Submitted:

21 June 2024

Posted:

21 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

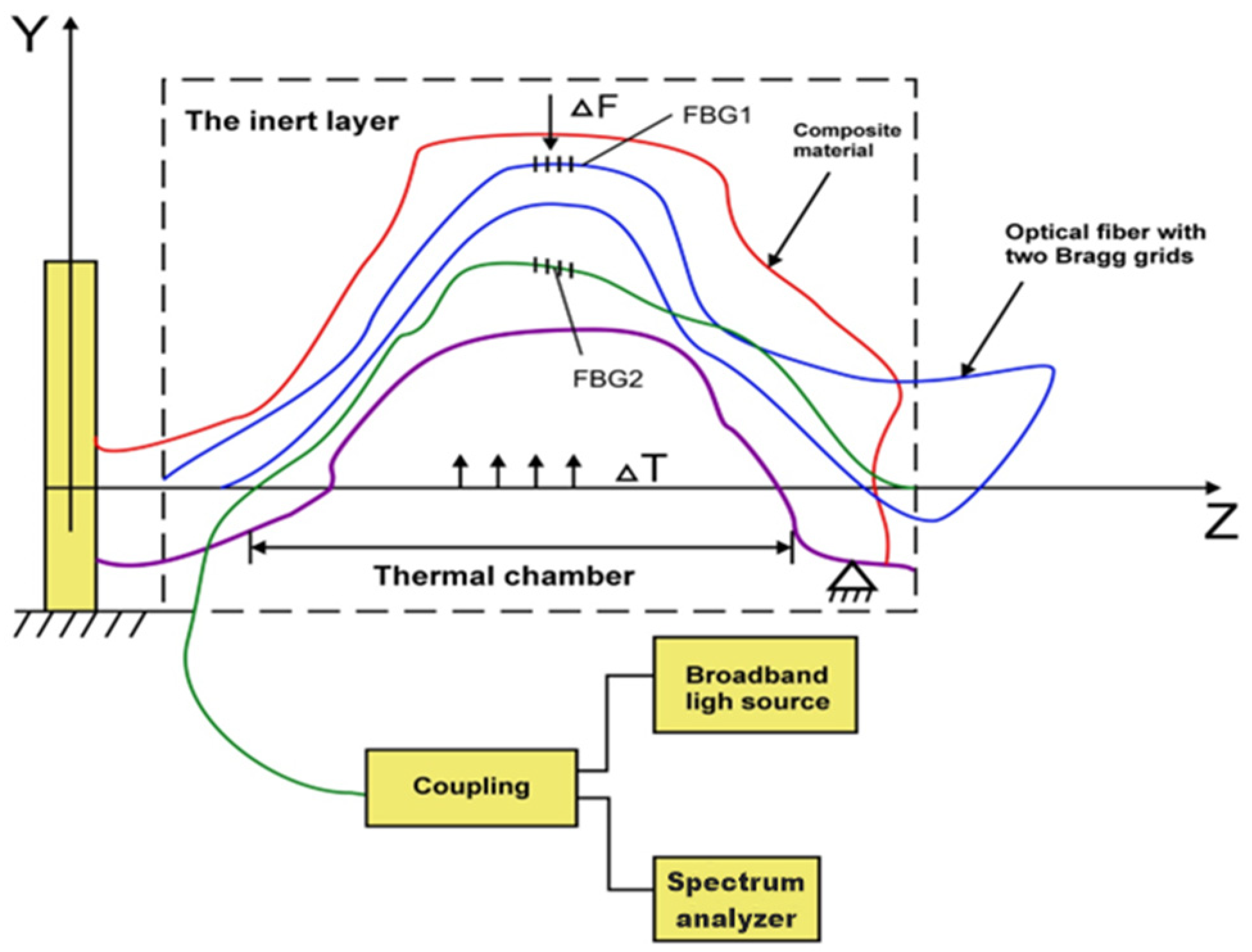

