Submitted:

13 June 2024

Posted:

13 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites Preparation

2.3. Flexural Test

2.4. Impact Test

2.5. Morphological Analysis

3. Results and Discussion

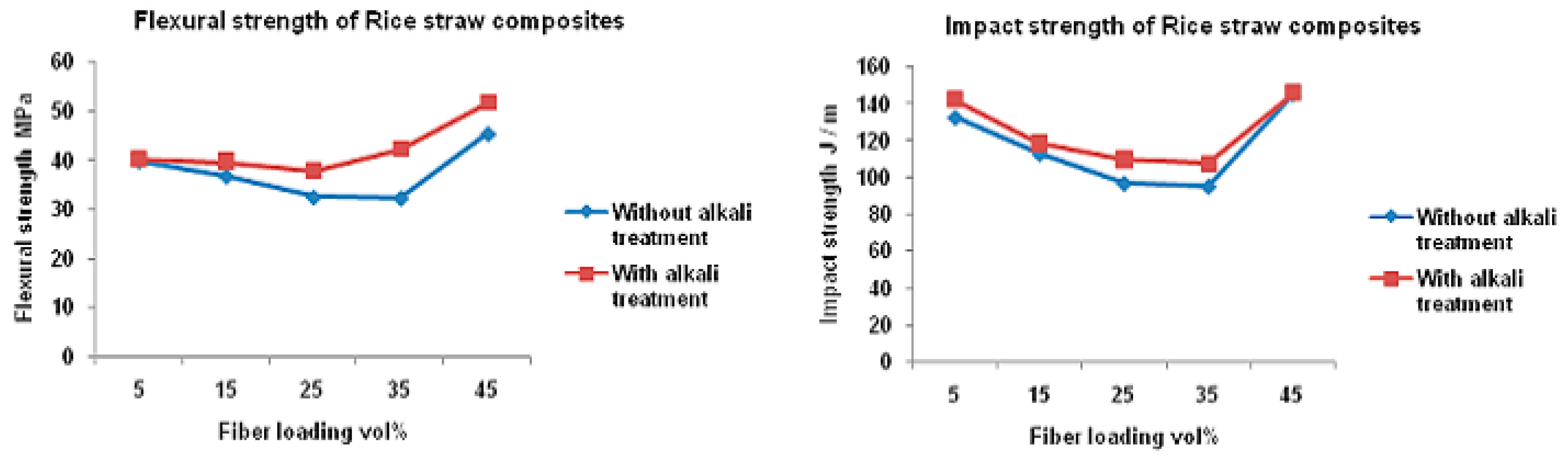

3.1. Rice Straw Composites

3.1.1. Flexural Strength

3.1.2. Impact Strength

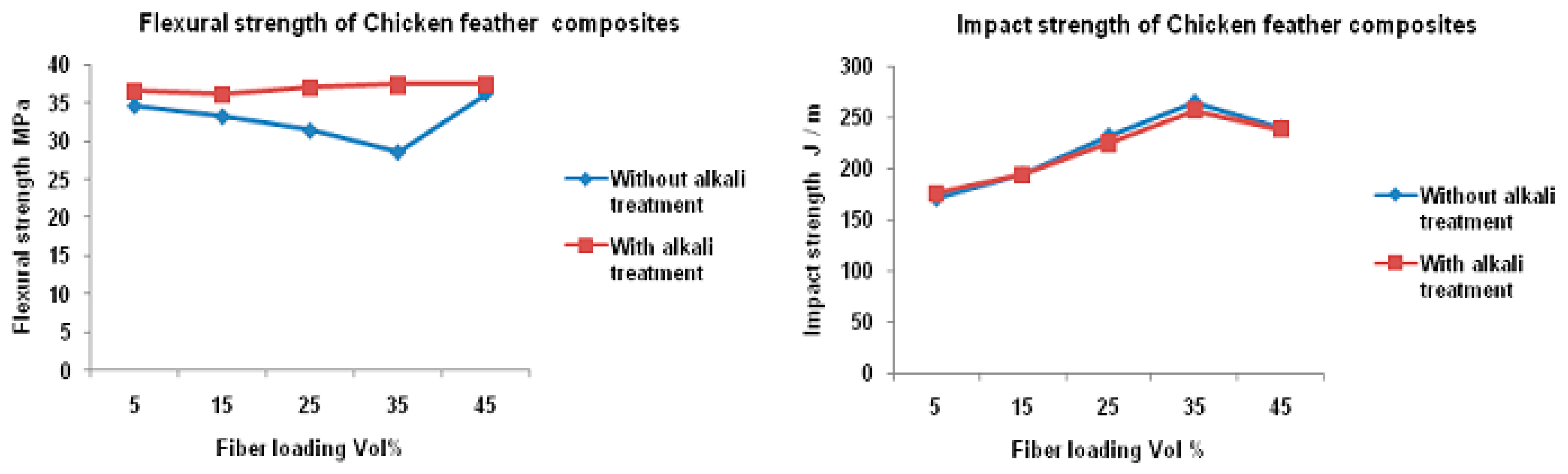

3.2. Chicken Feather Composites

