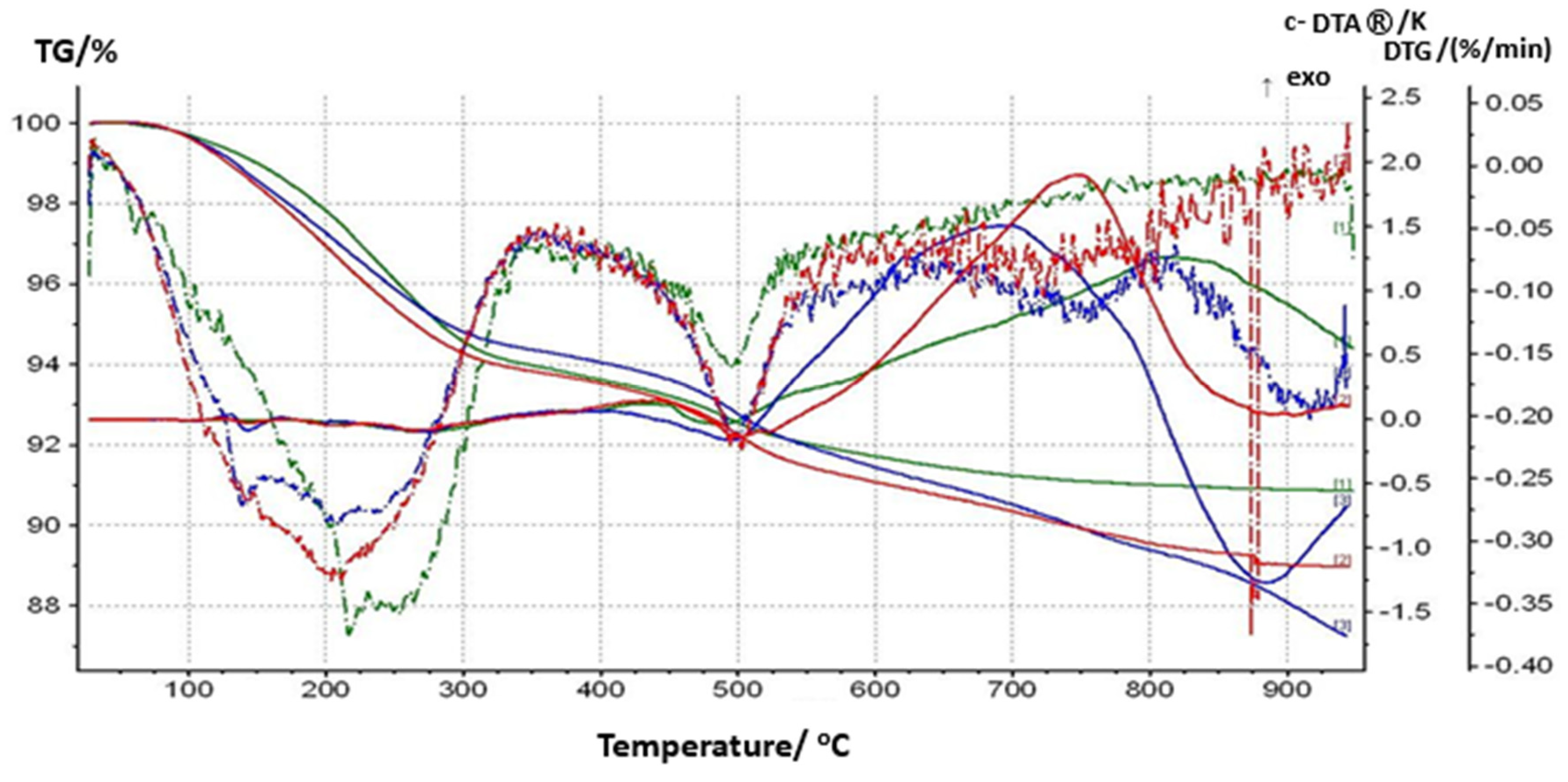

Figure 2 shows the results of thermal analysis of diatomite samples from Utesai, Zhalpak and Kyrgyz deposits. The thermogravimetric analysis (TG) curve shows three stages of mass loss of the samples during the heating process. The first of these begins immediately after the start of heating and continues until about 350

0C. This partially dehydrates the natural diatomites and reduces the mass of the samples by about 6%. At further heating in the temperature range 400 – 600

0C along with continuing dehydration of small-scale pores and pore channels of amorphous silicon dioxide particles, there is an intensive burning of organic material residues in flaps and shell fragments of diatom algae, as well as other impurities of organogenic origin. These processes are recorded on the thermogravimetric analysis diagram as an endothermic peak around 500

0C. The mass loss at this stage is approximately 2.5 %.