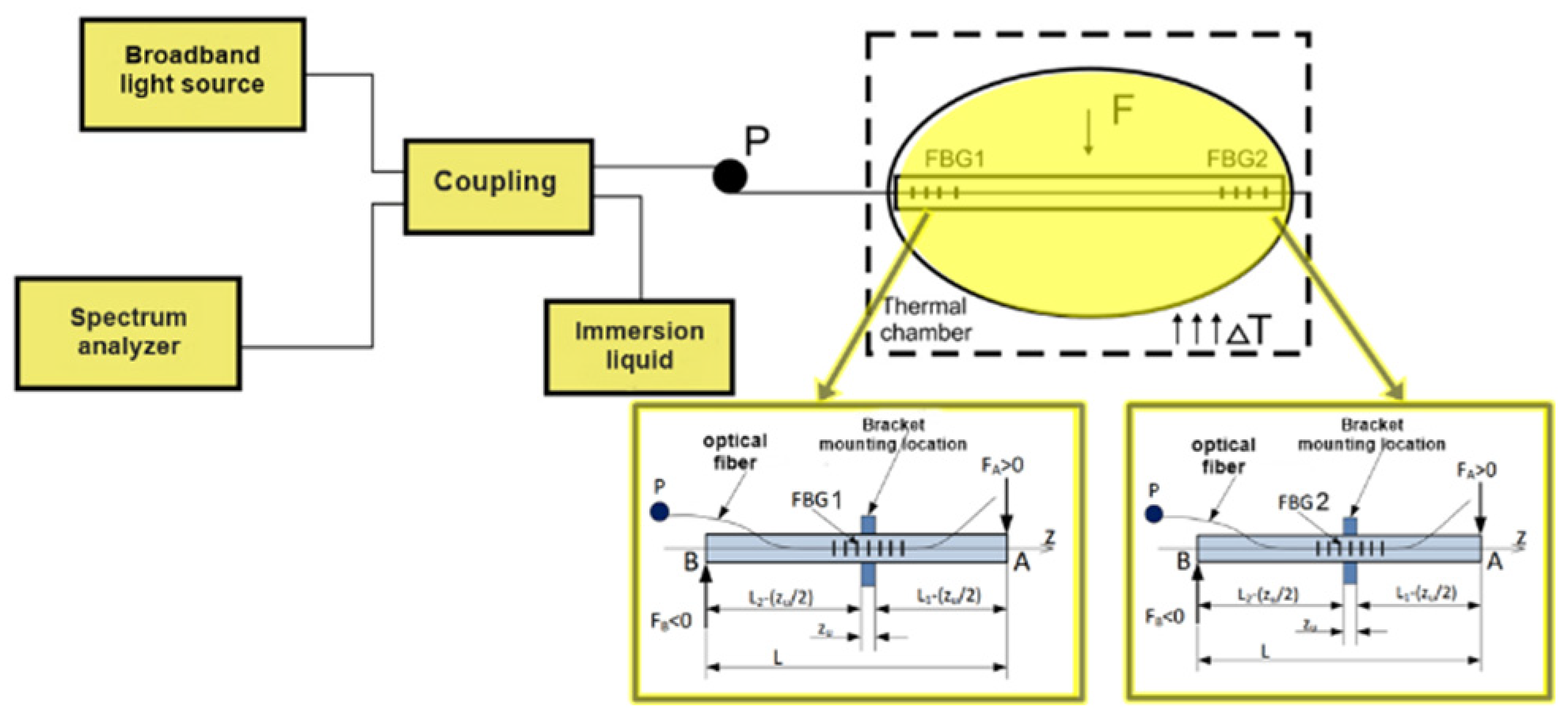

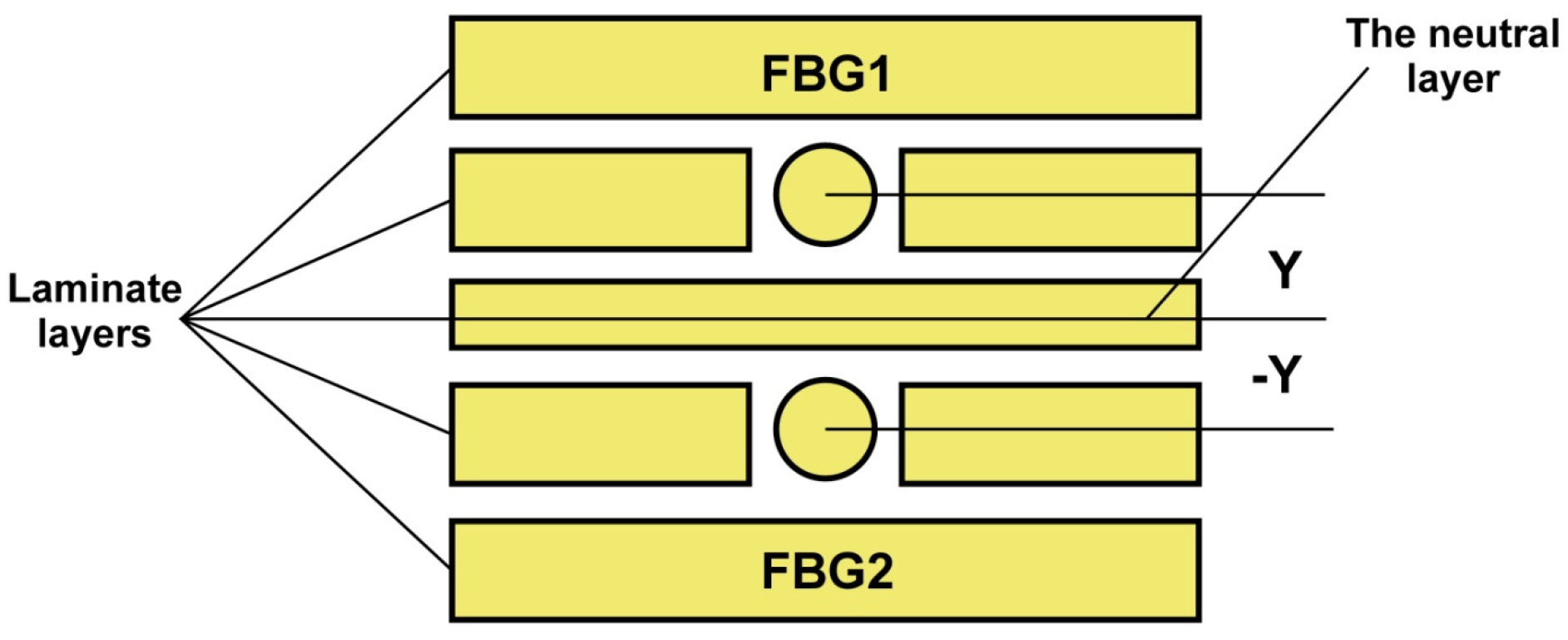

2.1. Sensor Diagram

2.2. Theory

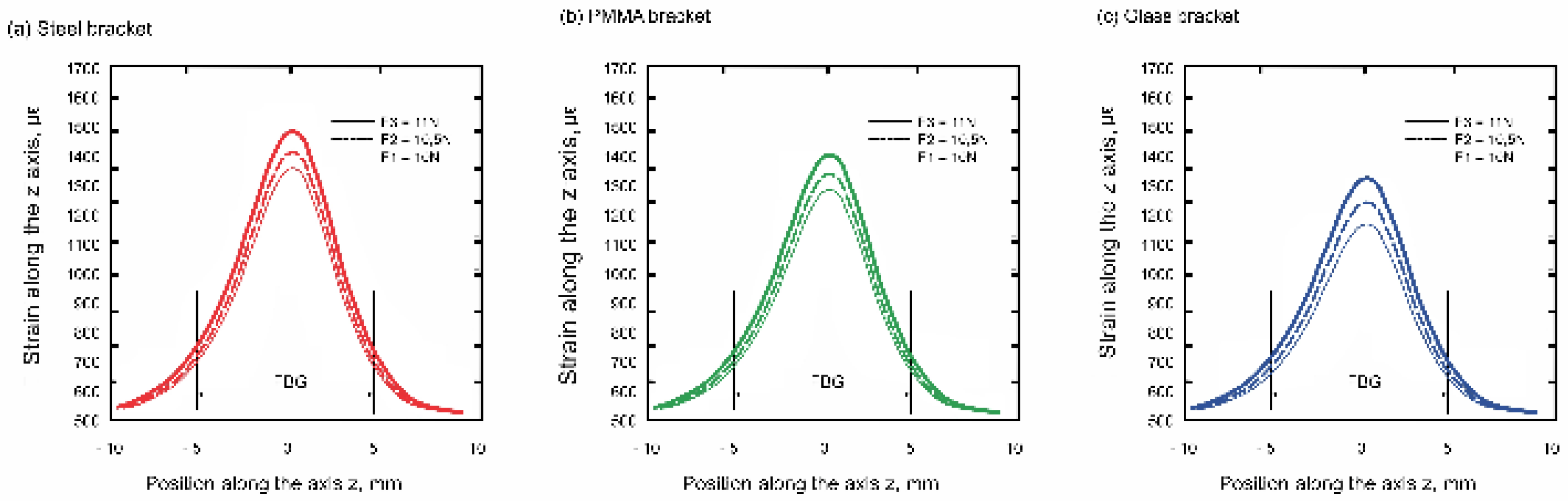

