Submitted:

07 June 2024

Posted:

10 June 2024

You are already at the latest version

Abstract

Keywords:

II. Introduction

- Must allow individuals with only one arm functionality to be able to tighten their shoes.

- Must be lightweight.

- Must not apply too much counter torque on the arms of the individual.

- Must be usable on any shoe.

III. Related Work

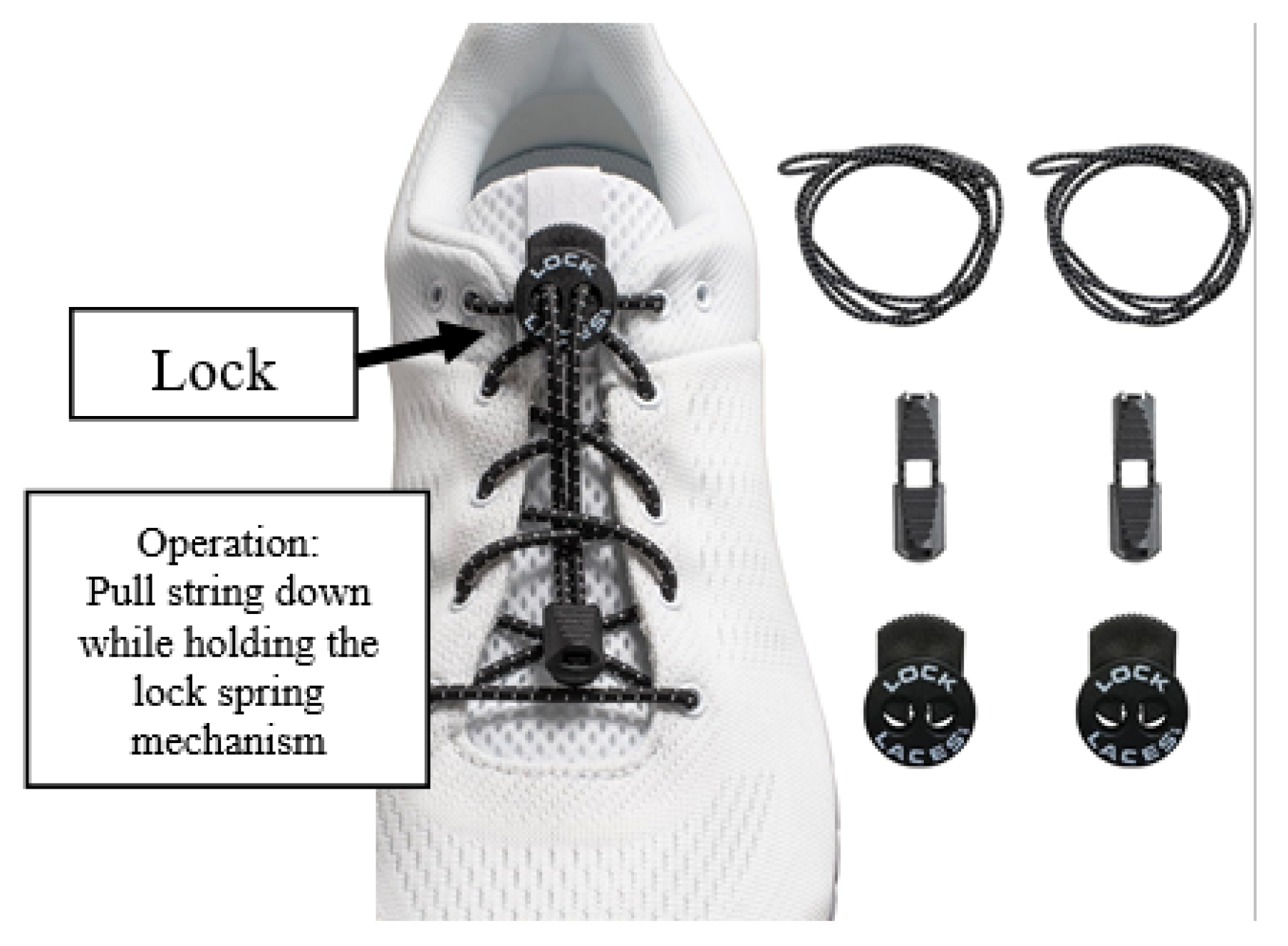

-

Simple to install.

- o

- Can be installed on most shoes.

- Simple to operate.

- Cheap and extremely cost-effective.