3.2.1. Flexural Strength

3.2.2. Impact Strength

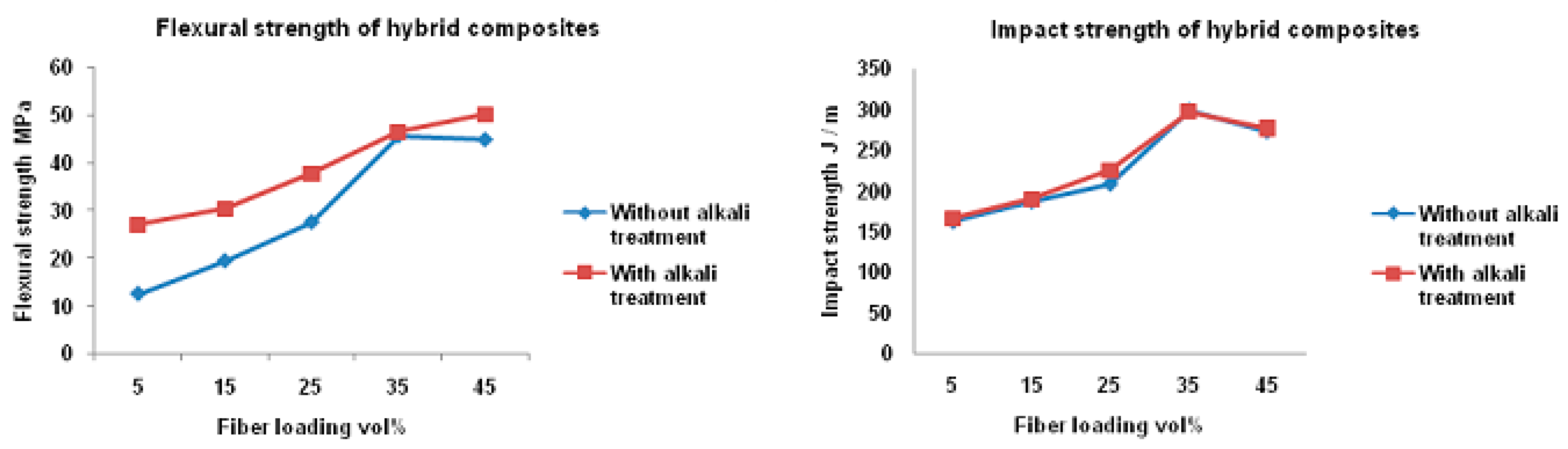

3.3. Hybrid Composites

3.3.1. Flexural Strength

3.3.2. Impact Strength

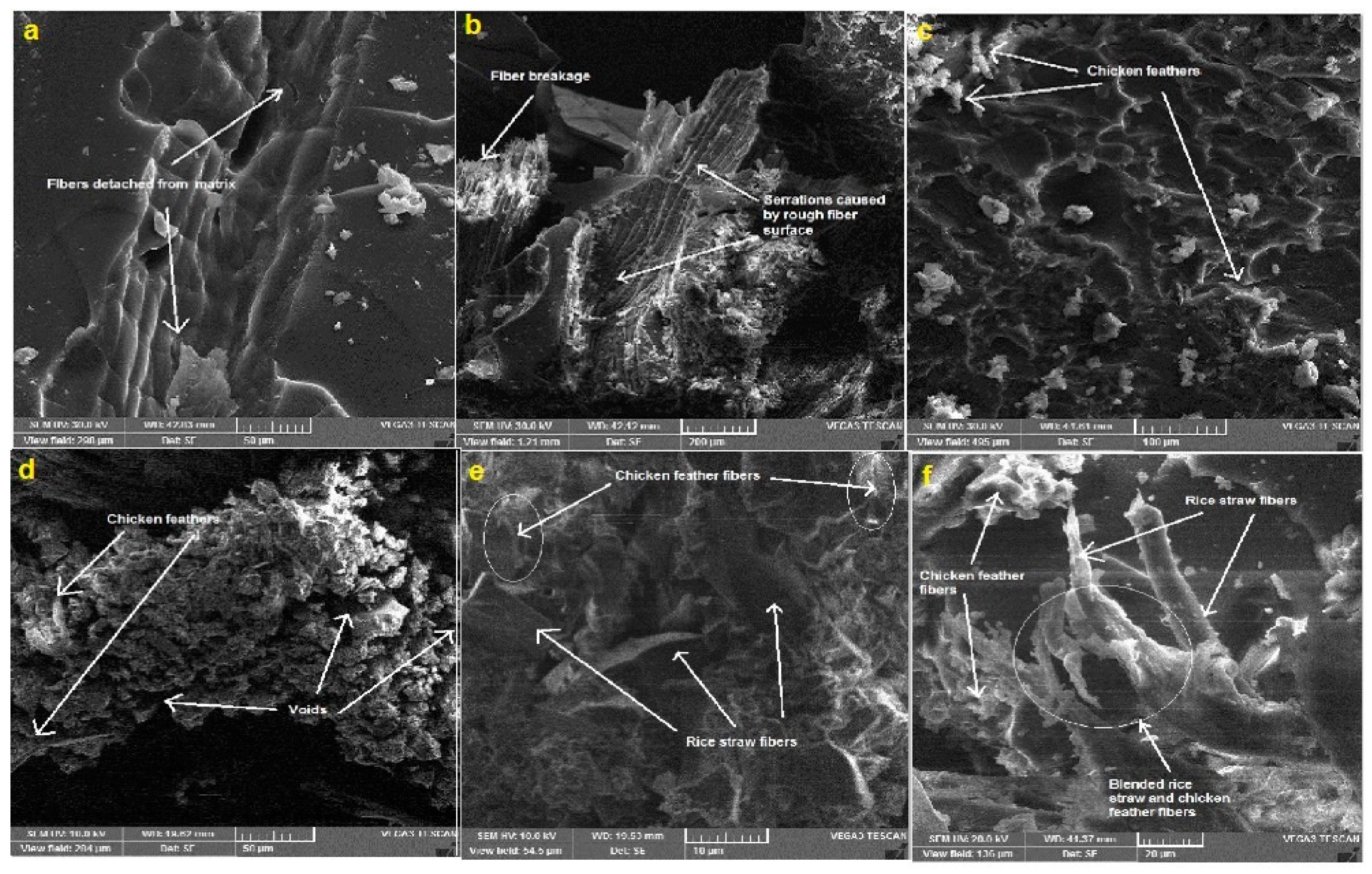

3.4. Morphological Analysis

4. Conclusions

- The flexural strength of the rice straw and chicken feather fibers decreased on fiber loading till 35%, while on the contrary, the hybrid composites showed improved flexural strength with fiber loading.

- The impact strengths of the rice straw fibers reinforced composites decreased on fiber loading, whereas the impact strength of both the chicken feather and the hybrid composites showed increase with in fiber loading exhibiting maximum impact values of 265.4 J/m and 298.8 J/m respectively.