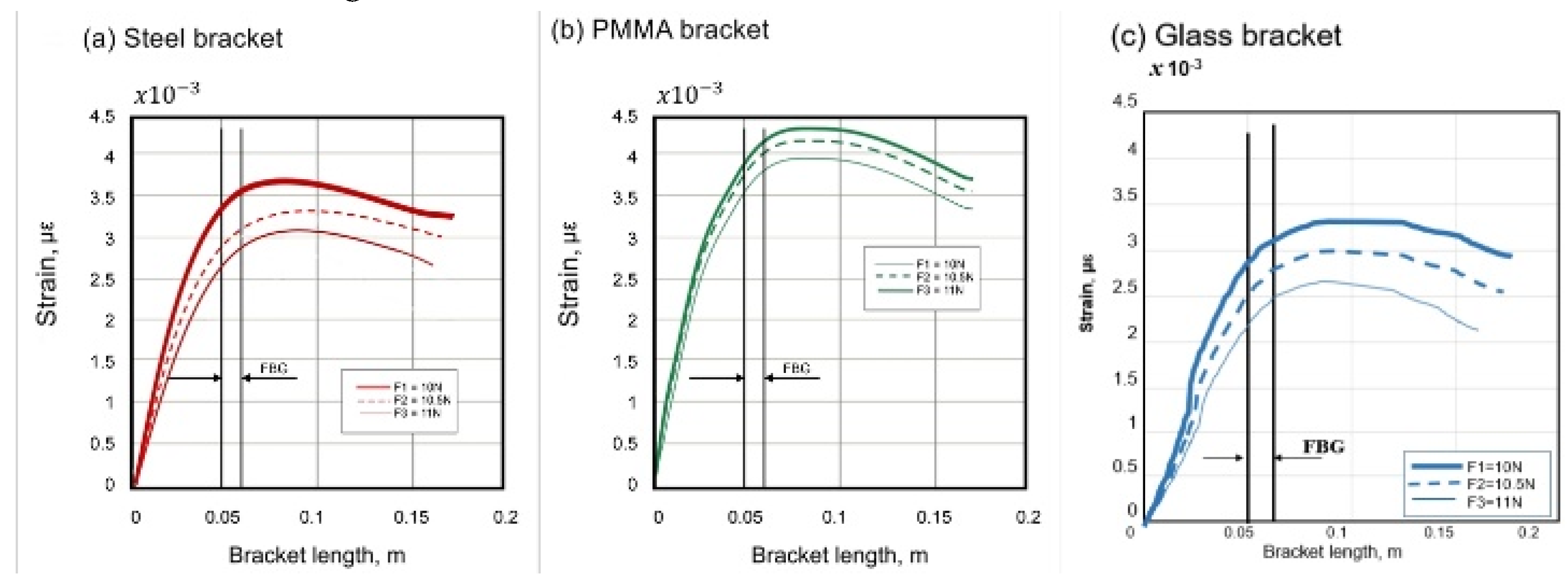

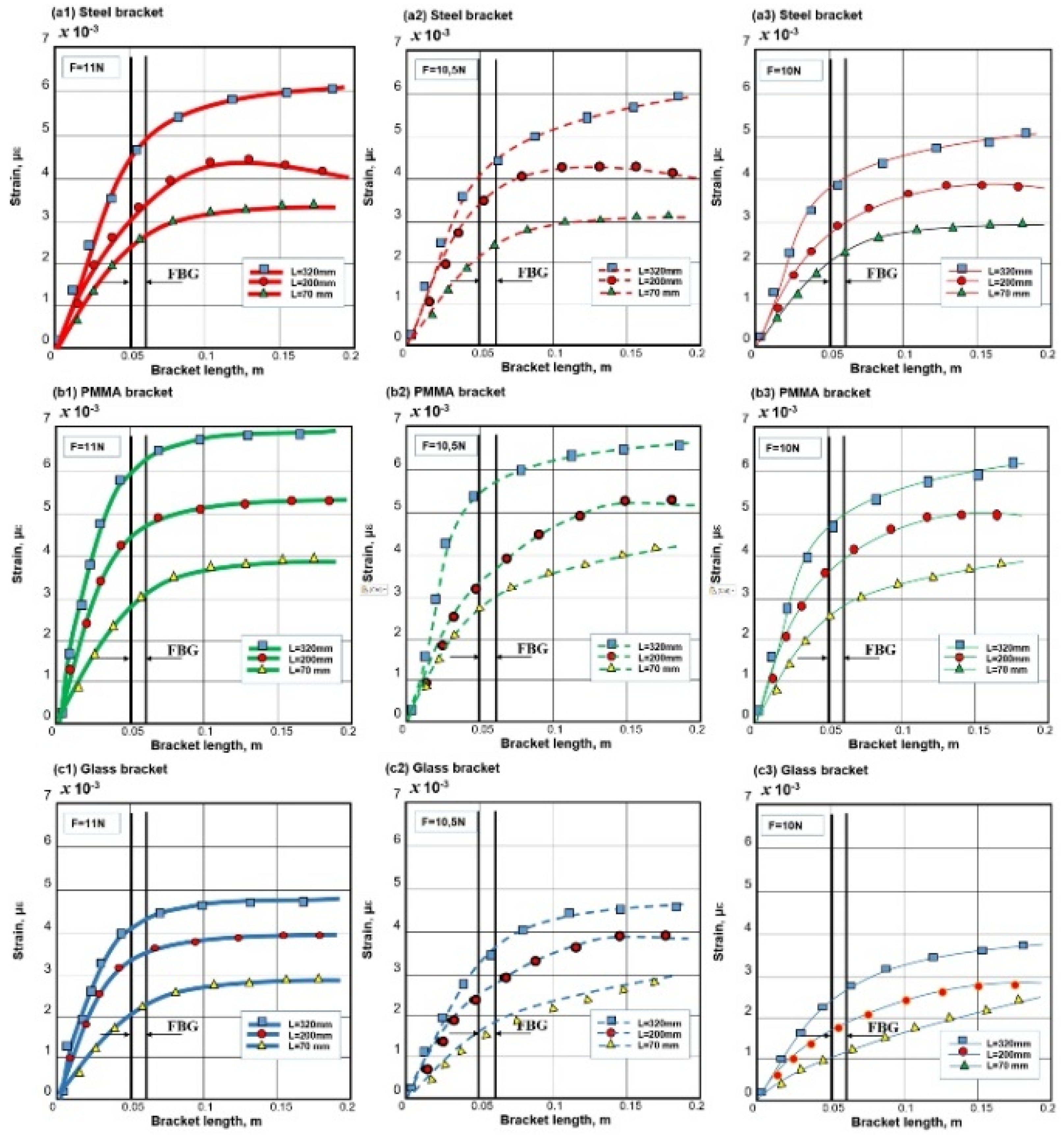

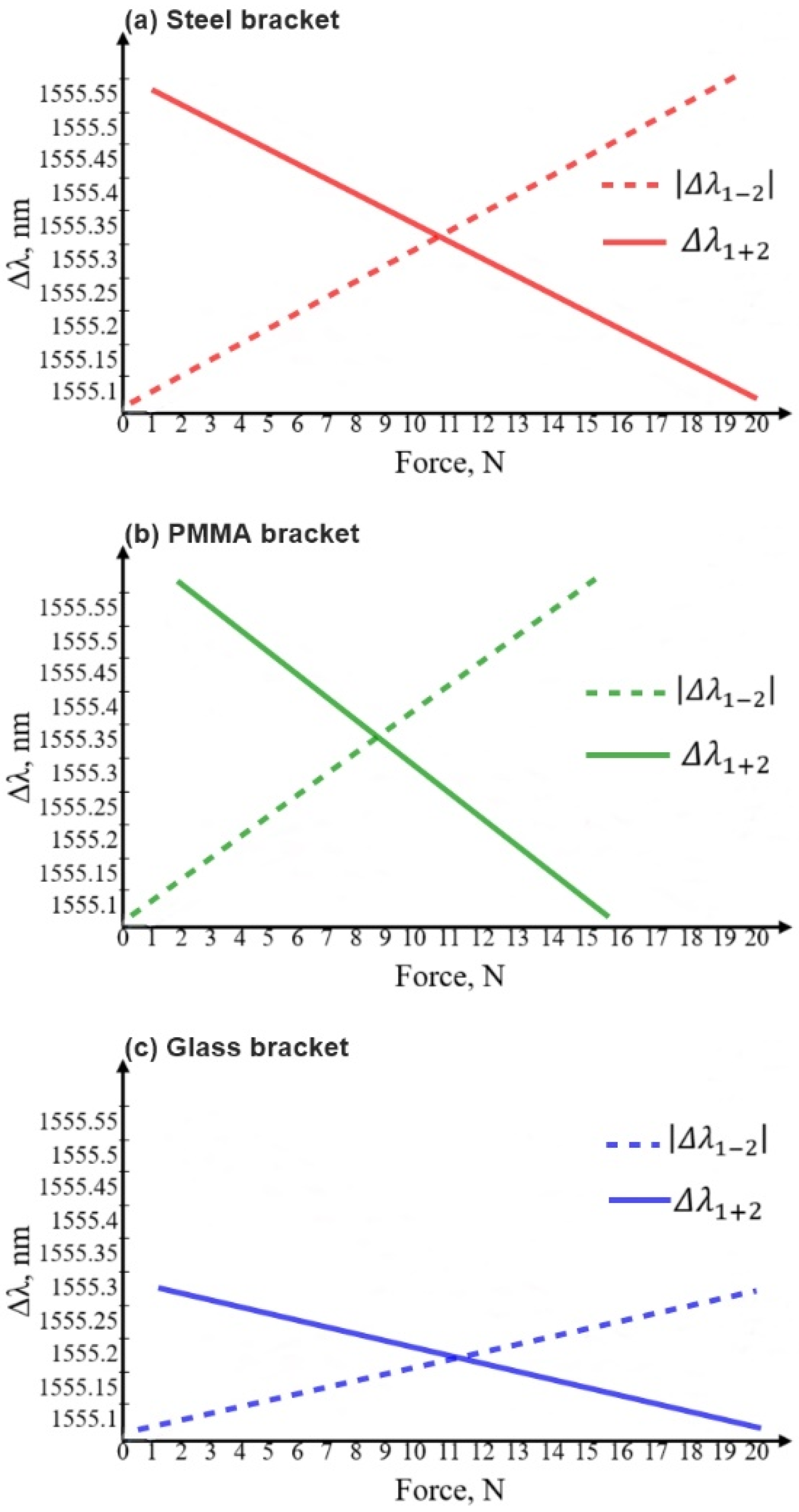

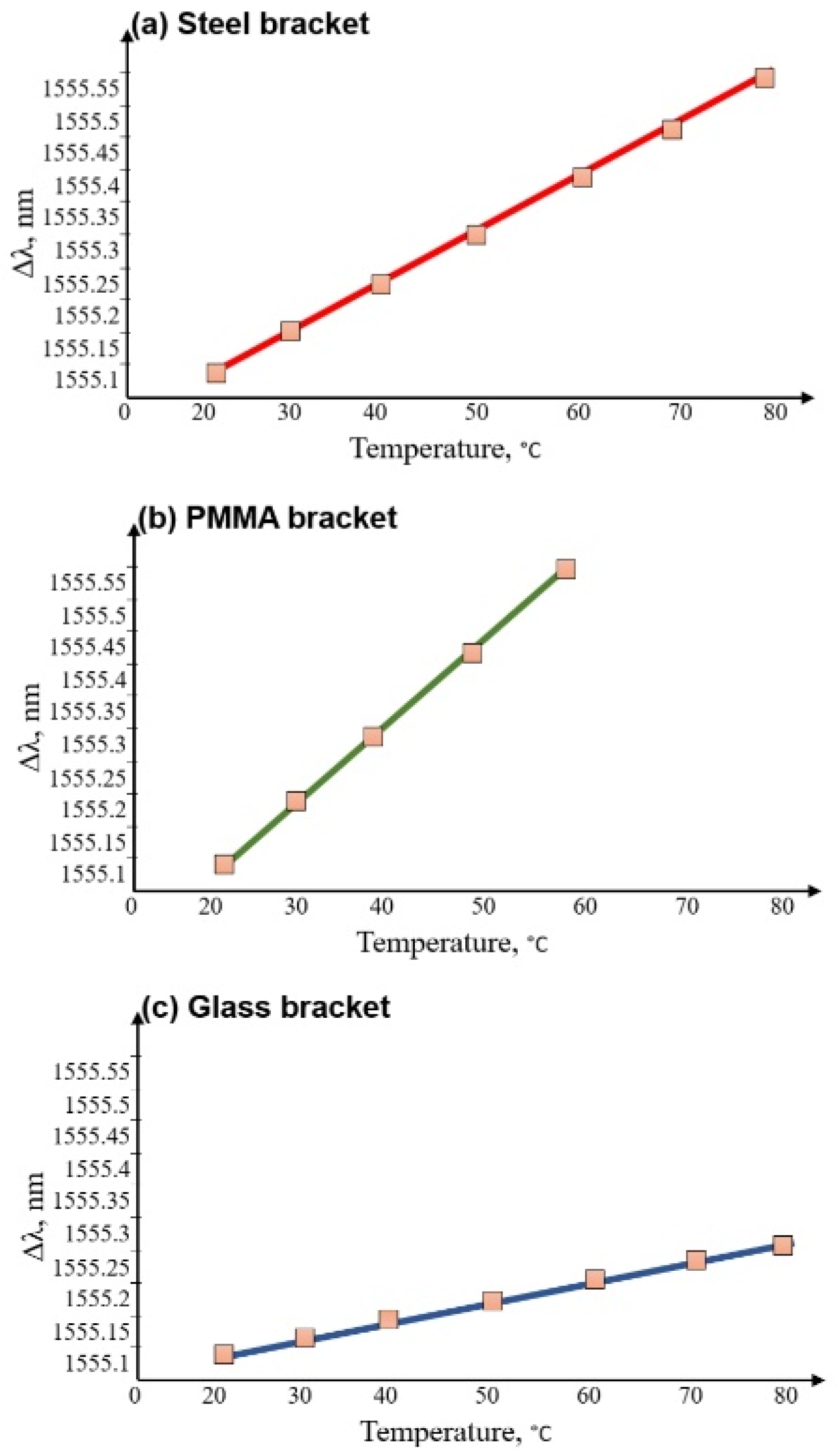

3. Results

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Xian, G., Guo, R., Li, C. (2022). Combined effects of sustained bending loading, water immersion and fiber hybrid mode on the mechanical properties of carbon/ glass fiber reinforced polymer composite. Composite Structures, 281, 115060. [CrossRef]