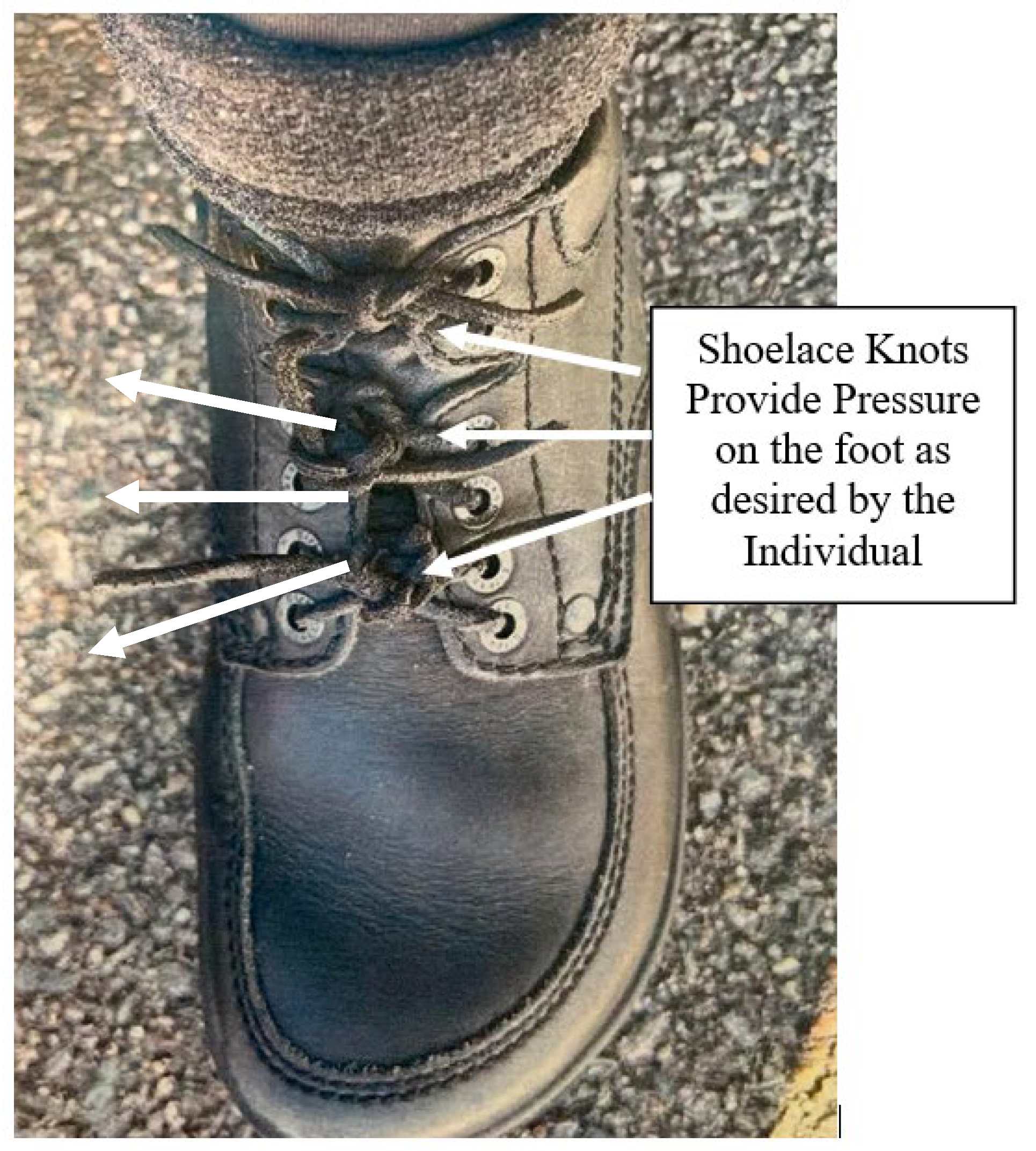

- Requires two hands to operate.

-

Doesn’t provide sufficient tightness.

- o

- Doesn’t provide tightness at the necessary locations.

- o

- Spring lock tightness depreciates over time.

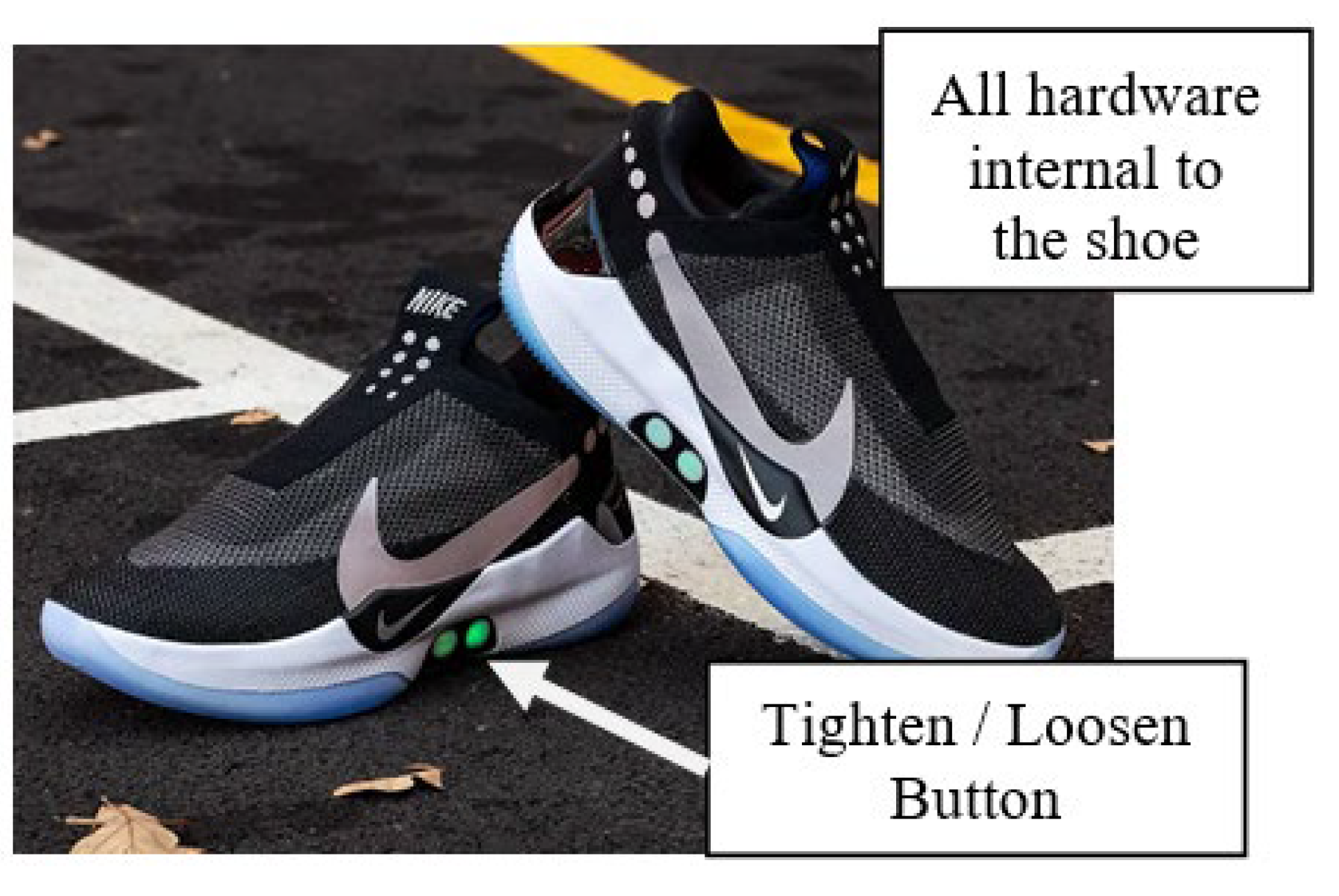

- No shoelace is required to utilize the shoe.

- Simple to operate and wear.

-

Requires the purchase of a new shoe.

- o

- Nike shoes (shown in Figure 3) cost ~125$.

-

Does not provide the tightness required by individuals with CP.

- o

- Figure 1 shows the location where tightness is required on a shoe for an individual with CP.

- Over time, the tightness of the shoes will be lost as they are tight-fitted shoes that will expand over time.

-

If true tightness is required, a customized shoe will need to be created for the individual.

- o

- This will increase the cost of manufacturing dramatically.

-

Easy to operate.

- o

- The motorized system does not require anything but the press of a button to operate.

-

Expensive

- o

- Requires the purchase of a new shoe, estimated at around 450$.

-

Heavy

- o

- With a built-in motor and battery, the shoe is much heavier than a regular shoe.

-

Battery operated

- o

- There is no way to operate the current shoe if the battery dies.

- o

- equires better battery technology to be efficient.

-

Overly complex

- o

- Simple devices (shoes) became much more complex with this design.

- o

- Technology can bug or damage.