- Improvement in flexural strength and impact strength of the composites was noticed after surface treatment of the fibers using NaOH owing to the removal of waxy layer on the rice straw. No significant change in the flexural strength of the chicken feather composites was seen with fiber loading where as marginal improvement in impact strength of the chicken feather composites was seen post treatment.

- Hybrid composites pronounced enhanced flexural strength with treated fibers than raw fibers, while only a marginal increase in impact strength was found after mercerization. Hybridization of the fibers was compatible with one another resulting in synergistic effect on the mechanical properties of the composites.

Acknowledgements

References

- Bledzki, A.K. and Gassan, J., 1999. Composites reinforced with cellulose based fibres. Progress in polymer science, 24(2), pp.221-274. [CrossRef]

- Begum, S., Fawzia, S. and Hashmi, M.S.J., 2020. Polymer matrix composite with natural and synthetic fibres. Advances in Materials and Processing Technologies, 6(3), pp.547-564. [CrossRef]

- NagarajaGanesh, B. , Rekha, B. and Yoganandam, K., 2022. Assessment of thermal insulation and flame retardancy of cellulose fibers reinforced polymer composites for automobile interiors. Journal of Natural Fibers, 19(15), pp.11021-11029. [CrossRef]

- Pickering, K.L. , Efendy, M.A. and Le, T.M., 2016. A review of recent developments in natural fibre composites and their mechanical performance. Composites Part A: Applied Science and Manufacturing, 83, pp.98-112. [CrossRef]

- Vaisanen, T. , Das, O. and Tomppo, L., 2017. A review on new bio-based constituents for natural fiber-polymer composites. Journal of Cleaner Production, 149, pp.582-596. [CrossRef]

- NagarajaGanesh, B. , Sugumaran, P. and Sridhar, R., 2012. Mechanical properties of rice straw and chicken feather fibers. International Journal of Composite Materials and Manufacturing, 2, pp.22-26.

- Bangar, S.P. , Kajla, P. and Ghosh, T., 2023. Valorization of wheat straw in food packaging: A source of cellulose. International Journal of Biological Macromolecules, 227, pp.762-776. [CrossRef]

- Jagadeesan, Y. , Meenakshisundaram, S., Saravanan, V. and Balaiah, A., 2022. Greener and sustainable biovalorization of poultry waste into peptone via Bacto-enzymatic digestion: a breakthrough chemical-free bioeconomy waste management approach. Waste and Biomass Valorization, 13(7), pp.3197-3219. [CrossRef]

- Singh, G. and Arya, S.K., 2021. A review on management of rice straw by use of cleaner technologies: Abundant opportunities and expectations for Indian farming. Journal of Cleaner Production, 291, p.125278. [CrossRef]

- Ortega, F. , Versino, F., López, O.V. and García, M.A., 2022. Biobased composites from agro-industrial wastes and by-products. Emergent Materials, 5(3), pp.873-921. [CrossRef]

- Thyagarajan, D. , Barathi, M. and Sakthivadivu, R., 2013. Scope of poultry waste utilization. IOSR J Agric Vet Sci, 6(5), pp.29-35.

- Prasanthi, N. , Bhargavi, S. and Machiraju, P.V.S., 2016. Chicken feather waste: a threat to the environment. International Journal of Innovative Research in Science and Technology, 5(9), pp.16759-16764.

- Belarmino, D.D. , Ladchumananandasivam, R., Belarmino, L.D., Pimentel, J.R.D.M., da Rocha, B.G., Galv, A.O. and de Andrade, S.M., 2012. Physical and morphological structure of chicken feathers (keratin biofiber) in natural, chemically and thermally modified forms.