- Das, T.K., Ghosh, P., Das, N.C. (2019). Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review. Advanced Composites and Hybrid Materials, 2(12), 214-233. [CrossRef]

- Chung, D.D.L. (2017). Processing-structure-property relationships of continuous carbon fiber polymer-matrix composites. Materials Science and Engineering R Reports, 113,1-29. [CrossRef]

- Akman, F., Ogul, H., Ozkan, I., Kaçal, M.R., Agar, O., Polat, H., Dilsiz, K. (2022). Study on gamma radiation attenuation and non-ionizing shielding effectiveness of niobium-reinforced novel polymer composite, Nuclear Engineering and Technology, 54(1), 283-292. [CrossRef]

- Ramadan, W., Sakr, K., Sayed, M., Maziad, N., El-Faramawy, N. (2020). Investigation of acrylic/boric acid composite gel for neutron attenuation, Nuclear Engineering and Technology, 52, 2607-2612. [CrossRef]

- Jang, J., Hong, S., Kim, J., Goo, N., Yu, W. (2021). Accelerated testing method for predicting long-term properties of carbon fiber-reinforced shape memory polymer composites in a low earth orbit environment, Polymers, 13 (10) 1628. [CrossRef]

- Wang, L., Zhang, F., Liu, Y. (2019). Y-rays radiation resistant shape memory cyanate ester resin and its composites with high transition temperature, Smart Materials and Structures, 28(7), 075039. [CrossRef]

- Nishida, M., Hongo, A., Hiraiwa, Y., Higashide, M. (2019). Effects of gamma ray irradiation on penetration hole in and fragment size from carbon fiber reinforced composite plates in hypervelocity impacts, Composites Part B Engineering, 169(1–4), 229-238. [CrossRef]

- Pastore, R., Delfini, A., Albano, M., Vricella, A., Marchetti, M., Santoni, F., Piergentili, F. (2020). Outgassing effect in polymeric composites exposed to space environment thermal-vacuum conditionsю Acta Astronautica, 170(6). 466-471. [CrossRef]

- Jang, J.H., Hong, S.B., Kim, J., Goo, N.S., Lee, H., Yu, W. (2019). Long-term properties of carbon fiber-reinforced shape memory epoxy/polymer composites exposed to vacuum and ultraviolet radiation, Smart Materials and Structures, 28, 115013. [CrossRef]

- Zheng, L., Wang, L., Wang, Z., Wang, L. (2018) Effects of g-ray irradiation on the fatigue strength, thermal conductivities and thermal stabilities of the glass fibres/ epoxy resins composites, Acta Metallurgica Sinica (English Letters), 31, 105-112. [CrossRef]

- Sekulic, D., Stevanovic, M.M. (2011). Effects of gamma irradiation and post-irradiation annealing on carbon/epoxy UDC properties deduced by methods of local loading, Journal of Nuclear Materials, 412(1),190-194. [CrossRef]

- Wu, Z.X., Li J.W., Huang, C.J., Huang, R.J., Li, L.F. (2013). Effect of gamma irradiation on the mechanical behavior, thermal properties and structure of epoxy/glassfiber composite. Journal of Nuclear Materials, 441(s 1–3),67–72. [CrossRef]

- Liu, L., Feng, L., Ma, T., Xu, Z., Pei, X., Liu, Y., Shi, H., Tang, Y., Liu, L., Deng, H., Wang, C. (2022). Mechanical properties, thermal stability and microstructure evolution of carbon fiber-reinforced epoxy composites exposed to high-dose grays. Radiation Physics and Chemistry, 194(4),110056. [CrossRef]

- Li, R., Gu, Y., Yang, Z., Li, M., Wang, S., Zhang, Z. (2015). Effect of g irradiation on the properties of basalt fiber reinforced epoxy resin matrix composite. Journal of Nuclear Materials, 466. [CrossRef]

- Hoffman, E.N., Skidmore, T.E. (2009). Radiation effects on epoxy/carbon-fiber composite. Journal of Nuclear Materials, 392(2):371-378. [CrossRef]

- Hassani, S., Mousavi, M., Gandomi, A.H. (2022). Structural health monitoring in composite structures: a comprehensive review. Sensors, 22(1),153. [CrossRef]

- Goossens, S., Berghmans, F., Sharif Khodaei, Z., Lambinet, F., Karachalios, E., Saenz-Castillo, D., Geernaert, T. (2021). Practicalities of BVID detection on aerospacegrade CFRP materials with optical fibre sensors, Composite Structures, 259 113243. [CrossRef]

- Tuloup, C., Harizi, W., Aboura, Z., Meyer, Y., Khellil, K., Lachat, R. (2019). On the use of insitu piezoelectric sensors for the manufacturing and structural health monitoring of polymer-matrix composites: a literature review. Composite Structures, 215, 127-149. [CrossRef]