- o

- No easy way to take off shoes once an issue occurs.

-

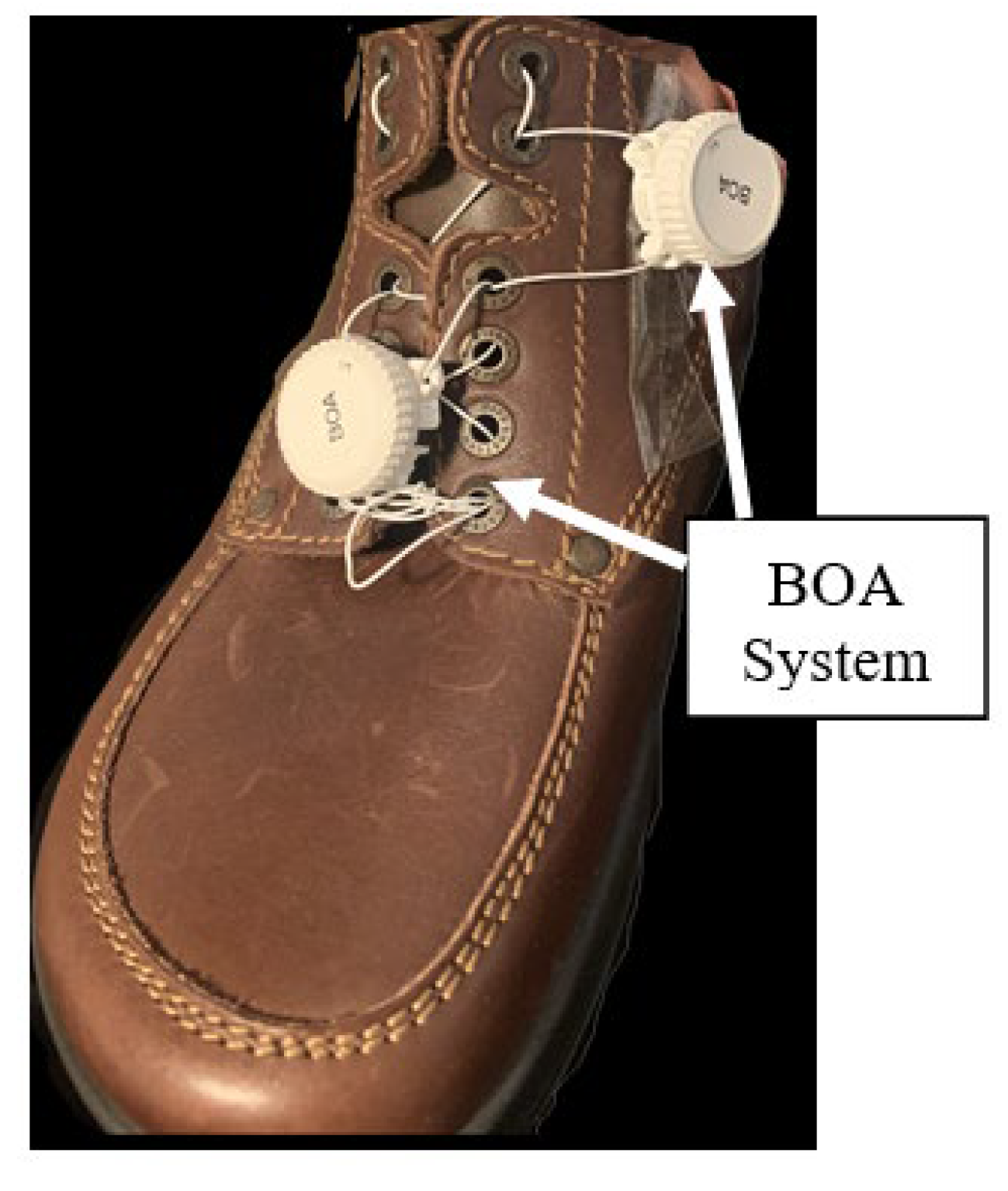

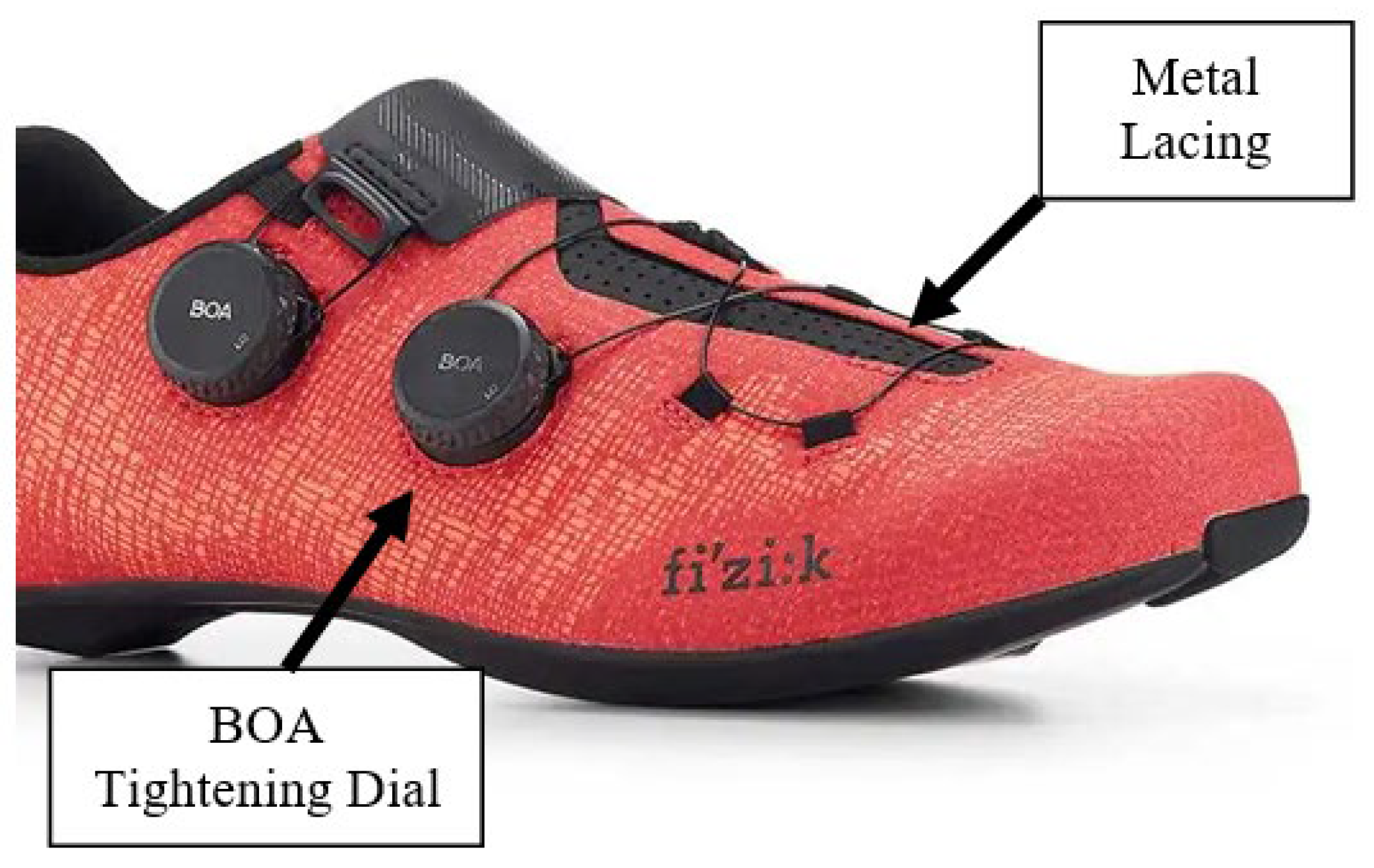

Simple

- o

- Spin a dial to tighten the shoe.

- o

- Pull vertically will loosen the system.

-

Reasonable Pricing

- o

- BOA system will cost between 40 and 50$

- Can be operated with one hand.

-

BOA system shoes are not exactly manufactured for people with CP. As such, the individual will be required to install the BOA system on the desired shoe.

- o

- No simple way to install BOA onto shoes.

- After a certain amount of tightness, the counter torque produced when spinning the dial is too great for some individuals with CP.

- Design 1 lacks the required tightening capability in crucial areas.

- Similar to Design 1, Design 2 also falls short of providing sufficient tightening.

- Design 3’s additional technology adds considerable weight, making it challenging for the individual to walk.

- Design 4 is difficult to operate due to the excessive torque needed for tightening.

IV. Design Choices

- Should enable individuals with single-arm functionality to tighten shoes effectively.

- Should be lightweight.

- Should avoid exerting excessive counter-torque on the individual’s arms.

- Should be compatible with any type of shoe.

- The system must not interfere with or prevent the individual from any foot movement.