- Poole, A.J. , Church, J.S. and Huson, M.G., 2009. Environmentally sustainable fibers from regenerated protein. Biomacromolecules, 10(1), pp.1-8. [CrossRef]

- Tesfaye, T. , Sithole, B. and Ramjugernath, D., 2017. Valorisation of chicken feathers: a review on recycling and recovery route—current status and future prospects. Clean Technologies and Environmental Policy, 19, pp.2363-2378. [CrossRef]

- Basak, A.K. , Hossain, M.R., Pramanik, A., Shah, D.R., Prakash, C., Shankar, S. and Debnath, S., 2021. Use of duck feather waste as a reinforcement medium in polymer composites. Cleaner Materials, 1, p.100014. [CrossRef]

- Bangar, S.P. , Whiteside, W.S., Kajla, P. and Tavassoli, M., 2023. Value addition of rice straw cellulose fibers as a reinforcer in packaging applications. International Journal of Biological Macromolecules, p.125320. [CrossRef]

- NagarajaGanesh, B. and Rekha, B., 2019. Effect of mercerization on the physico-chemical properties of matured and seasoned Cocos nucifera fibers for making sustainable composites. Materials Research Express, 6(12), p.125102. [CrossRef]

- Zhu, W.H. , Tobias, B.C. and Coutts, R.S.P., 1995. Banana fibre strands reinforced polyester composites. Journal of materials science letters, 14(7), pp.508-510. [CrossRef]

- Prasad, S.V. , Pavithran, C. and Rohatgi, P.K., 1983. Alkali treatment of coir fibres for coir-polyester composites. Journal of materials science, 18, pp.1443-1454. [CrossRef]

- Ganesh, B.N. and Rekha, B., 2013. A comparative study on tensile behaviour of plant and animal fiber reinforced composites. International Journal of Innovation and Applied Studies, 2(4), pp.645-48.

- Ray, D. , Sarkar, B.K., Rana, A.K. and Bose, N.R., 2001. The mechanical properties of vinylester resin matrix composites reinforced with alkali-treated jute fibres. Composites Part A: applied science and manufacturing, 32(1), pp.119-127. [CrossRef]

- Xie, X. , Zhou, Z., Jiang, M., Xu, X., Wang, Z. and Hui, D., 2015. Cellulosic fibers from rice straw and bamboo used as reinforcement of cement-based composites for remarkably improving mechanical properties. Composites Part B: Engineering, 78, pp.153-161. [CrossRef]

- NagarajaGanesh, B. and Rekha, B., 2020. Intrinsic cellulosic fiber architecture and their effect on the mechanical properties of hybrid composites. Archives of Civil and Mechanical Engineering, 20, pp.1-12. [CrossRef]

- Peng, Z. , Mao, X., Zhang, J., Du, G. and Chen, J., 2019. Effective biodegradation of chicken feather waste by co-cultivation of keratinase producing strains. Microbial cell factories, 18, pp.1-11. [CrossRef]

- Ali, M.F. , Hossain, M.S., Moin, T.S., Ahmed, S. and Chowdhury, A.S., 2021. Utilization of waste chicken feather for the preparation of eco-friendly and sustainable composite. Cleaner Engineering and Technology, 4, p.100190.

- Vlaev, L. , Turmanova, S. and Dimitrova, A., 2009. Kinetics and thermodynamics of water adsorption onto rice husks ash filled polypropene composites during soaking. Journal of polymer research, 16, pp.151-164. [CrossRef]

- Raj, R.G. , Kokta, B.V., Dembele, F. and Sanschagrain, B., 1989. Compounding of cellulose fibers with polypropylene: Effect of fiber treatment on dispersion in the polymer matirx. Journal of applied polymer science, 38(11), pp.1987-1996. [CrossRef]

- Kazayawoko et al., 1999. Kazayawoko, M., Balatinecz, J.J., Matuana, L.M., 1999. Surface modification and adhesion mechanisms in woodfiber-polypropylene composites. J. Mater. Sci. 34 (24), 6189–6199. [CrossRef]

- Nguyen, D.D. , Vadivel, M., Shobana, S., Arvindnarayan, S., Dharmaraja, J., Priya, R.K., Nguyen-Tri, P., Kumar, G. and Chang, S.W., 2020. Fabrication and modeling of prototype bike silencer using hybrid glass and chicken feather fiber/hydroxyapatite reinforced epoxy composites. Progress in Organic Coatings, 148, p.105871. [CrossRef]

- Uzun, M. , Sancak, E., Patel, I., Usta, I., Akalın, M. and Yuksek, M., 2011. Mechanical behaviour of chicken quills and chicken feather fibres reinforced polymeric composites. Archives of Materials Science and Engineering, 52(2), pp.82-86.