- Wronkowicz, A., Dragan, K., Lis, K. (2018). Assessment of uncertainty in damage evaluation by ultrasonic testing of composite structures. Composite Structures, 203, 71-84. [CrossRef]

- Sikdar, S., Liu, D., Kundu, A. (2022). Acoustic emission data based deep learning approach for classification and detection of damage-sources in a composite panel. Composites Part B Engineering, 228,109450. [CrossRef]

- Grassia, L., Iannone, M., Califano, A., D’Amore, A. (2019). Strain based method for monitoring the health state of composite structures. Composites Part B Engineering, 176, 107253. [CrossRef]

- Ahmed, O., Wang, X., Tran, M., Ismadi, M. (2021). Advancements in fiber-reinforced polymer composite materials damage detection methods: towards achieving energy-efficient SHM systems. Composites Part B Engineering, 223, 109136. [CrossRef]

- Rifaie-Graham, O., Apebende, E.A., Bast, L.K., Bruns, N. (2018). Self-reporting fiberreinforced composites that mimic the ability of biological materials to sense and report damage, Advanced Materials, 30(19):1705483. [CrossRef]

- Di Sante, R. (2015). Fibre optic sensors for structural health monitoring of aircraft composite structures: recent advances and applications. Sensors, 15, 18666-18713. [CrossRef]

- Frieden, J., Cugnoni, J., Botsis, J., Gmür, T., Coric, D. (2010). High-speed internal strain measurements in composite structures under dynamic load using embedded FBG sensors. Composite Structures, 92, 1905-1912. [CrossRef]

- Kim, H., Yoon, J., Kim, H., Han, J. (2010). Measurement of the thermal expansion of space structures using fiber Bragg grating sensors and displacement measuring interferometers. Measurement Science and Technology, 21(8), 085704. [CrossRef]

- Mulle, M., Yudhanto, A., Lubineau, G., Yaldiz, R., Schijve, W., Verghese, N. (2019). Internal strain assessment using FBGs in a thermoplastic composite subjected to quasistatic indentation and low-velocity impact. Composite Structures, 215, 305-316. [CrossRef]

- Szebenyi, G., Bloßl, Y., Hegedüs, G., Tabi, T. T, Czigany, T., Schledjewski, R. (2020). Fatigue monitoring of flax fibre reinforced epoxy composites using integrated fibreoptical FBG sensors, Composites Science and Technology, 199(6),108317. [CrossRef]

- Mohanta, S., Padarthi, Y., Chokkapu, S., Gupta, J., Neogi, S. (2023). Ultra-violet health monitoring of smart composite laminate using embedded fiber Bragg grating sensors. Journal of Composite Materials, 54(22),002199832091170. [CrossRef]

- Gusarov, A.I., Starodubov, D.S., Berghmans, F. (1999). Design of a radiation-hard optical fiber Bragg grating temperature sensor. Proc. SPIE Vol. 3872, Conference on Photonics for Space and Enhanced Radiation Environments, EOS/SPIE Symposium on Remote Sensing, Florence, Italy, 43-50.

- Faustov, A.V., Gusarov, A.I., Megret, P., Wuilpart, M., Kinet, D., Zhukov, A.V., Novikov, S.G., Svetukhin, V.V., Fotiadi, A.A. (2016). Gamma radiation-induced blue shift of resonance peaks of Bragg gratings in pure silica fibres. Quantum Electronics. 46(2),150-154. [CrossRef]

- Girard, S., Kuhnhenn, J., Gusarov, A., Brichard, B., Van Uffelen, M., Ouerdane, Y., Boukenter, A., Marcandella, C. (2013). Radiation effects on silica-based optical fibers: recent advances and future challenges, IEEE Transactions on Nuclear Science, 60(3), 2015-2036. [CrossRef]

- Gusarov, A., Hoeffgen, S.K. (2013). Radiation effects on fiber gratings. IEEE Transactions on Nuclear Science, 60(3),2037-2053. [CrossRef]

- Kinet, D., Broadway, C., Gusarov, A., Megret, P., Caucheteur, C., Kalli, K., O’Keeffe, S.O., Brambilla, G. (2019). Fibre Bragg gratings wavelength evolution and thermal sensitivity under gamma irradiation. Conference: Seventh European Workshop on Optical Fibre Sensors, Limassol, Cyprus. [CrossRef]

- Zaghloul, M.A.S, Wang, M., Huang, S., Hnatovsky, C.,., Mihailov, S., D. Carpenter, Li, M., Hu,L., Daw, J., Laffont, G., Nehr, S., Chen, K.P. (2018). Radiation resistant fiber Bragg grating in random air-line fibers for sensing applications in nuclear reactor cores. Optics Express, 26(9),11775. [CrossRef]

- He, J., Xu, B., Xu X., Liao, C., Wang, Y. (2021). Review of femtosecond-laser-inscribed fiber Bragg gratings: fabrication technologies and sensing applications. Photonic Sensors, 11(8). [CrossRef]

- Chen, J., Wang, J., Li, X., Sun, L., Li, S. (2020). Ding A., Monitoring of temperature and cure-induced strain gradient in laminated composite plate with FBG sensors. Composite Structures, 242(17), 112168. [CrossRef]

- Birri, A., Wilson, B.A., Blue, T.E. (2019). Deduced refractive index profile changes of type I and type II gratings when subjected to ionizing radiation. IEEE Sensors Journal, PP(99), 1-1. [CrossRef]