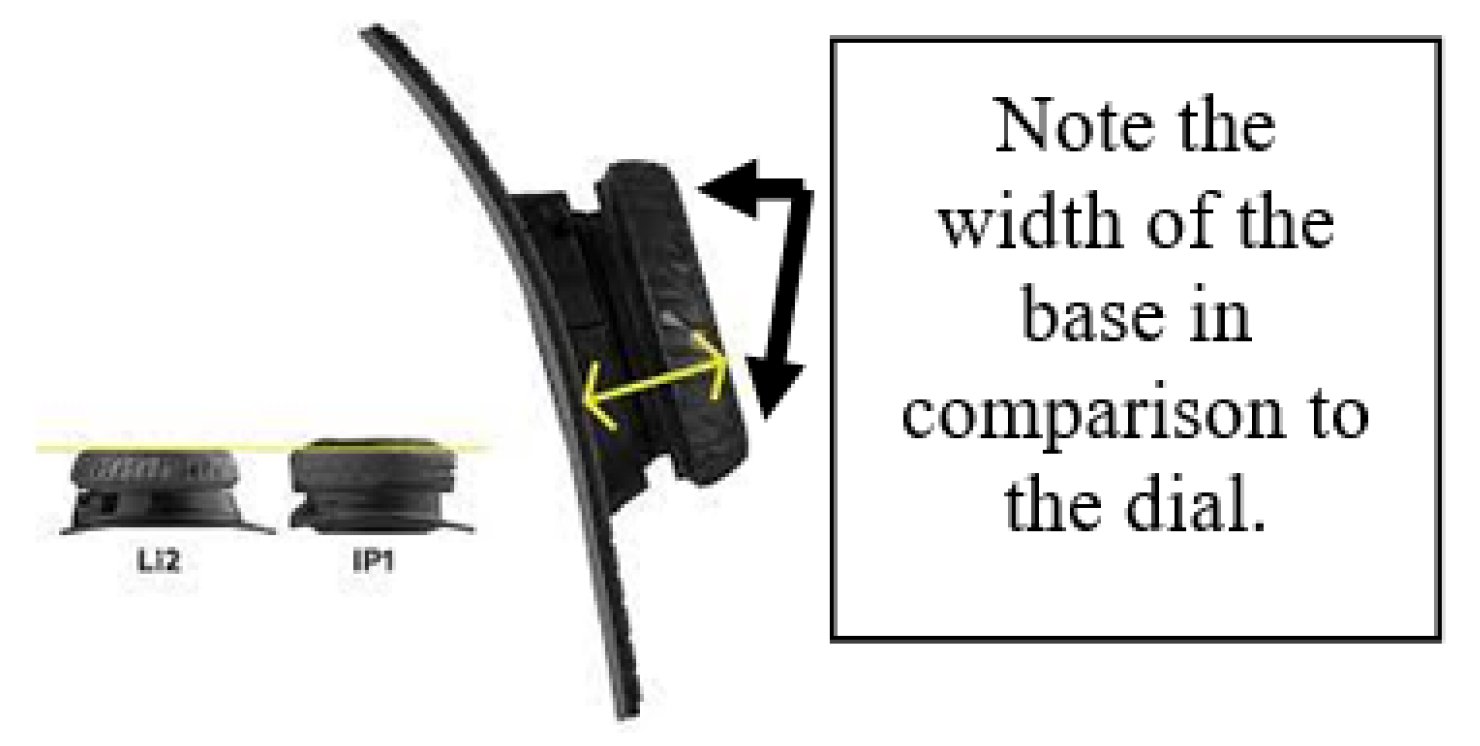

A. Shoe Tightening Mechanism

B. Shoe Tightening Tool

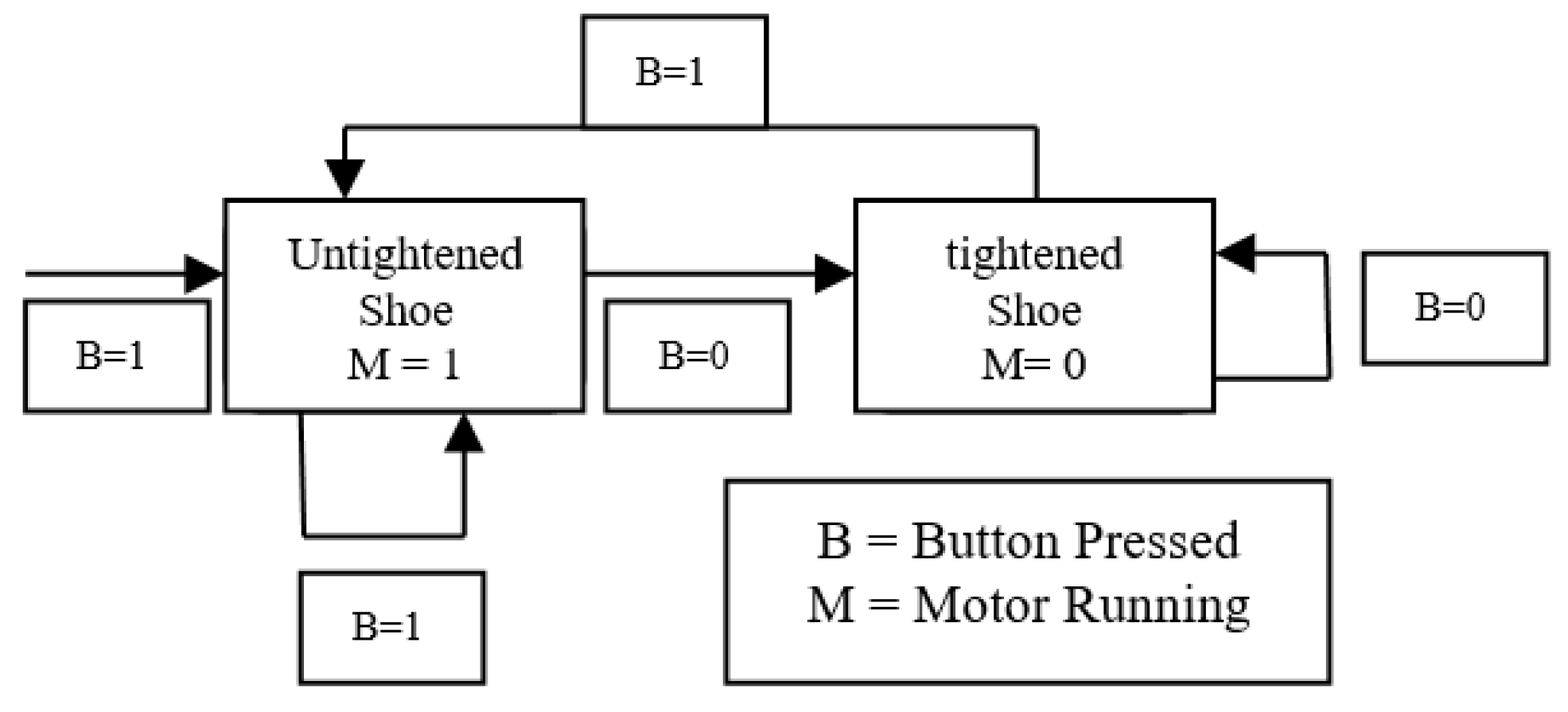