Heating of dispersed material from 600 to 1000 0C is also accompanied by a decrease in the mass of diatomite samples. The minimum mass loss is observed in diatomite of Zhalpak deposit, the maximum - in diatomite of Kyrgyz deposit. In total during the heating cycle diatomite of Utesai deposit loses ~ 11%, Zhalpak ~ 9%, Kyrgyz ~ 13% of the initial mass.

The average molecular weight of the acrylic polymer was determined by cryoscopy method [

29]. The M value for the acrylic film former is 1250, and for the polyether siloxane copolymer and sodium, polyacrylate is 1120 and 1190, respectively.

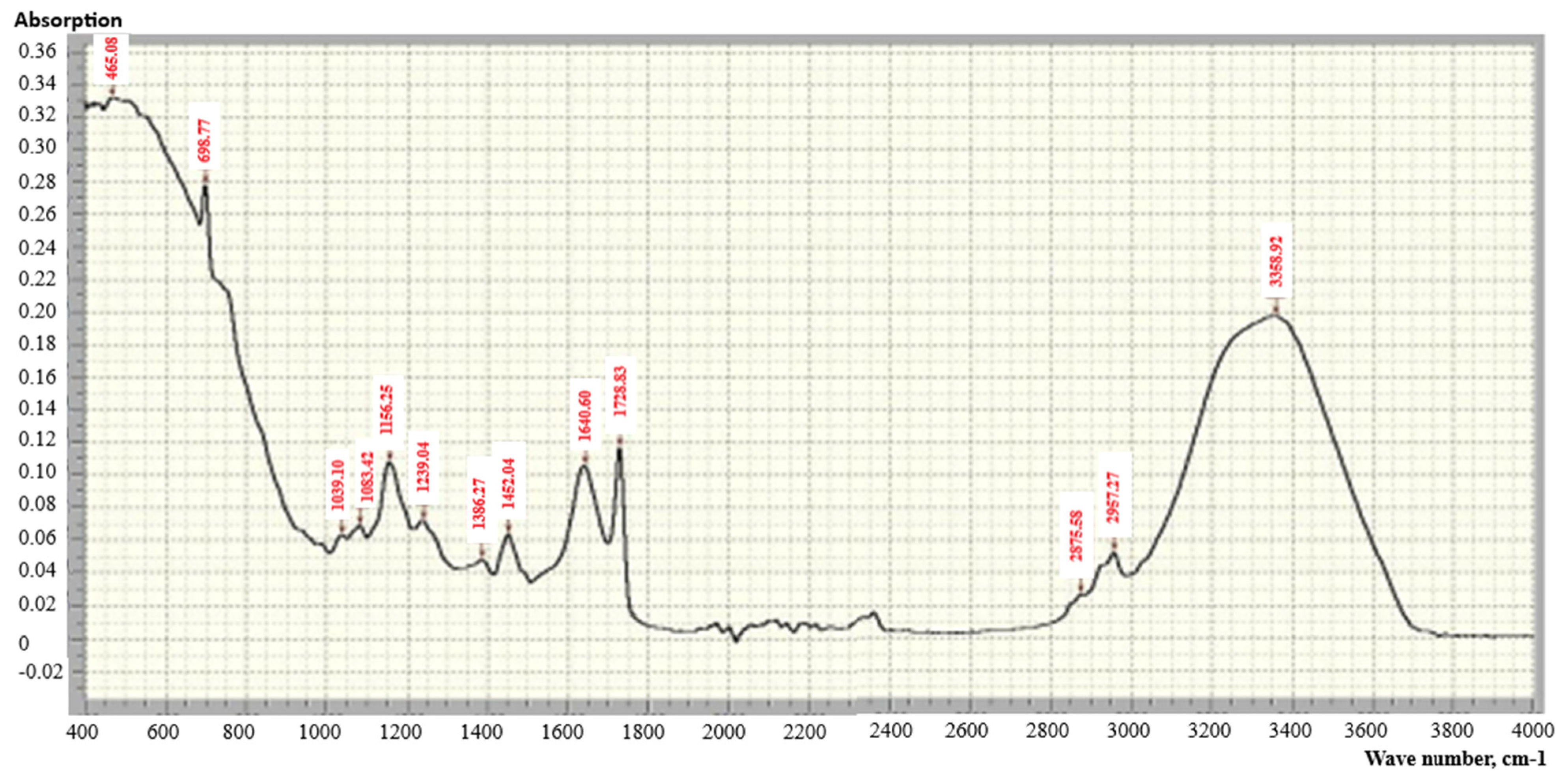

The composition and structural characteristics of the samples were established by IR spectroscopy [