- Huda, S. and Yang, Y., 2008. Composites from ground chicken quill and polypropylene. Composites science and technology, 68(3-4), pp.790-798. [CrossRef]

- Prum, R.O. , 1999. Development and evolutionary origin of feathers. Journal of Experimental Zoology, 285(4), pp.291-306.

- NagarajaGanesh, B. and Rekha, B., 2019. Morphology and damage mechanism of lignocellulosic fruit fibers reinforced polymer composites: A comparative study. SN Applied Sciences, 1, pp.1-11. [CrossRef]

- Kailasanathan, C. , Gopi Krishna, M. and NagarajaGanesh, B., 2022. Investigation of mechanical and thermal conductivity properties of Sansevieria roxburghiana leaf fibers reinforced composites: effect of fiber loading. Journal of Natural Fibers, 19(16), pp.13401-13414. [CrossRef]

- Alomayri, T. , Shaikh, F.U.A. and Low, I.M., 2013. Characterisation of cotton fibre-reinforced geopolymer composites. Composites Part B: Engineering, 50, pp.1-6. [CrossRef]

- Omrani, E. , Menezes, P.L. and Rohatgi, P.K., 2016. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Engineering Science and Technology, an International Journal, 19(2), pp.717-736. [CrossRef]

- Ganesh, B.N. and Muralikannan, R., 2016. Comprehensive characterization of lignocellulosic fruit fibers reinforced hybrid polyester composites. International Journal of Material Science and Applications, 5(6), pp.302-307.

- Zhu, S. , Wu, Y., Yu, Z., Liao, J. and Zhang, Y., 2005. Pretreatment by microwave/alkali of rice straw and its enzymic hydrolysis. Process biochemistry, 40(9), pp.3082-3086. [CrossRef]

- Zhang, Q. and Cai, W., 2008. Enzymatic hydrolysis of alkali-pretreated rice straw by Trichoderma reesei ZM4-F3. Biomass and Bioenergy, 32(12), pp.1130-1135. [CrossRef]

- Saini, S. , Kardam, S.K., Kadam, A.A., Kumar, V. and Gaikwad, K.K., 2022. Green and energy-efficient extraction of cellulose nano-fibrils from rice straw and its coating to improve functional properties of rice straw paperboard made via refiner mechanical pulping. Progress in Organic Coatings, 165, p.106747. [CrossRef]

- Gazzotti, S. , Rampazzo, R., Hakkarainen, M., Bussini, D., Ortenzi, M.A., Farina, H., Lesma, G. and Silvani, A., 2019. Cellulose nanofibrils as reinforcing agents for PLA-based nanocomposites: An in situ approach. Composites Science and Technology, 171, pp.94-102. [CrossRef]

- Xiao, L. , Mai, Y., He, F., Yu, L., Zhang, L., Tang, H. and Yang, G., 2012. Bio-based green composites with high performance from poly (lactic acid) and surface-modified microcrystalline cellulose. Journal of Materials Chemistry, 22(31), pp.15732-15739. [CrossRef]

- Nair SN, Dasari A, Yue CY, Narasimalu S. 2017. Failure Behavior of Unidirectional Composites under Compression Loading: Effect of Fiber Waviness. Materials. 10(8): 909. [CrossRef]

- Murata, T. , Qiu, J., Zhang, M., Lin, M., Shao, L., Kudo, M. and Li, Y., 2009. Mechanical Properties and Morphologies Observation of Biodegradable Polymer Composites filled with Rice Straw. Information-An International Interdisciplinary Journal, 12(5), pp.1121-1126.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).