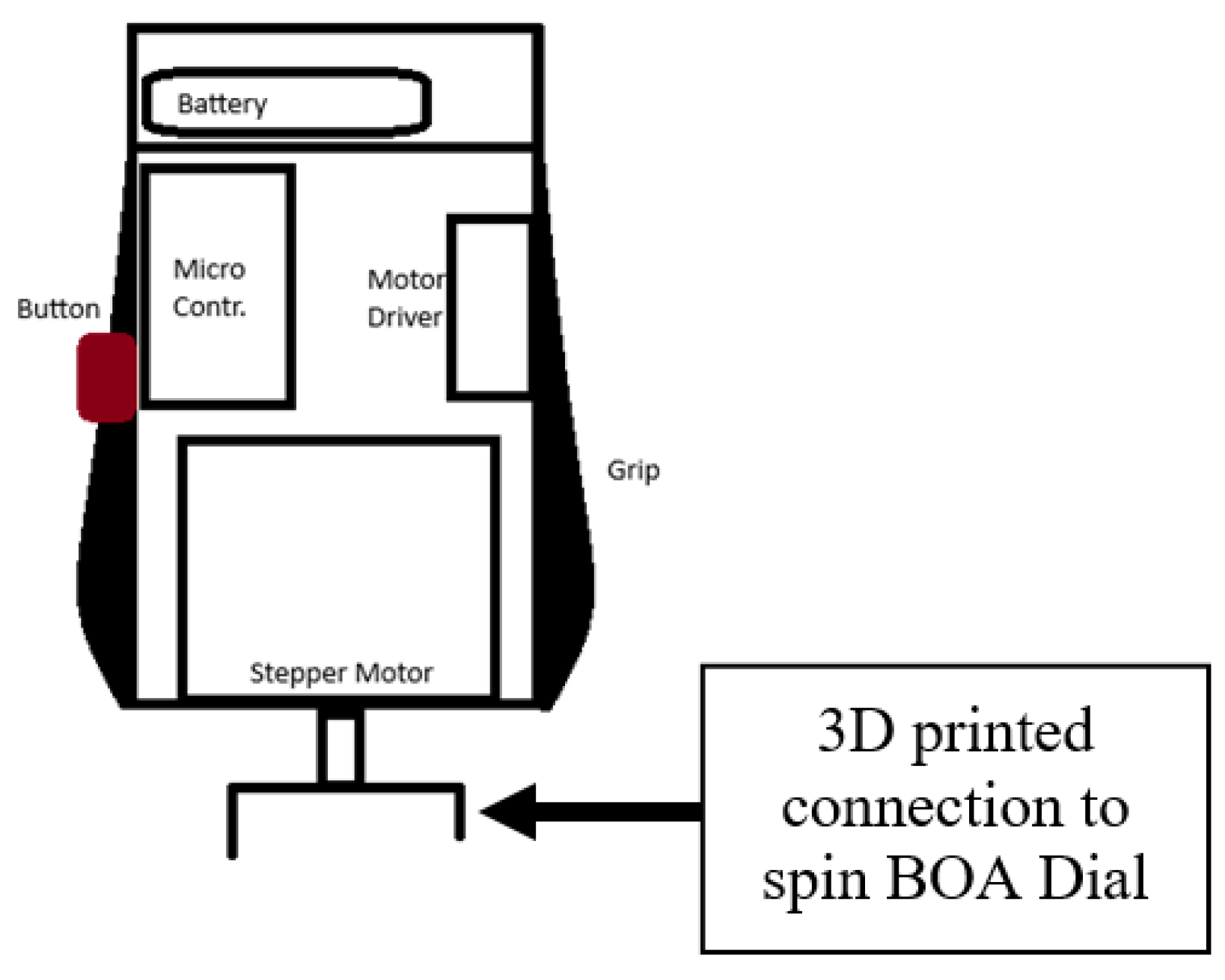

1) Motorized System

-

The initial press will activate the motor.