30]. Free carboxyl groups were observed in the IR spectra of the acrylic film former, as evidenced by the presence of absorption peaks characteristic of hydroxyl groups (3650-3200) in the 3358 cm

-1 region and carbonyl groups (1800 cm

-1 -1650 cm

-1) in the 1728 cm

-1 region

Figure 3. The shift to the shorter wavelength region of the spectrum of the carbonyl group proves the alkyl structure of the hydrocarbon skeleton connected to the carboxyl group (1725 cm

-1-1700 cm

-1).

Water-dispersion paint is a finishing paint and varnish composition, the main component of which are synthetic polymers, often resin or oil. The solvent of the paint is water, which is why the material is considered environmentally friendly, harmless and fireproof. The peculiarity of finishing walls with water-dispersion paint is that in a few hours after opening the container with paint from the surface water evaporates, and solid particles form a dense impermeable layer, resistant to moisture and fire. This material is produced as a thick suspension, which can be diluted with water to the required consistency if necessary. Water-dispersion paint can be white in colour, or it can be colored in a variety of shades. Traditionally, the following components are present in the composition of such paint:

1. Film-forming materials (binder) are the base of the paint, which creates a polymer film on the surface that is impervious to water and resistant to abrasion.

2. Dyes (pigments) - components that give the paint a certain shade and are responsible for the decorative qualities of the material.

3. Fillers - they are responsible for the operational and technical features of the paint. These components are calcite, talc, dolomite, copper, marble chips, etc.

4. Special additives (addives) give water-dispersion paint additional properties, for example, are responsible for the speed of drying of the composition on the surface; accelerate the process of dispersion of colorants, etc.

The main task of the research was to study the influence of mineral natural filler on the characteristics of polymer-based water-dispersion composite.

Table 2 presents a comprehensive study of the effect of the mineral additive diatomite in water-dispersion composite, designed for interior finishing works, on some standardized indicators of paint quality.

The addition of diatomite to the composite was carried out directly during the mixing of the components in the dispersing unit. In this case, the study of composite properties was carried out in two stages: immediately after mixing and preparation of the composite, as well as after 2 months of composite storage. The latter study is due to the need to evaluate the influence of the degree of diatomite coagulation on the composite properties. The results of the research are presented in

Table 3.

4. Discussion

The introduction of diatomite into the water-dispersion composite did not particularly change the regulatory quality parameters such as density and dry residue. When diatomite is added, a significant increase in viscosity and hiding power of the composite is observed. At the same time, the influence of diatomite on these indicators is significantly higher, which is probably due to the different values of the wetting edge angle of these materials. The covering power as one of the main indicators of composite quality at introduction of diatomite increases very insignificantly and is practically within the normative limits. It should be noted that a slight increase in the viscosity of water-dispersion composites in the process of production while maintaining the other parameters is positive, because it allows to reduce the viscosity of the composite to dilute it with water to ensure the standardised quality, which, in turn, contributes to cheaper production and increased efficiency.

The addition of diatomite during the composite production process significantly increases its viscosity. However, after prolonged storage, the viscosity of the paint decreases to almost standard values. This effect can be favourably utilised when the composite is stored for long periods of time or transported long distances.

The conducted complex of researches has allowed defining the character of influence of the mineral natural filler introduced into water-dispersion composites on change of standard indicators of composites that gives the possibility of formation of a new complex of properties of water-dispersion composites (WDC) with simultaneous increase of efficiency of process of their industrial production.

Coatings and free films were obtained from the developed aqueous dispersion materials. Drying time of coatings up to degree 3 at temperature (20±2) °C is 1 h and does not change with the introduction of modified diatomite. The characteristics of the samples are summarized in

Table 4.