- Mihailov, S.J. (2012). Fiber Bragg grating sensors for harsh environments. Sensors, 12(2),1898-918. [CrossRef]

- Henschel, H., Grobnic, D., Hoeffgen, S.K., Kuhnhenn, J., Mihailov, S.J., Weinand, U. (2011). Development of highly radiation resistant fiber Bragg gratings. IEEE Transactions on Nuclear Science, 58(4),2103-2110. [CrossRef]

- Theodosiou, A., Leal-Junior, A., Marques, C., Frizera, A., Fernandes, A.J.S., Stancalie, A., Ioannou, A., Ighigeanu, D., Mihalcea, R., Negut, C.D., Kalli, K. (2021). Comparative study of g- and e-radiation-induced effects on FBGs using different femtosecond laser inscription methods. Sensors, 21(24),8379. [CrossRef]

- Morana, A., Girard,S., Marin, E., Marcandella, C., Rizzolo, S., Perisse, J., Mace, J., Taouri, A., Boukenter A., Cannas M., Ouerdane Y., Radiation vulnerability of fiber Bragg gratings in harsh environments. Journal of Lightwave Technology, 33(12), 2646-2651. [CrossRef]

- Remy, L., Cheymol, G., Gusarov, A. (2016). Compaction in optical fibres and fibre Bragg gratings under nuclear reactor high neutron and gamma fluence. IEEE Trans. Nucl. Sci. 63, 2317-2322. [CrossRef]

- Yang, X.; Lin, M.; Shoulin, J.; Zuyuan, H. (2017). Effect of kGy dose level gamma radiation on Ge-doped FBGs and femtosecond-laser-inscribed pure-silica-core FBGs. 16th International Conference on Optical Communications and Networks, Wuzhen, China. [CrossRef]

- Hao, J.Z., Ong, L.C., Gong, Y.D., Cai, Z.H., Ng, J.H., Varghese P. (2007). A Temperature-independent Lateral Force Sensor using a Pair of FBGs. Proceedings of Asia-Pacific Microwave Conference. [CrossRef]

- Pant J., Mitra A., Tiwari U., Mondal S., Singh N., Jain S., Kapur P. (2008) Temperature Compensated Transverse Load Sensor Based on Dual FBG Sensor. Proceedings of International Conference on Microwave-08, IEEE. 395-397. [CrossRef]

- Dong B, Zhao Q., Zhao L., Jin L., Miao Y., Liao T., Zeng X. (2008). Simultaneous measurement of temperature and force based on a special- strain-function-chirped FBG. Sensors and Actuators A Physical, 147(1), 169-172. [CrossRef]

- Sorensen L., Botsis J., Gmur T., Cugnoni J. (2007). Delamination detection and characterisation of bridging tractions using long FBG optical sensors. Composites Part A Applied Science and Manufacturing, 38(10), 2087-2096. [CrossRef]

- Shen C., Zhong C. (2011). Novel temperature-insensitive fiber Bragg grating sensor for displacement measurement. Sensors and Actuators A Physical, 170,51-54. [CrossRef]

- Zhang W., Dong X., Zhao Q., Kai G., Yuan S. (2001). FBG-Type Sensor for Simultaneous Measurement of Force (or Displacement) and Temperature Based on Bilateral Cantilever Beam. IEEE Photonics Technology Letters, 13, 1340-1342. [CrossRef]

- Dong B., Zhao Q., Liu L., Huang G., Jin L., Zhou J., Liao T. (2008). Tunable Chirped Fiber Bragg Grating Filter Based on Special Strain Function Modulation and Its Application in Fiber Sensor. Journal of Lightwave Technology, 26, 4, 2286- 2290. [CrossRef]

- Zhi, Zh., Thomas, W.G., Luke, H., Jin-ping, O. (2003). Techniques of Advanced FBG sensors: fabrication, demodulation, encapsulation and their application in the structural health monitoring of bridges. Pacific Science Review, 5, 116-121.

| Bracket | Steel (unit) | PMMA (unit) | Glass (unit) | |

| Parameters | ||||

| 1,2nm/mε | 0,554mn/mε | 0,987 mn/mε | ||

| E Young’s modulus | 200GPa | 3GPa | 73,5GPa | |

| s the width of the composite | 10mm | 10mm | 10mm | |

| g is its thickness | 1mm | 1mm | 1mm | |

| 9,45pm/0C | 7,6745pm/0C | 14,3445pm/0C | ||

| 2,6*10-3nm/N | 1,2*10-3nm/N | 3,5*10-3nm/N | ||

| 8,35 pm/0C | 5,57 pm/0C | 6,24 pm/0C | ||

| 1,2*10-3km/N | 2,78*10-3km/N | 3,89*10-3km/N | ||

| photo elastic constant | 210 GPa | 45 GPa | 71,4 GPa | |

| the wavelength used for the Bragg grating | 1555nm | 1555nm | 1555nm | |

| coefficient of thermal expansion of the rack | 1,2*10-5 1/K | 5*10-51/K | 5,8*10-71/K | |

| coefficient of thermal expansion of the holder | 1,3*10-61/K | 4,6*10-61/K | 8,6*10-61/K | |

| the coefficient of thermal expansion of the stand | 0,55*10-61/K | 3,5*10-61/K | 4*10-61/K | |

| the length of the Bragg grating | 530 nm | 530nm | 530nm | |

| the effective refractive index of the fiber | 100 | 100 | 150 | |

| Λ period | 100mkm | 100mkm | 100mkm | |

| 55nm | 55nm | 55nm | ||

| 60nm | 60nm | 60nm | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).