- o

- If the button is held, the motor will continue operating.

- Once un-pressed, the motor will stop tightening.

- Battery

- Microcontroller

- Button

- Stepper Motor

- Motor Driver

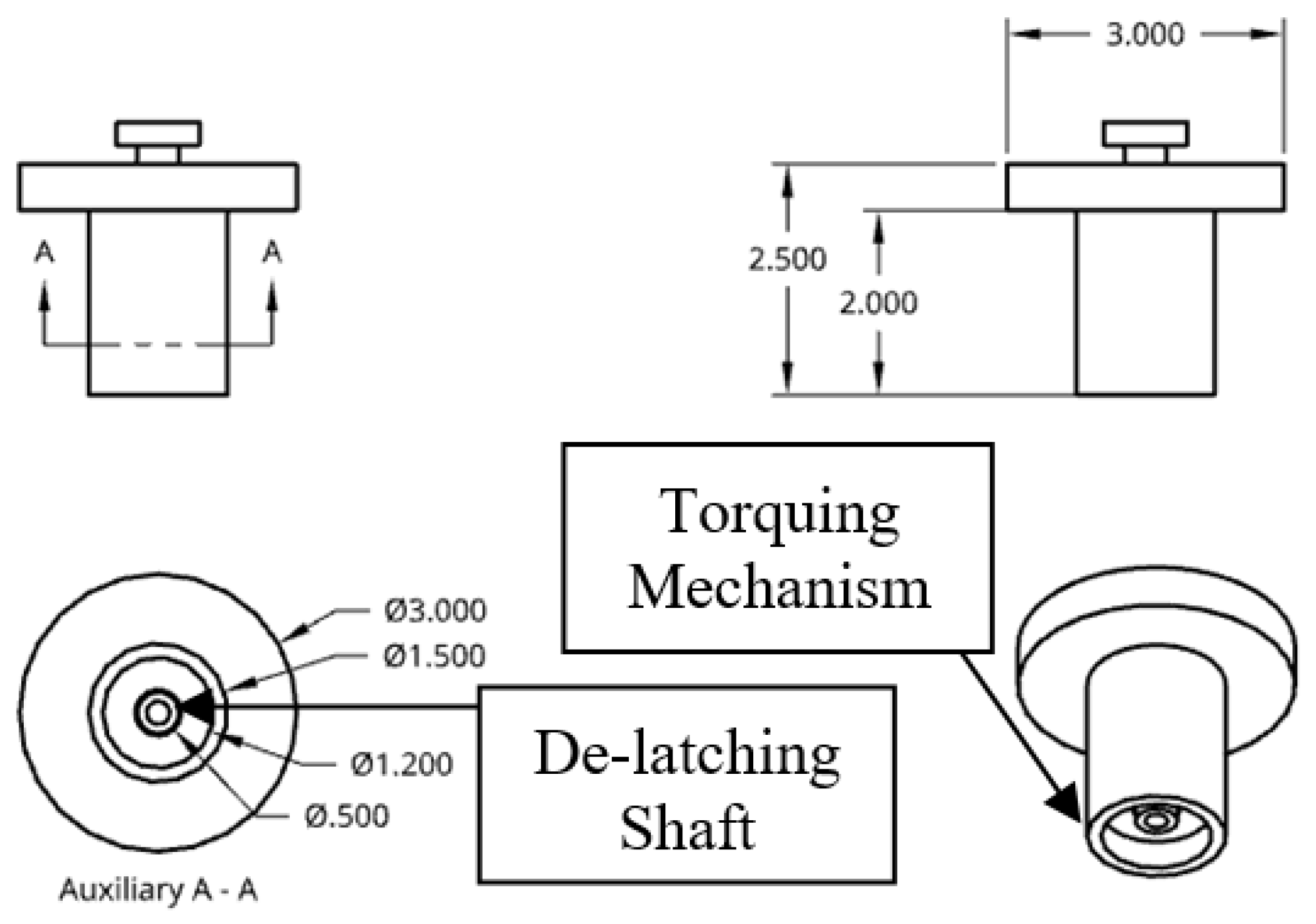

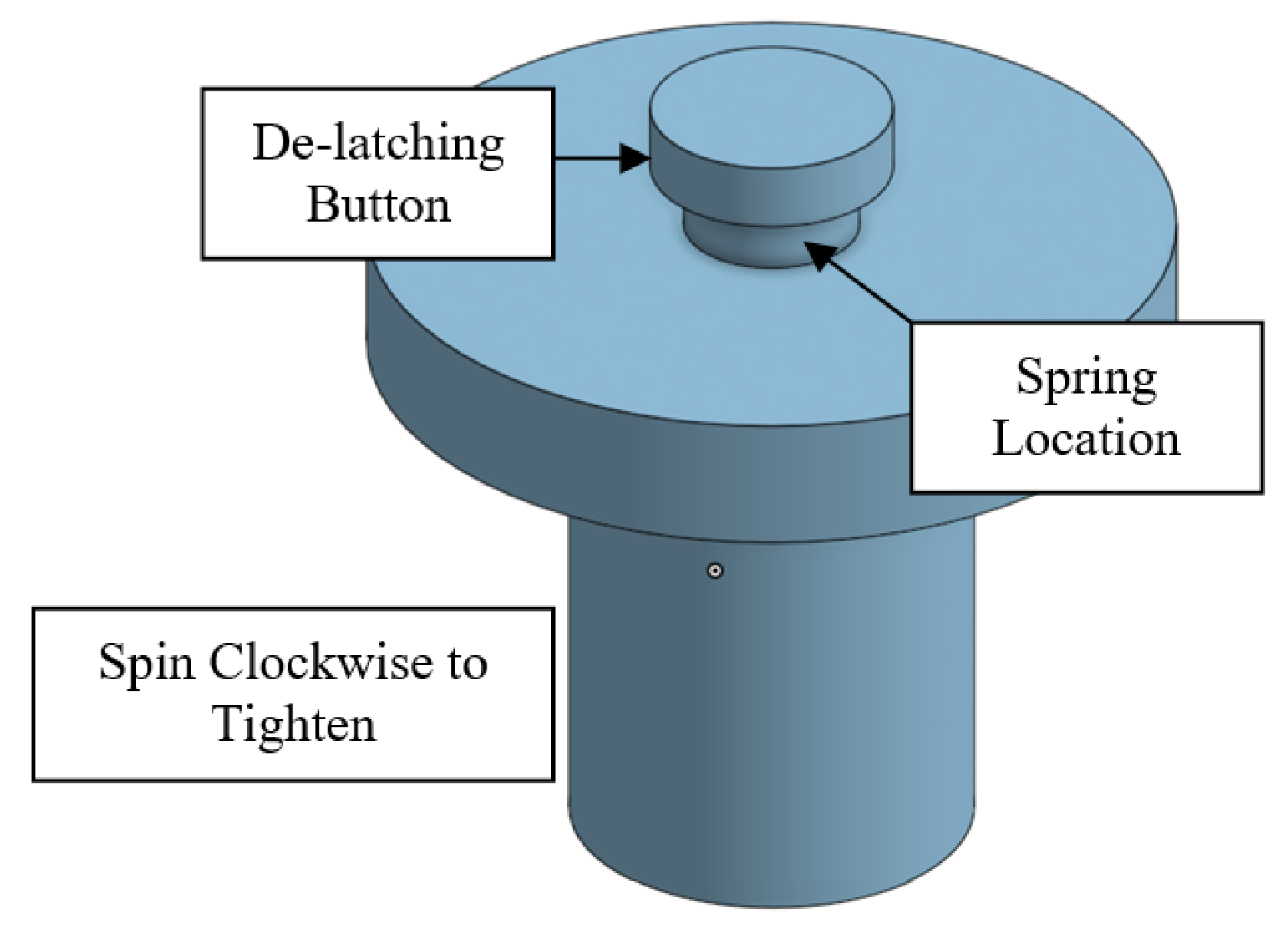

2) Manual Handheld System

- Engage the BOA system.

- Torque as necessary.

- Disengage the BOA system.

-

Round handle

- o

- The round handle allows the user to twist the system easily while keeping a downward vertical force on the BOA system.

-

Latching system

V. Final Design