It can be seen from the data in

Table 4 that modification with activated diatomite provides a significant increase in the elastic modulus of the composite films without reducing the tensile strength. This indicates high adhesion strength at the interfacial boundary

“polymer - modified diatomite

” and, accordingly, good compatibility of modified diatomite and polymer matrix (acrylate binder). Adhesion strengthening of both pigment-free and pigmented developed coatings is provided. The introduction of modified diatomite into the sample with pigment does not lead to a decrease in the covering power of the paint material. Combined with the ability to control the rheological properties of the dispersion during modification, this can help to reduce paint consumption during painting. Modified coatings with modified diatomite are characterized by increased hardness, this is presumably due to the ordering of polymer chains near the aluminosilicate surface, which is often observed in the case of good compatibility between the polymer and the highly dispersed filler [

31], the polymer boundary layer formed is characterized by increased physical and mechanical properties compared to the polymer in the volume. Modification of coatings with diatomite allows to provide a significant reduction in water absorption of coatings (2.6 times when 2% of modified diatomite is introduced). This may also be due to the densification of the supramolecular structure of the polymer matrix, in addition, the introduction of ultrafine nanoparticles reduces the diffusion coefficient of water molecules in the composite [

32]. The sharp decrease in the water absorption of the coating when increasing the modified diatomite content from 1 to 2% wt., % may be due to a change in the nanostructure of the composite; in [

33], in this concentration range of modified diatomite in the polymer dispersion, a transition from an exfoliated morphology of the nanocomposite to an intercalated morphology characterized by a higher degree of particle ordering was observed.

Thus, modification of aqueous dispersions with silica-activated diatomite helps to eliminate the main disadvantages of materials and coatings based on acrylate binder - low water resistance and low physical and mechanical characteristics. Low cost of modified diatomite, simplicity of introduction into water-dispersion materials, possibility of regulation of rheological properties of dispersion and achieved improvement of characteristics of modified coatings determine the prospects of practical application of water-dispersion materials modified by activated diatomite, including acrylate polymer-based paints and varnishes.

Water-based paints based on modified fillers are attracting increased interest from consumers and manufacturers of paints and varnishes. With their high specific surface area, the granules of dispersed modified fillers create strong bonds between the components and fill the voids between them, forming a homogeneous and durable coating.

Dispersed silica granules are known to be hollow spheres that form the porous structure of the paint.

In this regard, we conducted a series of experiments:

- determination of porosity, adhesion, elasticity, covering power of the control composition;

- porosity, adhesion, elasticity, hiding power of modified filler.

The formulated amount of additive was introduced into a 200 ml glass beaker and stirred at room temperature using a magnetic stirrer for 5 min.

The experimental results are summarised in the tables of the first series of experiment 5-9.

Table 5.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (without the additive - modified diatomite).

Table 5.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (without the additive - modified diatomite).

| Sample number, No. |

Adhesion, % |

Porosity, number of points per 40 cm2

|

| Field test time, days |

|

| 1 |

7 |

14 |

1 |

7 |

14 |

| 1 |

94 |

95 |

95 |

4 |

5 |

5 |

| 2 |

95 |

96 |

96 |

5 |

4 |

5 |

| 3 |

96 |

96 |

94 |

4 |

5 |

5 |

| 4 |

95 |

96 |

95 |

5 |

5 |

5 |

| 5 |

94 |

95 |

94 |

5 |

5 |

5 |

Table 6.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (20 parts by weight)).

Table 6.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (20 parts by weight)).

| Sample number, No. |

Adhesion, % |

Porosity, number of points per 40 cm2

|

| Field test time, days |

|

| 1 |

7 |

14 |

1 |

7 |

14 |

| 1 |

91 |

91 |

90 |

4 |

5 |

4 |

| 2 |

91 |

92 |

91 |

5 |

5 |

6 |

| 3 |

91 |

92 |

92 |

4 |

5 |

5 |

| 4 |

92 |

91 |

90 |

6 |

4 |

6 |

| 5 |

90 |

91 |

92 |

5 |

5 |

5 |

Table 7.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (10 parts by mass)).

Table 7.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (10 parts by mass)).

| Sample number, No. |

Adhesion, % |

Porosity, number of points per 40 cm2

|

| Field test time, days |

|

| 1 |

7 |

14 |

1 |

7 |

14 |

| 1 |

93 |

94 |

95 |

3 |

4 |

3 |

| 2 |

95 |

94 |

95 |

4 |

4 |

5 |

| 3 |

94 |

93 |

95 |

3 |

5 |

4 |

| 4 |

96 |

95 |

94 |

4 |

5 |

5 |

| 5 |

93 |

95 |

94 |

5 |

4 |

5 |

Table 8.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (40 parts by weight)).

Table 8.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (40 parts by weight)).

| Sample number, No. |

Adhesion, % |

Porosity, number of points per 40 cm2

|

| Field test time, days |

|

| 1 |

7 |

14 |

1 |

7 |

14 |

| 1 |

96 |

95 |

96 |

5 |

5 |

5 |

| 2 |

95 |

95 |

96 |

5 |

5 |

5 |

| 3 |

94 |

96 |

96 |

5 |

5 |

5 |

| 4 |

96 |

96 |

96 |

5 |

5 |

5 |

| 5 |

95 |

96 |

96 |

5 |

5 |

5 |

Table 9.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (13 parts by weight)).

Table 9.

The influence of full-scale testing time on the performance characteristics of paint and varnish coatings (with the additive content - modified diatomite (13 parts by weight)).

| Sample number, No. |

Adhesion, % |

Porosity, number of points per 40 cm2

|

| Field test time, days |

|

| 1 |

7 |

14 |

1 |

7 |

14 |

| 1 |

93 |

94 |

95 |

4 |

4 |

4 |

| 2 |

93 |

94 |

95 |

4 |

4 |

5 |

| 3 |

92 |

94 |

95 |

4 |

4 |

5 |

| 4 |

93 |

93 |

95 |

4 |

4 |

5 |

| 5 |

91 |

93 |

94 |

4 |

4 |

5 |

It has been established that the introduction of modified diatomite into acrylate-based water emulsion paint does not lead to deterioration of the main performance characteristics of paint and varnish coatings - porosity, adhesion, elasticity and hiding power. The influence of filler - modified diatomite on the performance characteristics of the paintwork is insignificant, at the level of experimental error.

The insignificant influence of the time of full-scale tests in the investigated small range regardless of the quantitative composition of the modified diatomite on the performance characteristics of the paint and varnish coatings was shown.

5. Conclusions

The results of the conducted research allowed us to formulate the following main conclusions:

1. Modification of aqueous dispersions with silica-activated diatomite helps to eliminate the main disadvantages of materials and coatings based on acrylate binder - low water resistance and low physical and mechanical characteristics. Low cost of modified diatomite, simplicity of introduction into water-dispersion materials, possibility of regulation of rheological properties of dispersion and achieved improvement of characteristics of modified coatings determine the prospects of practical application of water-dispersion materials modified by activated diatomite, including acrylate polymer-based paints and varnishes.

2. The introduction of diatomite into the water-dispersion composite did not particularly change the normative quality parameters such as density and dry residue.

3. When diatomite is added, a significant increase in viscosity and covering power of the composite is observed. At the same time, the influence of diatomite on these indicators is significantly higher, which is probably due to the different values of the wetting edge angle of these materials. The covering power as one of the main indicators of composite quality at introduction of diatomite increases very insignificantly and is practically within the normative limits. It should be noted that a slight increase in the viscosity of water-dispersion composites in the process of production while maintaining the other parameters is positive, because it allows to reduce the viscosity of the composite to dilute it with water to ensure the standardized quality, which, in turn, contributes to cheaper production and increased efficiency.

4. The addition of diatomite during the composite production process significantly increases its viscosity. However, after long-term storage, the viscosity of the paint decreases to almost standard values. This effect can be utilized positively for long-term storage or long distance transport of the composite.

The conducted complex of researches has allowed defining the character of influence of the mineral natural filler introduced into water-dispersion composites on change of standard indicators of composites that gives the possibility of formation of a new complex of WDC properties with simultaneous increase of efficiency of process of their industrial production.

Thus, the use of diatomite as a filler of water-dispersion composite in optimal ratios allows obtaining compositions with the required covering power and mass fraction of non-volatile substances, which confirms the feasibility of using mineral filler of Aktobe deposit for the production of water-dispersion paints.