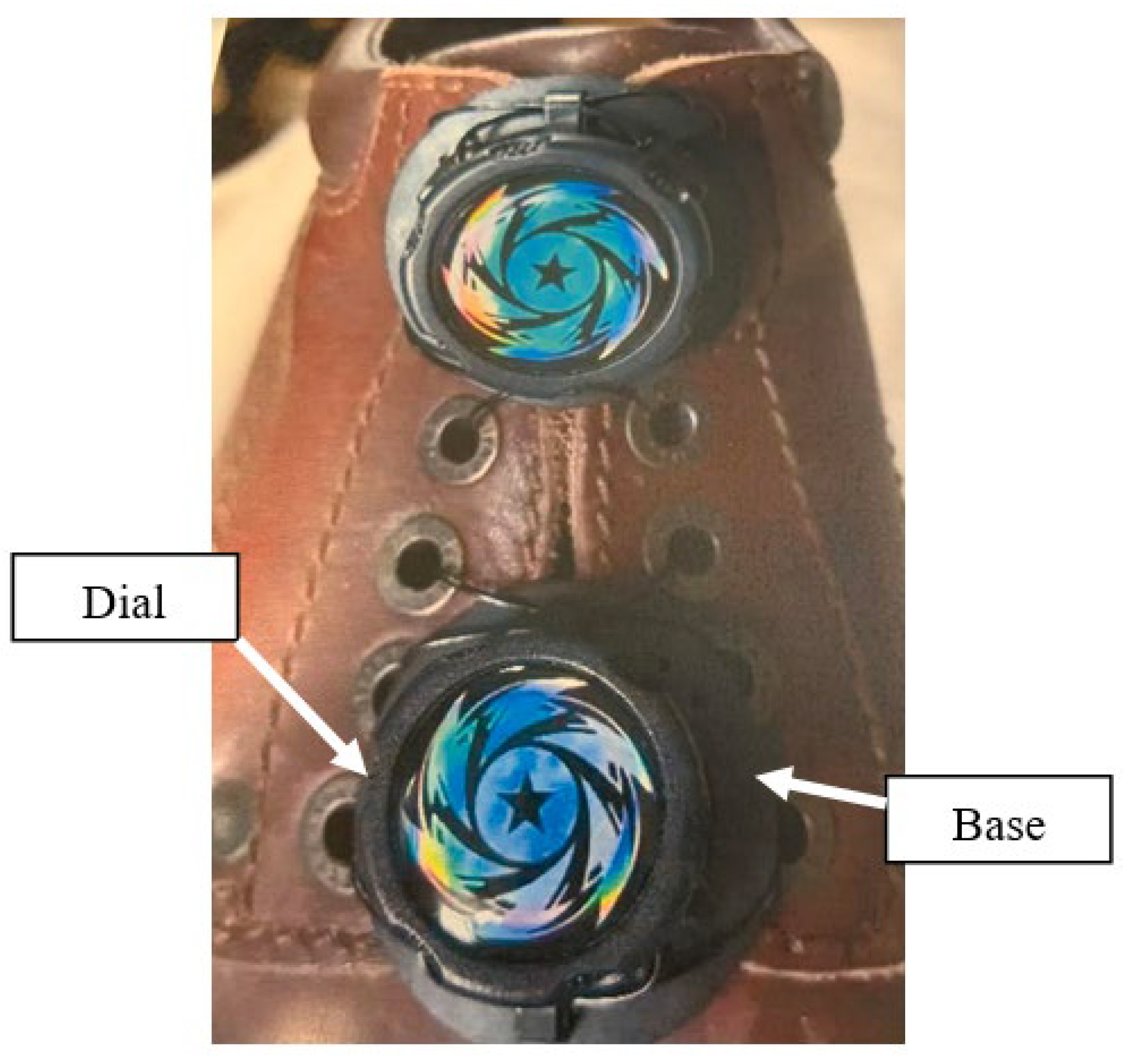

-

Both dials on the laces (Figure 6)

- o

-

Uncomfortable

- ▪

- The base of the dials interfered with the movement of the foot.

- o

-

Hard to wear

- ▪

- Installing the dials on the tongue of the shoe prevents the tongue’s movement and hinders the process of wearing the shoe.

-

One dial on the tongue, the other on the side (Figure 7)

- o

- As per the previous description, installing the dials on the tongue of the shoe prevented the tongue’s movement and hindered the process of wearing the shoe.