Author Contributions

Conceptualization, R.E.N. and Z.O.Z.; methodology, Z.N.A. and A.S.Y.; software, Y.S.O.; validation, R.E.N. and Z.O.Z.; formal analysis, Y.S.O. and Z.O.Z.; investigation, Z.N.A., A.S.Y. and Y.S.O.; resources, E.I.K., R.E.N. and Z.O.Z.; data curation, R.E.N. and Z.O.Z.; writing—original draft preparation, R.E.N.; writing—review and editing, E.I.K. and Z.O.Z.; visualization, E.I.K., Z.N.A. and A.S.Y.; supervision, R.E.N.; project administration, E.I.K.,; funding acquisition, E.I.K., R.E.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Committee of Science of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. BR21882292—“Integrated development of sustainable construction industries: innovative technologies, optimization of production, effective use of resources and creation of technological park”).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mariaenrica Frigione., Mariateresa Lettieri., Francesca Lionetto and Leno Mascia. Experimental cold-cured nanostructured epoxy-based hybrid formulations: Properties and durability performance. Polymers. [CrossRef]

- Pchelnikov, A.V.; Pichugin, A.P. Formation of physical and chemical structure of paint and varnish coatings at their nanomodification. Construction Materials. 2023. No. 8. P. 63-71. [CrossRef]

- Pichugin, A.P.; Pchelnikov, A.V.; Khritankov, V.F.; Tulyaganov, A.K. Evaluation of the efficiency of nano-additives in protective coatings. Construction Materials. 2023. No. 3. P. 20-26. [CrossRef]

- Abdelkader Dehbi., Abdel-Hamid I. Mourad., Amar Bouaza. Degradation assessment of LDPE multilayer films used as a greenhouse cover: Natural and artificial aging impacts // Journal of Applied Polymer Science, 2011. Vol. 124, Is.4. P. 2702–2716. [CrossRef]

- Zhanar, O. Zhumadilova., Vladimir P. Selyaev., Ruslan E. Nurlybayev., Yelzhan S. Orynbekov., Indira B. Sangulova., Erzhan I. Kuldeyev. Prediction of Durability of Thermal Insulating Epoxy Coatings with Regard to Climatic Ageing. Polymers 2022, 14, 1650. [Google Scholar] [CrossRef]

- Zhanar, O. Zhumadilova., Ruslan E. Nurlybayev.,Yelzhan S. Orynbekov., Aidos A. Joldassov and Malik N. Abdikarimov. Protective Properties of Thermal-Insulation Coatings under Conditions of Long-Term Exposure to Natural Climatic Factors. Coatings 2022, 12, 1925. [Google Scholar] [CrossRef]

- Kondrashov, E.K. , Kozlova A.A. Paint and varnish coatings with special optical properties. Proceedings of VIAM. 2023. No. 9 (127). P. 09. URL: http://www.viam-works. [CrossRef]

- Kozlova A.A., Kondrashov E.K., Barbotko S.L., Vereninova N.P. Heat-reflective coating for protection of expandable structure on against influence of the heat transfer rate. Trudy VIAM, No. 4 (64), paper no. 09. Available at: http://www.viam-works.ru (accessed: June 28, 2023). 2018. [CrossRef]

- Kondrashov, E.K. , Malova N.E. Paint and varnish coatings based on trifluorochloroethylene copolymers. Aviation Materials and Technologies. 2015. No. 2 (35). P. 39-44. [CrossRef]

- Katnov, V.E. Katnov V.E., Stepin S.N., Katnova R.R., Mingalieva R.R., Grishin P.V. Coatings based on aqueous polyacrylate dispersions filled with nanosized silicon oxide. Bulletin of Kazan Technological University. No. 7, P. 95-96. https://www.kstu.ru/article.jsp?id_e=23840. 2012. [Google Scholar]

- Serdtselyubova A.S., Merkulova Yu.I., Zagora A.G., Kurshev E.V. Research of film-forming parameters and protective properties of basecoat/clearcoat system. Serdtselyubova A.S., Merkulova Yu.I., Zagora A.G., Kurshev E.V. Research of film-forming parameters and protective properties of basecoat/clearcoat system, No. 1 (70), paper No. 07. Available at: http://www.journal.viam.ru (accessed: July 03, 2023). 2023. [CrossRef]

- Kazakova, E. E. Water-dispersion acrylic paint and varnish materials for construction purposes. M.: Paint-media, 2003. 136 p. https://science.totalarch.com/book/1848.

- Titanium dioxide for the production of paints and plastics [Electronic resource]. Mode of access: http://www.bpcchem.ru/products/pigments/917/1079/.

- GOST 9980.2-2014 Paint and varnish materials and raw materials for them. Sampling, control and preparation of samples for testing. 2016. https://files.stroyinf.ru/Data2/1/4293762/4293762719.pdf.