- Simplicity

- Weight

- Safety

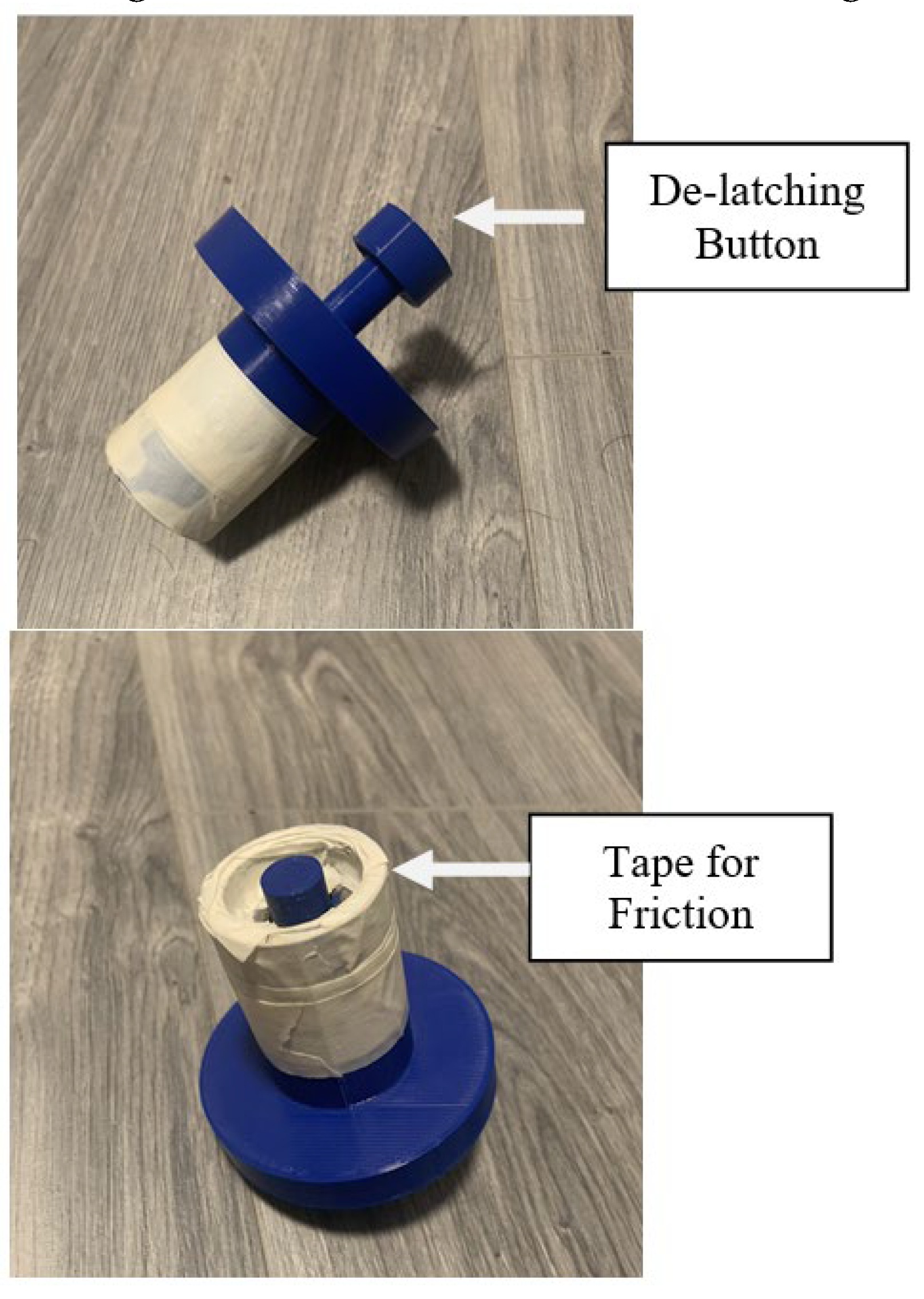

VI. Testing

- Only utilize one hand

- Only tighten with the torquing tool

- Wear the Shoe

- Align the shoe tongue as desired

- Install the torquing tool on the first BOA dial

- Torque as necessary, de-latch when satisfactory

- Repeat steps 3 and 4 for the other BOA dial

- Loosen the torque dials

- Take off shoe

- Be operated with on-hand

- Tighten the shoe to the comfort desired

- The process was performed in under 1 minute

VII. Discussion and Conclusion

- Rougher material surfaces at the connection point.

- Replace the circular gripping shape to increase hand comfortability.

-

Motorized system

- o

- This system would allow everyone to utilize it, including personnel with no hand usage.

- o

- The system must include capabilities for children to utilize without any safety risks.

-

Other methods for attaching the BOA system

- o

- The current BOA system requires that the torque dial be stitched onto the shoe. This could limit the ability of some individuals to utilize this system. Additional methods are required for attaching are required.

References

- Centers for Disease Control and Prevention. “Facts about Cerebral Palsy.” Centers for Disease Control and Prevention, National Center on Birth Defects and Developmental Disabilities, 1 Dec. 2021, www.cdc.gov/ncbddd/cp/facts.html.

- Kim, Ju Yong, et al. “Long-term Follow-up of Botulinum Toxin-A Treatment for Lower Limb Spasticity in Children with Cerebral Palsy: A Prospective Study.” Annals of Rehabilitation Medicine, vol. 44, no. 1, 2020, pp. 31–40. [CrossRef]

- Adie, Sam, et al. “Robotics and virtual reality for upper limb training in patients with chronic stroke: A protocol for a randomized controlled trial.” Journal of Rehabilitation and Assistive Technologies Engineering, vol. 6, 2019, pp. 1–7. [CrossRef]

- Barker, Scott M., et al. “Unilateral versus Bilateral Casting for Clubfoot: A Systematic Review and Meta-Analysis.” Journal of Pediatric Orthopedics, vol. 39, no. 2, 2019, pp. e143-e149. [CrossRef]

- Nike Innovate C.V. “Motorized Footwear System.” US Patent US8769844B2, filed 7 June 2012, issued 8 July 2014.

- Pukall, Caroline. “DIY Back to the Future Shoes Powered by Arduino.” Make:, 4 Nov. 2014, makezine.com/article/technology/arduino/diy-back-to-the-future-shoes-powe.

- Ren, Y., et al. “The Impact of Self-Lacing Technology on Foot Containment during Dynamic Cutting.” Journal of Sports Sciences, vol.39,no.1,2021, pp. 107-113. [CrossRef]

- Ren, Y., et al. “Motorized Self-Lacing Technology Reduces Foot-Shoe Motion in Basketball Shoes during Dynamic Cutting Tasks.” Journal of Applied Biomechanics, vol. 36, no. 4, 2020, pp. 297-302. [CrossRef]

- “LI2 Dial Platforms.” BOA Fit System, www.boafit.com/en-us/innovation/dial-platforms/li2.

- “Nike Go FlyEase: Easy On, Easy Off Shoes.” Nike.

- “Nike Adapt BB Black/Pure Platinum - US 14.” StockX.

- “Lock Laces Elastic No Tie Shoelaces (Pack of 2).” Amazon, www.amazon.com/Lock-Laces-Elastic-Shoe-Pack/dp/B07JLXXYYP.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).