- GOST 28196-89 Water-dispersion paints. Technical conditions. Moscow. Standardinform, 2007. https://meganorm.ru/Data/13/1312.pdf.

- GOST 8784-75 Paint and varnish materials. Methods of determination of hiding power. Moscow. IPK Publishing House of Standards, 2002. https://spektrlkm.ru/upload/8784-75.

- GOST 6709-72 Distilled water. Technical conditions (with changes N 1, 2). Moscow. Standardinform, 2007. https://cdn.termexlab.ru/files/0eeb3068/7ba8/4715/83fd/22ff34ac9ea3.

- GOST R 52020-2003 Water-dispersion paint and varnish materials. General technical conditions. Moscow. IPK Publishing House of Standards, 2003. https://meganorm.ru/Data2/1/4294844/4294844934.

- GOST 31939-2012 (ISO 3251:2008) Paint and varnish materials. Determination of mass fraction of non-volatile substances. Moscow. Standardinform, 2014. https://files.stroyinf.ru/Data/548/54893.

- GOST R 53654.1-2009 (ISO 2811-1:1997) Paint and varnish materials. Method for determination of density. Part 1. Pycnometric method. Moscow. Standardinform, 2010. https://meganorm.ru/Data2/1/4293819/4293819844.

- GOST 31149-2014 (ISO 2409:2013) Paint and varnish materials. Determination of adhesion by the lattice notch method. Moscow. Standardinform, 2014. https://img.izm.by/d/gost.31149.

- GOST 31973-2013 (ISO 1524:2000, MOD) Paint and varnish materials. Method for determining the degree of rubbing. Moscow. Standardinform, 2014. https://www.ntcexpert.ru/documents/gost-31973-2013.

- GOST 9.403-80 (ST SEV 5260-85) Unified system of corrosion and ageing protection (USPP). Paint and varnish coatings. Test methods for resistance to static impact of liquids. Moscow. IPK Publishing House of Standards, 2002. https://meganorm.ru/Data/78/7887.

- GOST 25898-2012 Construction materials and products. Methods of determination of vapour permeability and vapour permeability resistance. Moscow. Standardinform, 2014. https://meganorm.ru/Data2/1/4293782/4293782184.

- GOST 21903-76 Paint and varnish materials. Methods of determination of conditional light fastness. Moscow. Standards Publishing House, 1988. https://meganorm.ru/Data2/1/4294831/4294831840.

- GOST 6992-68 Paint and varnish coatings. method of testing for resistance in atmospheric conditions. Moscow. IPK Publishing House of Standards, 2003. https://meganorm.ru/Data2/1/4294822/4294822784.

- GOST 9.074-77 Unified system of protection against corrosion and ageing. Paint and varnish coatings for products intended for operation in areas with temperate climate. General technical requirements and methods of accelerated tests. Moscow. Gosstandart, 1986. https://meganorm.ru/Data2/1/4294718/4294718680.

- Selyaev V., P. , Osipov A. K., Kupriyashkina L. I., Sedova A. A., Kechutkina E. L., Suponina L. A. Possibility of creating thermal insulation materials based on nanostructured microsilica from diatomite. Nauka: 21 Century - 2011. – No. 3(15). P. 76 - 86.

- Avvakumova, N.I. , Budarina L.A. S.M. Divgun. Practicum on chemistry and physics of polymers. Moscow: Khimiya, 1990. 304 p.

- Mostovoy, A.; Yakovlev, A.; Tseluikin, V.; Lopukhova, M. Epoxy Nanocomposites Reinforced with Functionalized Carbon Nanotubes. Polymers 2020, 12, 1816. [Google Scholar] [CrossRef] [PubMed]

- Maljaee, H.; Ghiassi, B.; Lourenço, P.B. Effect of synergistic environmental conditions on thermal properties of a cold curing epoxy resin. Compos. Part B Eng. 2017, 113, 152–163. [Google Scholar] [CrossRef]

- Choudalakis, G. , Gotsis A.D. Permeability of polymer/clay nanocompo-sites: a review. Eur. Polym. J. 2009. V. 45. N 4. P. 967–984. [CrossRef]

- Gerasin, V.A. , Kurenkov V.V., Pashkov O.V., Ilyin S.O. Structure and rheology of aqueous poly (vinyl acetate) dispersions modified with montmoril-lonite. Colloid. J. 2017. V. 79. N 5. P. 588–595. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).